Method of preparing heat-resistant ABS polymer by continuous noumenon method

A polymer, heat-resistant technology, applied in the field of polymer chemistry, which can solve problems such as compatibility problems, unmentioned compatibility problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

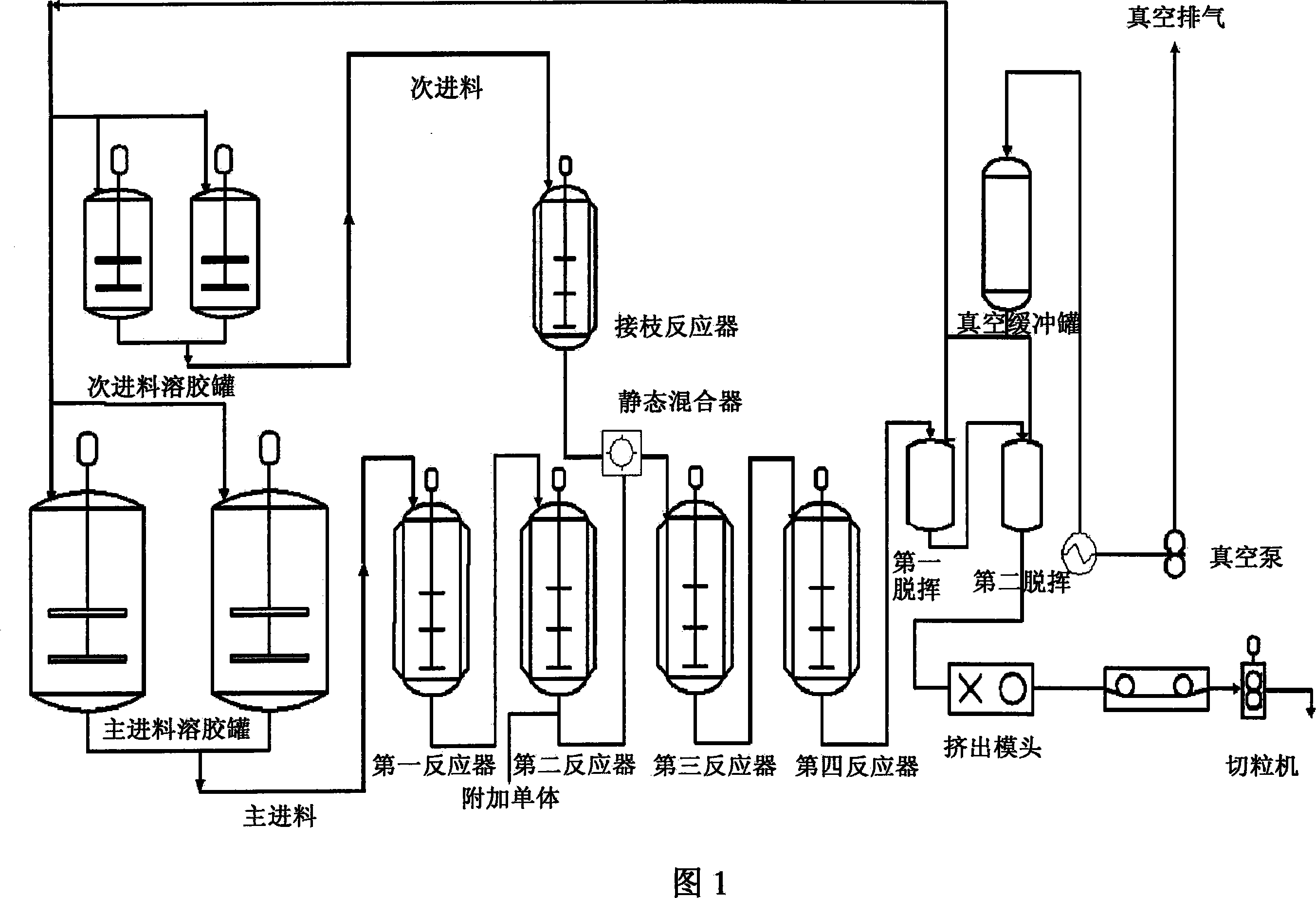

Method used

Image

Examples

Embodiment 1

[0083] The reaction system of this embodiment adopts four reactors in series, and the process mode in which all the materials are added to the first reactor.

[0084] Add 20kg of ethylbenzene and 47.97kg of styrene to the rubber dissolving tank, start stirring, and add 8kg of Asahi AsapreneTM 730AX rubber cut into 10*10mm into the rubber dissolving tank through the glue inlet, and stir and dissolve at room temperature for 8 hours. Then add 18.85kg of acrylonitrile, 3kg of nitrogen phenyl maleimide, continue dissolving for 3 hours, then add 1.40% of white oil, 0.30% of antioxidant 3,5-tert-butyl-4-hydroxyl-phenyl - Octadecyl ester, 0.35% chain transfer agent dimerized a-methyl styrene, 0.015% initiator tert-butyl perbenzoate, and continued to stir and disperse for 30 minutes.

