Patents

Literature

130results about How to "Simple performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

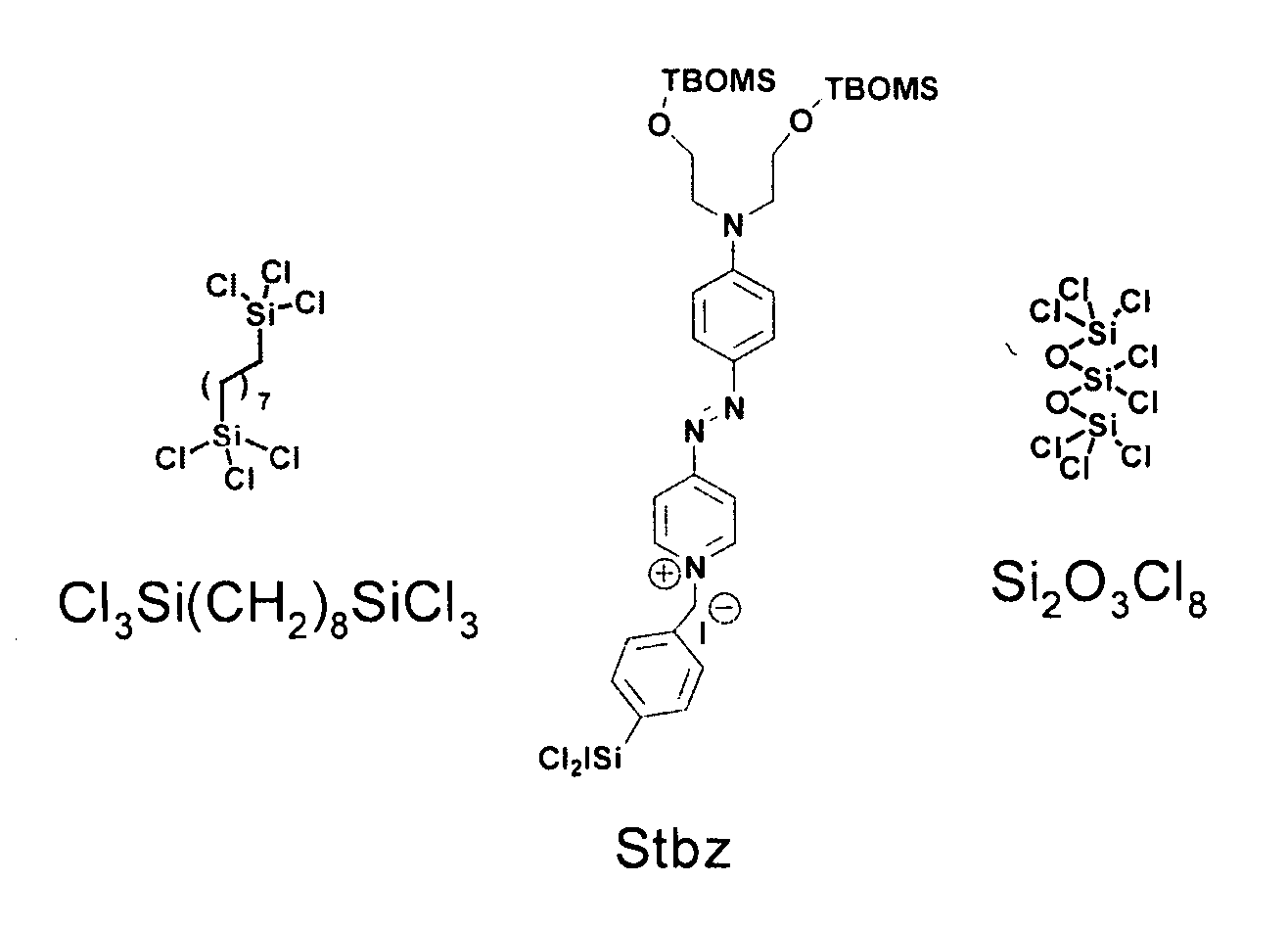

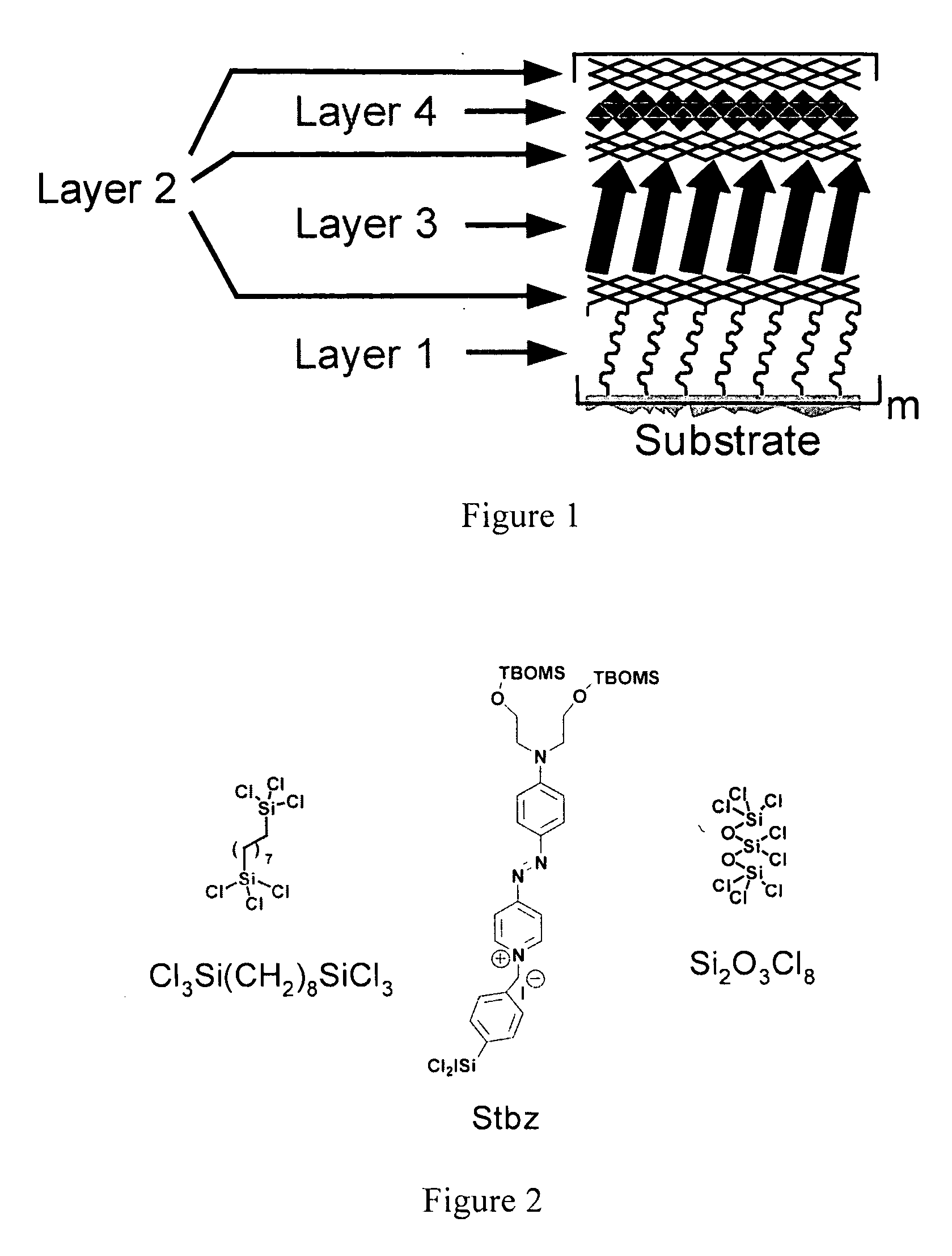

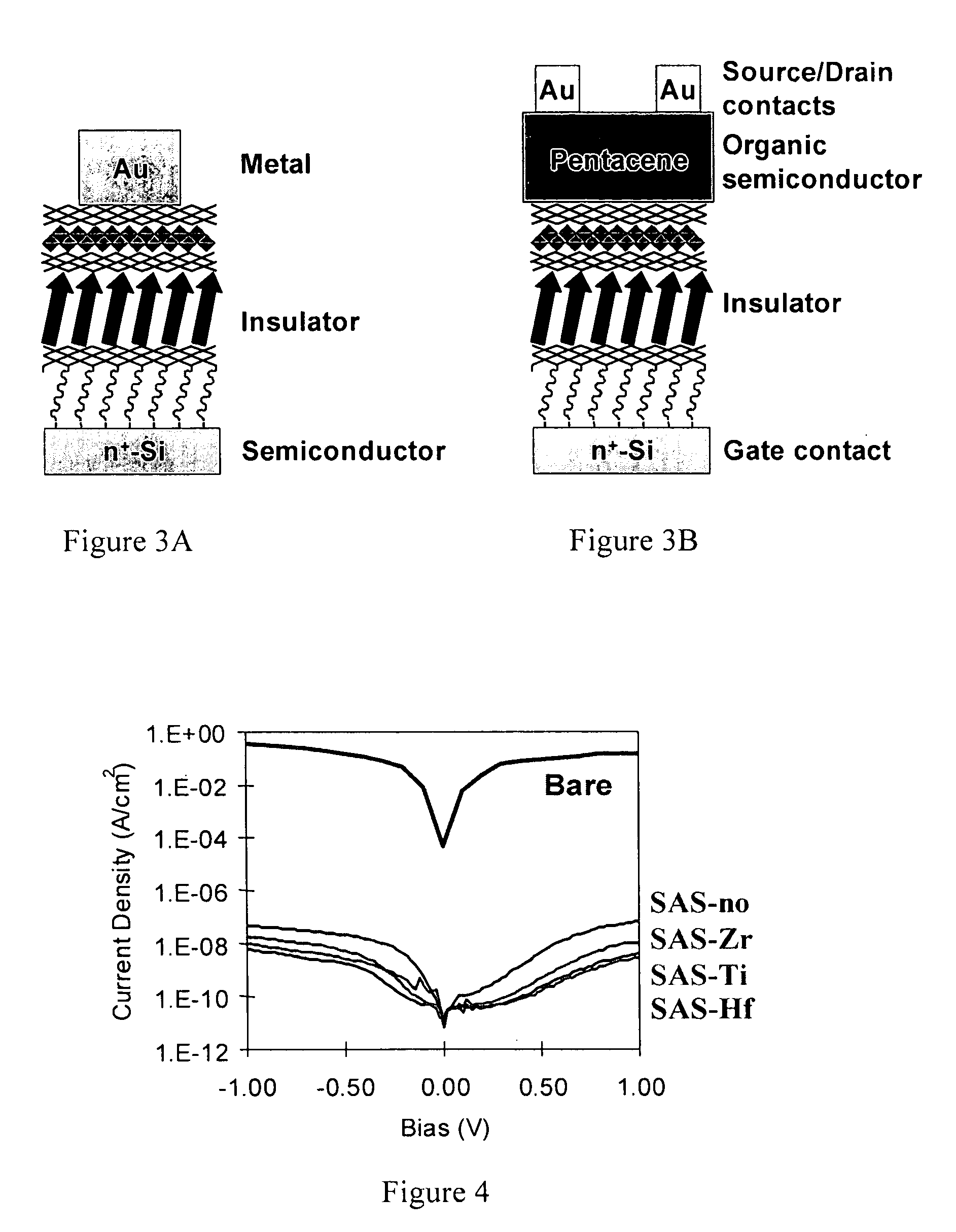

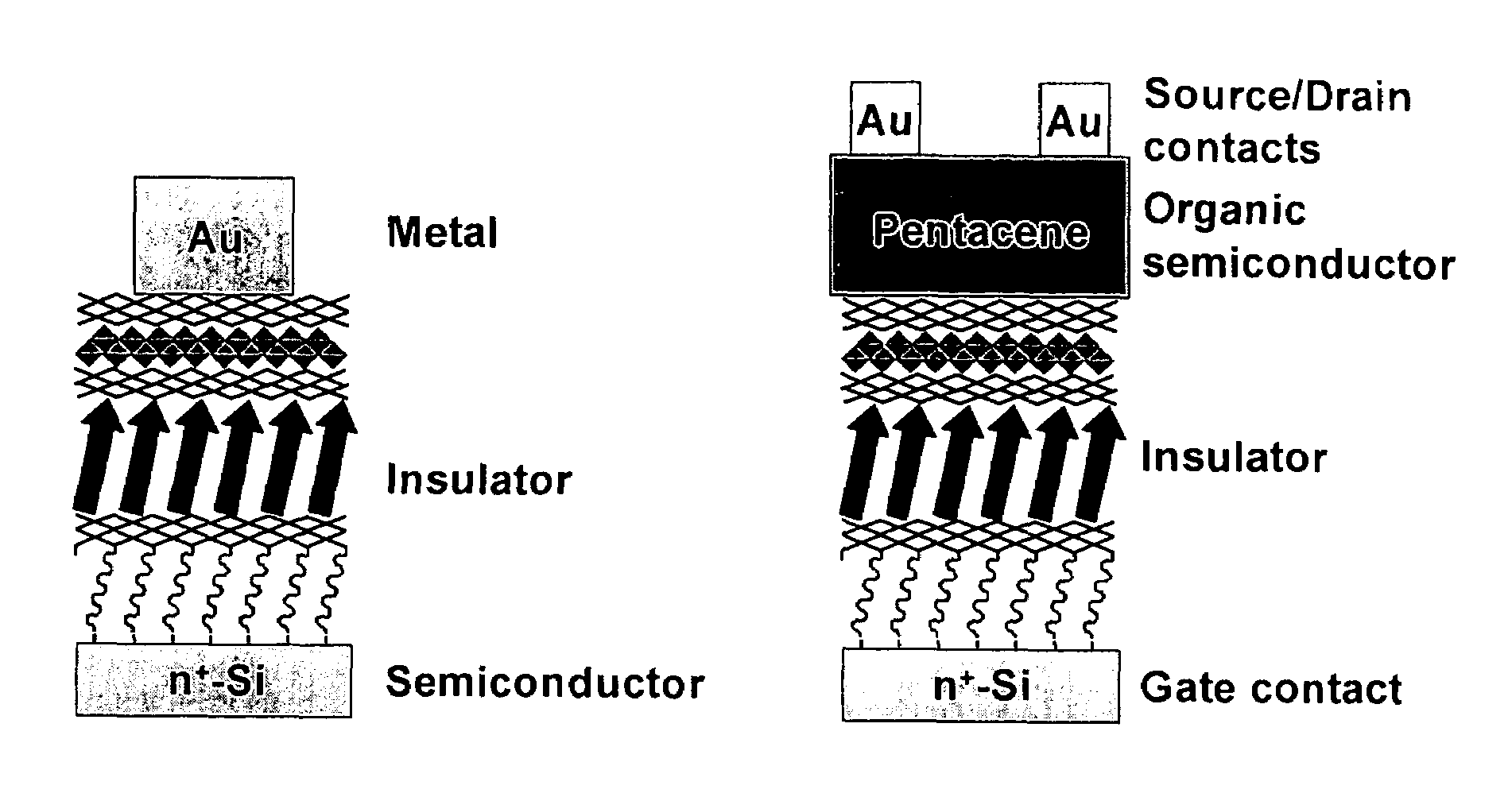

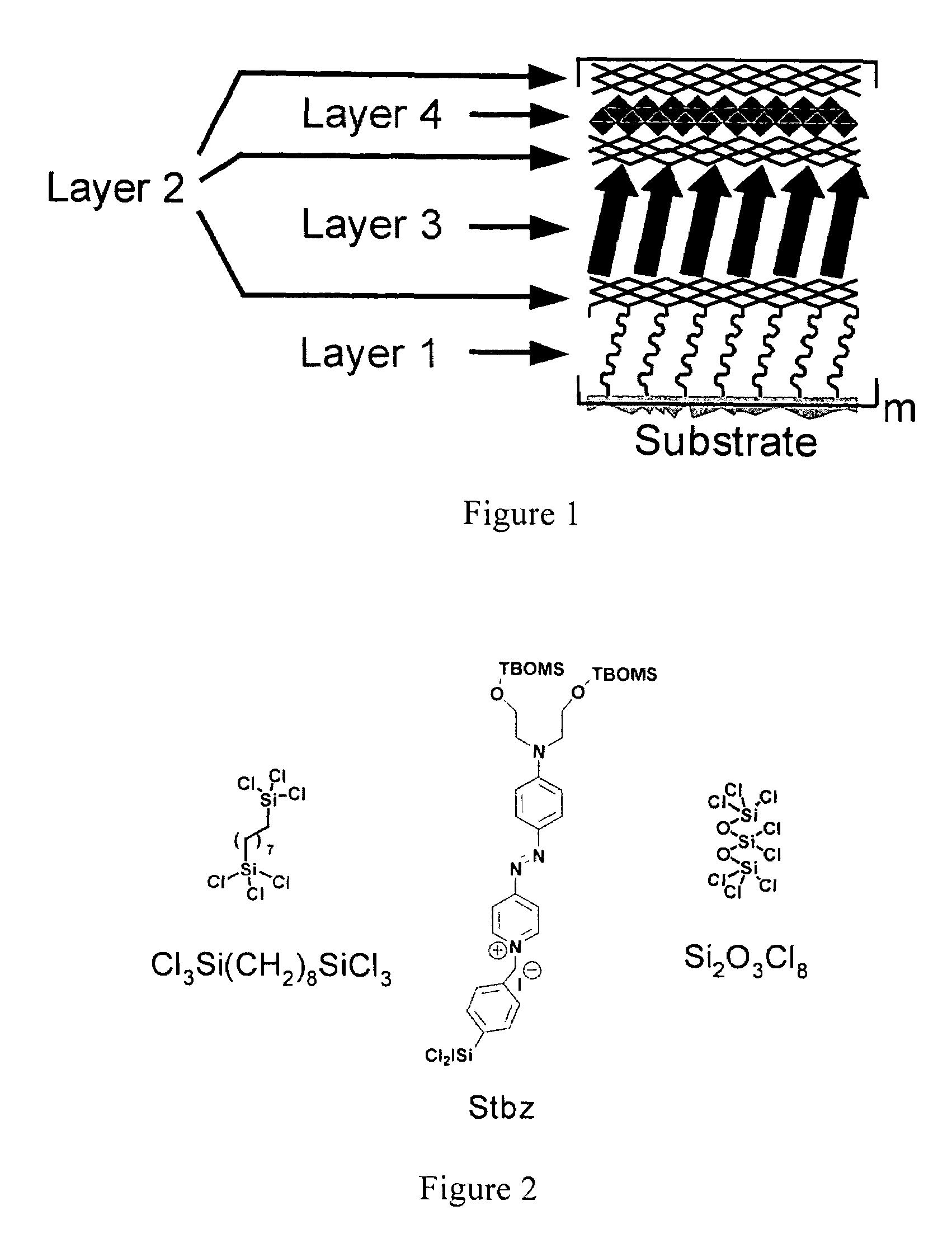

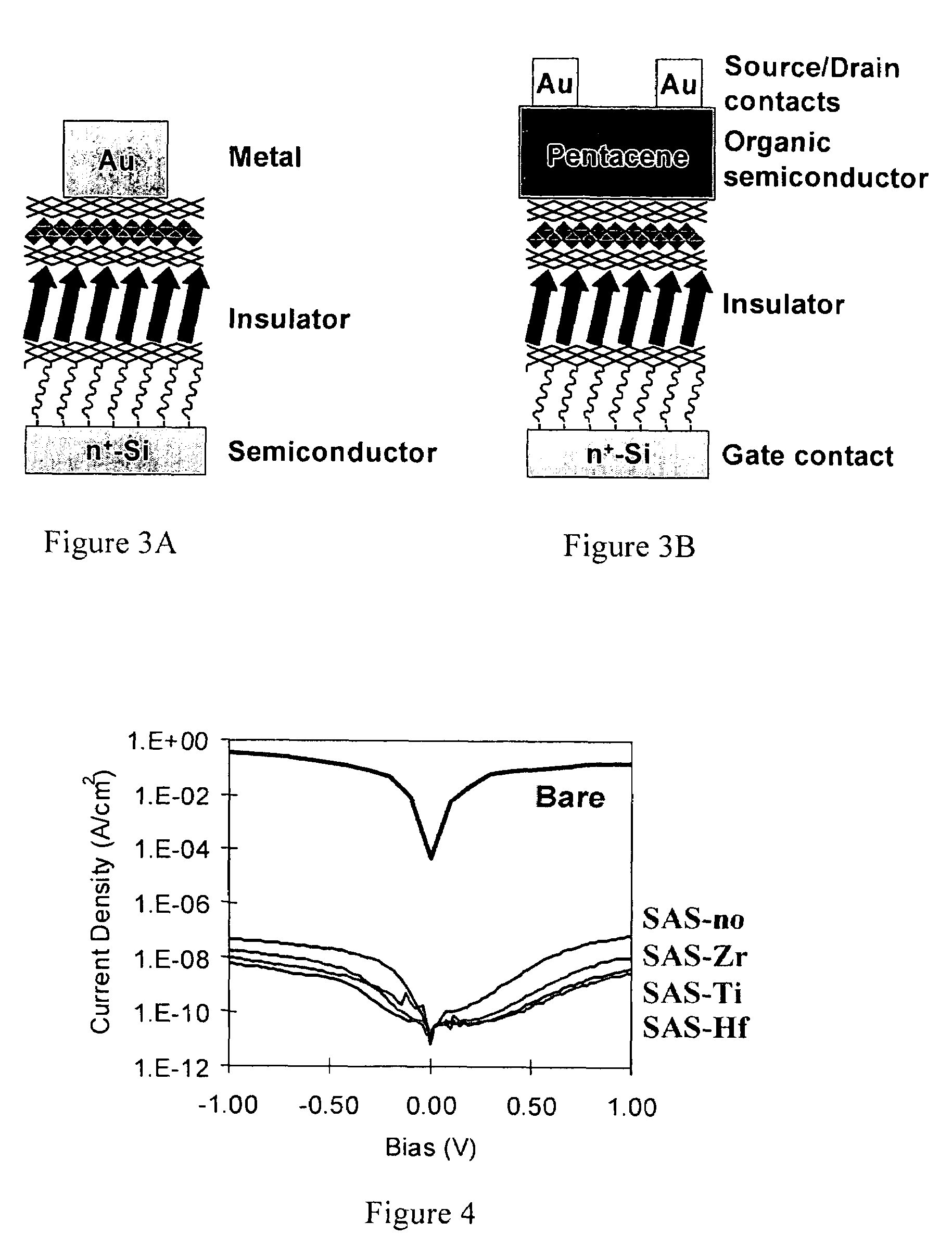

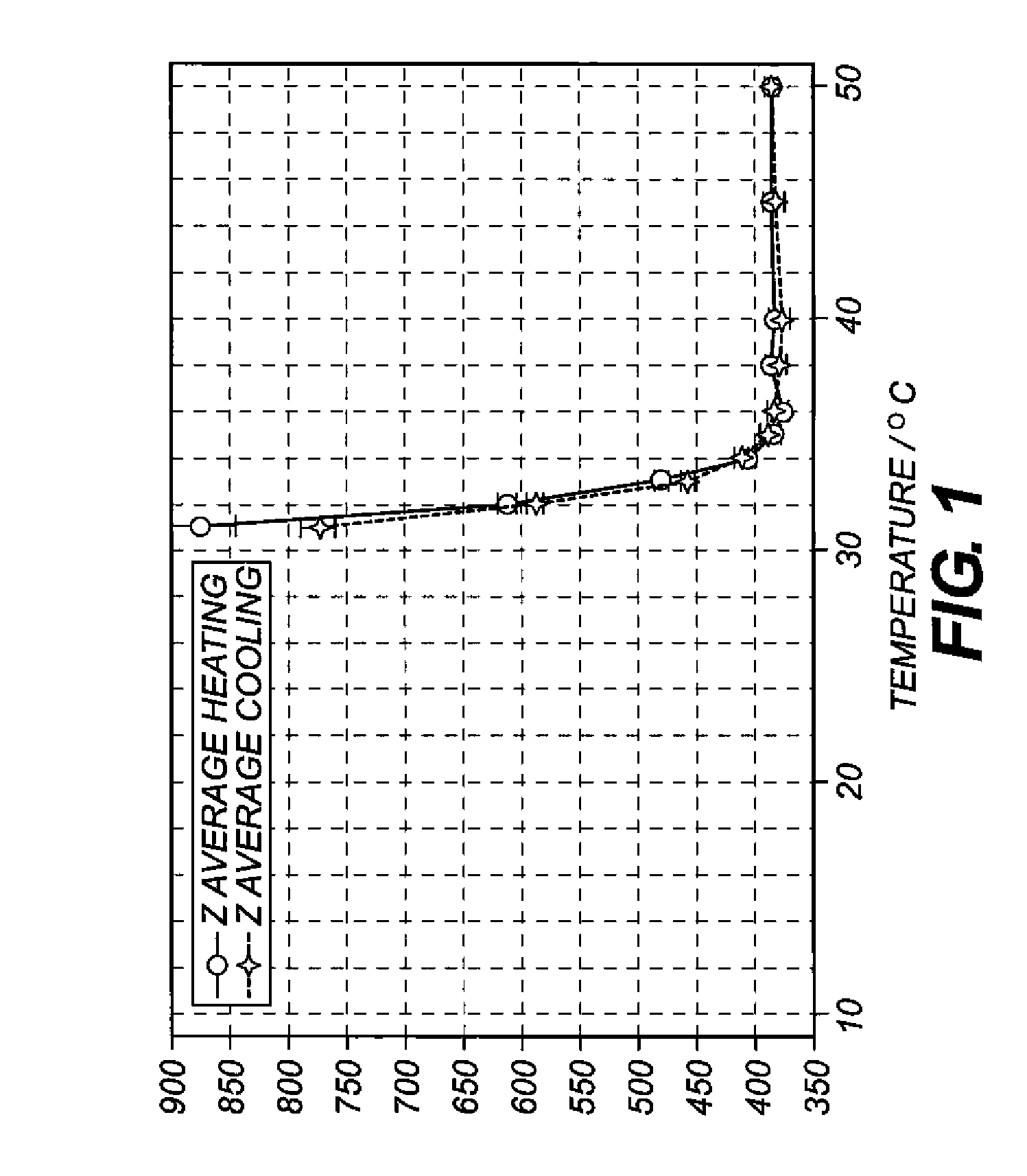

Intercalated superlattice compositions and related methods for modulating dielectric property

ActiveUS20070181961A1Low working voltageDrain current increasesMaterial nanotechnologyLiquid surface applicatorsDielectricSuperlattice

Compositions, methods of using inorganic moieties for dielectric modulation, and related device structures.

