Patents

Literature

116results about How to "White appearance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Anti bacteria natural silk composite nano-fiber material and its preparation method

InactiveCN1904159AGood tissue compatibilityNon-toxicConjugated cellulose/protein artificial filamentsWet spinning methodsTextile fiberResist

This invention discloses a compound antibacterial silk nanometer fibrous material, accounting for weight its component proportion are: Sericin protein 58-90%; chitosan or chitin 0-40%, antibacterial agent 0-5%, electric conduction 1-4%,crossing linking 1-4%. Its process is: dissolve the pure sericin protein, antibiotics separately in polar solvent, join electric conduction medicinal preparation and crosslinking agent, using the static electricity spinning technique, making the average aperture for 0.5-5.0 micron, factor of porosity 60-90%, the mean diameter is 40-100nm and the material is nanometer textile fiber adhesive-bonded membrane. This invention has good organization compatibility with human body, Antibiotics and sericin insoluble is in homogeneous solvent, massive holes among the nanometer textile fiber adhesive-bonded membrane, which has outstanding aqueous percolation permeability, antibacterial agent distributes evenly in the nanometer textile fiber, and the medicine release effect is perfect, so it can be a kind of ideal resist bacteria injured medical material.

Owner:SUZHOU UNIV

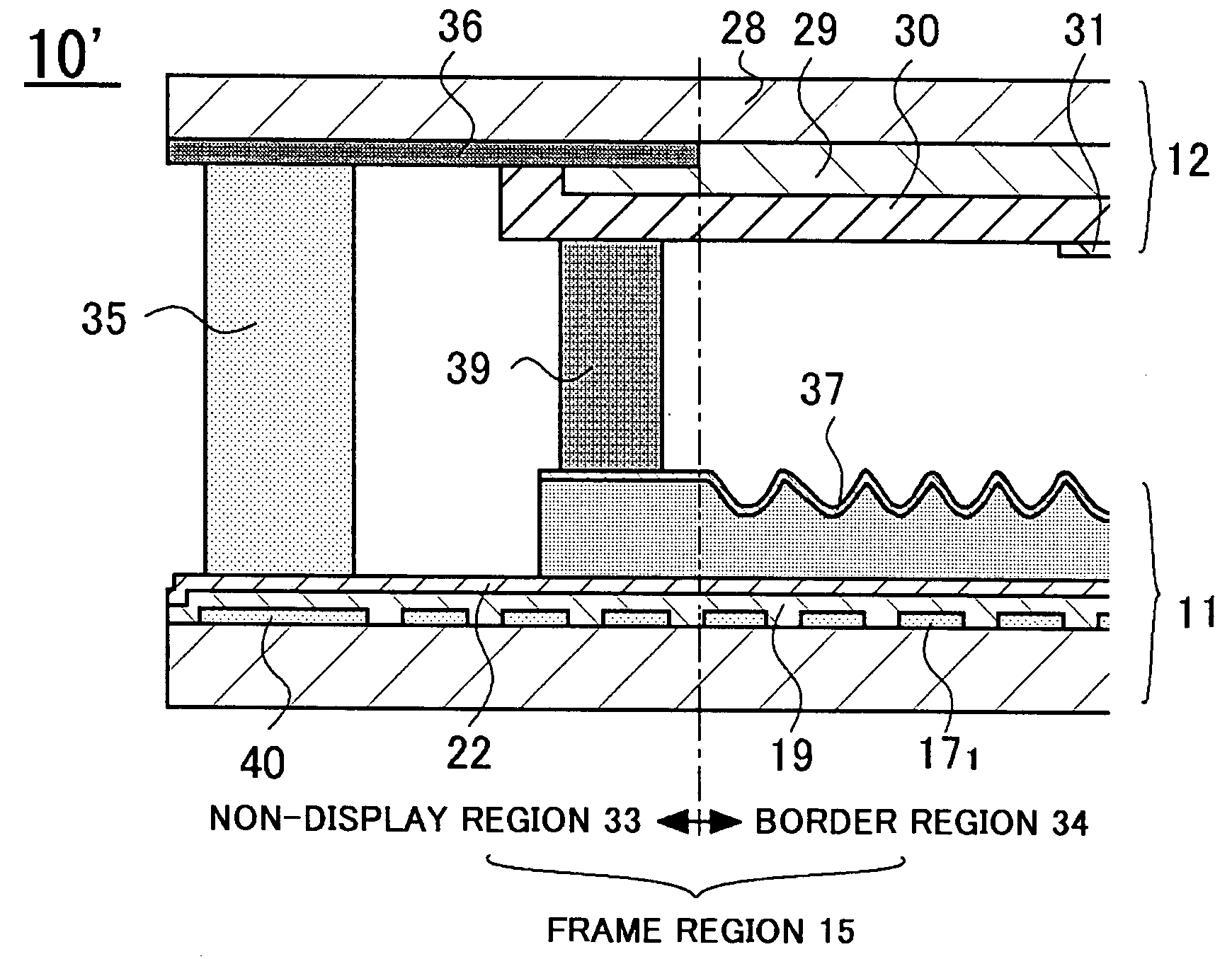

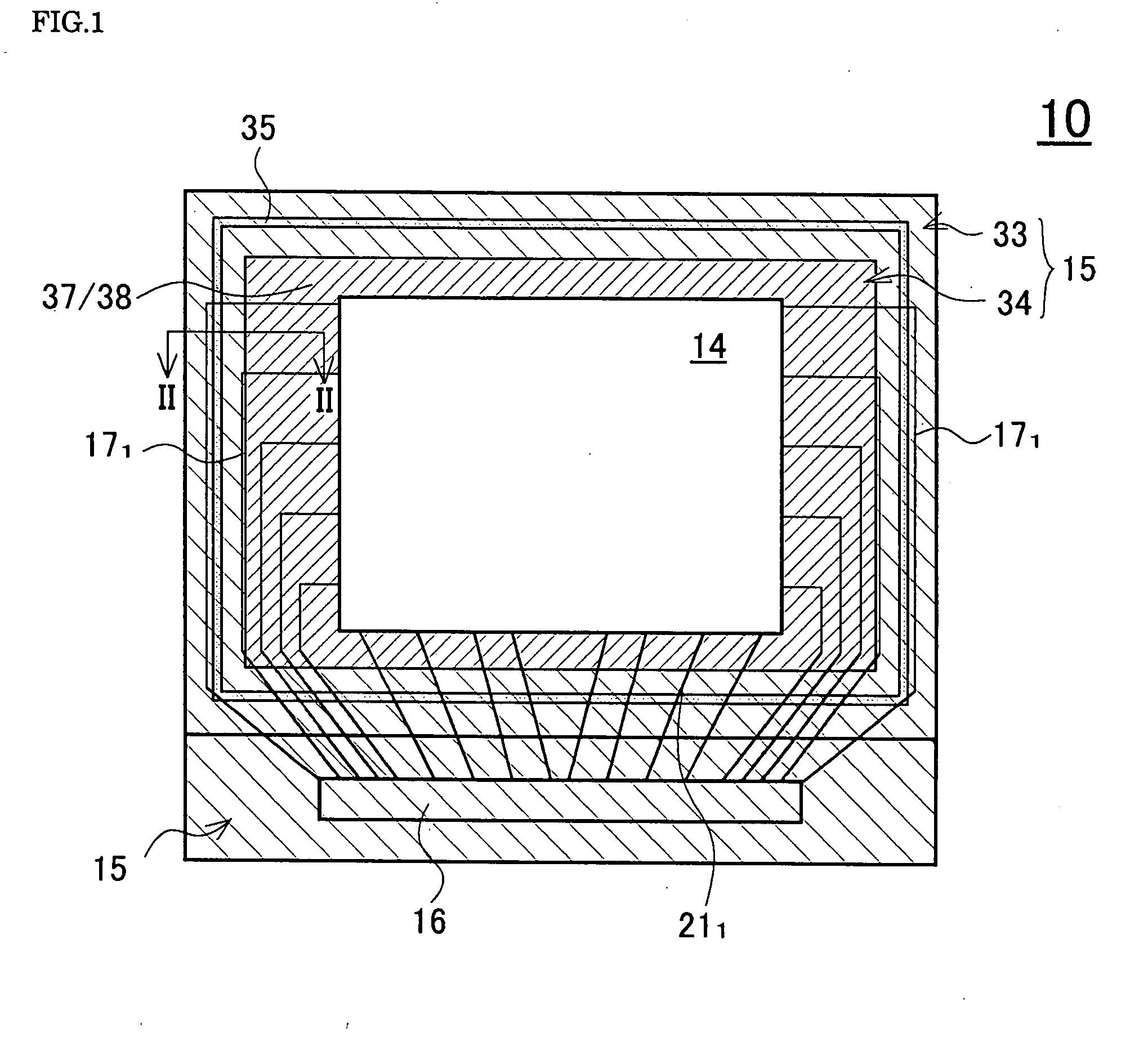

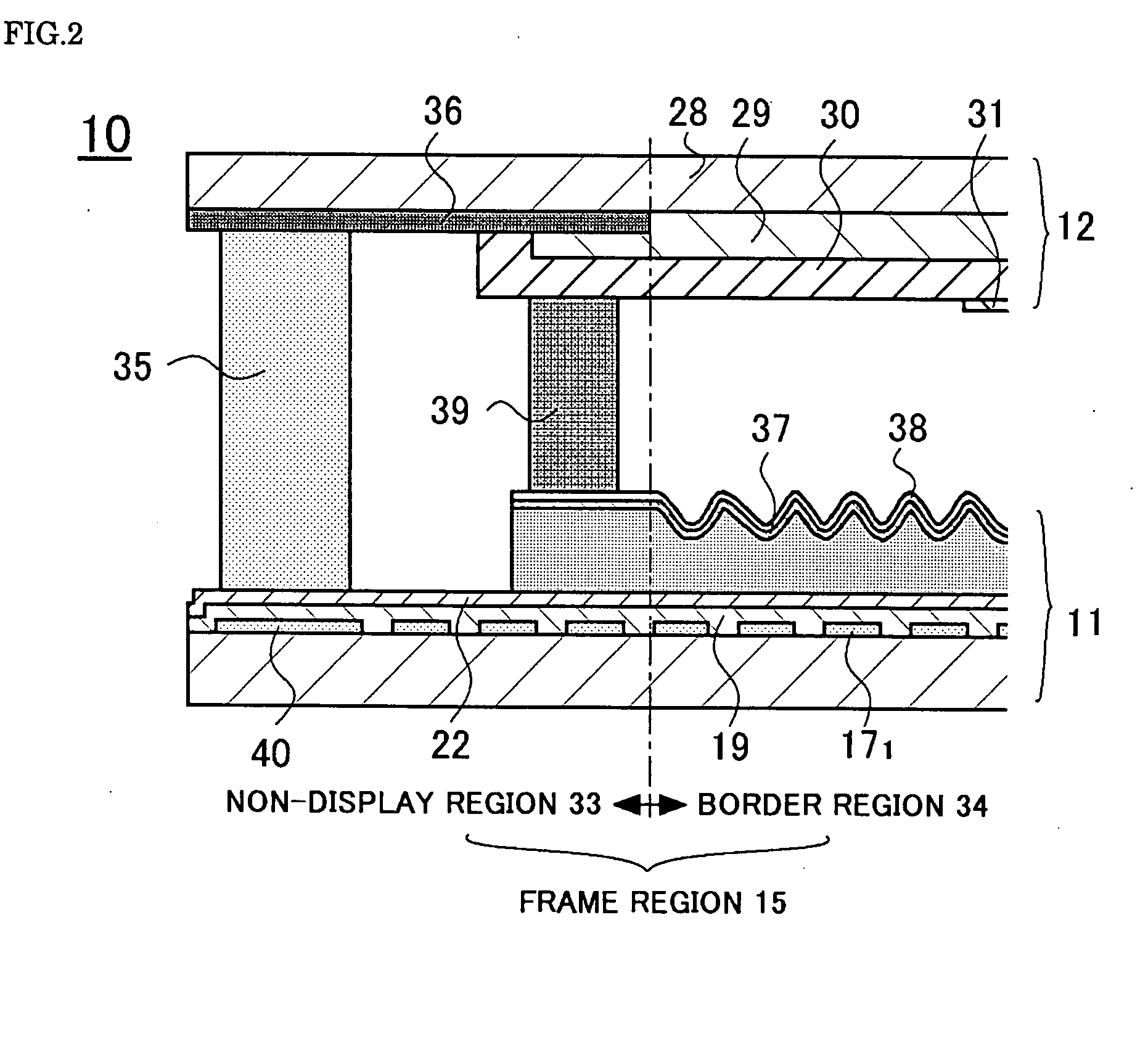

Liquid crystal display panel

InactiveUS20070291203A1Easy to viewWhite appearanceNon-linear opticsNight visionLiquid-crystal display

A liquid crystal display panel 10 of the present invention includes an array substrate 11 with a display region in which a pixel electrode is formed in each of the regions enclosed by a plurality of signal lines and scan lines deployed as matrices, a opposed substrate 12 with a common electrode 31, a sealing agent 35 sealing a peripheral portion of the array substrate 11 and the opposed substrate 12, a liquid crystal layer sealed between both substrates, a border region 34 including a reflector 37 and a transparent electrode 38 is formed on an interlayer 23 at a periphery of the display region of the array substrate 11, and at least a part of an outer peripheral side is lacking from the common electrode 31 at a position corresponding to the border region 34. Thanks to such structure, the border region improves the appearance at the periphery of the display region, and the phenomenon of night vision alongside the scan line wiring does not occur.

