Patents

Literature

114 results about "Chrome ferroalloy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

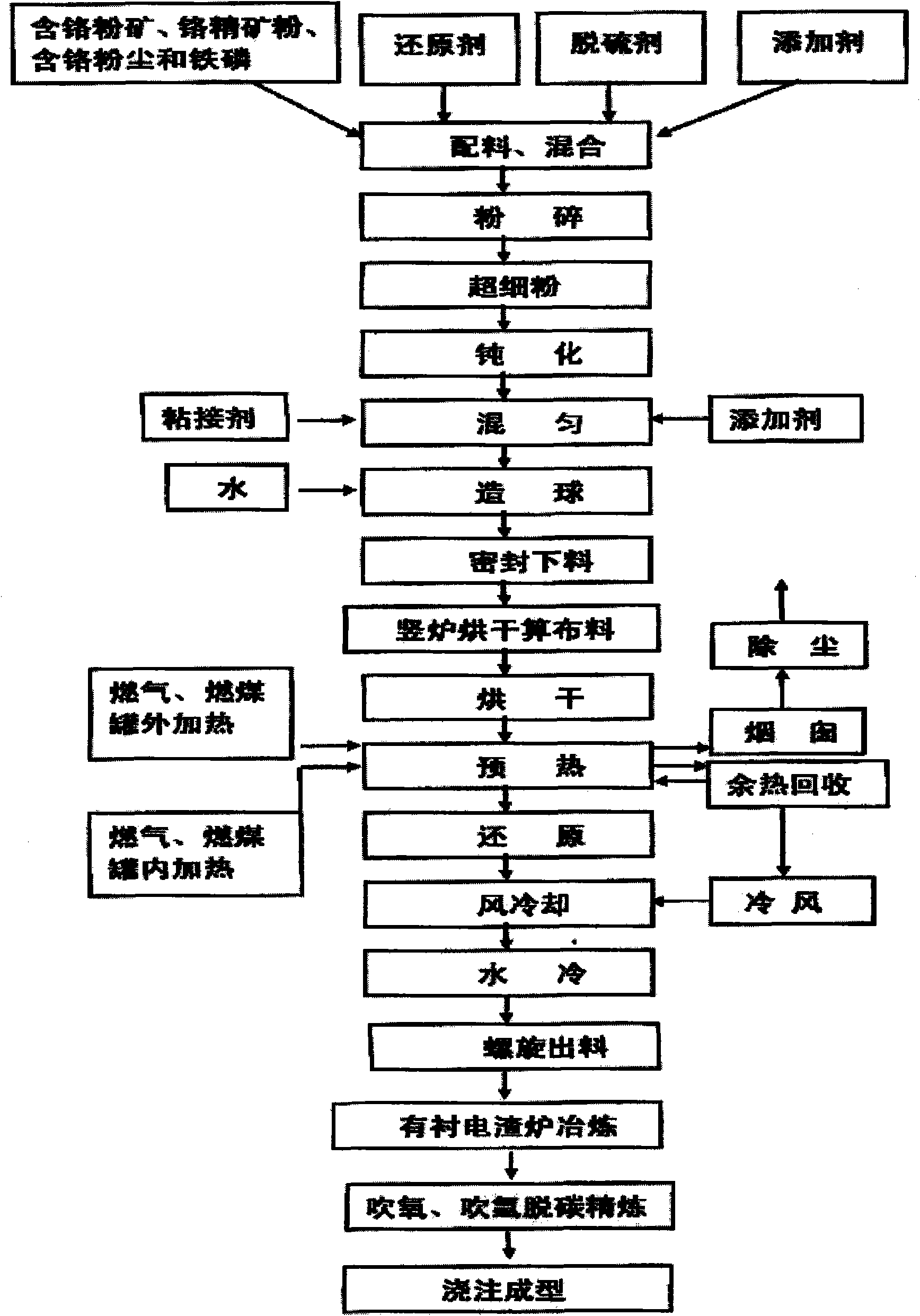

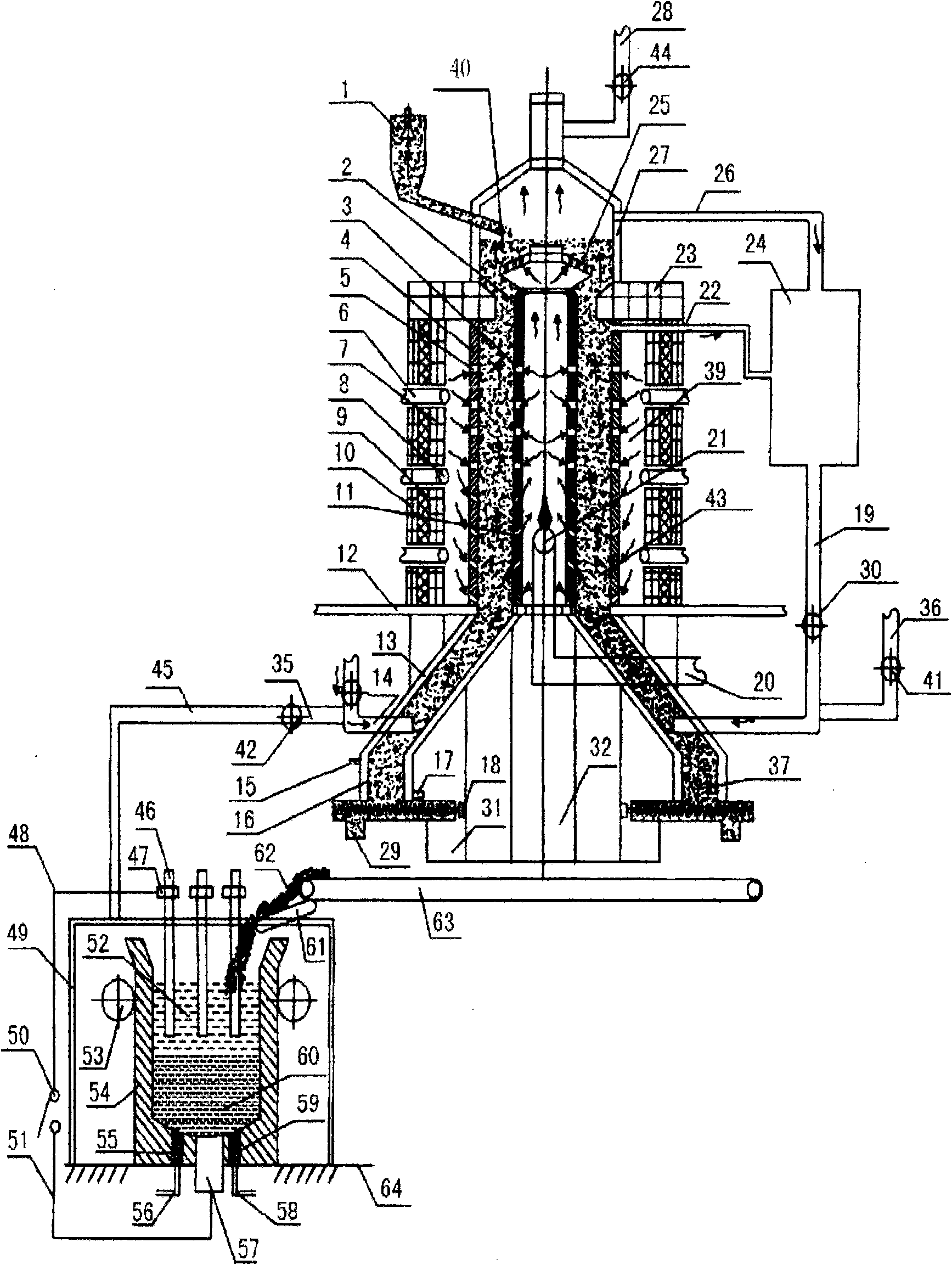

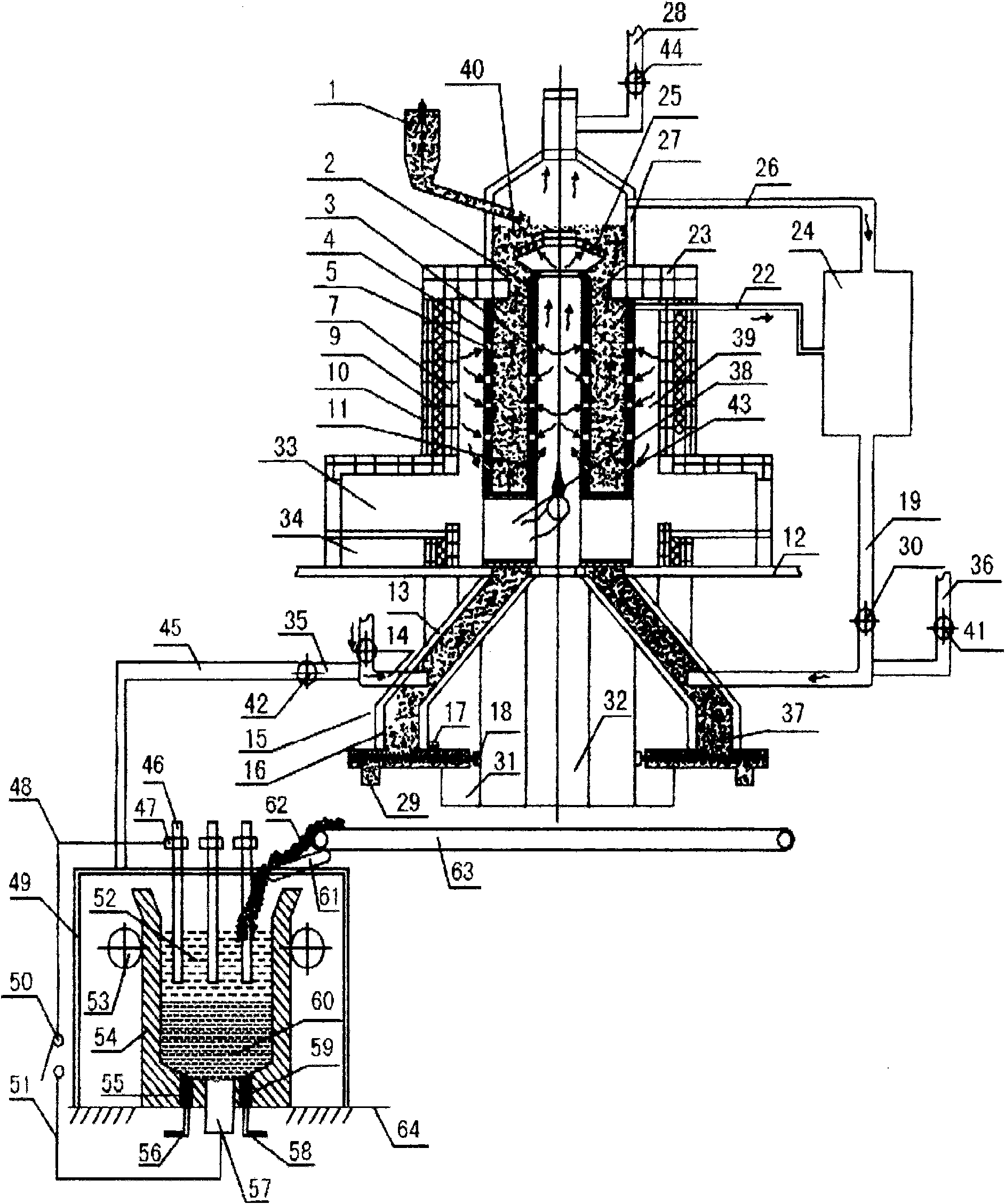

Process and device for smelting chromium irons and chromium-containing molten iron by using chromium ore powder

InactiveCN101538629AImprove applicabilityHigh recovery rateProcess efficiency improvementShaft furnaceUltra fineSolvent

The invention relates to a process and a device for smelting chromium irons and chromium-containing molten iron by using chromium ore powder, which belongs to metallurgical industry steel-making raw material. The process comprises the following steps: mixing chromium iron containing raw materials with reducing agent, solvent and catalyst to prepare ultra fine powder, mixing to make pelletizing materials, sending the pelletizing materials into a reducing furnace, obtaining chromium irons pellets after the reduction reaction, and directly adding reduced pellets into a lining electroslag furnace for being smelted into the chromium-iron alloy or the chromium-containing molten iron. The device comprises an internal-external heating vertical reducing furnace, a lining electroslag furnace and a residual heat recovery system. The invention has the advantages that: firstly, the reduction temperature is low, the speed is high, the energy consumption is reduced, the production cost is lowered, the production efficiency is high, and the uniformity of the quality is good; secondly, the degree of mechanization is high, the procedure is simple, the yield is large, the mass production can be performed; thirdly, the waste of raw materials is reduced, the environment pollution is lowered; fourthly, the source of raw materials adopting the chromium ore powder and chromium-containing waste, the cost is low; fifthly, the waste resource can be recycled so as to save the resource consumption; and sixthly, the high-temperature pellets are directly smelted by adopting the lining electroslag furnace, the heat efficiency is high, the energy consumption is low, the material purity is high and the quality is good, and the device is simple with less investment.