Owner:NORTHWESTERN UNIV

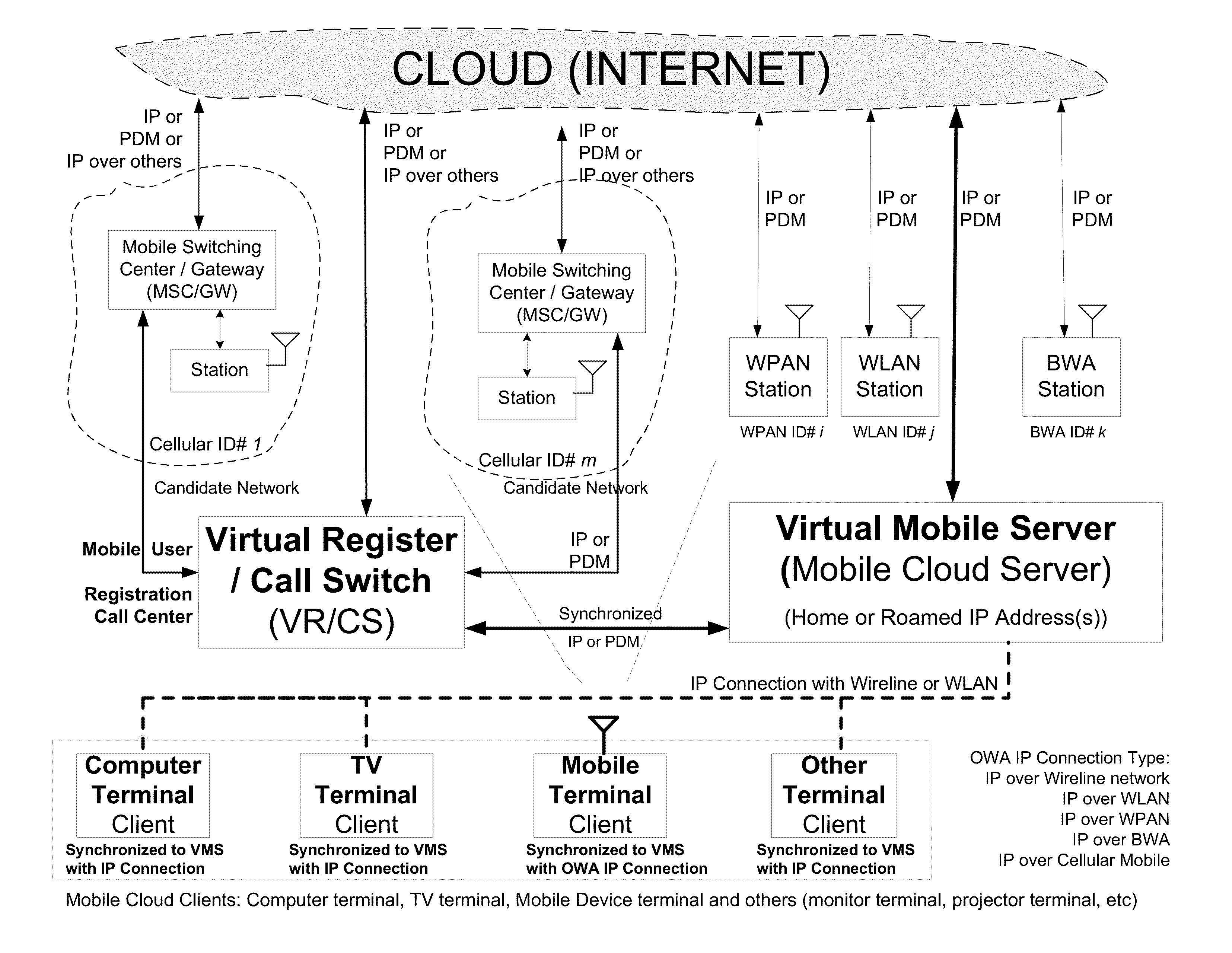

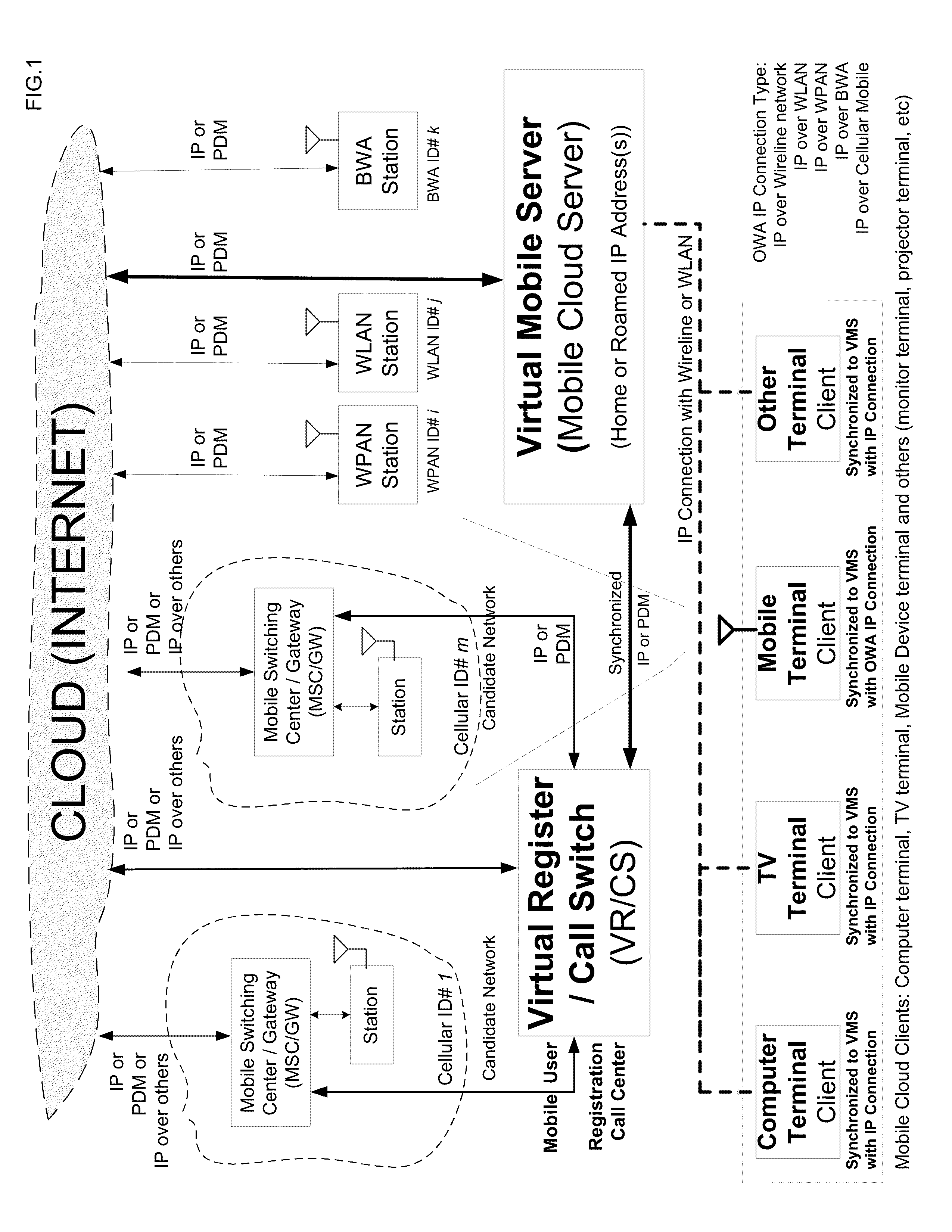

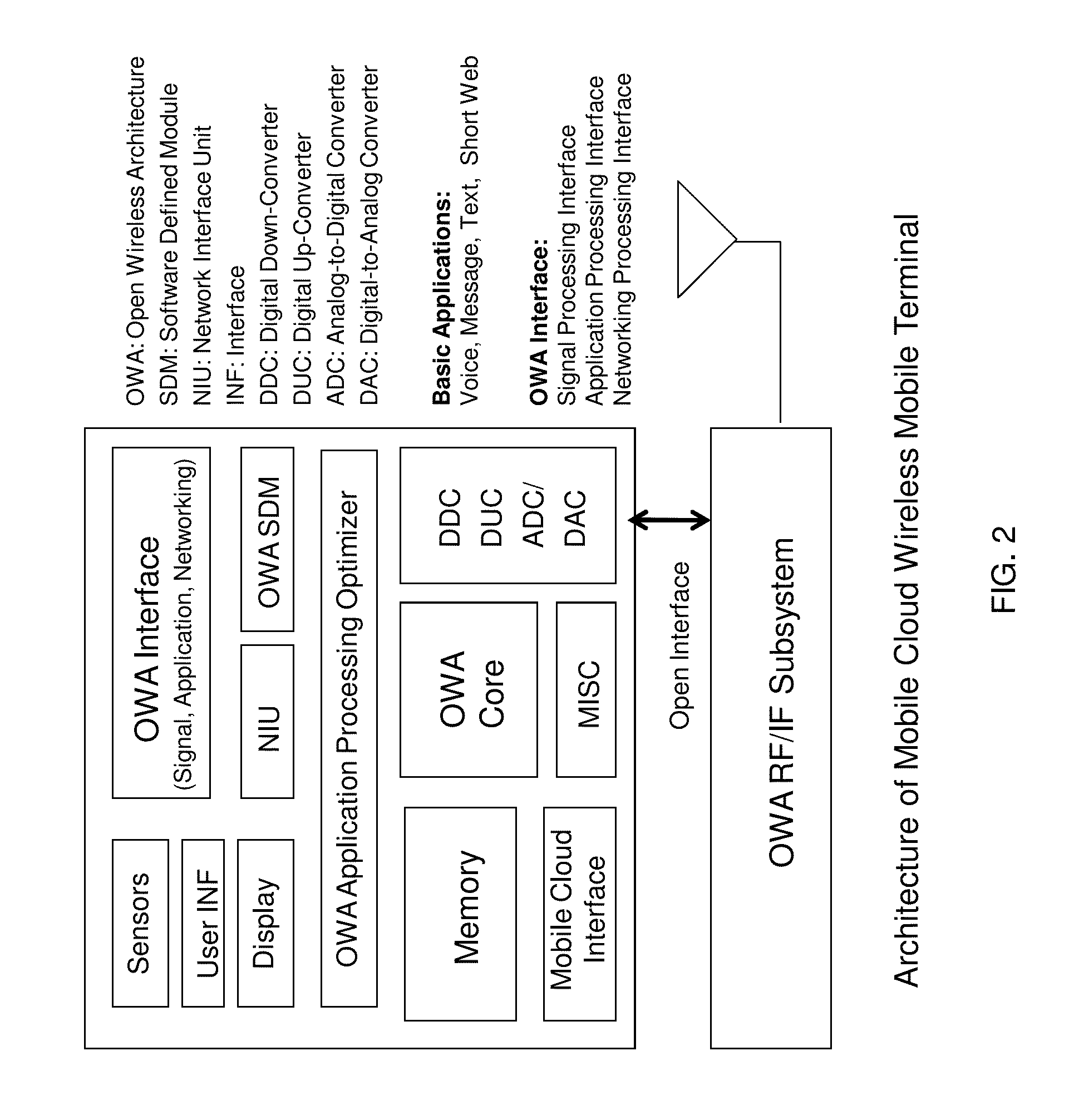

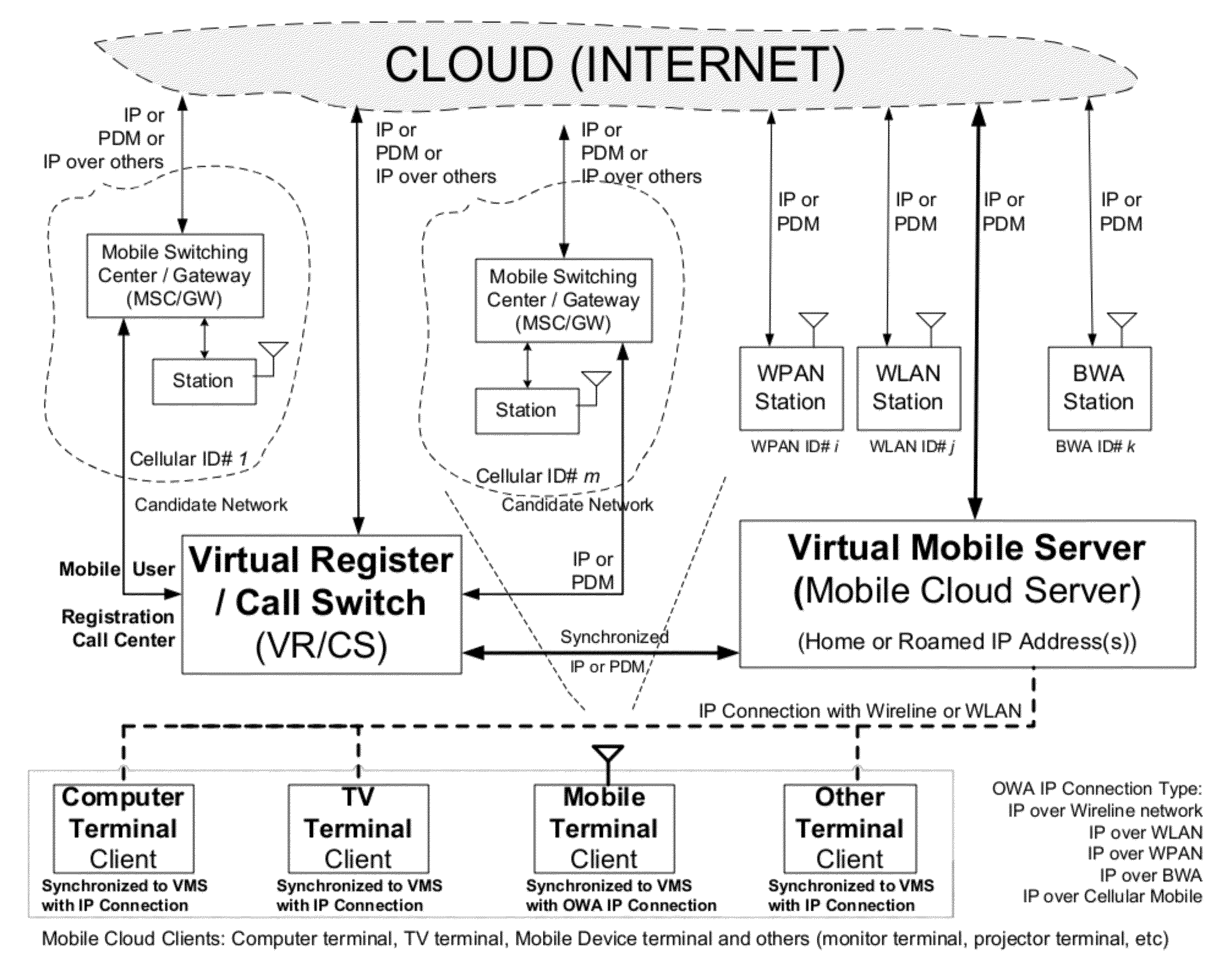

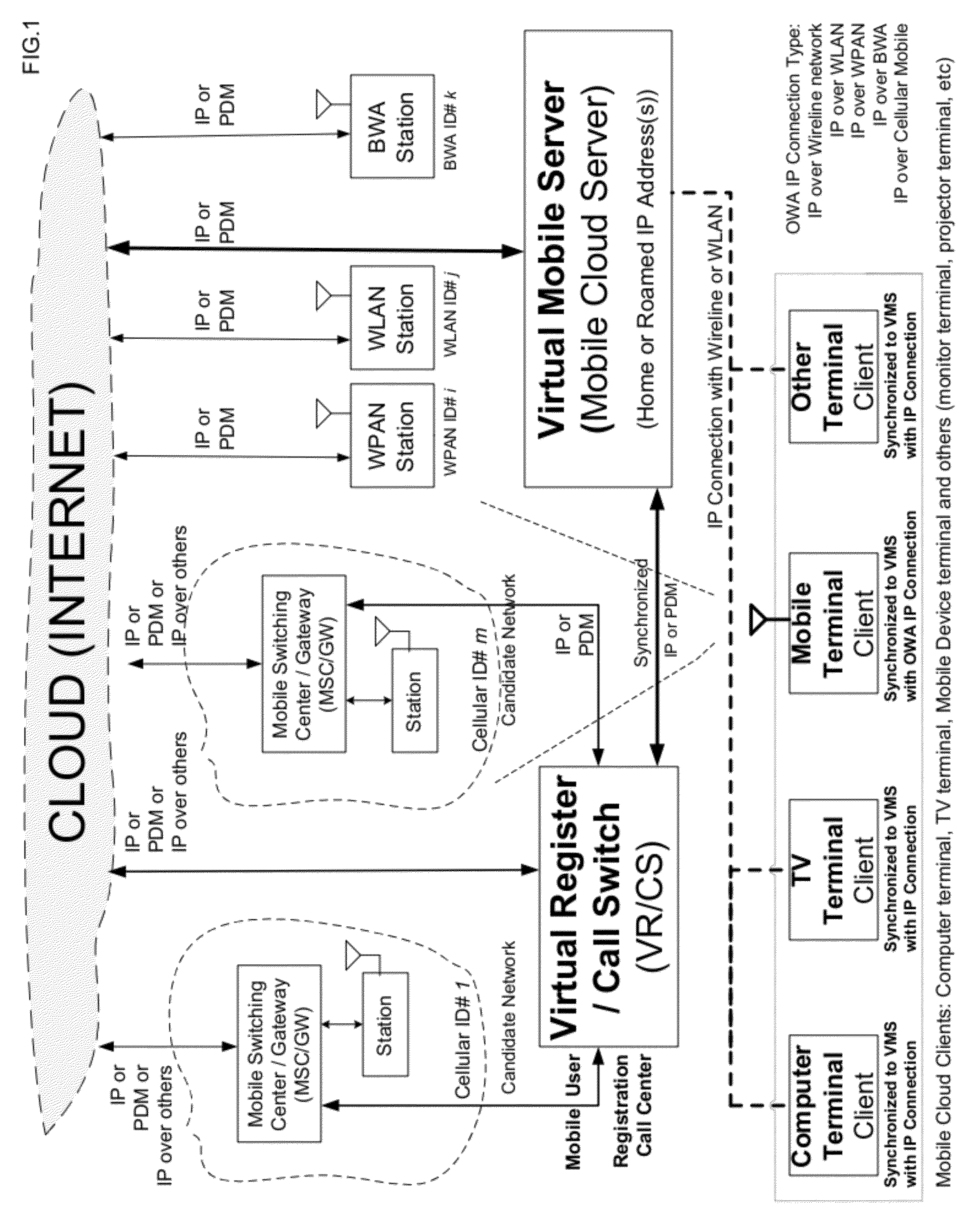

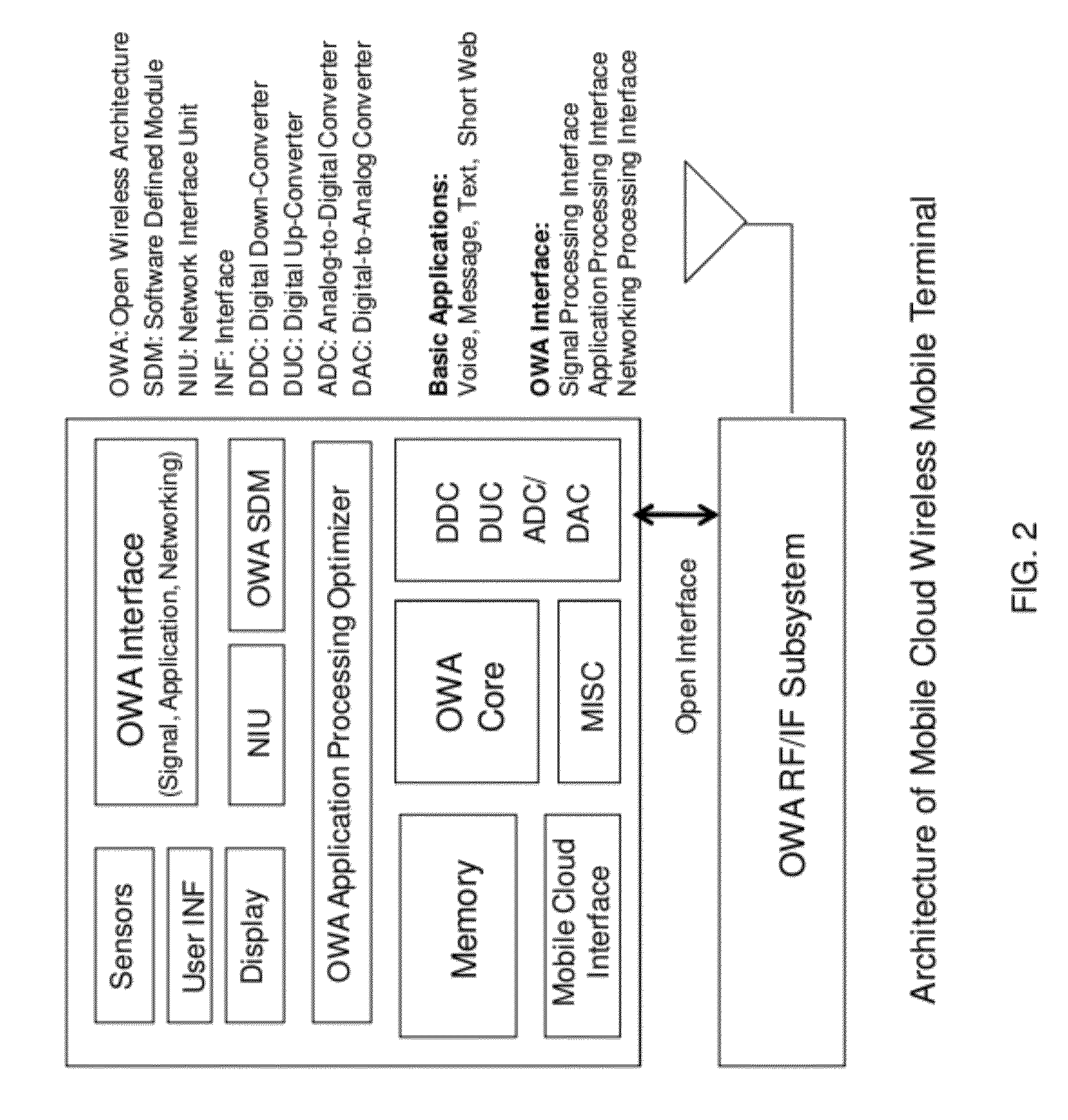

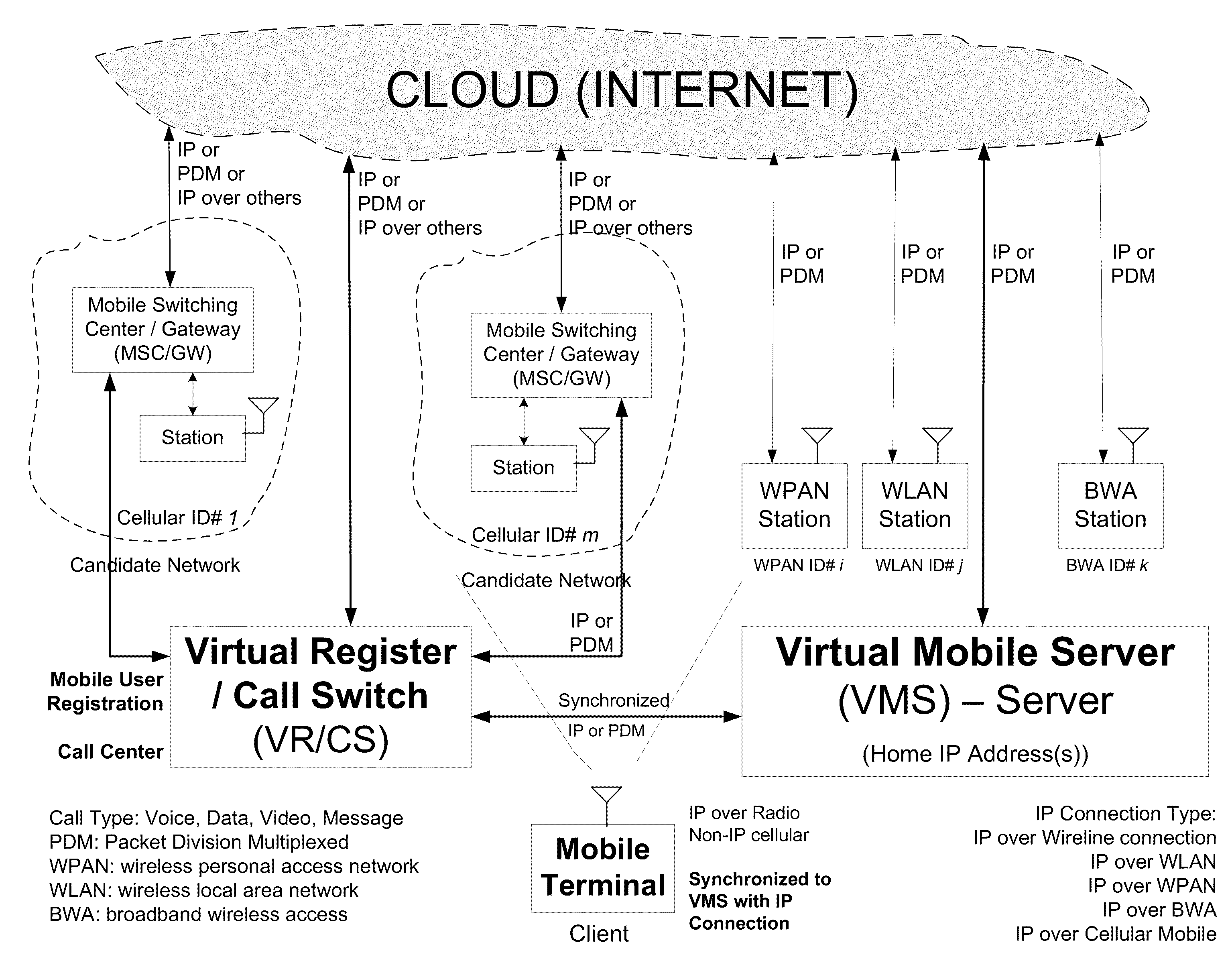

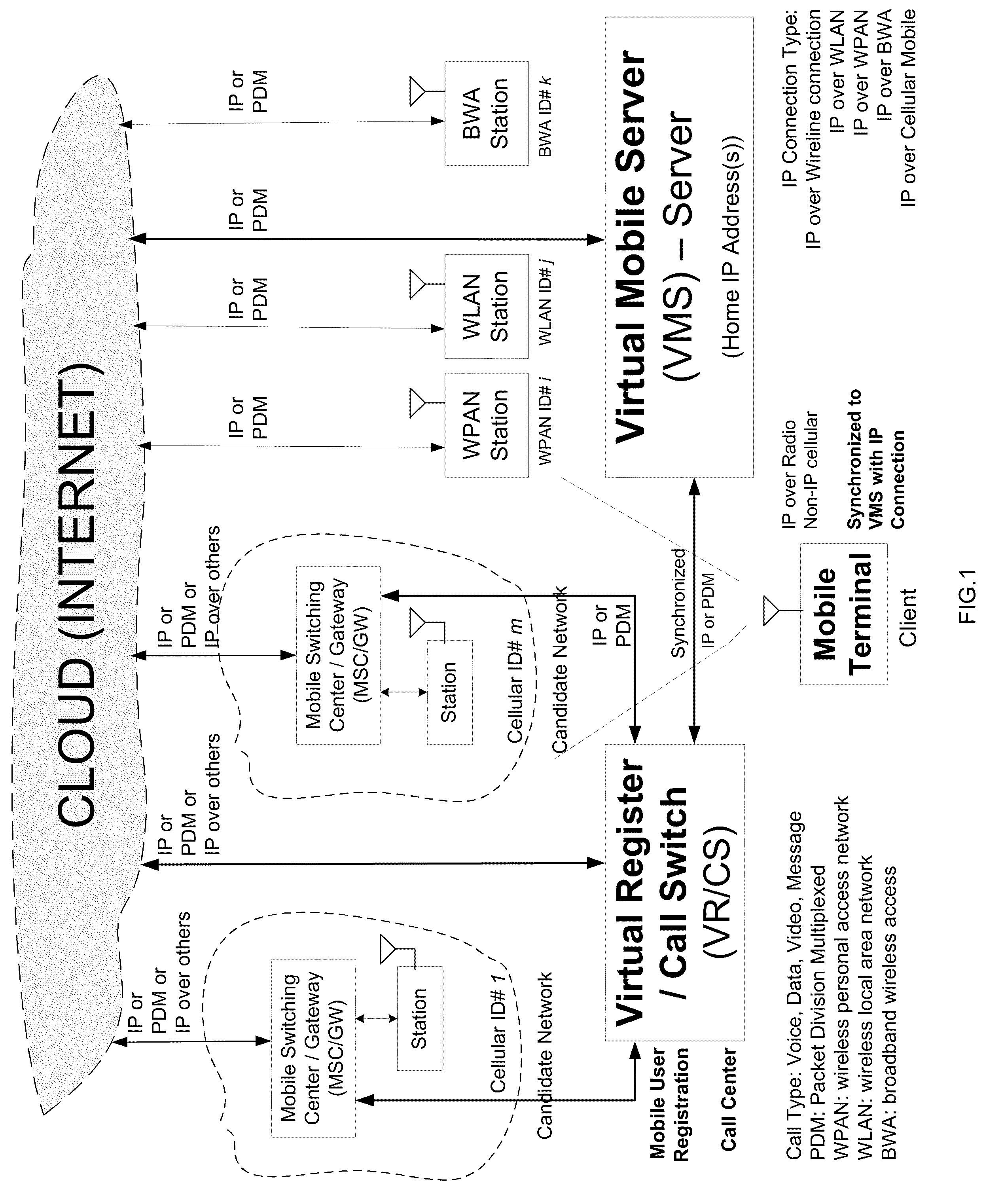

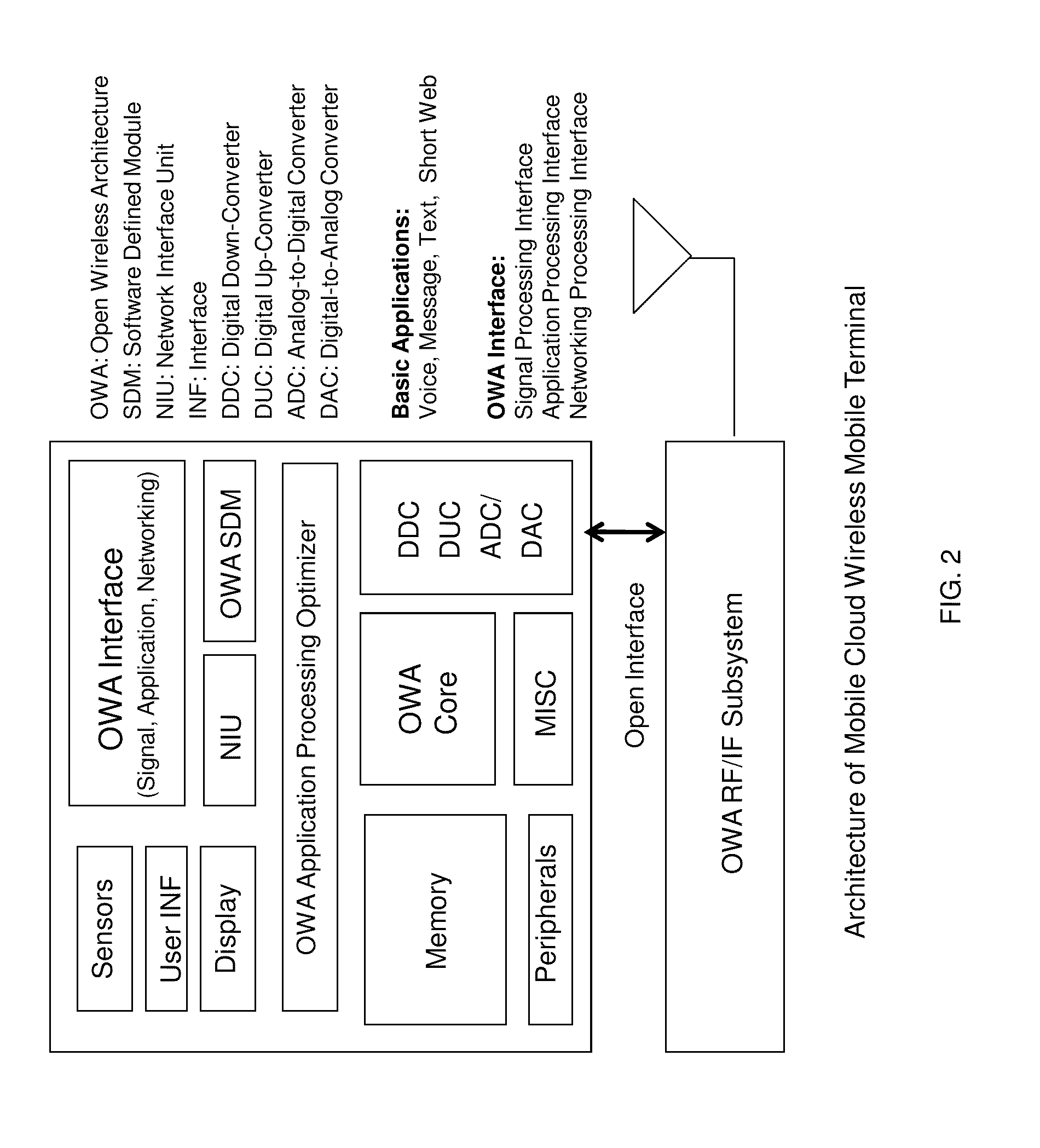

Open wireless architecture (OWA) mobile cloud infrastructure and method

ActiveUS20150229713A1Spectrum efficiency is improvedOptimize network resourcesPower managementNetwork traffic/resource managementWireless transmissionFrequency spectrum

An advanced mobile terminal converging multiple wireless transmission technologies by utilizing a cost-effective and spectrum-efficient mobile cloud solution by introducing Virtual Mobile Server (VMS) and Virtual Register and Call Switch (VR / CS) systems and methods based on the innovative open wireless architecture (OWA) technology platform, and the mobile terminal shared with other mobile cloud clients including computer terminal and television terminal fully synchronized through the VMS for the integrated smart home and smart office platform for the enterprise mobility solutions between home and enterprise.

