Patents

Literature

56results about How to "Lower the build temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing land plaster whiskers from phosphoric acid

InactiveCN1584130ALower the build temperatureShortened growth timePolycrystalline material growthFrom normal temperature solutionsGypsumPhosphoric acid

Production of gypsum in phosphorous liquid involves preparing a phosphorous extracting liquid and a gypsum crystal whisker suspending liquid. The phosphorous extracting liquid is prepared by extracting 30 - 40% phosphorous acid with ores at 50 - 95deg.C for 2 - 4h, separating liquid phase and filtering to obtain products with H3PO4 3 - 4mol / L and Ca2+ 0.8 - 1.2mol / L. The suspending liquid is prepared by adding the said liquid into 30 - 35% sulfuric acid solution gradually, stirring and reacting at (50 - 100)deg.C for 120 - 150min. Hemi-hydrated or anhydrous gypsum whiskers are obtained after filtering the suspending liquid, cleansing with boiled water, and drying at (120 - 200)deg.C. The process reduces generating temperature and cost in production, shortens production time, and qualifies their performance, so that it can be widely used in production of gypsum whiskers.

Owner:QINGDAO UNIV OF SCI & TECH

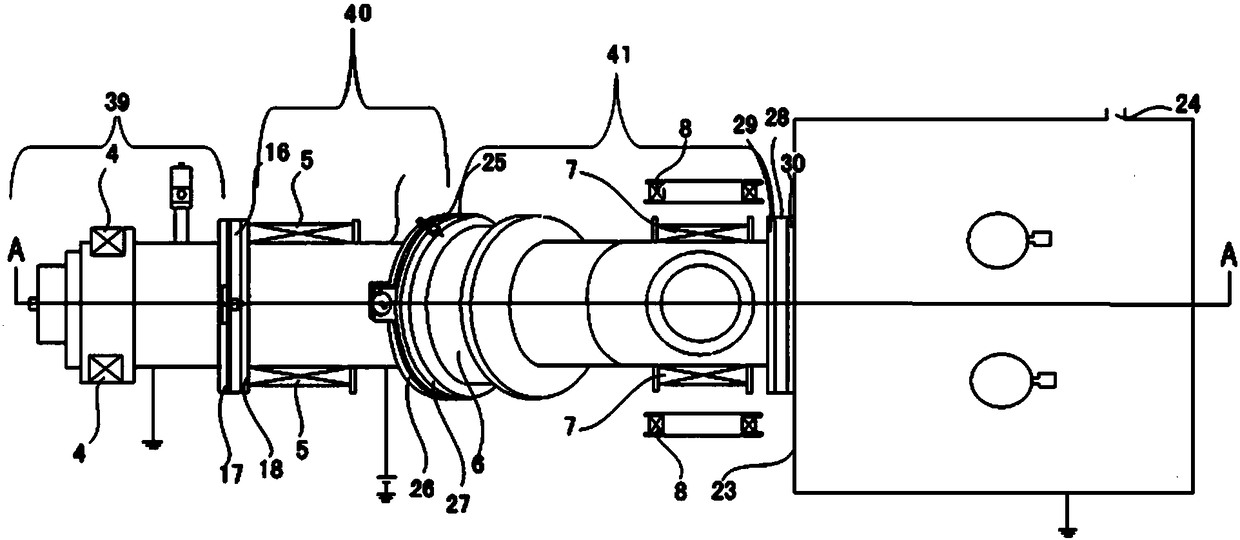

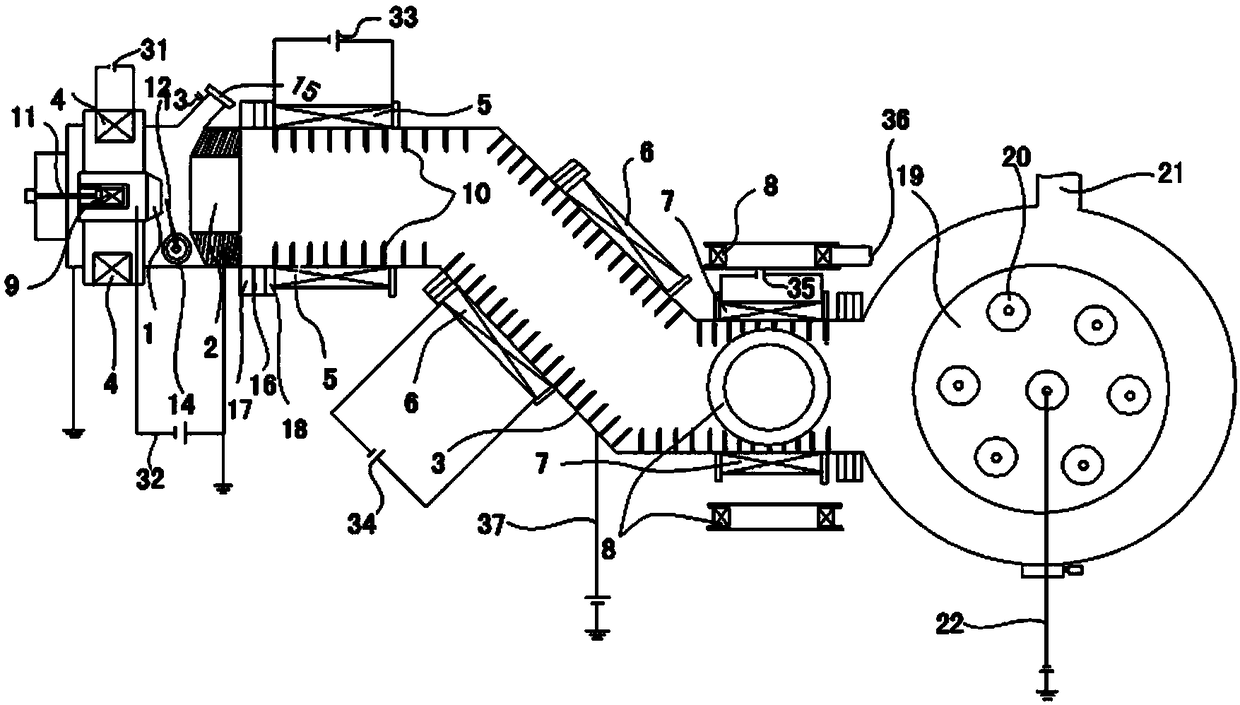

Method for improving quality of high-chromium vanadium and titanium sinter

The invention provides a method for improving the quality of high-chromium vanadium and titanium sinter and belongs to the technical field of ferrous metallurgy. The method mainly comprises the steps that sintering return mines, high-chromium vanadium and titanium concentrate fines, ordinary iron ore concentrate powder, boron iron ore concentrate, metallurgical lime, magnesite, coke powder and other sintering raw materials are subjected to secondary atomization injection and blowing blending, wetting and pelletizing at a certain proportion; then distribution, ignition and sintering are conducted; and finally grain settlement and screening are conducted to obtain the high-chromium vanadium and titanium sinter good in metallurgical performance. The method has the characteristics of being simple in process, high in raw material adaptability, high in production efficiency, low in cost and the like. The quality of the high-chromium vanadium and titanium sinter and the sintering production efficiency can be improved remarkably; the method has important realistic significance for development and utilization of the high-chromium vanadium and titanium sinter and has wide application prospects.

Owner:NORTHEASTERN UNIV

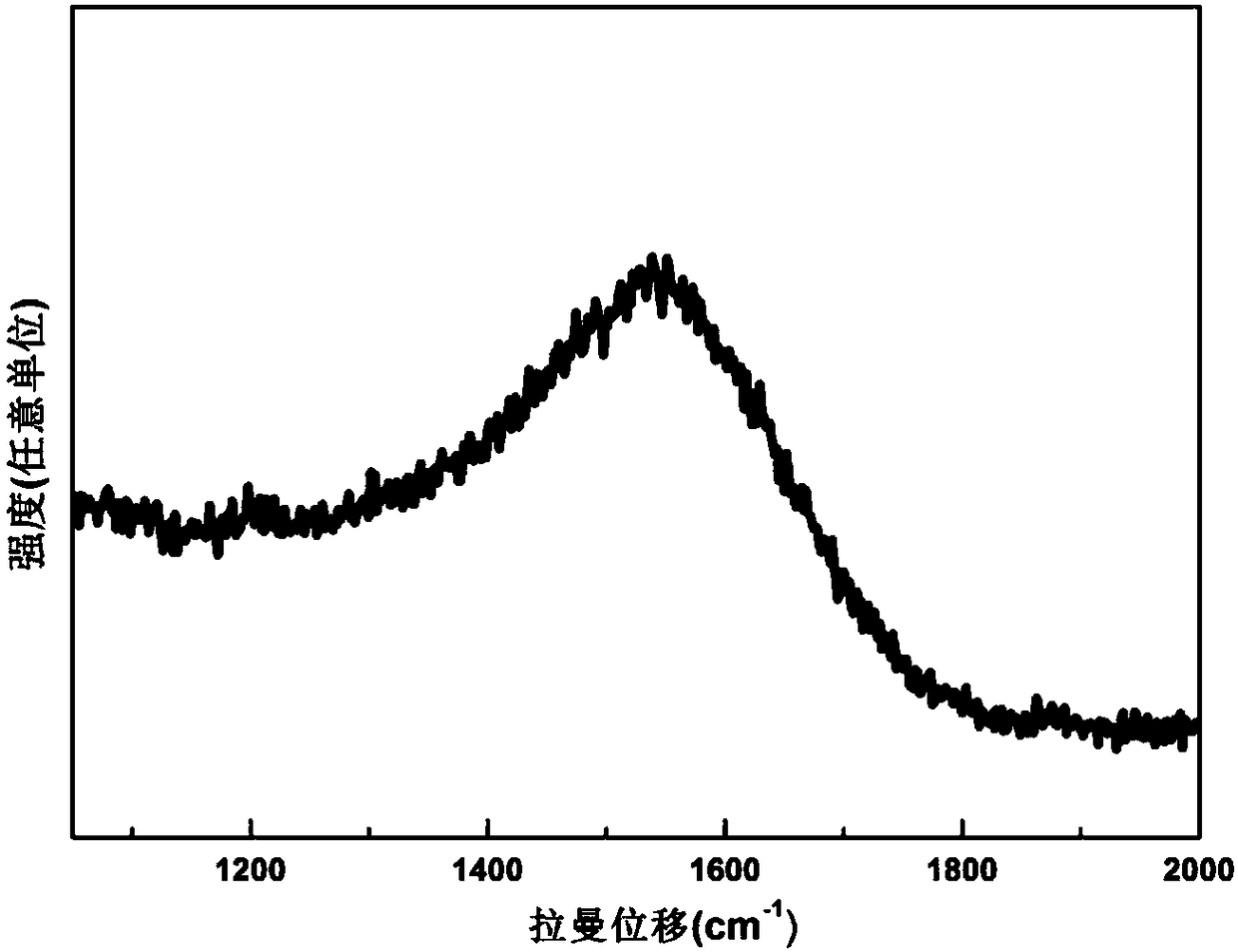

Graphene preparation method

ActiveCN108203090ASimple processLow costVacuum evaporation coatingSputtering coatingEvaporationCvd graphene