Owner:JAPAN DISPLAY WEST

Method for producing stabhyose, and method for producing stabhyose and catalpol by using rehmannia root

ActiveCN101003551APrevent spoilageImprove the breaking effectSugar derivativesChemical industryFiltrationIon-exchange resin

This invention provides a method for separating and extracting high-purity stachyose product from Rehmannia glutinosa and Stachys sieboldii. This invention also provides a method for continuously separating and extracting stachyose and catalpol from Rehmannia glutinosa. The method comprises: separating and purifying the extract by passing through continuous pressure-filtration, microfiltration, ultrafine filtration and nanofiltration membranes, and active carbon column, macroporous adsorption resin column, cation exchange resin column, and anion exchange resin column chromatography to obtain stachyose and catalpol. The method has scuh advantages as increased product quality, low wnwegy consumption, and increased raw material utility.

Owner:GUANGDONG APOLLO GRP

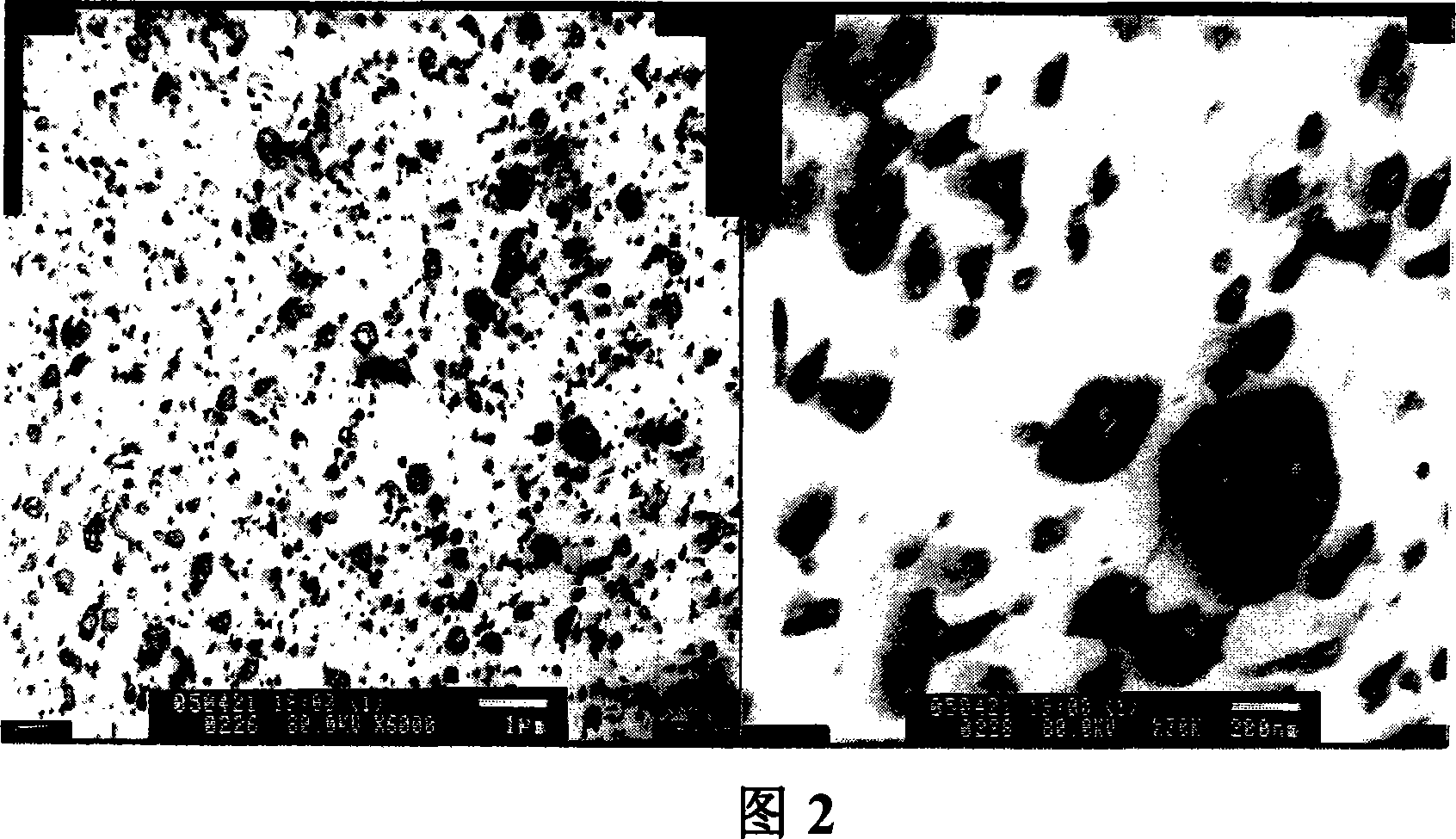

Nylon 6/inorganic particle nano composite material direct preparation method

The invention discloses a nylon 6 / inorganic particle nano composite material and the direct preparing method. It makes the hydrolyzation on inorganic acid ester or inorganic acid salt to obtain the even solution, adds the solution in melting hexyl end-amide to mix to make the even solution, makes gelation under the high-purity nitrogen protection at 20-200 C degree for 0.5-720 hour, makes polymerization on the gelatin under the high-purity introgen protection to obtain the composite material, and then makes purification to obtain the invention. It is produced at the original position; the nano particles and the nylon 6 are produced synchronously.

Owner:XIANGTAN UNIV

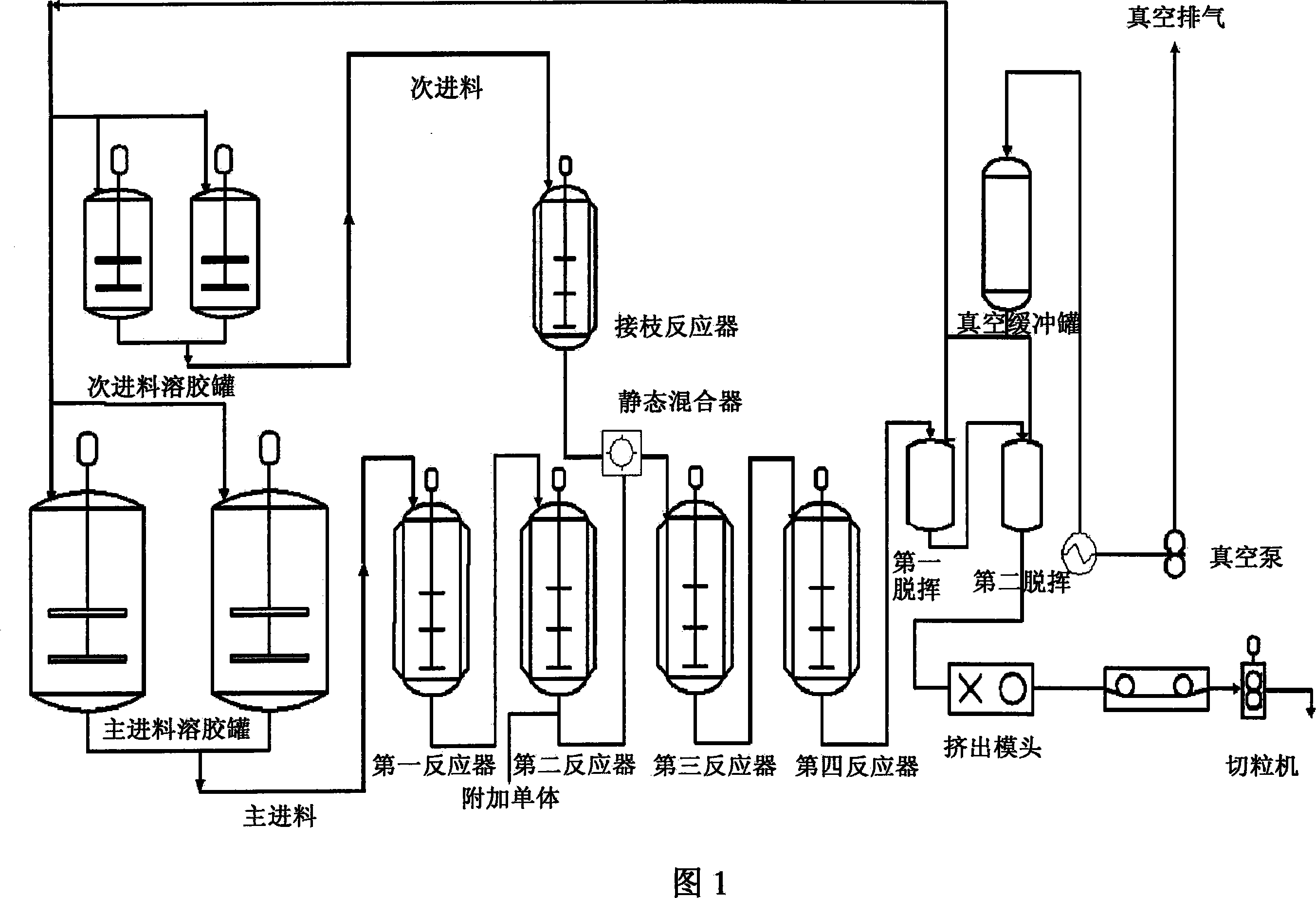

Method of preparing heat-resistant ABS polymer by continuous noumenon method

The invention discloses a making method of heat-proof ABS polymer through continuous bulk method, which comprises the following steps: inputting main material; inputting secondary material; grafting main material to transform phase; grafting the secondary material to transform phase; blending main material and secondary material; obtaining the product with swelling index at 9-15, rubber content at 14-16% and grain size at 1-2um; fitting for heat-proof modification and accessory manufacturing in the automobile domain.

Owner:中国中化股份有限公司 +1

Solid glue stick and method for producing the same

InactiveCN101220252AImprove mechanical propertiesImprove performancePolyureas/polyurethane adhesivesN-vinyl-pyrrolidone polymer adhesivesSodium stearatePolyurethane adhesive

The invention discloses a solid glue stick, and is prepared with watercraft polyurethane latex as a major glue component, water as solvent, sodium stearate as gel, and polyvinyl alcohol and polyethylene pyrrole azululanone as accessory ingredients, and moderate glycerol added as humectant, wherein a self-emulsion method is adopted for the preparation of the watercraft polyurethane latex. The invention has the advantages that coated surface of the watercraft polyurethane adhesive adopted in preparing the solid glue stick is not easy to be damaged; the mechanical property is excellent; the modification is easy; the compatibility with paint is good; the prepared solid glue stick has obvious advantages in properties of assigned model, hardness, coating, and splicing, etc.; the exterior is pure white; the feeling is subtle; the splicing property is good; the drying speed is high; time for paper tearing is less than one minute; the hydrating period is as long as one year; the reserve property is fine.