Owner:PALO ALTO RES

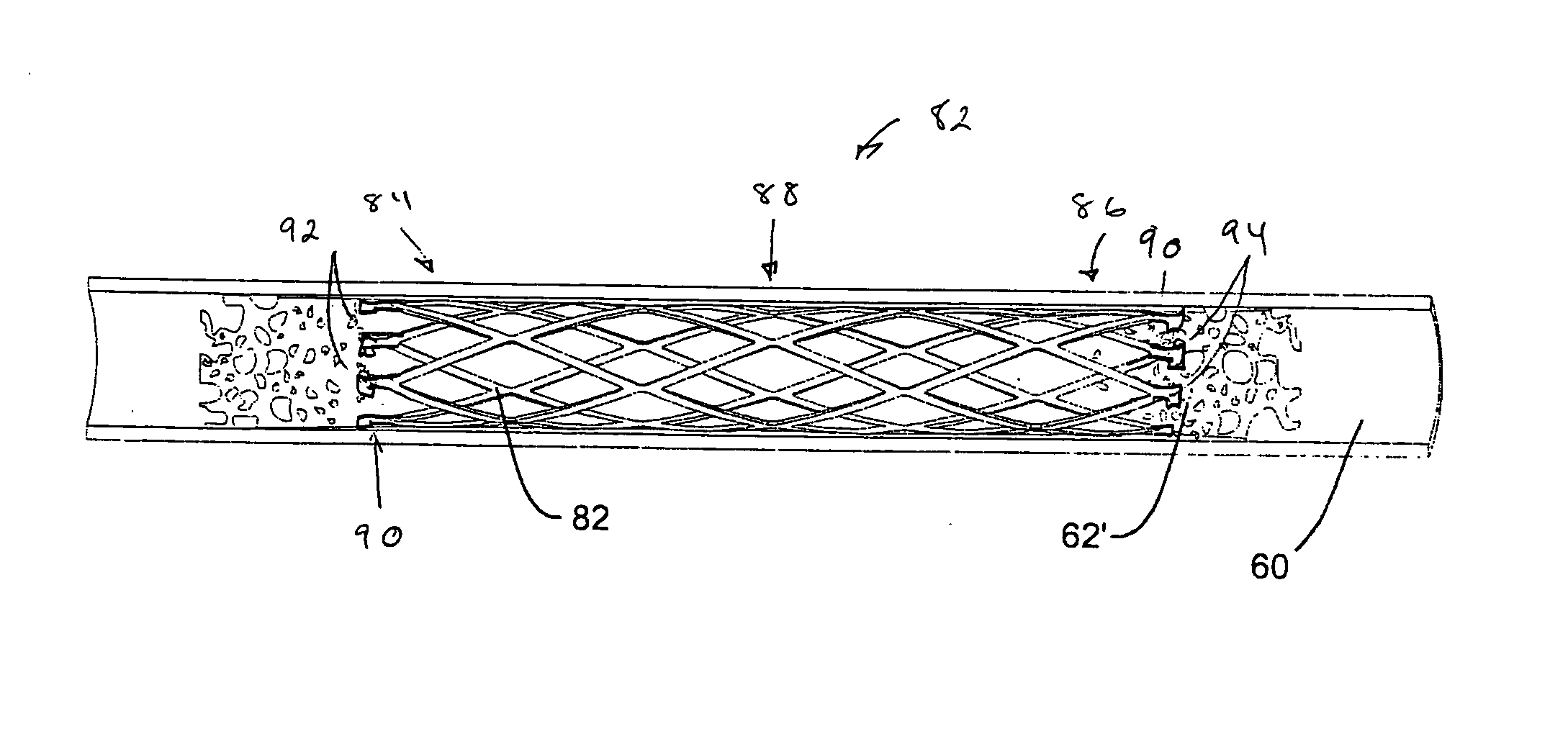

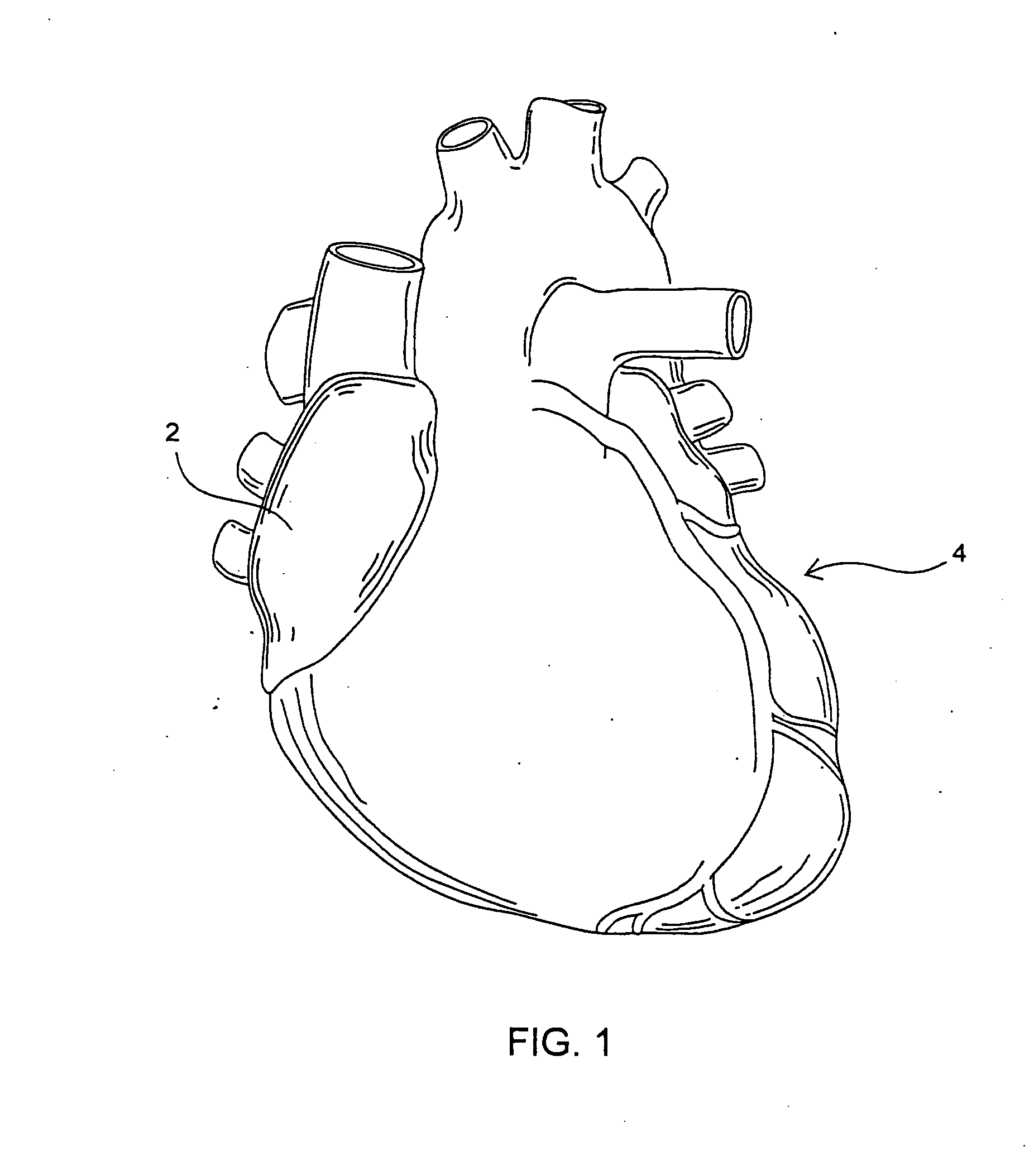

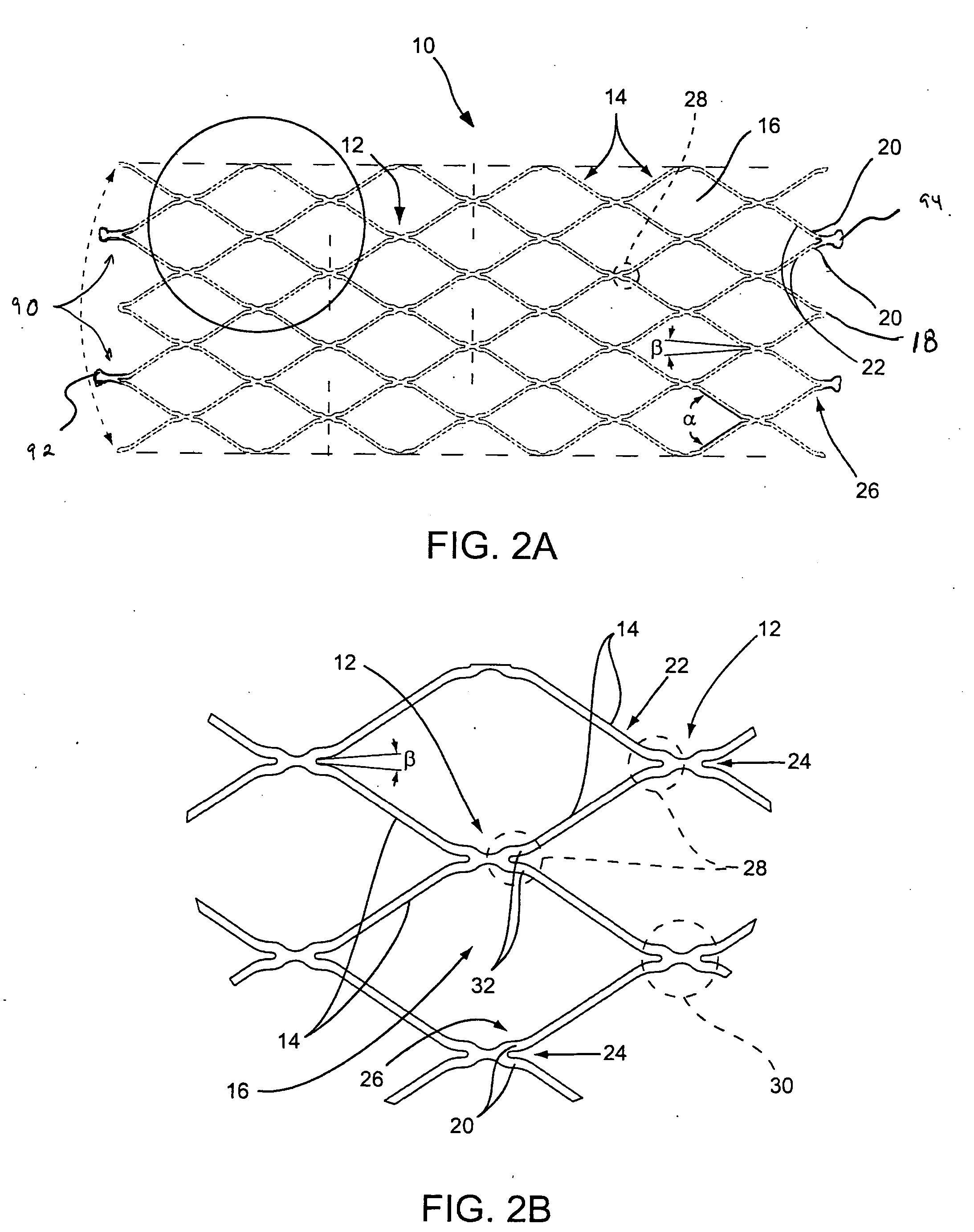

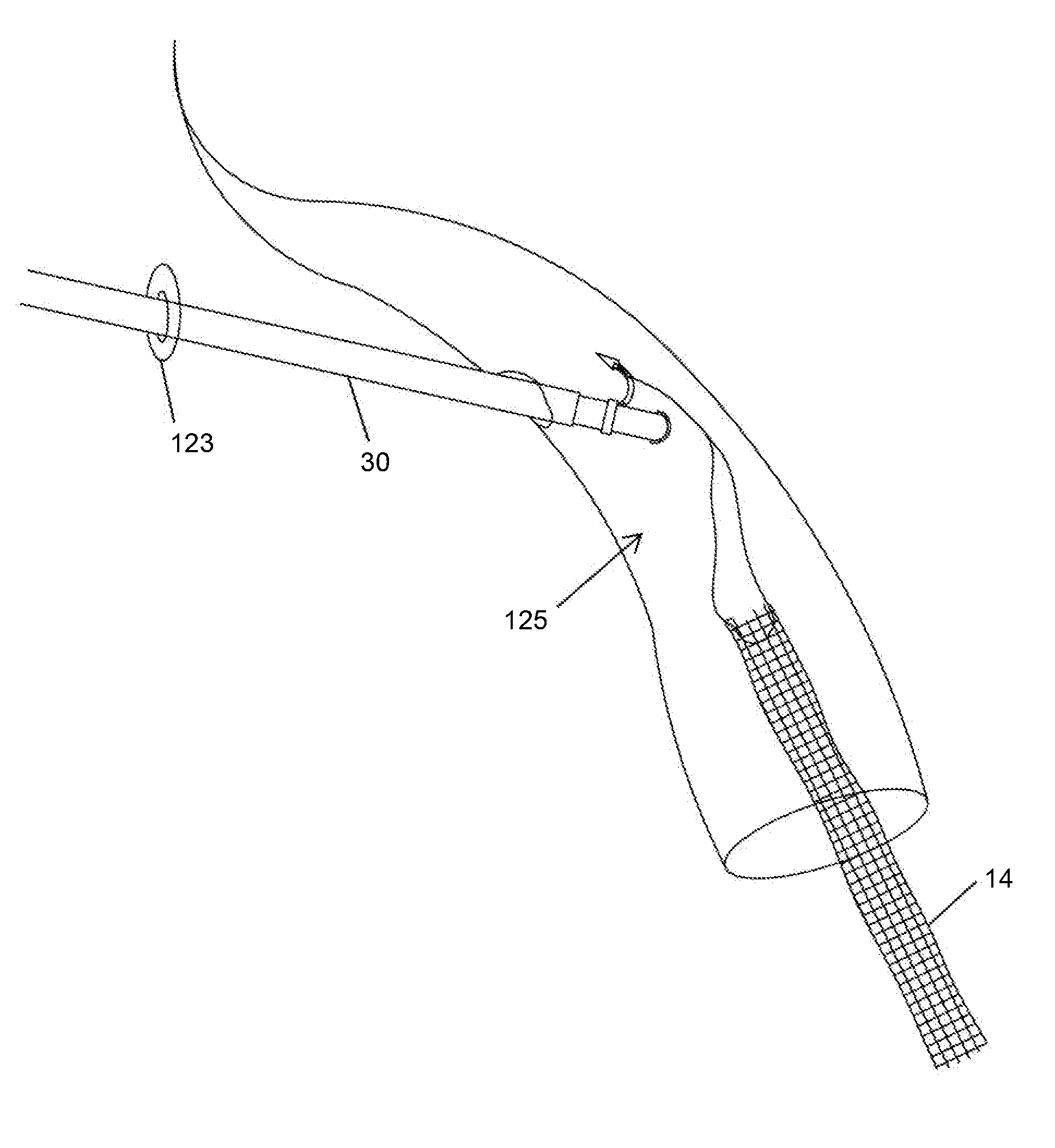

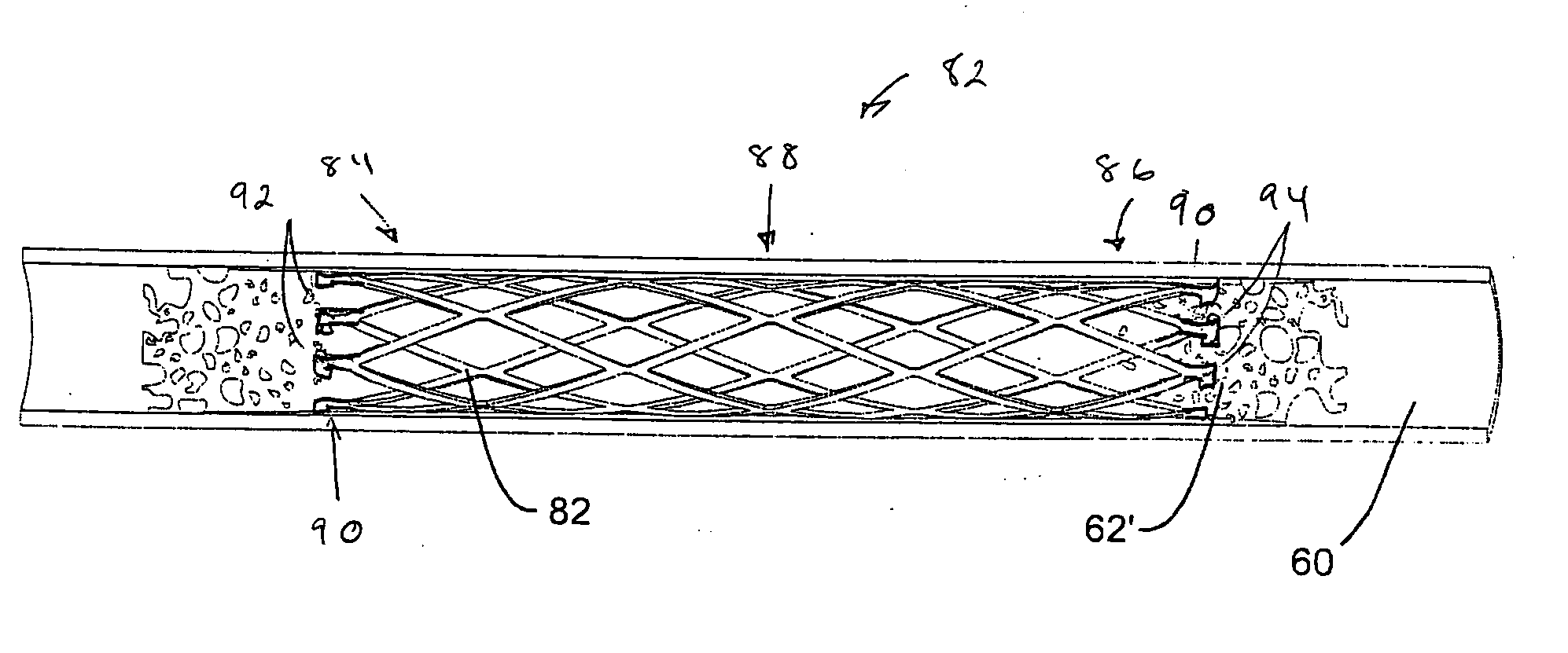

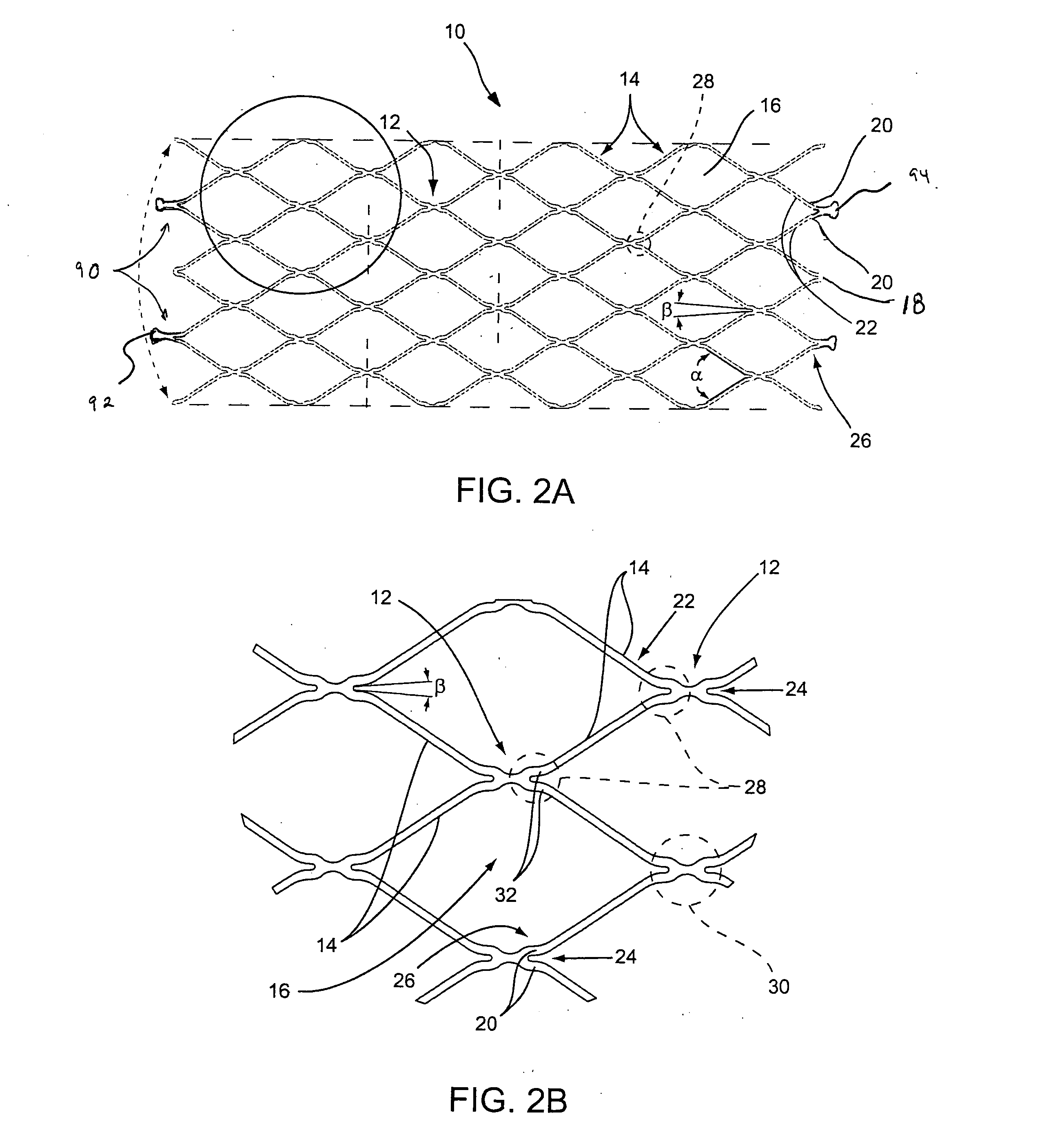

Tubular restraint release approaches for electrolytic implant delivery system

InactiveUS20070100419A1Reduce forceParticularly space-efficientStentsBlood vesselsBody organsProsthesis

Medical devices and methods for delivery or implantation of prostheses within hollow body organs and vessels or other luminal anatomy are disclosed. The subject technologies may be used in the treatment of atherosclerosis in stenting procedures or be used in variety of other procedures. The systems may employ a self expanding stent restrained by one or more members released by an electrolytically erodable latch. Such release means do not connect directly to the implant, though one or more portions may contact it.

Owner:BIOSENSORS INT GROUP

Open wireless architecture (OWA) mobile cloud infrastructure and method

InactiveUS20120296963A1Spectrum efficiency is improvedOptimize network resourcesNetwork topologiesWireless commuication servicesWireless transmissionFrequency spectrum

A future mobile terminal converging multiple wireless transmission technologies by utilizing a cost-effective and spectrum-efficient mobile cloud solution by introducing Virtual Mobile Server (VMS) and Virtual Register and Call Switch (VR / CS) systems and methods based on the innovative open wireless architecture (OWA) technology platform, and the mobile terminal extended to other mobile cloud clients including computer terminal and television terminal fully synchronized through the VMS.

Owner:PALO ALTO RES

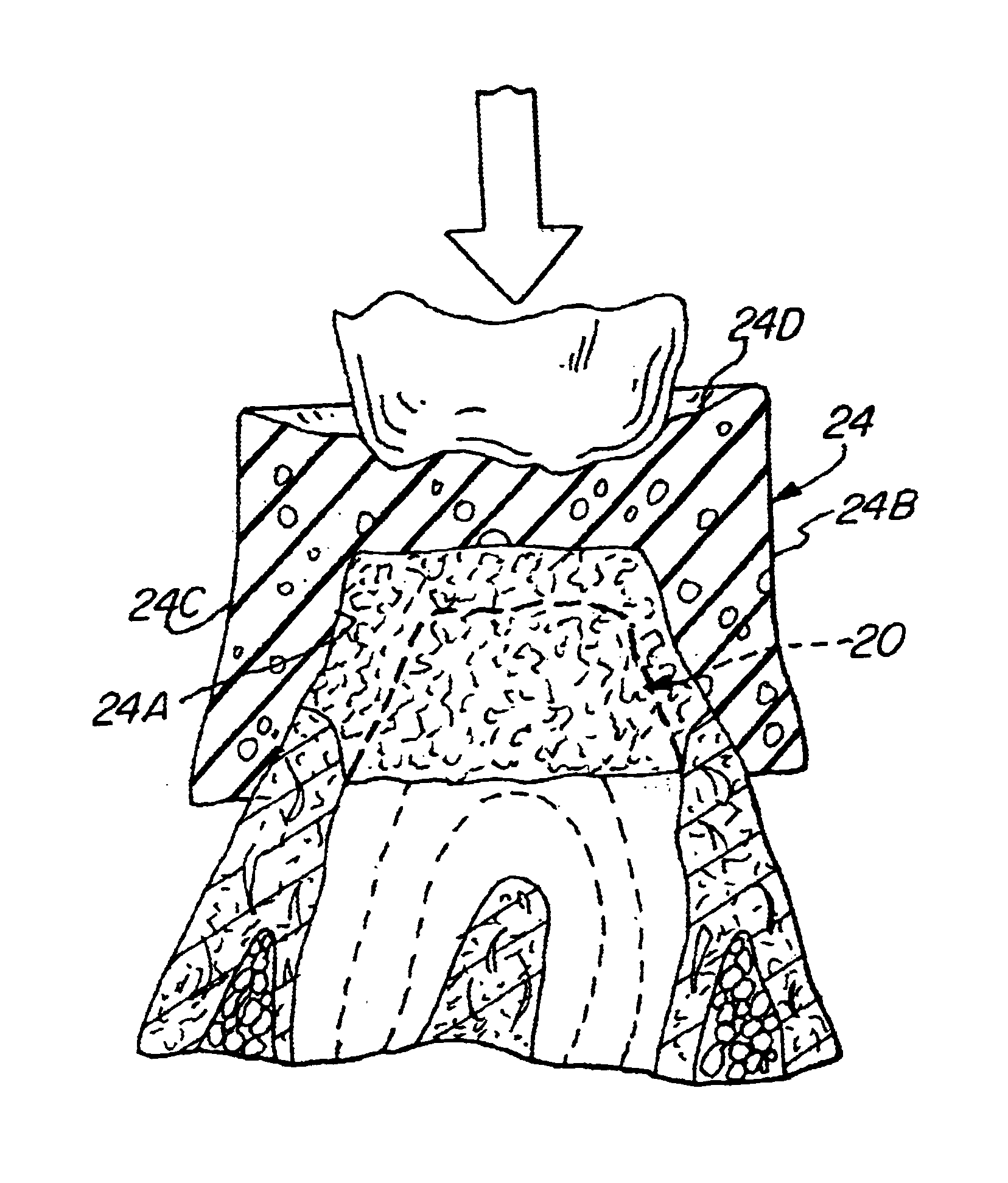

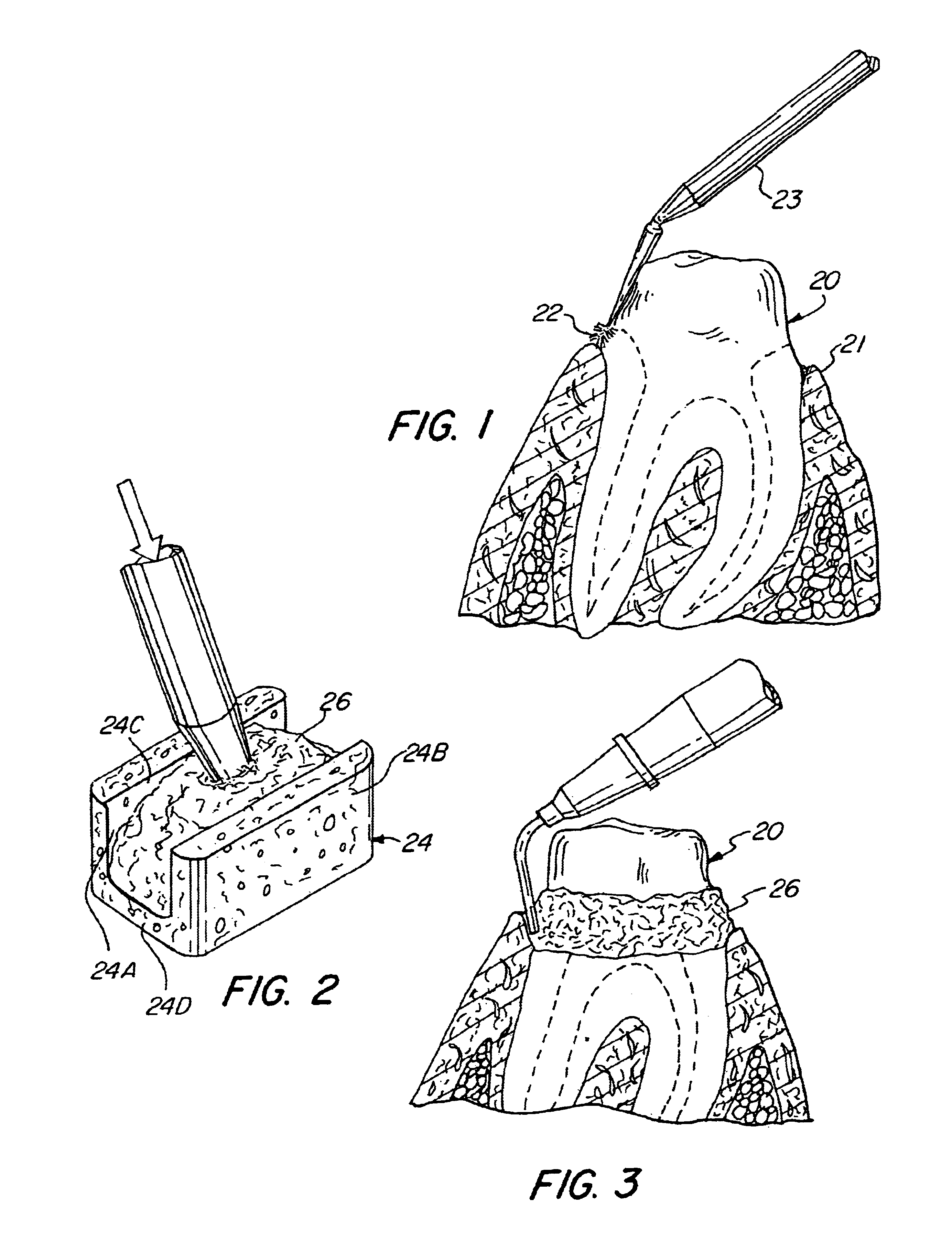

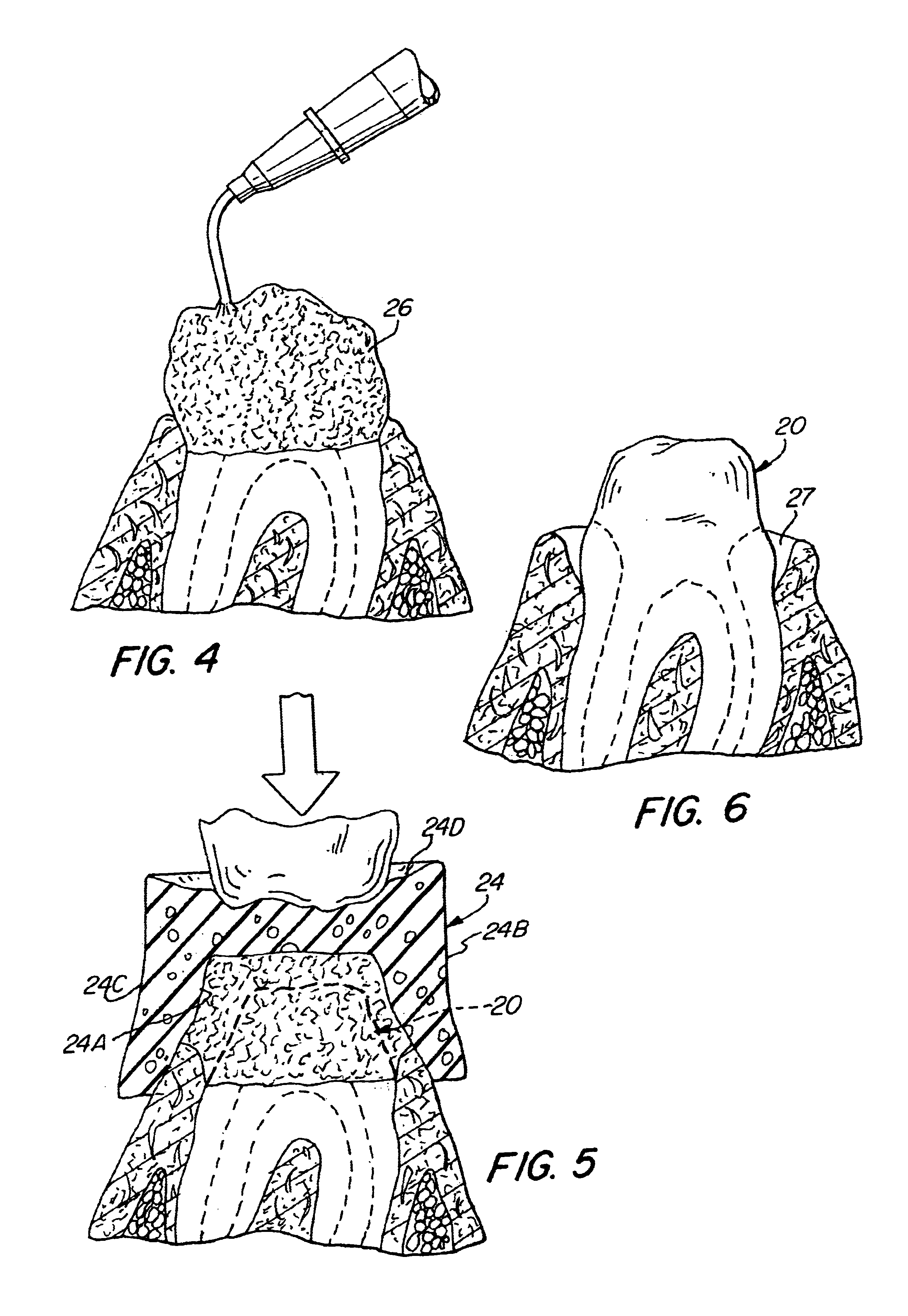

Method and device for the retraction and hemostasis of tissue during crown and bridge procedures

InactiveUS6890177B2Positive in operationEasy to operateImpression capsDental aidsBite force quotientGingival space

A method and a device for effecting the cordless retraction of the gingival sulcus tissue prior to the taking of an impression of a tooth for making a crown or bridge which is attained by controlling any bleeding in the gingival sulcus area, and utilizing a dental dam preferably formed of a sponge or foam like material to contain an astringent fortified silicone impression material embedded about the prepared tooth, and using the patient's biting force to apply the necessary pressure onto the dam until the silicone impression material sets and adheres to the dam to enhance easy removal of the set impression material from the tooth. The dam is formed to accommodate either the posterior teeth or the anterior teeth.

Owner:CENTRIX

Open wireless architecture (OWA) mobile cloud infrastructure and method

ActiveUS20110176528A1Spectrum efficiency is improvedOptimize network resourcesNetwork topologiesWireless network protocolsWireless transmissionFrequency spectrum

A future mobile terminal converging multiple wireless transmission technologies by utilizing a cost-effective and spectrum-efficient mobile cloud solution by introducing the Virtual Mobile Server (VMS) and Virtual Register and Call Switch (VR / CS) systems and methods based on the innovative open wireless architecture (OWA) technology platform.

Owner:LU WEI +3

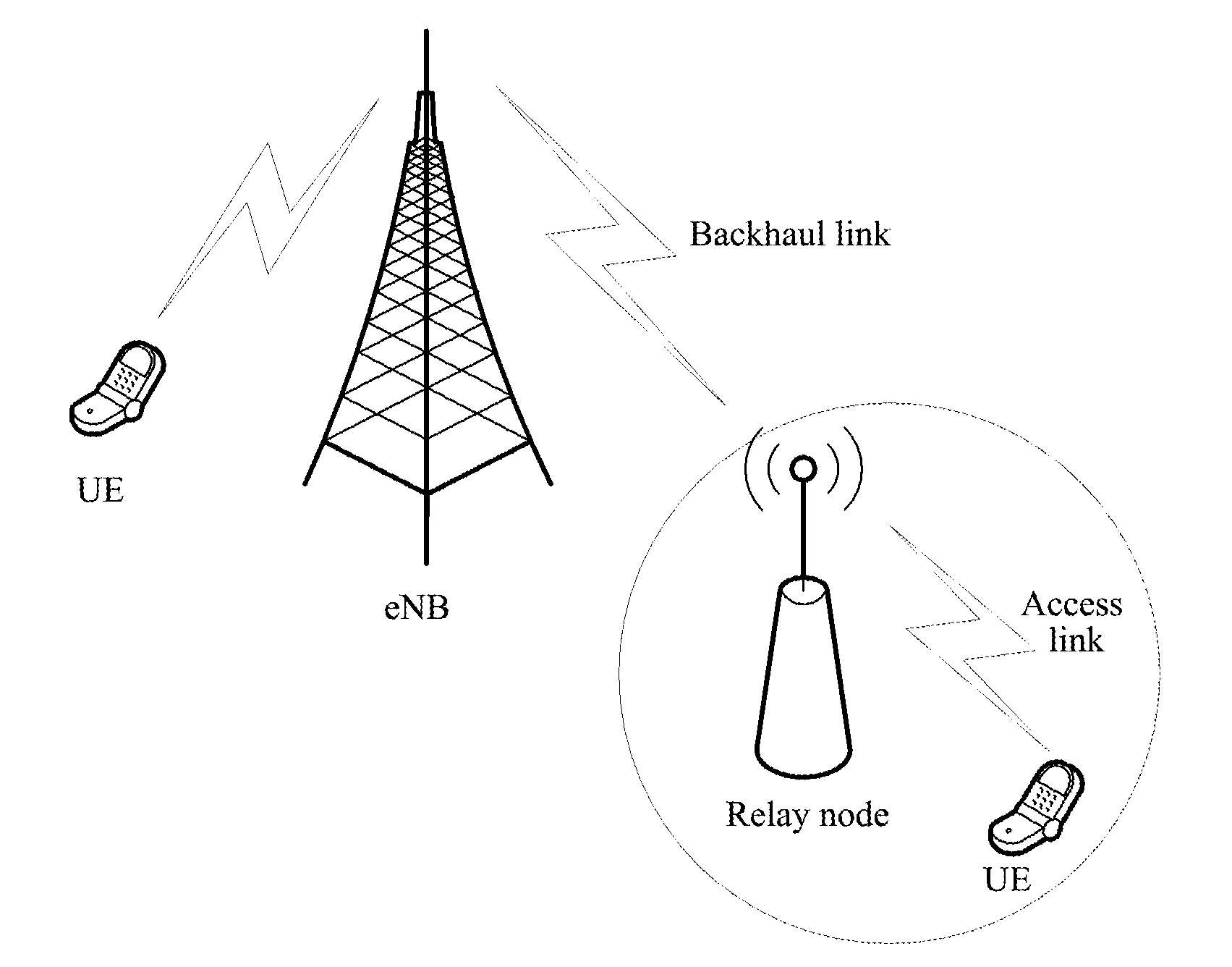

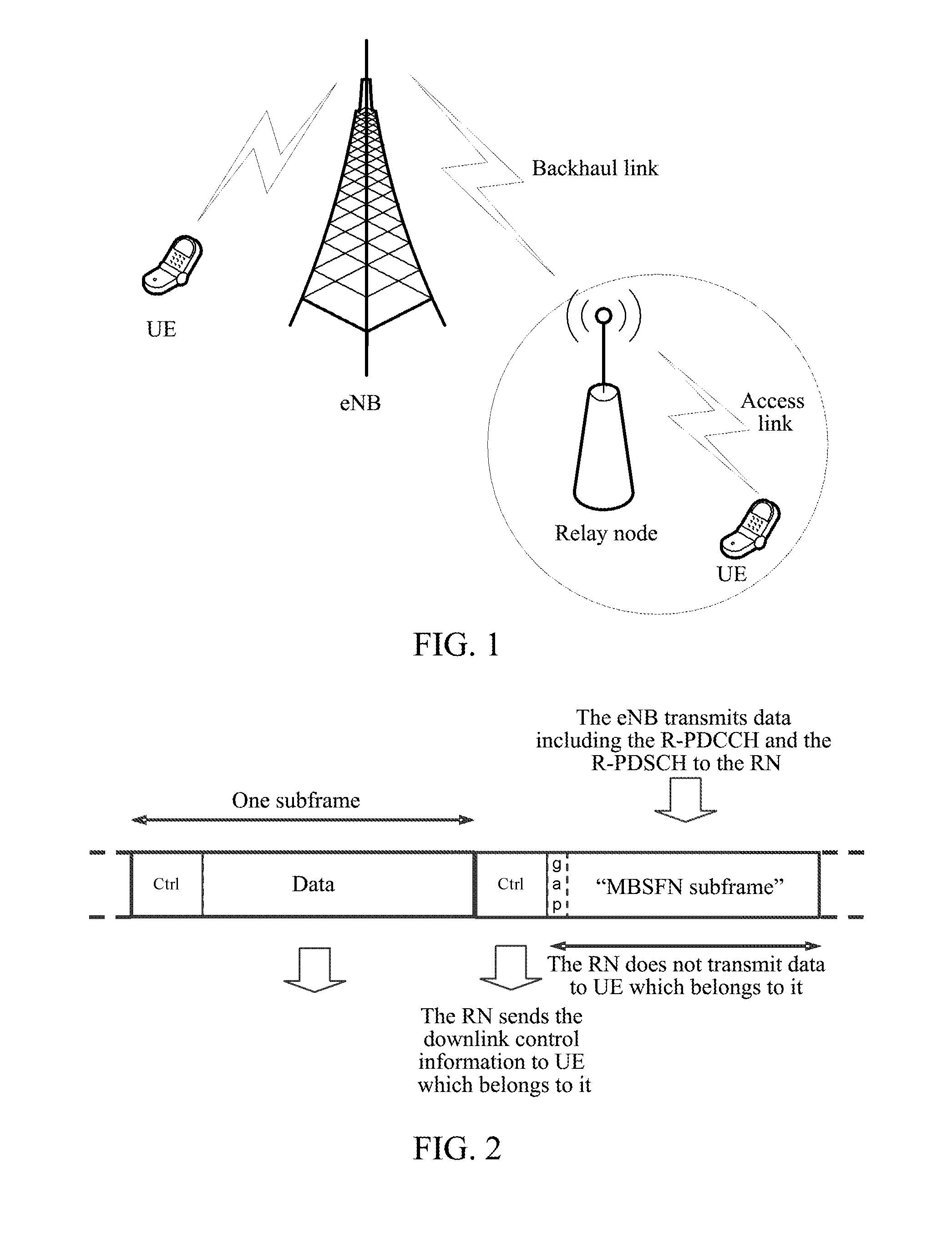

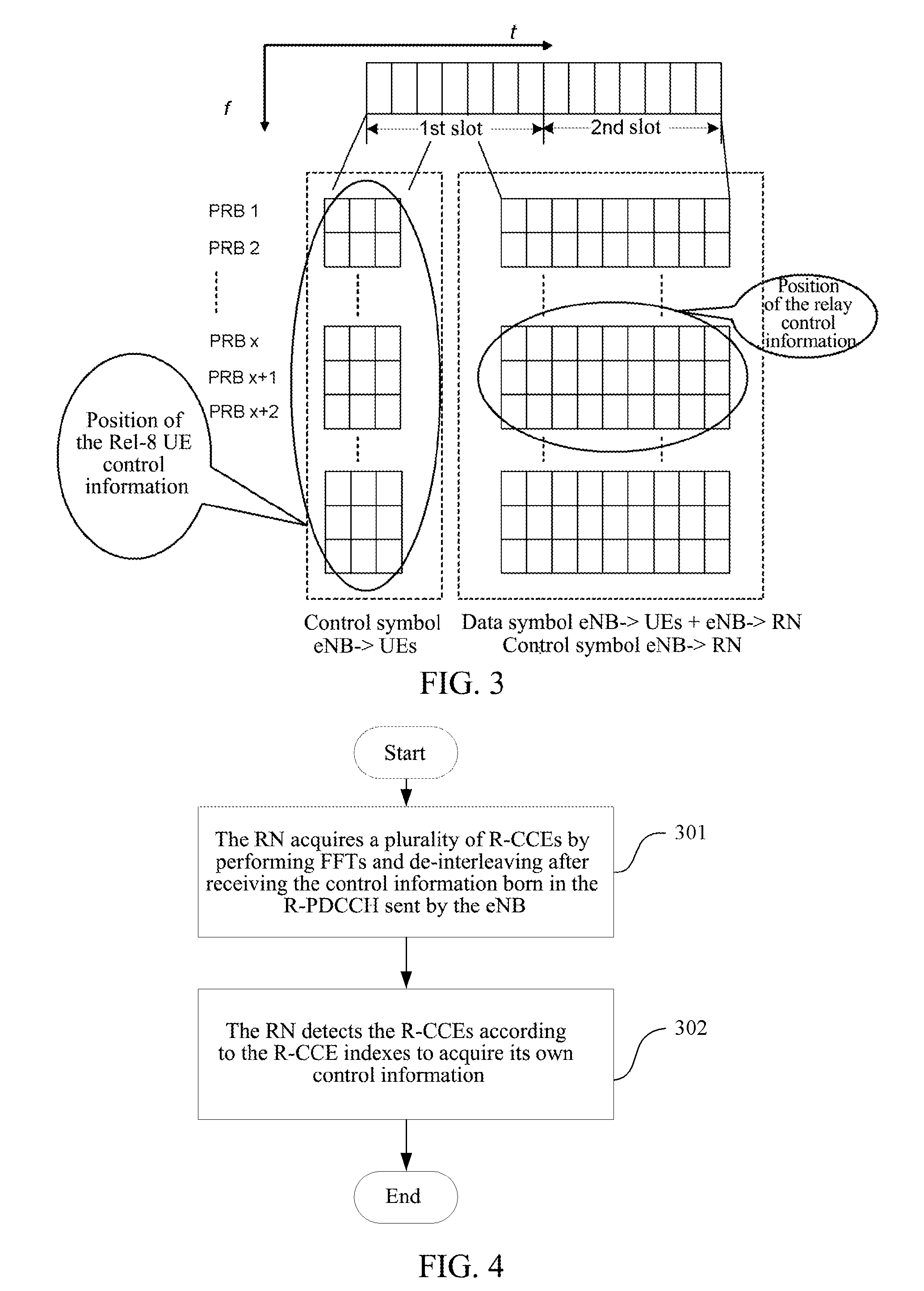

Method and device for detecting downlink control information

ActiveUS20120093063A1Simple performanceSave overheadFrequency-division multiplex detailsAssess restrictionComputer networkResource block

The present invention discloses a method and a device for detecting downlink control information. The method includes: a Relay Node (RN) receiving control information born in a Relay Physical Downlink Control Channel (R-PDCCH) sent by an evolved Node B (eNB) to acquire a control resource; the RN performing detection on the control resource according to an index of the control resource to acquire own control information; wherein the control resource is a Relay Control Channel Element (R-CCE) or a Physical Resource Block (PRB). The present invention can save system overhead and improve system transmission efficiency.