The invention provides a graphene preparation method, which combines a cathode vacuum electric arc deposition technology, an electron beam evaporation plating technology and a vacuum annealing process. According to the method, by optimizing process parameters, an amorphous carbon film with high sp3 content is deposited on the surface of a matrix, a catalyst film is subjected to evaporation platingat the surface through an electron beam, and finally annealing is performed at a temperature of 450-500 DEG C to diffuse and precipitate carbon onto the surface of the catalyst film so as to convertthe structure into the graphene structure to form the few-layer or multi-layer graphene. Compared to the existing graphene preparation process, the graphene preparation process of the invention has advantages of simpleness, easy performing, low annealing temperature and reduced cost; and the used carbon source is not the gas but the solid, and the number of the layers of graphene can be controlledby controlling the thickness of the carbon source so as to achieve the controlled preparation of graphene.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Efficient and non-corrosive hydrate inhibitor

ActiveCN101608111AReduce dosageSimplify subsequent processingDrilling compositionPetroleumCalcium nitrate

The invention provides a high-efficient non-corrosive hydrate inhibitor, relating to the technical field of oil-gas hydrate. The hydrate inhibitor is a mixture of an anti-agglomerant and a urea or a calcium nitrate and is used at the pressure of 1.5 to 25 MPa and at the temperature of minus 20 DEG C to 25 DEG C. The hydrate inhibitor overcomes the defects of the prior art, reduces the nucleary, the growth and the coalescence speed of hydrate after being filled in petroleum fluid in production or conveying by mixing at low concentration and has the characteristics of wide application, low cost and no corrosion to pipelines.

Owner:SOUTH CHINA UNIV OF TECH

Preparation method of high-toughness pressureless sintered boron carbide ceramic

InactiveCN108911753AReduce temperature sensitivityHigh particle size concentrationBoron carbideSlurry

The invention relates to a preparation method of high-toughness pressureless sintered boron carbide ceramic. 65 to 78 wt% of boron carbide powder, 10 to 17 wt% of a sintering aid and 8-20 wt% of a ceramic additive are added into a stirring mill, and a certain amount of solvent is added, stirring ball milling-sand mill treatment-stirring ball milling process is performed, the solid content of ceramic slurry is 45 to 60 wt%, granulated powder is obtained by centrifugal spray granulation, the granulated powder is pressed into a green body, the green body is placed in a graphite sagger, graphite balls are placed around the green body, the graphite sagger is placed in a high-temperature vacuum sintering furnace for pressureless sintering, and finally the boron carbide ceramic is obtained. The low-price large-particle boron carbide powder is used as a raw material, and a multi-component eutectic non-oxide liquid phase is introduced to promote the densification of the boron carbide ceramic.

Owner:扬州北方三山工业陶瓷有限公司

Method for producing vanadium-nitrogen alloy

The invention relates to a production method for vanadium-nitrogen alloy, which comprises following steps: evenly mixing oxide of powder vanadium or ammonium metavanadate, carbon powder and binder, continuously adding into an external-heating rotary kiln in nitrogen atmosphere after briquetting and forming, and presintering to below 1000 DEG C under the protection of nitrogen; collecting the presintered block product which is cooled to ambient temperature under the protection of nitrogen at a discharge opening, pushing into an improved soft magnetic nitrogen atmosphere furnace kiln, heating to 1000 to 1500 DEG C for carbonization and nitridation reaction, and vanadium-nitrogen alloy product is obtained after discharge. The composition of the vanadium-nitrogen alloy: V is 78 to 83%, N is 16 to 21%, C is 6% max, and silicon, phosphorus and aluminum are less than 0.10%; the apparent density is greater than 3.5g / cm<3>. The production method for vanadium-nitrogen alloy has the advantages of adopting rotary kiln for precalcination, removing harmful impurities and corrosive elements, reducing stacking volume, greatly improving productivity of carbonization and nitridation working procedures, and greatly prolonging service life of nitriding furnace kiln.

Owner:刘先松 +1

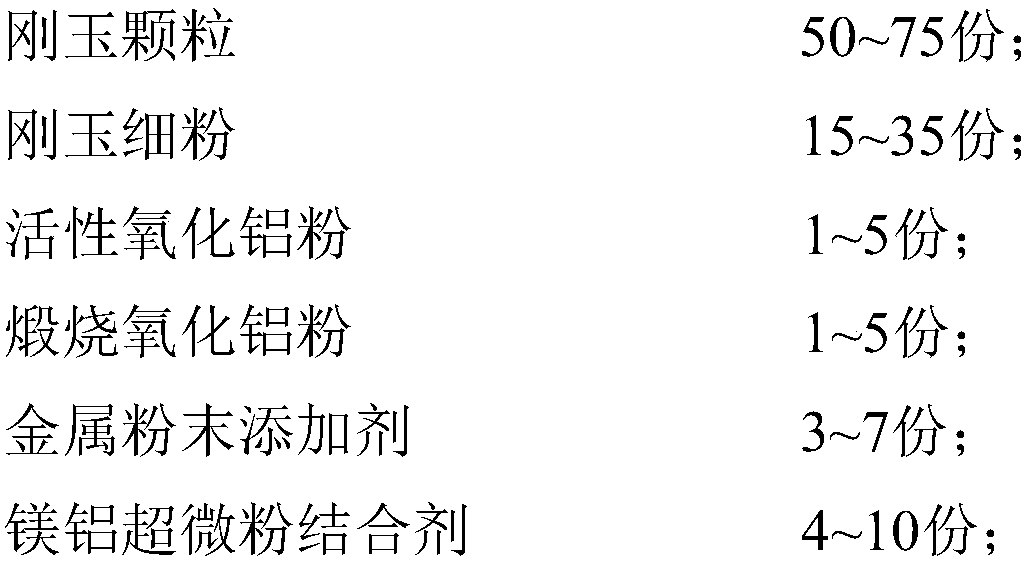

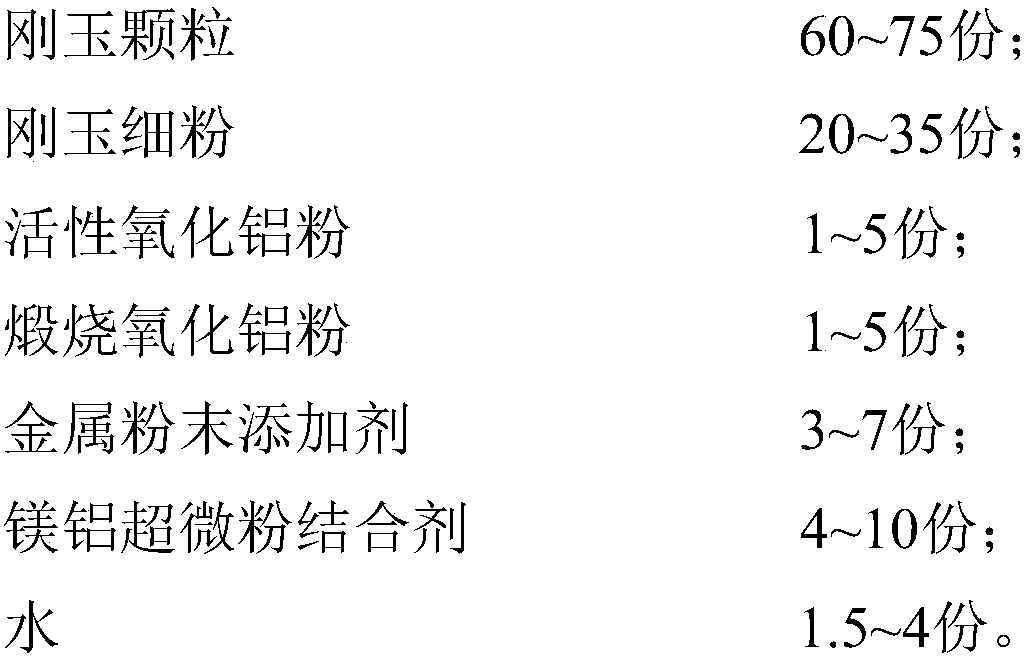

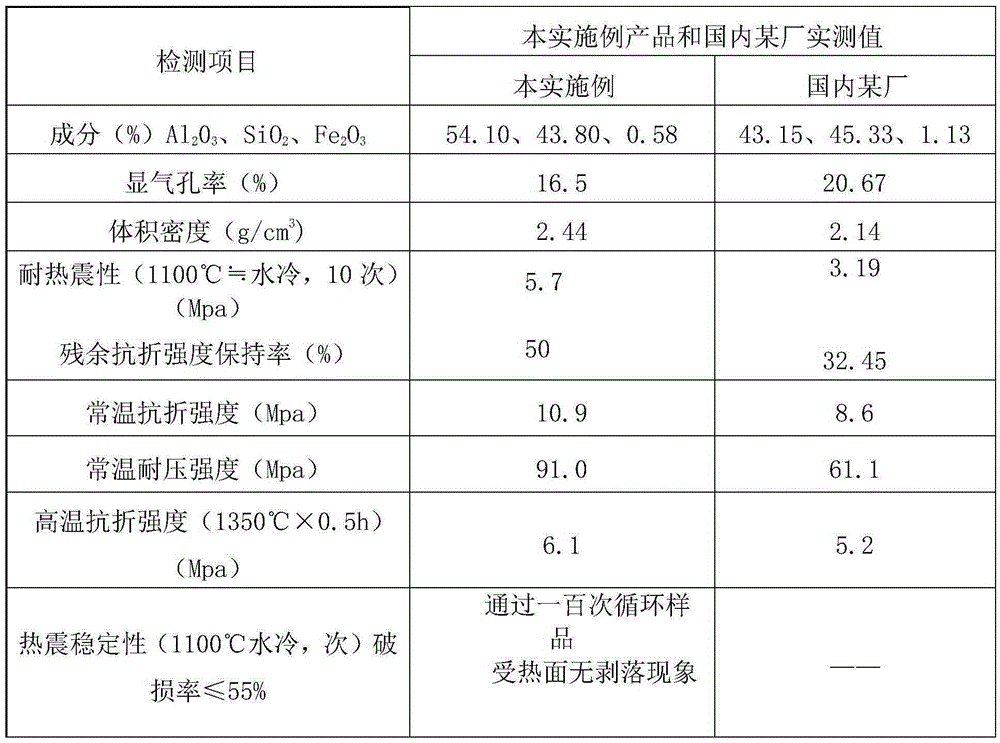

Carbon-free high-purity aluminum magnesium machine pressing brick for refining steel ladles as well as preparation method thereof

The invention discloses a carbon-free high-purity aluminum magnesium machine pressing brick for refining steel ladles as well as a preparation method thereof. The carbon-free high-purity aluminum magnesium machine pressing brick comprises the following raw materials in parts by weight: 50 to 75 parts of corundum particles, 15 to 35 parts of a corundum fine powder, 1 to 5 parts of an activated aluminum oxide powder, 1 to 55 parts of a calcined aluminum oxide powder, 3 to 7 parts of a metal powder additive, 4 to 10 parts of a magnesium aluminum ultrafine powder binding agent and 1.5 to 4 parts of water. The carbon-free high-purity aluminum magnesium machine pressing brick prepared by the method has the characteristics of compact structure, high normal-temperature, medium-temperature and high-temperature strength, high thermal shock stability, slag erosion resistance, excellent permeability and the like, and can greatly prolong the service life when serving as a steel ladle work lining resistant material.