Owner:丁家伟

Ni-Cr-Fe alloy and its production process

InactiveCN1847440ASave resourcesOptimize the smelting processBlast furnace detailsRecycling and recovery technologiesGranularityManganese

The present invention is Ni-Cr-Fe alloy and its production process. The Ni-Cr-Fe alloy contains Ni 1.5-6.0 wt%, Cr 3.0-21.0 wt%, Si 0.6-2.0 wt% and Mn 0.3-0.8 wt%, except Fe, and can meet the requirement for use as material smelting stainless steel. The production process includes the following steps: producing Ni-Cr agglomerate with industrial Ni-Cr waste, Ni-Cr ore powder of granularity smaller than 10 mm, flux, coke and water and through pelletizing, sintering and sieving; and smelting with the Ni-Cr agglomerate, Ni-Cr ore of granularity greater than 10 mm, flux and coke in a blast furnace. The present invention has sang in resource and environment friendship.

Owner:DONGDA CASTING WUJIANG

Production method for reducing titanium content in high-carbon chromium bearing steel

The invention relates to a production method for reducing the titanium (Ti) content in high-carbon chromium (Cr) bearing steel. The production method comprises the following steps of: firstly, blowing oxygen into steel liquid in an electric furnace or a converter to remove Ti, pre-putting ferrochrome with Cr of 60 to 75 percent for smelting steel GCr15 into a steel ladle, and baking the steel ladle with the ferrochrome at the temperature of between 1,000 and 1,100 DEG C for 30 to 35 minutes; secondly, adding Si, Mn and Al for deoxygenation when the steel liquid enters 2 / 3 to 3 / 4 part of the steel ladle by using the characteristic of eccentric eriochrome black T (EBT) of the electric furnace, and then adding low-Ti and high-carbon ferrochrome; thirdly, blowing Ar and stirring during steel discharging, refining the steel liquid in a ladle furnace (LF) by adding the low-Ti ferrochrome, wherein the Ti content in the low-Ti ferrochrome is less than 0.12 percent; and finally, adjusting components of refined slag and adsorbing the Ti element in the steel liquid in a strengthening manner. The Ti content in the high-carbon Cr bearing steel prepared by using the method is 0.0016 to 0.0027 percent. The method is easy to operate, secure and high in Ti removing efficiency.

Owner:WUHAN IRON & STEEL GRP ECHENG IRON & STEEL CO LTD

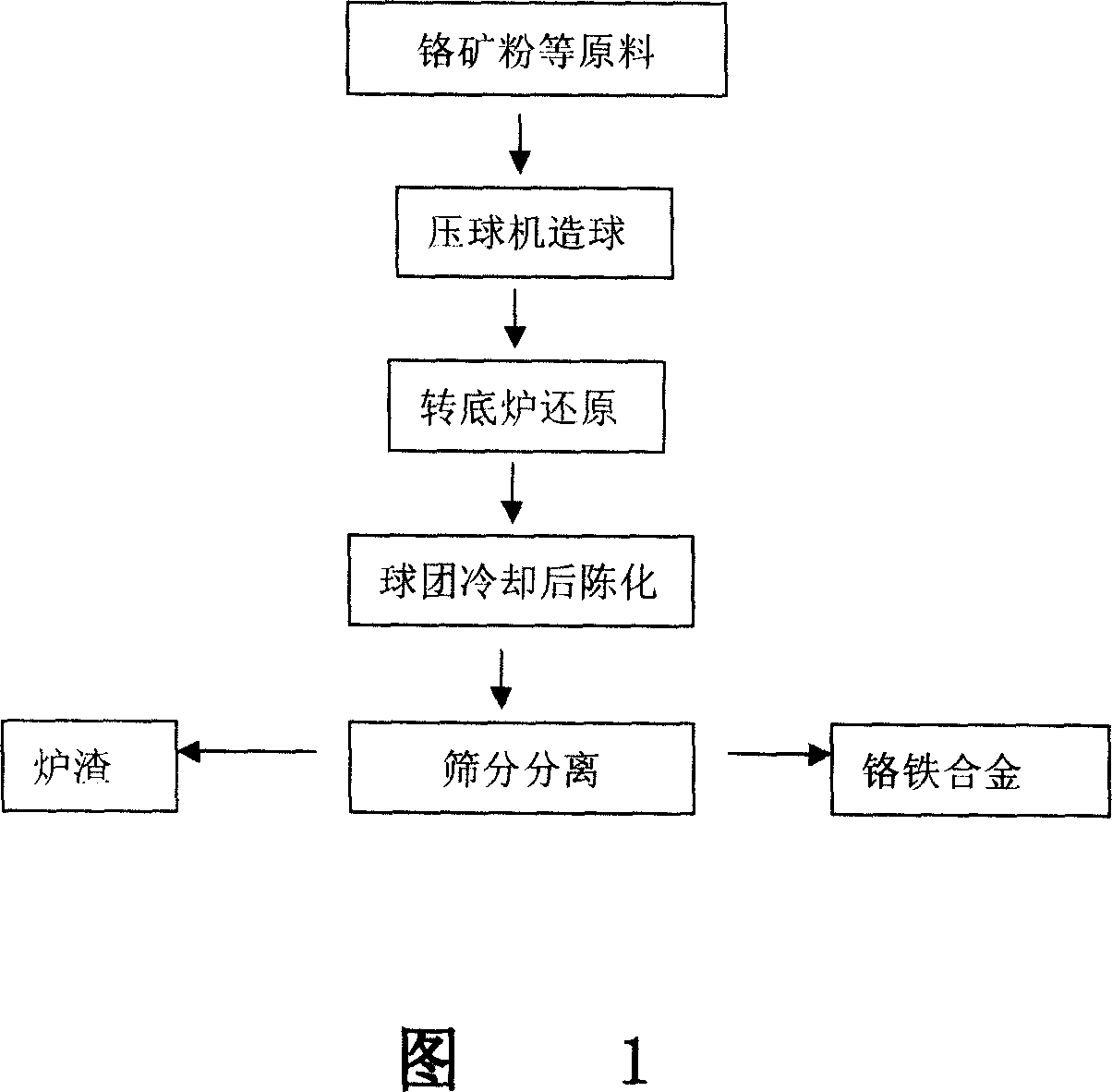

Method for directly producing ferrochromium from chrome ore powder and coal

InactiveCN101144110ARaise the reaction temperatureIncrease alkalinityRotary drum furnacesProcess efficiency improvementElectric arc furnaceReaction temperature

The present invention relates to a method for directly producing ferro chromium with chrome powder and coal. The chrome powder and the coal powder, etc are produced into carbon-bearing pellets, and the reaction temperature is controlled below the pellet soft melting temperature. The slag phase alkalinity is enhanced, to increase the reaction temperature as far as possible, thereby speeding up the reaction speed and improving the metal percent reduction. During the cooling process, the high alkalinity metallised pellet is naturally pulverized because of the existence of thermal stress and excessive carbon powder, and the ferro chromium can be obtained by sieving. Harmful elements of P, S, etc in the raw material are mainly reserved in the slag phase, and thereby the ferro chromium with low P and S content can be obtained. The method of the present invention replaces the traditional electric arc furnace smelting method, provides the ferro chromium with low cost for the smelting and the production of stainless steel, and reduces the dependence of the production of the ferro chromium on a large amount of electric power and lump ore. The ferro chromium is ferro chromium with low P and S content.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for processing steel slags containing chromium

A method for processing steel slags and optionally iron carriers such as, e.g., electric furnace slags, converter slags, dusts derived from steel production, mill scale or secondary metallurgical residues, in which the molten steel slags or iron carriers are supplemented with chromium ores or chromium-containing and / or nickel-containing dusts in order to adjust a slag basicity of 1.2 to 1.6, whereby the bath temperature is maintained at above 1600° C., in particular between 1650° C. and 1800° C., and a carbon-containing iron bath is provided or formed. In addition to environmentally safe slags, a high-grade ferrochromium alloy may be recovered, thus enhancing the economy of the method.

Owner:HOLCIM

Method of producing Ni-Cr agglomerate with Ni-Cr ore and industrial Ni-Cr waste

The method of producing Ni-Cr agglomerate for smelting Ni-Cr-Fe alloy in blast furnace with Ni-Cr ore and industrial Ni-Cr waste includes mixing industrial Ni-Cr waste, Ni-Cr ore of granularity smaller than 10 mm, flux, coke powder and water in the first mixer; pelletizing the mixture in the second mixer; sintering the pellet in a sintering bogie, and sieving to obtain Ni-Cr agglomerate and returned material. The produced Ni-Cr agglomerate is used for smelting Ni-Cr-Fe alloy in blast furnace together with other material.

Owner:DONGDA CASTING WUJIANG

Mother liquid foam slag generating method for smelting stainless steel with electric furnace and dephosphorization melted iron

InactiveCN101096717AIncrease production capacityReduce power-on timeElectric furnaceMelting tankElectric arc furnace

The invention discloses a manufacturing method of stainless steel mother liquor foam slag through electric furnace dephosphorized molten iron, which comprises the following steps: 1)adding solid material with waste stainless steel, ferrochromium and silicon into electric furnace through material basket; energising to smelt; setting the quantity of siliconat at 8.5-12kg / t; 2)adding dephosphorized molten iron when the power consumption is 15-22 Mwh; controlling C content of mother liquor at 1.50-4.00%; 3)forming basic smelting pond in the furnace when the power consumption is 160-200Kwh / t; starting to blow carbon powder with content at 2-4kg / t; jetting oxygen with quantity at 2500Nm3 / h-3500Nm3 / h.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for smelting stainless steel by top and bottom combined blown converter

ActiveCN101139679ARealize the purpose of direct smelting stainless steel processLow costPresent methodSlag

The invention provides a method for smelting stainless steel by a top-bottom blowing converter, which comprises the following procedures: I. adding ion melt into the top-bottom blowing converter, adding coke, blowing oxygen and argon to smelt; II. when the molten steel temperature is more than 1600 DEG C, adding ferromanganese iron, chromium iron alloy, blowing oxygen and argon to smelt, adding slag to adjust the slag; III. when the molten steel temperature is more than 1630 DEG C, adding again ferromanganese iron, chromium iron alloy, blowing oxygen and argon to smelt, adding slag to adjust the slag; IV. when the actually measured temperature of the molten steel is more than the calculated temperature, adding the remainder alloy ferromanganese iron, chromium iron and nickel, blowing oxygen and argon to smelt, adding lime and small amount of fluorspar to adjust the slag; V. reducing gradually the blown oxygen and increasing the blown argon; VI. stopping blowing oxygen from bottom but only blowing argon, agitating 1.5-2.5 min.; VII. adding silicon iron and adding slag; VIII. blowing argon from bottom for reducing and agitating for >=5 min.; IX. sampling and analyzing components, and tapping steel. The present method for smelting stainless steel by a top-bottom blowing converter is of low cost.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Non-metallic thread sealant and anti-seize compound having improved anti-galling properties for metal alloys

An anti-seize compound is disclosed for use on surfaces of threaded connections made of speciality alloys such as high nickel or chrome ferrous alloys or other speciality alloys prone to galling under high stress conditions. The compound using a metal fluoride as the anti-seize film forming agent at least above about 5 wt %.

