Early-strength micro-expanding synchronous grouting material prepared from shield tailings and preparation method of synchronous grouting material

A technology of shield tailings and synchronous grouting, which is applied in the direction of sustainable waste treatment, solid waste management, climate sustainability, etc., can solve the problems of adverse impact on the living environment, occupying urban space, etc., and achieve good water dispersion resistance , Improve the flow performance and pumping performance, and reduce the loss of fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~7

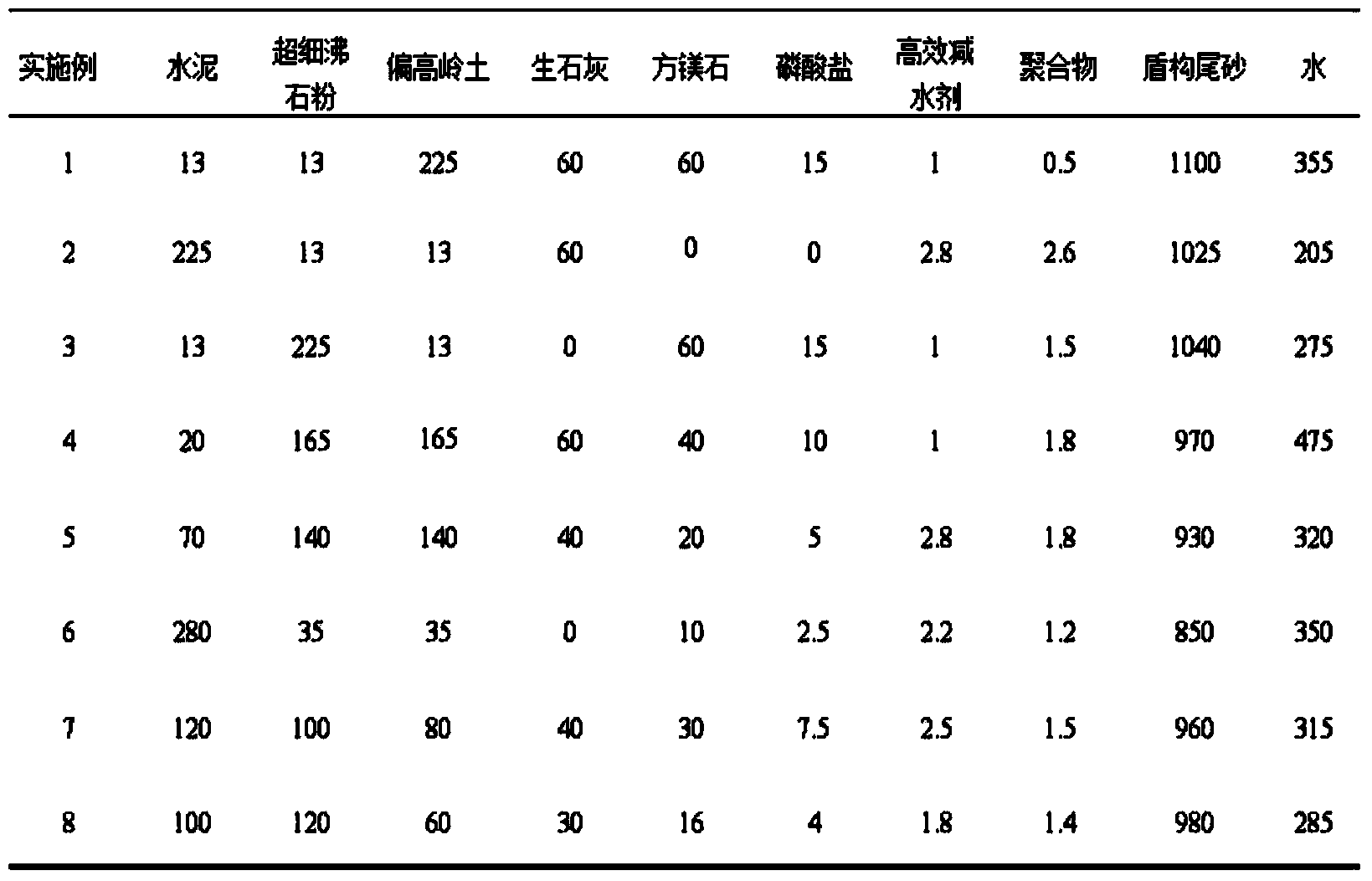

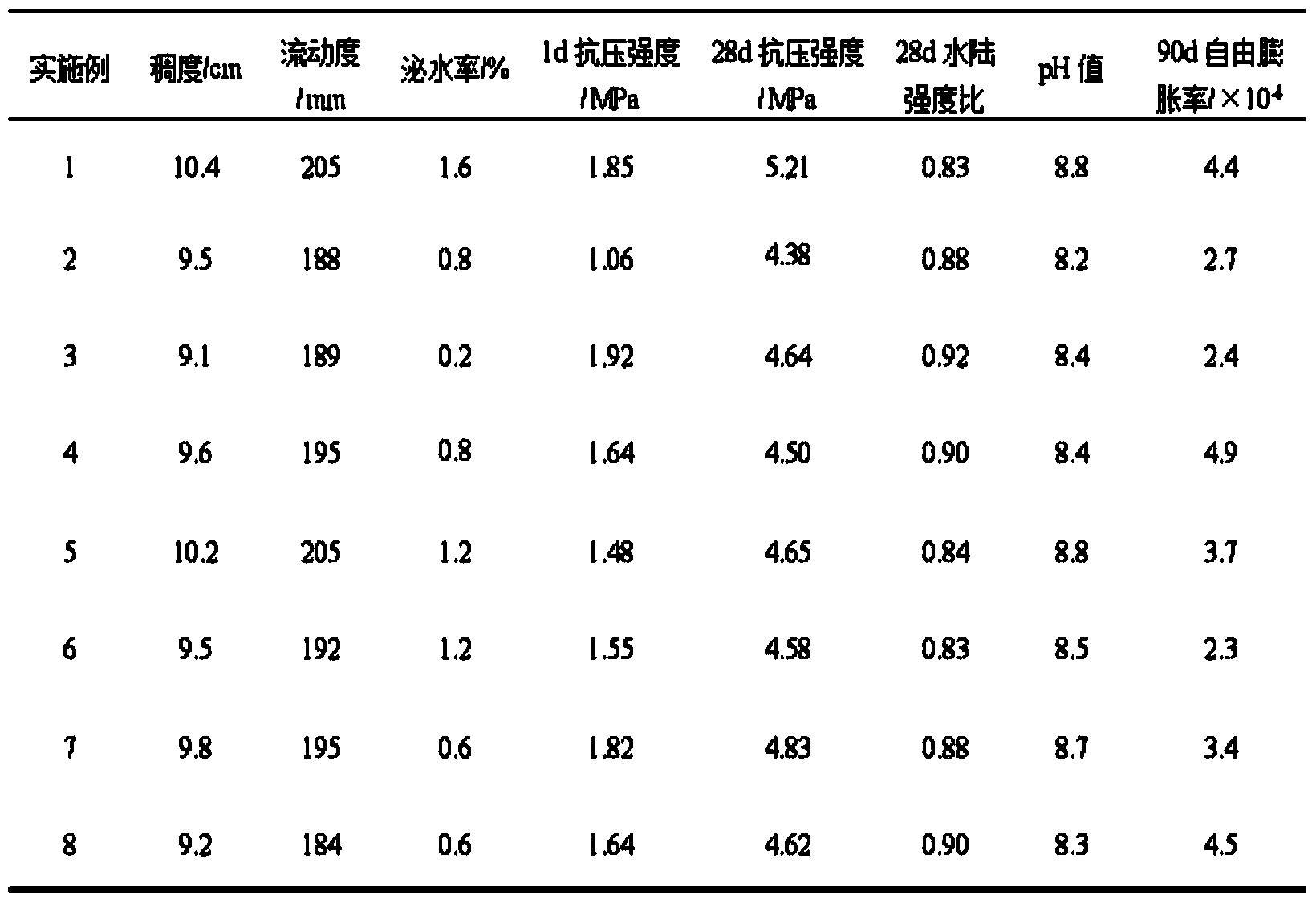

[0042] A shield tunnel synchronous grouting material prepared by using shield tailings instead of bentonite and river sand, the preparation method comprising the following steps:

[0043] (1) Weigh the component raw materials according to the weight ratio: cement, ultrafine zeolite powder, metakaolin, quicklime, periclase, phosphate, polymer, shield tailings, high-efficiency water reducer and water, and distribute each component For details, see Table 2 below;

[0044] (2) Mix cement, ultrafine zeolite powder, metakaolin, quicklime, periclase and polymer evenly, then add shield tailings, and dry mix together for 3 minutes to obtain a dry mixture;

[0045] (3) Dissolve the high-efficiency water reducer in water and stir it evenly, then add it to the dry mixture described in step (2), and mix and stir for 3 minutes to obtain a slurry, which should be kept stirring continuously during storage;

[0046] (4) Prepare the phosphate into a phosphate solution with a mass concentration...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Consistency | aaaaa | aaaaa |

| Liquidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com