Owner:ZHEJIANG ZILI HIGH TEMPERATURE TECH CO LTD

High-efficiency and environmentally-friendly hydrate inhibitor

InactiveCN101892038ALower the build temperatureIncrease build pressureDrilling compositionKinetic InhibitorNucleation

The invention provides a high-efficiency and environmentally-friendly hydrate inhibitor, and relates to the technical field of oil-gas hydrates. The hydrate inhibitor is a mixture of a dynamic inhibitor, nitrate and acetate. The suitable pressure of the hydrate inhibitor is 1 to 25MPa and the suitable temperature is between -25 and 25 DEG C. The inhibitor can overcome the defects of the prior art; the inhibitor at low concentration is mixed and injected into petroleum and natural gas fluid for production and transportation, so that the speed of nucleation and growth of the hydrate is reduced, the inhibiting effect and the application range of the hydrate inhibitor are greatly increased, and the hydrate inhibitor has the characteristics of wide applicability, economy, high efficiency and environmental protection.

Owner:SOUTH CHINA UNIV OF TECH

High strength thermal shock resistance push plate

The invention discloses a high strength thermal shock resistance push plate, which comprises components with parts by weight: 3-0.5mm mullite particles 20-30 parts, 1-0.5mm alundum particles 15-20 parts, 0.5-0.1mm quartz particles 10-15 parts, 320 meshes andalusite fine powder 15-20 parts, 220 meshes mullite fine powder 25-30 parts, 2Mumalumina micro powder 8-12 parts, 320 meshes alundum fine powder 5-10 parts, silica powder 5-15 parts, zirconite 5-10 parts, cerium oxide 0.5-2 parts, cerium oxide 2-10 parts, aluminum 5-10 parts, silicon 10-15 parts, white mud 10-15 parts and external binders 1-3 parts. The invention further discloses a method for preparing the high strength thermal shock resistance push plate. The high strength thermal shock resistance push plate is excellent in thermal shock resistance, high in mechanical strength, simple in preparation method and convenient for actual operation.

Owner:ANHUI NINGHUO NEW MATERIAL

Novel mixed matrix membrane for gas separation, and preparation method thereof

ActiveCN109173752AHigh strengthIncreased durabilitySemi-permeable membranesFiltration membraneSio2 nanoparticle

The invention discloses a novel mixed matrix membrane for gas separation and a preparation method thereof, belonging to the technical field of gas separation membranes. The matrix membrane comprises adouble-layer structure, wherein a lower layer is a support membrane, and an upper layer is a filtration membrane; the support membrane is a polysulfone porous membrane; the filtration membrane is a polymer membrane prepared through fusing-stretching of a high polymer material and a zeolite-AlN / SiO2 nanoparticle having a porous structure and used as an additive. The objective of the invention is to provide the novel mixed matrix membrane for gas separation and the preparation method thereof. The porous nanoparticle with a high specific surface area is added into the mixed matrix membrane so asto allow the mixed matrix membrane to have good mechanical properties, excellent permeation performance and excellent separation and selection performance; and the mixed matrix membrane has excellentseparation effect on gases.

Owner:杭州博大净化设备有限公司

High-efficiency hydrate inhibitor containing corrosion inhibitor

The invention discloses a high-efficiency hydrate inhibitor containing corrosion inhibitor, which relates to the technical field of oil-gas hydrate. The hydrate inhibitor is a mixture of anti-agglomerant, inorganic salt and corrosion inhibitor. The use condition of the hydrate inhibitor is as follows: the pressure is 1.5 to 25 MPa, the temperature is minus 20 DEG C to 25 DEG C, and the volume percentage of systematic water is lower than 50 percent. The hydrate inhibitor can overcome the deficiency of the prior art, can be mixed at low concentrate and injected into oil flow in production or delivery, reduce the speed of nucleation, growth and agglomeration of the hydrate, and simultaneously reduce the corrosion rate of pipelines, slow down the corrosion and damage of salt to the pipelines,and is characterized by wide applicability, low cost and no corrosion to the pipelines.

Owner:SOUTH CHINA UNIV OF TECH

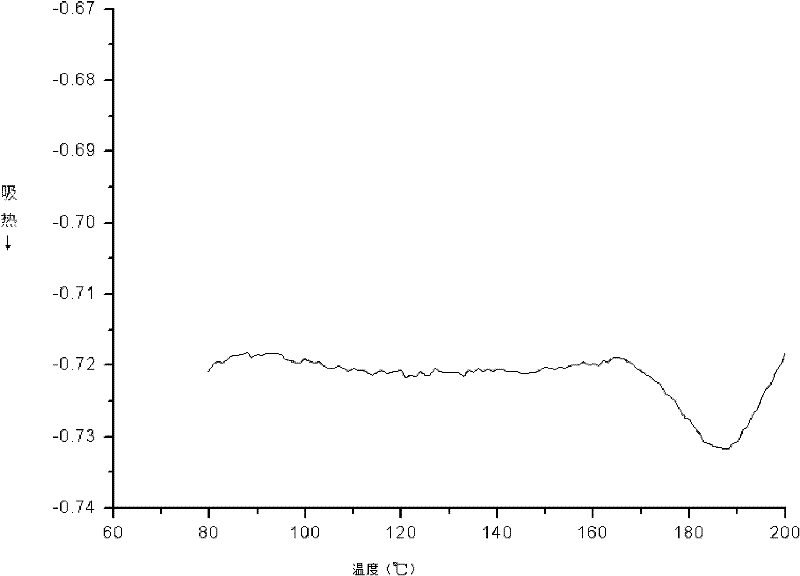

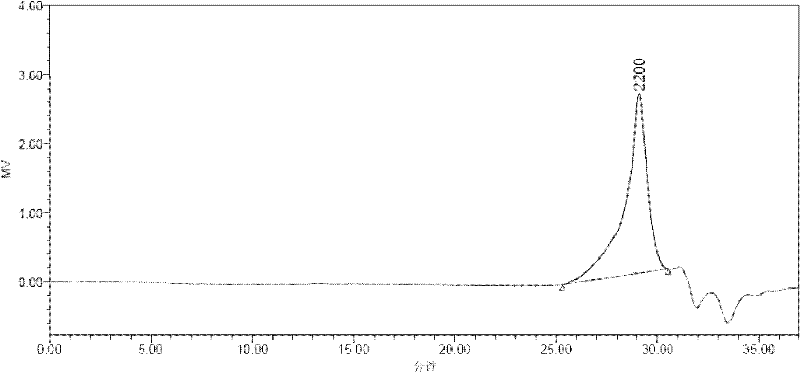

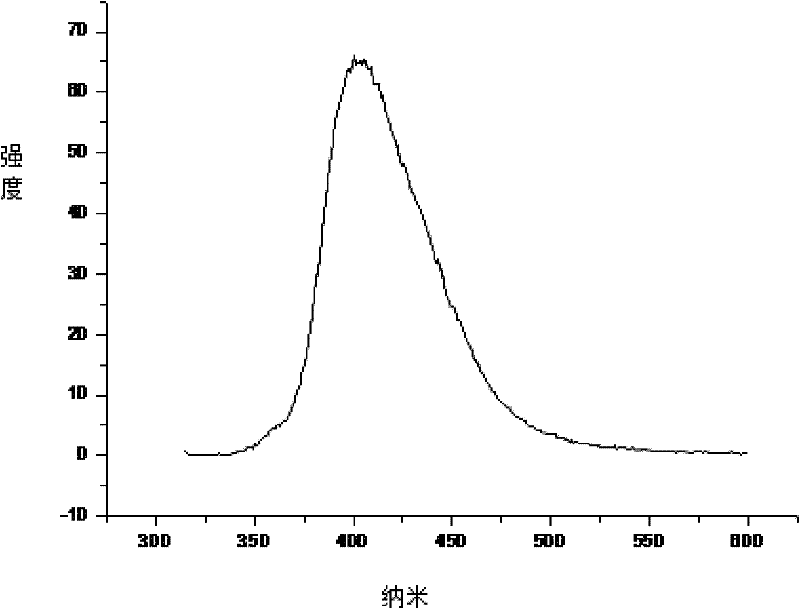

Preparation method of carbazole schiff base copolymer

InactiveCN102241821ANo pollution in the processHigh purityLuminescent compositionsCarbazoleFluorescence

The invention belongs to the field of polymer electroluminescent materials, and in particular relates to a preparation method of a carbazole schiff base copolymer. According to the preparation method, condensation reaction is preformed on an aldehyde group and an amino group to synthesize a carbazole ring containing schiff base copolymer of a large molecular weight. The main chain of the preparedcopolymer contains a carbazole group and a schiff base group, wherein the glass transition temperature reaches 178 DEG C, the molecular weight reaches 2200 and the fluorescent maximum peak is 400nm. Shown by the data, the product has better heat resisting property and excellent hole transport capacity, and can excite blue light with higher luminance purity.

