Low-cost high-corrosion-resistance steel bar and production method thereof

A production method and high corrosion resistance technology, which are applied in the production of low-cost and high-corrosion-resistant steel bars, and in the field of low-cost and high-corrosion-resistant steel bars, can solve the problem of short service life of epoxy resin coating or galvanized layer, and poor welding performance of stainless steel steel bars. , complex production process and other problems, to achieve excellent corrosion resistance and comprehensive mechanical properties, high social significance and economic effects, process operation is simple and easy to control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

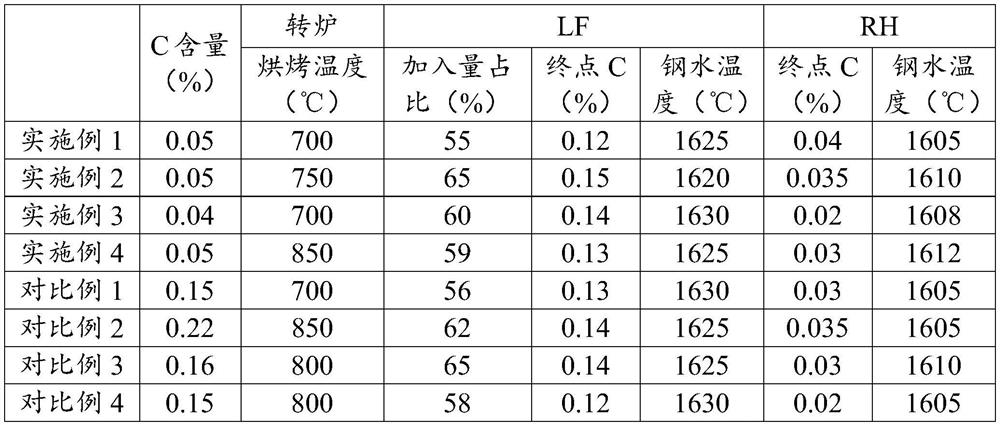

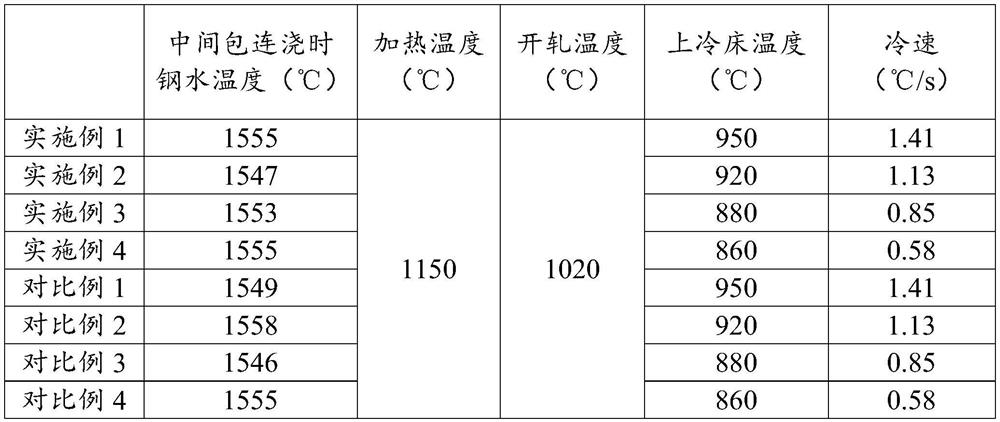

[0037] The technical solution of the present invention will be further introduced below in conjunction with specific embodiments, but the scope of protection is not limited to the description.

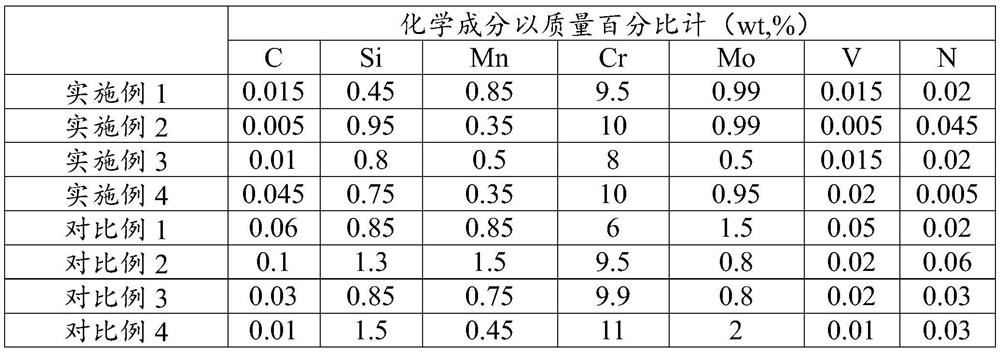

[0038] An embodiment of the present invention provides a steel bar, which is specifically a low-cost high-corrosion-resistant steel bar, that is, the steel bar has high corrosion resistance and low cost. Specifically, the chemical composition of the steel bar includes: C≤0.05%, N: 0.005%-0.05%, Si≤1.0%, Mn≤1.0%, Cr: 7.5%-10.0%, Mo≤1.0%. , V: 0.01% ~ 0.2%, the balance is Fe and unavoidable impurities.

[0039] Moreover, the mass percentages of C, N, Si, Mn, Cr, Mo and V in the chemical composition of the steel bars also satisfy: C+N: 0.02% to 0.1%, Si+Mn: 1.0% to 2.0%, Cr+ Mo+V: 8.5% to 11.0%.

[0040] Moreover, in the chemical composition of the steel bar, chromium equivalent Creq=Cr+Mo+1.5Si+0.5Nb, nickel equivalent Nieq=Ni+30(C+N)+0.5Mn, 7.0≤Creq / Nieq≤9.0. That is, the chromium eq...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Self-corrosion current density | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com