Wear-resistant transparent glaze, wear-resistant glazed brick and preparation method thereof

A technology of transparent glaze and glazed tiles is applied in the field of building ceramic materials, which can solve the problems of poor transparency, non-wear-resistant glass phase, low cordierite hardness, etc., and achieves the effects of increasing growth rate, reducing generation temperature and excellent performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

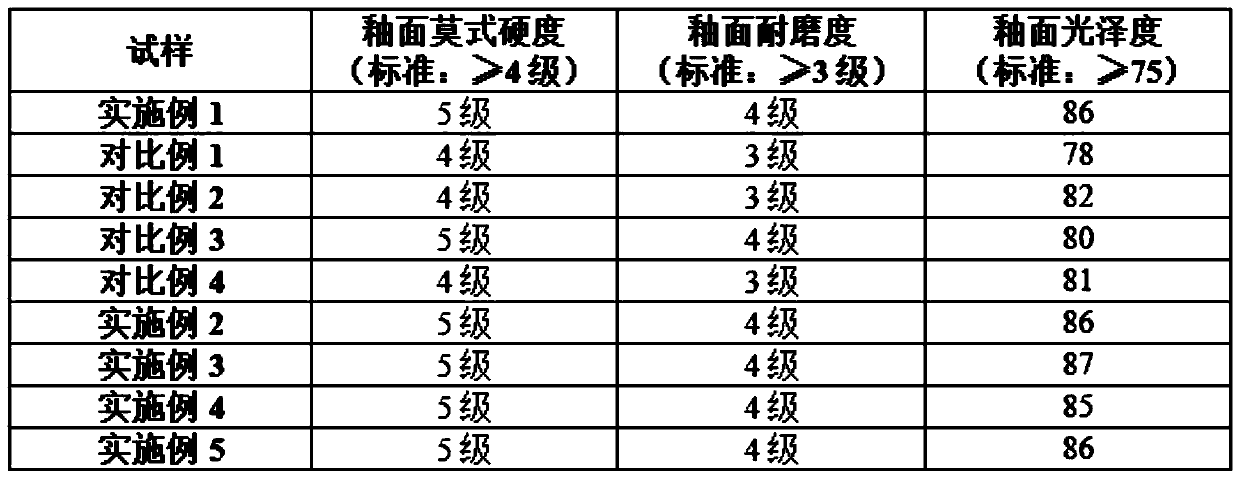

Examples

Embodiment 1

[0025] A wear-resistant transparent glaze, which comprises: 3% of nano-scale anorthite with a particle size of 100nm, 20% of albite, 28% of fused quartz, 6% of kaolin, 42.89% of Transparent frit, 0.01% sodium tripolyphosphate, 0.1% polymethylcellulose.

[0026] Preparation:

[0027] 1) Mix and ball mill 28% calcite, 20% quartz and 45% kaolin according to the weight percentage of raw materials until more than 98% of the particles are less than 50 μm, then dehydrate and dry the dried powder at a temperature of 1450°C Calcining for 2 hours to synthesize coarse anorthite particles, and then crushing, grinding, dehydrating, and drying the anorthite coarse particles to obtain nano-scale anorthite. After testing, the hardness after firing is 6.5, and the density is 2.55g / cm 3 , Refractive index 1.588, spare;

[0028] 2) 23% of calcite, 30% of kaolin, 35% of feldspar, 8% of dolomite, 1% of zinc oxide, 3% of borax are mixed, melted and fired to obtain a transparent frit according t...

Embodiment 2

[0056] A kind of wear-resistant transparent glaze, which comprises: 7% of nano-scale anorthite with a particle size of 10nm, 24.49% of albite, 18% of fused quartz, 10% of kaolin, 40% of Transparent frit, 0.5% sodium tripolyphosphate, 0.01% polymethylcellulose.

[0057] Preparation:

[0058] 1) Mix and ball mill 32% calcite, 16% quartz and 52% kaolin according to the weight percentage of raw materials until more than 98% of the particles are less than 50 μm, then dehydrate and dry the dried powder at 1400°C Calcining for 4 hours to synthesize coarse anorthite particles, and then crushing, grinding, dehydrating, and drying the anorthite coarse particles to obtain nano-scale anorthite. After testing, the hardness after firing is 6 and the density is 2.67g / cm 3 , Refractive index 1.572, spare;

[0059] 2) 28% of calcite, 26% of kaolin, 36% of feldspar, 8% of dolomite, 1% of zinc oxide, 1% of borax are mixed, melted and fired to obtain transparent frit by raw material weight pe...

Embodiment 3

[0062] A wear-resistant transparent glaze, which comprises: 5% of nano-scale anorthite with a particle size of 50nm, 25% of albite, 20% of fused quartz, 8% of kaolin, 41.75% of Transparent frit, 0.2% sodium tripolyphosphate, 0.05% polymethylcellulose.

[0063] Preparation:

[0064] 1) Mix and ball mill 30% calcite, 18% quartz and 52% kaolin according to the weight percentage of raw materials until more than 98% of the particles are less than 50 μm, then dehydrate and dry the dried powder at a temperature of 1425°C Calcining for 3 hours to synthesize coarse anorthite particles, and then crushing, grinding, dehydrating, and drying the anorthite coarse particles to obtain nano-scale anorthite. After testing, the hardness after firing is 6.2, and the density is 2.6g / cm 3, Refractive index 1.58, spare;

[0065] 2) 25% of calcite, 30% of kaolin, 40% of feldspar, 3% of dolomite, 1% of zinc oxide, 1% of borax are mixed, melted and fired to obtain a transparent frit according to th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com