Owner:JET LUBE

Smelting method for ferrite stainless steel mother liquid

The ferritic stainless steel mother liquid smelting process in the charge mixture mode of dephosphorized molten iron+waste carbon steel+ferrochromium includes the following steps: feeding dephosphorized molten iron, waste carbon steel and ferrochromium and powering on; adding ferrosilicon after powering for 2.0-4.0 Mwh; beginning oxygen blast after powering for 5.0-7.0 Mwh; regulating the oxygen flow rat to 2500 Nm3 / h and total oxygen amount to 9-10 Nm3 / t after power consumption reaches 8.0-12.0 Mwh; adding lime after power consumption reaches 7.0-10.0 Mwh; spraying carbon powder after power consumption reaches 16.0-20.0 Mwh; adding dolomite after power consumption reaches 15.0-18.0 Mwh; reducing after power consumption reaches 220-240 Kwh / t and the measured temperature reaches 1610 deg.c; and tapping after power consumption reaches 250-320 Kwh / t and the measured temperature reaches 1630-1660 deg.c. The present invention has low power consumption and other advantages.

Owner:BAOSHAN IRON & STEEL CO LTD

Technique for smelting mother liquor of stainless steel from electric furnace

InactiveCN1796586ALow cost of ingredientsAlleviate the tension of insufficient resourcesElectric arc furnaceFerrosilicon

This invention relates to an electric furnace smelting technique for crude stainless steel liquid with its process including: a) materials proportioning. Waste stainless steel shares 15~25% in total added metal. Chromium-iron alloy shares 15~25% in total added metal. Lime is added to an amount of 30~45 kg per ton of added metal. And dephosphorized molten iron shares 35~60% with its element content of 2.50~3.80% of C, less than 0.020% of phosphorus, less than 0.040% of sulfur. b) Smelting. Oxygen blowing amount is controlled at 5~10 cu m / t and blowing flux is controlled at 1500~2500N cu m / h. c) reduction. Ferrosilicon powders are spitted at 2.5~3.5kg / t and carbon powders at 1.5~2.5kg / t. Or ferrosilicon is added at 2.5~3.5kg / t and aluminium at 1.5~2.5kg / t. d) tapping, with ultimate temperature controlled at 1640~1660 deg.C. This invention employs dephosphorized molten iron, which reduces the raw materials proportioning cost and smelting time as well as the consumption of electricity power, electrodes and patching materials in electric furnaces.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for producing ferroalloy

InactiveCN1426487AIncrease production capacityHigh recovery rateProcess efficiency improvementElectric furnaceCarbideFerrochrome

