Ordered mesopore ZSM-5 molecular sieve and preparation method thereof

A ZSM-5, ordered mesoporous technology, applied in the direction of crystalline aluminosilicate zeolite, borocarbane silicone crystalline aluminosilicate zeolite, etc., can solve the problems of poor catalytic effect and selectivity of molecular sieves, and achieve excellent catalytic performance performance, high performance, conversion-increasing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Add 0.8000g cetyltrimethylammonium bromide (0.0022mol), 2.8ml 0.2mol / L sodium hydroxide solution, and 384ml water into a three-necked flask, mechanically stir at 80°C for 1.5h, then add 4ml Tetraethyl orthosilicate (0.02mol), continue to stir for 2 hours, and stand at 80°C for 20 hours. After the reaction, filter and wash repeatedly with deionized water to remove impurity ions adsorbed on the surface, and put Oven dry.

[0027] (2) Put the dried solid above into a mortar and grind it into powder, add it into a three-necked flask, then add 2.6600g (0.01mol) of tetrapropylammonium bromide, 0.0735g of aluminum isopropoxide (0.36mmol), 100ml of water, after ultrasonication for 0.5h, reflux at 90°C for 20h.

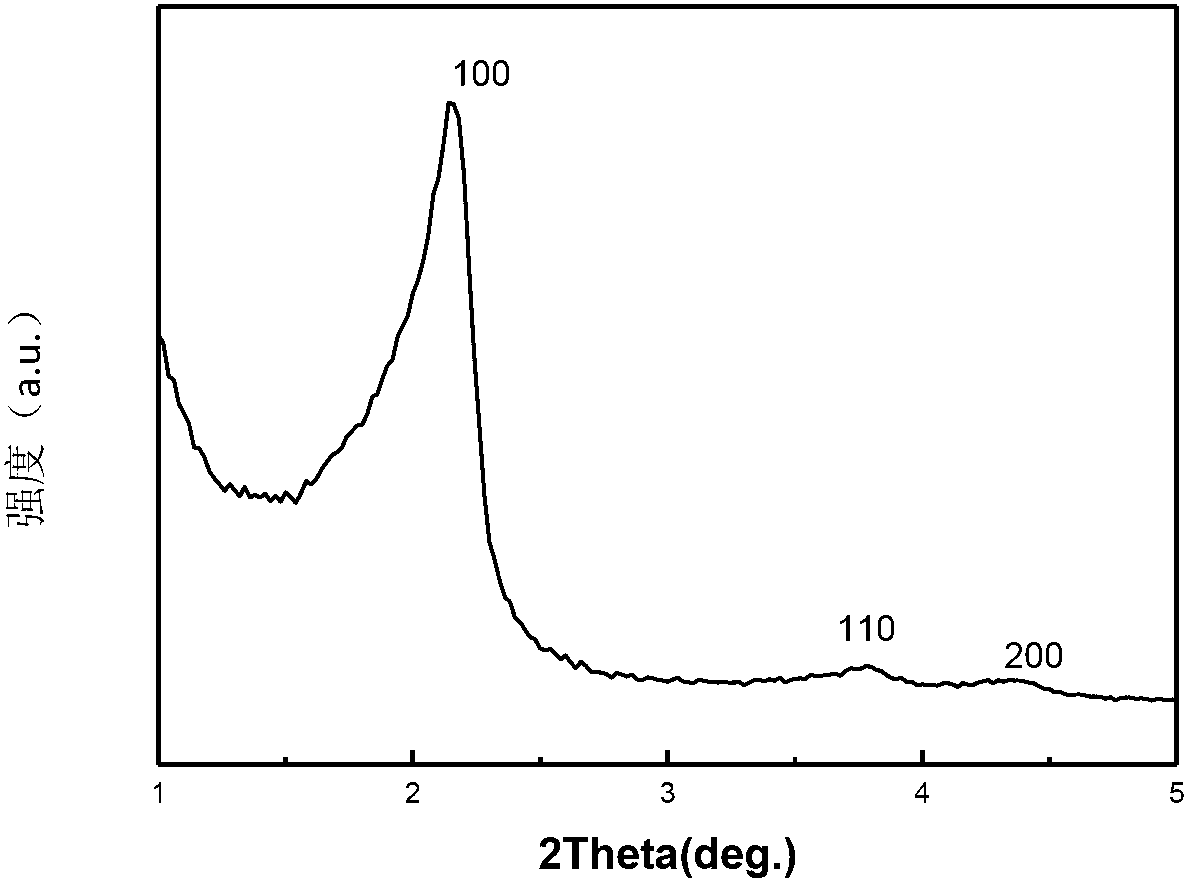

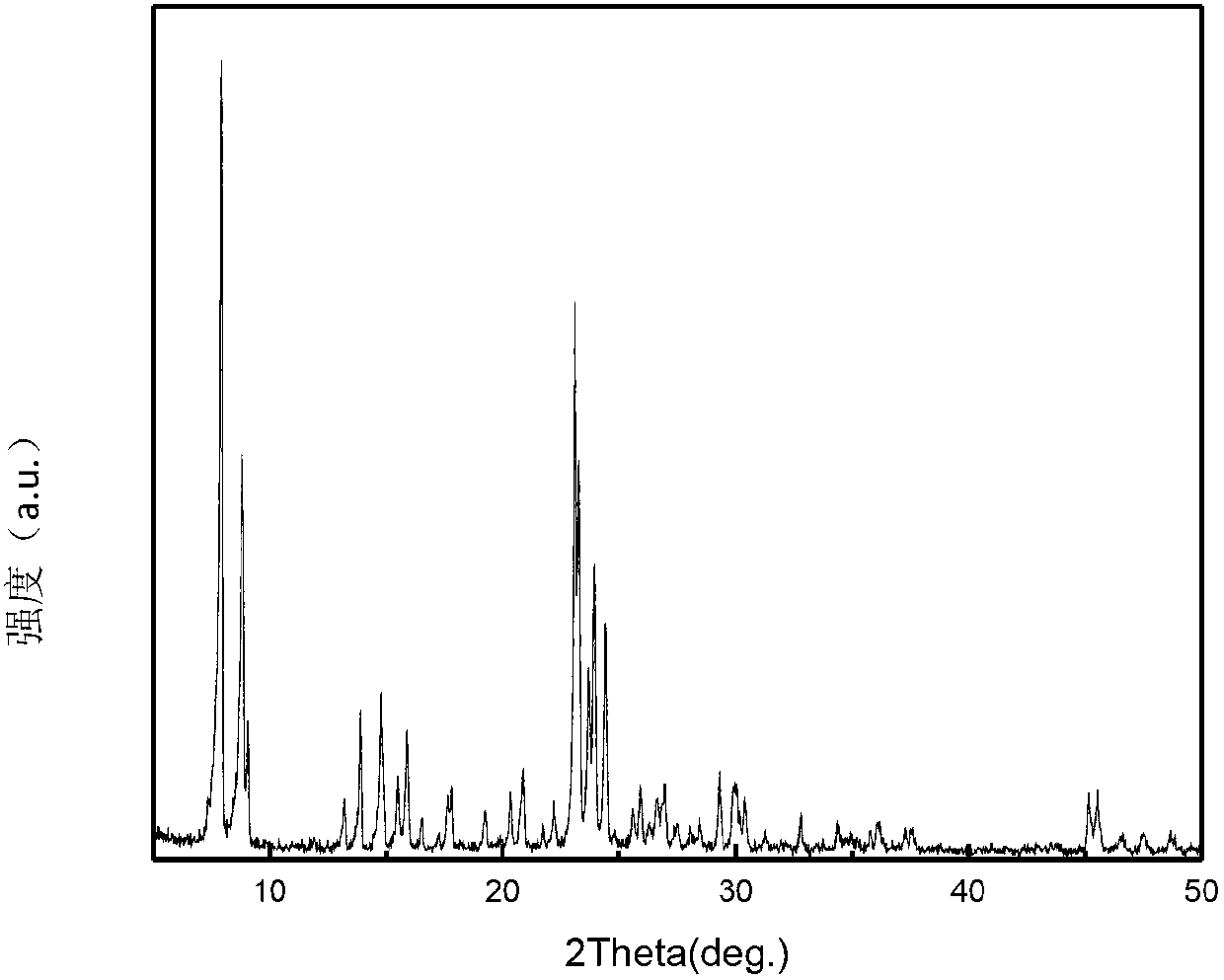

[0028] (3) Put the above solution into a stainless steel reaction kettle, put it in a 130°C oven, and crystallize for 7 days. Washing, filtering, drying, and calcination at 550° C. for 5 hours to obtain a ZSM-5 molecular sieve with ordered mesopores.

[0029] The...

Embodiment 2

[0031] (1) Add 0.8000g cetyltrimethylammonium bromide (0.0022mol), 2.8ml 0.2mol / L sodium hydroxide solution, and 384ml water into a three-necked flask, mechanically stir at 80°C for 1.5h, then add 4ml (0.02mol) tetraethyl orthosilicate, continue to stir for 2 hours, and stand at 80°C for 20 hours. After the reaction, filter and wash repeatedly with deionized water to remove impurity ions adsorbed on the surface, and put it in the Oven dry.