Owner:BEIJING UNIV OF CHEM TECH

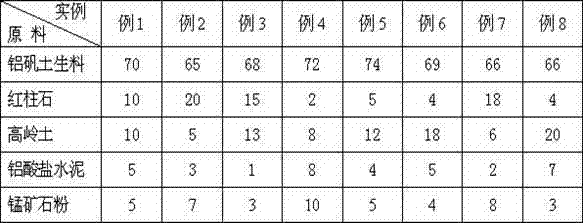

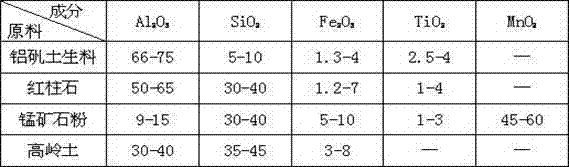

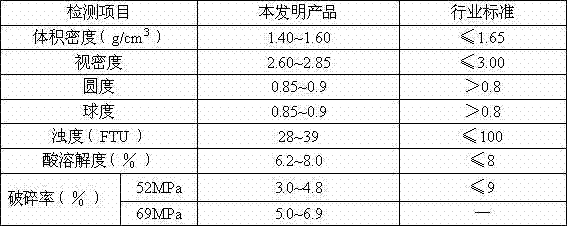

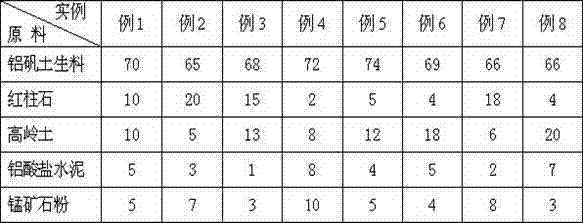

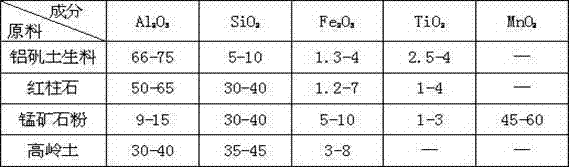

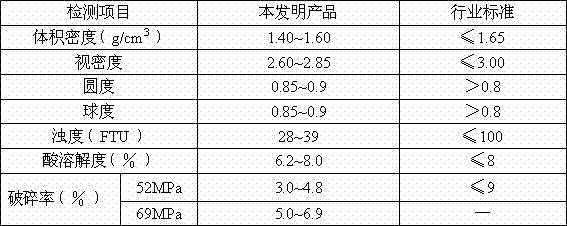

Low-density high-strength andalusite fracturing proppant and production method thereof

ActiveCN102268248ACompatibility is reasonableHigh compressive strengthFluid removalKaolin clayEngineering

The invention relates to a low-density high-strength andalusite fracturing propping agent and a production method thereof. The raw materials comprise: 65-75% of bauxite raw meal, 2-20% of andalusite, 5-20% of kaolinite, 1-8% of calcium aluminate cement, 3-10% of manganese ore powder. The production method comprises the following steps: weighing raw materials, grinding into fine powder, sieving, well mixing, adding into a rotating granulator for granulation, adding atomized aqueous vapor till the mixture becomes a spherical semifinished product, drying; sintering the semifinished product in a rotary kiln for 6-10 h with a kiln head temperature of 1300-1400 DEG C and a kiln tail temperature of 280-320 DEG C, taking the product out of the kiln to obtain a finished product. The product of theinvention has broken rates of 4.8% and 6.9% under pressures of 52 MPa and 69 MPa respectively, and has strength higher than that of other products of the same kind; the product has bulk density of 1.40-1.60 g / cm3, and apparent density of 2.60-2.85 g / cm3, and the density is lower than industrial standard; the product has high surface fineness, and can effectively reduce cost of petroleum fracturing.

Owner:郑州德赛尔陶粒有限公司

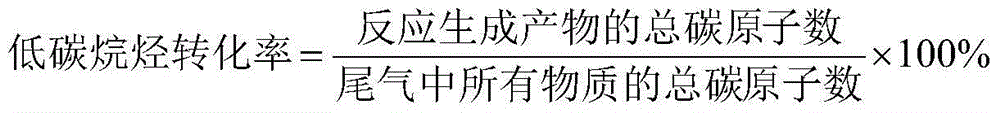

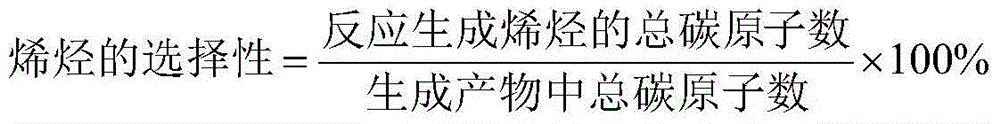

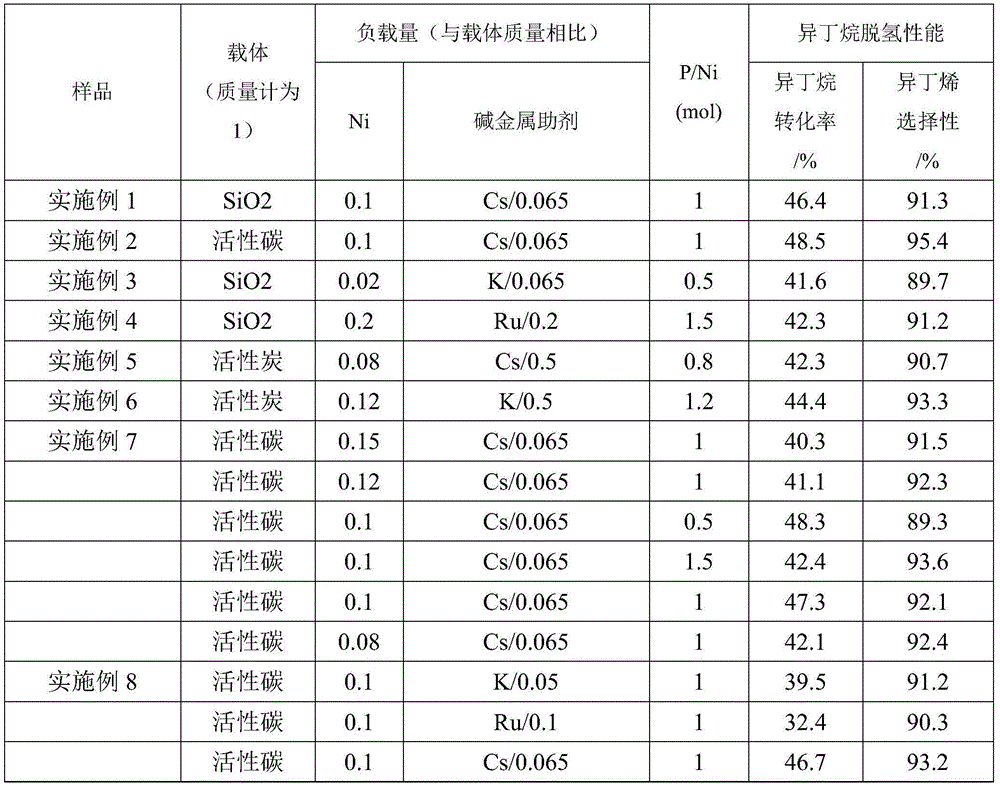

Low alkane-to-olefin catalyst by dehydrogenation and preparation method

InactiveCN105214697AGood dispersionReduce surface acidityPhysical/chemical process catalystsHydrocarbonsAlkaneDehydrogenation

The invention discloses a low alkane-to-olefin catalyst by dehydrogenation and a preparation method. The catalyst is loaded with nickel phosphide and alkaline metals by taking SiO2 spheres or active carbon spheres as a carrier, wherein the mass ratio of the carrier to Ni to the alkaline metals is 1: (0.02-0.2): (0.01-0.2) and the P / Ni molar ratio is 0.5-1.5. In the aspect of dehydrogenation performance of the low-carbon alkane of the catalyst, compared with commercially available d Pt-serial catalysts, the iso-butane conversion ratio is slightly high, and the iso-butane selectivity is equivalent. However, compared with the existing industrially applied PT-serial catalyst preparation process, the preparation cost is low. Compared with Cr-serial catalysts, the catalyst further has a good environmental-friendly advantage.

Owner:TIANJIN UNIV

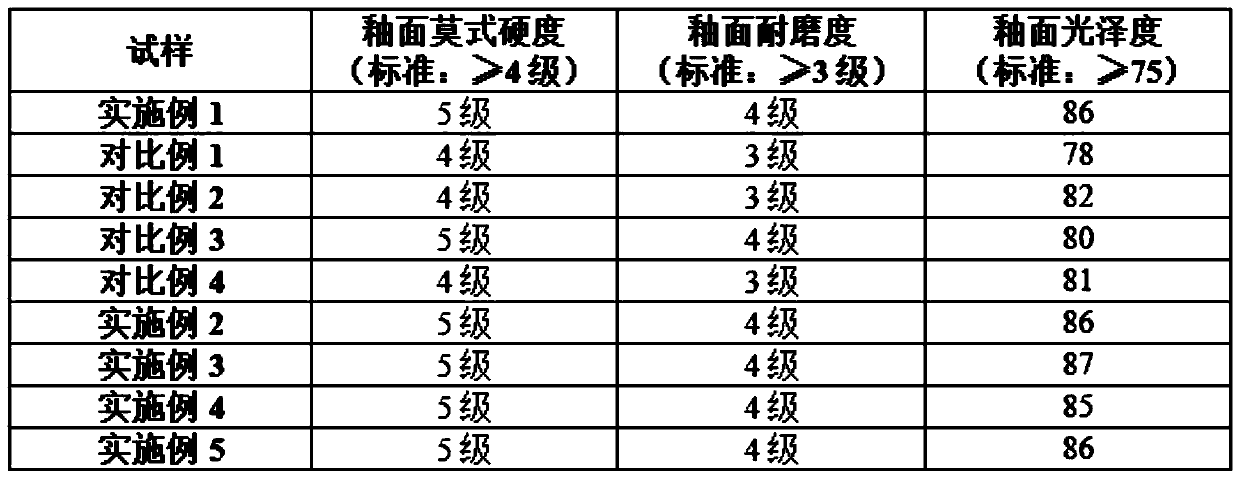

Wear-resistant transparent glaze, wear-resistant glazed brick and preparation method thereof

The invention discloses a wear-resistant transparent glaze that is prepared from the following raw materials in percentage by weight: 3 to 7 percent of nanoscale anorthite, 20 to 30 percent of albite,18 to 28 percent of fused quartz, 6 to 10 percent of kaolin, 40 to 50 percent of transparent frit, 0.01 to 0.5 percent of dispersing agent and 0.01 to 0.1 percent of plasticizer. By introducing special raw material components such as nanoscale anorthite, fused quartz and transparent frit, the raw material components of the glaze can play a synergistic effect in the conventional fusing and firingprocess, so a large amount of anorthite crystalline phases can be efficiently generated, and then the hardness, wear resistance and light transmission performance of the glaze are effectively and synchronously improved.