Owner:マックスレッド (プロプライエタリー) リミテッド

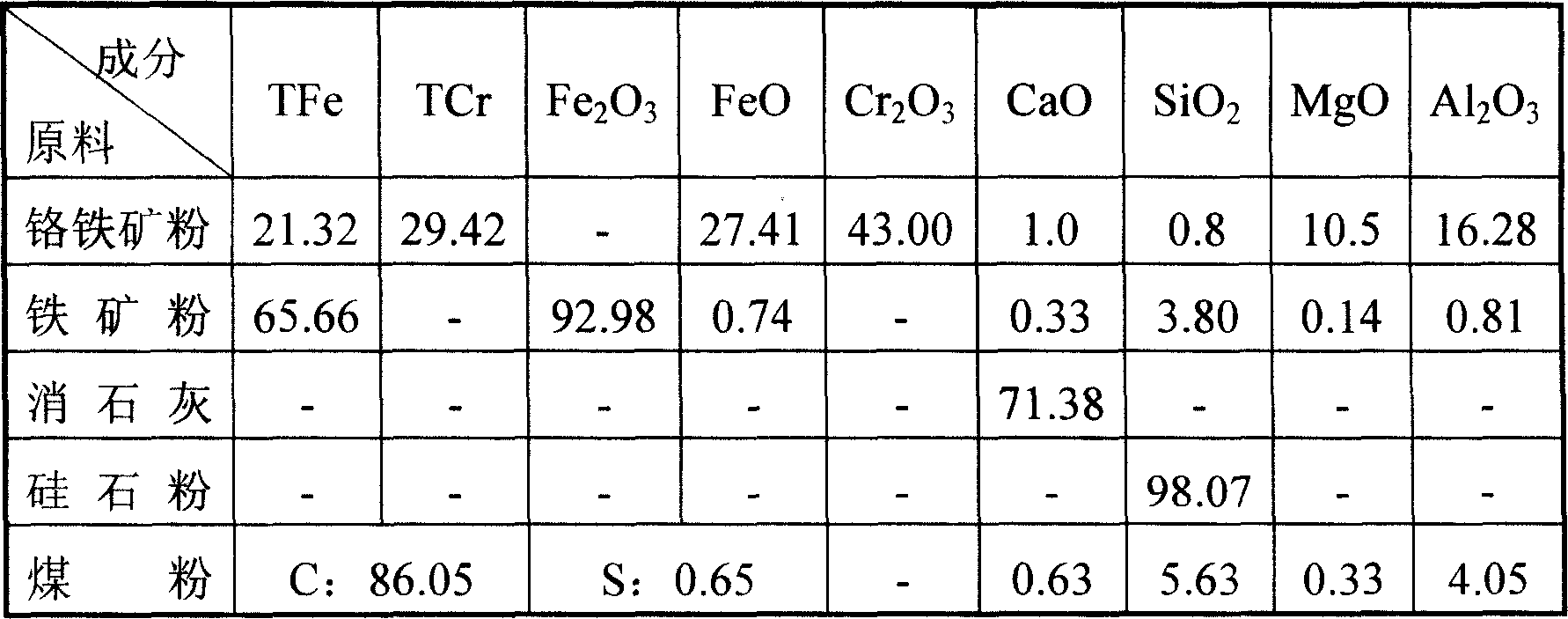

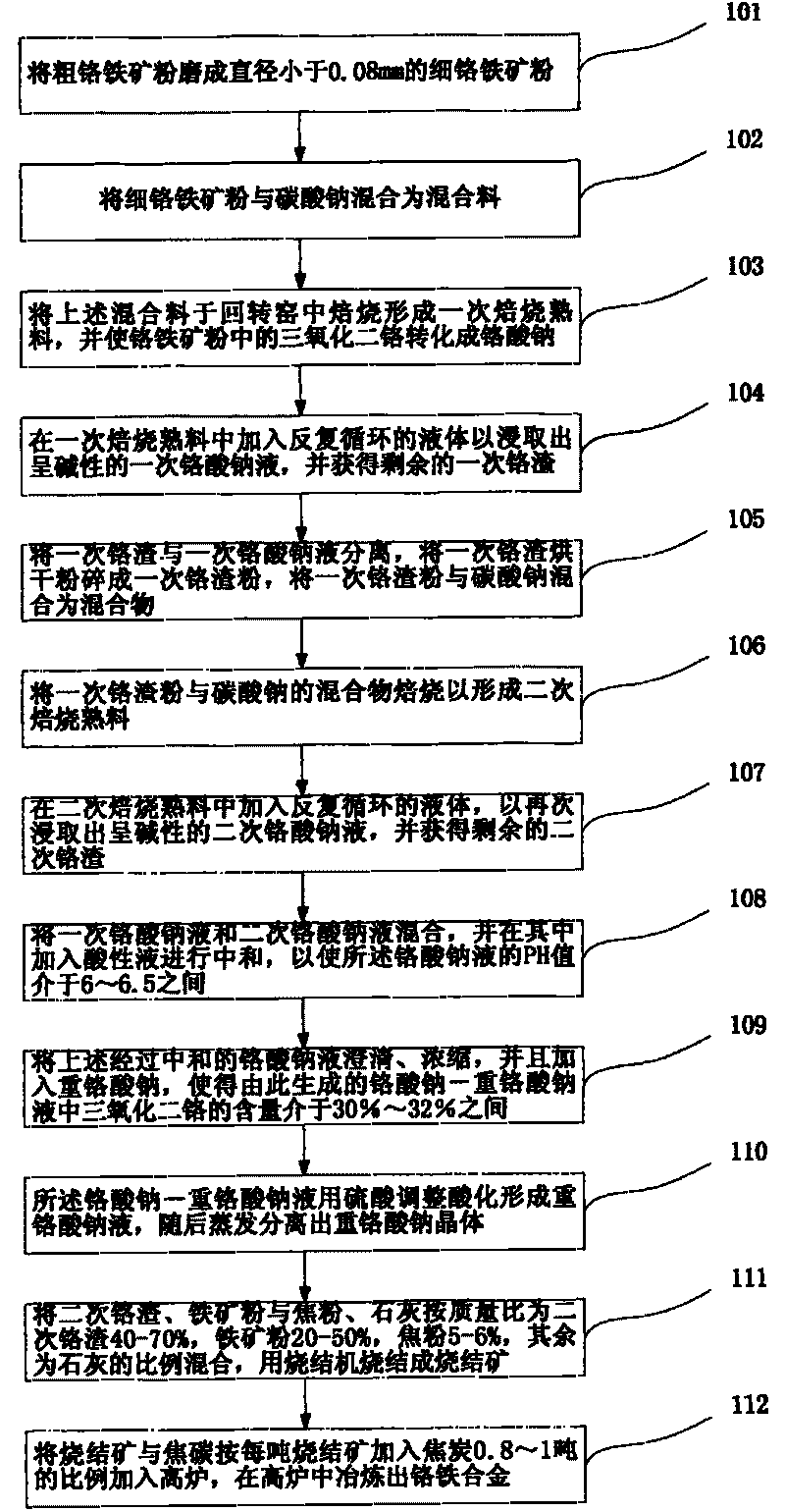

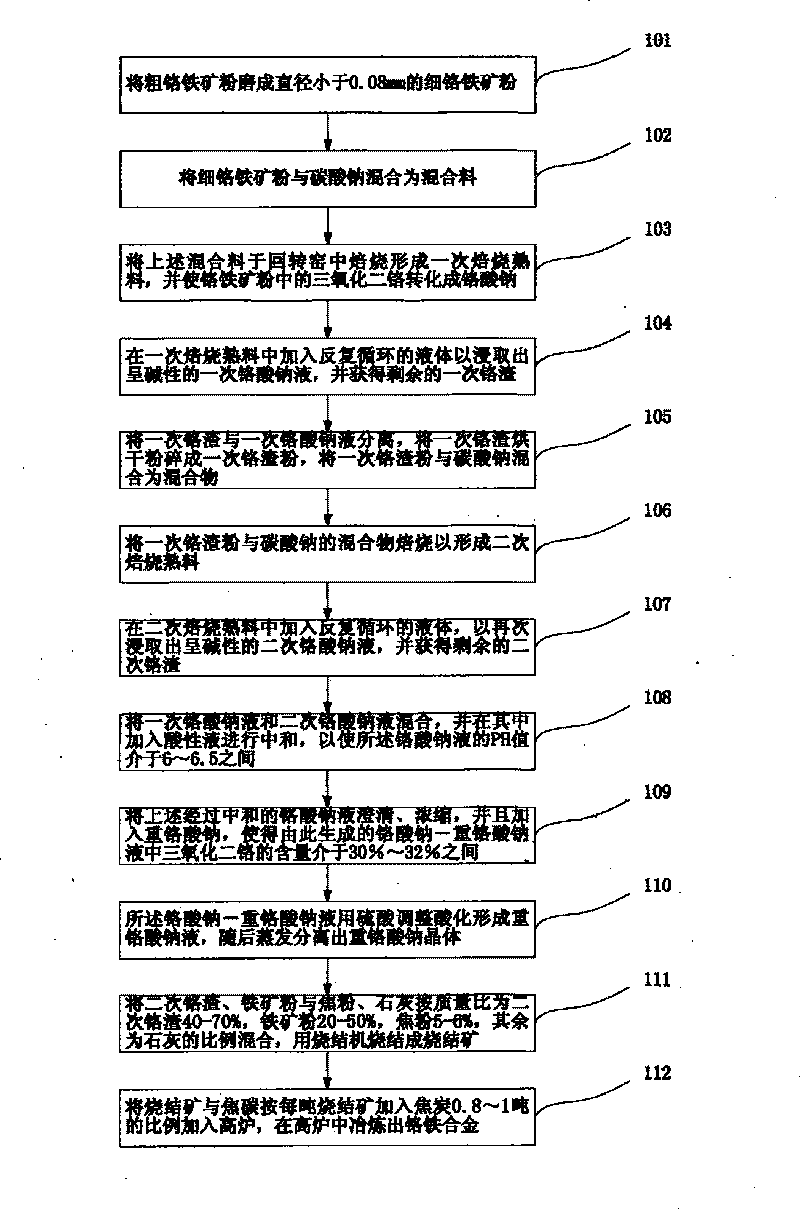

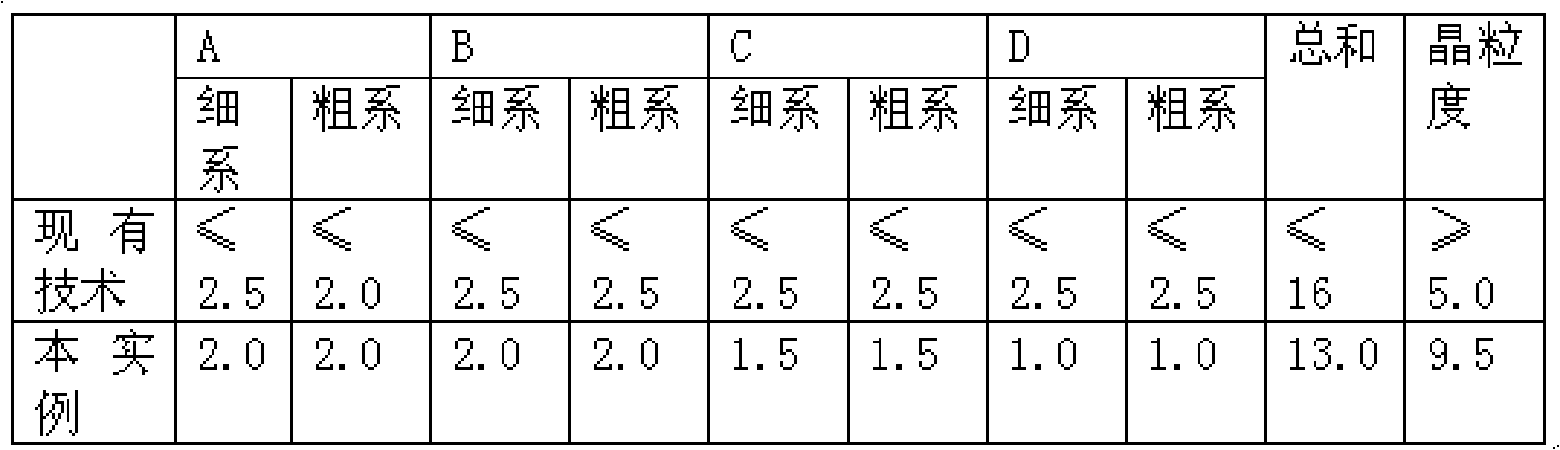

Method for jointly producing chromium salt and ferrochromium alloy by sintering with wet and fire methods

InactiveCN101709369AAchieving zero emissionsBlast furnace detailsChromium compoundsSodium dichromateFerrochrome

Owner:XINJIANG SING HORN GRP CO LTD

Method for smelting ferritic stainless steel from total molten iron

This invention relates to a molten iron smelting method of ferritic stainless steel which includes: a) temperature-controlled smelting. The temperature is raised to 1580~1600 deg.C before converting. Ferrosilicon containing 4~15kg of steels per ton is added followed by temperature-raising. b) When temperature in molten pool is raised to 1670~1720 deg.C, chromium-iron alloy is added at a rate of 2~3 ton per minute with a total amount of up to 250~280 kg per ton of steel. Then hold the temperature. c) Decarbonization, when it is finished, the carbon concentration is 0.03~0.05% and the temperature is held at 1700~1730 deg.C. d) Reduction and desulfurization. This invention adopts hot metal smelting all through the process and avoids the influences of impure waste iron. Besides the AOD direct smelting technique doesní»t need any crude stainless steel liquid in electric furnace.

Owner:BAOSHAN IRON & STEEL CO LTD

Method for revolving furnace smelting 45CrMnMo steel

InactiveCN101550516AImprove toughnessGood anti-fatigueManufacturing convertersManganeseEconomic benefits

The invention relates to a producing method for revolving furnace smelting 45CrMnMo steel, which belongs to metallurgy field. The technical scheme includes the following steps: a) adding desulphurizing hot-metal into the revolving furnace, and smelting with adding lime stock, b) gradually adding the chromium irons, ferro-molybdenum and silicon-manganese alloy confected by proportion into molten steel parcel during the revolving furnace exporting molten steel, and adding coherer aluminum into the molten steel parcel to be deoxidized at the same time, c) blowing argon gas into the molten steel in the ladle after tapping, d) vacuum treating the molten steel and carrying through micro-adjustment with the chemical constituents in the vacuum procedure at the same time, then casting 45CrMnMo steel. The invention provides a method for revolving furnace producing 45CrMnMo steel, in which the recovery rate of chromium iron is higher, saves more time, improves economic benefit, and provides a better choice for producing 45CrMnMo steel.

Owner:PANGANG GROUP RESEARCH INSTITUTE CO LTD +2

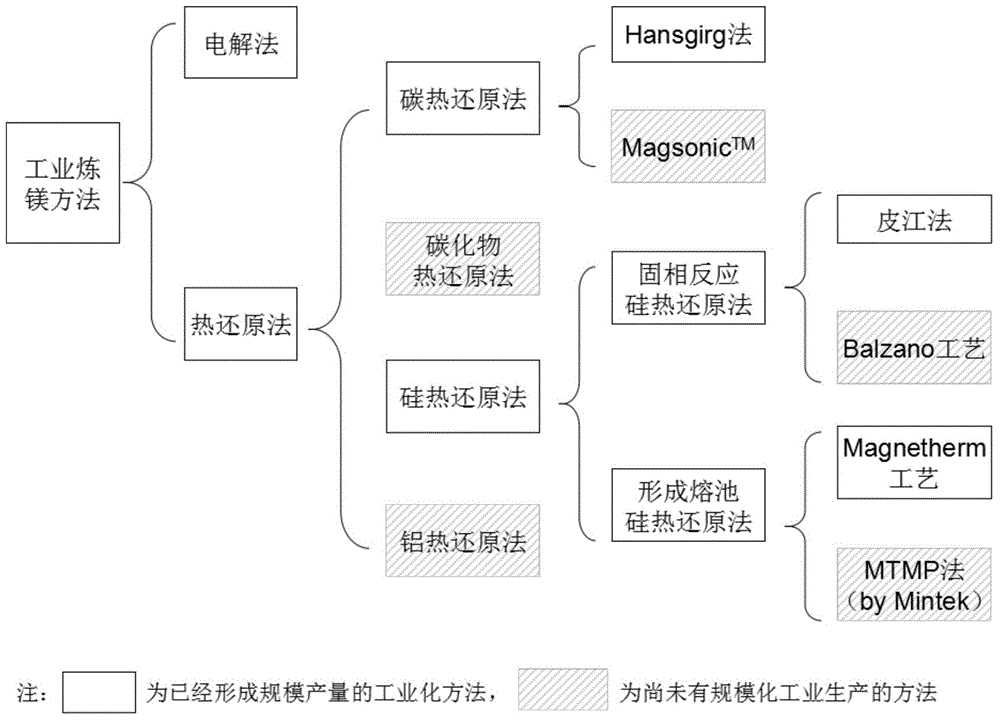

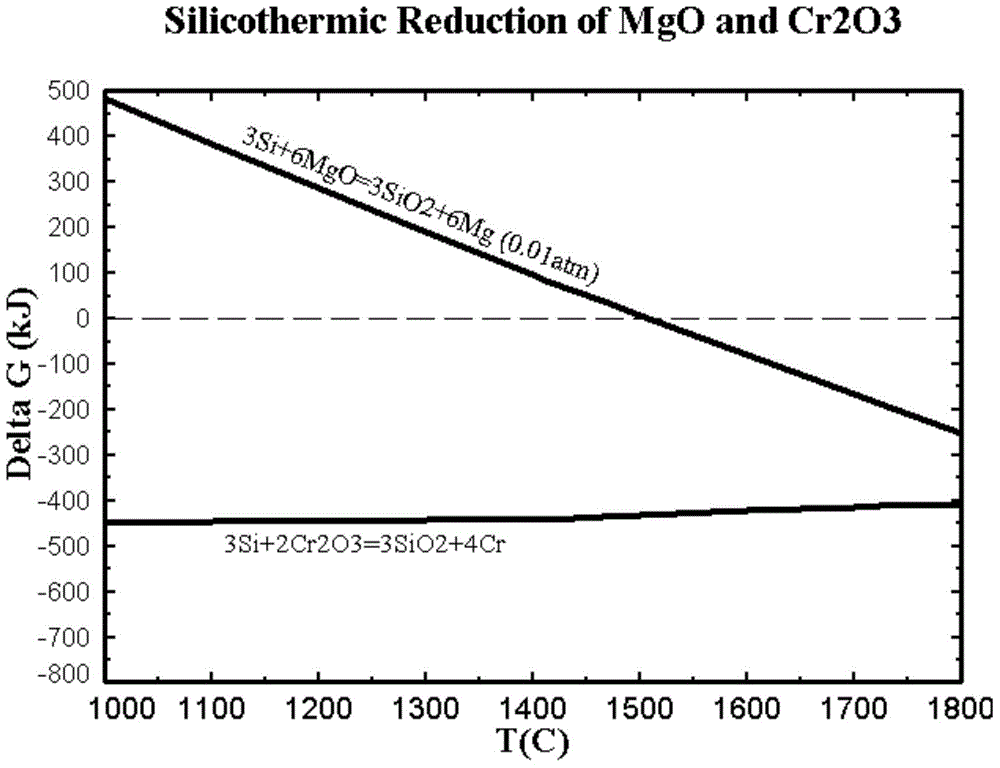

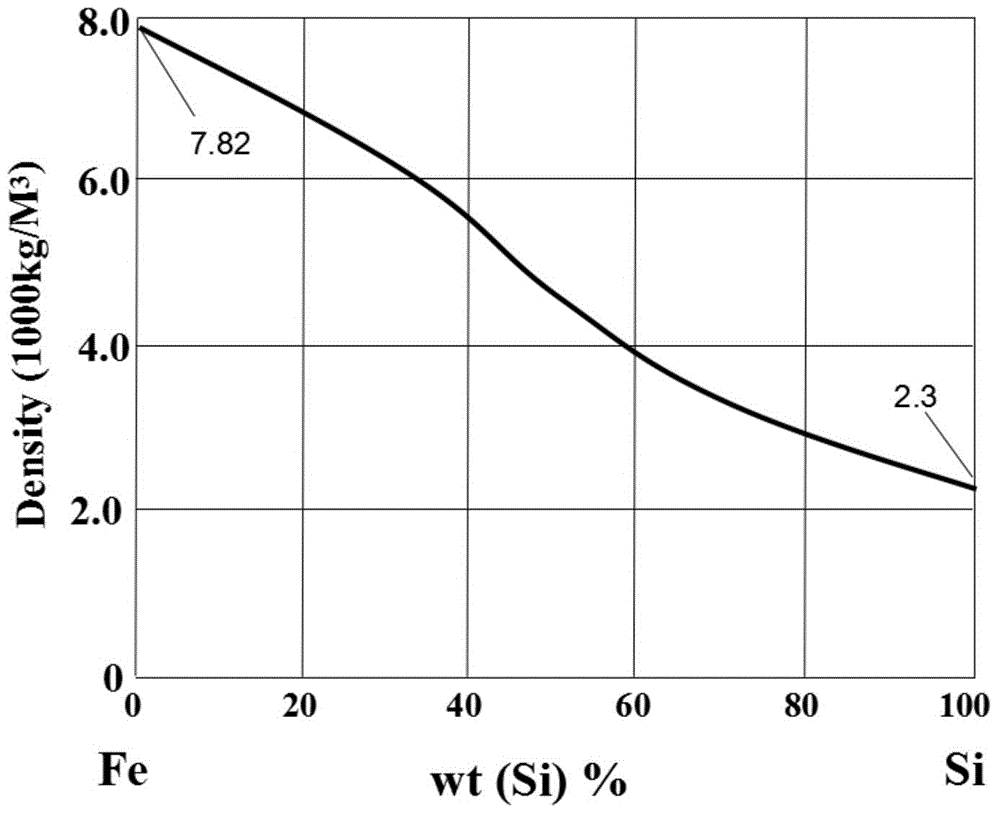

Method for smelting magnesium and co-producing ferrochrome-containing liquid with ferrosilicon bath stair reduction silicothermic method

The invention relates to a method for smelting magnesium and co-producing ferrochrome-containing liquid with a ferrosilicon bath stair reduction silicothermic method, belongs to the technical field of nonferrous magnesium metal extraction and also belongs to technical field of chromium-containing stainless steel and ferrochrome smelting of ferrous metallurgy. Ferrosilicon bath much higher in theoretical chemical demand quantity is used as a silicothermic reducing agent and carrier of chemical reaction, reaction interfacial area is increased and convective heat transfer and mass transfer abilities are strengthened to realize reinforcement of reduction process through intense stirring. After reduction is completed, magnesium smelting reduction slag is eliminated, excessive ferrosilicon is mixed with a new batch of magnesium ore to smelt magnesium until the concentration of ferrosilicon liquid is lower than that of lower silicon, and lower ferrosilicon liquid is mixed with chrome ore to carry out chromium reduction to obtain chromium-containing stainless steel mother liquid. The excessive ferrosilicon bath is respectively used for smelting magnesium and ferrochrome at high concentration and low concentration, ferrochrome raw material is completely utilized, the reaction efficiency is high, energy is saved, carbon, phosphorus and sulphur in the ferrochrome liquid are little, and the co-production cost of magnesium and stainless steel liquid is obviously reduced in comparison with sum of the production cost of magnesium and the production cost of stainless steel liquid.