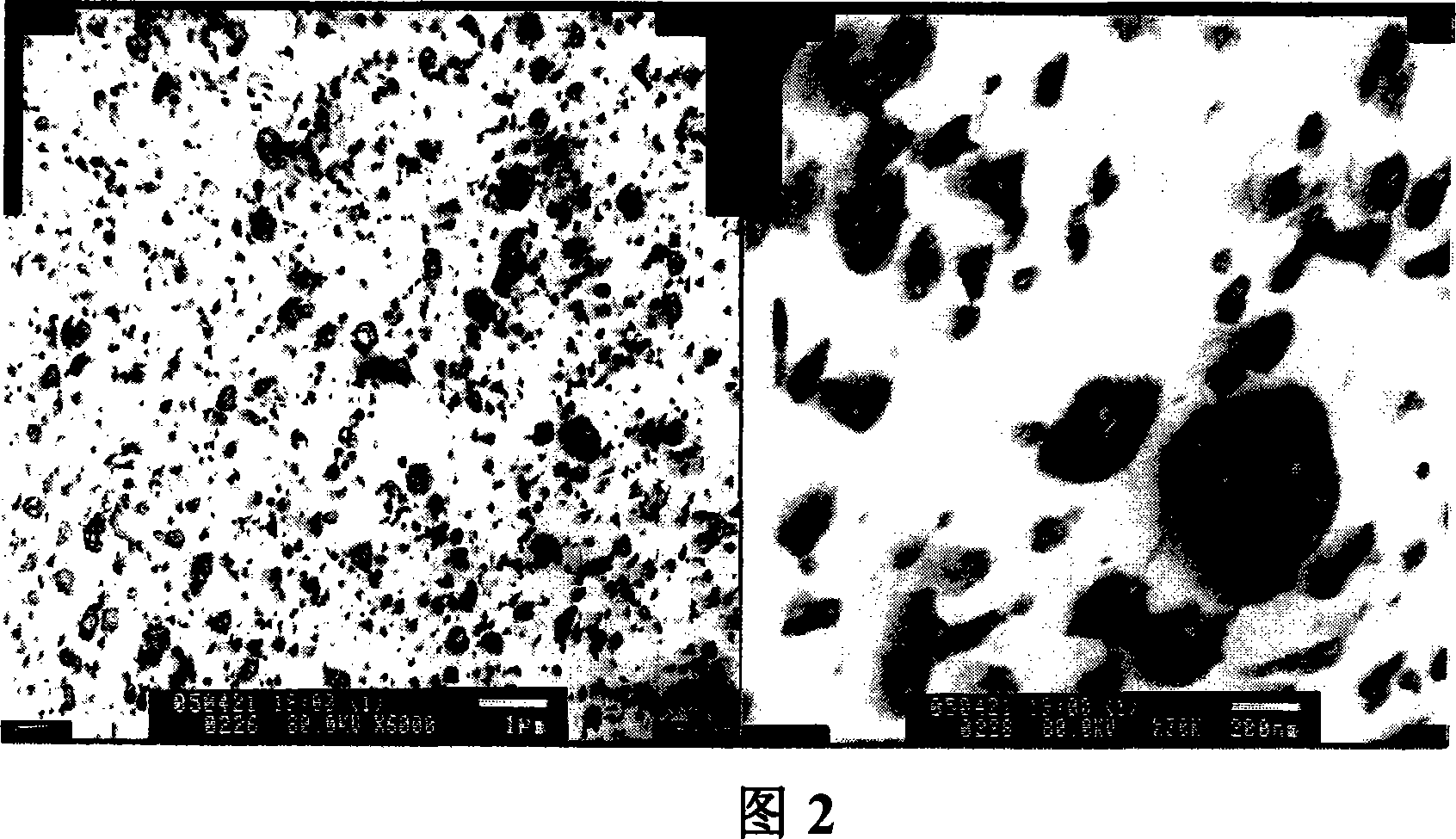

[0085] The feed rate of the reactor is 1540mL / h; the system pressure is controlled between 0.9MPa; the reaction temperature of the four reactors is 92°C; 110°C; 117°C; 150°C; the stirring speed of the re...

Embodiment 2

[0090] The reaction system of this embodiment adopts five reactors, and part of the material (main feed) is added to the first reactor; part of the material (secondary feed) is added to the grafting reactor to obtain a certain degree of grafting and achieve phase inversion. , and then added to the subsequent third reactor.

[0091] Add 20kg of ethylbenzene and 46.50kg of styrene to the rubber dissolving tank, start stirring, and add 10.94kg of Asahi AsapreneTM 730AX rubber cut into 10*10mm into the rubber dissolving tank through the glue inlet, and stir to dissolve at room temperature for 8 hours. Then add 15.50kg of acrylonitrile, 5kg of nitrogen phenyl maleimide, continue dissolving for 3 hours, then add 1.40% of plasticizer white oil, 0.30% of antioxidant 3,5-tert-butyl-4-hydroxy -Phenyl-octadecyl ester, 0.35% chain transfer agent dimerized a-methyl styrene, 0.015% initiator tert-butyl perbenzoate, and continued to stir and disperse for 30 minutes.