Owner:GUANGXI OCEANO CERAMICS CO LTD

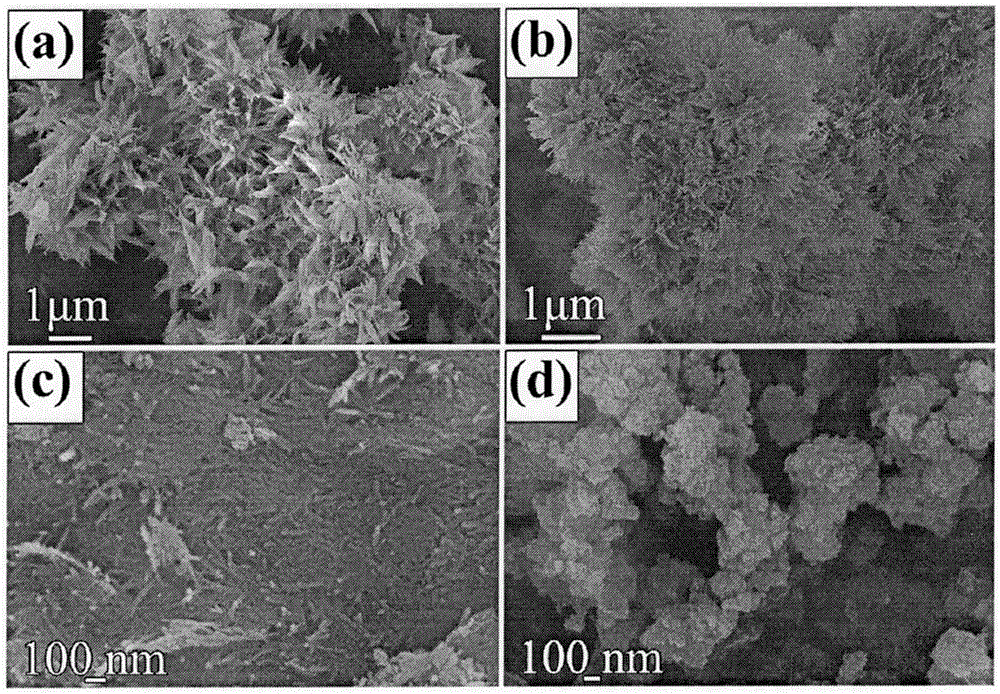

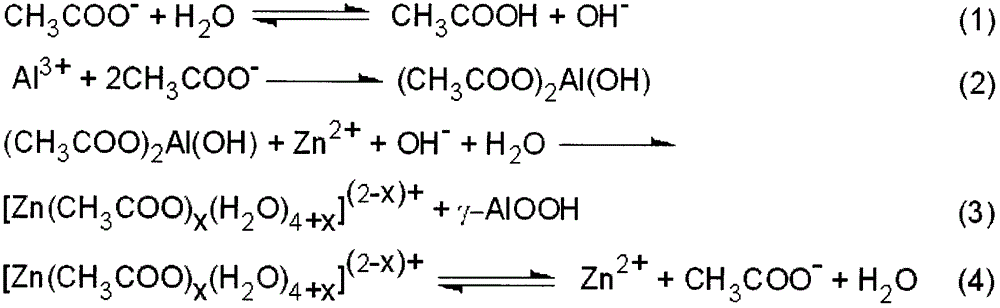

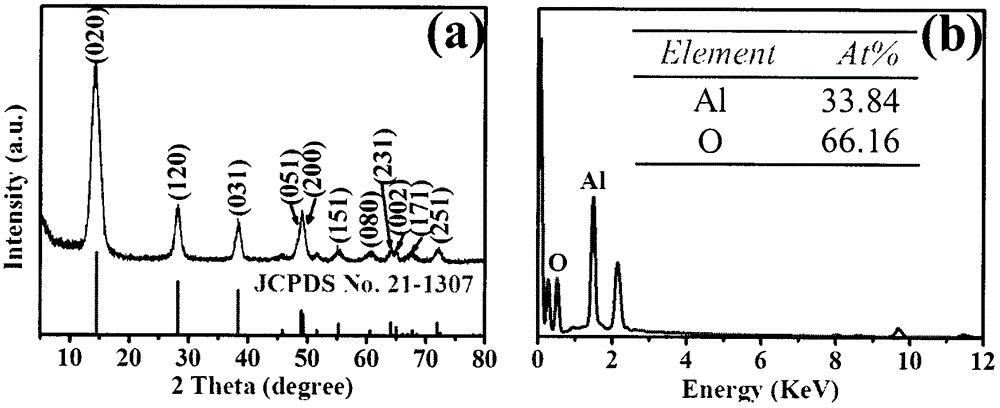

Preparation method of gamma-AlOOH and gamma-Al2O3 nanotube and nanostructure

InactiveCN105948087ALower the build temperatureReduce pressure requirementsMaterial nanotechnologyAluminium oxide/hydroxide preparationMuffle furnaceAluminium salts

Disclosed is a method for preparing gamma-AlOOH and gamma-Al2O3 through ionic-liquid-assisted hydrothermal synthesis. The method is characterized in that divalent metal ions are utilized to drive a decomposition reaction of a precursor so as to generate gamma-AlOOH in a mild condition. The method comprises main steps: 1) dissolving aluminium salt, an ionic liquid and divalent metal ions in deionized water according to different ratios, and performing uniform stirring; 2) transferring the obtained solution to a reactor and performing a reaction at different reaction temperatures for a while; 3) after the reaction is over, performing cooling to the room temperature, performing centrifugalization, performing alternate washing with deionized water and absolute ethanol, and performing drying to obtain a precursor of gamma-AlOOH; and 4) putting the precursor of gamma-AlOOH in a muffle furnace, and carrying out calcination to obtain a gamma-Al2O3 nanometer material with the identical shape. According to the method, gamma-AlOOH in the shape of a needle-shaped crystal whisker, a nanotube, and a bamboo-leaf-shaped nanometer flower and gamma-Al2O3 converted from gamma-AlOOH are synthesized. The obtained gamma-Al2O3 is relatively high in degree of crystallinity and specific surface area and has comparatively high potential of large-scale production.

Owner:NANKAI UNIV

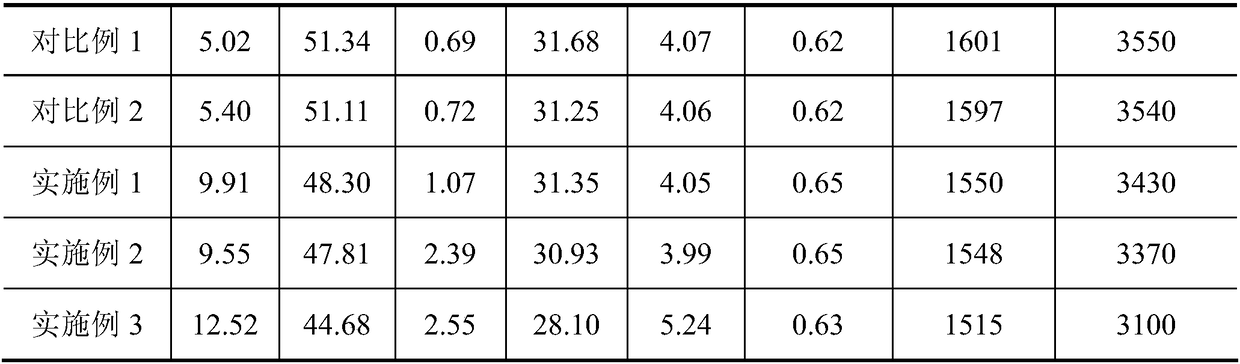

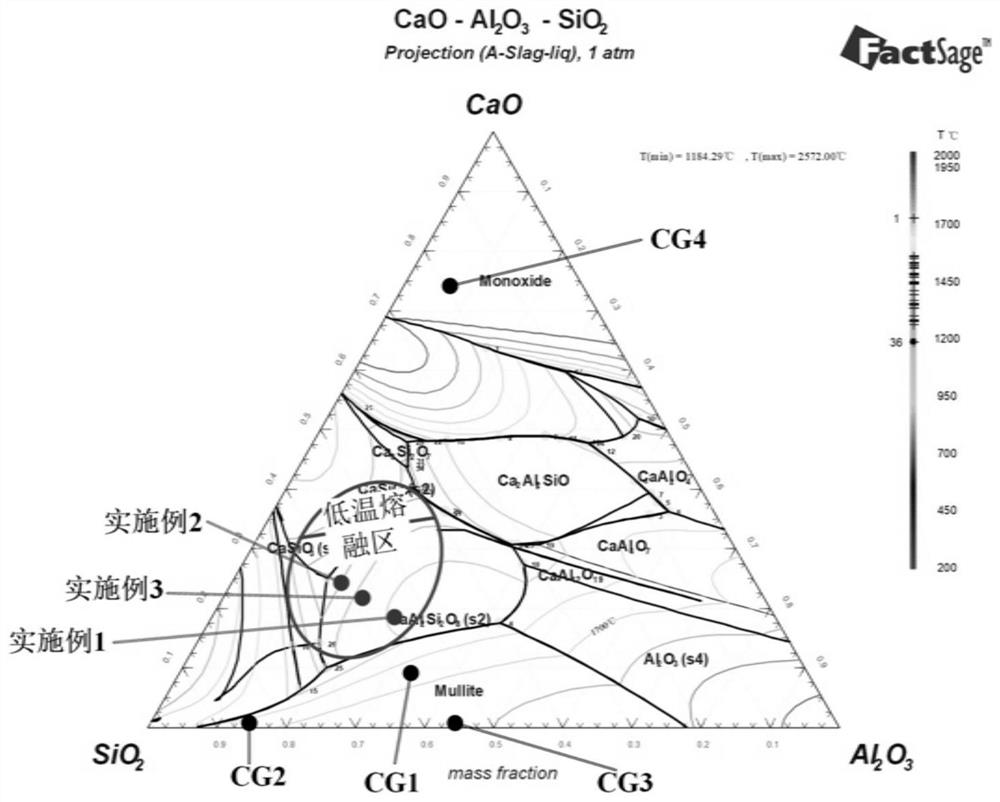

Ceramsite preparation method using waste incineration fly ash and ceramsite prepared by method

PendingCN113213891ALower the build temperatureAids in melt solidificationCeramic materials productionClaywaresProcess engineeringEnvironmental engineering

The invention discloses a preparation method of ceramsite by utilizing waste incineration fly ash and the ceramsite prepared by the preparation method. According to the invention, the waste incineration fly ash is used as a raw material, limestone and a high-silicon substance are added, and the generation amount of a liquid phase in a roasting process is controlled by regulating and controlling the mass ratio of the main components as follows: CaO / SiO2=0.2-0.35, and (SiO2+Al2O3) / (CaO+Fe2O3+MgO)=5-8. Therefore, the cylinder compressive strength of the ceramsite is improved, and the roasting temperature is reduced. The waste incineration fly ash, the limestone, the high-silicon substance and water are uniformly mixed according to the mass ratio, pelletizing is conducted, drying is conducted, and roasting is conducted at the temperature of 800-1200 DEG C for 5-30 minutes to obtain the ceramsite with excellent performance. The method has the advantages of being simple in process, low in production cost, high in resource utilization rate, environmentally friendly and the like, thorough detoxification and efficient resource utilization of the waste incineration fly ash can be synchronously achieved, raw materials can be provided for the ceramsite industry, and dependence on natural raw materials is reduced.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Method for coating chromium carbide on diamond micro powder surface

ActiveCN106925775AAbundant raw materialsLow priceTransportation and packagingMetal-working apparatusChromium carbideMicrowave oven

