Method for manufacturing TiB<2> ceramic-reinforced wear-resistant surfacing flux-cored welding wire

A welding flux and welding wire technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of low service life of wear-resistant metal components, poor metal fluidity, and wear resistance that does not meet the requirements for use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

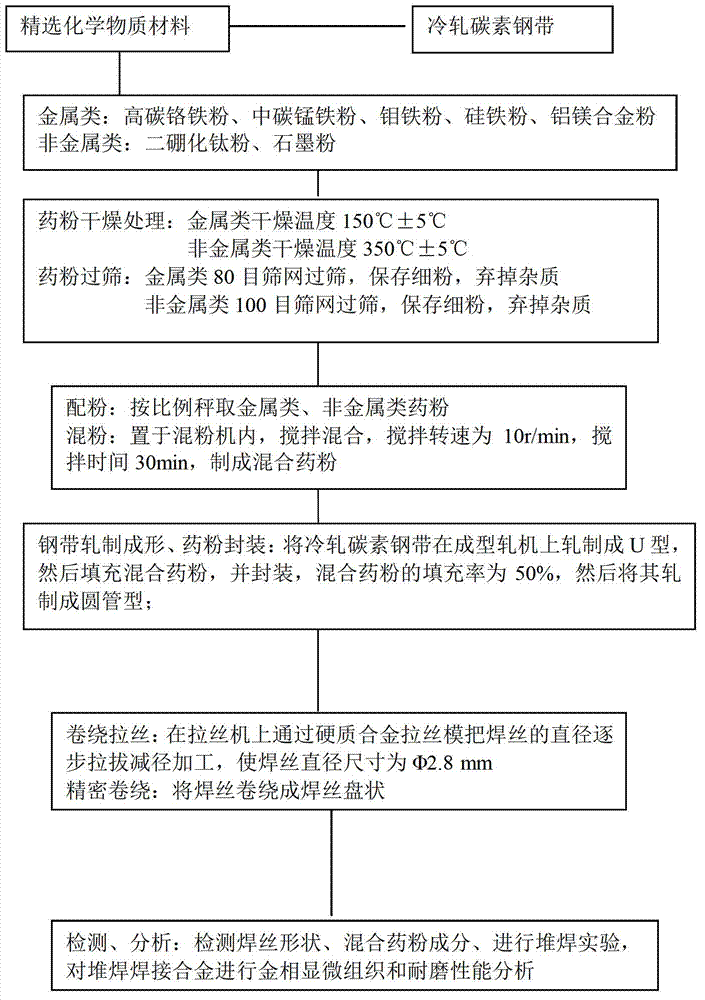

Method used

Image

Examples

Embodiment 1

[0057] The welding method is as follows:

[0058] Deltaweld-852 welding machine is used for welding, DC reverse connection, no shielding gas, open arc surfacing welding, welding process parameters: voltage 27-36V, current 460-500A, wire feeding speed: 460-500mm / min, welding wire The dry elongation is 20-30mm; a hard phase is formed in the surfacing alloy—TiC-TiB 2 The composite compound is dispersed in the primary carbide and matrix structure, forming high hardness and wear-resistant particles, which improves the hardness and wear resistance of the surfacing alloy.

PUM

| Property | Measurement | Unit |

|---|---|---|

| microhardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com