Manufacture method of energy-dissipating shear wall system of steel plate with weakened strength by heat treatment

A shear wall and steel plate technology, applied in heat treatment furnaces, heat treatment equipment, walls, etc., can solve the problem of high steel prices, achieve the effect of convenient production, avoid serious damage, and reduce the possibility of damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to further understand the invention content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

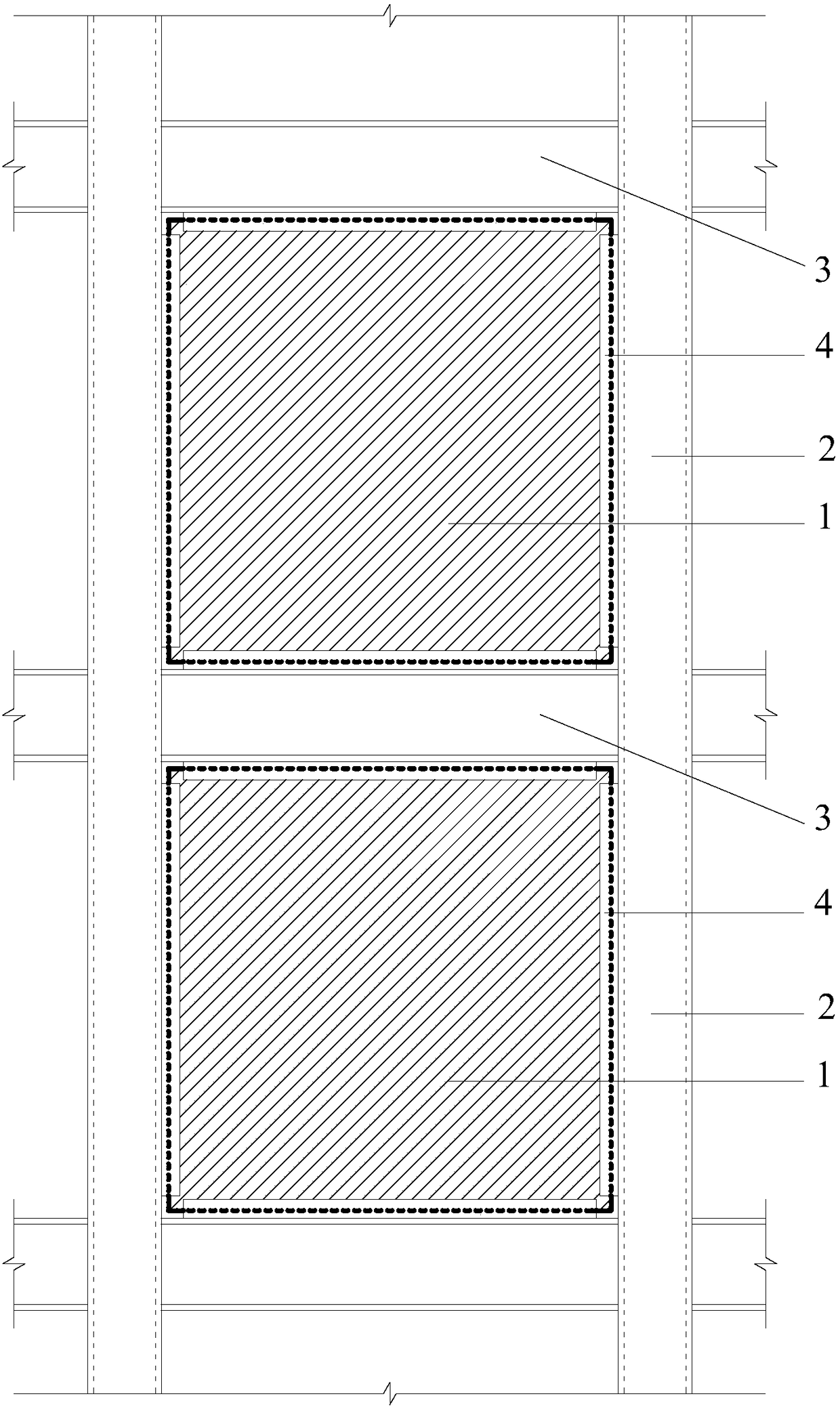

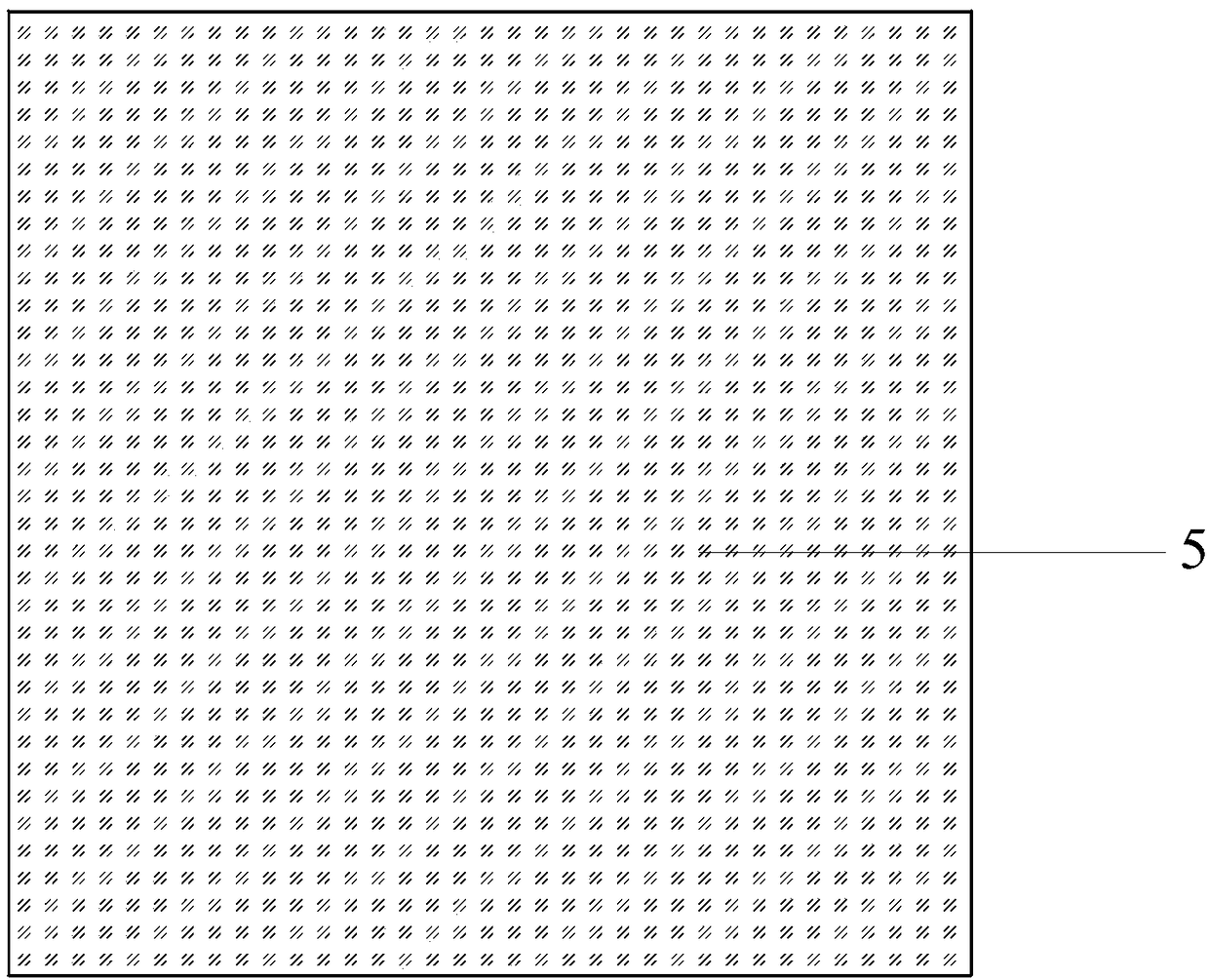

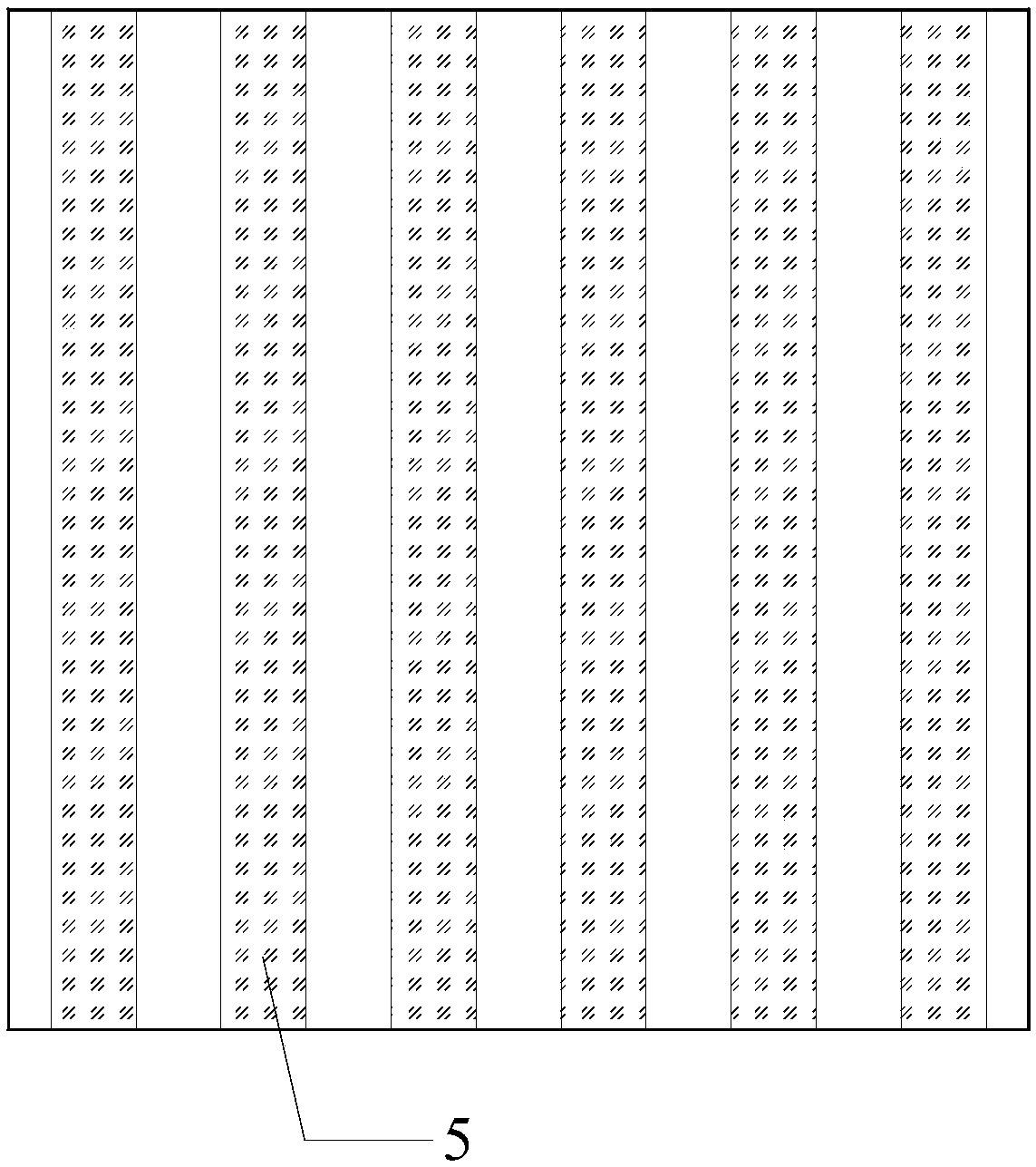

[0027] see Figure 1 to Figure 12 , a construction method of steel plate energy-dissipative shear wall system that adopts heat treatment to weaken the strength. Firstly, the main structure including frame column 2 and frame beam 3 is constructed. After the main structure is capped, the embedded steel plate 1 of each steel plate shear wall and The fishplate 4 is connected, and the embedded steel plate 4 is a heat-treated carbon structural steel plate, and the heat treatment process meets the following requirements: when the carbon structural steel plate adopts Q235 steel plate, the yield strength is reduced by 24%-31%, The ultimate strength is reduced by 10%-12%, and the yield ratio is 0.49-0.54; when the carbon structural steel plate adopts Q...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com