Owner:杭州吉幔铁氢能科技有限公司

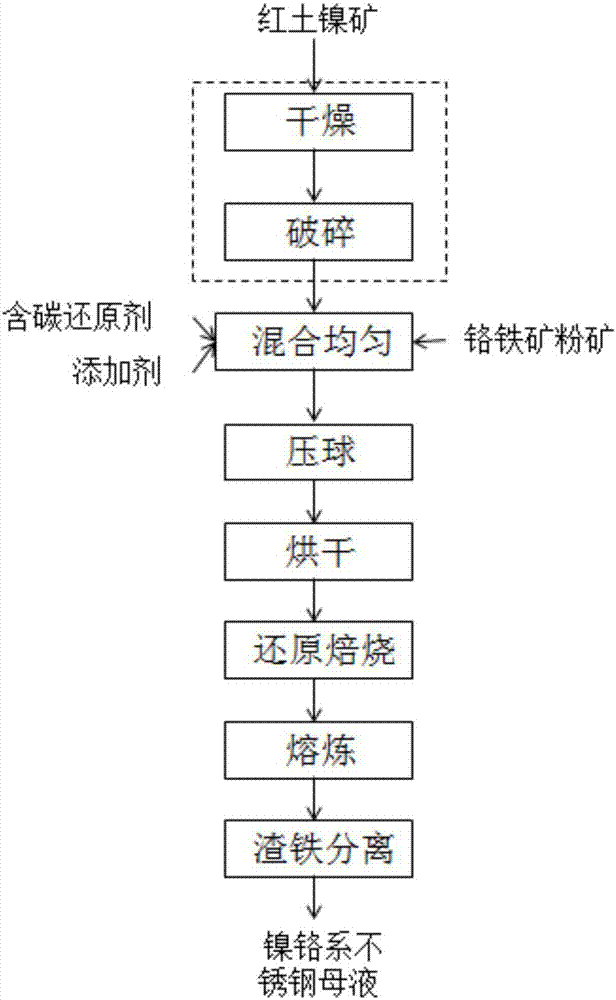

Preparation method for mother liquid of nickel chrome stainless steel

The invention relates to a preparation method for mother liquid of nickel chrome stainless steel. The preparation method comprises the steps that laterite-nickel ore, chromite fine ore, a carbonous reducing agent and an annexing agent are evenly mixed according to the mass ratio of 40%-60% : 20%-40% : 8%-15% : 1%-6%, a mixed material is obtained, wherein the water content of the laterite-nickel ore is 5%-20%; the mixed material is pressed into balls and dried, and pellets are obtained; and the pellets are roasted under a reducing atmosphere at 1250-1400 DEG C, and pre-reduced pellets are obtained; and the pre-reduced pellets are transported to a smelting furnace in a hot transportation mode to be smelted, and then the mother liquid of the nickel chrome stainless steel is obtained after slag-iron separation. According to the preparation method for the mother liquid of the nickel chrome stainless steel, the smelting cycle is shortened, the materials are extensive in source and low in price, and the smelting cost of stainless steel is reduced greatly; and compared with the prior art in which the treatments on ferro-nickel and ferrochrome are two independent technologies correspondingly, the preparation method for the mother liquid of the nickel chrome stainless steel overcomes the defects that existing technologies are complex, the technological process is long, the energy consumption is high, pollution is severe, and the operation cost is high, and the energy consumption of smelting of an electric furnace is effectively reduced.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

Chrome molybdenum vermicular graphite cast iron non-cracking brake drum of high thermal fatigue resistance performance and production process thereof

InactiveCN104480375AImprove thermal fatigue resistanceHigh strengthFurnace typesProcess efficiency improvementThermal fatigueGraphite

The invention discloses a chrome molybdenum vermicular graphite cast iron non-cracking brake drum of high thermal fatigue resistance performance and a production process thereof. The production process comprises the steps of adding 0.40 percent-0.80 percent of ferrochrome and 0.40 percent-1.20 percent of ferrochrome to common vermicular graphite cast iron base iron according to the weight ratio, smelting the vermicular graphite cast iron base iron, performing vermicular inoculation on the vermicular graphite cast iron base iron to obtain chrome molybdenum vermicular graphite cast iron final molten iron, pouring the chrome molybdenum vermicular graphite cast iron final molten iron, cooling and cleaning a poured casting to obtain a chrome molybdenum vermicular graphite cast iron brake drum casting, performing complete austenitizing normalizing treatment on the chrome molybdenum vermicular graphite cast iron brake drum casting at the temperature ranging from 900 DEG C to 950 DEG C by keeping the temperature for 1.0-1.2 hours, machining the chrome molybdenum vermicular graphite cast iron brake drum casting after the chrome molybdenum vermicular graphite cast iron brake drum casting is discharged out of a furnace and cooled down, and checking out the chrome molybdenum vermicular graphite cast iron brake drum casting to obtain the chrome molybdenum vermicular graphite cast iron non-cracking brake drum of high thermal fatigue resistance performance if the chrome molybdenum vermicular graphite cast iron brake drum casting is qualified. By means of the production process, the brake drum of a heavy-load vehicle is durable and unlikely to crack to ensure transportation safety.

Owner:罗建华

High-hardness compound abrasion-resistant ball

InactiveCN105013574ANot easy to go off trackWeight increaseGrain treatmentsBoron nitrideMixed materials

The invention discloses a high-hardness compound abrasion-resistant ball which comprises a first semi-ball and a second semi-ball. A process for preparing the first semi-ball or the second semi-ball comprises sequentially placing 120-140 parts of scrap steel, 140-160 parts of ferrochrome, 90-110 parts of pig iron, 10-15 parts of tungsten ingot, 25-50 parts of manganese ingot and 2.4-3.0 parts of borax in an induction furnace and melting the mixture, adding 40-55 parts of carbon powder and 6-10 parts of silica powder and closing a furnace door to perform vacuumizing to produce liquid alloy; performing pouring and tempering to obtain an alloy semi-ball body; evenly mixing 20-40 parts of silicon dioxide micro powder, 30-35 parts of aluminum oxide micro powder, 80-95 parts of cubic boron nitride and 50-60 parts of resin binder to obtain a mixed material; and pressing the surface to obtain the semi-ball or the second semi-ball. The high-hardness compound abrasion-resistant ball is high in hardness, excellent in abrasion resistance, simple in structure and convenient to assemble, recycle and forge.

Owner:ANHUI NINGGUO RUNHUI WEAR RESISTANT MATERIAL

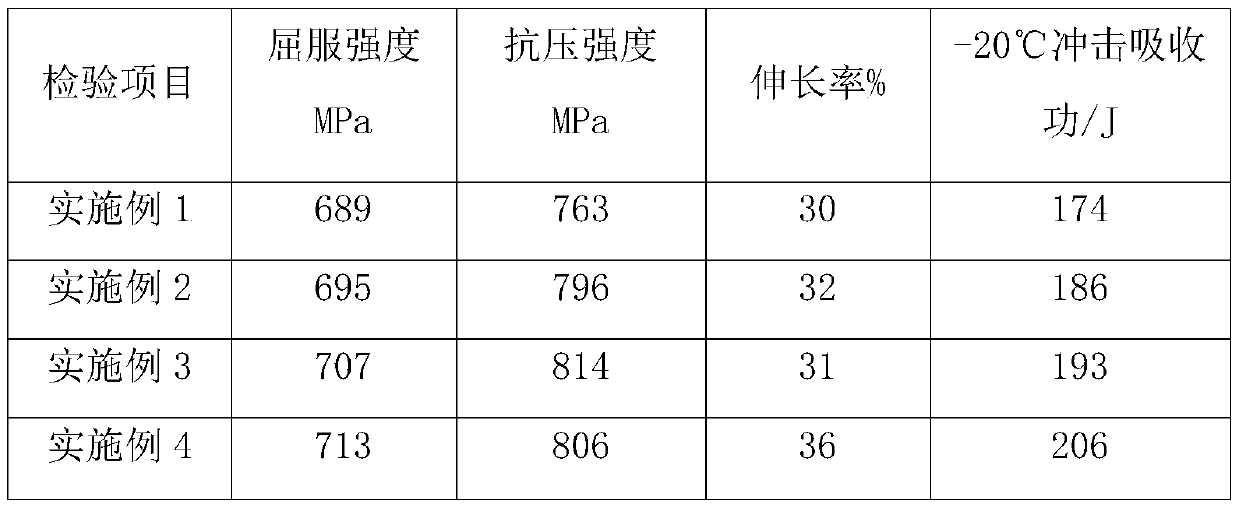

Flux-cored wire for oil and gas transfer pipeline and preparation method thereof

ActiveCN110788519ABeautiful weld shapeArc stabilizationWelding/cutting media/materialsSoldering mediaSilicon alloyManganese

The invention relates to a flux-cored wire for an oil and gas transfer pipeline and a preparation method thereof. The flux-cored wire is characterized by being composed of a flux core and a low carbonsteel band wrapping the flux core, wherein the weight of the flux core accounts for 12-20% of the total weight of the flux-cored wire for the oil and gas transfer pipeline, the flux core comprises, by mass, 5-10% of rutile powder, 3-6% of nickel powder, 3-6% of zirconium powder, 1-4% of white corundum powder, 1-3% of yttria, 2-5% of manganese-silicon alloy powder, 1-5% of ferrochrome powder, 1-4%of magnesia powder, 0.5-2% of ferro-molybdenum alloy powder, 0.5-2% of tungsten carbide powder, 0.5-2% of rare earth fluoride, 0.1-0.5% of ceric oxide and the balance iron powder, and the sum of themass percentages of all the components is 100%. The flux-cored wire for the oil and gas transfer pipeline has the advantages that the welded joint appearance is attractive, deslagging is facilitated,little spatter is caused and an electric arc is stable, and welded joint structure alloy is excellent in low-temperature toughness, low-temperature impact resistance and strength.

Owner:GUILIN UNIV OF AEROSPACE TECH

Manufacture technology for anti-corrosion, low-cost, refined and environment-friendly stainless steel wire

InactiveCN110760755AImprove liquidityHigh speedProcess efficiency improvementElectric furnaceFurnace temperatureElectric arc furnace

The invention discloses a manufacture technology for an anti-corrosion, low-cost, refined and environment-friendly stainless steel wire. The manufacture technology comprises the technological steps that ingredients including ferrochrome and ferronickel are used; the ingredients are successively put into an electric arc furnace for heating and melting; contents of each of the elements are detected,and temperature preservation is conducted during detection; each of the chemical ingredients is adjusted again according to detection results; then, slagging is conducted; and slagging-off and steeltapping are carried out when a furnace temperature reaches 1650 DEG C; a spiral flow duct of which the height is lower than the bottom wall of a furnace cavity is disposed at an outlet of the electricarc furnace; the detected elements include C, Si, Mn, Cr, Ni, P and S; after entry of molten steel in a primary forging furnace, a mixed gas of Ar (N2) + O2 is blown into the furnace, the content ofN is detected, and a blowing process is divided into an oxidation stage, a reduction stage and a refinement stage; continuous casting is carried out; and the wire is manufactured after continuous rolling. The manufacture technology disclosed by the invention has the beneficial effects that the molten steel with the uniform ingredients can be obtained through opening or closing of a molten steel valve during molten steel taking, so accuracy of the detection results is increased, cost is reduced and production efficiency is increased; and on the premise that stainlessness is not reduced, the content of Ni is reduced, but a corrosion resisting rate is increased.