Owner:ZTE CORP

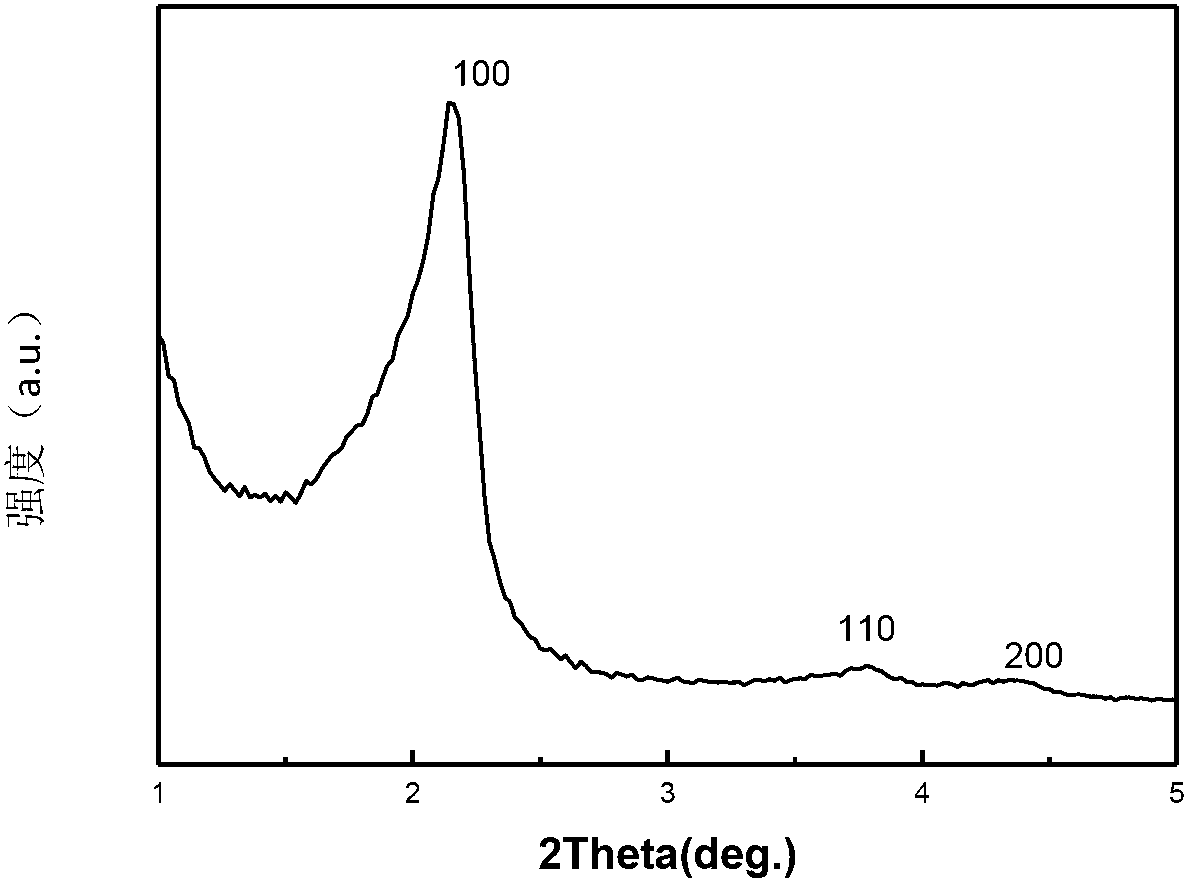

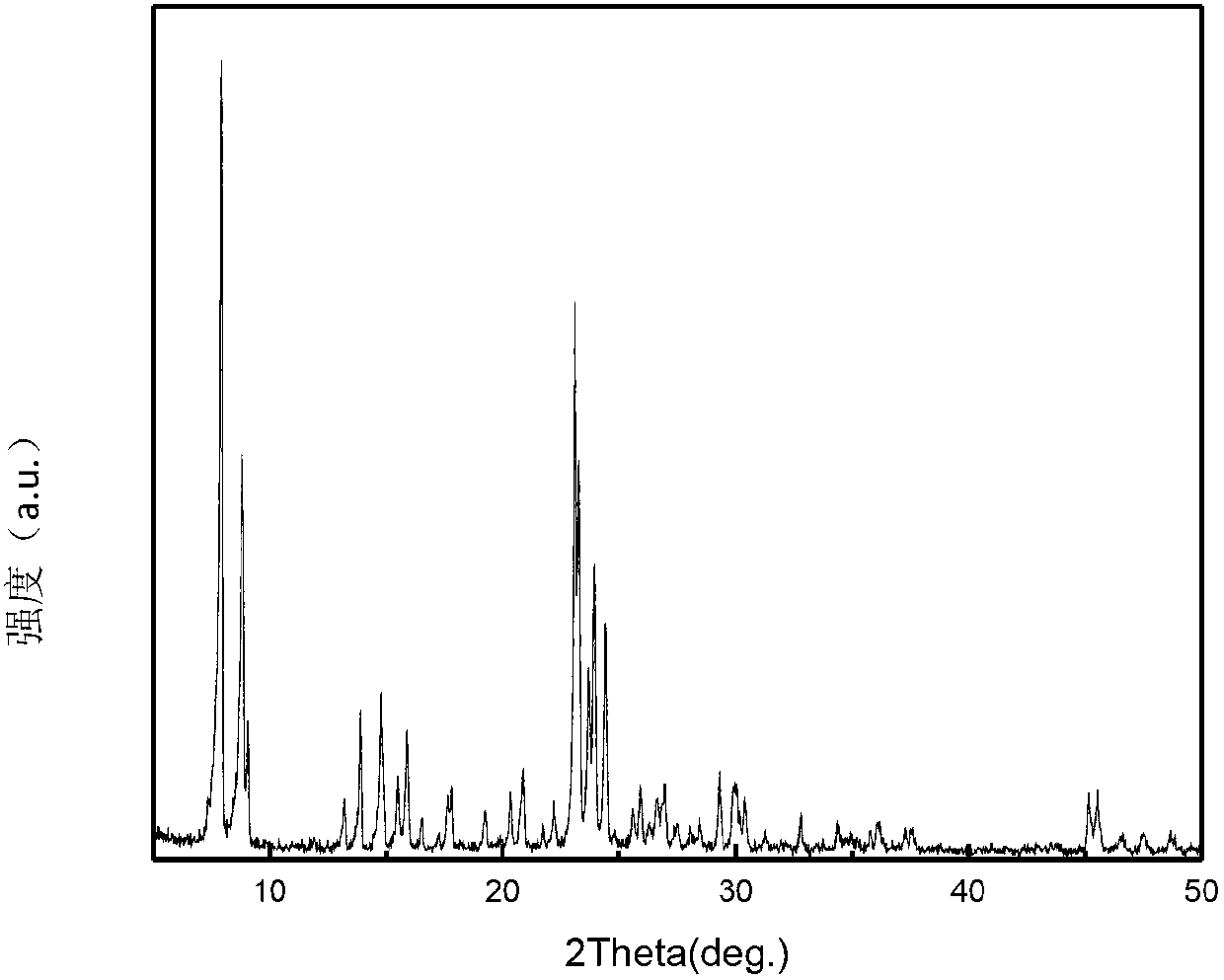

Ordered mesopore ZSM-5 molecular sieve and preparation method thereof

InactiveCN103101930AImprove performanceRemarkable resultsPentasil aluminosilicate zeolitePore diameterPetrochemical

The invention discloses a preparation method of an ordered mesopore ZSM-5 molecular sieve. The preparation method comprises the following steps of: firstly preparing an ordered mesopore silicon oxide molecular sieve serving as a silicon source through an organic template method; and then transforming the ordered mesopore silicon oxide molecular sieve into the ordered mesopore ZSM-5 molecular sieve in situ by adopting a hydrothermal method. The ordered mesopore ZSM-5 molecular sieve disclosed by the invention is provided with ordered micropores with pore diameter being 0.2-2 nanometers and ordered mesopores with pore diameter being 2-50 nanometers and has wide application prospect in the fields of petrochemical industry, petroleum processing, coal chemical industry, and the like.

Owner:SHANGHAI NORMAL UNIVERSITY

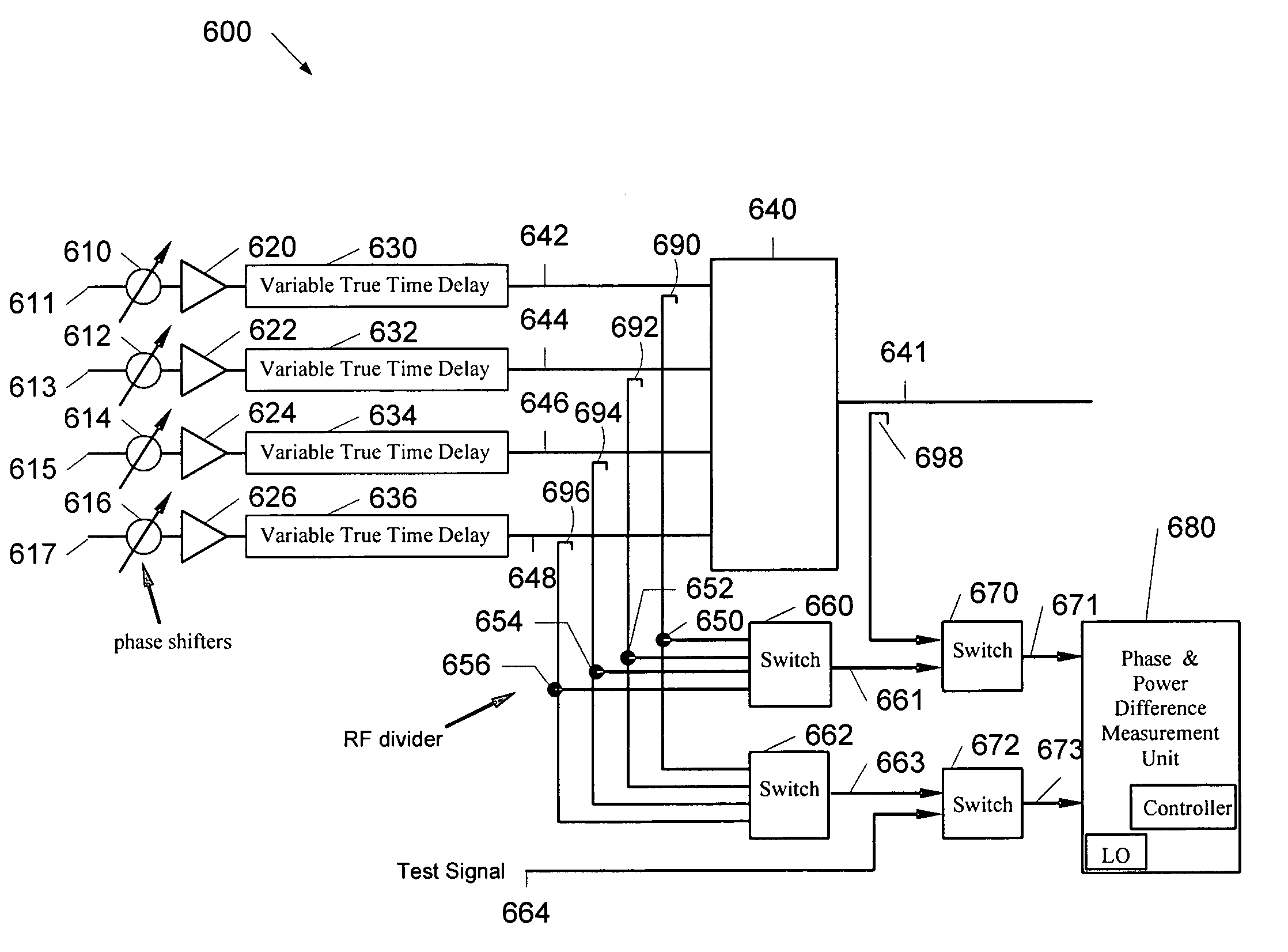

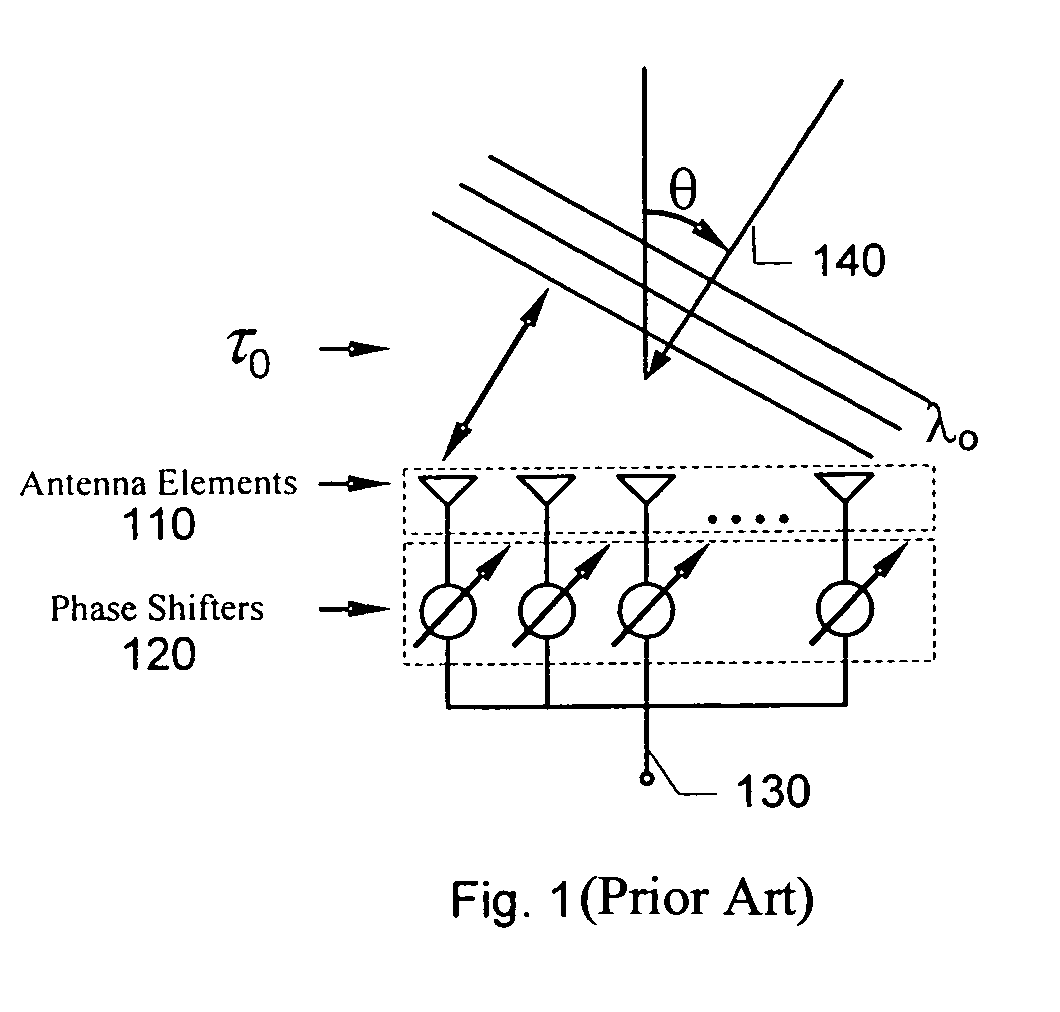

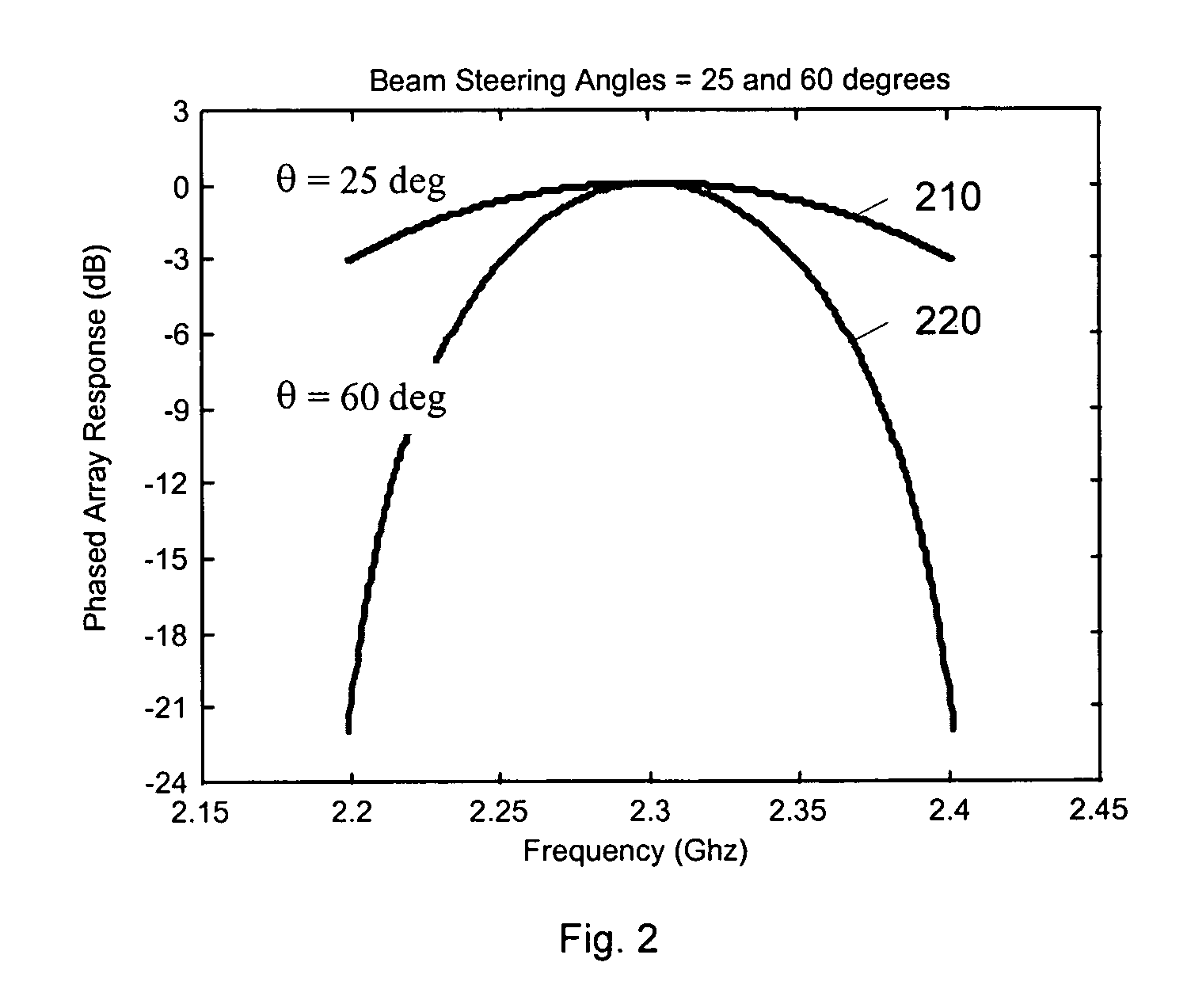

Adaptive variable true time delay beam-forming system and method

System and method for signal processing and beam forming. A system for processing signals includes a first phase shifter, a second phase shifter, a first variable time delay system, and a second variable time delay system. Additionally, the system includes a first signal processing system and a sampling system. Moreover, the system includes a switching system and a measuring system.

Owner:LOCKHEED MARTIN CORP

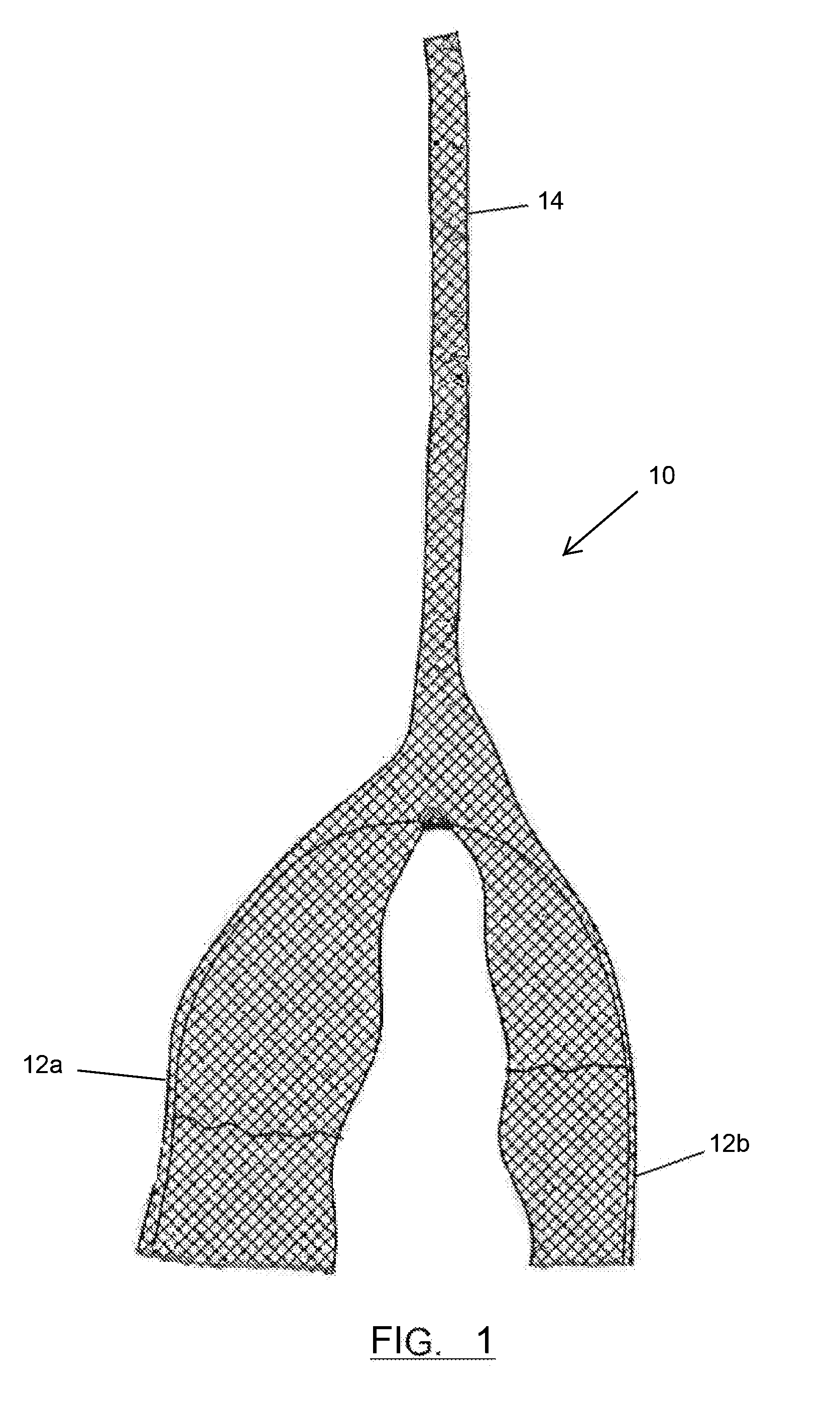

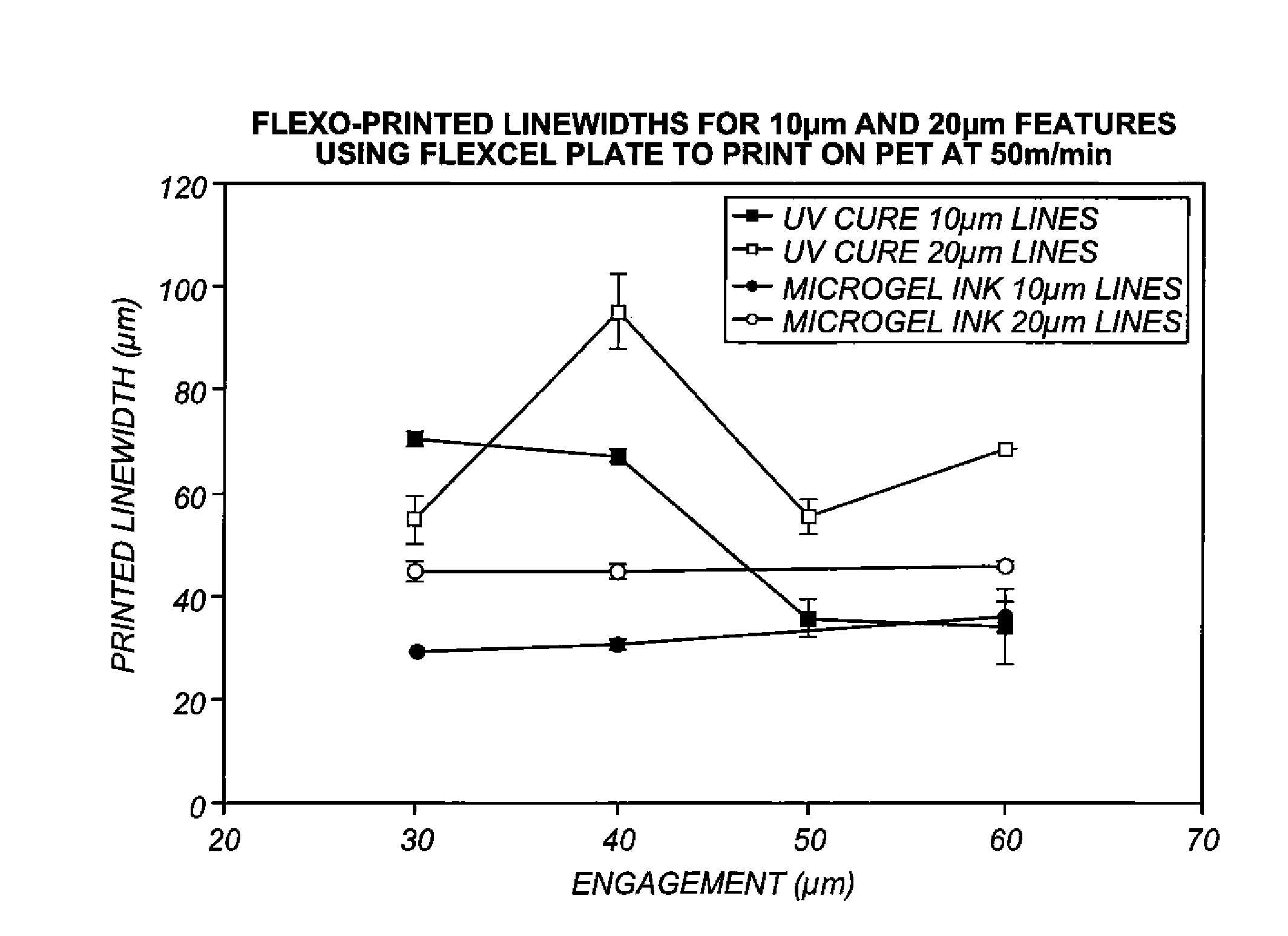

System and Method for Treating Prolapse and Incontinence

ActiveUS20110105836A1Preventing recurring prolapseLow mesh loadAnti-incontinence devicesTubular organ implantsVaginal ProlapsesAnatomical structures

A system and method of treating vaginal prolapse and incontinence comprises a kit. The kit includes a mesh graft configured for attachment to the anterior and posterior vaginal walls to thereby treat the vaginal prolapse. A graft delivery device is also provided for introducing and placing the mesh graft to a location deep within the peritoneal cavity and for attaching the graft thereto. A leg assembly is provided and coupled to an end of the mesh graft and cooperates with the graft delivery device to anchor and affix the mesh graft to the desired anatomical structures. The method according to the present invention contemplates a laparoscopic graft placement utilizing the components of the kit.

Owner:BOSTON SCI SCIMED INC

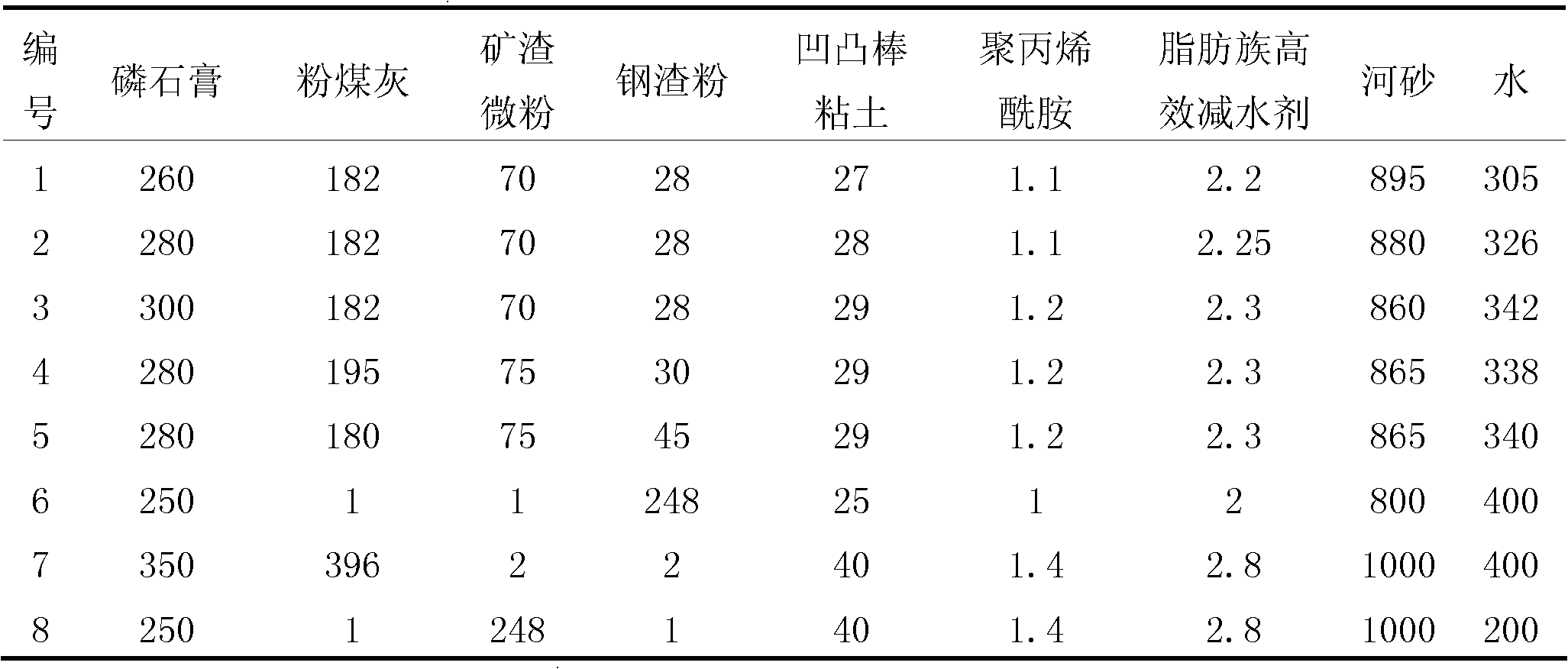

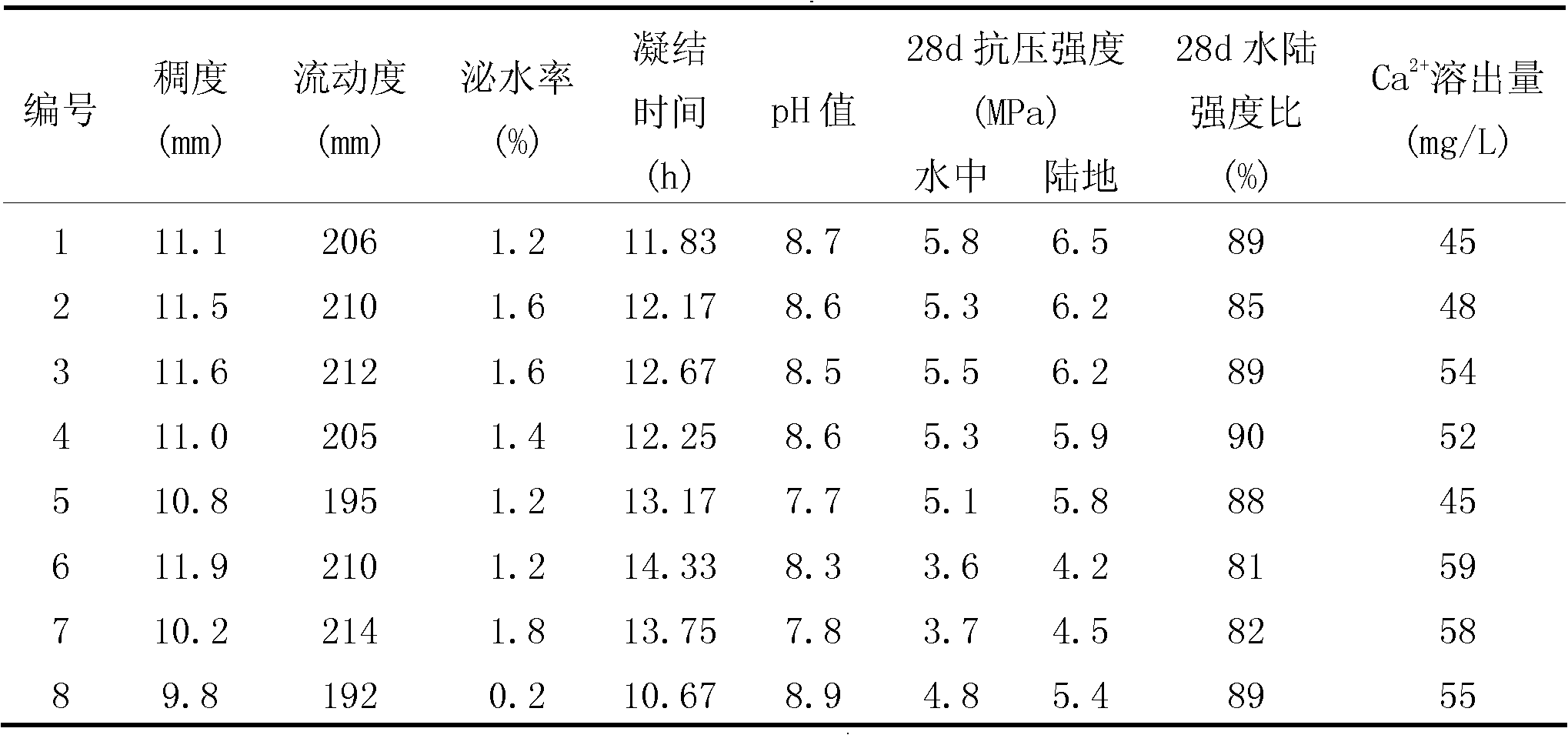

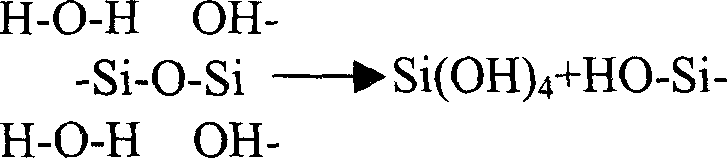

Cement-free anti-water dispersion and anti-water corrosion synchronous grouting material and its preparation method

InactiveCN102617095AResistant to water dispersionWith water corrosion resistanceSlagSuperplasticizer

The invention relates to a synchronous grouting material of shield tunneling and its preparation method. A cement-free anti-water dispersion and anti-water corrosion synchronous grouting material is mainly composed of the following components by weight ratio: 250-350kg / m<3> of phosphogypsum, 250-400kg / m<3> of fly ash, slag powder and steel slag powder, 25-40kg / m<3> of attapulgite clay, 1-1.4kg / m<3> of polyacrylamide, 2-2.8kg / m<3> of an aliphatic high efficiency water reducer, 800-1000kg / m<3> of river sand, and 200-400kg / m<3> of water. Specifically, for the sum of the weight of the fly ash, the slag powder and the steel slag powder, the fly ash accounts for 0.5-99%, the slag powder accounts for 0.5-99%, and the steel slag powder accounts for 0.5-99%. Mixing and stirring of the materials can obtain the required synchronous grouting material, which has the characteristics of anti-water dispersion, anti-water corrosion, good fluidity, good construction performance, no pipe blockage, long usable time, and fast increase of later strength.

