Production of chromium iron alloys directly from chromite ore

a technology of chromite ore and chromium iron, which is applied in the direction of fluidised-bed furnaces, furnace types, furnace types, etc., can solve the problems of inability to produce chromium iron alloys directly from chromite ore, high cost of producing stainless steel, and high cost of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

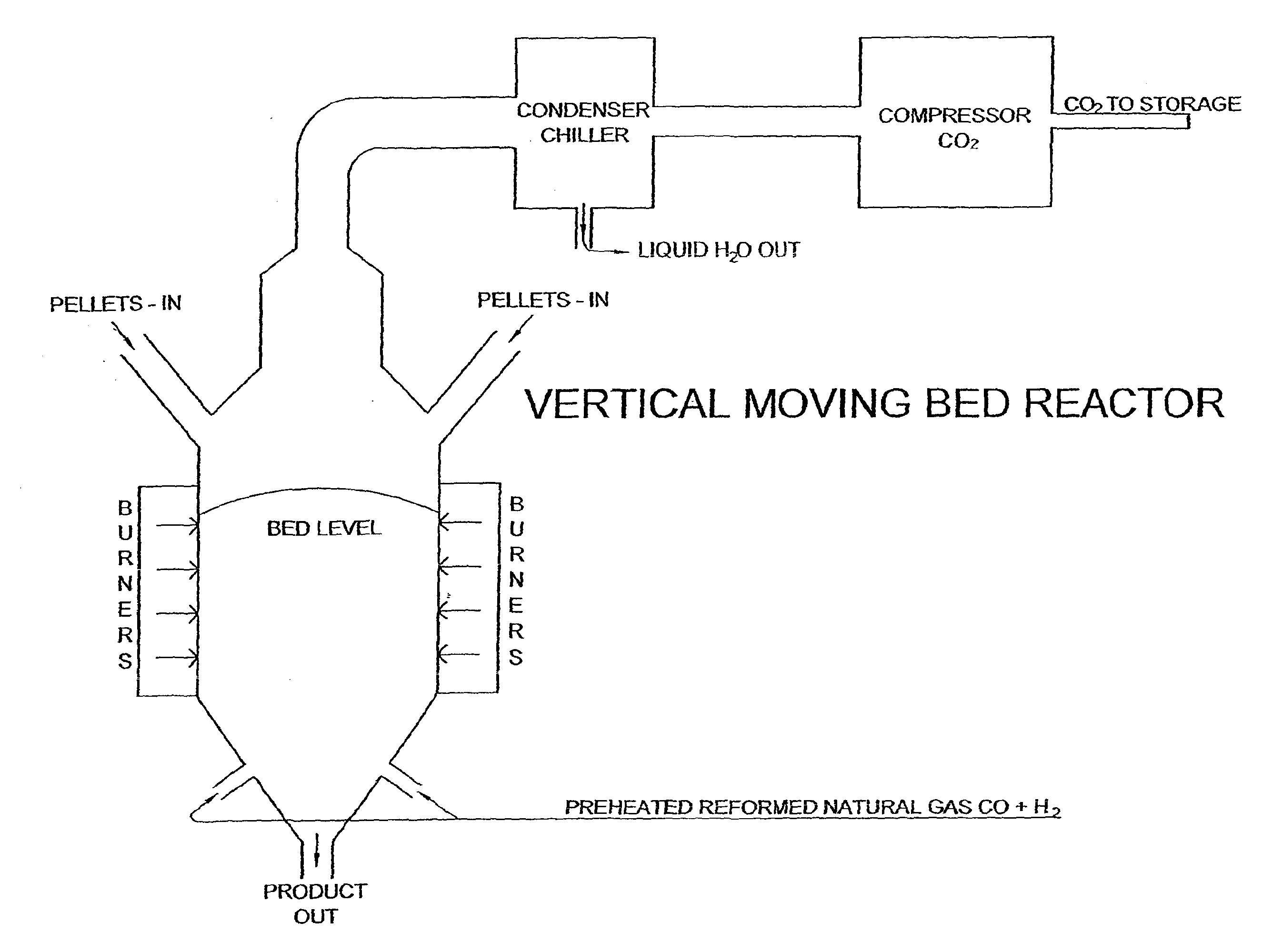

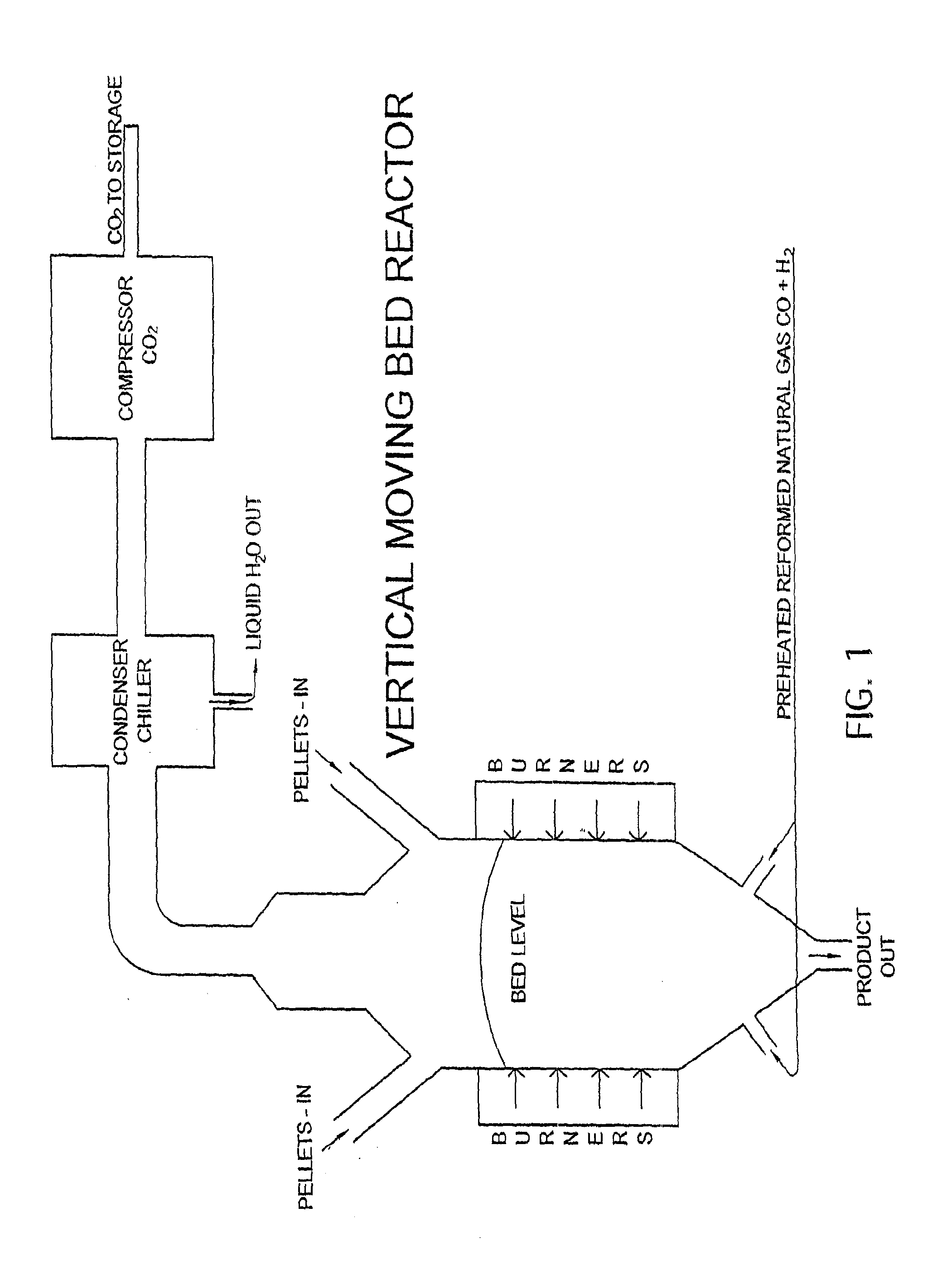

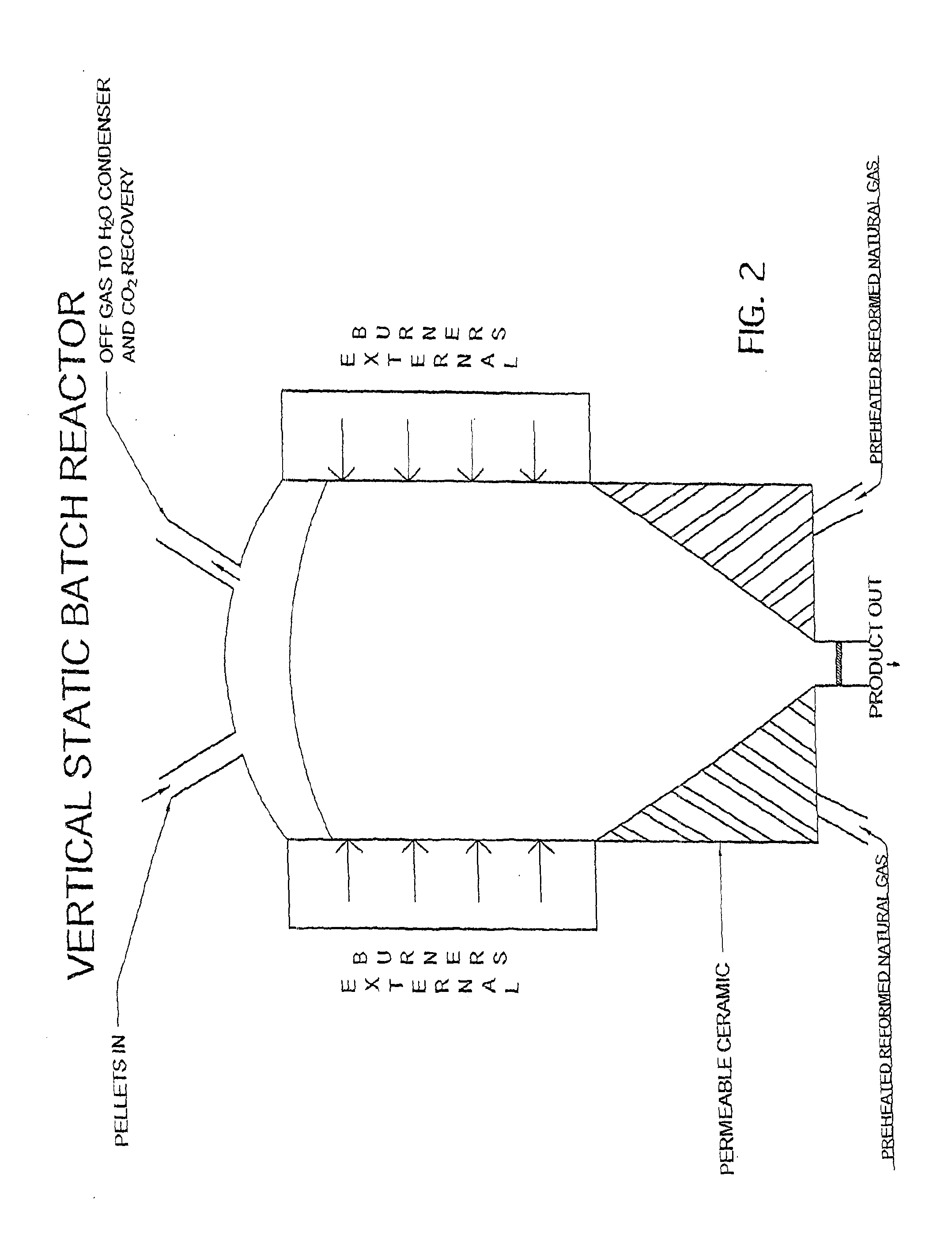

[0023]The process for producing chromium iron alloys suitable for steel making directly from chromite ore in accordance with the teachings of the present invention is carried out as described and outlined in the afore-described Summary of the Invention, preferably utilizing ROF chromite ore.

[0024]Extensive laboratory work has been completed which demonstrates the validity of the present invention. Samples of chromite ore concentrates from a deposit within the ROF have been successfully reduced in accordance with the teachings of the present invention to a highly metallised chromium iron alloy suitable for steel making. The temperature required for the reduction of chromium is much higher than that for the reduction of iron alone. In order to enable the reduction process to proceed at an acceptable rate at lower temperatures an accelerator is used. The chromite ore concentrate is supplied as fines and needs to be agglomerated prior to the reduction stage. This may be accomplished by ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperatures | aaaaa | aaaaa |

| temperatures | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com