Owner:ZHONGBEI UNIV +1

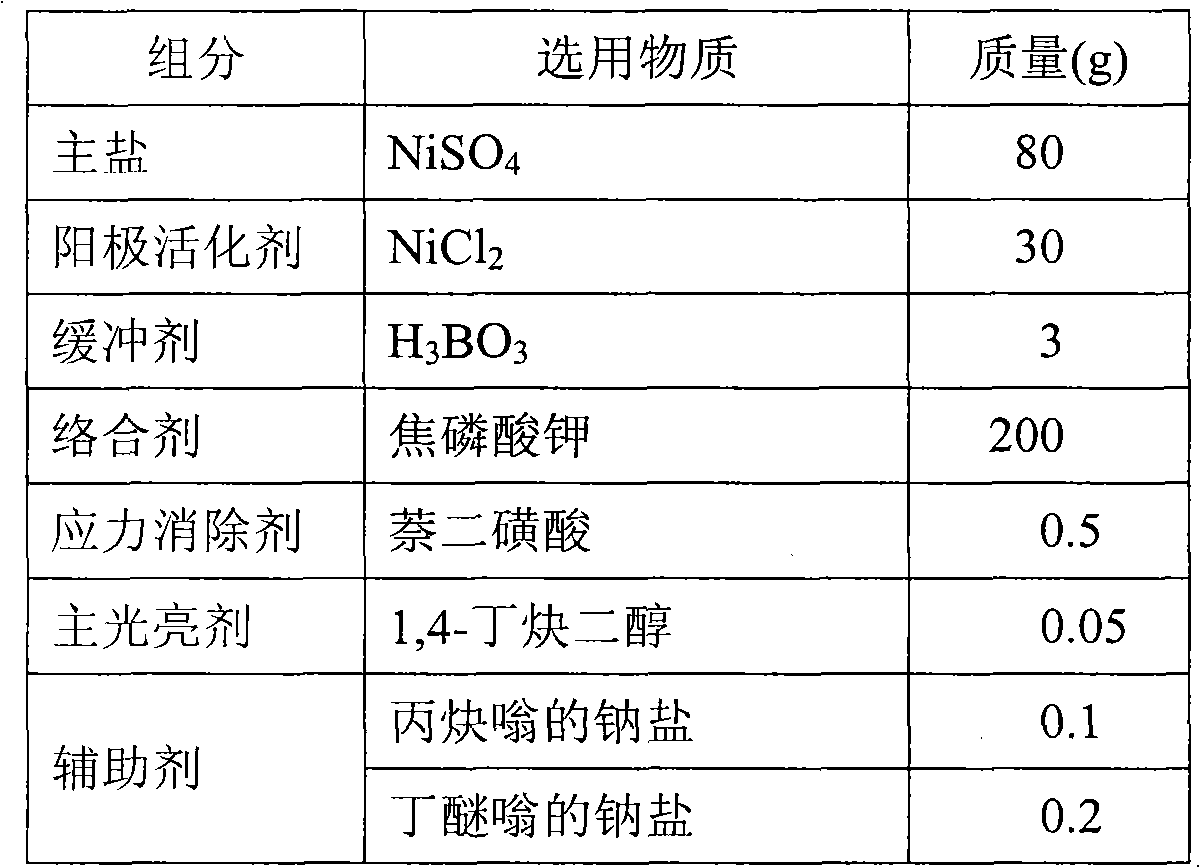

Plating solution for tumble-plating and tumble-plating method of steel battery shell

The invention relates to a treatment process of a carrier of a device which is used to directly change chemical energy to electrical energy, in particular to a plating solution for tumble-plating and a tumble-plating method of a steel battery shell. The plating solution comprises the following components in parts by weight: 80-120 or 200-350 parts of main salt, 30-100 parts of anode activator, 3-60 parts of buffering agent, 20-30 or 180-250 parts of complexant, 0.5-2.5 parts of stress reducer, 0.005-0.1 part of main brightener and 0.3-1.0 part of auxiliary agent and is prepared by dissolving the components in water. The tumble-plating method of the invention comprises the following steps in turn: degreasing, tumble-plating and bleaching, wherein during tumble-plating, the pH value of the plating solution is 4.0-4.6 or 6.5-8.5, the temperature is 40-70 DEG C, the current density is 0.2-3A / dm<2>, the rotational speed of the drum is 4-12rpm, and the tumble-plating time is 180-300 minutes. The coating of the invention has write and bright appearance, high luminance brightness and powerful corrosion resistance.

Owner:上海金杨金属表面处理有限公司

Voltage endurance vitamin E microcapsule and its preparing process

InactiveCN1927188AHigh mechanical strengthWhite appearanceOrganic active ingredientsMetabolism disorderChemistryOctenyl succinate

The invention relates to pressure resistant vitamin E capsules, wherein the constituents include (by weight percent) vitamin E oil 50-70%, capsule material 1-25%, auxiliary capsule material 5-30%, octenylsuccinate starch 10-30%, flow aid 0.5-2%. The invention also relates to the process for preparing the capsules.

Owner:PKU HEALTHCARE CORP LTD

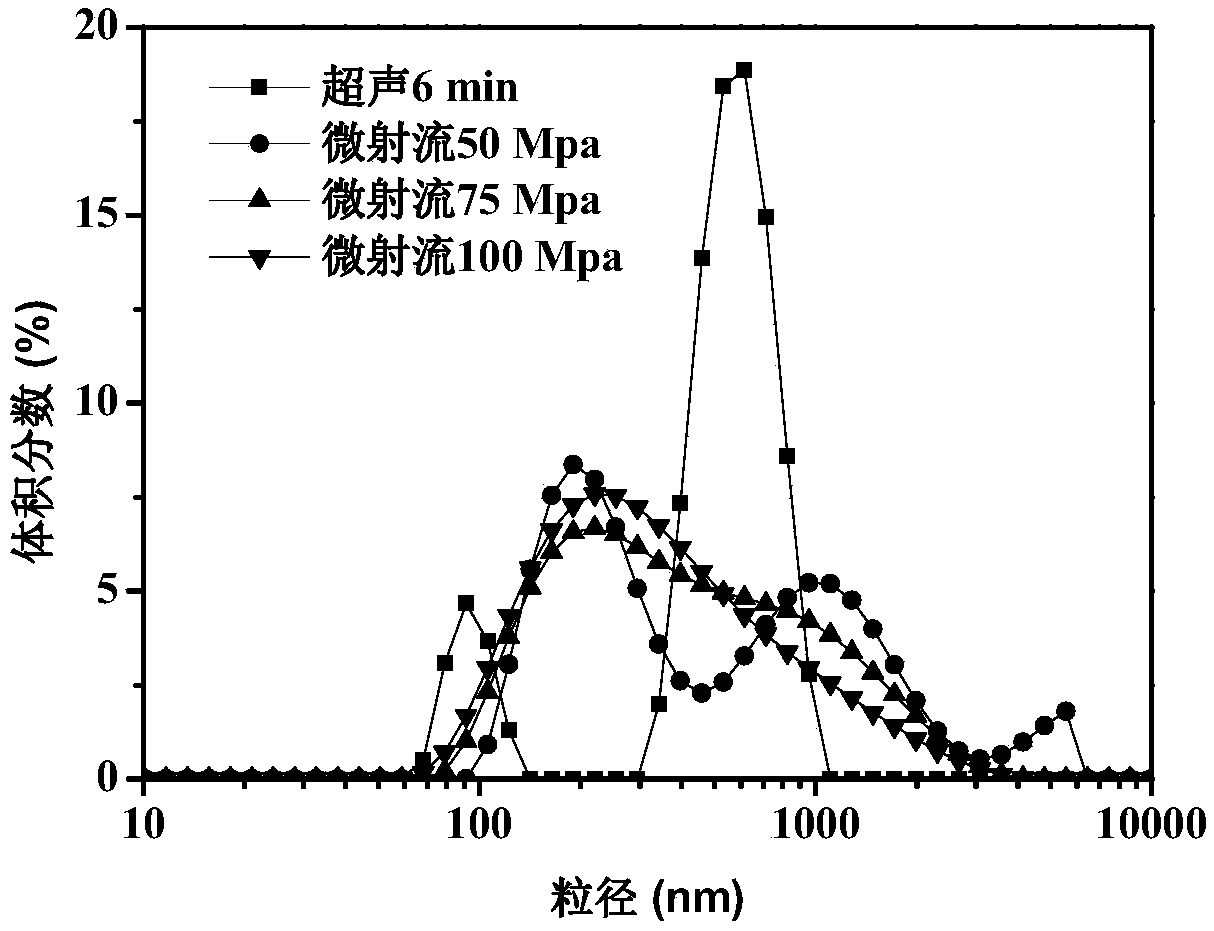

Stable phytosterol nanometer emulsion compounded by soy protein-stevioside, and preparation method and application thereof

ActiveCN108618146AGood resolubilityUniform particlesMilk preparationFood ingredientsProtein solutionOil phase

The invention discloses stable phytosterol nanometer emulsion compounded by soy protein-stevioside, and a preparation method and application thereof. The method comprises the steps of mixing a soy isolate protein solution and a stevioside solution to prepare a composite stable system; dissolving phytosterol into sunflower seed oil being 90 to 99 DEG C to obtain an oil phase; adding thw oil phase dissolved with the phytosterol into a water phase of soy protein-stevioside; controlling the mass ratio of the oil phase to the water phase to be 10:90-50:50; after the homogenizing, performing ultrasonic treatment or high-pressure micro jet flow treatment to obtain the stable phytosterol nanometer emulsion compounded by soy protein-stevioside. A powder product with high redissolving performance loaded with phytosterol can be prepared through spray drying treatment on the nanometer emulsion. The process conditions are simple and mild; the natural effect and safety are realized; the fast continuous production can be performed; products applied to food, medicine and cosmetics can be prepared through operating and controlling the process conditions; the industrialized and scaled application values are realized.

Owner:SOUTH CHINA UNIV OF TECH

Method for preparing potassium sorbate with membrane chemical reactor

ActiveCN102381959ASimple processGood choiceCarboxylic acid salt preparationFiltrationChemical reactor

The invention discloses a method for preparing potassium sorbate with a membrane chemical reactor. The method comprises the following steps: 1, weighting potassium hydroxide (KOH) and potassium sorbate according to a mass ratio of 1:1-1.5:1 at 50-90DEG C, alternately adding them to the membrane chemical reactor with water in batches until the pH value of the formed reaction solution reaches 7.0-9.5; 2, keeping the temperature of the reaction solution at 65-85DEG C for 30-40min after finishing the material addition, and controlling the pH value of the reaction solution at 7.0-9.5; and 3, sequentially carrying out press filtration, crystallization, dehydration, drying, granulation and redrying after finishing the reaction in the membrane chemical reactor to obtain potassium sorbate particles. The method for preparing the potassium sorbate particles with the membrane chemical reactor has the advantages of simple technology, and good parallel reaction selectivity and security; and prepared potassium sorbate has the advantages of white appearance, purity of more than 99.5 WT%, and stable quality.