Owner:WUHAN METRO GROUP +1

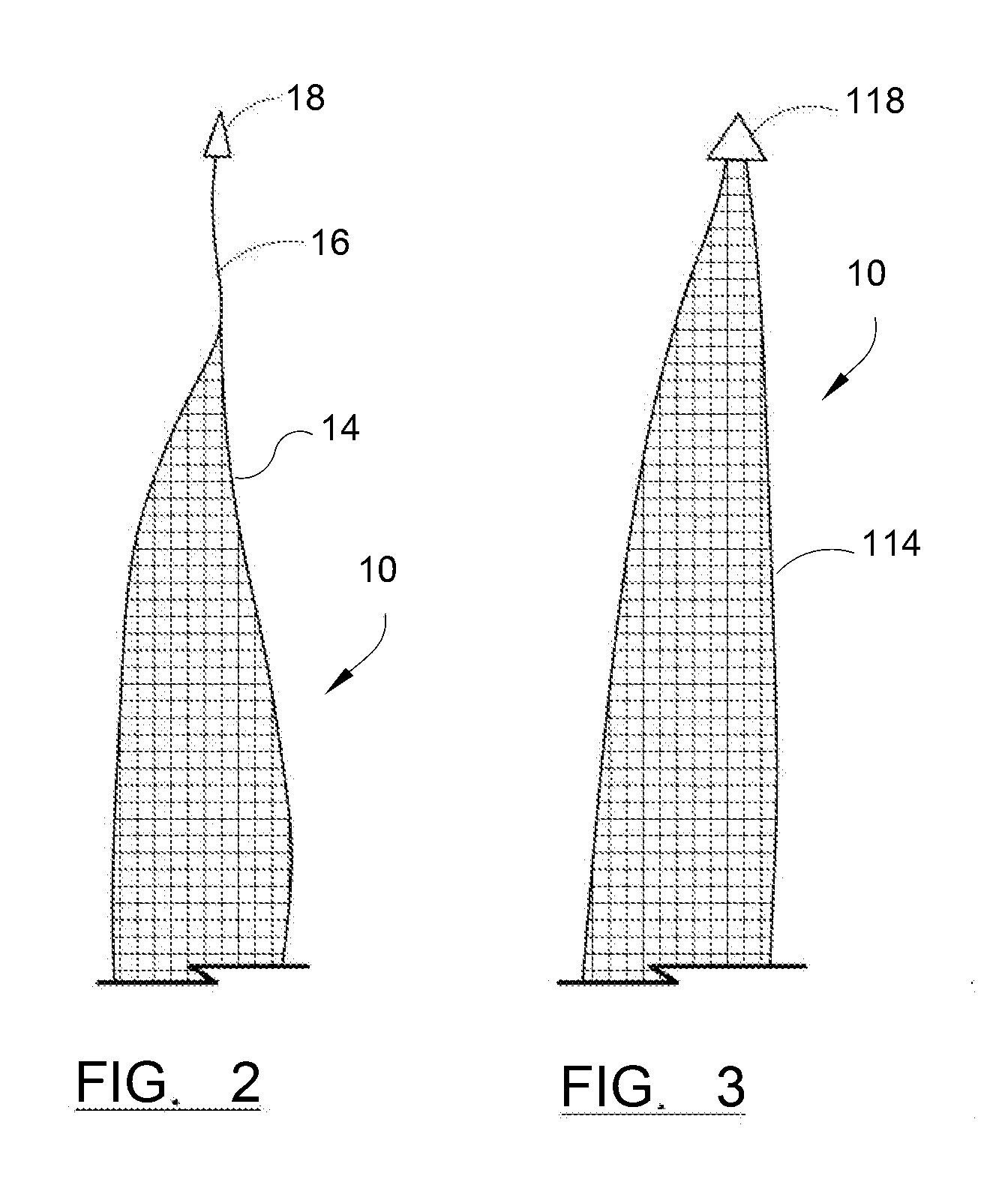

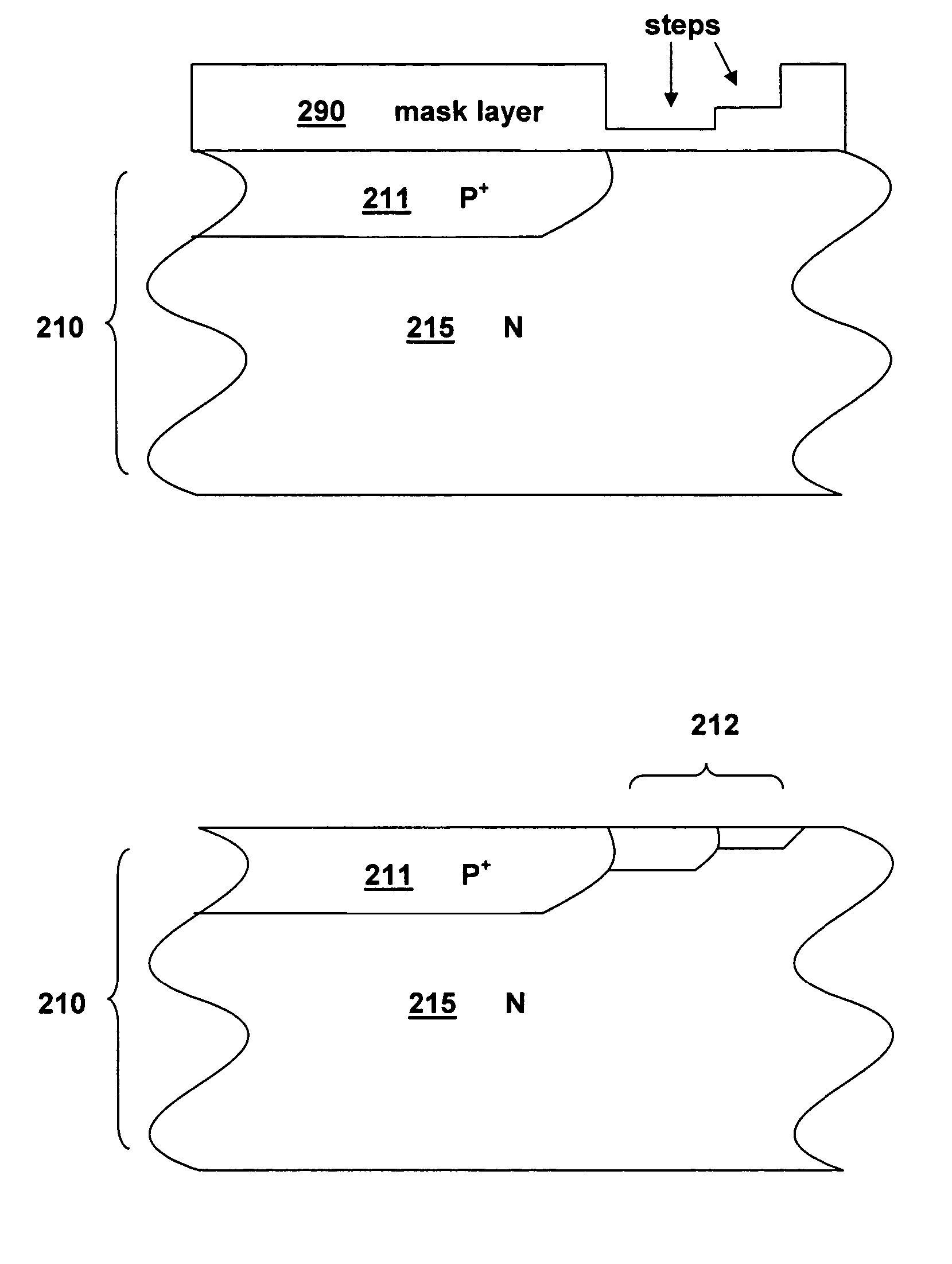

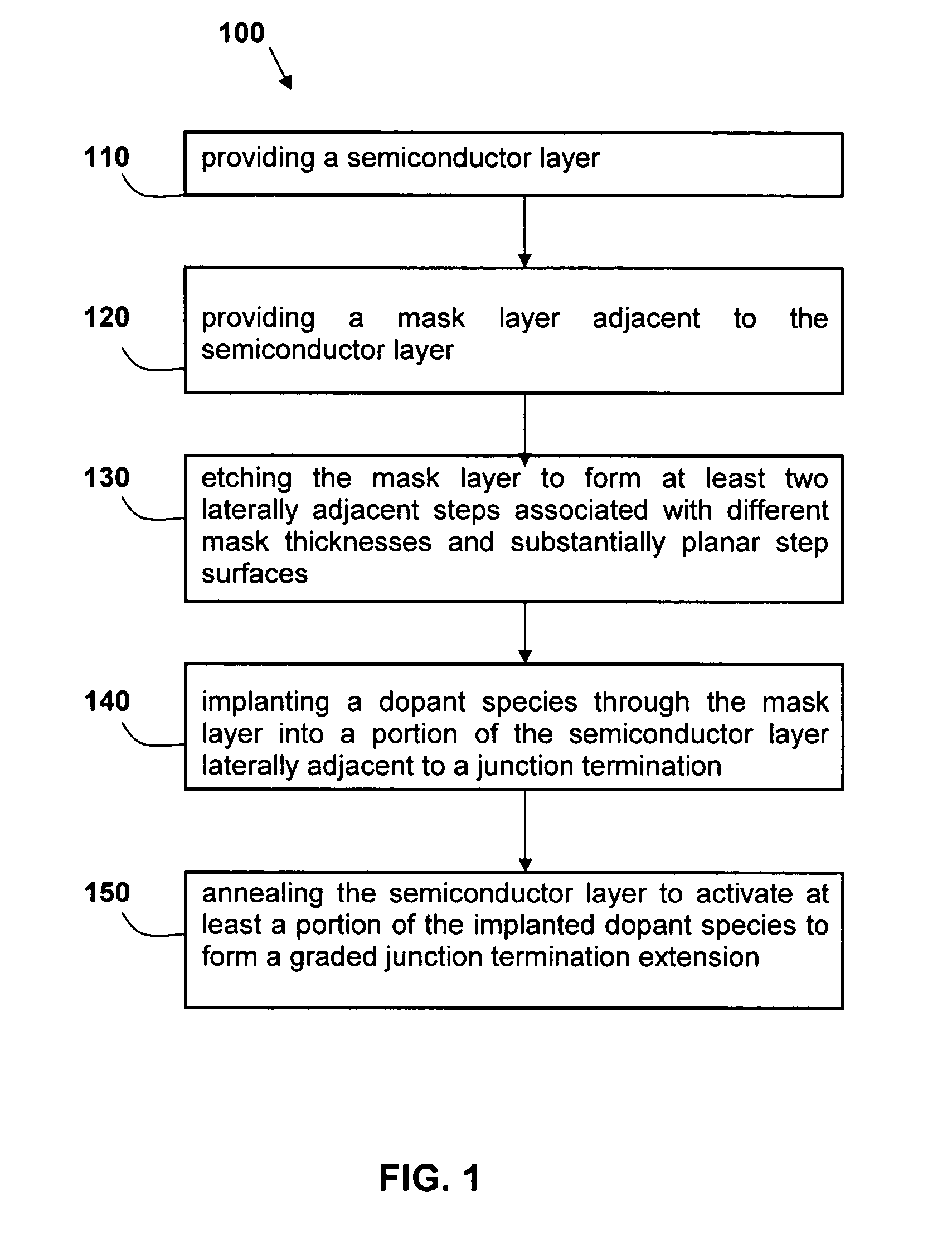

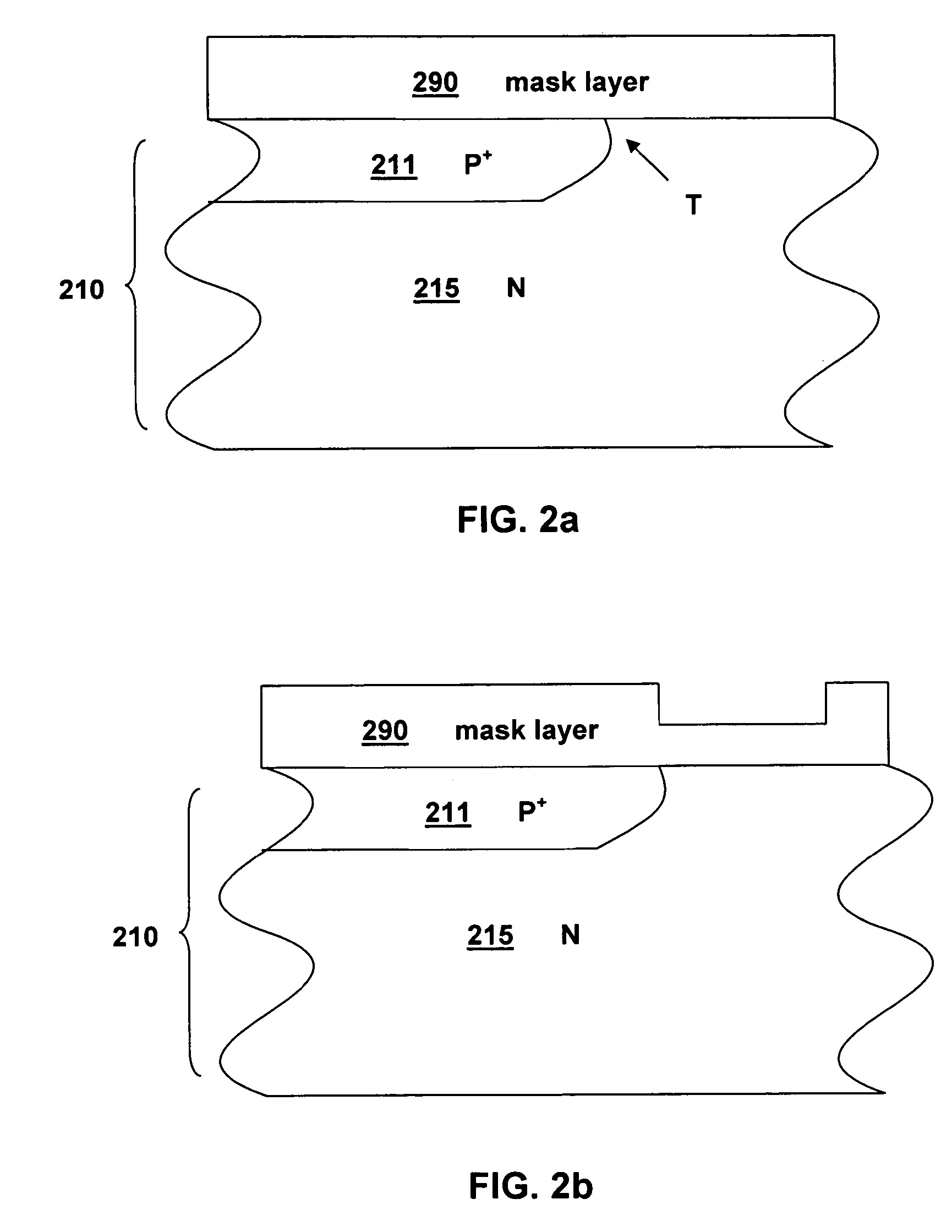

Semiconductor device having multiple-zone junction termination extension, and method for fabricating the same

ActiveUS7144797B2Simplify fabricationSimple performanceSemiconductor/solid-state device manufacturingSemiconductor devicesDopantSemiconductor

A semiconductor device includes a graded junction termination extension. A method for fabricating the device includes providing a semiconductor layer having a pn junction, providing a mask layer adjacent to the semiconductor layer, etching the mask layer to form at least two laterally adjacent steps associated with different mask thicknesses and substantially planar step surfaces, and implanting a dopant species through the mask layer into a portion of the semiconductor layer adjacent to the termination of the pn junction. The semiconductor layer is annealed to activate at least a portion of the implanted dopant species to form the graded junction termination extension.

Owner:RENESSELAER POLYTECHNIC INST

Intercalated superlattice compositions and related methods for modulating dielectric property

ActiveUS7678463B2Low working voltageDrain current increasesMaterial nanotechnologySolid-state devicesCrystallographyDielectric

Compositions, methods of using inorganic moieties for dielectric modulation, and related device structures.

Owner:NORTHWESTERN UNIV

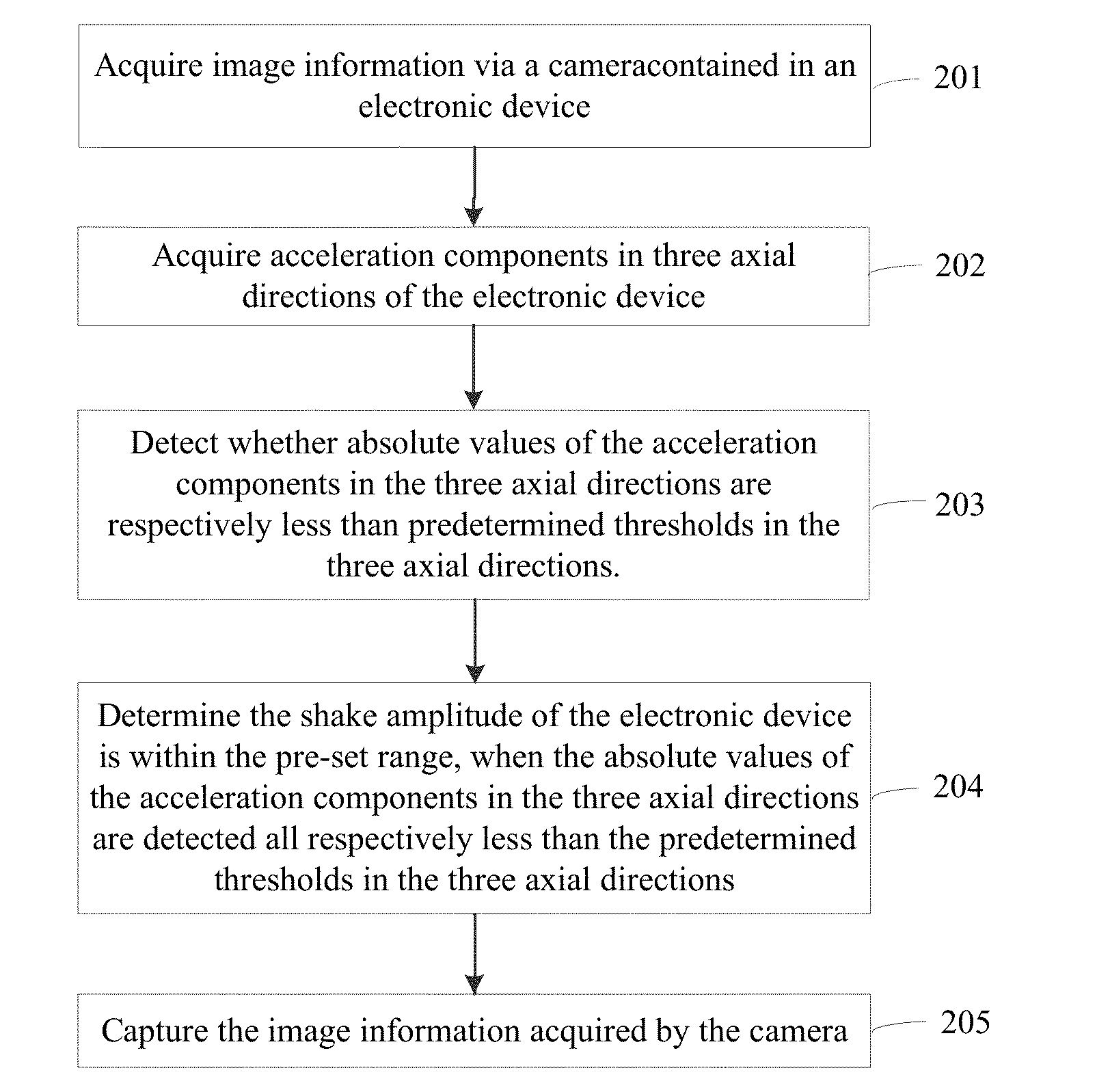

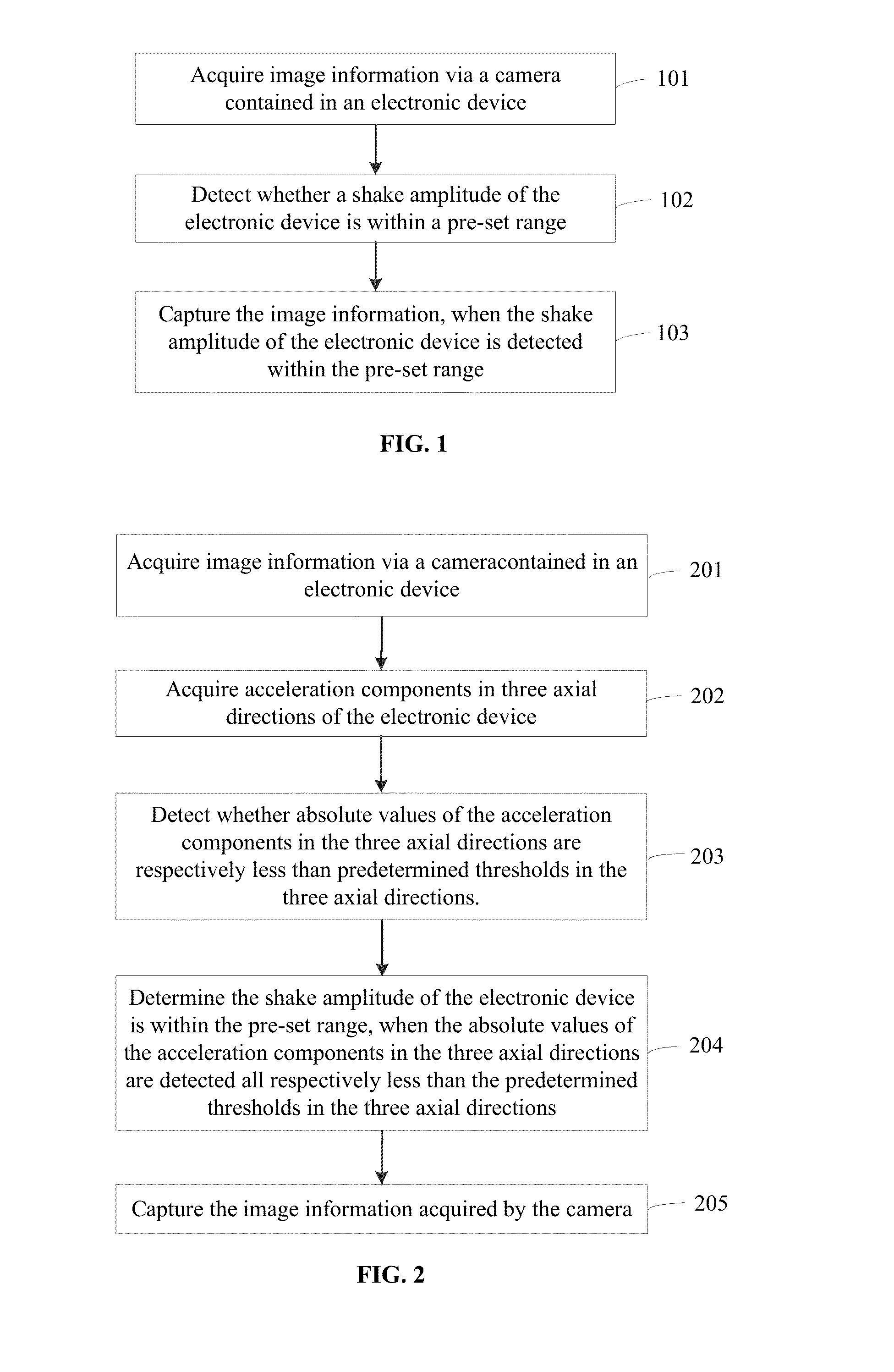

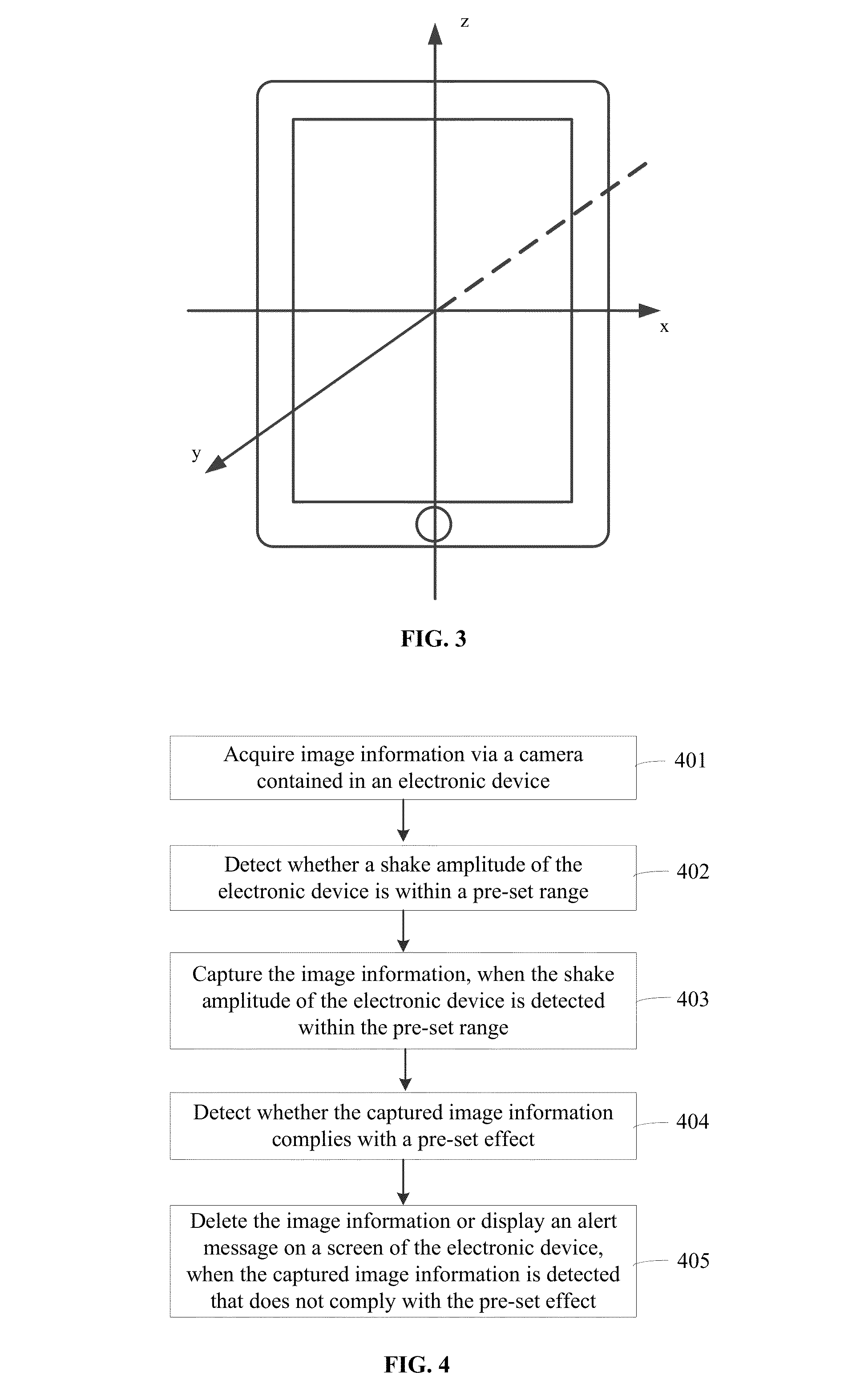

Image capturing method, apparatus, and electronic device

ActiveUS20150138382A1Unclear imageSimple performanceTelevision system detailsColor television detailsComputer visionElectronic equipment

Owner:TENCENT TECH (SHENZHEN) CO LTD

Early strength asater resistant dispersion and anti-dissolving shielding tunnel back lining filling material and its preparation method

ActiveCN1868956AHigh viscosityImprove the coagulation effectSolid waste managementSlagFilling materials

An early-strengthening grouting material for the back liner of tunnel to resist against dispersing in water and denudation is proportionally prepared from powdered coal ash, slag, steel dregs, meta-kaolin, sodium fluorosilicate, stellite, hydroxyethyl methylcellulose, sand, water, and water glass solution. Its preparing process is also disclosed.

Owner:武汉市城市建设投资开发集团有限公司 +3

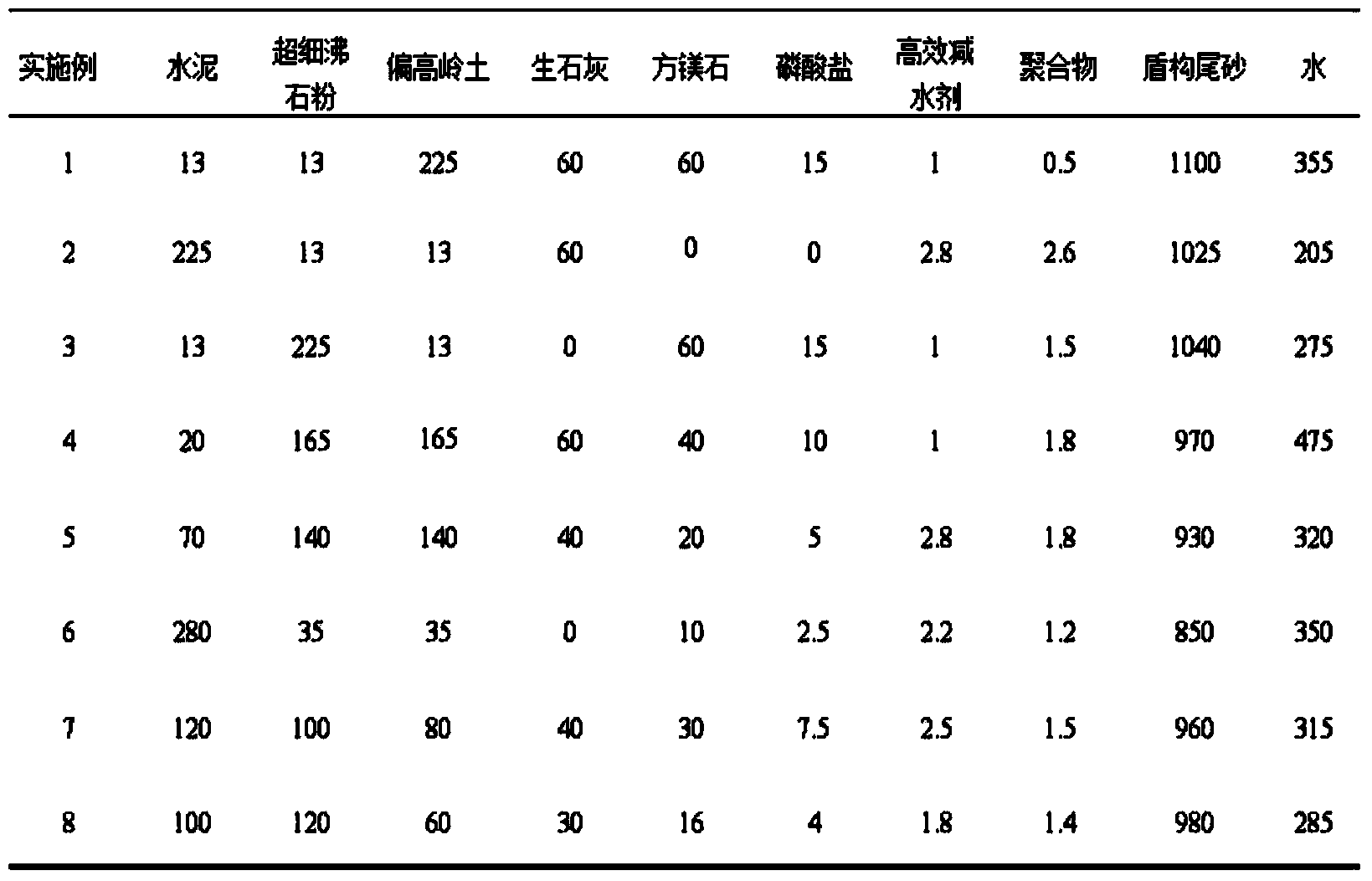

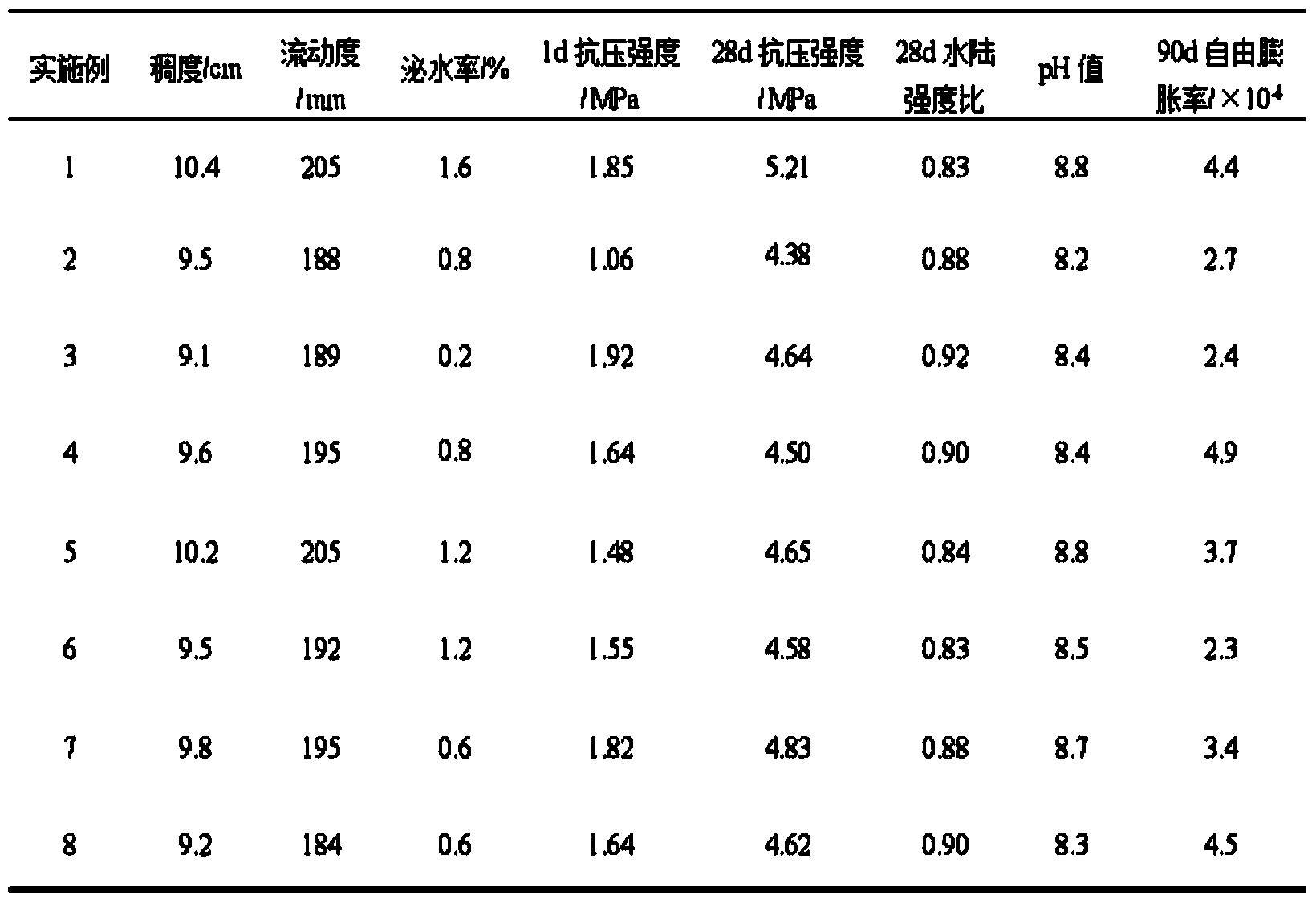

Early-strength micro-expanding synchronous grouting material prepared from shield tailings and preparation method of synchronous grouting material

InactiveCN103449762AGood working performanceImproved flow and pumpabilitySolid waste managementPericlaseBuilding material

The invention belongs to inorganic non-metallic building materials, and particularly relates to a synchronous grouting material for shield tunnels and a preparation method of the synchronous grouting material. The synchronous grouting material disclosed by the invention comprises the following components in parts by weight (kg / m<3>): 250-350 parts of a cementing material, 0-60 parts of quick lime, 0-60 parts of periclase, 0-15 parts of phosphates, 1-2.8 parts of a high-efficiency water reducing agent, 0.5-2.6 parts of polymers, 850-1100 parts of shield tailings, and 205-475 parts of water. The synchronous grouting material prepared from the shield tailings is good in early strength, micro-expanding performance, working performance and water dispersion resistance. According to the synchronous grouting material disclosed by the invention, underground tailings brought out in the process of shield construction are reasonably used, thus the impact on the environment is reduced; the synchronous grouting material is simple in ingredients, low in manufacturing cost, easy to produce, and good in workability, and can satisfy the requirements of grouting equipment.

