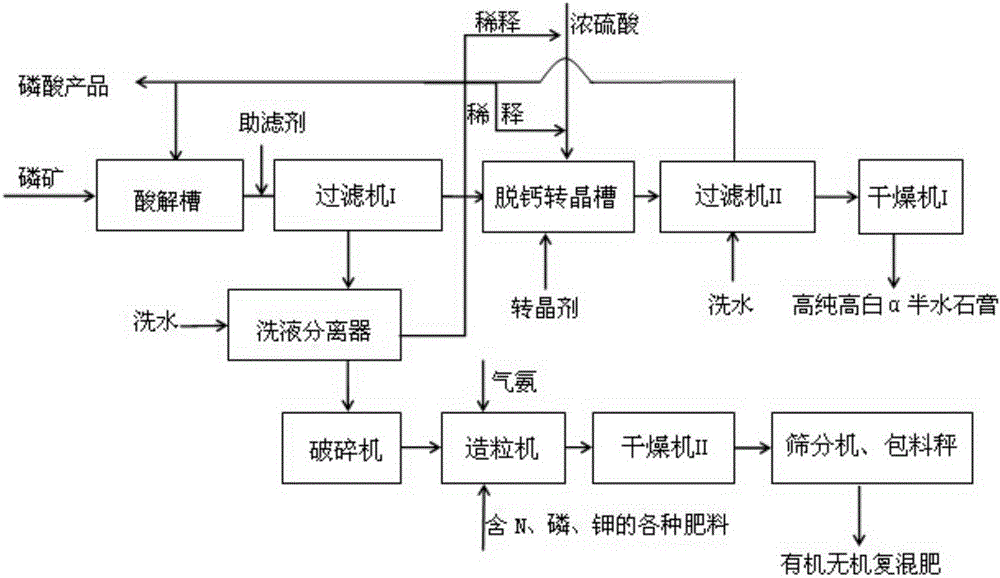

Production method of wet phosphoric acid byproducts comprising highly pure and highly white alpha-semi-hydrated gypsum and inorganic-organic compound fertilizer

A technology of hemihydrate gypsum and a production method, which is applied to fertilization devices, fertilizer mixtures, applications, etc., can solve the problems of discharging acid-insoluble impurities, etc., and achieve the effects of simple process, elimination of waste, and low energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Raw material 1: phosphate rock, collection location: Guizhou Jinde Mining;

[0048] The main chemical composition is shown in the table below:

[0049] chemical components P 2 o 5 CaO MgO SiO 2 Fe 2 o 3 Al 2 o 3 Contentwt% 30.24 50.14 5.44 1.75 0.05 0.19

[0050] Raw material 2: sulfuric acid, concentration is 97wt%, commercially available;

[0051] Raw material 3: sodium citrate, commercially available;

[0052] Raw material 4: iron sulfate, commercially available;

[0053] Raw material 5: humic acid, commercially available;

[0054] Raw material 6: Potassium chloride: Potassium oxide content 60%;

[0055] Raw Material 7: Monoammonium Phosphate: Total Nutrients (N+P 2 o 5 )55%;

[0056] The sulfuric acid solution used in this example is obtained by diluting concentrated sulfuric acid with a concentration of 97 wt%.

[0057] A production method of wet-process phosphoric acid by-product high-purity and high-whiteness...

Embodiment 2

[0071] Raw material 1: phosphate rock, collection location: Guizhou Lufa Mining;

[0072] The main chemical composition is shown in the table below:

[0073] chemical components P 2 o 5 CaO MgO SiO 2 Fe 2 o 3 Al 2 o 3 Contentwt% 29.46 51.21 5.46 1.76 0.34 0.21

[0074] Raw material 2: sulfuric acid, concentration is 97%, commercially available;

[0075] Raw material 3: sodium citrate, commercially available;

[0076] Raw material 4: aluminum sulfate, commercially available;

[0077] Raw material 5: humic acid, commercially available;

[0078] Raw material 6: potassium chloride: potassium oxide content 60%, commercially available;

[0079] The sulfuric acid solution used in this example is obtained by diluting concentrated sulfuric acid with a concentration of 97 wt%.

[0080] A production method of wet-process phosphoric acid by-product high-purity and high-whiteness α-hemihydrate gypsum and organic-inorganic compound fertili...

Embodiment 3

[0094] Raw material 1: phosphate rock, collection location: Guizhou Lufa Mining;

[0095] The main chemical composition is shown in the table below:

[0096] chemical components P 2 o 5 CaO MgO SiO 2 Fe 2 o 3 al 2 o 3 Contentwt% 29.46 52.21 5.46 1.76 0.34 0.21

[0097] Raw material 2: sulfuric acid, concentration is 97%, commercially available;

[0098] Raw material 3: ferric citrate, commercially available;

[0099] Raw material 4: sodium dodecylsulfonate, commercially available;

[0100] Raw material 5: humic acid, commercially available;

[0101] Raw material 6: potassium chloride: potassium oxide content 60%, commercially available;

[0102] Raw Material 7: Monoammonium Phosphate: Total Nutrients (N+P 2 o 5 )56%, commercially available;

[0103] The sulfuric acid solution used in this example is obtained by diluting concentrated sulfuric acid with a concentration of 97 wt%.

[0104] A production method of wet-process p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com