Owner:NANTONG ALCHEMY BIOTECH DEV

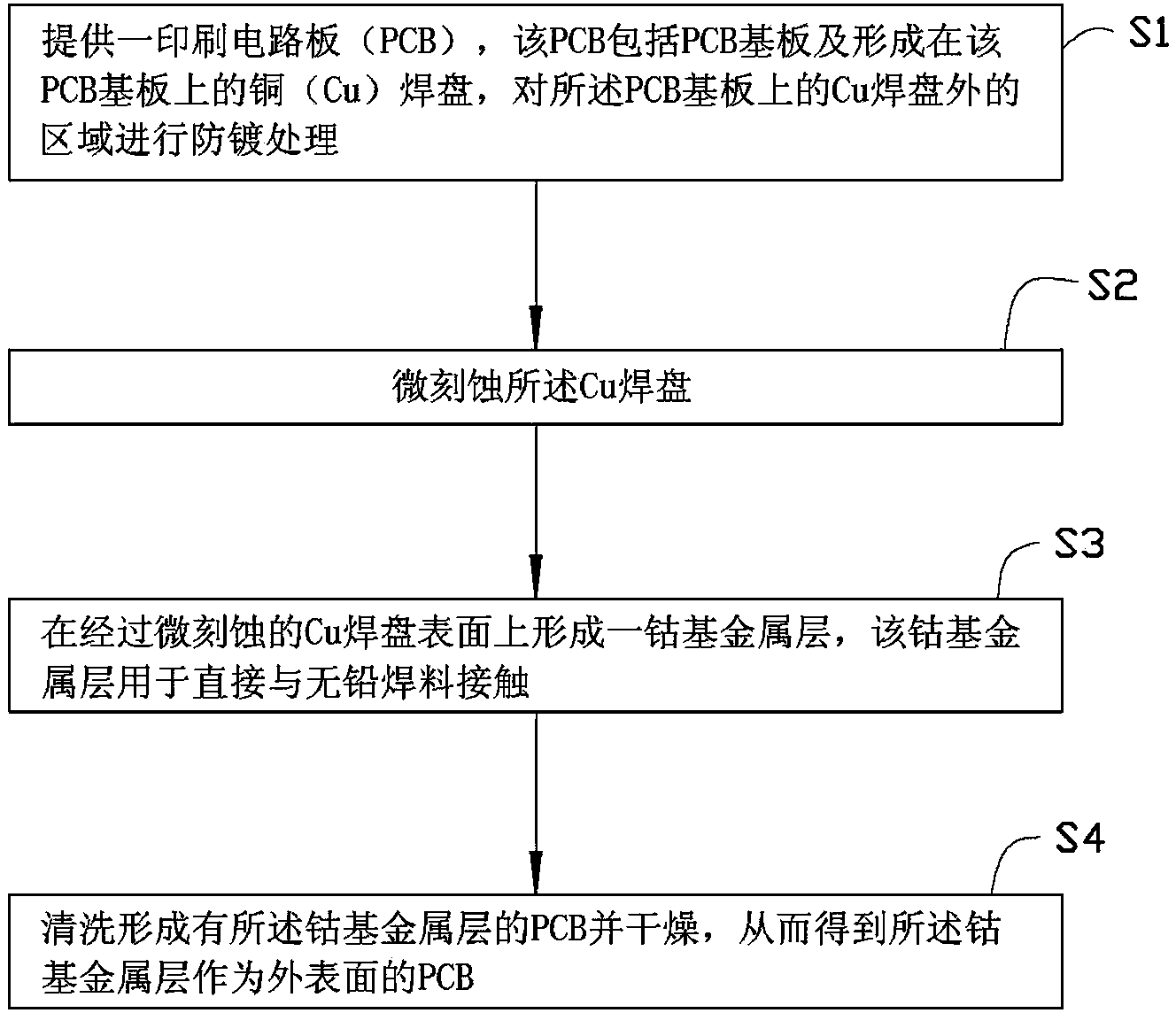

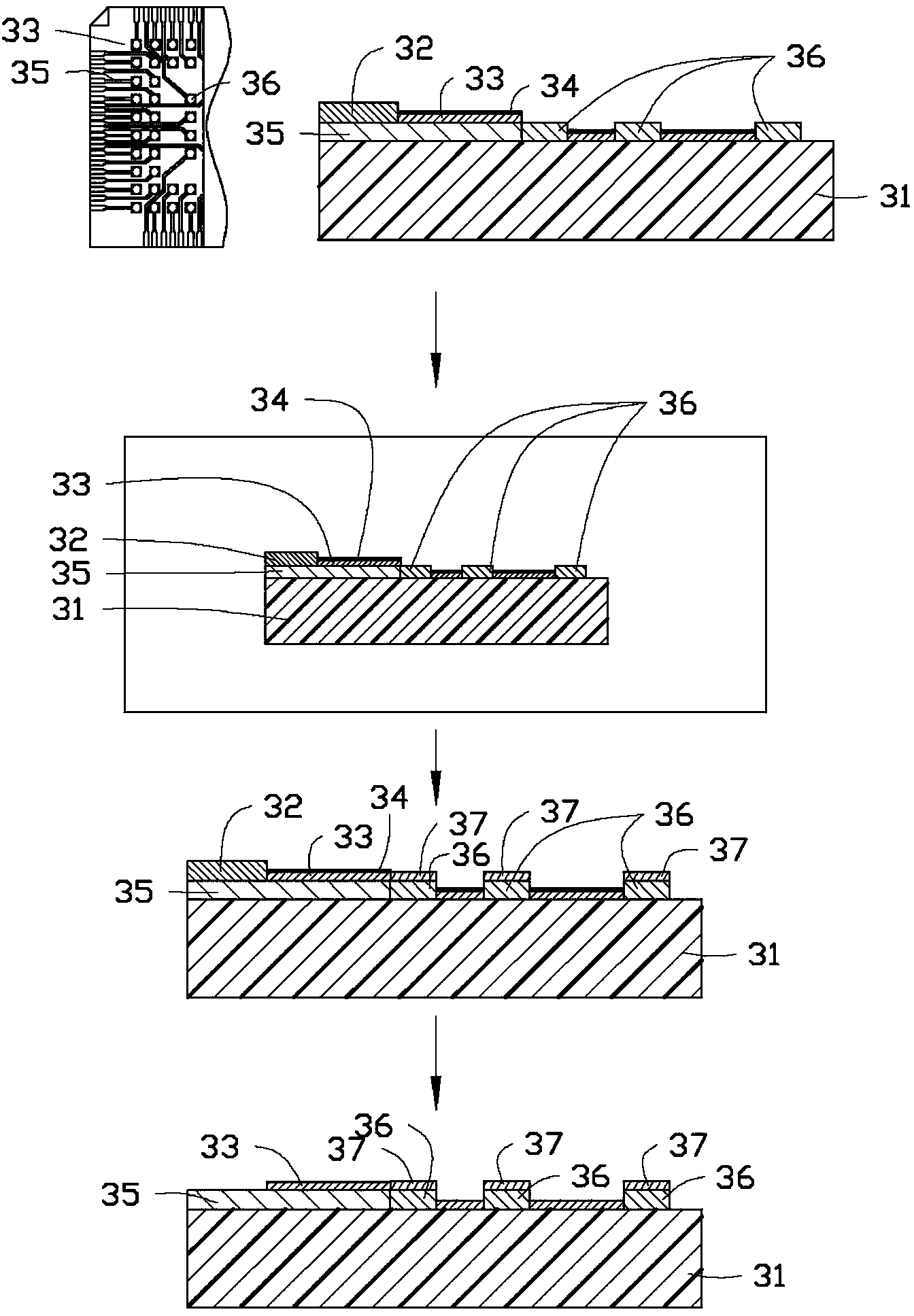

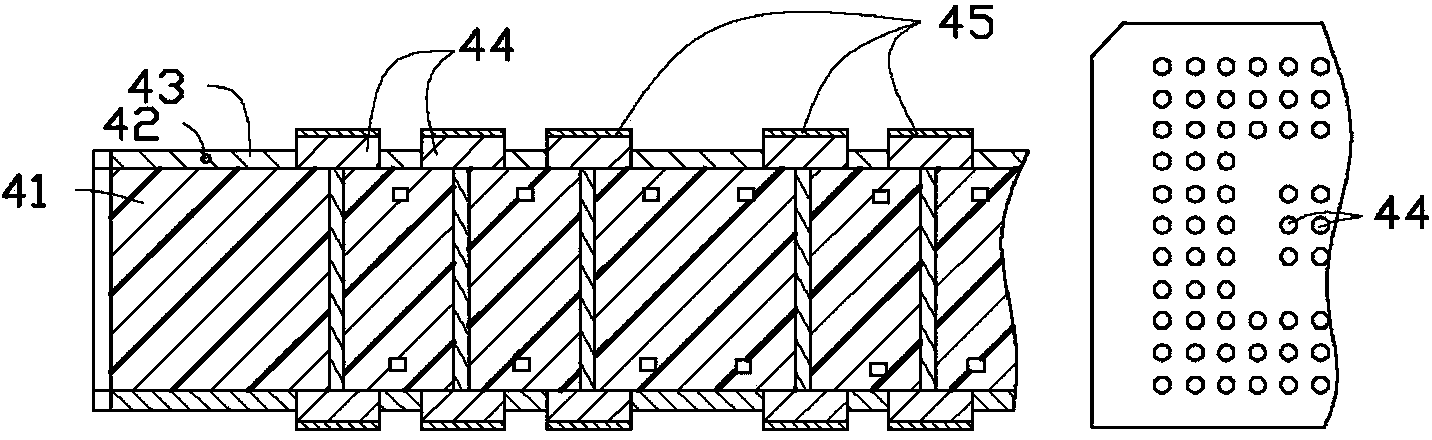

Printed circuit board and method for processing surface of printed circuit board

The invention discloses a method for processing the surface of a printed circuit board. The method comprises the steps that the printed circuit board is provided, the printed circuit board comprises a printed circuit board substrate and a brazing disc formed on the printed circuit board substrate, welding resistance processing and anti-plating processing are conducted on zones outside the brazing disc on the printed circuit board substrate; micro-etching is conducted on the brazing disc; a cobalt-based metal layer is formed on the surface of the brazing disc which undergoes micro-etching and the cobalt-based metal layer is used for directly making contact with lead-free solder, and the printed circuit board with the cobalt-based metal layer is cleaned and dried. The invention further provides the printed circuit board which undergoes the processes.

Owner:TSINGHUA UNIV

Method for producing sodium diacetate

InactiveCN104892397AWhite appearanceHigh purityOrganic compound preparationCarboxylic acid salt preparationAcetic acidGas phase

The invention discloses a method for producing sodium diacetate by taking a gas phase reaction as a main mode, which comprises the following steps: placing the metered sodium carbonate in a reactor and stirring, then slowly dropping glacial acetic acid in a reactor according to mass ratio of 1: 2.125 at temperature of 40 DEG C, controlling the temperature to 75-90 DEG C while dropping; after feeding, insulating and reacting for 30 minutes at 75-90 DEG C during a reaction process; after gas phase reaction is completed, drying under negative pressure, and cooling to obtain the sodium diacetate crystallization particles. According to the invention, sodium diacetate is produced during the gas phase reaction in a horizontal reactor, a solvent medium is not required, the crystallization product has the advantages of uniform particles, good dispersibility, simple production process, easily available raw materials, low production cost, no three waste discharge during the reaction process, high product purity and simple operation.

Owner:秦健

Method for preparing sodium diacetate

ActiveCN103694102AWhite appearanceHigh purityOrganic compound preparationCarboxylic acid salt preparationSodium acetateAcetic acid

The invention discloses a method for preparing sodium diacetate mainly through a gas-phase reaction, which comprises the following steps of firstly adding metered sodium carbonate into a reactor and stirring; slowly dropwise adding glacial acetic acid into the reactor at 40 DEG C according to a mass ratio of sodium carbonate to glacial acetic acid of 1:2.125 while controlling the temperature at 75-90 DEG C; after the feeding, performing a thermal insulation reaction of the reaction process for 30 minutes at 75-90 DEG C; after the gas-phase reaction, performing negative-pressure drying and cooling to obtain crystalline particles of sodium diacetate. According to the method disclosed by the invention, sodium diacetate is prepared through a gas-phase reaction process in a horizontal reactor without adding a solvent medium, and the obtained crystalline product particles are uniform and have good dispersity; moreover, the production process is simple, the raw materials are easily available, the production cost is low, the discharge of 'three wastes' in the reaction process is avoided, the product purity is high, and the operation is simple.