The invention discloses a method for coating chromium carbide on a diamond micro powder surface, and belongs to the field of diamond surface treatment. The method comprises the following main steps of: putting pretreated diamond micro powder into a chromium ammonium salt containing solution to uniformly stir, heating to prepare a precursor, and putting the precursor into a microwave oven; performing heating and plating under flowing protective atmosphere; and finally, performing cleaning treatment, thereby obtaining diamond micro powder coated with chromium carbide on surface. According to the method disclosed by the invention, operations are simple, raw materials are cheap and easily available, coating efficiency is high, cost is high, and relatively high binding force is provided between the coating and diamond.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

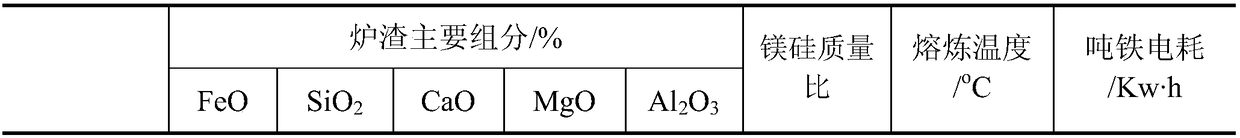

Method for reducing energy consumption of ferronickel production adopting RKEF technology

The invention provides a method for reducing the energy consumption of ferronickel production adopting an RKEF technology. According to the method, pre-reduced calcine with the content of ferrous oxide of 15-25% serves as early slags for smelting, and the content of the ferrous oxide in final slags is controlled to be 5-15% in the smelting process; the early slags comprise CaO, MgO, Al2O3, SiO2 and FeO; and in the early slags, the mass percentage of calcium oxide is 1-10%, the mass percentage of aluminum oxide is 2-10%, and the mass ratio of magnesium to silicon 0.5-0.7. according to the method, by means of reasonable selection, regulation and control of a laterite-nickel ore slag system, the reduction atmosphere is enhanced to selectively reduce iron oxide in the pre-reducing and smeltingprocesses, under the common regulation and control effect of different components of the slag system, the generation temperature of early slag liquid phase of laterite-nickel ore materials in an electric furnace is decreased, the generation speed is increased, the smelting temperature is decreased by 50-90 DEG C, and therefore the electricity consumption required for smelting the ferronickel canbe effectively reduced. The method has the advantages that the technological energy consumption of production of the ferronickel using the laterite-nickel ore and adopting RKEF technology can be remarkably reduced, and the production cost of the ferronickel can be lowered by 5-10%.

Owner:CENT SOUTH UNIV

Low temperature high-performance silicon carbide film and preparation method thereof

InactiveCN109761612AReduce resistanceGood alkali resistanceSemi-permeable membranesCeramicwareRare earthNetwork structure

The invention relates to a low temperature high-performance silicon carbide film and a preparation method thereof. The preparation method comprises the steps that oxidation of silicon carbide powder in high temperature environment is utilized for generating silicon dioxide on the surfaces of particles, silicon dioxide reacts with added nanoscale alumina sol coating the surfaces of the silicon carbide particles to build a mullite network structure, the particle interface strength is enhanced, liquid phase generating temperature is lowered by utilizing existence of nanoscale rare earth oxide molecules, growth of mullite seed crystals is inhibited, so that the aggregate molecular grain size in the film is even, and accordingly the resistance of the film is reduced. The atmosphere does not need to be controlled in the burning process of the silicon carbide film layer, and the oxidation degree of silicon carbide is adjusted through the burning temperature and the adding proportion of alumina sol. The whole preparation technology is simple and controllable, the burning temperature of the film is greatly lowered compared with that of an existing silicon carbide film, burning energy consumption is correspondingly remarkably reduced, and the preparation cost is saved greatly.

Owner:SHANDONG RES & DESIGN ACADEMY OF IND CERAMICS

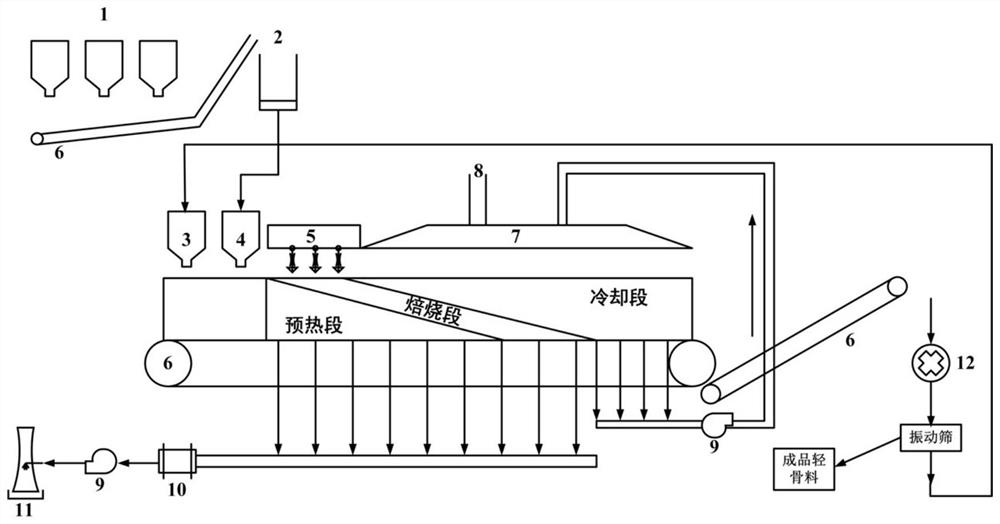

Method for preparing lightweight aggregate through low-temperature self-heating sintering of multiple types of coal gangues

ActiveCN113387605AEasy to handleRealize multi-level utilizationCeramic materials productionCeramicwareUltimate tensile strengthParticle-size distribution

The invention discloses a method for preparing lightweight aggregate through low-temperature self-heating sintering of multiple types of coal gangues. The method comprises the following steps: crushing, proportioning, mixing, granulating, distributing, igniting, sintering, cooling, crushing and screening multiple different types of coal gangues in sequence to obtain the lightweight aggregate with the density grade of 500-700. According to the method, multiple types of coal gangues are matched and combined for use, the lightweight aggregate with small density and high mechanical strength is obtained through self component adjustment under the condition of not additionally using a sintering additive, and a large amount of multiple types of coal gangue solid waste can be consumed at the same time; in the preparation process of the lightweight aggregate, the aim of reducing the sintering temperature is achieved by adjusting the particle size distribution and proportion of the raw materials, so that the addition of a fluxing agent can be avoided; and the method realizes low energy consumption, high yield and low cost in the production process of the coal gangue lightweight aggregate, has the advantage of large quantity by utilizing a sintering machine for treatment, and is beneficial to large-scale popularization and application.

Owner:CENT SOUTH UNIV

Method for producing land plaster whiskers from phosphoric acid

InactiveCN1314840CLower the build temperatureShortened growth timePolycrystalline material growthFrom normal temperature solutionsPhosphorous acidChemical reaction

Production of gypsum in phosphorous liquid involves preparing a phosphorous extracting liquid and a gypsum crystal whisker suspending liquid. The phosphorous extracting liquid is prepared by extracting 30 - 40% phosphorous acid with ores at 50 - 95deg.C for 2 - 4h, separating liquid phase and filtering to obtain products with H3PO4 3 - 4mol / L and Ca2+ 0.8 - 1.2mol / L. The suspending liquid is prepared by adding the said liquid into 30 - 35% sulfuric acid solution gradually, stirring and reacting at (50 - 100)deg.C for 120 - 150min. Hemi-hydrated or anhydrous gypsum whiskers are obtained after filtering the suspending liquid, cleansing with boiled water, and drying at (120 - 200)deg.C. The process reduces generating temperature and cost in production, shortens production time, and qualifies their performance, so that it can be widely used in production of gypsum whiskers.