Owner:JIANGYIN KANGRUI MOLDING TECH CO LTD

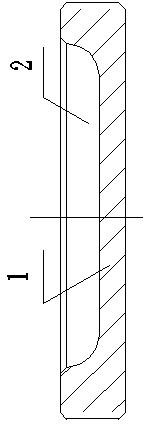

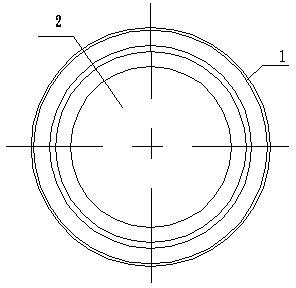

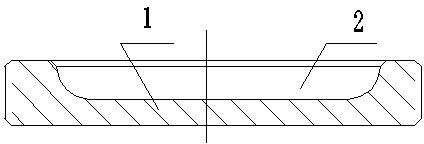

Large-diameter thin plate sealing membrane and turning anti-deformation method

ActiveCN102581303ASolve difficultySolve processabilityHeat exhanger sealing arrangementPositioning apparatusThin slabNichrome

The invention discloses a large-diameter thin plate sealing membrane and a turning anti-deformation method. The large-diameter thin plate sealing membrane is applied to high-temperature high-pressure heat exchanger products. A sealing membrane made of a nickel-chromium-iron alloy SB-168NO6600 material is expensive in price, high in requirements of manufacturing precision and strict in requirements of surface roughness and unevenness of parts due to application of sealing. The turning anti-deformation method of the large-diameter thin plate sealing membrane comprises the steps of: machining a disc-shaped steel plate part into a saucer shape (1); making a blind hole (2) with a concentric diameter smaller than the disc diameter and a thickness smaller than that of the disc on the disc; additionally mounting an auxiliary cushion plate with an enough thickness below a part to be processed; providing an opening on the cushion plate; firmly point-welding the cushion plate with the part at the position of the opening, and placing the assembly in a bowl-shaped part filled with water for fixing; carrying out underwater vertical turning; and timely dissipating the cutting heat produced in a turning process in the machining process. The large-diameter thin plate sealing membrane is applied to the sealing of high-temperature high-pressure heat exchangers.

Owner:HARBIN BOILER

Preparation method and application of three-dimensional multicolor CQDs@MeOOH anti-infrared nanometer functional material

InactiveCN107674462ALow costAchieve recyclingReflecting/signal paintsMulticolor effect coatingsSlagAlloy

The invention discloses a preparation method and application of a three-dimensional multicolor CQDs@MeOOH anti-infrared nanometer functional material and belongs to the technical field of fine chemical engineering materials. The prepared fine chemical engineering can be applied to various equipment and / or buildings needing to be cooled or heat-insulated. Aiming at the limitations that the conventional anti-infrared nanometer functional material is high in cost and low in efficiency and durability, on the basis of preliminary study, due to overall consideration in economy and efficiency aspects, the invention provides a preparation method of the CQDs@MeOOH anti-infrared nanometer functional material. Economically low cost is realized by taking waste ferrochrome, low-value ferrochrome slag and biomass as raw materials; by combining an in-situ seeding method and a hydrothermal aging qualitative process, a novel high-reflectance high-thermal shielding efficiency and ultraviolet-proof CQDs-based composite nanometer functional material with good stability and appropriate forbidden bandwidth is prepared and is a technical improvement of the traditional nanometer functional base material,and the development and application of the material can be facilitated at high efficiency, high stability and low cost.

Owner:DALIAN UNIV OF TECH

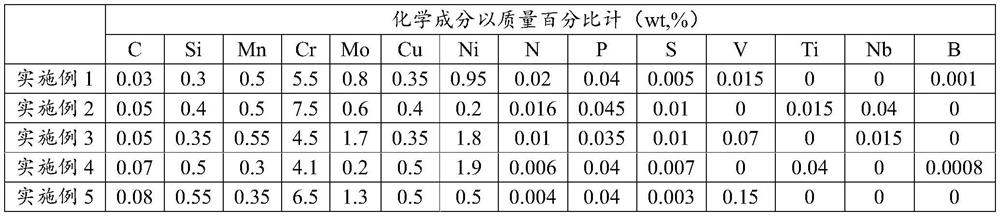

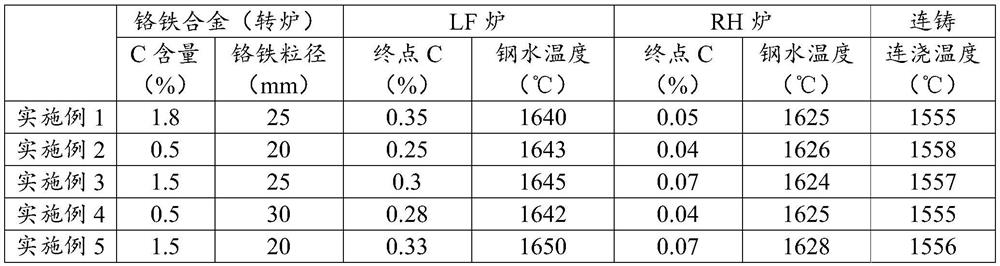

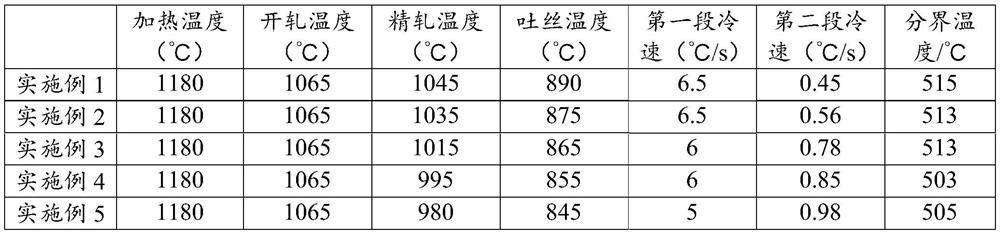

Corrosion-resistant steel bar and production method of corrosion-resistant steel bar

ActiveCN113528962AHigh mechanical strengthImprove corrosion resistanceUltimate tensile strengthContinuous rolling

The invention discloses a corrosion-resistant steel bar and a production method of the corrosion-resistant steel bar. Chemical components of the steel bar comprise 0.02%-0.08% of C, not larger than 1% of Si, not larger than 1% of Mn, 4%-8% of Cr, not larger than 2% of Mo, 0.3%-0.6% of Cu, not larger than 2% of Ni, not larger than 0.02% of N, larger than 0.03% and not larger than 0.05% of P, not larger than 0.01% of S, not larger than 1% of Si + Mn, 4%-8.5% of Cr + Mo, 0.5%-2.5% of Cu + Ni + P and the balance iron. In production, the sulfur upper limit at the end point of molten iron pre-desulfurization can be 0.002%; the carbon upper limit of added ferrochrome after converter smelting tapping is finished is 2.0%; LF furnace refining is carried out; RH furnace refining is carried out; square billet continuous casting is carried out; hot continuous rolling is carried out; and Stelmor cooling is carried out, wherein cooling is firstly carried out to 500 + / -20 DEG C at the speed of 4-7 DEG C / s, and then cooling is carried out to room temperature at the speed smaller than or equal to 1 DEG C / s. The production difficulty and cost are low, and corrosion resistance, strength, the yield ratio and plasticity are all excellent.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

Low-phosphorus smelting process for martensitic stainless steel main shaft

InactiveCN110423859AImprove uniformityShorten the smelting cycleElectric furnaceProcess efficiency improvementMartensitic stainless steelInduction furnace

The invention relates to a martensitic stainless steel smelting process for a main shaft used on an esterification reactor. The smelting process adopts a smelting method of electric furnace+inductionfurnace smelting-LF steel ladle refining-vacuum refining and comprises the following steps that high-phosphorus-content molybdenum iron alloy and a nickel plate are loaded into a furnace along with furnace materials, and the phosphorus content brought in steel by the molybdenum iron alloy is removed through dephosphorization reaction in the electric furnace smelting process after melting; low-phosphorus alloy steel material heads are selected and are mixed into a steel ladle together with chromium iron alloy after being melted utilizing an induction furnace, and the low phosphorus content is guaranteed to obtain; and the vacuum refining is performed after electric furnace and induction furnace primary smelting liquid steel is mixed into the steel ladle, and steel ingot pouring is performedafter the temperature and the composition are adjusted to be qualified. By means of the low-phosphorus smelting process for a martensitic stainless steel main shaft, the produced liquid steel can remove the phosphorus content brought in the steel by the high-phosphorus alloy sufficiently, and a good precondition is created for obtaining of the final low-phosphorus liquid steel; an electric furnace and the induction furnace smelt the primary smelting liquid steel simultaneously, the smelting cycle can be shortened, and the production efficiency is improved; and the composition uniformity can be improved, local high phosphorus caused by component segregation is reduced, and expectation of the low-phosphorus liquid steel is obtained.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