Owner:WUHAN UNIV OF TECH +1

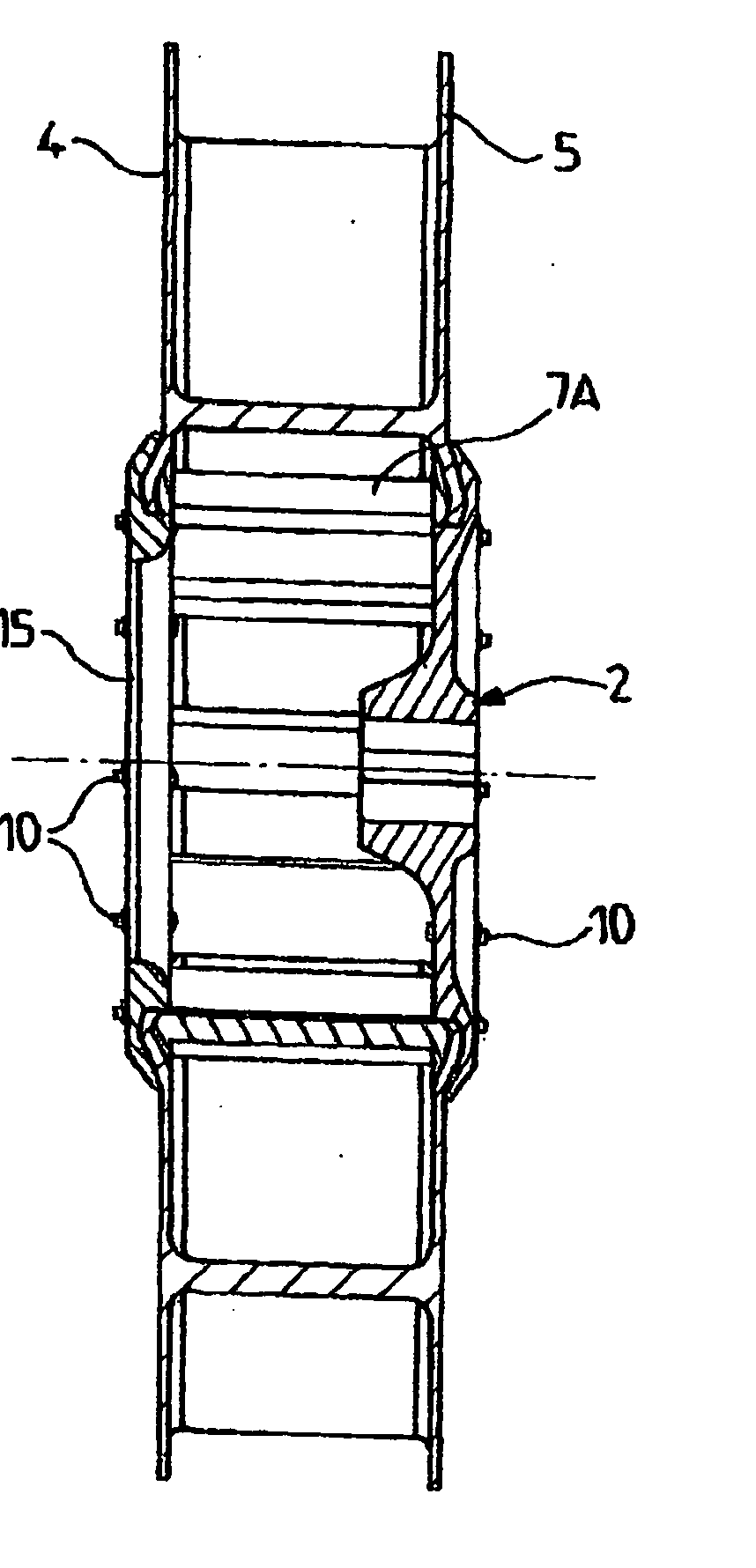

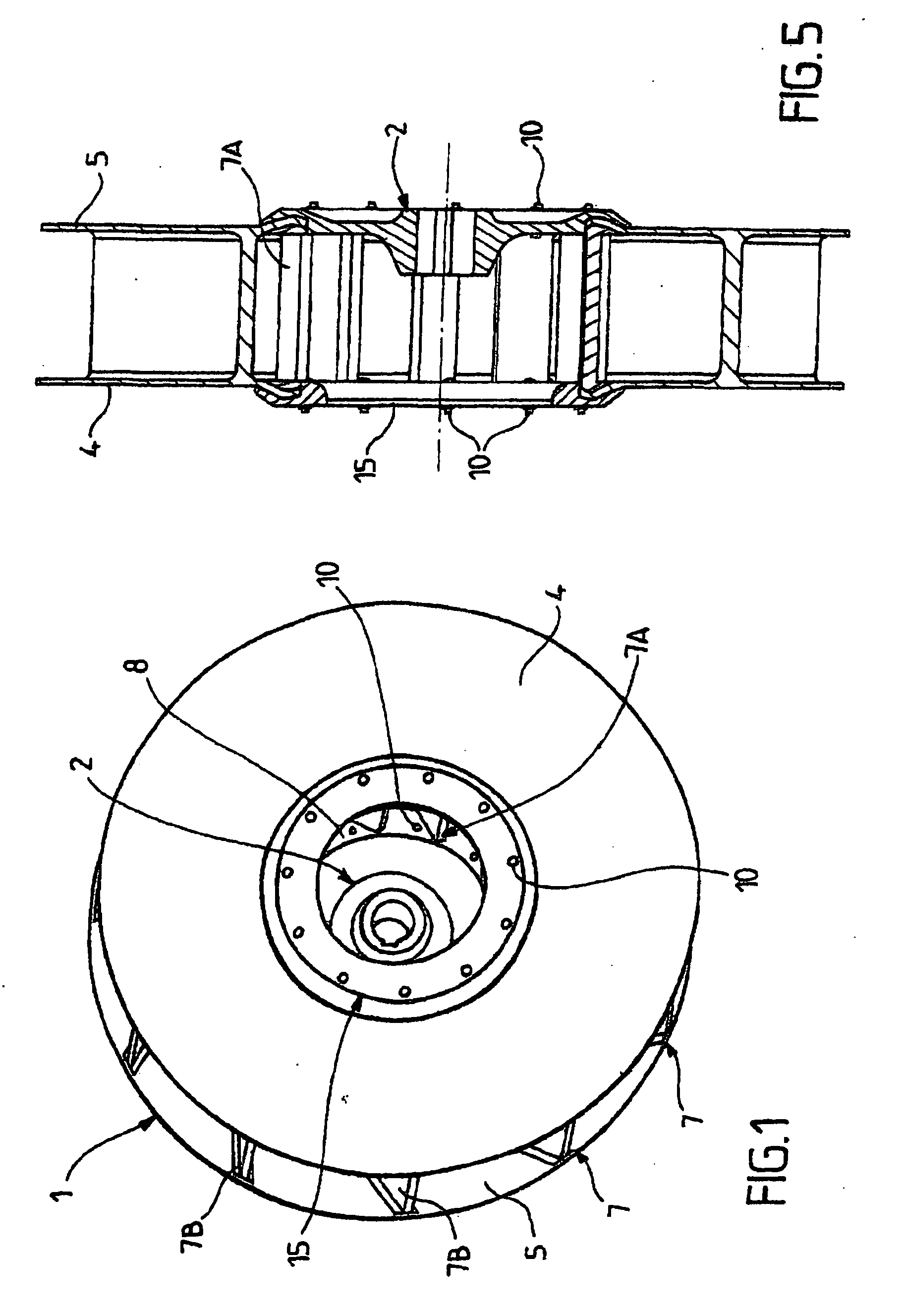

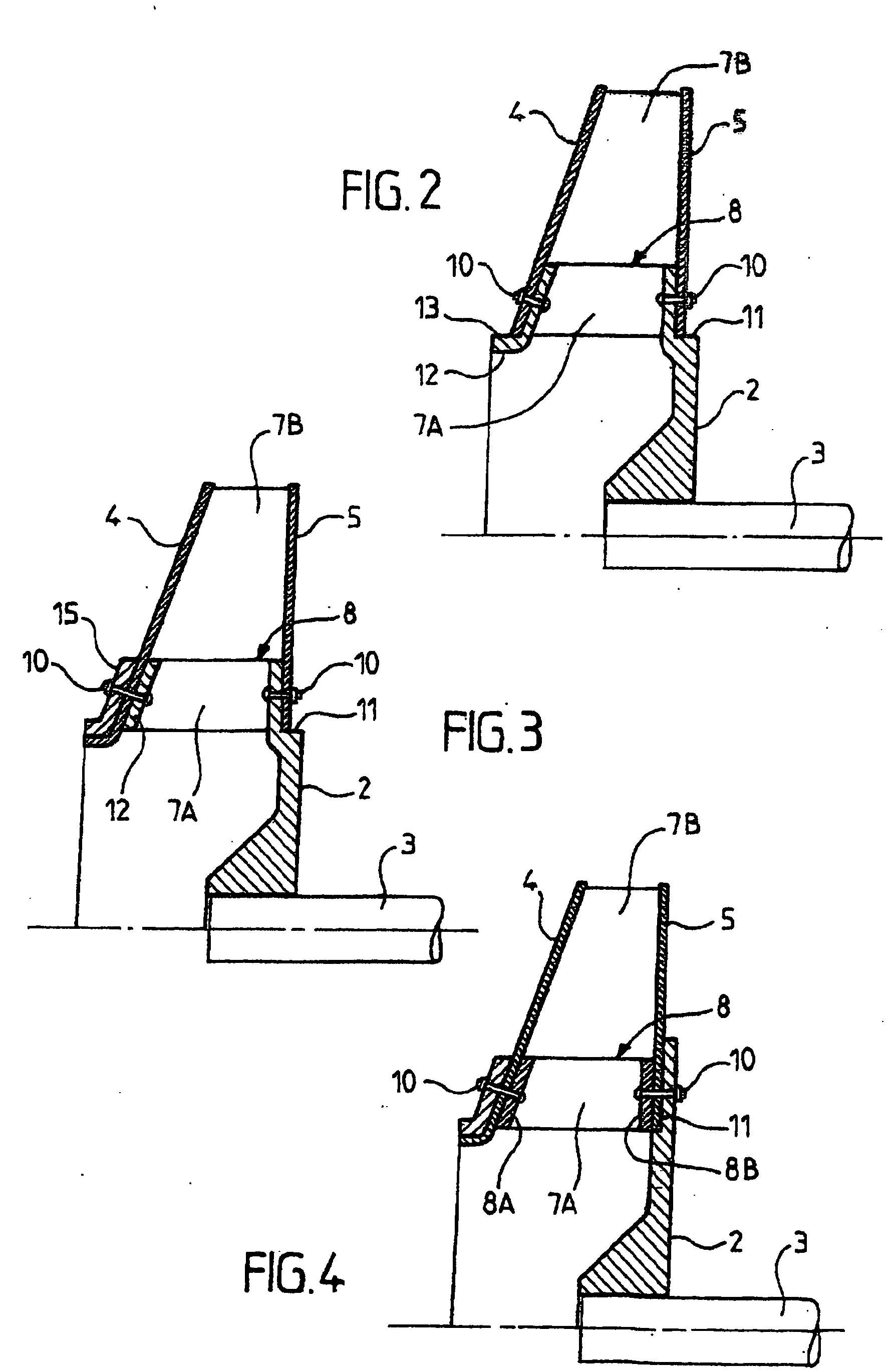

Centrifugal wheel

InactiveUS20040241000A1Easy to assembleSimple to mountPropellersRotary propellersDrive shaftEngineering

A centrifugal compressor wheel including a metal hub (2) for connecting to a drive shaft (3), an inlet plate (4) and an outlet plate (5) fixed to the metal hub (2), and a plurality of blades (7), each blade having a beginning and a peripheral portion (7b), fixed between the inner plate (4) and the outer plate (5). The wheel further includes an annular metal insert (8) integrated in the central portion of the wheel at a periphery of the hub (2), the annular metal insert (8) having metal elements (7A) forming the beginnings of the blades of the wheel. The inlet plate (4), the outlet plate (5), and the peripheral portions (7B) of the blades are made of a composite material, thereby constituting a composite portion of the wheel.

Owner:FLAKT SOLYVENT VENTEC

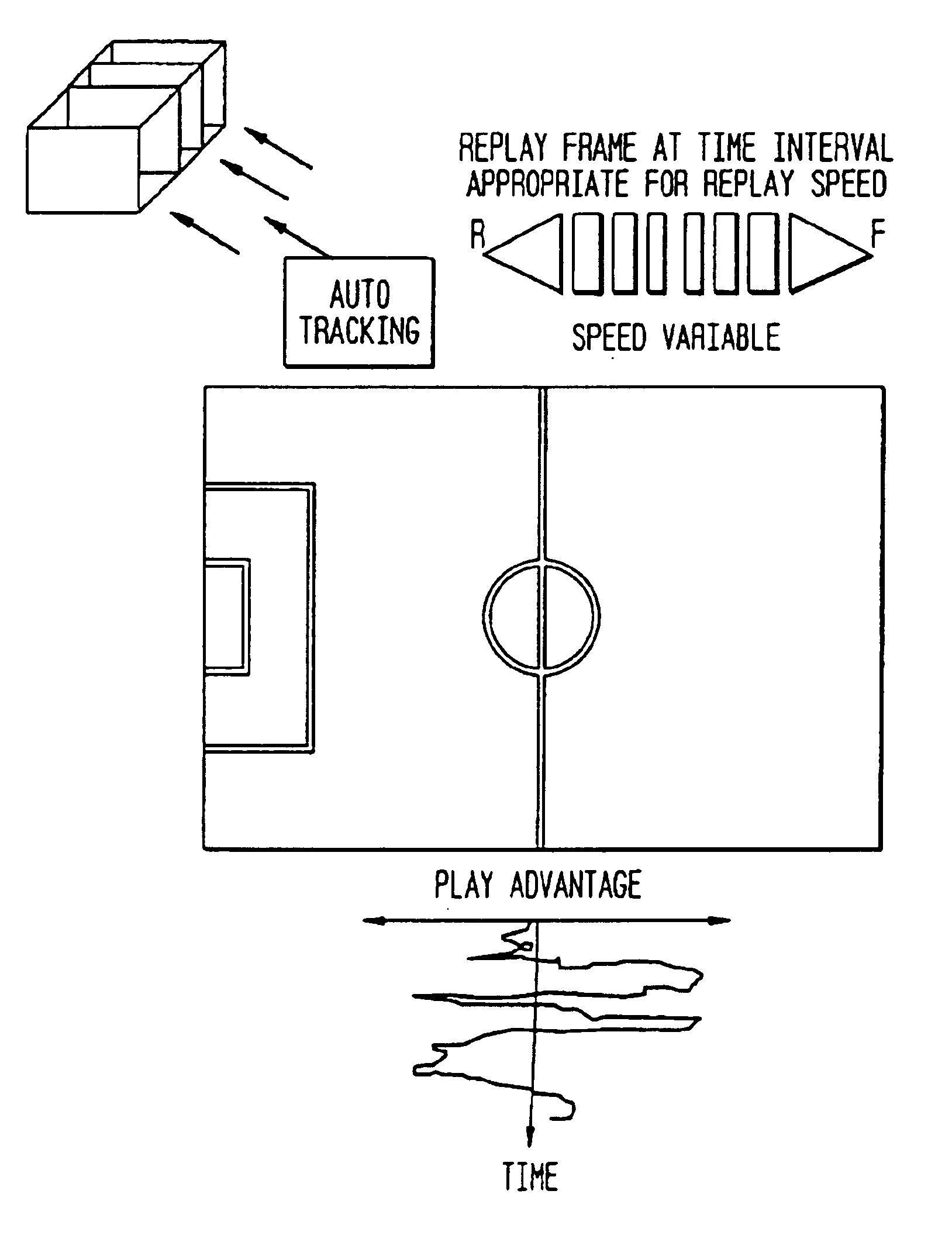

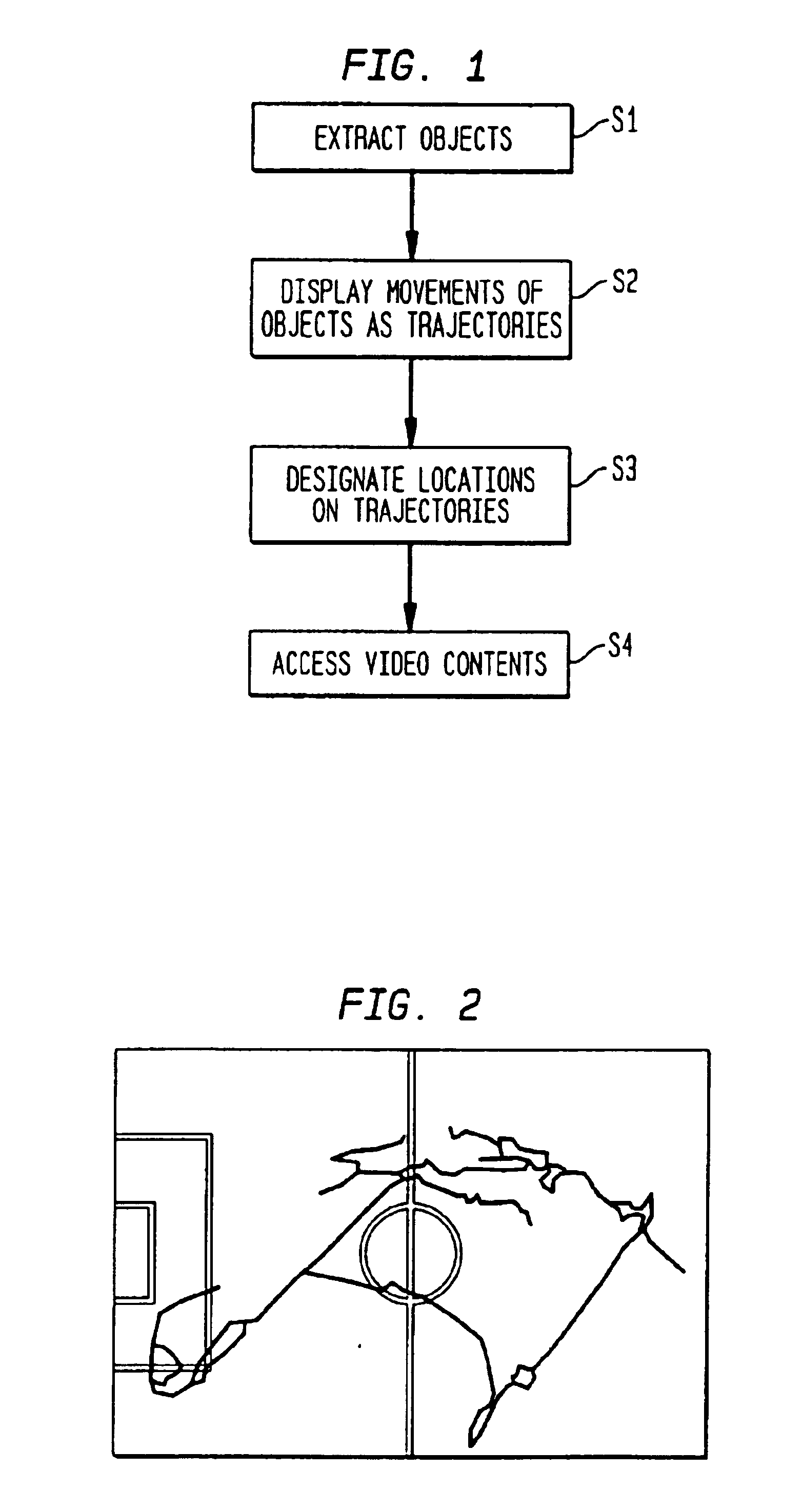

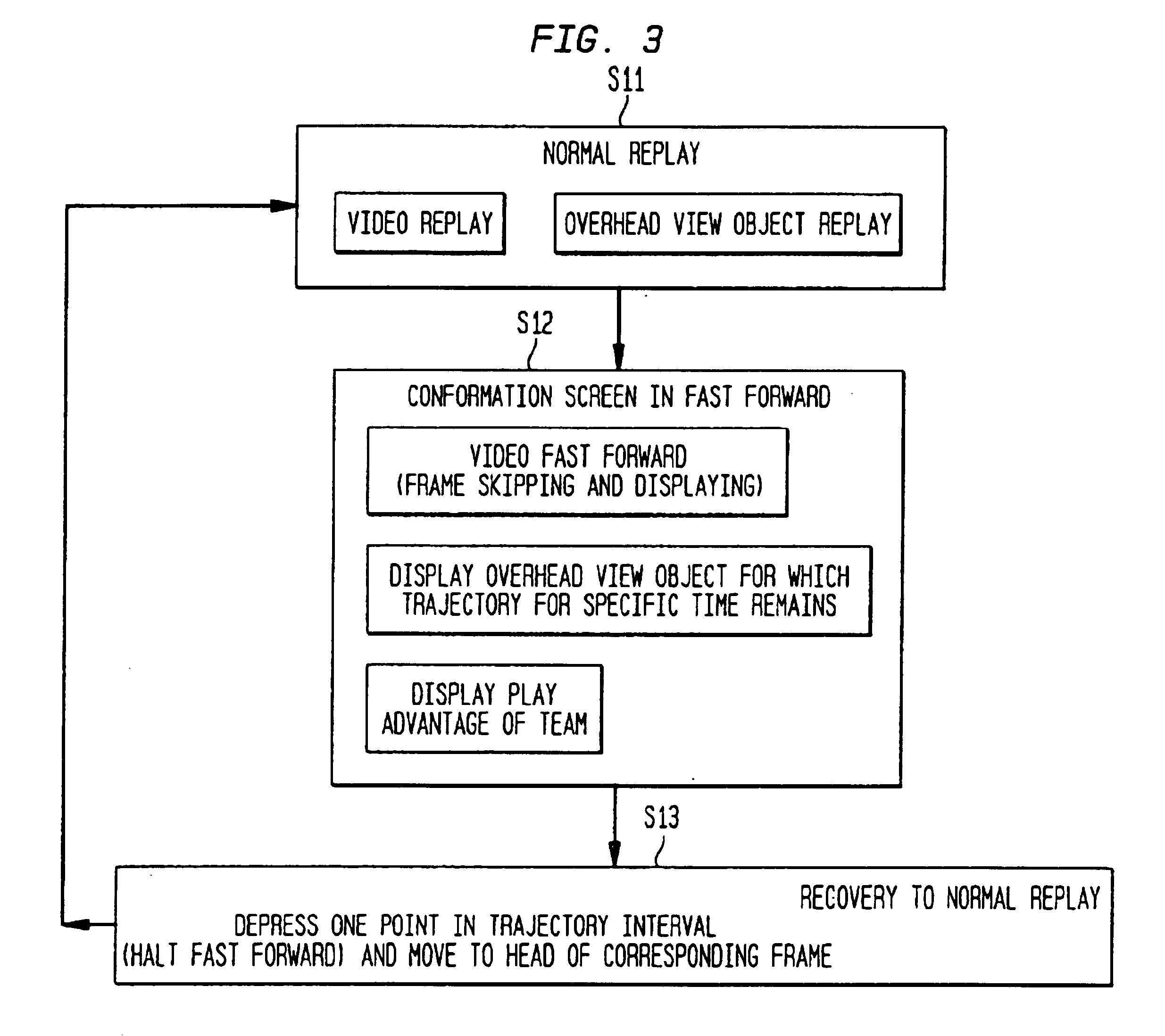

Video contents access method that uses trajectories of objects and apparatus therefor

InactiveUS6833849B1Efficiently specified and displayedSimple performanceTelevision system detailsUsing detectable carrier informationAccess methodProjection screen

A method and an apparatus for using the trajectory of an object to access video contents, for example, to specify and display a specific video image scene. Such a video contents access method comprises the steps of: extracting objects from video contents; displaying movements of the objects as trajectories on a specific projection screen; specifying locations on the trajectories; and accessing a desired scene of the video contents. An apparatus is so designed that it performs the above method.

