Method for revolving furnace smelting 45CrMnMo steel

A converter smelting and converter technology, applied in the field of metallurgy, can solve the problems of low alloy yield, prolonged smelting time, less than 90%, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

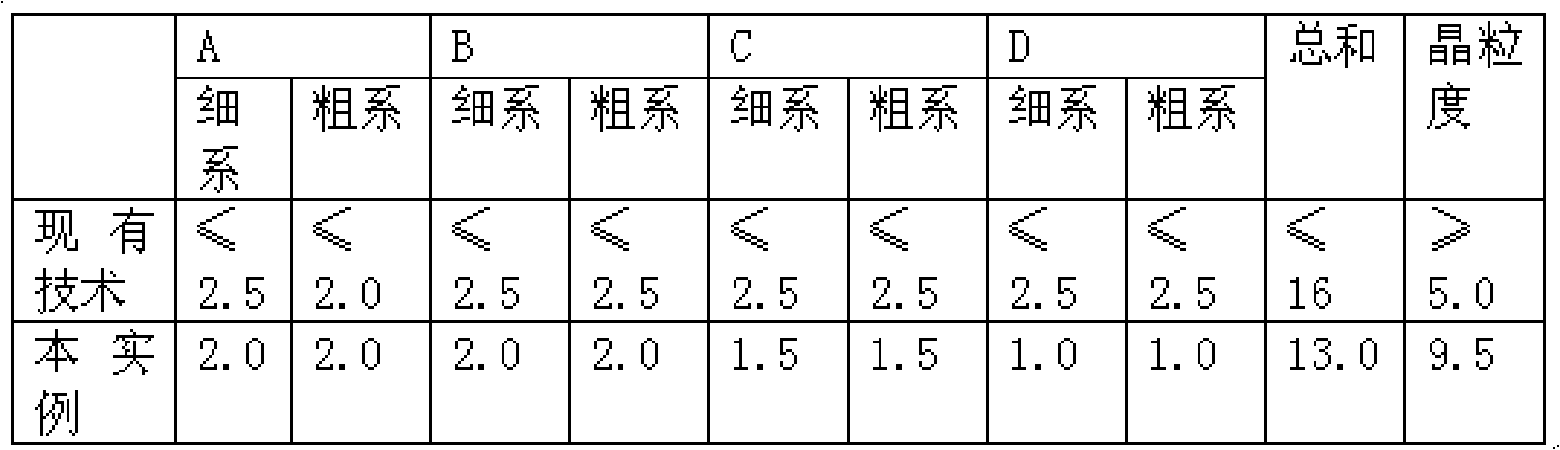

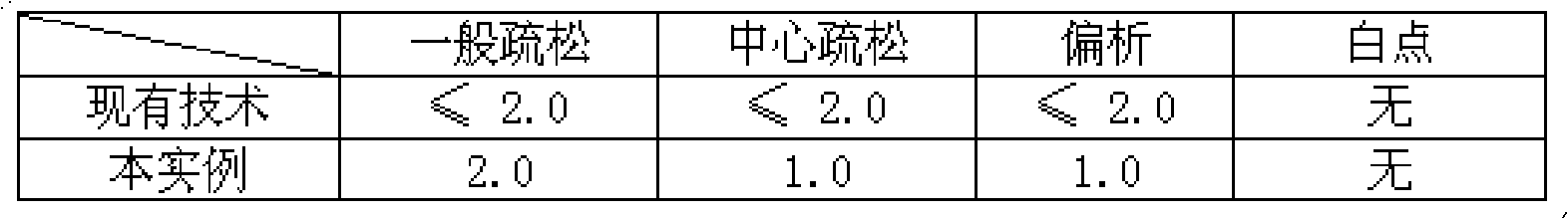

Examples

Embodiment 1

[0019] Embodiment one uses the inventive method to produce 45CrMnMo steel

[0020] Add 140 tons of molten iron with a sulfur content of ≤0.020% into the converter, and add 5 tons of lime material for conventional oxygen top blowing smelting before tapping. The carbon at the end point of tapping is controlled within the range of 0.35-0.45%, the tapping temperature is controlled at 1660-1700°C, and 2,500kg of ferrochromium containing 60% chromium and molybdenum containing 60% molybdenum are prepared according to 140 tons of molten steel during tapping. 620kg of iron and 1950kg of silicon-manganese alloy containing 66% of manganese and 16% of silicon are gradually added into the molten steel ladle. Metal aluminum is added into the molten steel ladle for deoxidation, and 50Kg of metal aluminum is added to the molten steel together with iron alloys such as ferrochromium and ferromolybdenum for every 140 tons of molten steel. After the steel is tapped, blow argon gas into the molte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com