High-fluidity neutron-radiation-resistant concrete and preparation method thereof

A technology for preventing neutron radiation and concrete, which is applied in the fields of climate sustainability, reactors, sustainable waste treatment, etc. Good, strength-enhancing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

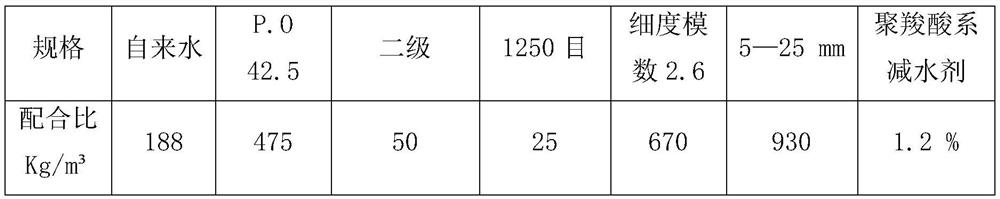

[0041]The ratio of each component in Example 2 is shown in Table 4, and the properties of the concrete obtained in Example 2 are shown in Table 5.

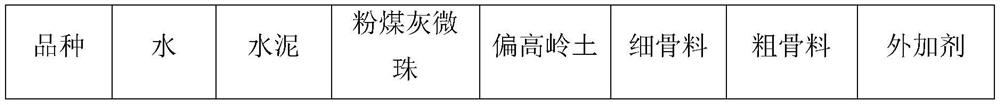

[0042] Table 4

[0043]

[0044] table 5

[0045] project Slump 28-day compressive strength Hydrogen content index 210mm 35.3 MPa 1.53%

Embodiment 1

[0046] Examples 1 and 2 show that the anti-neutron radiation serpentine concrete with a hydrogen content of more than 1.5% and a 28-day compressive strength greater than 30Mpa has been obtained by the method of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com