Method for jointly producing chromium salt and ferrochromium alloy by sintering with wet and fire methods

A ferrochromium alloy, roasting technology, applied in the direction of chromium compounds, chemical instruments and methods, process efficiency improvement, etc., can solve problems such as instability, difficult smelting, lack of practical value, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

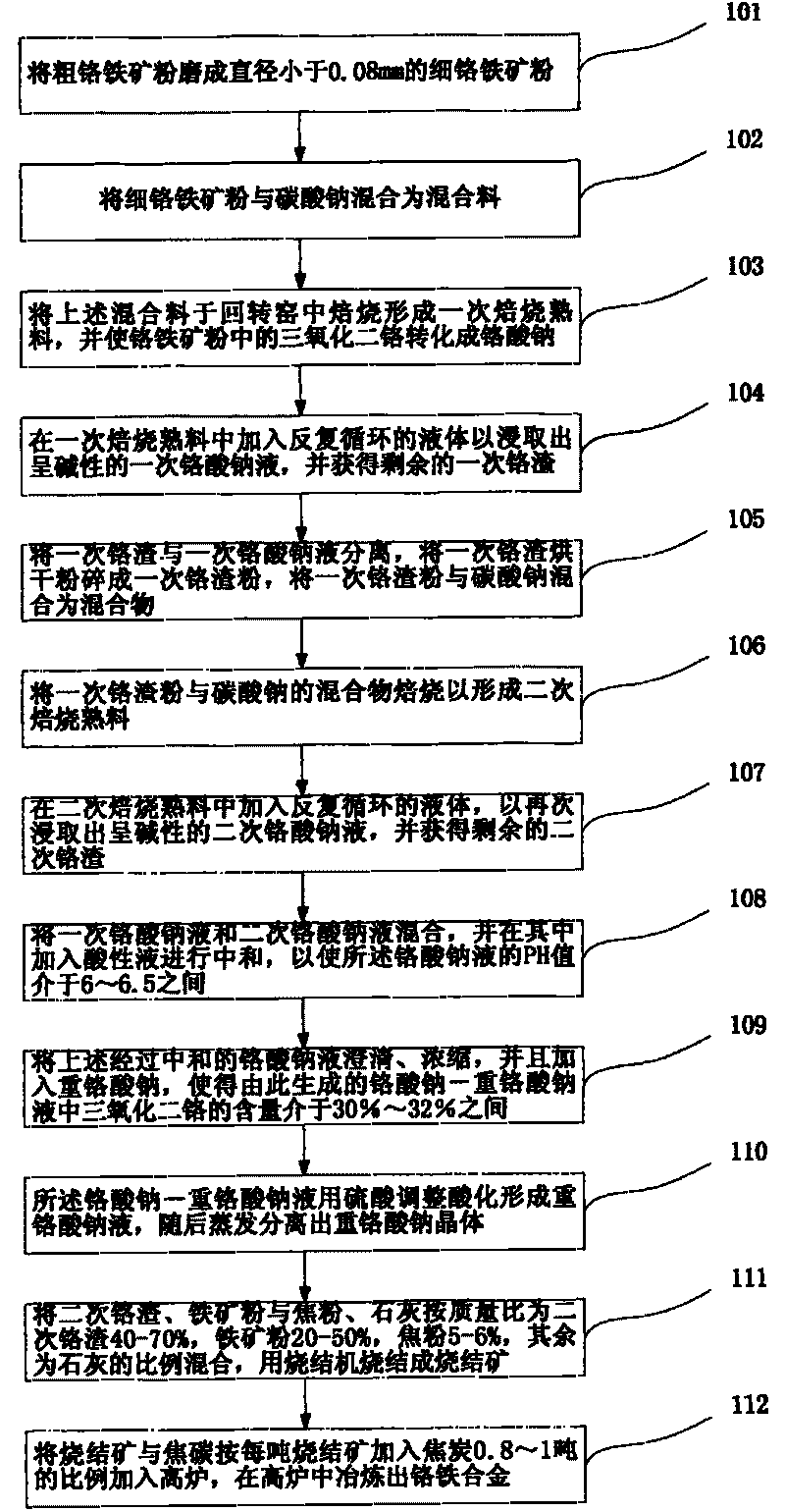

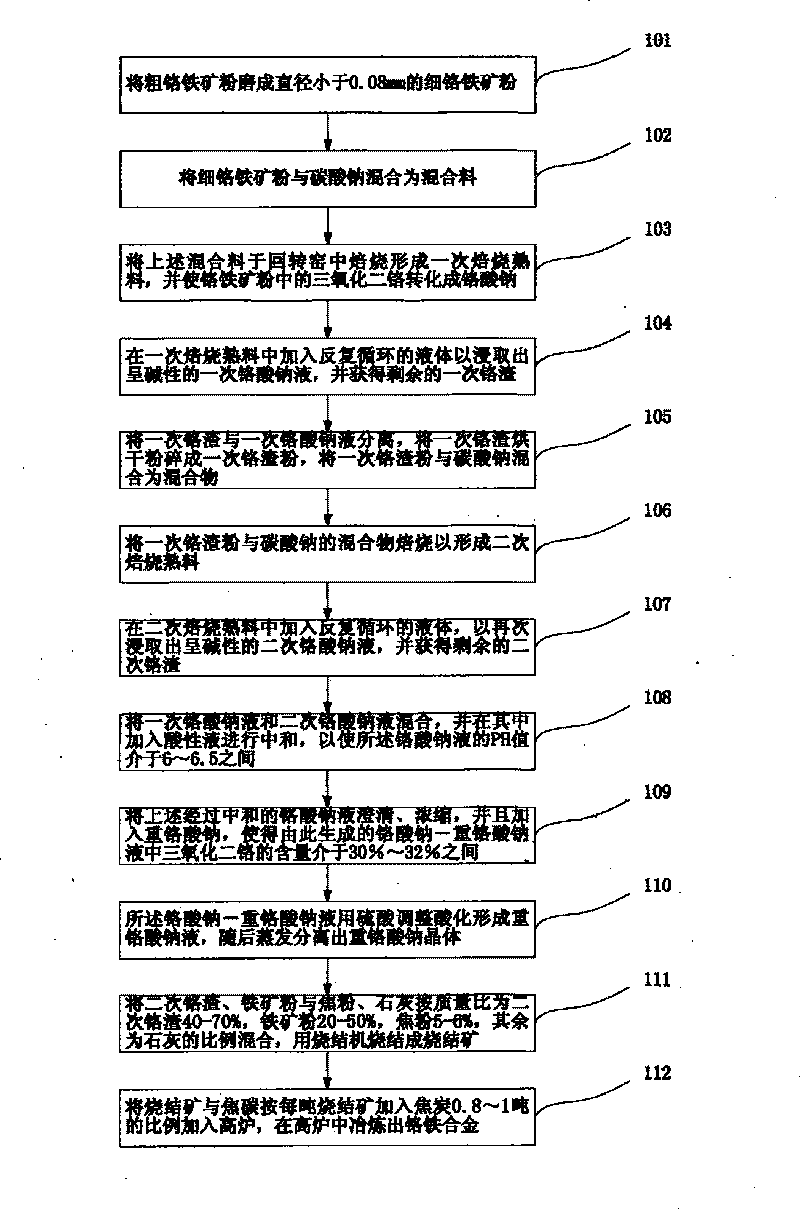

[0022] The present invention will be further described below in conjunction with the accompanying drawings, so that those of ordinary skill in the art can implement it after referring to this specification.

[0023] Such as figure 1 Shown, the method for roasting wet method-fire method coproduction of the present invention chromium salt, ferrochrome alloy comprises the steps:

[0024] In step 101, the coarse chromite ore powder is sent to a ball mill through mechanical conveying equipment to be ground into fine chromite ore powder with a diameter less than 0.08 mm.

[0025] Step 102, mixing the fine chromite powder and sodium carbonate to form a mixture, and the mass of the sodium carbonate is 0.56-0.60 times of the theoretical amount of chromium trioxide in the fine chromite powder.

[0026] Step 103, transfer the above-mentioned mixture to a rotary kiln, and roast it under the condition of 1150° C. to 1200° C. to form primary roasted clinker, and convert the chromium trioxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com