Corrosion-resistant steel bar and production method of corrosion-resistant steel bar

A production method and steel bar technology, applied in the production field of corrosion-resistant steel bars and corrosion-resistant steel bars, can solve the problems of difficulty in steelmaking and increased production costs, and achieve the effects of avoiding plasticity reduction of steel bars, excellent plasticity of steel bars, and excellent overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

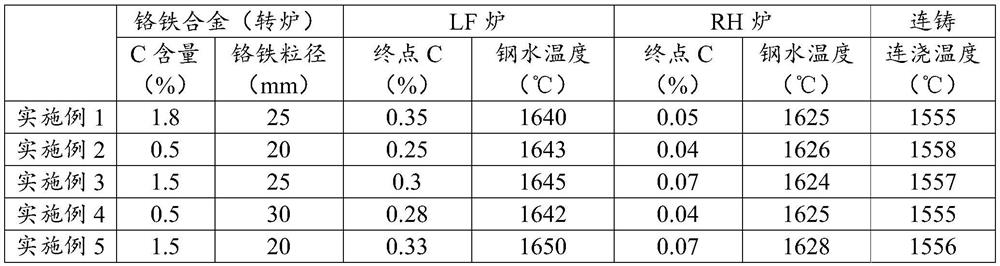

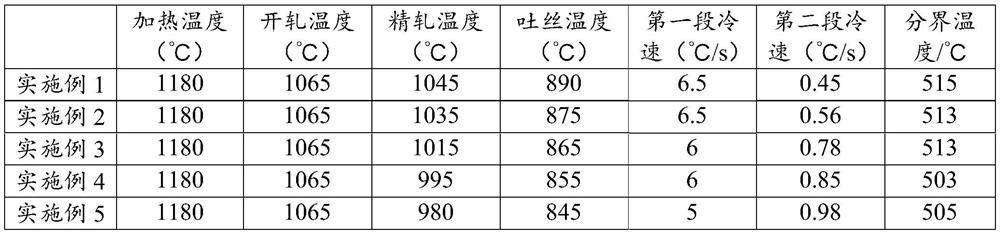

[0043] The technical solution of the present invention will be further introduced below in conjunction with specific embodiments, but the scope of protection is not limited to the description.

[0044] This embodiment provides a corrosion-resistant steel bar and a production method of the corrosion-resistant steel bar. In this embodiment, through the comprehensive improvement of chemical composition and production process, steel bars with better corrosion resistance and mechanical properties can be obtained under the condition of lower production difficulty and production cost, and the wide application of steel bars is greatly improved.

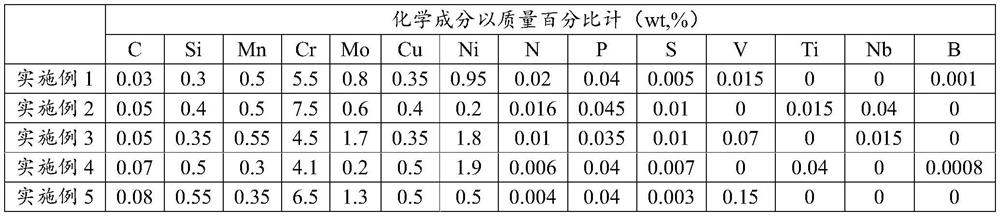

[0045] The chemical composition of the steel bars includes: C: 0.02% to 0.08%, Si≤1.0%, Mn≤1.0%, Cr: 4.0% to 8.0%, Mo≤2.0%, Cu: 0.3% to 0.6% in mass percentage , Ni≤2.0%, N≤0.02%, 0.03%<P≤0.05%, S≤0.01%, and the balance is Fe and unavoidable impurities.

[0046] Moreover, in the chemical composition of the steel bar, Si+Mn≤1.0%, Cr+Mo: 4.0%-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com