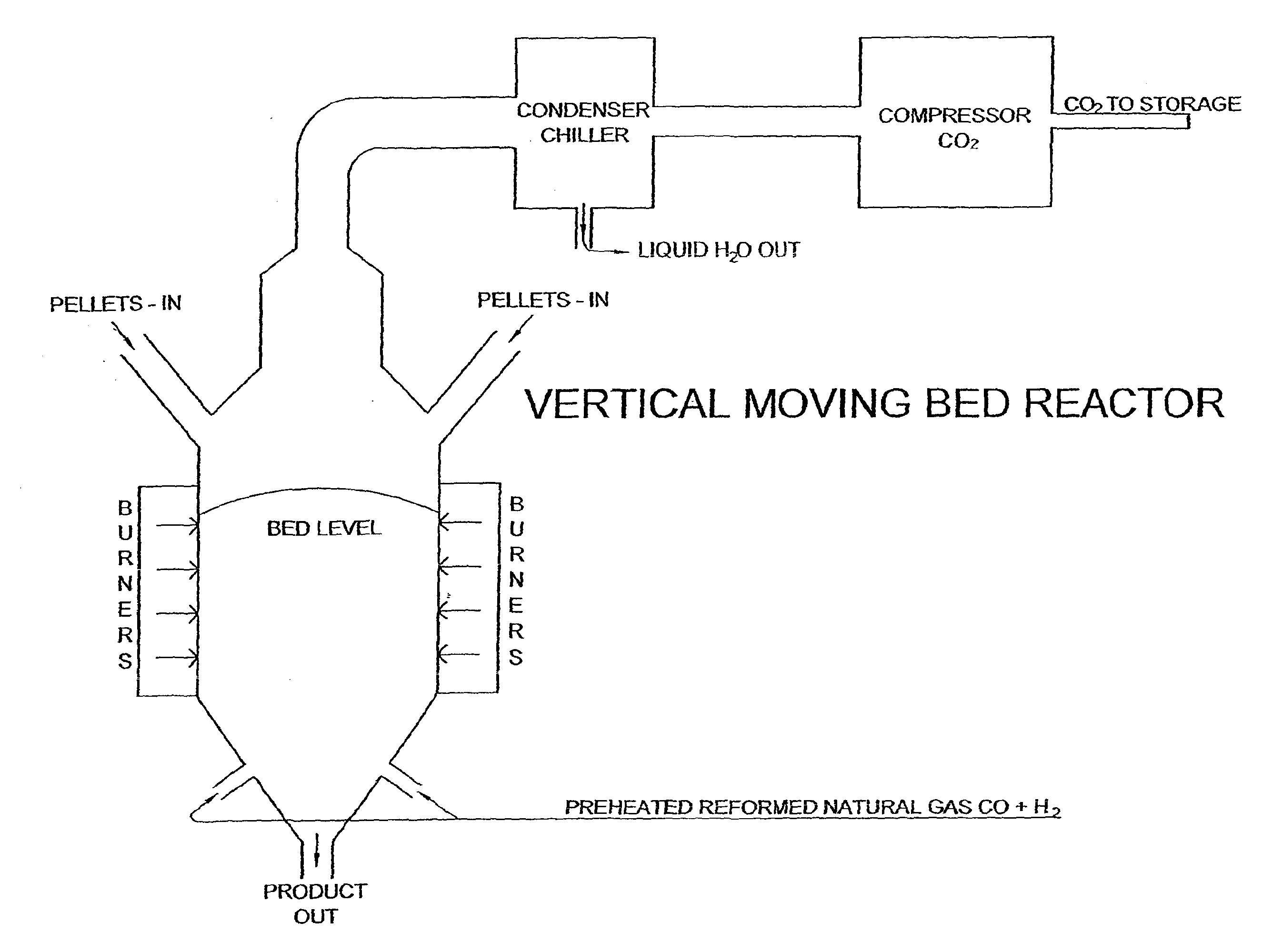

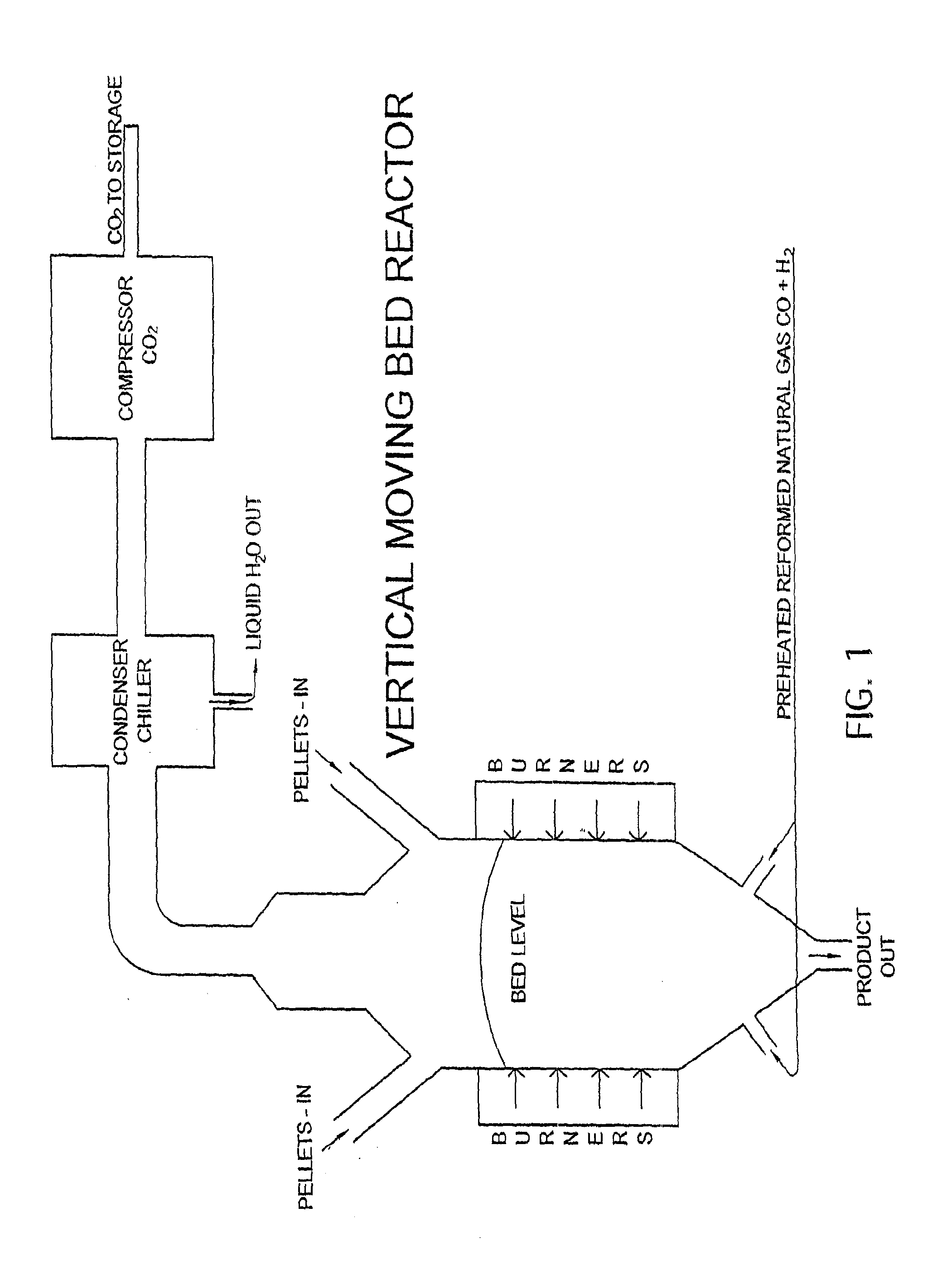

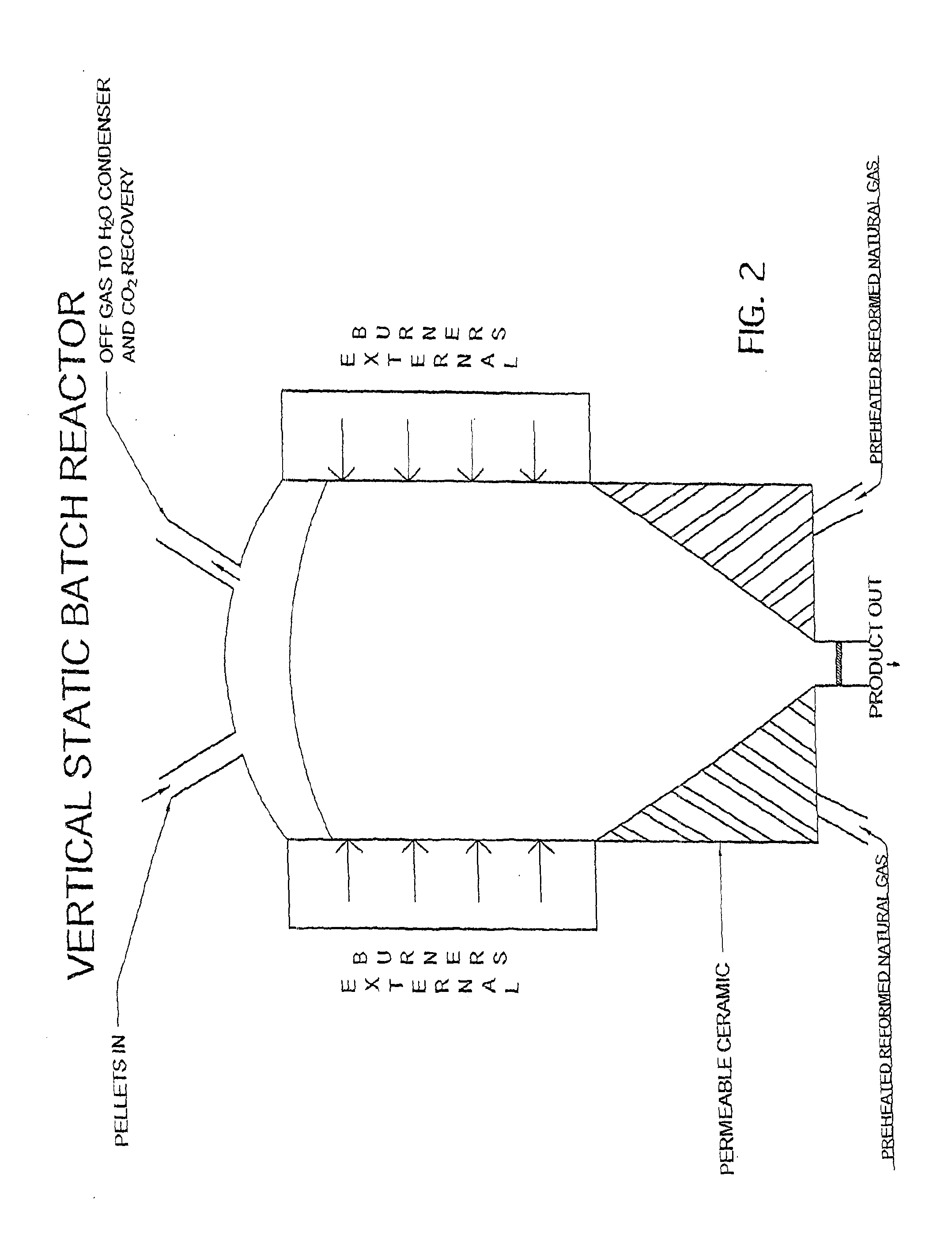

Production of chromium iron alloys directly from chromite ore

A process for producing chromium iron alloys suitable for steel making directly from chromite ore wherein fines of chromite ore with additions of carbon fines, and accelerant and a binder are agglomerated and the dry agglomerates are fed into a reaction vessel with natural gas as a reducing agent at elevated temperatures adequate for reduction for thereby producing a chromium iron alloy suitable for steel making. The preferred accelerant is an alkali in the form of an oxide, hydroxide or carbonate, sodium hydroxide being preferred.