Owner:NANTONG ALCHEMY BIOTECH DEV

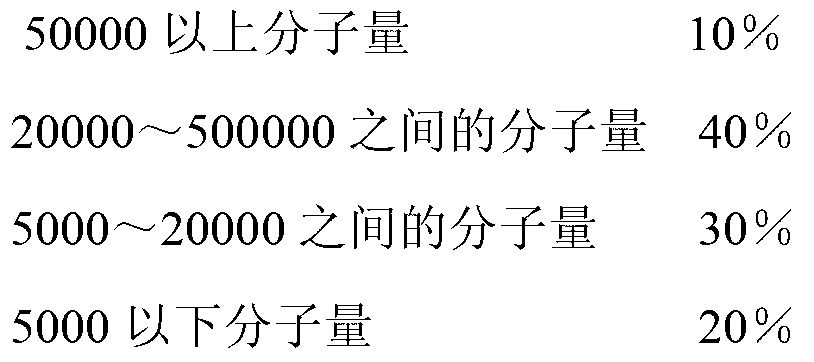

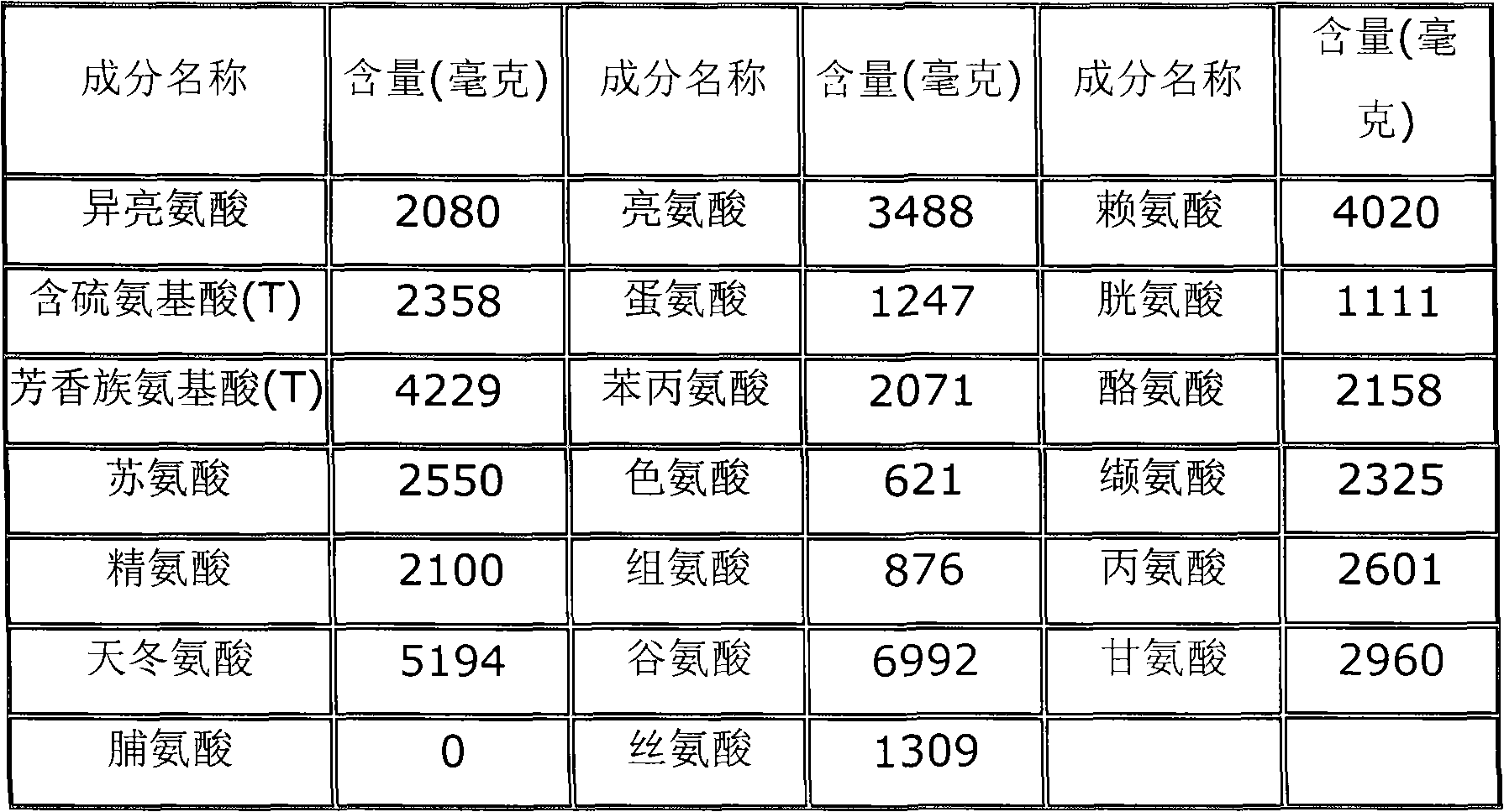

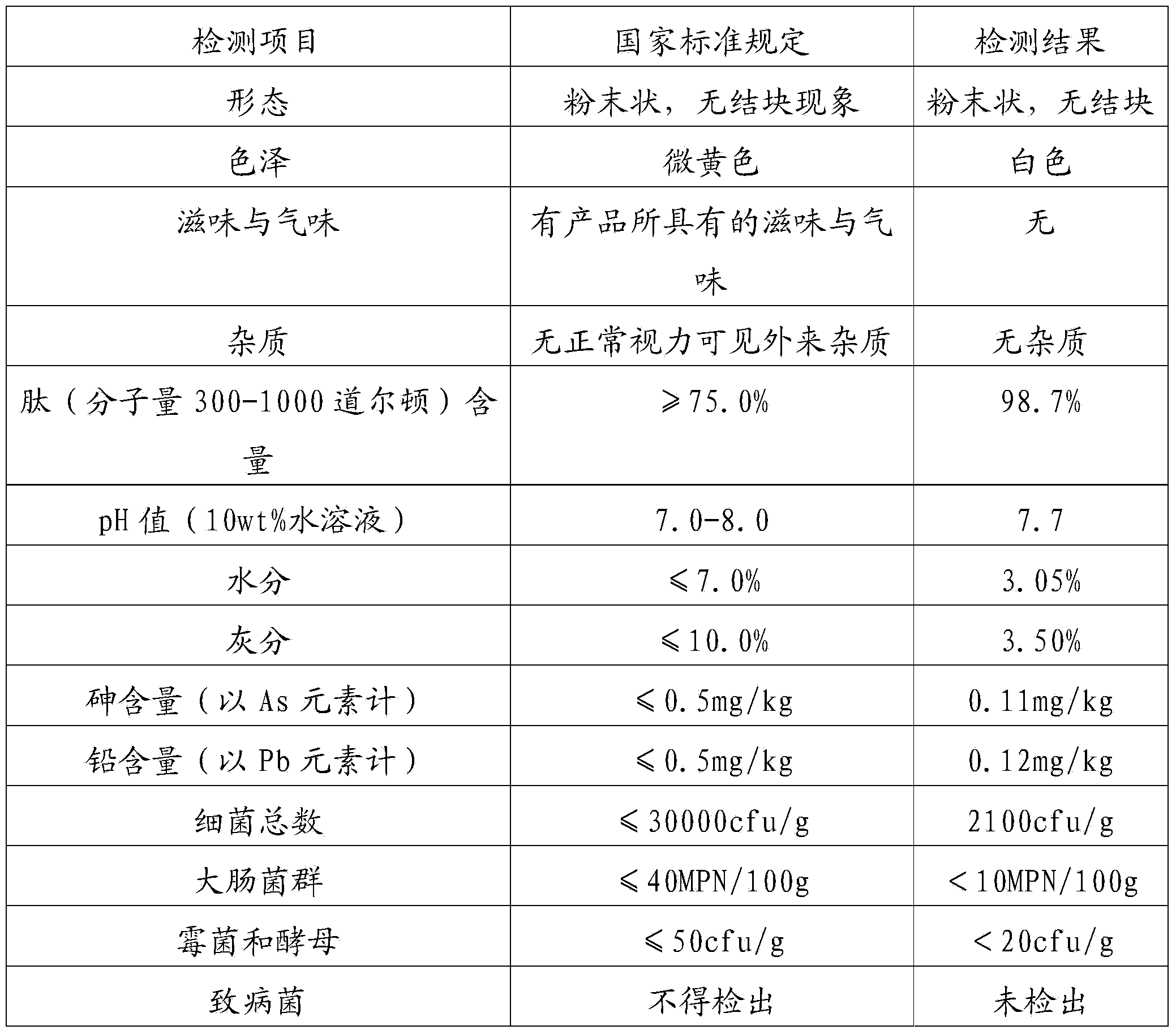

Production method of low-molecular-weight nutritional protein powder

ActiveCN102630947BScientific and reasonable compositionSmall molecular weightFood preparationPROTEIN S HEERLENNutrition

The invention discloses a production method of low-molecular-weight nutritional protein powder, which comprises the following steps: taking soy protein powder and whey protein powder as raw materials; adding water whose the temperature is 70-90 DEG C, and mixing the mixture into uniform suspension; filtering the suspension through a filtration film under the temperature no less than 60 DEG C, to be specific, firstly filtering the suspension through a 5,000-daltonian filtration film and then filtering the filtrate through a 500-daltonian filtration film; spraying and drying the obtained filtrate; adding sprayed and dried lecithin whose powder weight is 0.5-1.5%; and uniformly mixing the mixture. According to the production method of low-molecular-weight nutritional protein powder, the prepared protein powder has the advantages that the molecular weight is small, the composition of gamma-aminobutyric acid is scientific and reasonable, and is easy to absorb, the appearance is pure white and attractive, and no bean fishy smell and milk fishy smell can be generated; and the powder is easily dissolved into water, can be more quickly dissolved in cold water, is easy to disperse, and is particularly suitable for people who are lack of protein or feeble and sick, and tumor patients.

Owner:NANJING ZHONGKE PHARMA

Chicken beancurd

The invention discloses a chicken deep processed food, in particular to an edible chicken beancurd for hot pot, oil frying, frying and the like. The components of edible chicken beancurd are followingraw material: 40-60g of fresh grade breast, 10-20g of chicken skin, 1-3g of egg white powder, 15-20g of ice water, 1.3-1.8g of common salt, 1-2g of white sugar, 0.3-0.5g of monosodium glutamate and 0.05g of five-spice powder; and the preparation method comprises the following steps: high-speed cutting and stirring, dishing, stewing, slitting, quick freezing and package. As the invention adopts ascientific process and an advanced formula, the produced products have pure white appearance which is similar to the conventional beancurd; and the edible chicken beancurd has order cutting blocks, soft and tender mouthfeel, good integrity after longtime boiling, good chewing feeling, incapability of oil frying, stir frying, boiling, rich nutrition, easy digestion and special flavor.

