Method for preparing non-noble metal catalyst for light fraction conversion of C10<+> heavy aromatics

A technology for lightening heavy aromatics and non-precious metals, applied in the field of petrochemicals, can solve the problems of low hydrogenation activity, limit technology application, increase catalyst cost, etc., achieve the effect of improving catalyst activity, reducing aggregation, and reducing catalyst cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

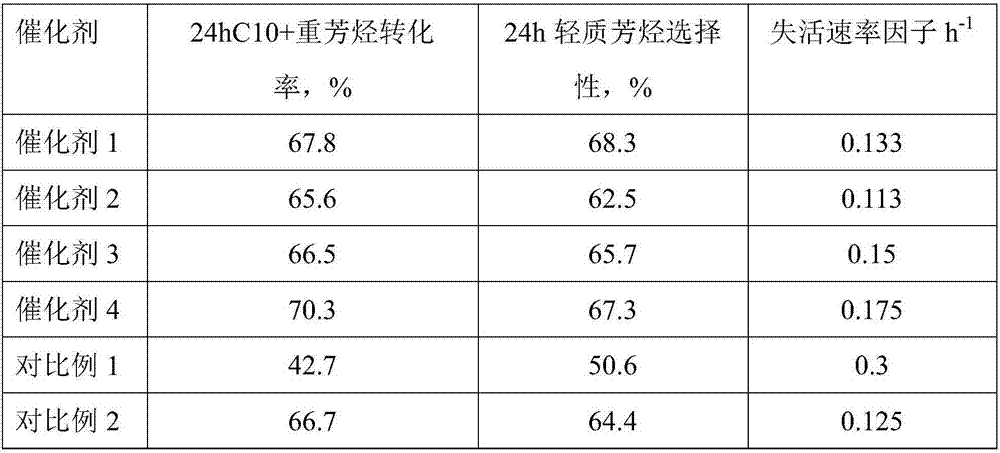

Examples

Embodiment 1

[0037] (1) Mix 65g HY molecular sieve (dry basis) with 25g pseudo-boehmite (dry basis) 4g sesame powder, add a dilute nitric acid solution with a mass concentration of 3%, and extrude the product into the form of Φ2 extrusion material. After air-drying, it was dried at 125°C for 15 hours, and then the temperature was programmed to 550°C and calcined for 8 hours to prepare a catalyst carrier. The water absorption rate of the carrier was measured to be 105%.

[0038] (2) Add the prepared catalyst carrier to 350ml of deionized water, heat the water bath to 50°C, add 39g of nickel nitrate hexahydrate and stir for 24h, put it in a 90°C blast drying oven to dry until there is no obvious residual liquid, and heat to Incubate at 110°C for 12 hours to obtain a nickel-loaded modified carrier.

[0039] (3) Add 4 g of oxalic acid into 94.5 g of deionized water, pour it into the carrier obtained in step (2) and let it stand for 8 hours after it is completely dissolved, and then increase the tem...

Embodiment 2

[0043] (1) Mix 55g HY molecular sieve (dry basis) and 40g pseudo-boehmite (dry basis) 3g sesame powder, add 4% dilute nitric acid solution, and extrude the product into Φ2 extrudate form After being dried naturally, it was dried at 120°C for 20 hours, and then the temperature was programmed to 500°C and calcined for 10 hours to prepare a catalyst carrier, and the water absorption rate of the carrier was measured to be 95%.

[0044] (2) Add the prepared catalyst carrier to 300ml of deionized water, heat the water bath to 60°C, add 51g of nickel nitrate hexahydrate and stir for 20h, put it in a 85°C blast drying oven and dry it until there is no obvious residual liquid, and heat it to Incubate at 120°C for 10 hours to obtain a nickel-loaded modified carrier.

[0045] (3) Add 8 g of formic acid into 90.3 g of deionized water, pour it into the carrier obtained in step (2) after being completely dissolved, and let it stand for 12 hours, and then increase the temperature to 130° C. and d...

Embodiment 3

[0049] (1) Mix 55gHβ molecular sieve (dry basis) with 40g pseudo-boehmite (dry basis) and 3g sesame powder, add 4% dilute nitric acid solution, and extrude the product into Φ2 extrudate form After being dried naturally, it was dried at 120°C for 20 hours, and then the temperature was programmed to 500°C and calcined for 10 hours to prepare a catalyst carrier. At the same time, the water absorption rate of the carrier was measured to be 102%.

[0050] (2) Add the prepared catalyst carrier to 300ml of deionized water, heat the water bath to 60°C, add 51g of nickel nitrate hexahydrate and stir for 20h, put it in a 85°C blast drying oven and dry it until there is no obvious residual liquid, and heat it to Incubate at 120°C for 10 hours to obtain a nickel-loaded modified carrier.

[0051] (3) Add 8 g of oxalic acid into 96.9 g of deionized water, and after completely dissolving, pour it into the carrier obtained in step (2), let it stand for 12 hours, and then raise the temperature to 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com