Owner:QINGDAO UNIV OF SCI & TECH

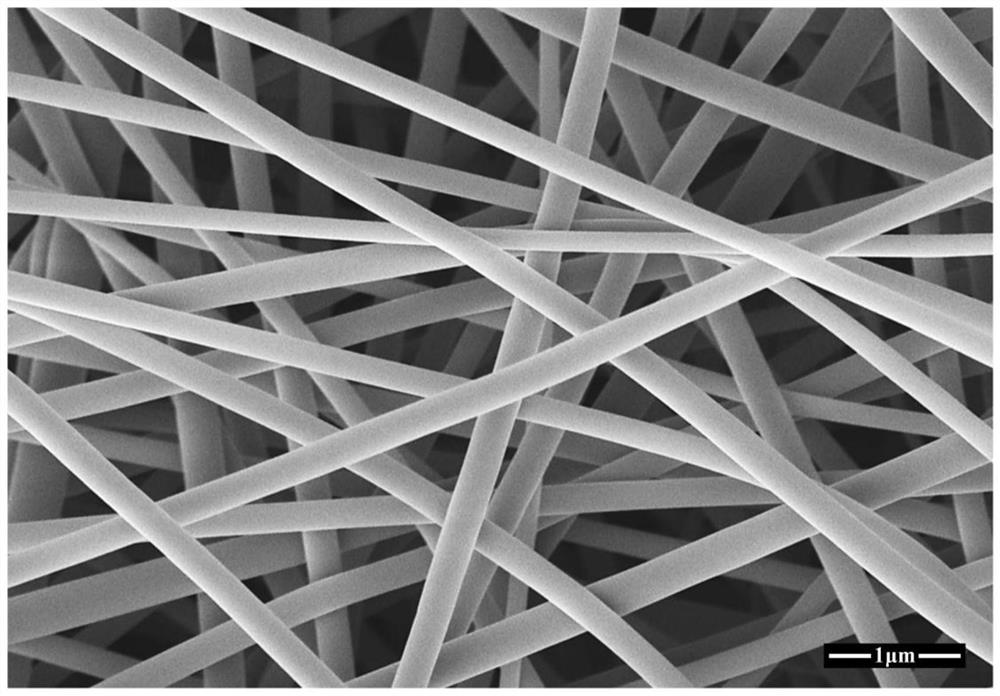

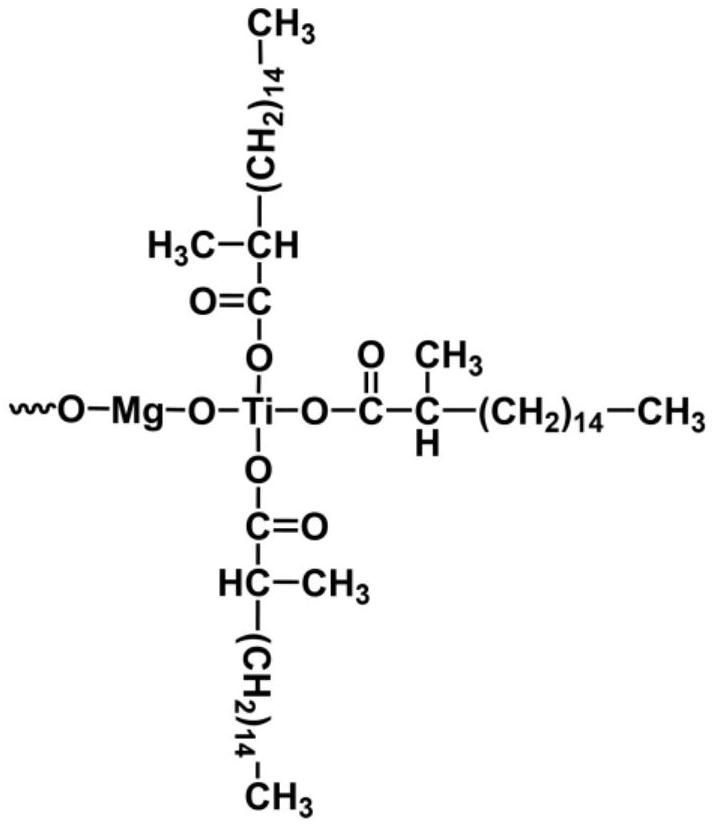

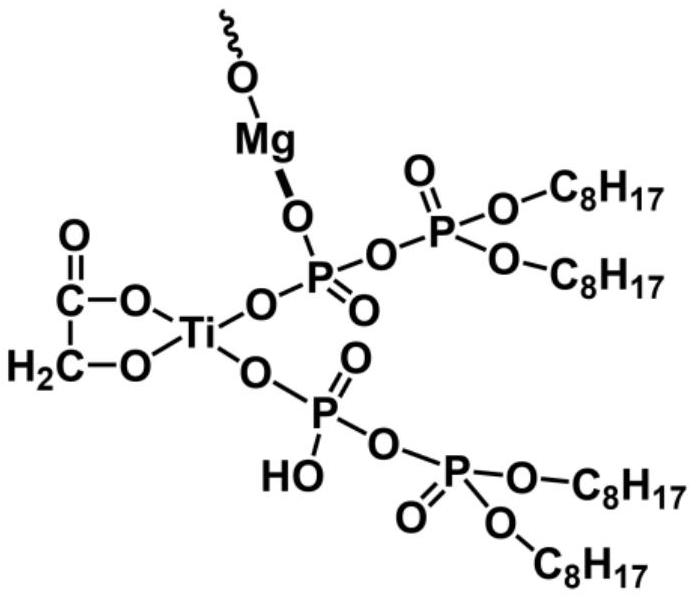

Self-supporting MgTiO3 nanofiber chemical warfare agent degradable material and preparation method thereof

ActiveCN113502596AIncrease elasticityGood stretchabilityHeating/cooling textile fabricsFibre chemical featuresFiberAir atmosphere

The invention discloses a self-supporting MgTiO3 nanofiber chemical warfare agent degradable material and a preparation method thereof. The preparation method comprises the following steps of firstly, preparing a precursor solution composed of magnesium salt, a titanate coupling agent, a grain inhibitor and a solvent; then carrying out electrostatic spinning to obtain a precursor fiber membrane; and finally, calcining the precursor fiber membrane in an inert atmosphere, and then carrying out low-temperature thermal oxidation treatment in an air atmosphere to obtain the self-supporting MgTiO3 nanofiber membrane. The precursor solution with certain viscoelasticity and spinnability is prepared under the condition that a macromolecular spinning aid is not added into the precursor solution, and the MgTiO3 nanofiber membrane obtained after calcination has relatively good flexibility and an excellent chemical warfare agent catalytic degradation effect.