[0032](2) Put the dried solid above into a mortar and grind it into powder, add it into a three-necked flask, then add 2.6600g (0.01mol) tetrapropylammonium bromide, 0.0363g aluminum isopropoxide (0.18mmol), 100ml of water, after ultrasonication for 0.5h, reflux at 90°C for 20h.

[0033] (3) Put the above solution into a stainless steel reaction kettle, put it in a 140°C oven, and crystallize for 7 days. After washing, filtering, drying, and calcination at 550°C for 5 hours, a ZSM-5 molecular sieve with ordered mesopores was obtained.

Embodiment 3

[0035] (1) Add 0.8000g cetyltrimethylammonium bromide, 2.8ml 0.2mol / L sodium hydroxide solution, 384ml water into a three-necked flask, mechanically stir at 60°C for 1.5h, then add 4ml (0.02mol) Tetraethyl orthosilicate, continue to stir for 2 hours, and stand at 60°C for 20 hours. After the reaction, filter and wash repeatedly with deionized water to remove impurity ions adsorbed on the surface, and dry in an oven at 80°C.

[0036] (2) Put the above-mentioned dry solid into a powder in a mortar, add it to a three-necked flask, and then add 2.6600g (0.01mol) tetrapropylammonium bromide, 0.0192g aluminum isopropoxide (0.09mmol), 100ml Water, after ultrasonication for 0.5h, was condensed and refluxed at 90°C for 20h.

[0037] (3) Put the above solution into a stainless steel reaction kettle, put it in a 150°C oven, and crystallize for 7 days. After washing, filtering, drying, and calcination at 550°C for 5 hours, a ZSM-5 molecular sieve with ordered mesopores was obtained.

[...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com