Owner:HENAN DAYONG INDUSTRIAL CO LTD

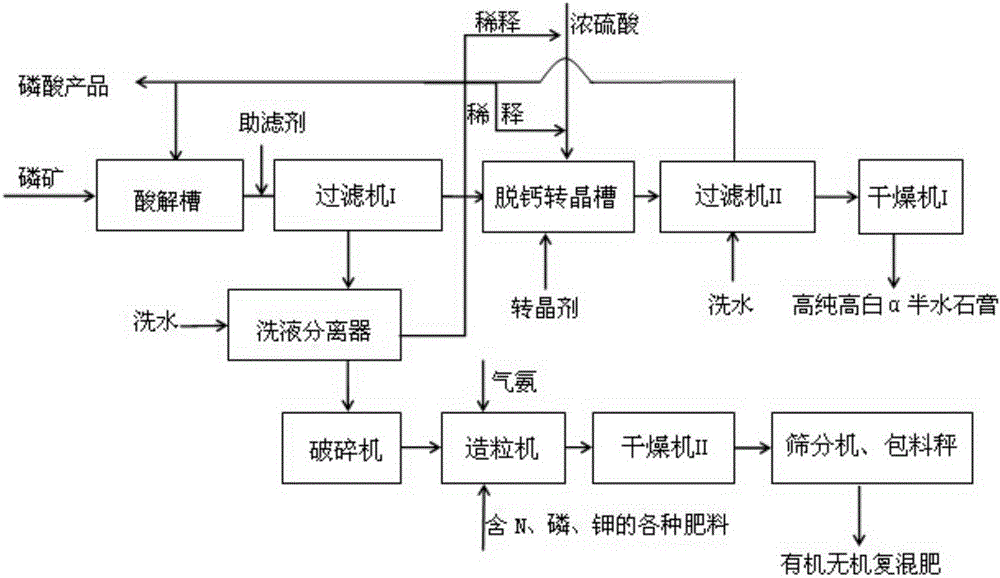

Production method of wet phosphoric acid byproducts comprising highly pure and highly white alpha-semi-hydrated gypsum and inorganic-organic compound fertilizer

ActiveCN105236778AEliminate emissionsHigh nitrogen contentFertilizer mixturesPhosphatePhosphoric acid

The invention relates to a production method of wet phosphoric acid byproducts comprising highly pure and highly white alpha-semi-hydrated gypsum and an inorganic-organic compound fertilizer. The method comprises the following steps: carrying out an acidolysis reaction on phosphoric acid and phosphate rock powder, adding a filter aid to a mixed slurry obtained after the reaction, carrying out solid-liquid separation, washing the obtained solid phase to obtain washing water and a solid, crushing the solid, sending the crushed solid into a granulator, reacting the crushed solid with gasified ammonia in the granulator, adding fertilizers with different formulas, granulating, drying the granulated material, screening, cooling, and packaging to obtain the inorganic-organic compound fertilizer; and introducing a clear liquid obtained after the acidolysis and solid-liquid separation into a decalcification and crystal transformation tank, adding a sulfuric acid solution and a crystal transformation agent, carrying out decalcification and crystal transformation reactions, carrying out solid-liquid separation to obtain a solid and a clear liquid, adding the solid into hot water, washing, and drying to obtain the highly pure and highly white alpha-semi-hydrated gypsum. The highly pure and highly white alpha-semi-hydrated gypsum with the advantages of excellent performances, white appearance and wide uses can be produced, and the inorganic-organic compound fertilizer can be produced by using organic matters, phosphorus and resources residual in acid insoluble substances.

Owner:贵州正磷科技有限公司

Method for drying devilstongue without sulfur

InactiveCN1559280AImprove protectionWhite appearanceFruit and vegetables preservationFood preparationSulfurCitric acid

A non-sulfur drying method for konjak includes such steps as washing fresh konjak, peeling, slitting, immersing in the solution of L-cysteine or the solution of L-cysteine and citric acid, and baking.

Owner:SOUTHWEST AGRICULTURAL UNIVERSITY

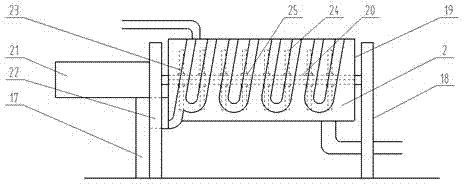

Special high-purity sodium diacetate production line device and operation method

ActiveCN104492366ASimple production processHigh degree of automationOrganic compound preparationRotary stirring mixersChemical industryProduction line

The invention relates to the field of chemical industry production automation, and particularly relates to a special high-purity sodium diacetate production line device and an operation method. According to the device and the method, a reaction kettle, a stirring refrigerator and a dry product material bin are connected with one another by a connecting pipe; the main production steps are carried out in the reaction kettle; the production method is simple; the device automation degree is high; the production efficiency is improved effectively; a manpower resource is reduced so as to reduce the safety hazard; moreover, an obtained crystallized product is uniform in particle, and is good in dispersibility; the production method is simple; raw materials are available; the production cost is low; 'three wastes' (waste gas, waste water and industrial residue) are not discharged in the reaction process, and the operation is simple. The reaction has favorable reaction selectivity and safety, and the produced sodium diacetate has the pure white appearance, is ordered in crystallization, is high product purity, and is stable in quality.

Owner:NANTONG ALCHEMY BIOTECH DEV

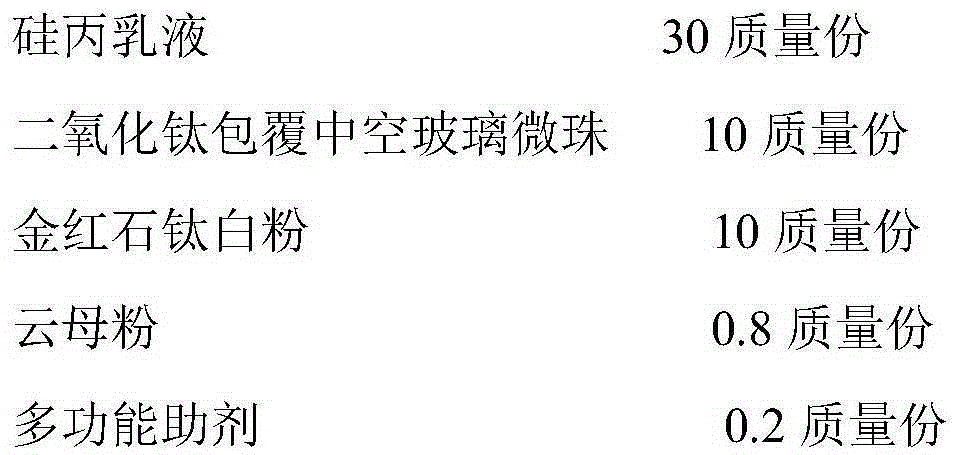

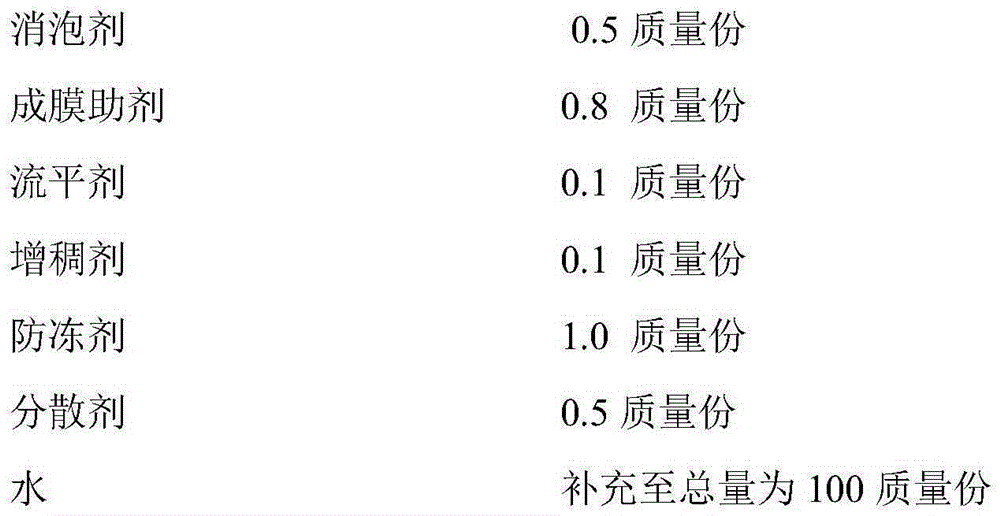

Composite thermal insulation coating and preparation method thereof

The invention provides a composite thermal insulation coating. The composite thermal insulation coating is prepared from, by mass, 20-40 parts of silicone acrylate emulsion, 15-25 parts of titanium dioxide-coated hollow microspheres, 8-12 parts of rutile titanium dioxide, 0.8-1.0 part of mica powder and 3.2-7.2 parts of an auxiliary. According to the composite thermal insulation coating, the hollow microspheres are obtained by adopting a titanium dioxide sol coating mode, titanium dioxide and the hollow microspheres are combined compactly and are not prone to falling, the microspheres are high in strength, white in appearance, high in reflectivity, and the obtained titanium dioxide-coated hollow microspheres both have the thermal reflection function of the titanium dioxide and have the thermal insulation function of the microspheres; the preparation technology is simple, equipment is low in requirement and easy to operate and control, and the production cost is low.

Owner:YANCHENG INST OF TECH

Processing method for mussel isolated protein

InactiveCN101965897AHigh extraction rateHigh purityProtein composition from fishSolubilityFreeze-drying

The invention discloses a processing method for mussel isolated protein, which sequentially comprises the following steps of: 1) cutting mussel meat into pieces, performing freeze drying, crushing, and defatting to obtain defatted mussel powder; 2) mixing the defatted mussel powder and water, adjusting pH to be between 10 and 12, soaking, and centrifuging to obtain filtrate I and filter residue; 3) soaking the filter residue in water, and centrifuging to obtain filtrate II and sediment; 4) combining the filtrate I and the filtrate II, and adjusting the pH to neutral to obtain total filtrate; and 5) concentrating and drying the total filtrate to obtain the mussel isolated protein. The mussel isolated protein prepared by the method has the characteristics of good solubility and high protein content.

Owner:ZHEJIANG UNIV

Method for producing sodium diacetate

InactiveCN106187744AWhite appearanceHigh purityOrganic compound preparationCarboxylic acid salt preparationAcetic acidGas phase

The invention discloses a method for producing sodium diacetate by taking a gas phase reaction as a main mode, wherein the method comprises the following steps: placing metered sodium carbonate in a reactor, starting to stir, then slowly dropping glacial acetic acid into a reactor according to the sodium carbonate / glacial acetic acid mass ratio of 1:2.125 at temperature of 40 DEG C, and controlling the temperature to be 75-90 DEG C while dropping; after feeding is finished, carrying out heat preservation reaction for 30 min at the temperature of 75-90 DEG C during a reaction process; and after the gas phase reaction is completed, drying under negative pressure, and cooling to obtain sodium diacetate crystallization particles. The sodium diacetate is produced through the gas phase reaction process in the horizontal reactor, a solvent medium is not required to be additionally added, the crystallization product has the advantages of uniform particles, good dispersibility, simple production process, easily available raw materials, low production cost, no 'three waste' discharge during the reaction process, high product purity and simple operation.

Owner:南通中兴多元复合钢管有限公司

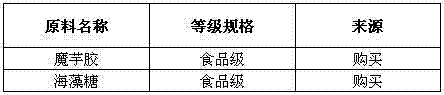

Anti-retrogradation rice powder and preparation method thereof

InactiveCN102771695ASolve the problem of easy aging and regenerationKeep the tasteFood preparationBiotechnologyNatural food

The invention belongs to the technical field of food processing methods, and particularly relates to an anti-retrogradation rice powder and a preparation method thereof. The anti-retrogradation rice powder is prepared by taking rice (polished round-grained rice, sticky rice), konjac gum and trehalose as raw materials, and processing the raw materials by the following steps: 1, preparing modified rice powder by the following step: (1) cleaning; (2) soaking; (3) grinding; (4) micronizing; (5) neutralizing; (6) neutralizing; and (7) drying; 2, adding auxiliary materials; and 3, metering and packaging. The anti-retrogradation rice powder is characterized in that the rice is chemically and physically modified to delay the rice powder retrogradation time, a natural food adjunct is added to further enhance the retrogradation capability, the difficult problems of easy ageing and retrogradation of rice foods are solved, the quality and stability of rice products are improved, and the processing field of the rice products is widened.