Owner:KWG RESOURCES

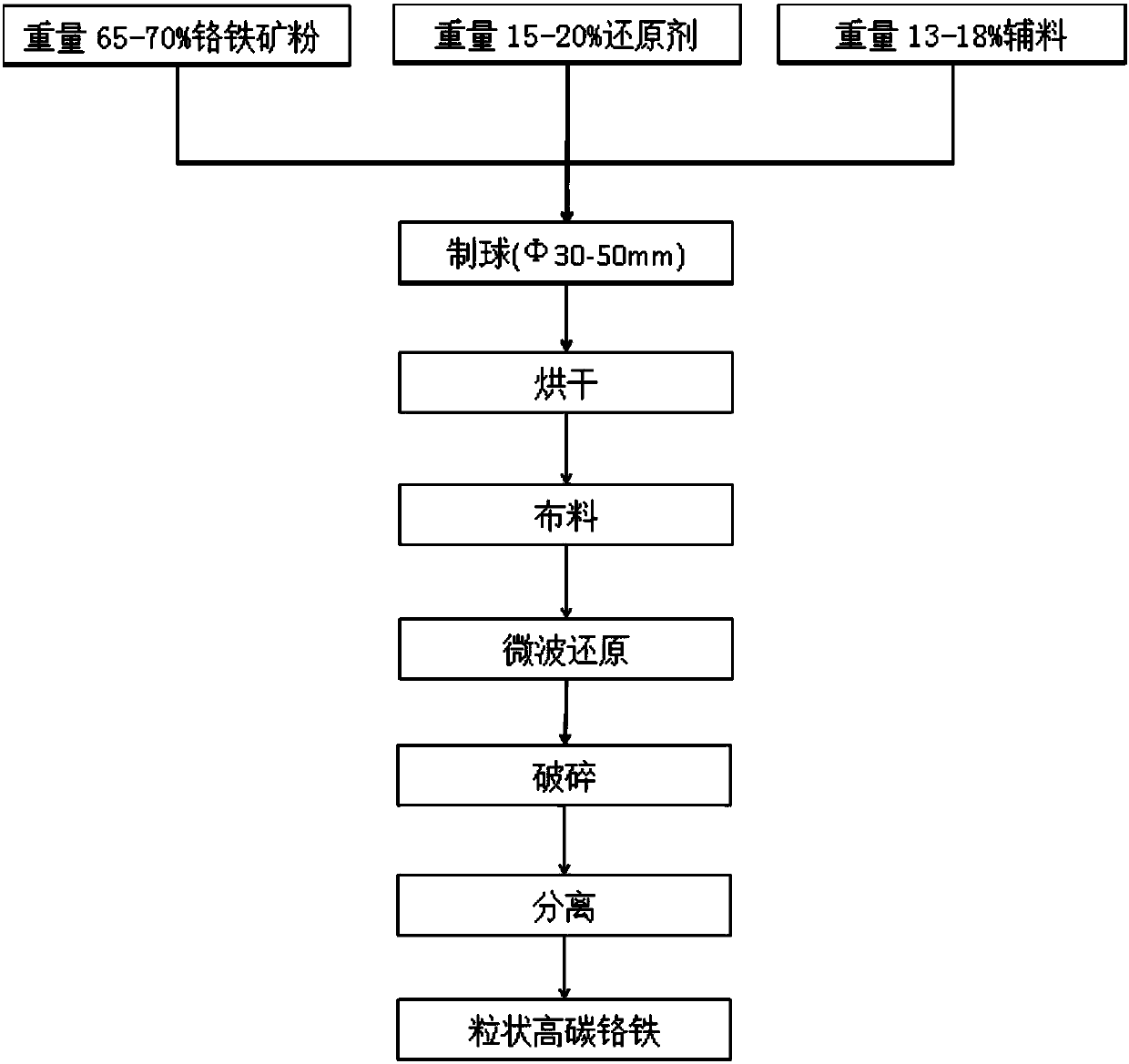

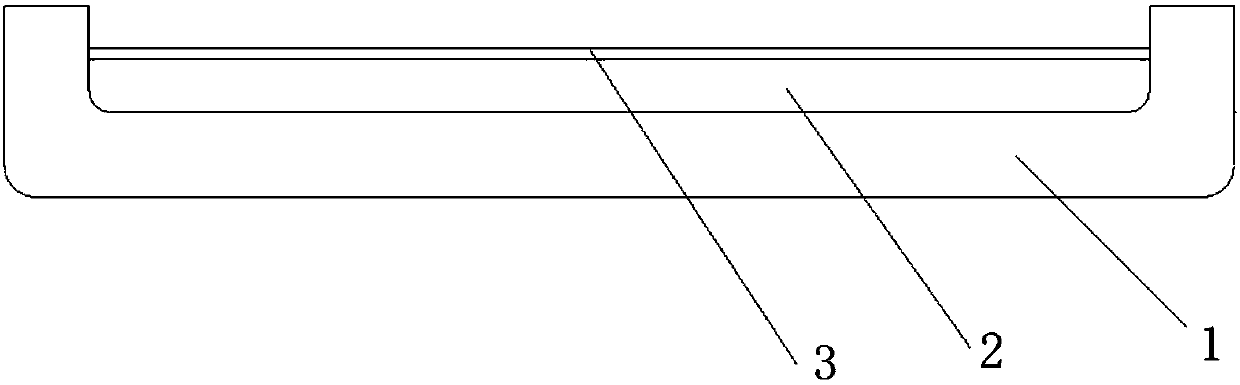

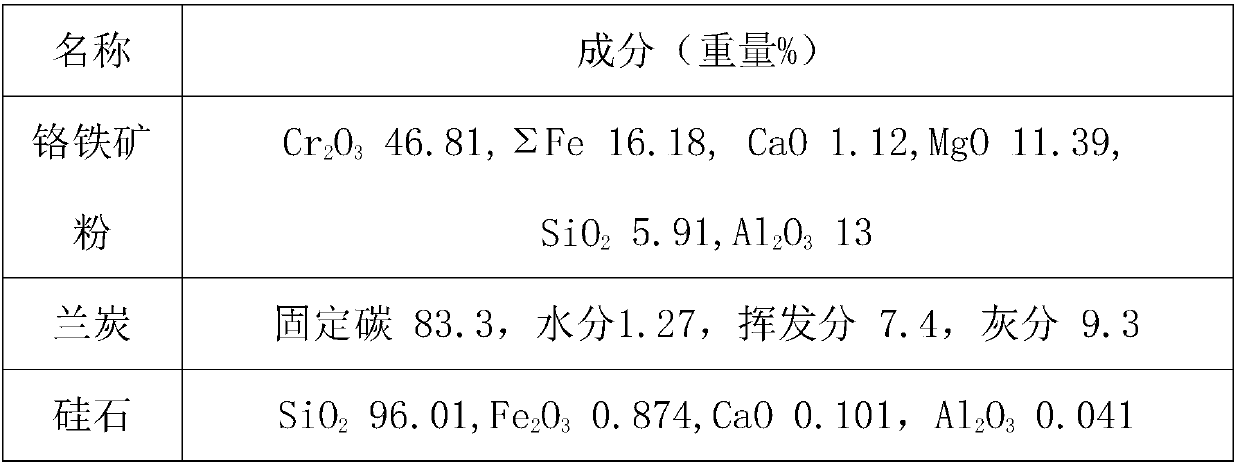

Preparation method of ferrochrome and crucible applied to method

The invention relates to a preparation method of ferrochrome and a crucible applied to the method. To achieve the purpose that ferrochrome is smelted through microwave heating and meanwhile solve thetechnical problem that the requirement for the crucible is relatively high in a method for smelting the ferrochrome through microwave heating, the preparation method comprises the following steps thatmaterials are prepared, furnace burden comprises ferrochrome mineral powder, a reducing agent and an auxiliary material, and the furnace burden comprises, by weight percent, 65%-70% of the ferrochrome mineral powder, 15%-20% of the reducing agent and 13%-18% of the auxiliary material; secondly, ball making is carried out, wherein the material powder of the furnace burden is mixed to be uniform according to the proportion, water is added, the furnace burden is pressed into balls, and the balls are dried; thirdly, the material balls are laid on the crucible, the thickness does not exceed 150 mm, and then the crucible is put into a microwave oven to be heated; and fourthly, the heated furnace burden is taken out and subjected to water cooling, jaw crushing and gravity separation, and ferrochrome particles are obtained. The Cr content of the high-carbon ferrochrome reduced through the method ranges from 55%-60%, the recovery rate of the Cr ranges from 85%-92%, the indexes are equivalent to the indexes of a traditional submerged arc furnace product, the power consumption and the dust pollution are reduced, and the furnace burden demolding problem of microwave metallurgy is economicallysolved.

Owner:陕西盛华冶化有限公司

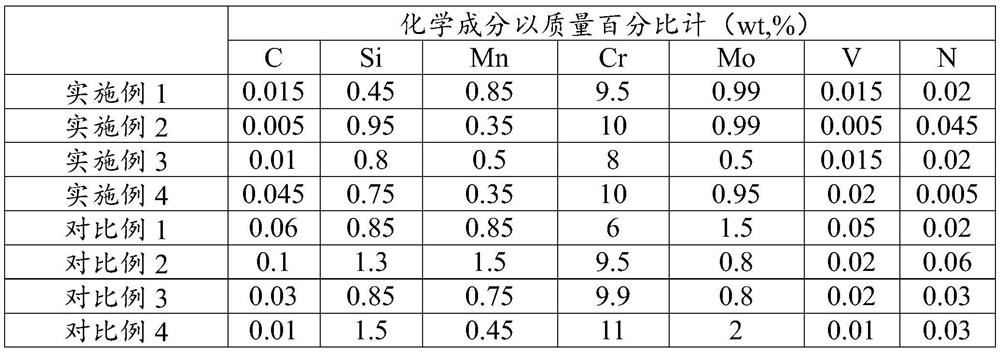

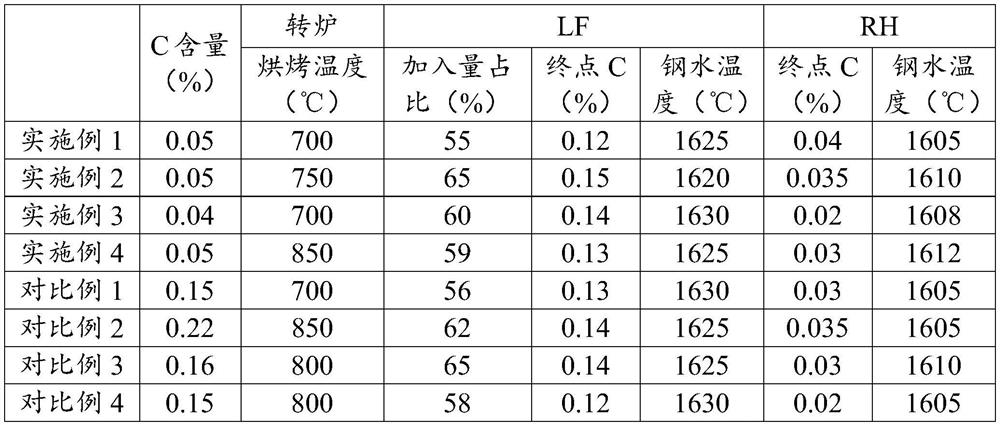

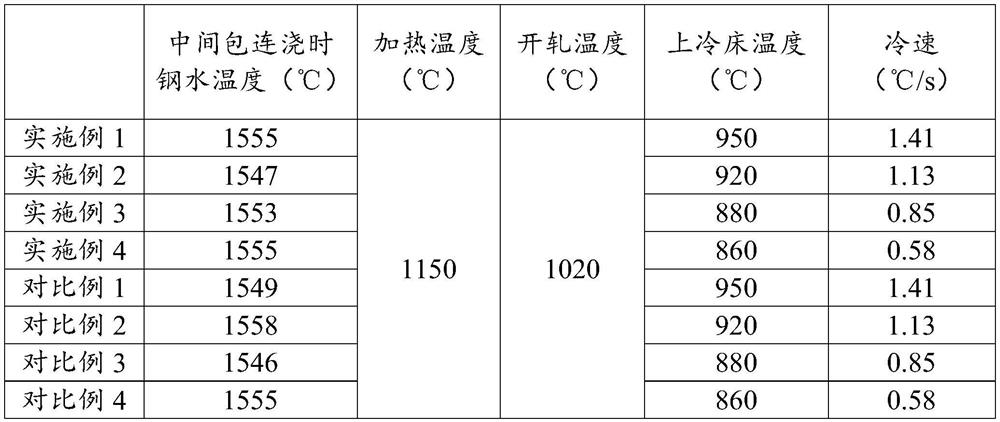

Low-cost high-corrosion-resistance steel bar and production method thereof

ActiveCN113355601AImprove corrosion resistanceImprove mechanical propertiesSteelmakingTemperature control

The invention discloses a low-cost high-corrosion-resistance steel bar and a production method thereof. The steel bar comprises the following chemical components: less than or equal to 0.05% of C, 0.005-0.05% of N, less than or equal to 1% of Si, less than or equal to 1% of Mn, 7.5-10% of Cr, more than 0 and less than or equal to 1% of Mo, 0.01-0.2% of V, 0.02-0.1% of C + N, 1-2% of Si + Mn, 8.5-11% of Cr + Mo + V and the balance of Fe; and the equivalence ratio of chromium to nickel is 7-9. In the production method, ferrochrome is added in two batches during steelmaking; the first batch of ferrochrome is added in converter smelting; the second batch of ferrochrome is added in LF furnace refining, and the ferrochrome accounts for 1 / 2-2 / 3 of the total amount; and the temperature of a cooling bed on the steel bar is greater than or equal to 840 DEG C, and the cooling speed is controlled to be less than or equal to 1.5 DEG C / s. The steel bar is excellent in corrosion resistance and mechanical property, low in cost and suitable for use requirements of ocean engineering.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +2

Converter chromium-preparation method for low-carbon Cr-containing alloy steel

ActiveCN106755709AReduce use costProduction rhythm matchingManufacturing convertersSteelmakingFerrosilicon

The invention discloses a converter chromium-preparation method for low-carbon Cr-containing alloy steel, belonging to the converter steelmaking field. According to the converter chromium-preparation method, oxygen blowing is stopped after decarbonization and heating in a later smelting period of a converter, ferrochromium alloy is added, the steel is discharged after the terminal temperature and the carbon content reach the standards, aluminum is added into a steel ladle in a steel discharging process so as to carry out deoxygenation, and the Cr content of molten steel reaches 5.0%-5.3%. The converter chromium-preparation method for low-carbon Cr-containing alloy steel has the beneficial effects that the alloy is mainly high-carbon ferrochrome and is reasonably matched with micro-carbon ferrochrome, the alloy cost is low, the yield of the Cr element is high, a terminal molten steel carbon content meets the processing capacity of subsequent vacuum refining, meanwhile, the step of adding silicon iron or aluminum powder to reduce the Cr element in the residue is omitted, the production cost is low, and the economic benefit is good.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

Technique for smelting mother liquor of stainless steel from electric furnace

InactiveCN100348765CLow cost of ingredientsAlleviate the tension of insufficient resourcesElectric arc furnaceFerrosilicon

This invention relates to an electric furnace smelting technique for crude stainless steel liquid with its process including: a) materials proportioning. Waste stainless steel shares 15~25% in total added metal. Chromium-iron alloy shares 15~25% in total added metal. Lime is added to an amount of 30~45 kg per ton of added metal. And dephosphorized molten iron shares 35~60% with its element content of 2.50~3.80% of C, less than 0.020% of phosphorus, less than 0.040% of sulfur. b) Smelting. Oxygen blowing amount is controlled at 5~10 cu m / t and blowing flux is controlled at 1500~2500N cu m / h. c) reduction. Ferrosilicon powders are spitted at 2.5~3.5kg / t and carbon powders at 1.5~2.5kg / t. Or ferrosilicon is added at 2.5~3.5kg / t and aluminium at 1.5~2.5kg / t. d) tapping, with ultimate temperature controlled at 1640~1660 deg.C. This invention employs dephosphorized molten iron, which reduces the raw materials proportioning cost and smelting time as well as the consumption of electricity power, electrodes and patching materials in electric furnaces.

Owner:BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com