Method for preparing chromium-nickel-containing iron ore oxidized pellets from chromite and laterite-nickel ore

A technology of laterite nickel ore and oxidized pellets, which is applied in the field of preparation of chromium-inconel-containing oxidized pellets, which can solve the problems of difficult separation of slag and iron, high energy consumption for smelting, poor quality of agglomerates, etc., and achieve excellent pelletizing performance , High crystal water content, poor ball forming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for strengthening chromite gas-based solid-state reduction, prepared according to the following steps:

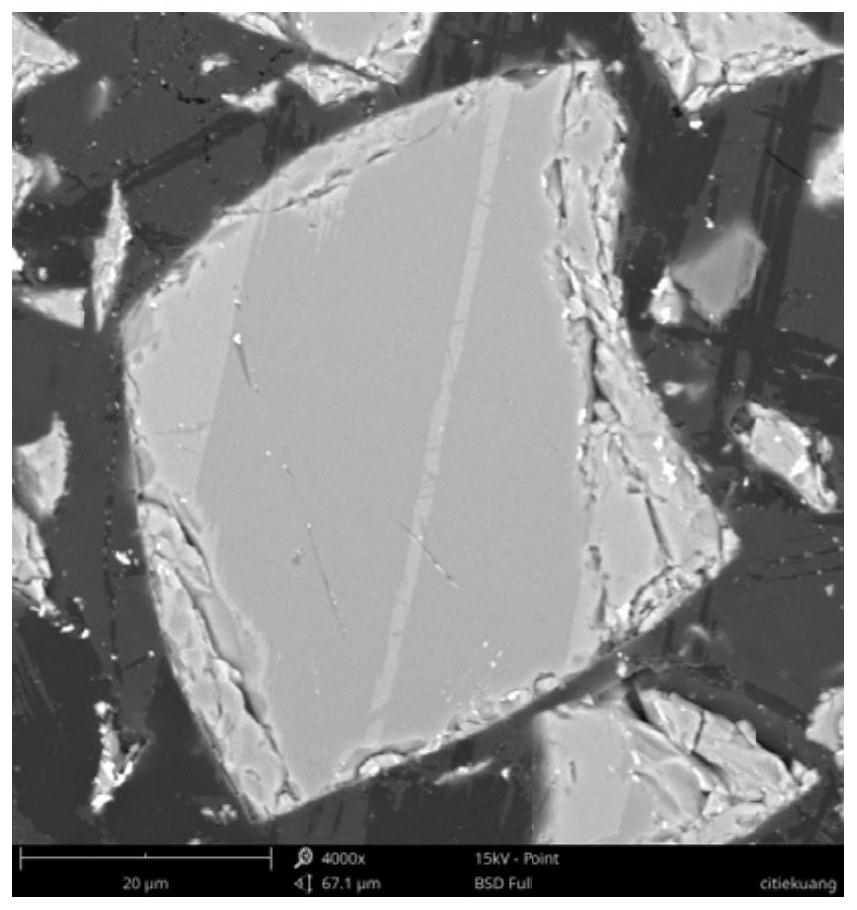

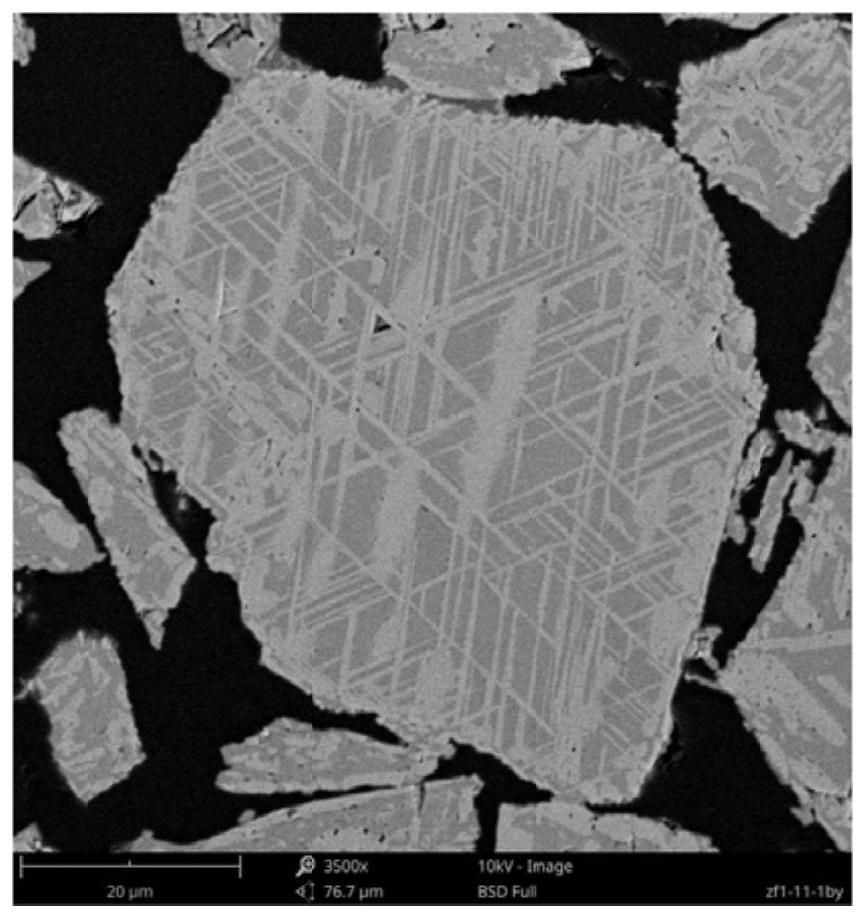

[0027] (1) Chromite pretreatment: 22.61% iron and Cr 2 o 3 42.55% of the chromite concentrate is subjected to wet ball milling until more than 90% of the particles in the chromite have a particle size of less than 0.074mm and a specific surface area of not less than 1500cm 2 / g to get pretreated chromite.