Owner:东莞市圣心食品有限公司

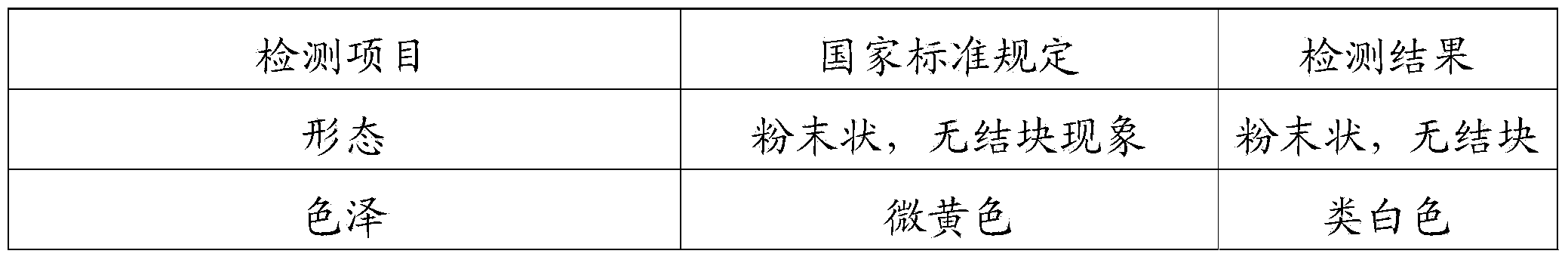

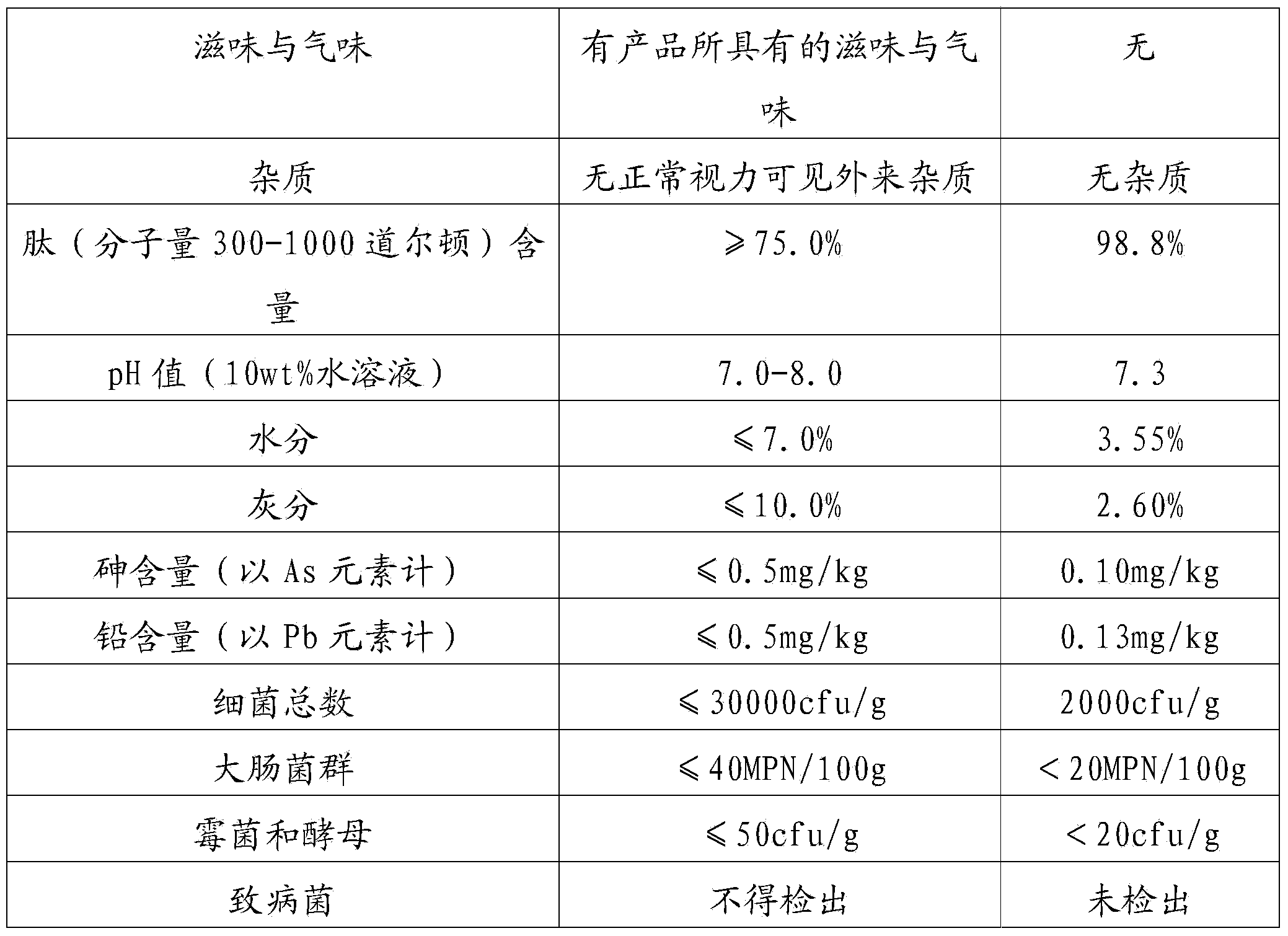

Extracting method of placenta

InactiveCN104372057AHigh yieldImprove production safetyPeptide preparation methodsFermentationChemistryNanofiltration

The invention discloses an extracting method of placenta. The extracting method comprises the following steps: (1) selecting and mincing a fresh pig uterus or pig embryo as a raw material, adding purified water to uniformly stir and cooking for 30-35 minutes; (2) cooling and regulating the pH value to 7.8-8.3, adding alkaline protease with active content of 15-20U / mg, reacting for 4-5 hours at a temperature of 50-55 DEG C, and keeping for 10-15 minutes at 90-95 DEG C; (3) centrifuging to remove fat and solid matters to obtain a placenta solution; (4) adding trichloroacetic acid, and then centrifuging and removing hybrid protein to obtain a clear solution; (5) adding active carbon to deodorize, and removing the active carbon to obtain filtrate; (6) using a nanofiltration membrane to separate, desalting and concentrating to obtain a concentrated solution; and (7) spraying and drying to obtain the placenta. The extracting method of the placenta disclosed by the invention is short in production period, low in cost, free of pollution, high in product purity, small in molecular weight, good in human body absorption, good in mouthfeel, and capable of being widely applied to the fields such as food, healthcare products, and medicines.

Owner:DELISI GROUP

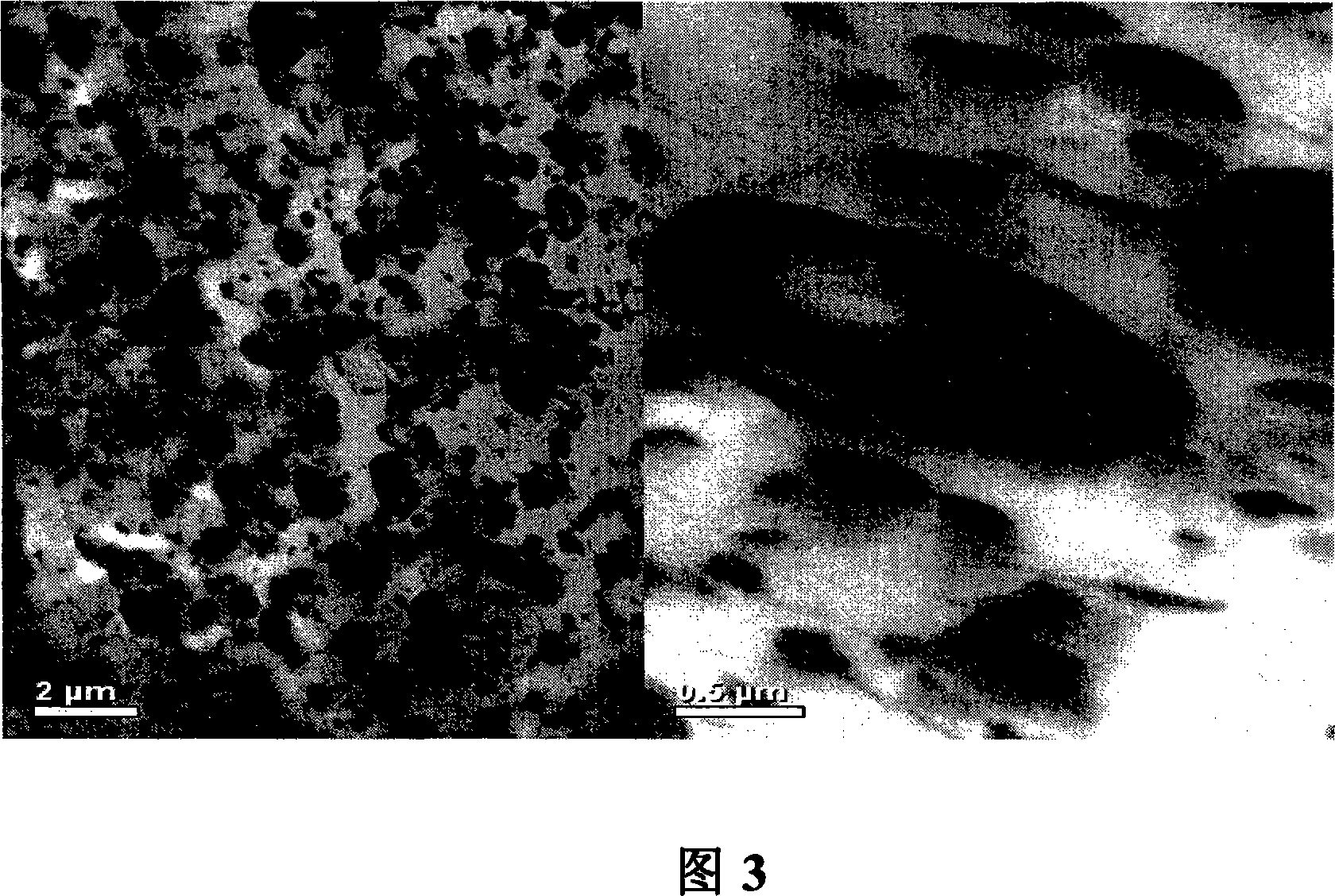

Nanometer composite nylon-6/inorganic particle/glass fiber and its direct prepn process

The nanometer composite nylon-6 / inorganic particle / glass fiber material consists of nylon-6 / inorganic particle in 90-99 wt% and glass fiber in 1-10 wt%. Its preparation process includes mixing nylon-6 / inorganic particle composition with glass fiber in a high speed stirrer, smelting at 230-245 deg.c under the protection of high purity nitrogen, extruding, drawing in water, cooling, pelletizing and drying. The nanometer composite nylon-6 / inorganic particle / glass fiber material has excellent mechanical, heat resisting, pressure resisting, solvent resisting and wear resisting performance, white, and other advantages.

Owner:XIANGTAN UNIV

Production method of polyquaternium-10

The invention provides a production method of polyquaternium-10. The production method comprises the following steps: preparing cationic etherifying agent ETA and preparing polyquaternium-10 by reaction between cationic etherifying agent and hydroxyethyl cellulose. The preparation method of the cationic etherifying agent ETA comprises the following steps: generating cationic etherifying agent ETA by reaction between epoxy chloropropane and trimethylamine, washing, and drying the cationic etherifying agent ETA. The preparation method of the cationic etherifying agent ETA is characterized by also comprising the step of refining after drying the cationic etherifying agent ETA, wherein the refining step particularly refers to the operation of carryin gout gas suction filtering for 2-3 hours at 30-50 DEG.C in a vacuum environment of -0.081Mpa to -0.1Mpa at a stirring speed is 40-50r / min. The prepared polyquaternium-10 has very good quality, high light transmittance (97.5-99.5%) and the ash content being not more than 3% and has 0-2 gel particles (4cm<2>); and the prepared polyquaternium-10 is whiter and uniform.