Owner:HULU

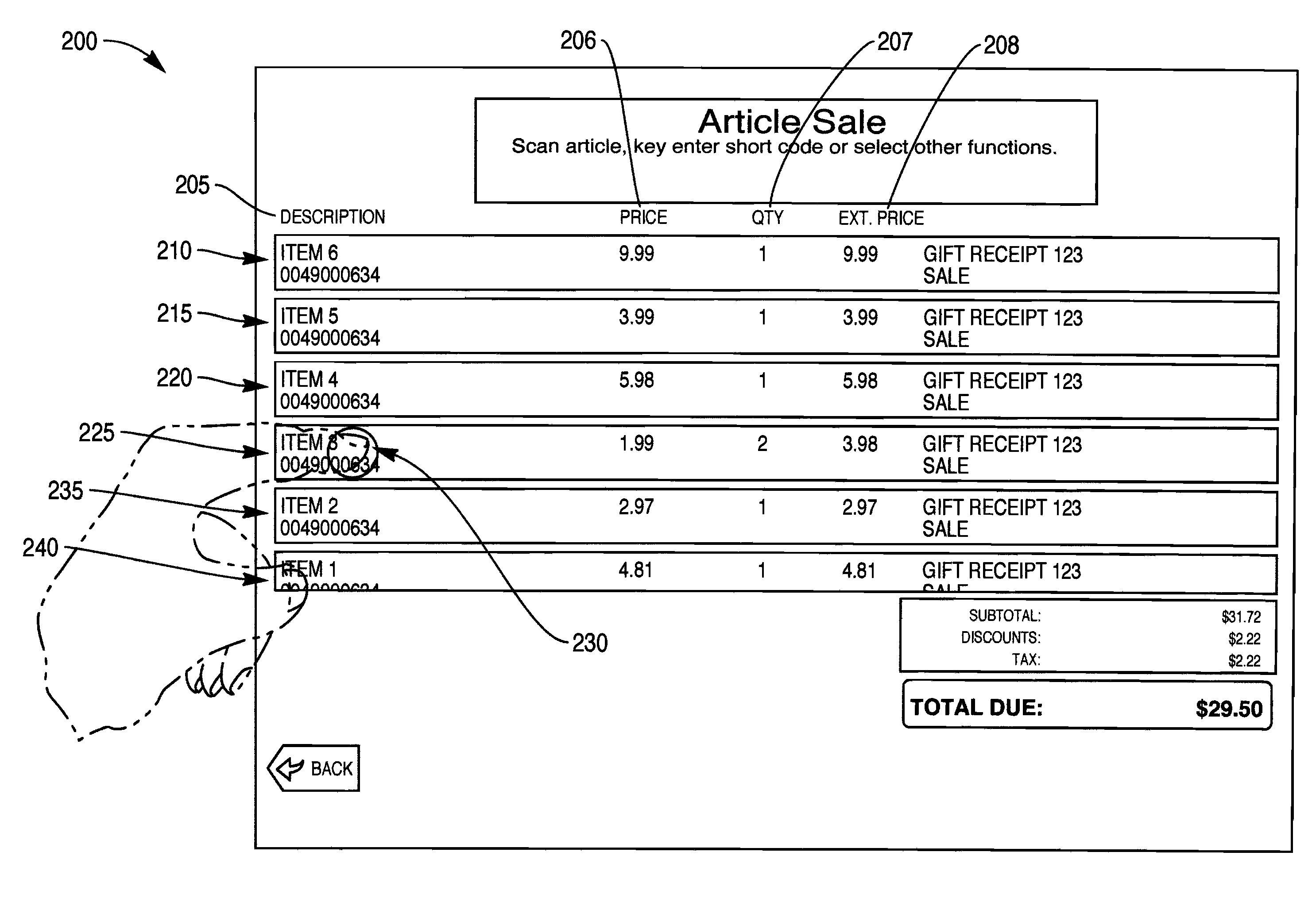

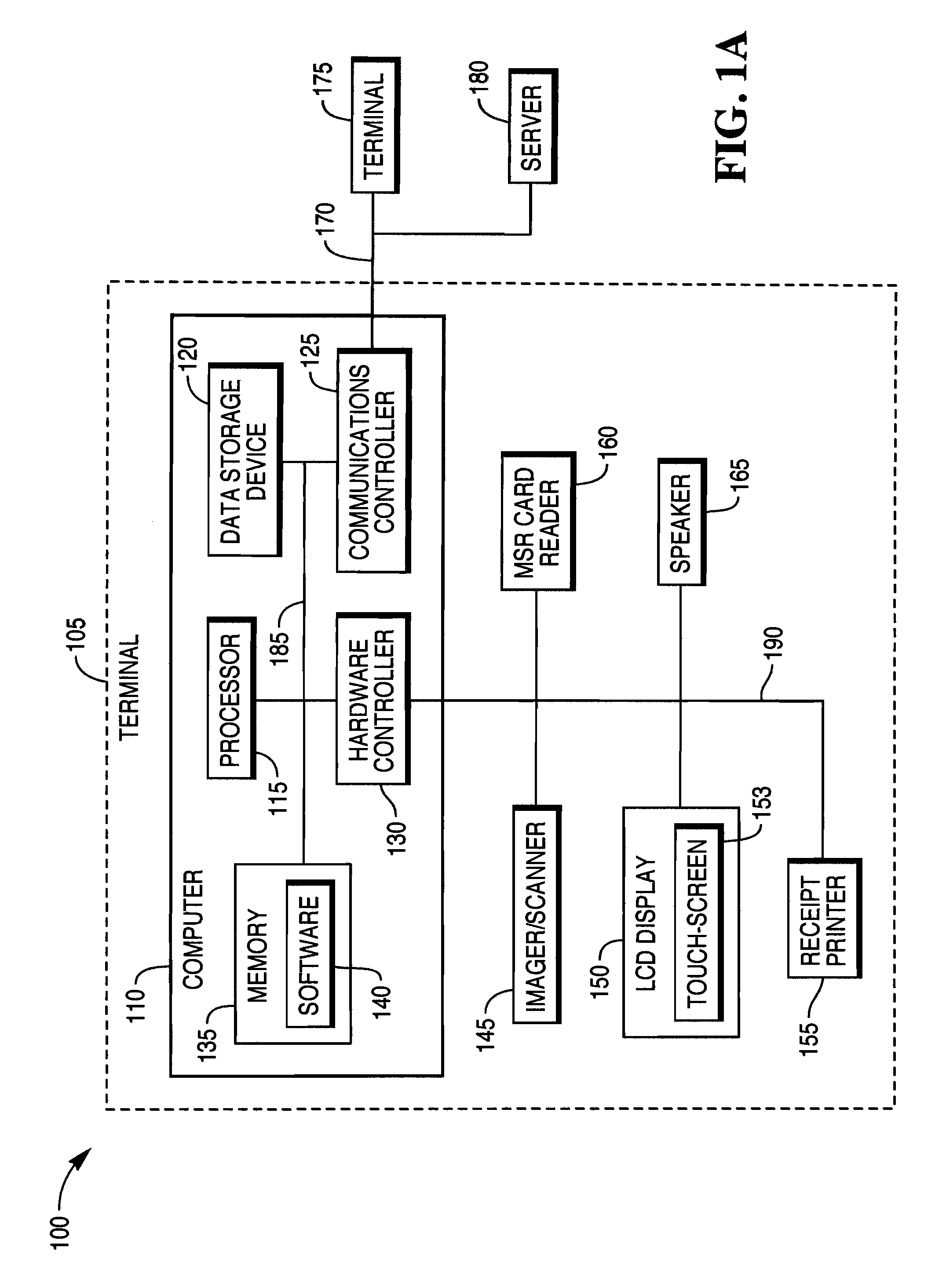

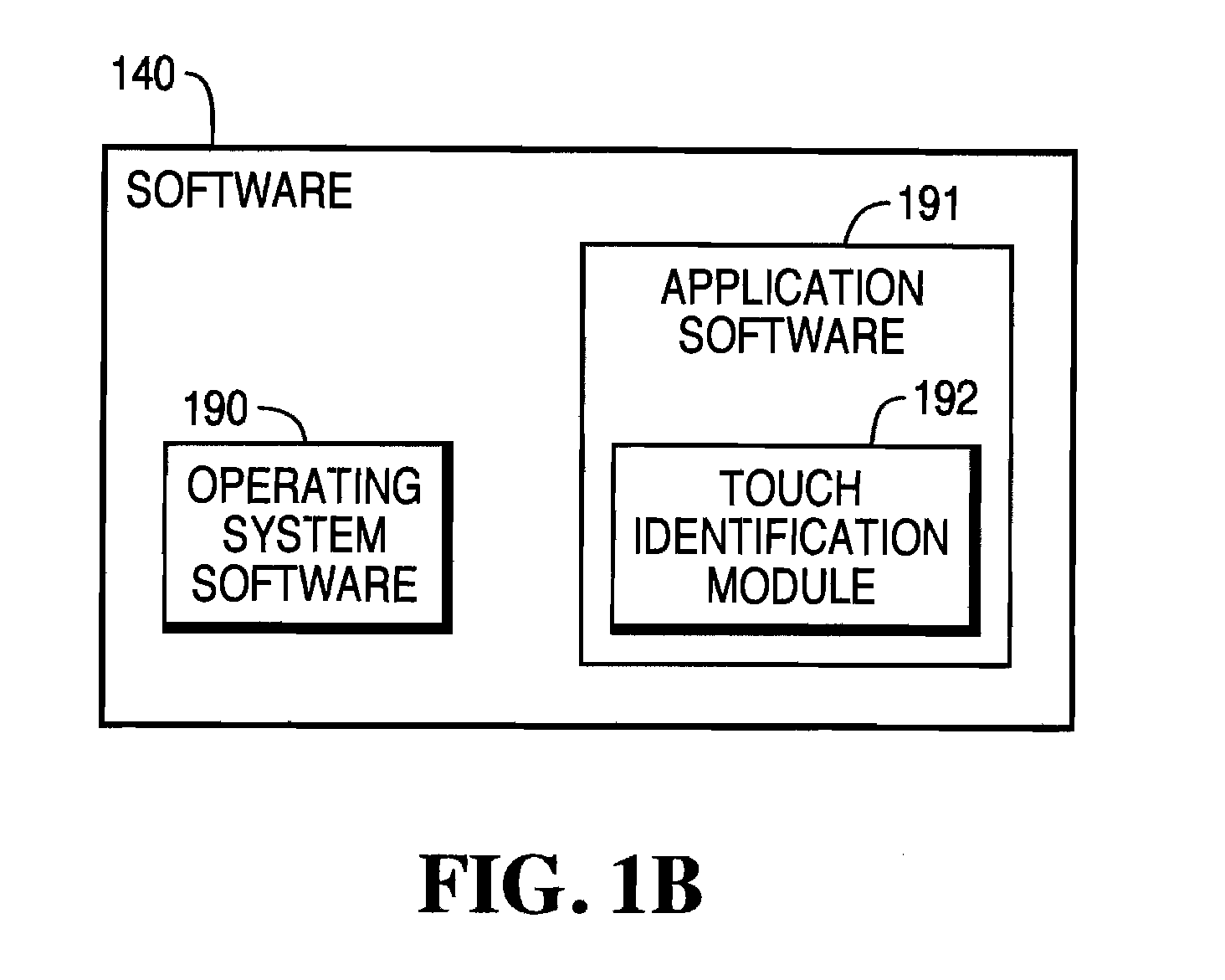

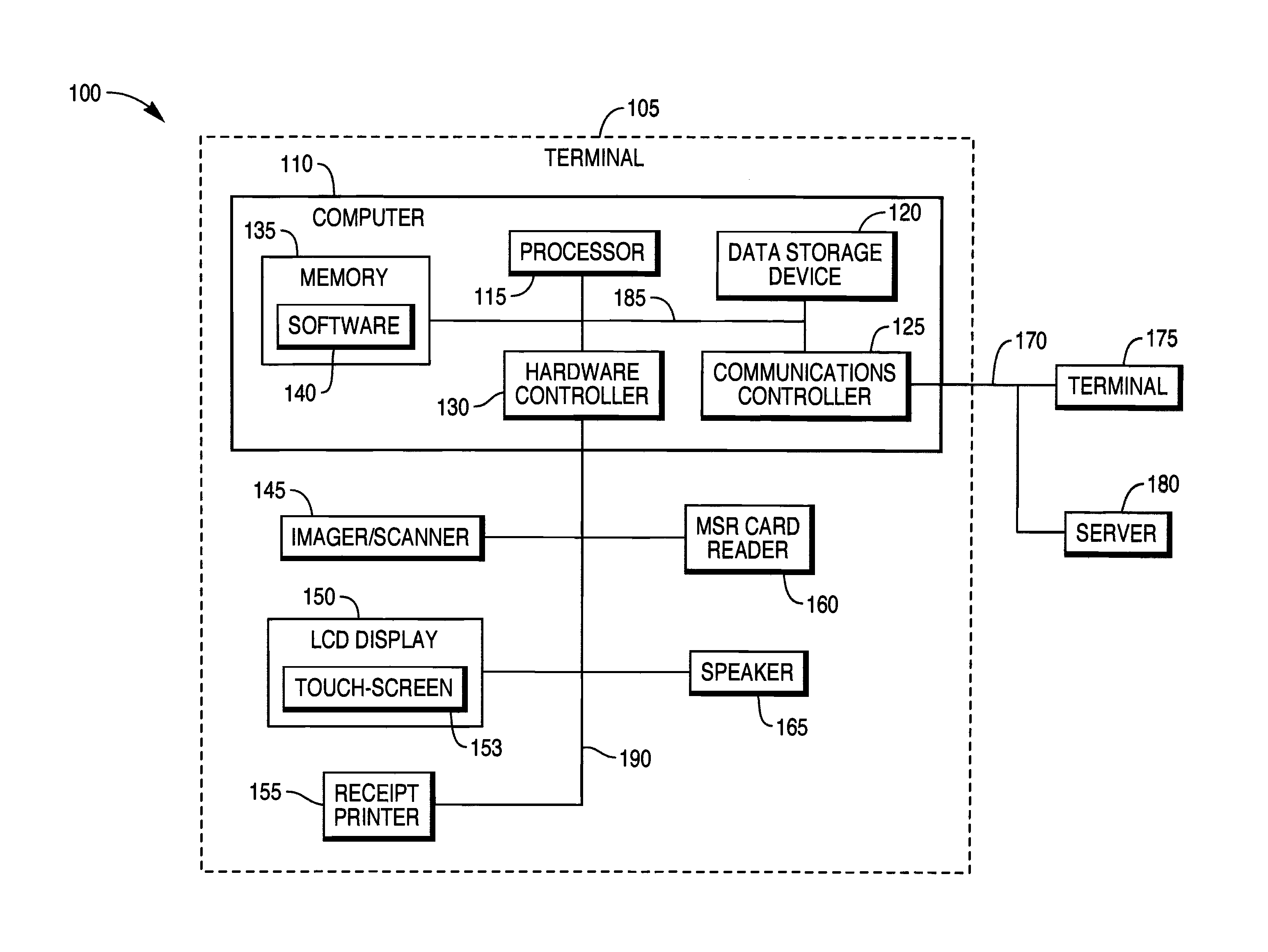

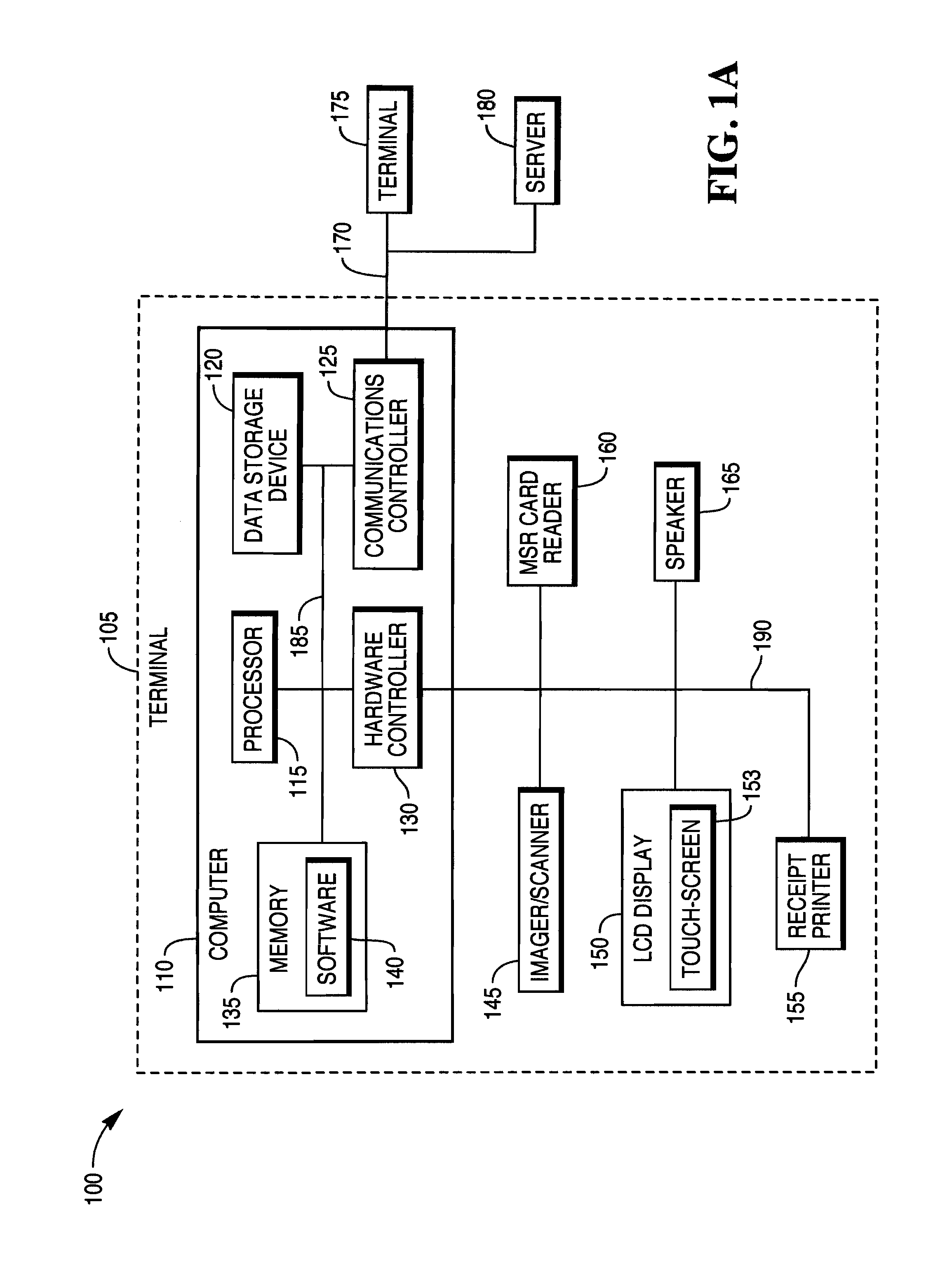

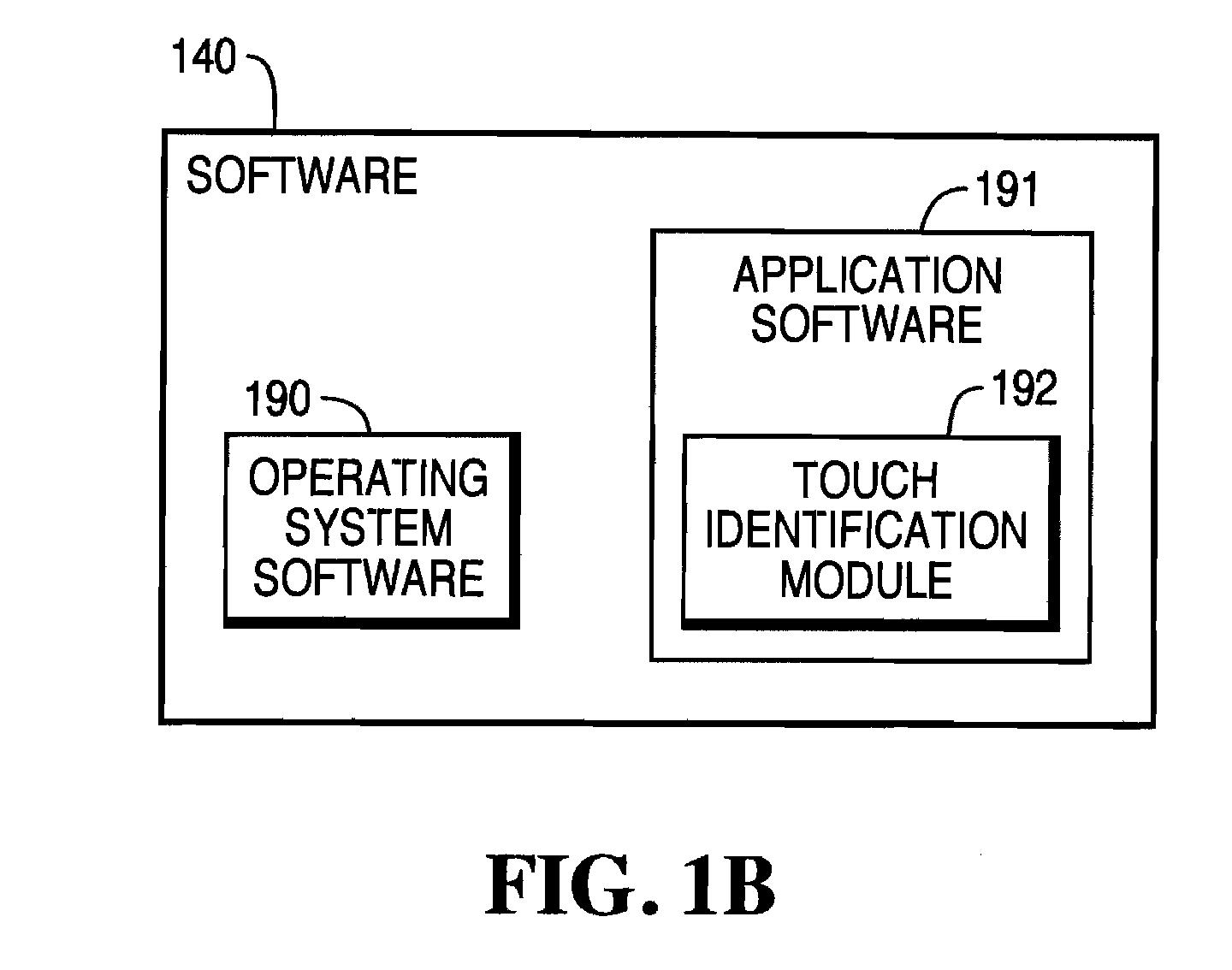

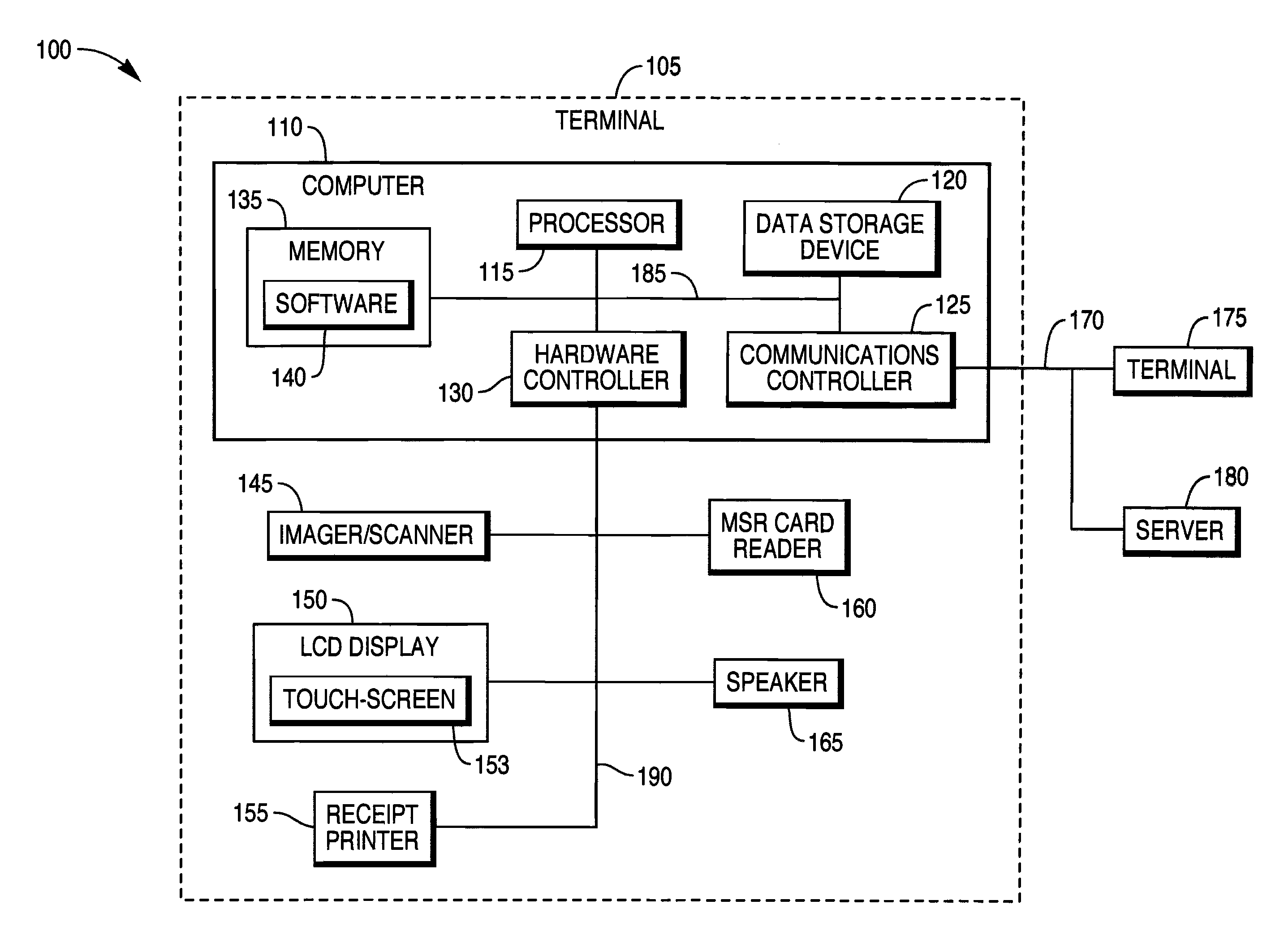

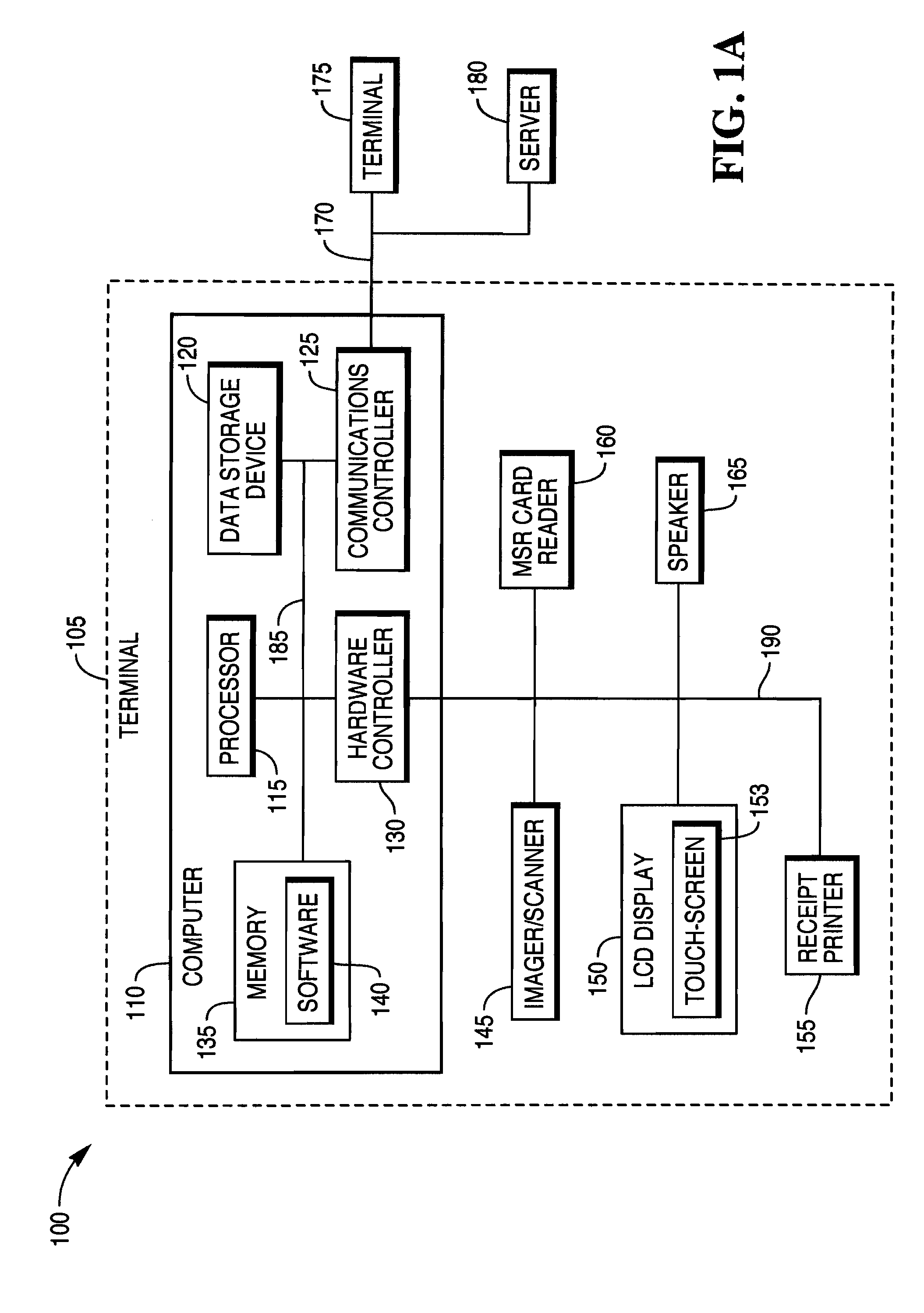

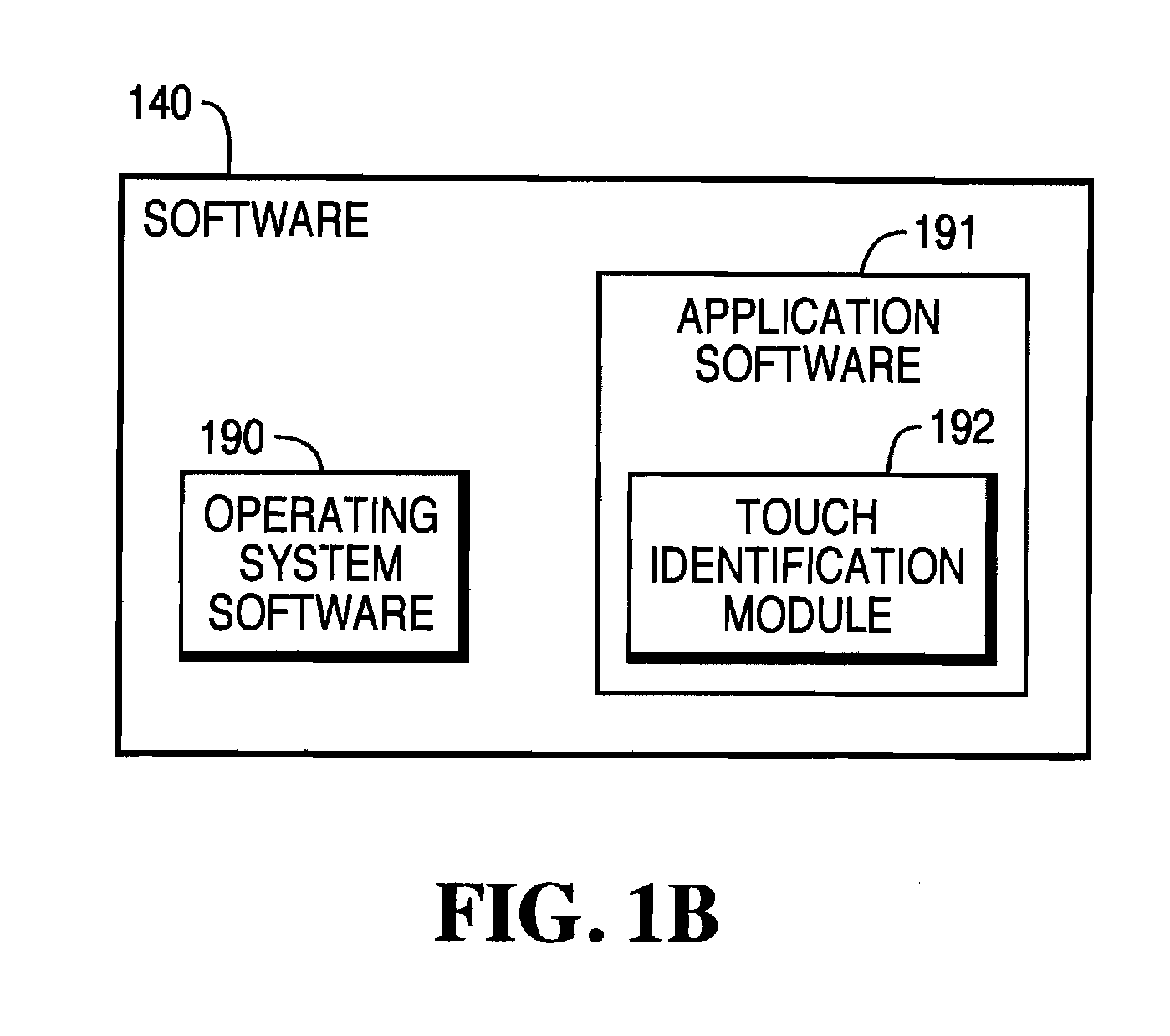

System, method and apparatus for implementing an improved user interface on a terminal

ActiveUS20120133596A1Slows down transactionInsufficient levelInput/output processes for data processingDisplay deviceTouchscreen

An apparatus, system and method are presented for implementing a user interface on a terminal. The terminal includes a processor, LCD display and touch-screen device. Software implemented by the processor receives input from the touch-screen device to determine complex interactions with the display that are then used to select and / or modify functions and features provided by the terminal.

Owner:NCR CORP

System, method and apparatus for implementing an improved user interface

ActiveUS20120136737A1Slows down transactionInsufficient levelPayment architectureBuying/selling/leasing transactionsDisplay deviceTouchscreen

An apparatus, system and method are presented for implementing a user interface on a self-service or assisted service terminal. The terminal includes a computer, LCD display and touch-screen device. Software implemented by the computer receives input from the touch-screen device to determine complex interactions with the display that are then used to select and / or modify functions and features provided by the terminal.

Owner:NCR CORP

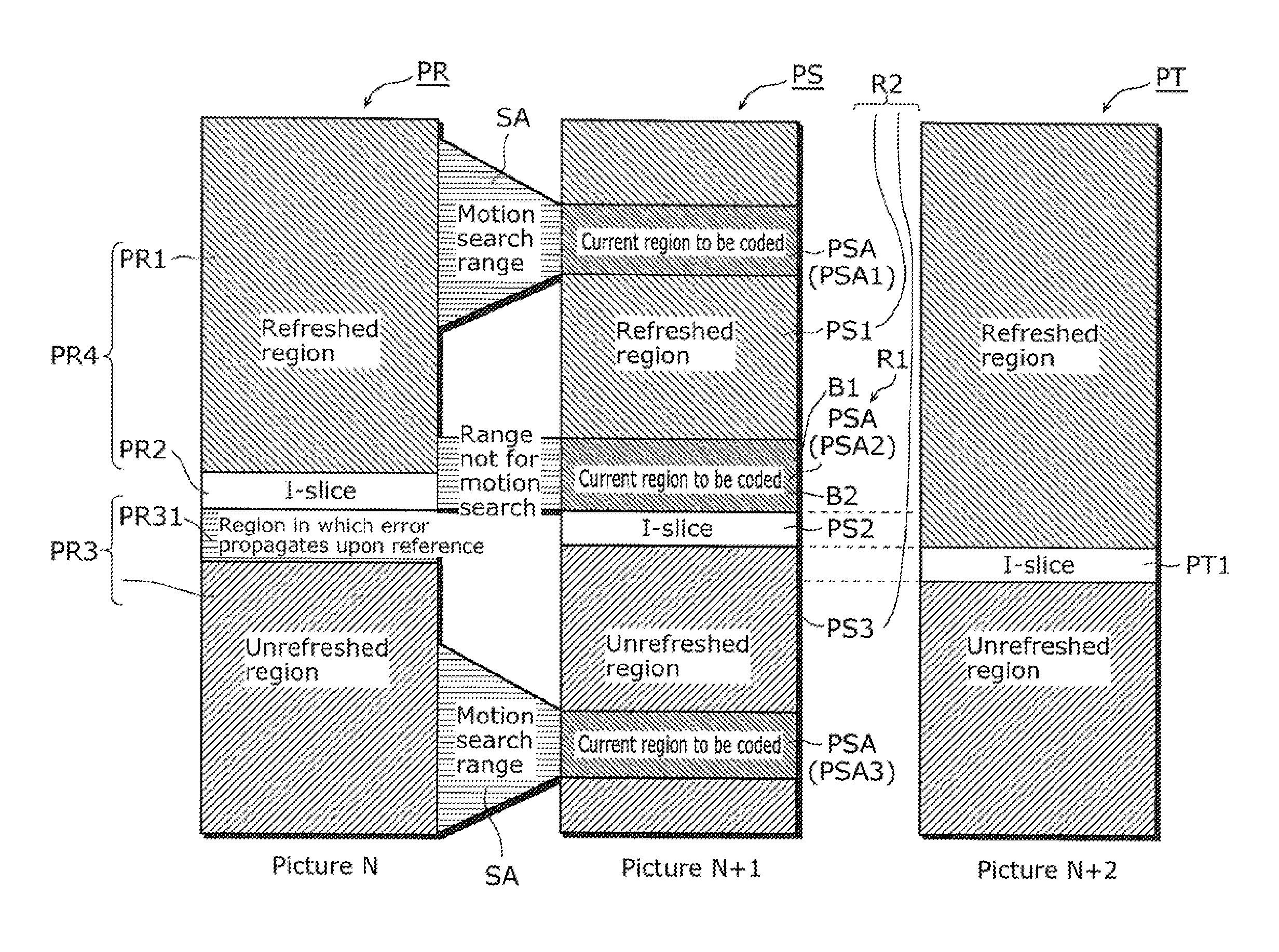

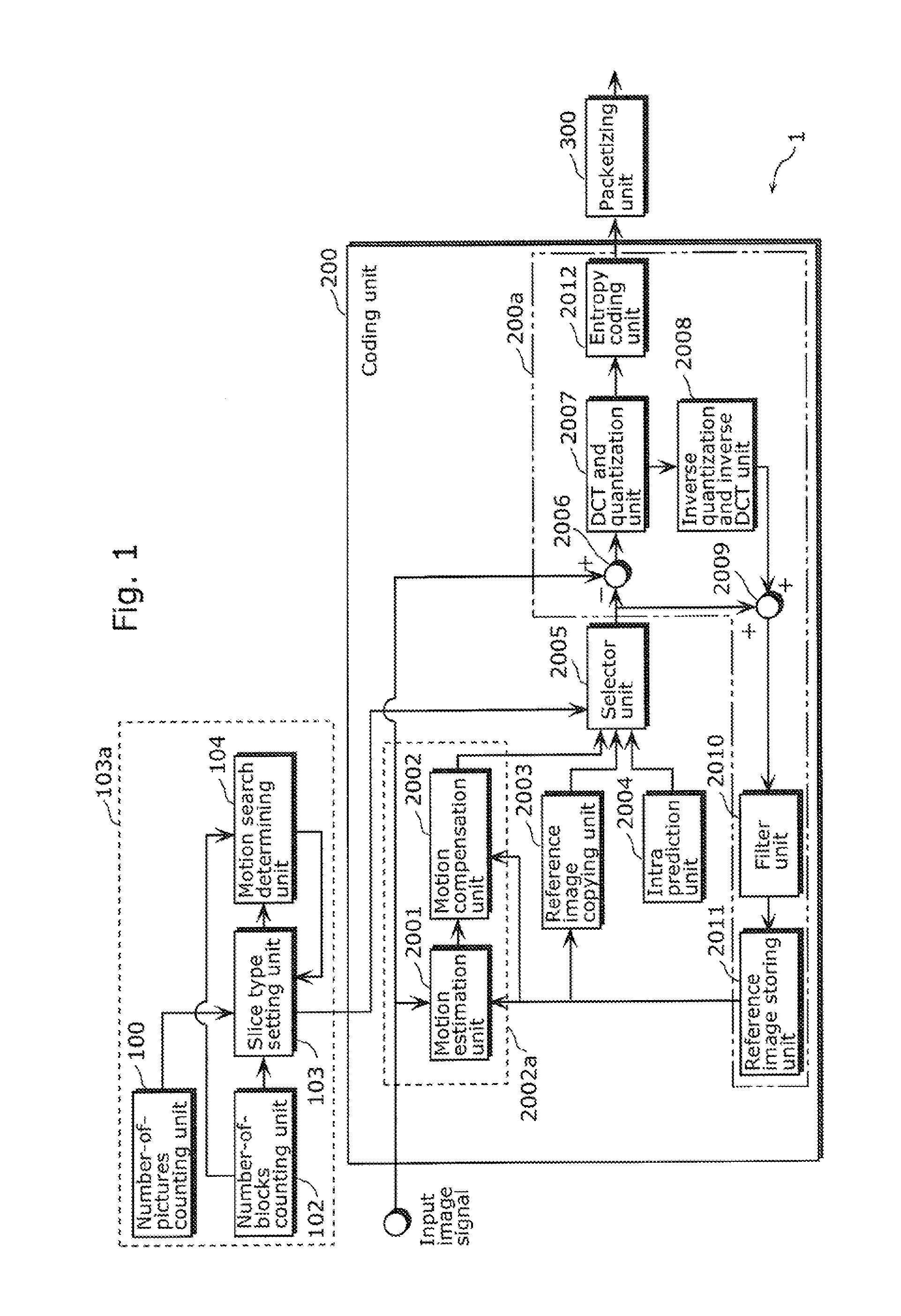

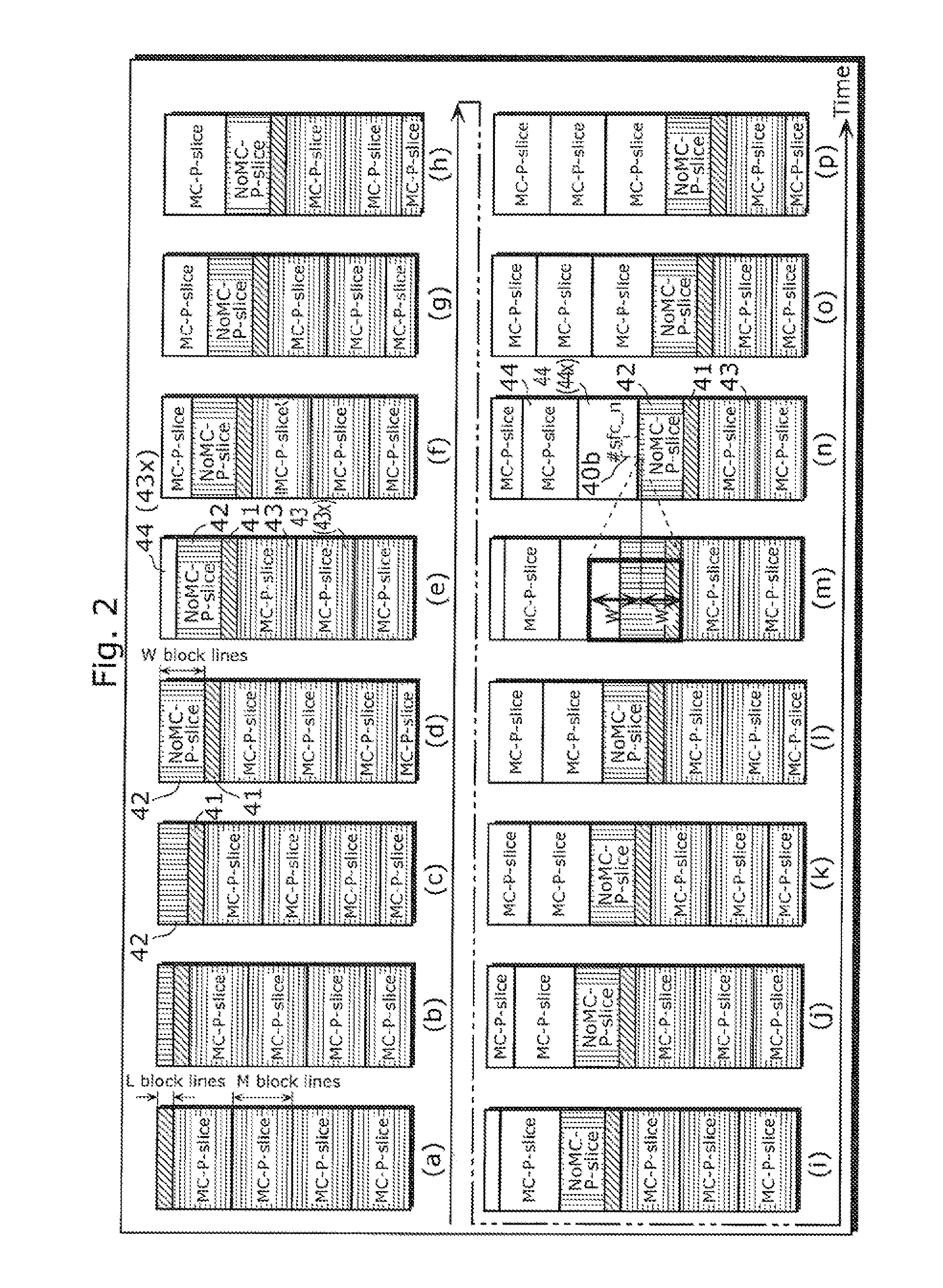

Moving picture coding method, apparatus, program, and integrated circuit

InactiveUS20120275518A1Prevention of undesirable image quality degradation propagationEasy to processColor television with pulse code modulationColor television with bandwidth reductionIntegrated circuitEngineering

A moving picture coding method in which the position of a current I-slice for a current picture is shifted in the vertical direction of the current picture, and which includes (i) performing inter coding on a first P-slice without using a motion vector (Sa1), and (ii) performing intra coding on a second P-slice using a motion vector (Sa2); the first P-slice is included in a first region that is adjacent to the current I-slice in the direction opposite to the forward direction for the shift in the vertical direction, and the second P-slice is included in a second region that is other than the first region within the current picture.

Owner:PANASONIC CORP

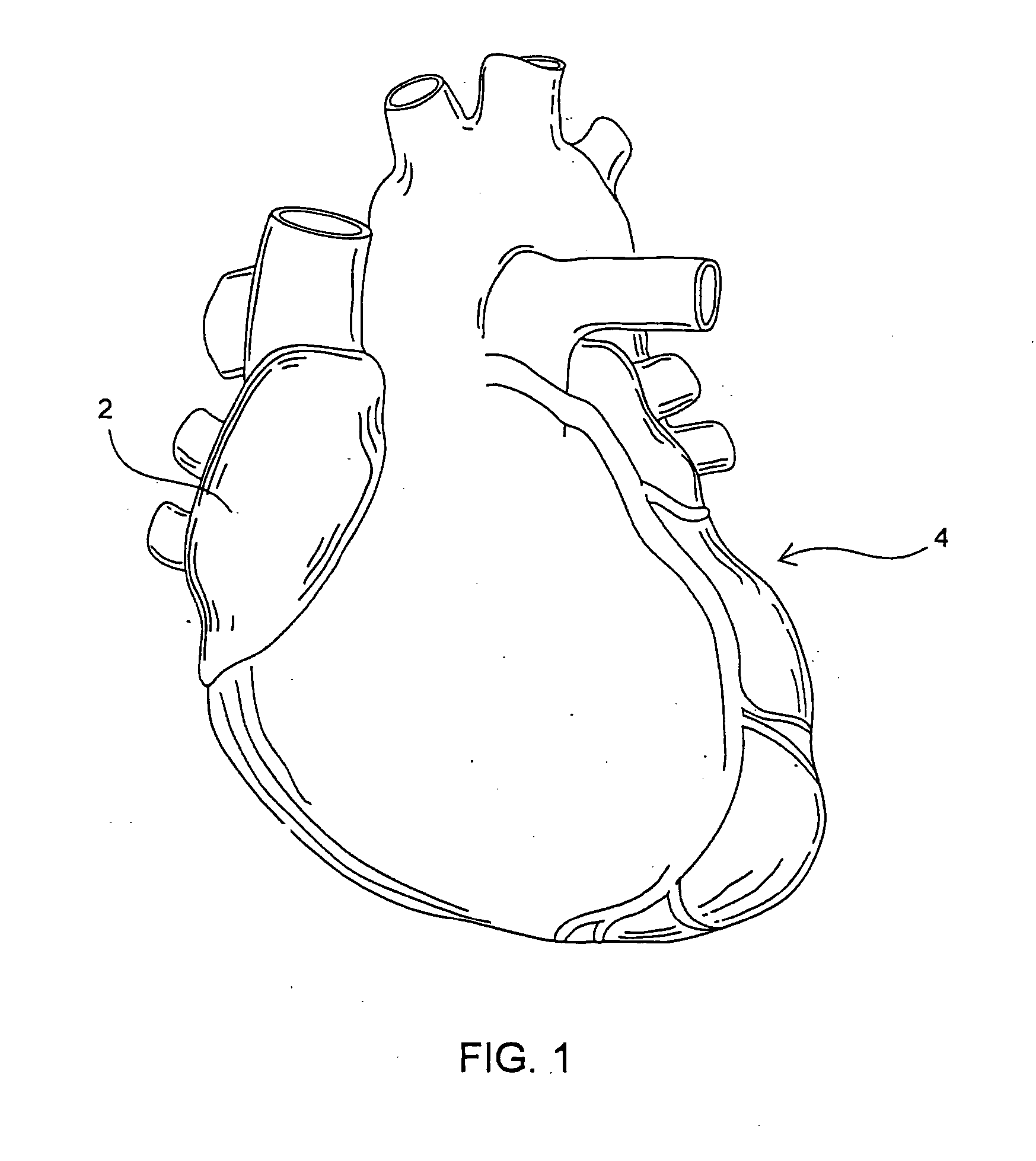

Pass-through restraint electrolytic implant delivery systems

InactiveUS20070100418A1Eliminate the problemHigh peak voltageStentsBlood vesselsBody organsProsthesis

Medical devices and methods for delivery or implantation of prostheses within hollow body organs and vessels or other luminal anatomy are disclosed. The subject technologies may be used in the treatment of atherosclerosis in stenting procedures or be used in variety of other procedures. The systems may employ a self expanding stent restrained by one or more members released by an electrolytically erodable latch. Such release means do not connect directly to the implant, though one or more portions may contact it.

Owner:BIOSENSORS INT GROUP

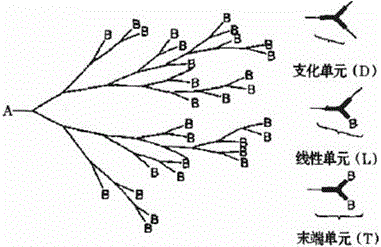

Hyperbranched UV (ultraviolet) resin as well as preparation method and application of hyperbranched UV resin in coating

The invention discloses hyperbranched UV (ultraviolet) resin as well as a preparation method and an application of the hyperbranched UV resin in a coating and belongs to the technical field of coatings. The method comprises steps as follows: 1) hyperbranched polyester, acrylic acid monomers and a solvent are dissolved at the temperature of 90-150 DEG C, a catalyst and a polymerization inhibitor are added, and the mixture reacts for 4-8 h; 2) a primary product is added to water, and the mixture is stirred for 0.5-1 h and left to stand; 3) water on the upper layer is separated, and a liquid on the lower layer is treated according to the step 2) until the pH (potential of hydrogen) of a water solution ranges from 6 to 7; 4) viscous materials are dried in a vacuum state at the temperature of 30-60 DEG C, and a product is obtained. The hyperbranched UV resin has advantages of multiple conventional resin, is low in cost, simple in process and high in performance cost ratio and has wide market prospect; the obtained coating is high in curing speed, small in curing volume shrinkage, high in glossiness, good in adhesion, high in hardness, excellent in flexibility, excellent in impact resistance, not prone to embrittlement and excellent in weather fastness, few solvents are evaporated, and the economic benefits are remarkable.

Owner:WEIHAI CY DENDRIMER TECH

Multifunctional additive for insulating dry-mixed motar

The invention discloses a multifunctional additive of thermal insulation dry-mixing slurry, which comprises the following parts: sodium carboxymethylcellulose, polyvinyl alcohol powder, urea-formaldehyde resin, polyethylene oxide (PEO), alta-mud and wood cellulose. The additive possesses even dispersion, which saves cost and protects environment.

Owner:潘传章

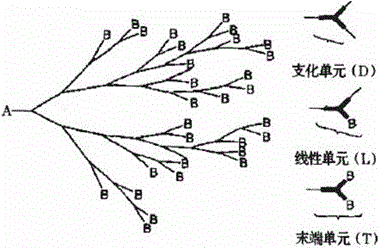

Flexographic printing inks

InactiveUS20110041715A1Improve printing effectImprove adhesionGroup 4/14 element organic compoundsInksImage resolutionCorona discharge

A flexographic printing composition which comprises a carrier-swellable particle composition, such as a microgel particle composition, has improved printing performance and printing resolution, especially where the flexographic printing composition is an aqueous printing composition and the carrier is water. The composition is particularly beneficial for flexographic printing of such an aqueous printing ink onto low-energy surface substrates or impermeable substrates, in which the ink has improved adhesion, even in the absence of corona discharge treatment. The use of surfactant in an amount of at least 0.5% by weight of the ink composition enhances printed density and / or reduces mottling in solid printed areas.

