Substation weeding robot

A technology for robots and substations, applied in the field of intelligent robots, can solve the problems of high cost of manual weeding, difficult to deal with in time, and the operation and maintenance personnel cannot know the weed situation of the substation in real time, so as to eliminate potential safety hazards, improve reliability, Good work performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

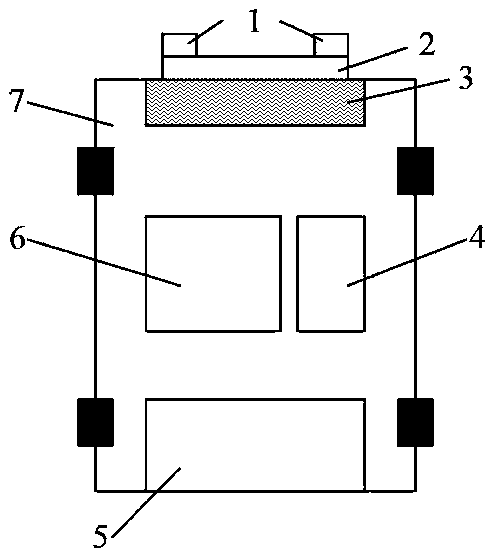

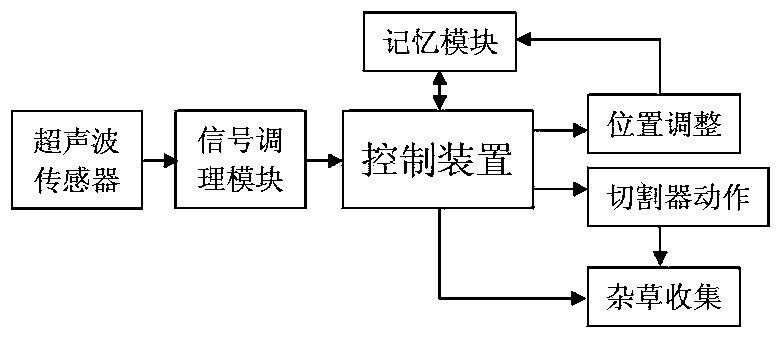

[0011] The structure of substation weeding robot of the present invention is as figure 1 As shown, it includes an ultrasonic sensor 1, a signal conditioning module 2, a control device 6, a memory module 4, a trolley 7, a cutter 3 and a recovery device 5, the ultrasonic sensor 1 is connected to the control device 6 through the signal conditioning module 2, and the memory module 4, The cutter 3 and the recovery device 5 are respectively connected to the control device 6 , and the control device 6 is connected to the trolley 7 .

[0012] The control device 6 adopts STM32F103 MCU embedded ARM single-chip microcomputer. Ultrasonic sensor 1 adopts URM07 sensor, the detection angle is 60°, the effective measurement distance is 7.5 meters, the acoustic frequency is 38~42KHz, and the data is automatically compensated. Memory module 4 adopts AT24C04 non-volatile EEPROM memory chip, power supply voltage 2.7-5.5V, serial IIC interface.

[0013] Utilize the above substation weeding robot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com