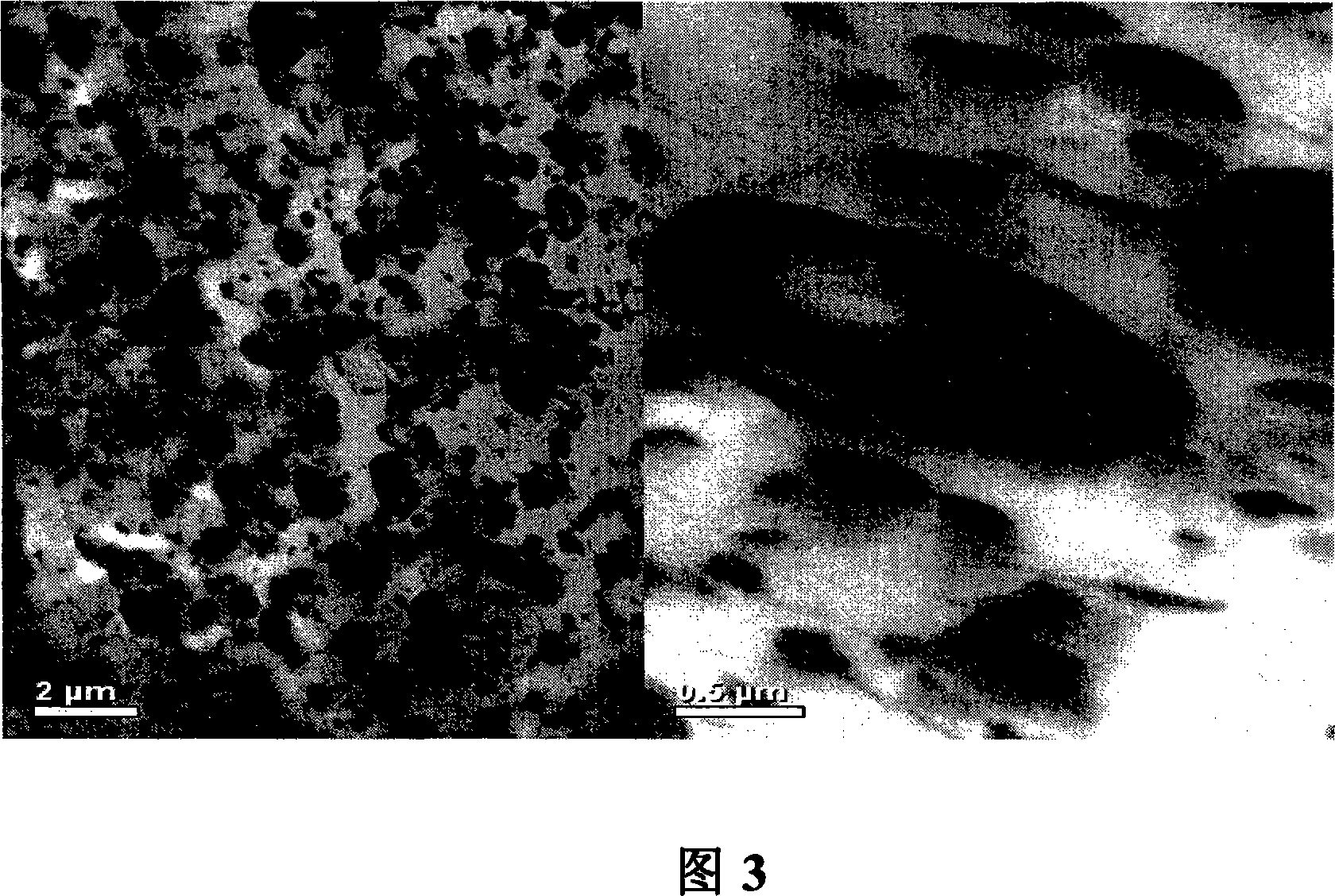

[0092] The main feed r...

Embodiment 3

[0099] The reaction system of this embodiment adopts five reactors, and part of the material (main feed) is added to the first reactor; part of the material (secondary feed) is added to the grafting reactor to obtain a certain degree of grafting and achieve phase inversion. , and then added to the subsequent third reactor.

[0100] Add 20kg of ethylbenzene and 46.49kg of styrene to the rubber dissolving tank, start stirring, and add 10kg of Asahi AsapreneTM610A rubber cut into 10*10mm into the rubber dissolving tank through the glue inlet, and stir and dissolve at room temperature for 8 hours. Then add 15.50kg of acrylonitrile, 6kg of nitrogen phenyl maleimide, continue dissolving for 3 hours, then add 1.40% of plasticizer white oil, 0.30% of antioxidant 3,5-tert-butyl-4-hydroxy -Phenyl-octadecyl ester, 0.30% chain transfer agent dimerized a-methyl styrene, 0.015% initiator tert-butyl perbenzoate, and continued to stir and disperse for 30 minutes.

[0101] The main feed rate ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heat deflection temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| Vicat softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com