Owner:NANTONG UNIVERSITY

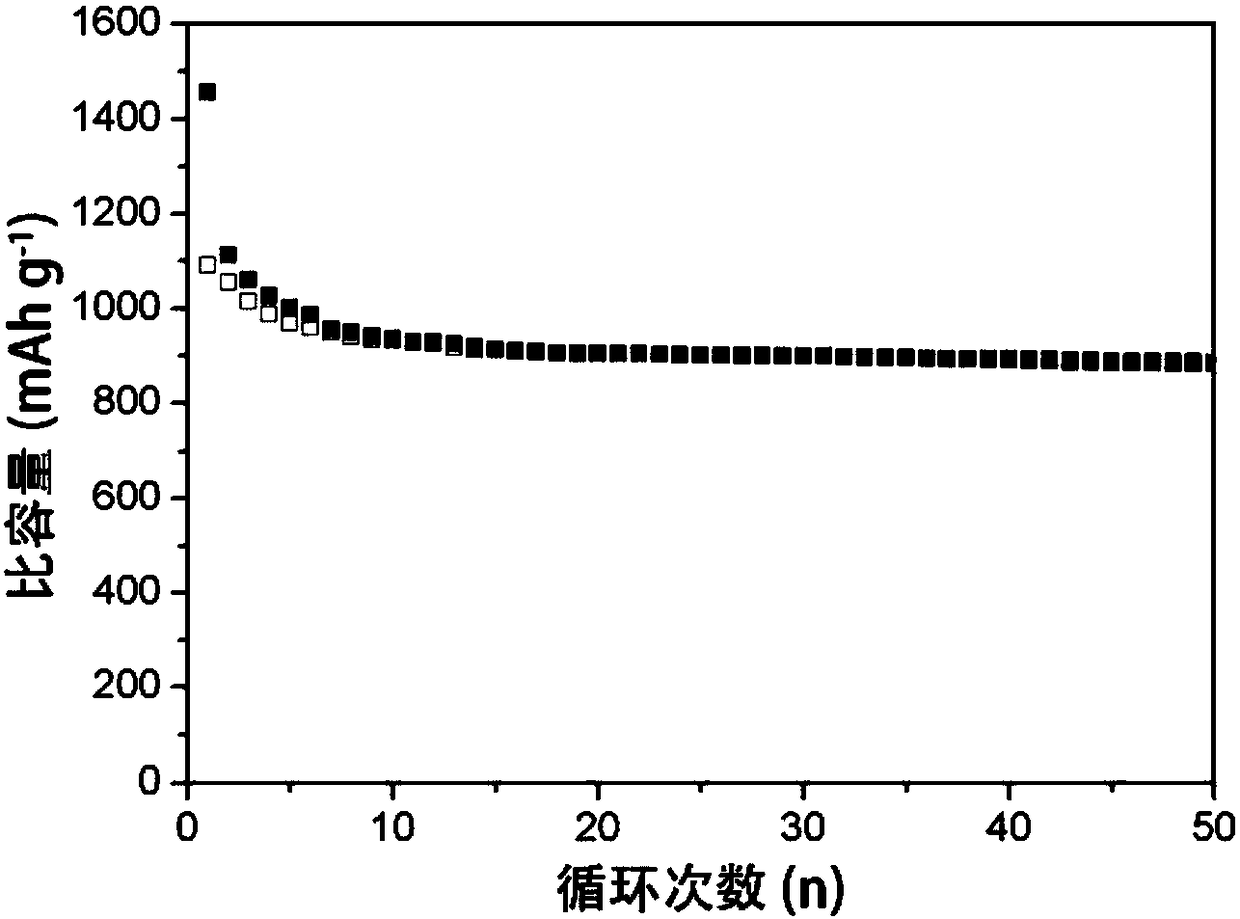

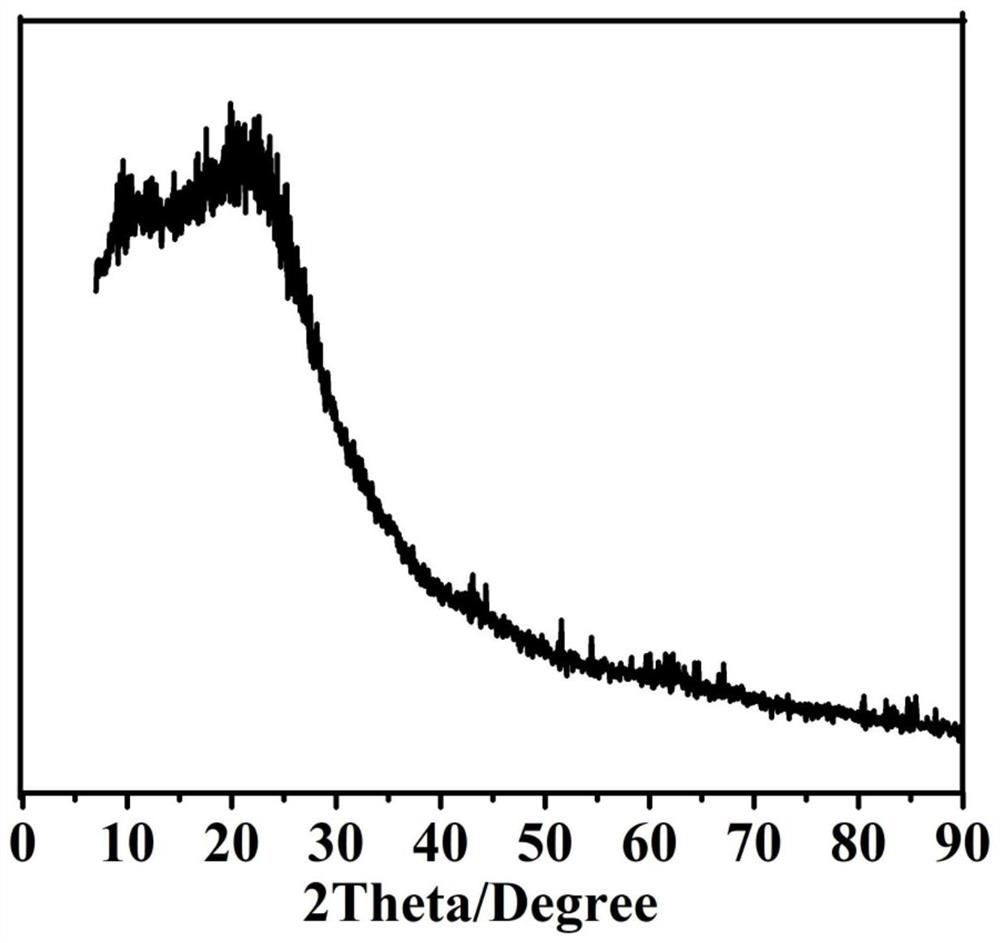

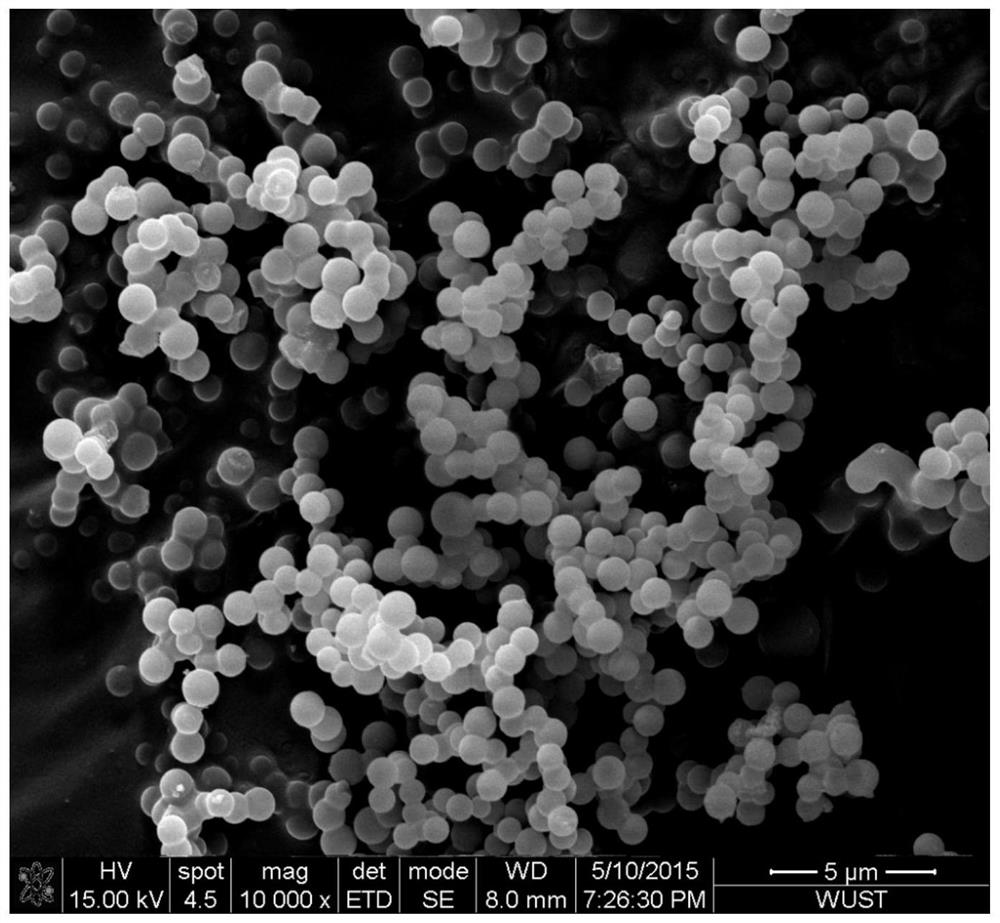

Molybdenum sulfide flexible electrode material and preparation method and application thereof

ActiveCN109285992AReduce manufacturing costLower the build temperatureMaterial nanotechnologyHybrid capacitor electrodesVulcanizationTwo step

The invention relates to a molybdenum sulfide flexible electrode material and a preparation method and application thereof. The method comprises the steps of spraying a single metal on a surface of acotton carbon source, mixing with a molybdenum source, ammonium fluoride and urea to carry out a hydrothermal reaction, after the reaction is completed, conducting solid-liquid separation to obtain aprecursor material, mixing the precursor material with a sulfur source, conducting a second hydrothermal reaction, after the completion of the reaction, performing the solid-liquid separation, and after heat treatment, obtaining the molybdenum sulfide flexible electrode material. The method directly uses a waste cotton material or a material mostly made of cottons as a carbon source and a template, and is economical and environmentally friendly; a metal is used as a catalyst, a two-step vulcanization method is adopted, the formation temperature of molybdenum sulfide is lowered, and the flexibility and integrity of the cotton material are maintained; the prepared molybdenum sulfide flexible electrode material has excellent electrochemical performance when used as a negative electrode material for lithium ion batteries, the reversible specific capacity of charge and discharge for the first time can reach 800-1400 mAh / g, and the molybdenum sulfide flexible electrode material has broad application prospects.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

High-entropy carbide nano-powder material with high sphericity degree and high activity as well as preparation method and application of high-entropy carbide nano-powder material

ActiveCN114180965AHigh sphericityLower the build temperatureMaterial nanotechnologyMicrosphereHigh activity

The invention belongs to the technical field of high-entropy ceramics, and particularly relates to a high-entropy carbide nano-powder material with high sphericity degree and high activity and a preparation method and application thereof, the chemical formula of the material is XC, X is at least four of Ti, Zr, Hf, V, Nb, Ta, Cr, Mo and W, but Mo and W cannot be contained at the same time; the preparation method comprises the following steps: firstly, preparing high-activity carbon microspheres with high specific surface area, low graphitization degree and high sphericity degree as a carbon source by adopting a hydrothermal carbonization method; then uniformly loading four or more than four transition metal salts containing metal cations with equal molar weight on the surfaces of the carbon microspheres, and carrying out hydrothermal reaction to obtain a high-entropy carbide precursor; and finally carrying out vacuum heat treatment. The high-entropy carbide nano-powder with high sphericity degree and high activity prepared by the method can be widely applied to preparation of high-temperature carbide thermal barrier coatings and carbide-enhanced metal ceramic-based composite materials, the hardness, wear resistance and corrosion resistance of the materials are remarkably improved, and the service life is prolonged.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Method for preparing chromium-nickel-containing iron ore oxidized pellets from chromite and laterite-nickel ore

The invention discloses a method for preparing chromium-nickel-containing iron ore oxidized pellets from chromite and laterite-nickel ore. The method comprises the following steps that (1) the pretreated chromite, the laterite-nickel ore, magnetite and a flux are mixed, then pelletizing is performed to obtain green pellets, and the flux is quicklime; and (2) the prepared green pellets are roasted, and the chromium-nickel-containing iron ore oxidized pellets are obtained. A new way is provided for efficient and comprehensive utilization of the chromite and the laterite-nickel ore. The pellets can be used as raw materials for smelting chromium-nickel-containing stainless steel mother liquor in a smelting reduction furnace, an electric furnace, a blast furnace and the like, the produced stainless steel mother liquor can replace part of ferrochrome and ferronickel, and the high-quality furnace charge is provided for smelting stainless steel.

Owner:GUIZHOU UNIV

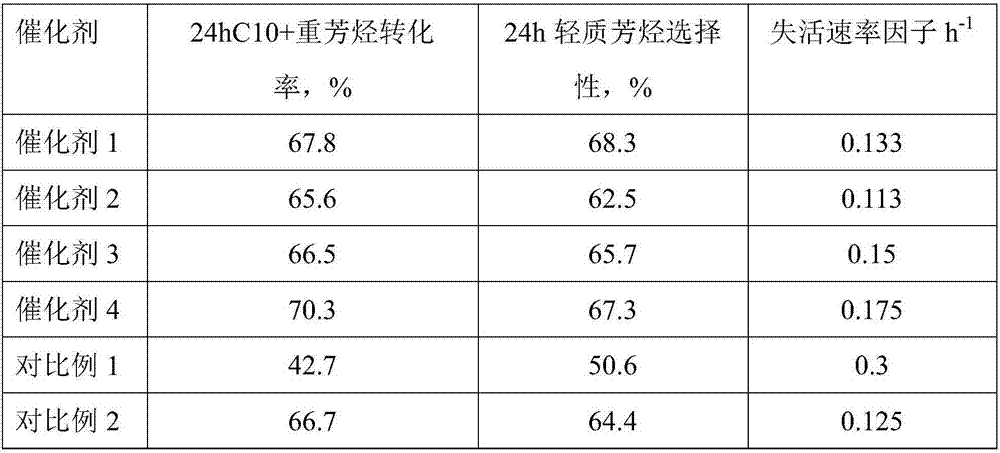

Method for preparing non-noble metal catalyst for light fraction conversion of C10<+> heavy aromatics

ActiveCN107376984AReduce reactivityLower the build temperatureMolecular sieve catalystsRefining by aromatic hydrocarbon hydrogenationSorbentALUMINUM PHOSPHATE

The invention relates to a method for preparing a non-noble metal catalyst for light fraction conversion of C10<+> heavy aromatics. According to the catalyst disclosed by the invention, elemental nickel and nickel phosphide (Ni2P) serve as an active phase, and a molecular sieve and alumina serve as a carrier. With the adoption of a competition adsorbent, the problem that the alumina in the carrier is reacted with phosphorus to produce aluminum phosphate so as to greatly reduce the reaction activity of the catalyst is solved; with the adoption of a low-boiling-point organic matter with strong reducing property, the nickel phosphide phase production temperature is reduced, the nickel phosphide particle aggregation is reduced, and the catalyst activity is greatly improved; the non-noble metal hydrogenation activity phase is adopted to replace noble metals, so that the catalyst cost is greatly reduced.

Owner:CHINA NAT OFFSHORE OIL CORP +2

High-efficiency hydrate inhibitor containing corrosion inhibitor

ActiveCN101666427BSuppress generationLower the build temperaturePipeline systemsInorganic saltsNucleation

Owner:SOUTH CHINA UNIV OF TECH

Efficient hydrate inhibitor

ActiveCN101608112ASuppress generationLower the build temperatureDrilling compositionPetroleumEthylene glycol

The invention provides an efficient hydrate inhibitor, relating to the technical field of oil-gas hydrate. The hydrate inhibitor is a mixture of an anti-agglomerant and a glycol or an isopropanol and is used at the pressure of 1.5 to 25 MPa and at the temperature of minus 20 DEG C to 25 DEG C. The hydrate inhibitor overcomes the defects of the prior art, reduces the nucleary, the growth and the coalescence speed of hydrate after being filled in petroleum fluid in production or conveying by mixing at low concentration and has the characteristics of wide application and low cost.

Owner:SOUTH CHINA UNIV OF TECH

Low-density high-strength andalusite fracturing propping agent and production method thereof

ActiveCN102268248BCompatibility is reasonableHigh compressive strengthFluid removalKaolin clayEngineering

The invention relates to a low-density high-strength andalusite fracturing propping agent and a production method thereof. The raw materials comprise: 65-75% of bauxite raw meal, 2-20% of andalusite, 5-20% of kaolinite, 1-8% of calcium aluminate cement, 3-10% of manganese ore powder. The production method comprises the following steps: weighing raw materials, grinding into fine powder, sieving, well mixing, adding into a rotating granulator for granulation, adding atomized aqueous vapor till the mixture becomes a spherical semifinished product, drying; sintering the semifinished product in a rotary kiln for 6-10 h with a kiln head temperature of 1300-1400 DEG C and a kiln tail temperature of 280-320 DEG C, taking the product out of the kiln to obtain a finished product. The product of theinvention has broken rates of 4.8% and 6.9% under pressures of 52 MPa and 69 MPa respectively, and has strength higher than that of other products of the same kind; the product has bulk density of 1.40-1.60 g / cm3, and apparent density of 2.60-2.85 g / cm3, and the density is lower than industrial standard; the product has high surface fineness, and can effectively reduce cost of petroleum fracturing.

Owner:郑州德赛尔陶粒有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com