Preparation method of ferrochrome and crucible applied to method

A ferrochrome alloy and crucible technology, which is applied in the field of high-carbon ferrochrome production, can solve the problems of high requirements for crucibles and difficult separation of furnace materials, and achieve the effects of energy saving and temperature reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

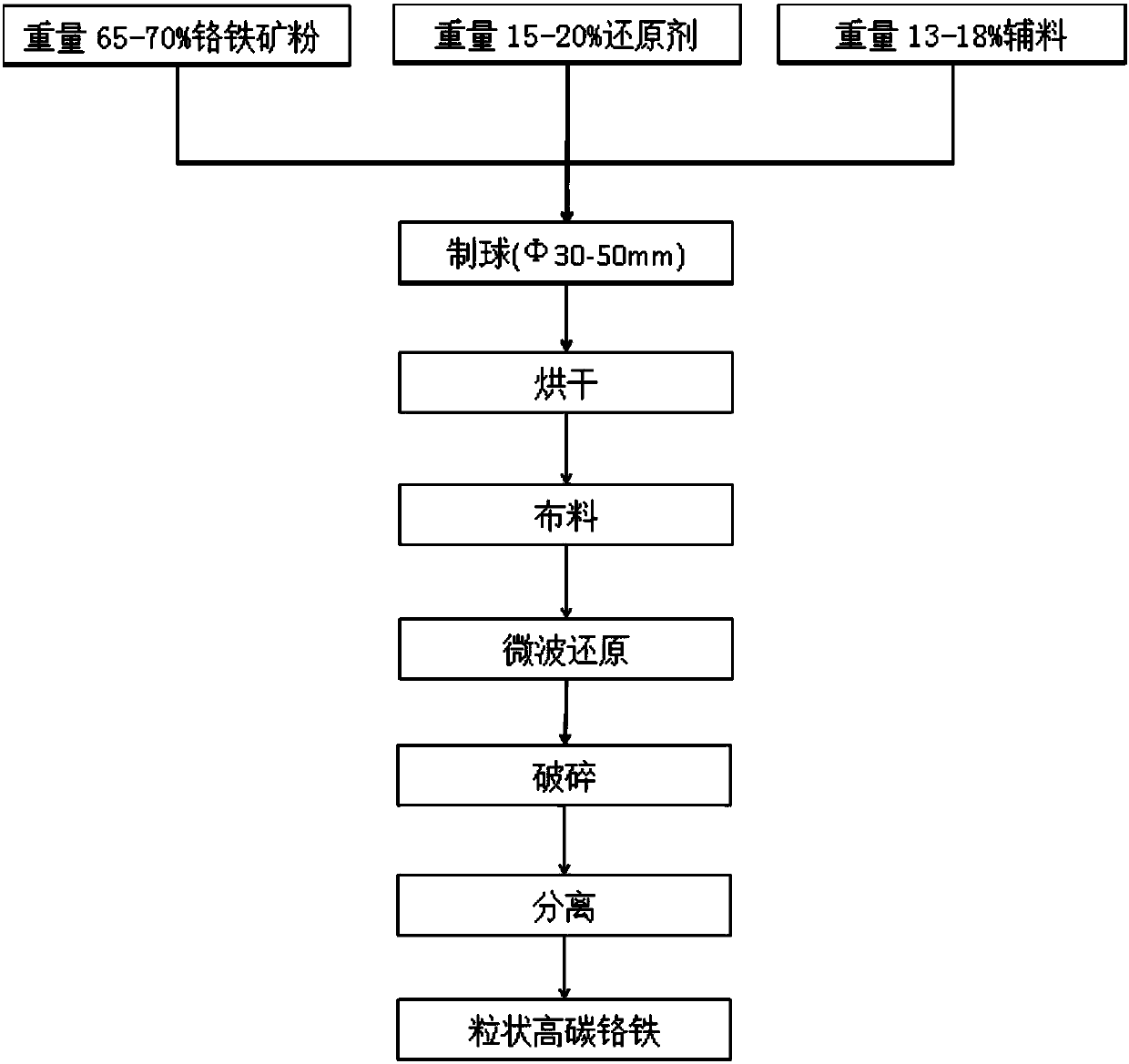

Method used

Image

Examples

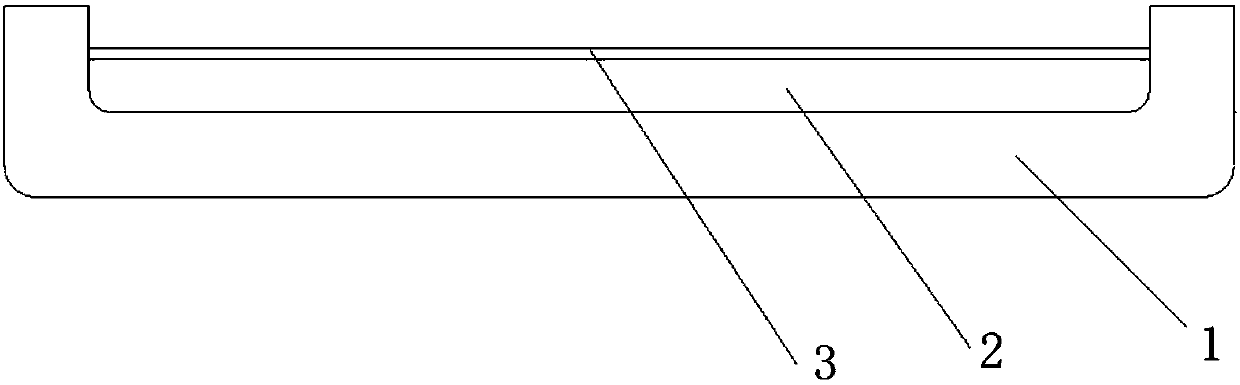

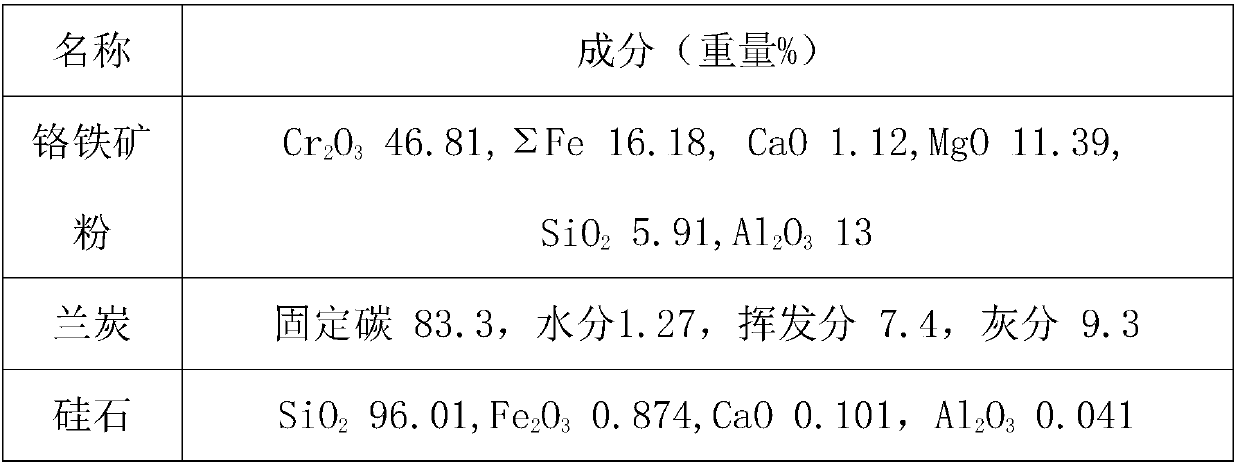

Embodiment 1

[0032] Example 1: 1960 g of chromite powder, 510 g of blue carbon powder, and 430 g of silica powder. After mixing, press water to form pellets with a diameter of 30 mm and dry them at 105°C. Spread 50 mm quartz sand + 10 mm graphite powder in a refractory crucible. Lay the dried material ball on the graphite powder layer; send it into 20KW microwave rate and heat for 140min to obtain 1032g alloy, in which Cr: 57.12%, Si1.37%, C7.5%, Cr recovery rate 85.3%.

Embodiment 2

[0033] Example 2: 2162g of chromite powder, 562g of blue charcoal powder, and 476g of silica powder. After mixing, press water to form a ball with a diameter of 50mm and dry at 105°C; spread 50mm quartz sand + 10mm graphite powder in a refractory crucible. Lay the dried material ball on the graphite powder layer; send it into 20KW microwave rate and heat for 150min to obtain 1178g alloy, in which Cr: 57.26%, Si1.43%, C8.1%, Cr recovery rate 88.5%.

Embodiment 3

[0034] Example 3: 1554 g of chromite powder, 404 g of blue carbon powder, and 342 g of silica powder were mixed and mixed and pressed into pellets with a diameter of 30 mm and dried at 105°C; the refractory crucible was spread with 50 mm quartz sand + 10 mm graphite powder. Lay the dried material ball on the graphite powder layer; send 20KW microwave rate and heat for 120min to obtain 893g alloy, in which Cr: 55.52%, Si1.13%, C6.9%, Cr recovery rate is 92.1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com