Owner:CHONGQING DONGHUAN SCI & TECH DEV

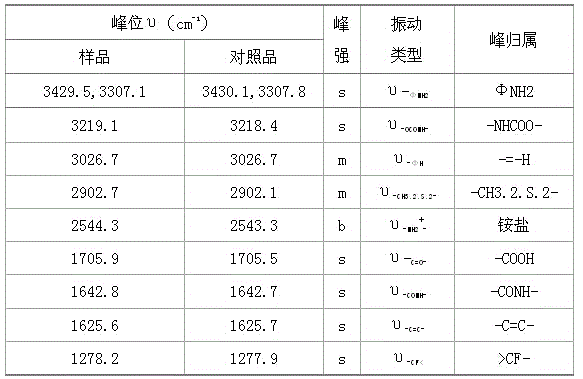

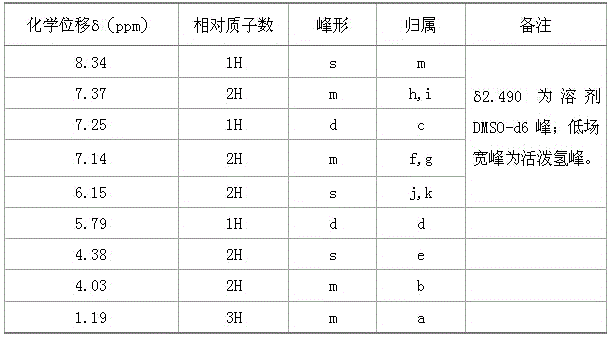

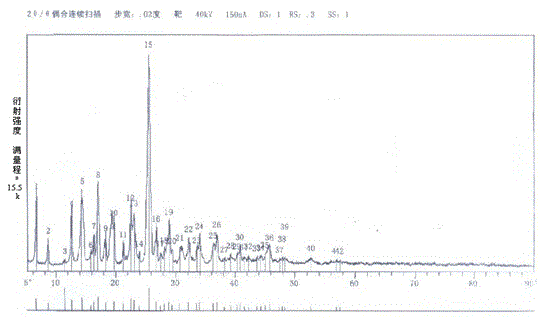

Synthesis method of flupirtine maleate

ActiveCN104086481AWhite appearanceHigh purityCarboxylic acid salt preparationCarboxylic compound separation/purificationSynthesis methodsReaction temperature

The invention provides a synthesis method of flupirtine maleate. Recrystallization by use of methanol is carried out in the refining step of the crude product of the flupirtine maleate so that the product is white in appearance and high in purity, and the crystal form of the product is pure A crystal and same as the crystal form of the commercial products. The optimal reaction solvent, reaction time and reaction temperature are explored and found out by use of a simplified process flow, and a method for preparing the flupirtine maleate in the pure A crystal form, which is high in yield, low in cost and simple to operate, uses easily available raw materials and is applicable to the industrial production is found.

Owner:SICHUAN XINSIDUN PHARMA

Die-casting mold releasing agent and preparation method thereof

InactiveCN107335777AImprove high temperature resistanceSpray lessFoundry mouldsFoundry coresWaxEmulsion

The invention provides a die-casting mold releasing agent and a preparation method thereof. The die-casting mold releasing agent is prepared from, by weight, 15%-18% of modified organic silicone oil, 3.2%-4% of oxidized polyethlene wax emulsion, 10%-12% of oleate emulsion, 1%-2% of Turkey red oil, 3%-5% of emulsifier and the balance water. The preparation method comprises the steps that (1), the modified organic silicone oil, the oxidized polyethlene wax emulsion, the oleate emulsion, the Turkey red oil, the emulsifier and the water are weighed according to the proportion for use; and (2), the modified organic silicone oil and the emulsifier are mixed firstly and then put into a high-speed shearing disperser, the silicone oil is emulsified through a reverse emulsifying method at normal temperature to obtain a silicone oil emulsion, then the oxidized polyethlene wax emulsion, the oleate emulsion and the Turkey red oil are added into the silicone oil emulsion, all the materials are mixed to be uniform to obtain a mixed emulsion, and then the mixed emulsion is subjected to homogenization treatment through a high pressure homogenizer, and therefore the die-casting mold releasing agent can be obtained. The die-casting mold releasing agent is good in high temperature resistance, the spray quantity of the mold releasing agent is small, the die-casting circulating period is shortened, and the production efficiency is improved.

Owner:佛山市高质压铸材料有限公司

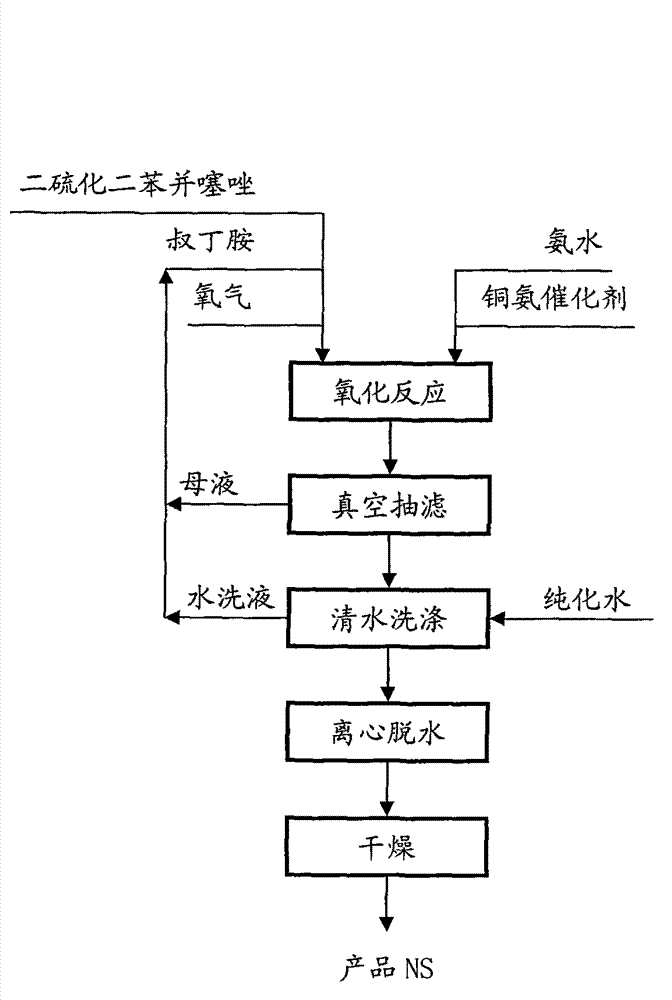

Preparation method of rubber vulcanization accelerator N-tert-butyl-2-benzothiazole sulfonamide (NS)

The invention provides a preparation method of a rubber vulcanization accelerator N-tert-butyl-2-benzothiazole sulfonamide (NS). A specific process as below: adding 30-60ml of ammonia; weighing 33.25g of Dithio-dibenzo thiazole, 0.10-0.25g of a copper ammonia catalyst and a surface active agent under oxygen pressure of 0.2-0.8MPa, and adding into a reaction kettle; slowly injecting 15.36-19.02g of tert-butylamine by a metering pump to generate a target product at a reasonable reaction temperature; and conducting centrifugation, washing and drying to obtain the product NS. The method provided by the invention can effectively reduce the treatment amount of organic wastewater, reduce comprehensive cost, and has advantages of few raw material varieties, high reaction selectivity, high yield and short cycle; and the method is better than a current production method, and can well meet the demand of high-end market.

Owner:WILLING NEW MATERIALS TECH CO LTD

Method for improving quality of diphenylguanidine product

InactiveCN105348149ASimple stepsEasy to operateOrganic chemistryOrganic compound preparationAmmonium hydroxideOxygen

Owner:SHANDONG SUNSINE CHEM

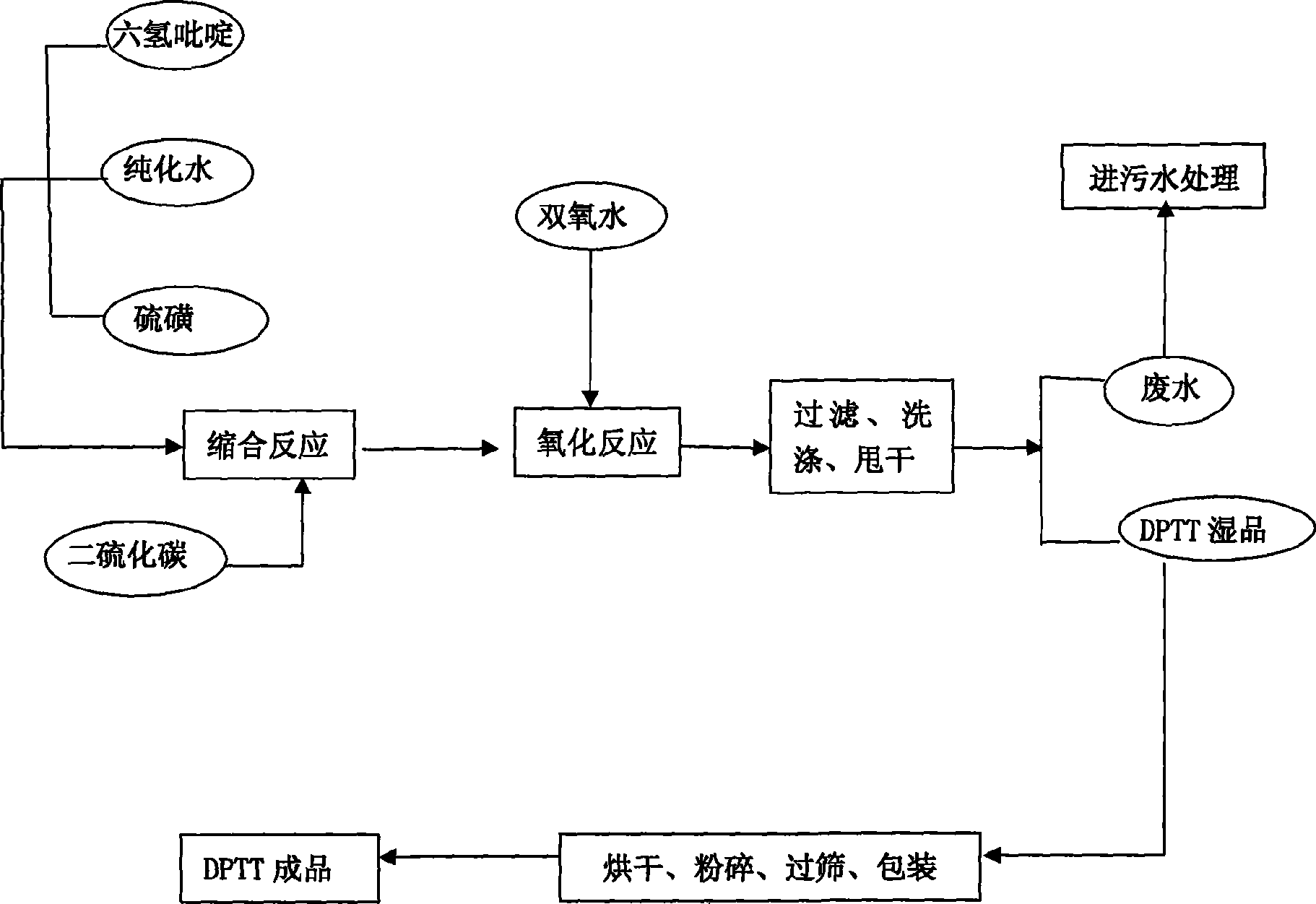

Process for producing rubber vulcanization accelerant penta-methylene thiuram tetrasulfide

The invention relates to a method for preparing a rubber vulcanization accelerator, namely dipentamethylenethiuram tetrasulfide, wherein the method takes water as a solvent; raw materials together with the molar ratio thereof used in the method are: the molar ratio of piperidine to carbon disulfide to sulfur to hydrogen peroxide is 1:1-1.3:1.8-2.5:0.4-0.7; the method comprises the following concrete technological processes: under normal pressure, the piperidine and the sulfur are sequentially added to a reaction kettle holding water in a stirring state; after adding is over, temperature is controlled in a range between 20 and 30 DEG C; then carbon disulfide liquid is dripped, and the dripping time is controlled to be 2 to 3 hours; after dripping is over, the pH value of a reaction solution is measured; after the pH value of the reaction solution is steady in the range between 6.5 and 7.5, the temperature of the reaction solution is controlled between 30 and 40 DEG C; hydrogen peroxide is dipped so as to perform oxidation reaction for 3 to 4 hours; after the oxidation reaction is over, the reaction solution is thermally insulated and reacts for 1 hour; then solid-liquid separation is performed; and an obtained solid is dried, ground, sieved and packaged so as to obtain a product. The method has the advantages that the method is short in production period, high in safety factor, nearly free from exhaust emission, high in product melting point, good in product appearance, high in yield, obviously superior to other preparation methods, low in comprehensive cost and capable of improving product quality, saving energy, reducing consumption and reducing three-waste pollution.

Owner:WILLING NEW MATERIALS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com