Owner:EASTMAN KODAK CO

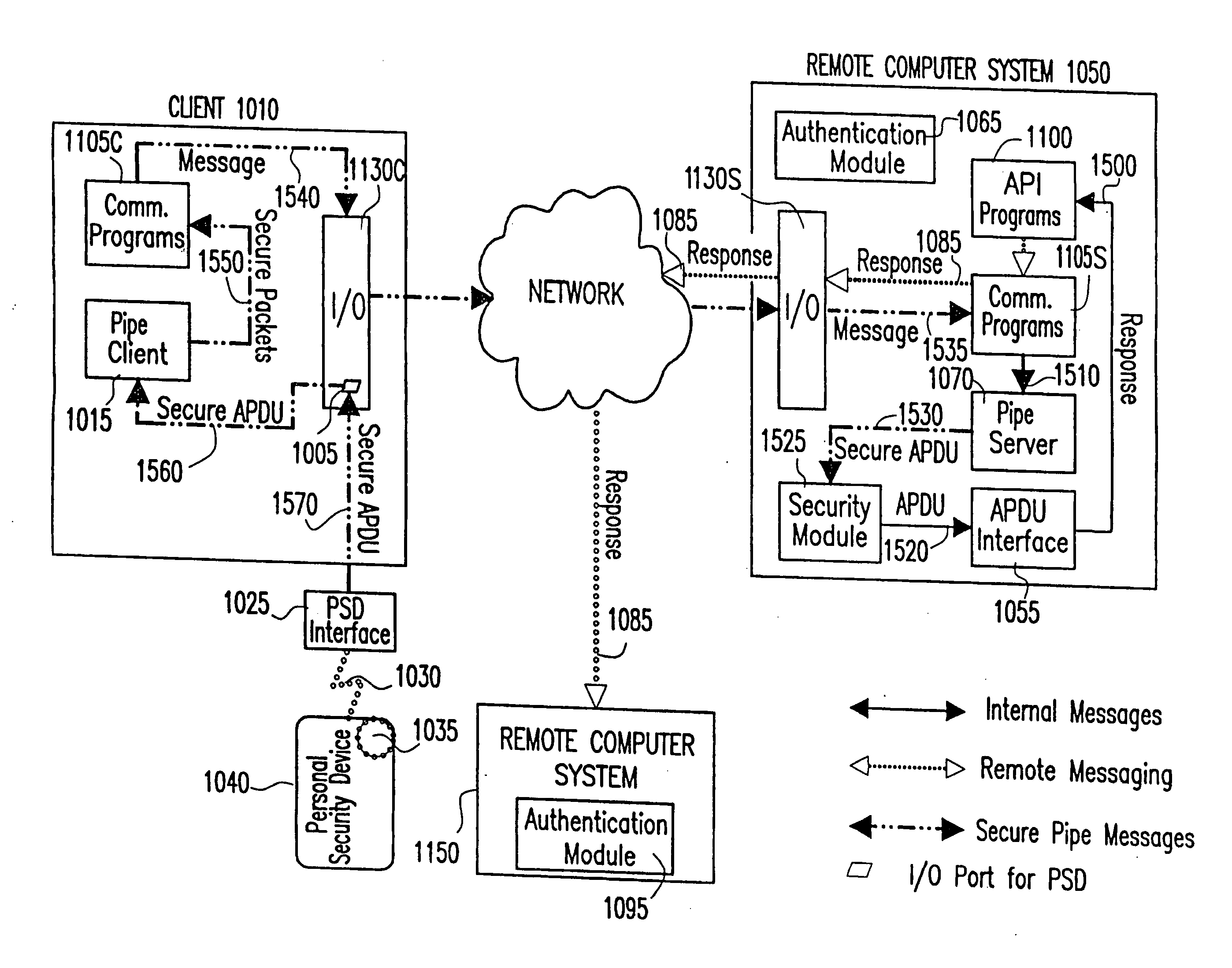

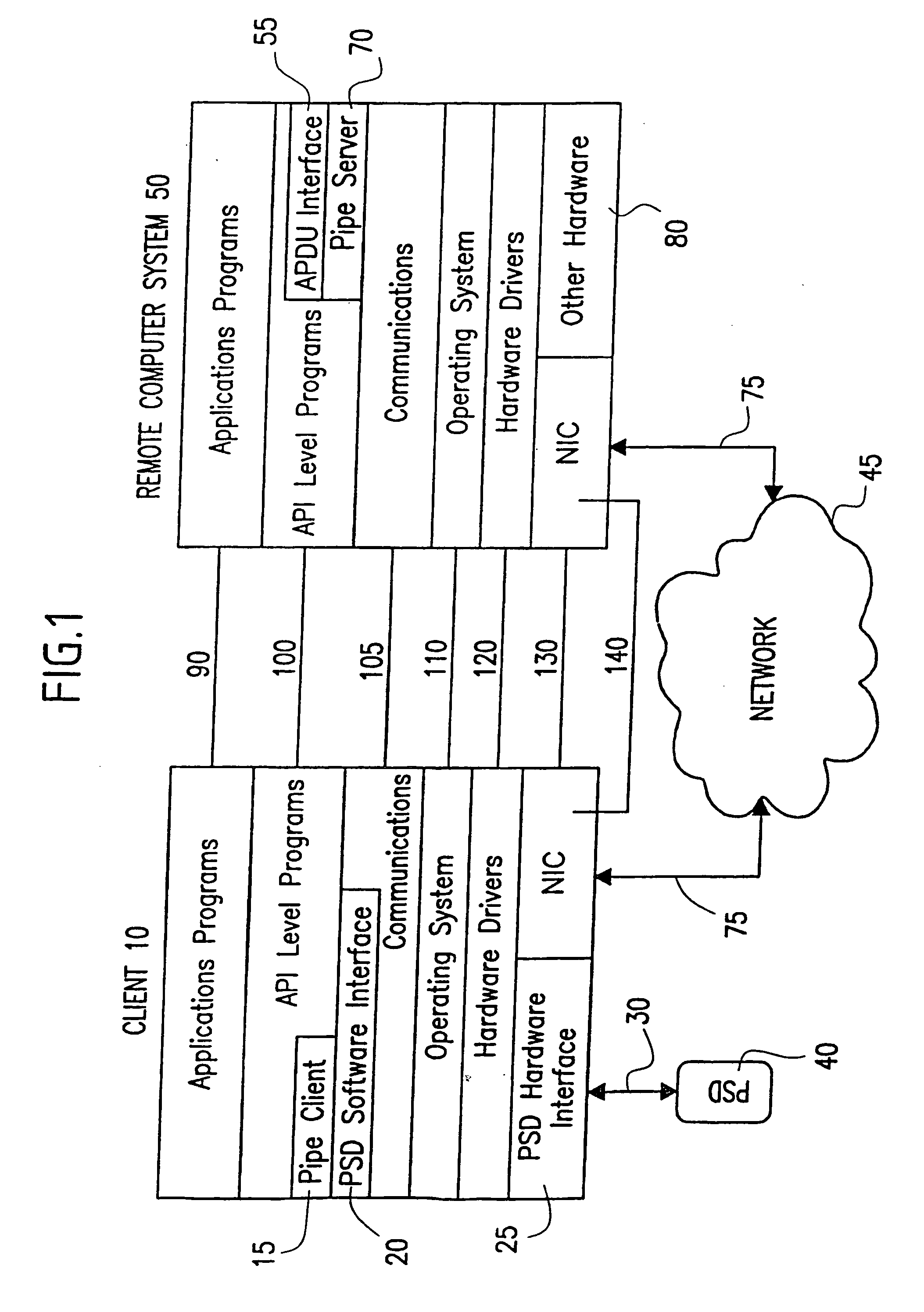

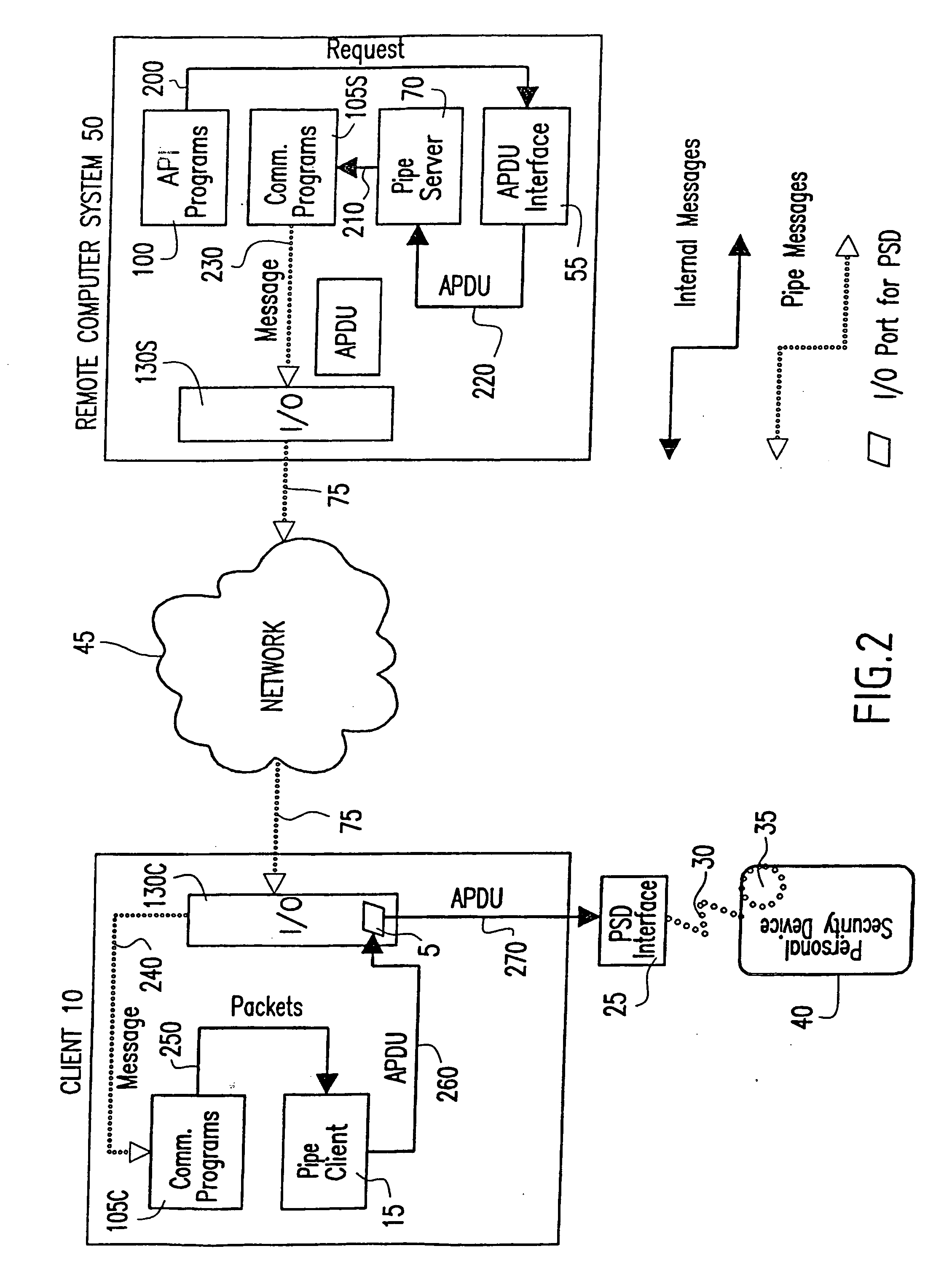

Method and system for authenticating a personal security device vis-a-vis at least one remote computer system

ActiveUS20040143762A1None of methods is secureReduce chanceDigital data processing detailsMultiple digital computer combinationsResponse processRemote computer

The present invention provides a method for authenticating at least one Personal Security Device PSD (1040) vis-ô-vis at least a first Remote Computer System (1050) over a first network (1045) using at least one Client (1010) as a host to said at least one PSD (1040), said method comprising the steps of: a) establishing at least one communications pipe (1075) over said first network (1045) between said at least one PSD (1040) and said at least first Remote Computer System (1050); and b) running a challenge / response process between said Remote Computer System (1050) and said at least one PSD (1040) through said at least one communications pipe (1075).

Owner:ASSA ABLOY AB

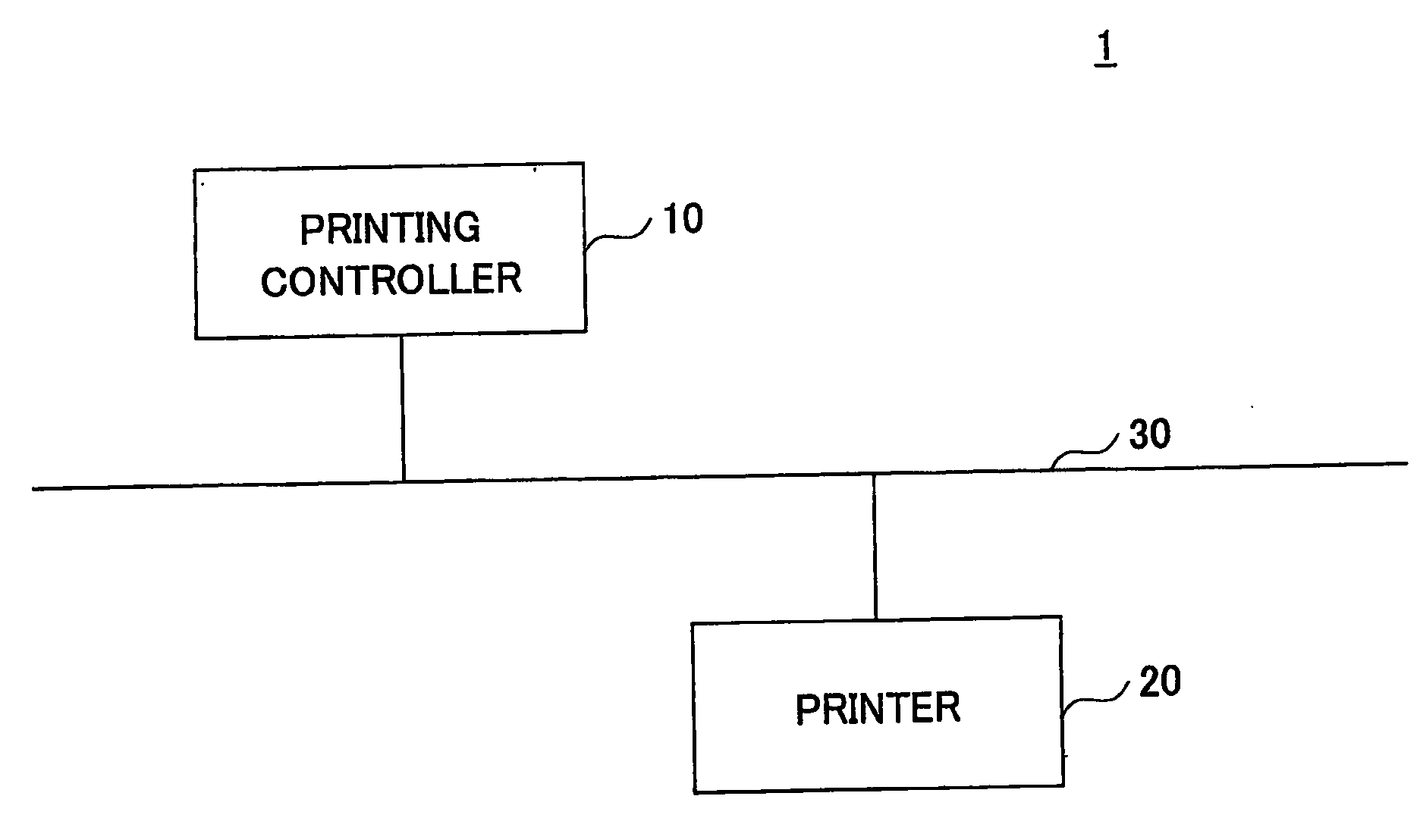

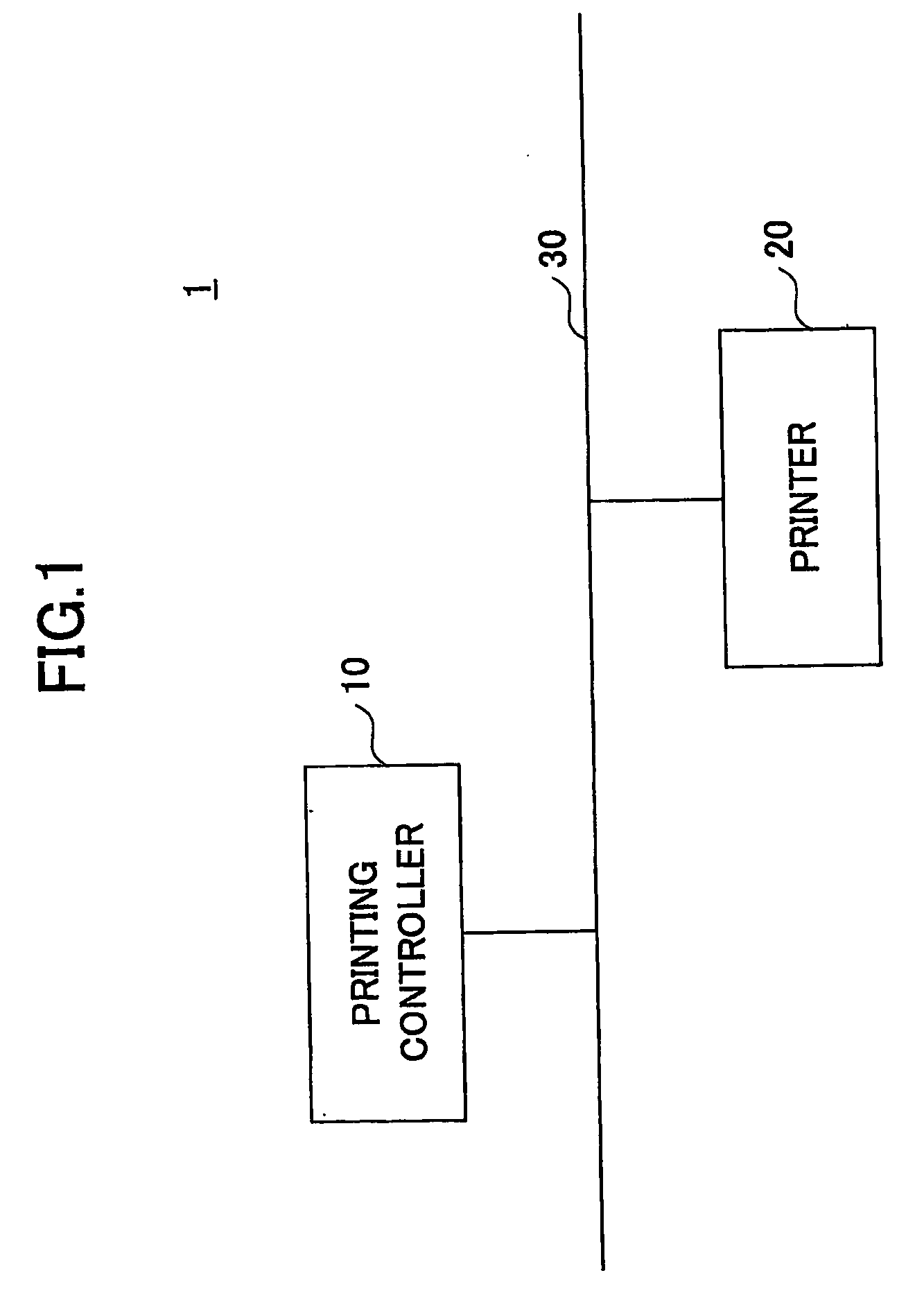

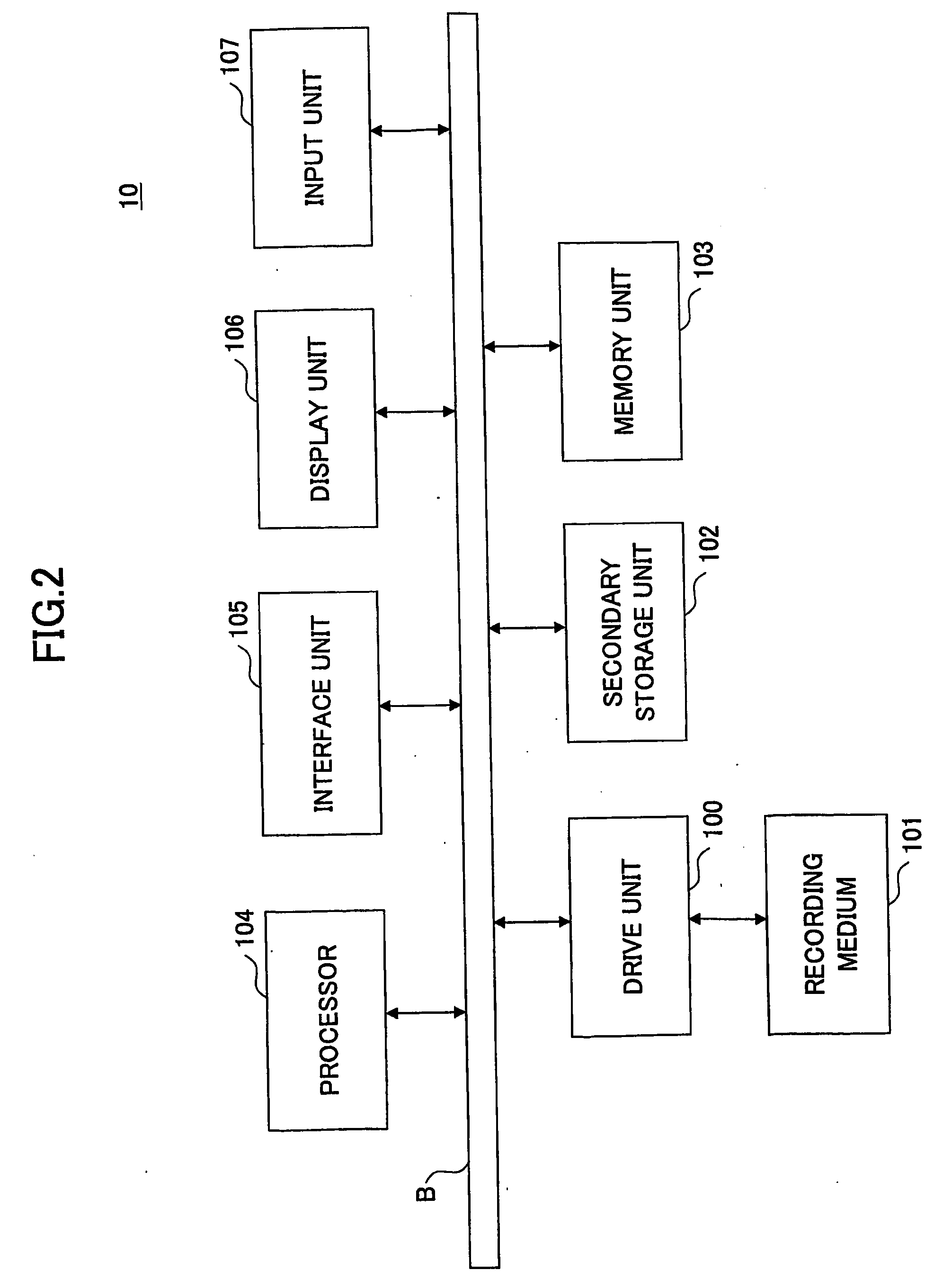

Printing controller, GUI display method, printer driver, and recording medium

InactiveUS20090303519A1Reduce resource consumptionEasy to operateDigital computer detailsExecution for user interfacesEmbedded systemPrint processor

Owner:RICOH KK

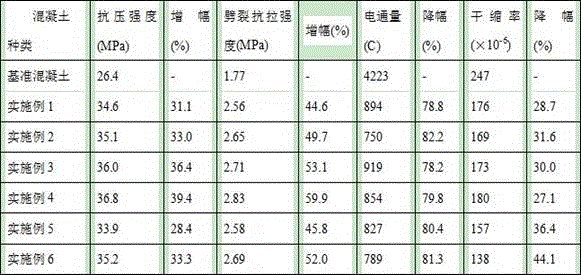

Anti-crack corrosion-resistant concrete admixture as well as preparation and application of anti-crack corrosion-resistant concrete admixture

The invention discloses an anti-crack corrosion-resistant concrete admixture as well as preparation and an application of the anti-crack corrosion-resistant concrete admixture. The anti-crack corrosion-resistant concrete admixture is prepared from the following raw materials by weight: 1.5-2.5 parts of fiber comprising a polypropylene fiber, a polyethylene fiber and a carbon fiber, 90-95 parts of an active mineral additive comprising a coal ash, metakaolin, slag and silica fume, and 3.5-7.5 parts of a reactive activator comprising nano dysprosium oxide, nano lanthanum oxide and nano yttrium oxide, the anti-crack corrosion-resistant concrete admixture is doped in a concrete, the weight ratio of a cement in the concrete is 10-40%, a proper amount of a polycarboxylic acid water reducer is added, and the specific doping amount is determined according to the coastal engineering. The pore structure of the concrete is thinned, the corrosion of harmful ions is reduced, the long-term strength of the concrete is guaranteed to improve stably, the carbon dioxide is absorbed, the peaceability, the compactness, the corrosion resistance, the early strength and the anti-cracking ability of the concrete are improved, the service life of the coastal engineering is prolonged, and the economic, social and ecological effects are better.

Owner:广西壮族自治区水利科学研究院

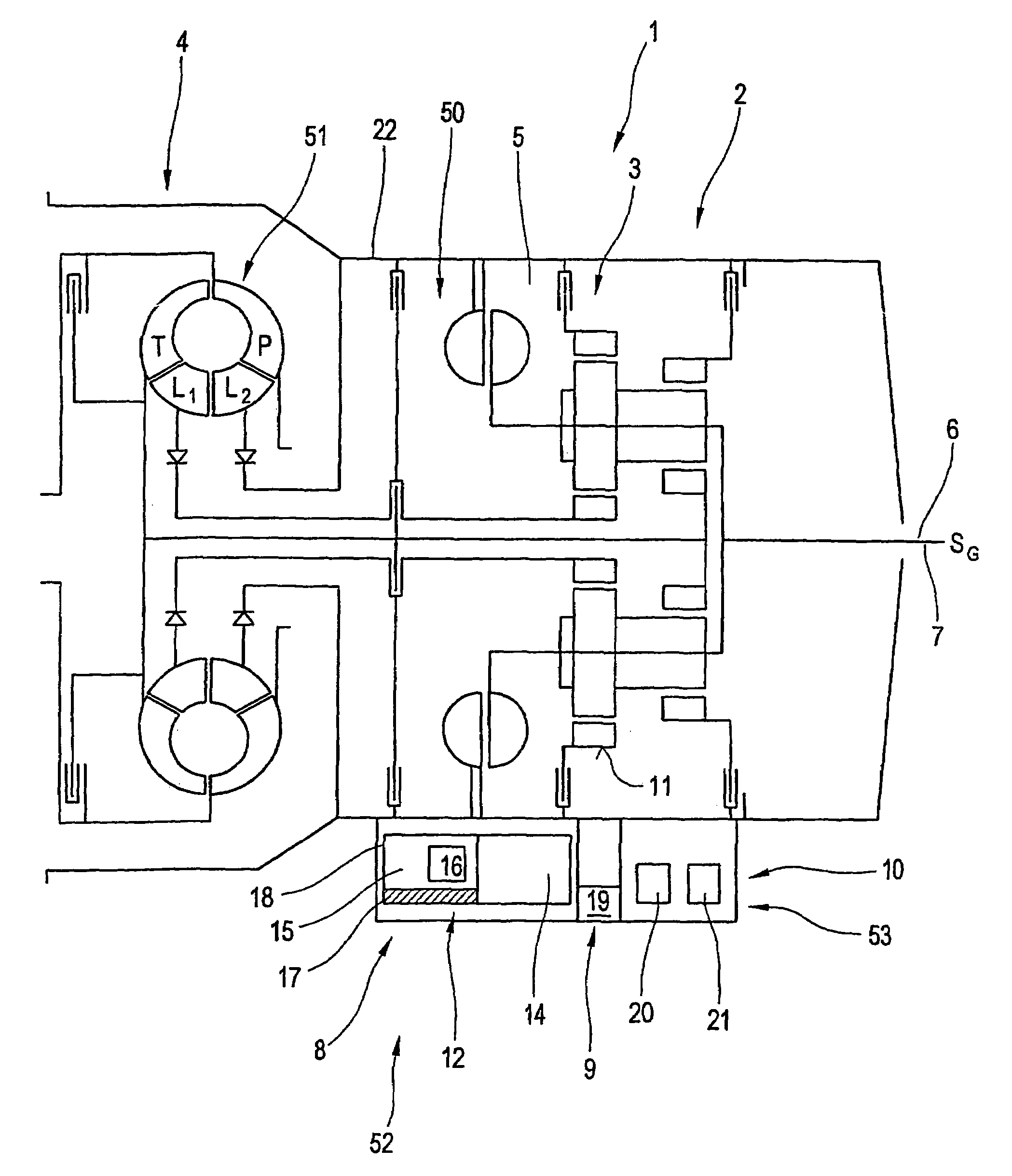

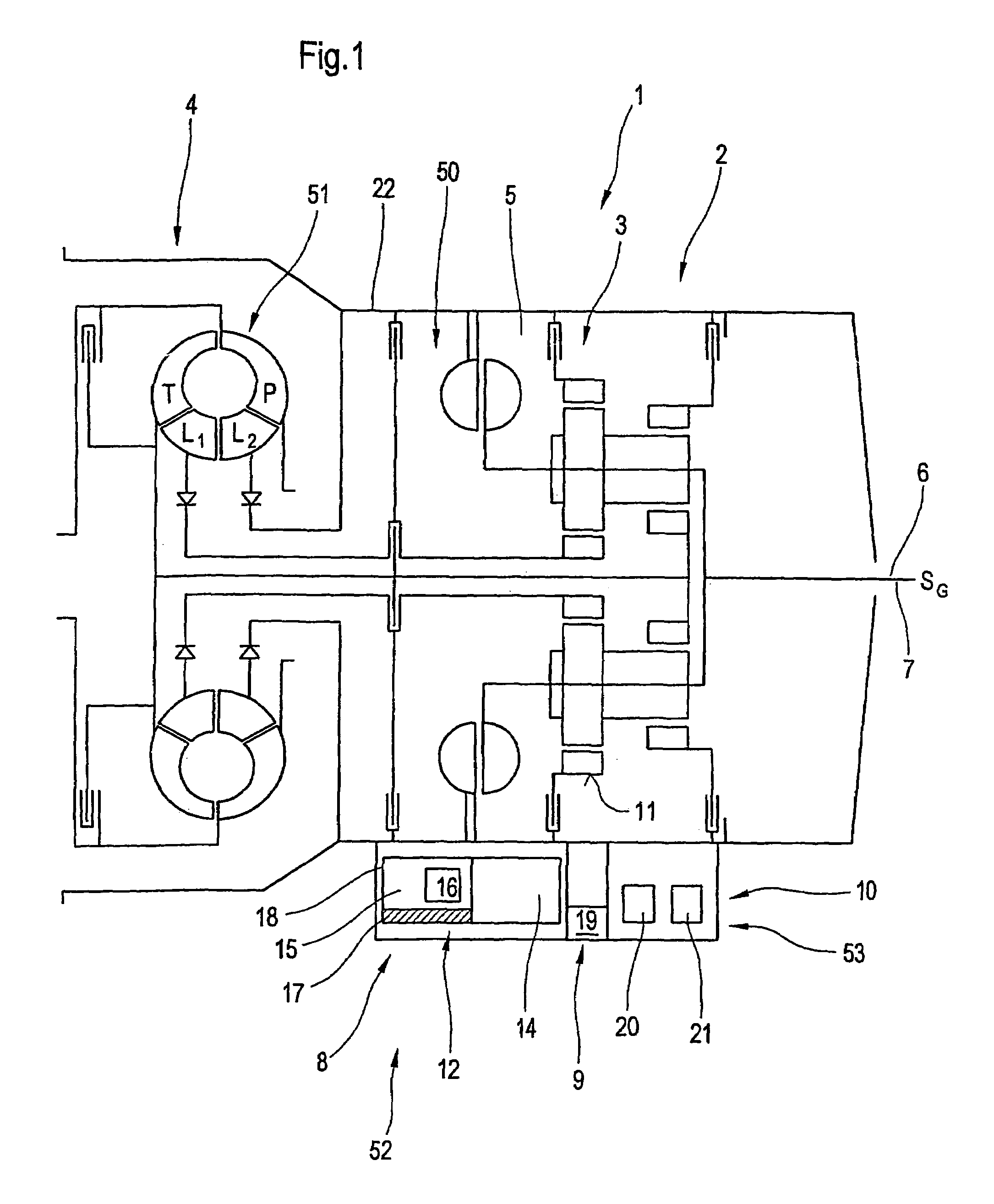

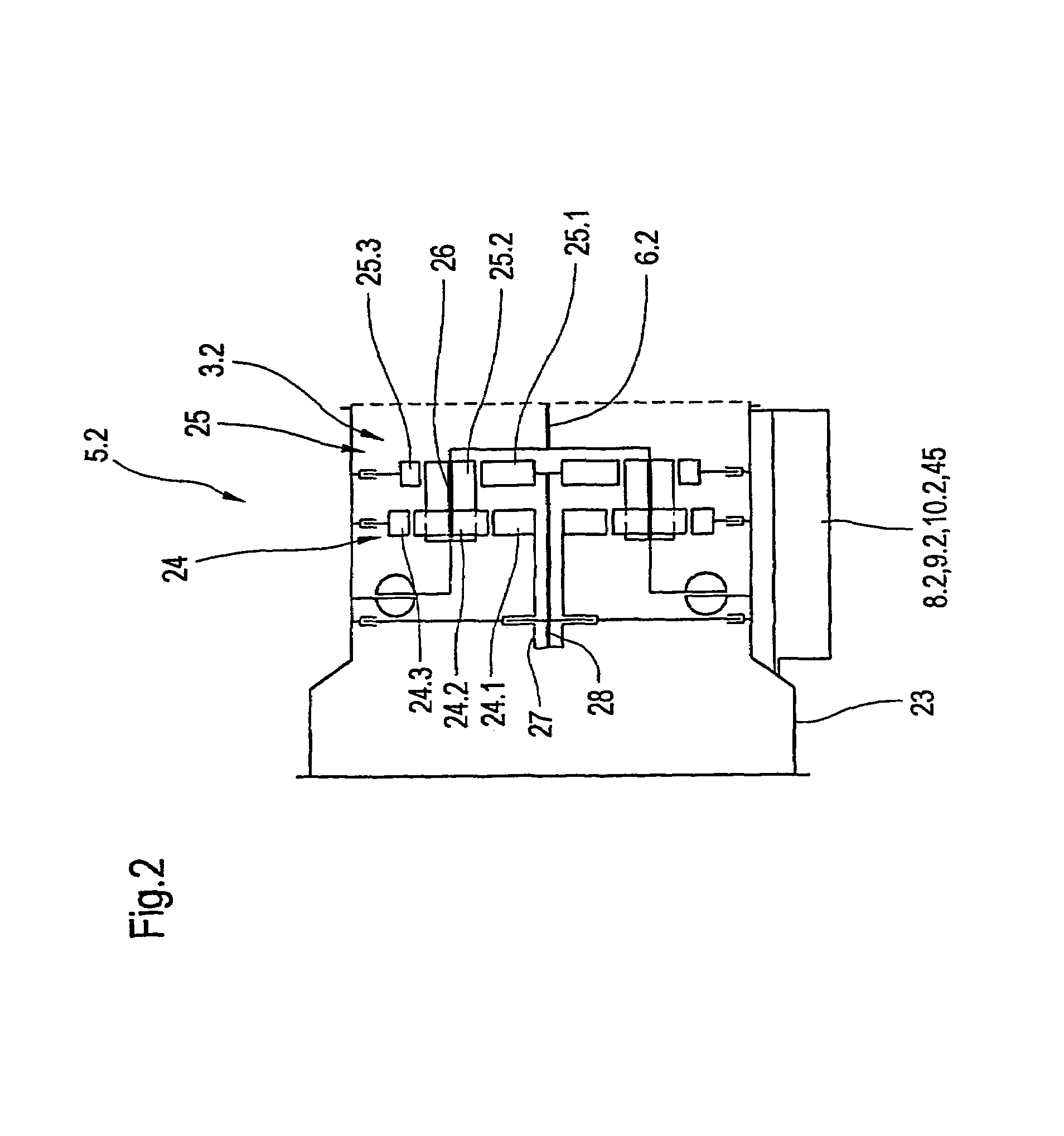

Transmission module

InactiveUS7131929B2Compact designConvenient ArrangementGearboxesToothed gearingsElectric power transmissionEngineering

A modular transmission system for the production of a plurality of modular transmission units that are modified for different applications purposes, comprising a transmission input and transmission output a power transmitting element comprising a mechanical transmission part that is arranged in a housing part and that forms with the latter a basic transmission module that includes at least one input and one output, and a control and supply unit integrated into the basic transmission module. The logic, control and supply units are arranged beneath the power transmitting element of the basic transmission module.

Owner:VOITH TURBO GMBH & CO KG

System, method and apparatus for implementing an improved user interface on a kiosk

ActiveUS20120133595A1Slows down transactionInsufficient levelInput/output processes for data processingSoftwareDisplay device

An apparatus, system and method are presented for implementing a user interface on a kiosk terminal. The terminal includes a processor, LCD display and touch-screen device. Software implemented by the processor receives input from the touch-screen device to determine complex interactions with the display that are then used to select and / or modify functions and features provided by the terminal.

Owner:NCR CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com