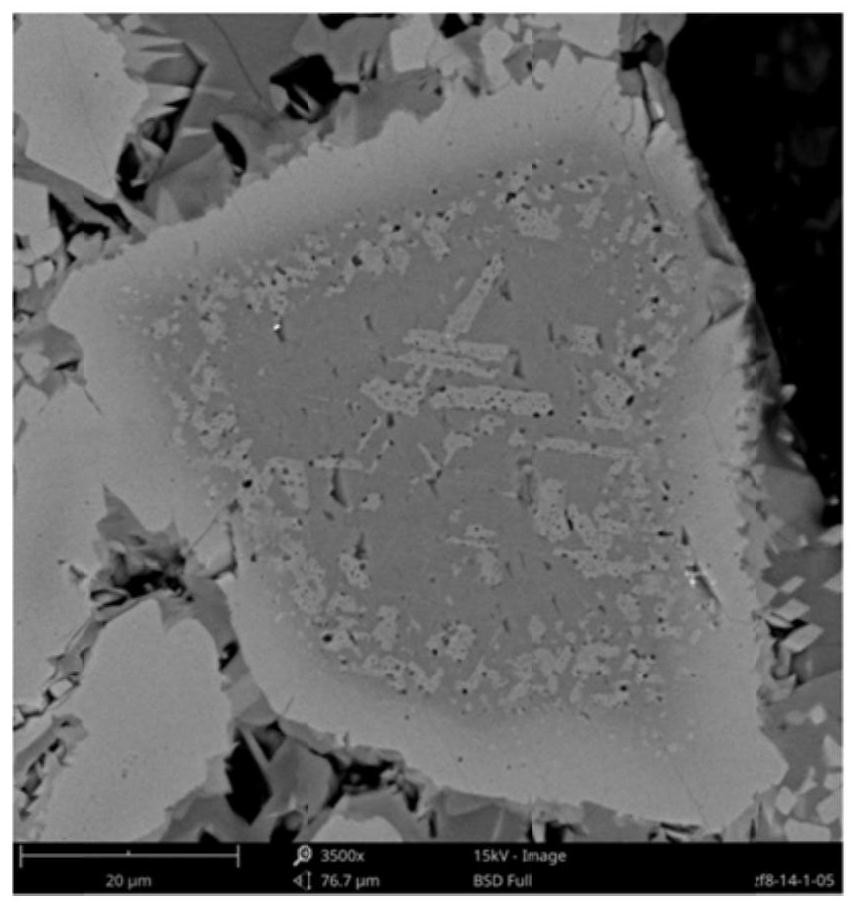

[0028] (2) Pretreatment of laterite nickel ore: dry the laterite nickel ore to a moisture content below 10% (weight), crush the laterite nickel ore to less than 3mm with a roller crusher, and then grind it to a particle size of more than 75% with a rod mill Less than 0.074mm, specific surface area not less than 1800cm 2 / g to obtain the pretreated laterite nickel ore.

[0029] (3) Batching: the particle size of magnetite less than 0.074mm accounts for more than 75wt%. The magnetite is mixed with the pretreated chromite and laterite nickel ore, and ...

Embodiment 2

[0033] A kind of preparation method of Inconel-containing oxidized pellet of the present invention, comprises the following steps:

[0034] (1) Chromite pretreatment: 22.61% iron and Cr 2 o 3 42.55% of the chromite concentrate is subjected to wet ball milling until more than 90% of the particles in the chromite have a particle size of less than 0.074mm and a specific surface area of not less than 1500cm 2 / g to get pretreated chromite.

[0035] (2) Pretreatment of laterite nickel ore: dry the laterite nickel ore to a moisture content below 10% (weight), crush the laterite nickel ore to less than 3mm with a roller crusher, and then grind it to a particle size of more than 75% with a rod mill Less than 0.074mm, specific surface area not less than 1800cm 2 / g to obtain the pretreated laterite nickel ore.

[0036] (3) Batching: the particle size of magnetite less than 0.074mm accounts for more than 75wt%. Magnetite is mixed with pretreated chromite and lateritic nickel ore,...

Embodiment 3

[0040]A kind of preparation method of Inconel-containing oxidized pellet of the present invention, comprises the following steps:

[0041] (1) Chromite pretreatment: 22.61% iron and Cr 2 o 3 42.55% of the chromite concentrate is subjected to wet ball milling until more than 90% of the particles in the chromite have a particle size of less than 0.074mm and a specific surface area of not less than 1500cm 2 / g to get pretreated chromite.

[0042] (2) Pretreatment of laterite nickel ore: dry the laterite nickel ore to a moisture content of less than 10%, crush the laterite nickel ore to less than 3mm with a double-roller crusher, and then use a rod mill to grind the laterite nickel ore to a particle size of more than 75% and less than 0.074mm , the specific surface area is not less than 1800cm 2 / g to obtain the pretreated laterite nickel ore.

[0043] (3) Ingredients: mix magnetite with pretreated chromite and laterite nickel ore, and the ore blending ratio is chromite: lat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com