Method for rapidly preparing double-layer structure foam with low residual monomer content, foam material and application thereof

A double-layer structure and foam material technology, applied in the field of foam materials, can solve the problems of poor operability and low foam transparency, and achieve the effects of rapid absorption, large cell size and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

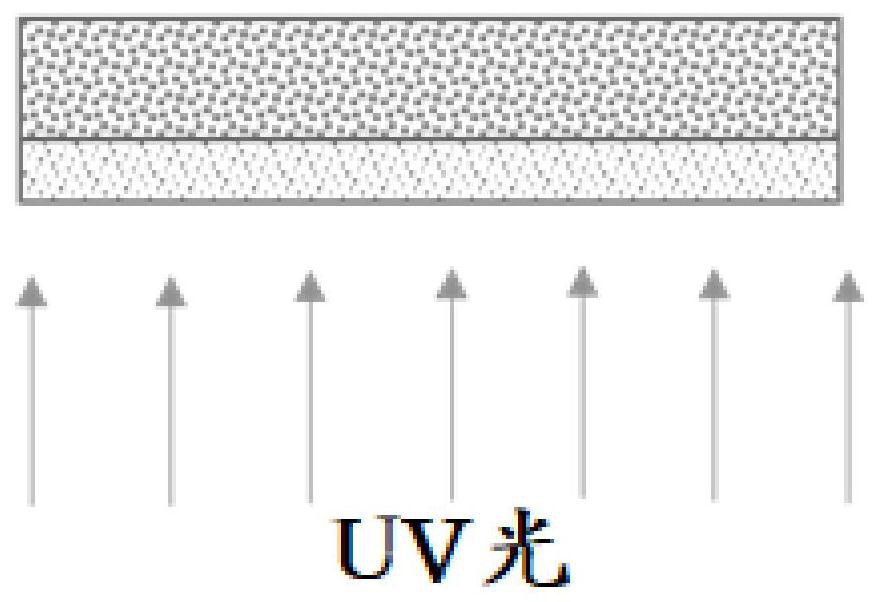

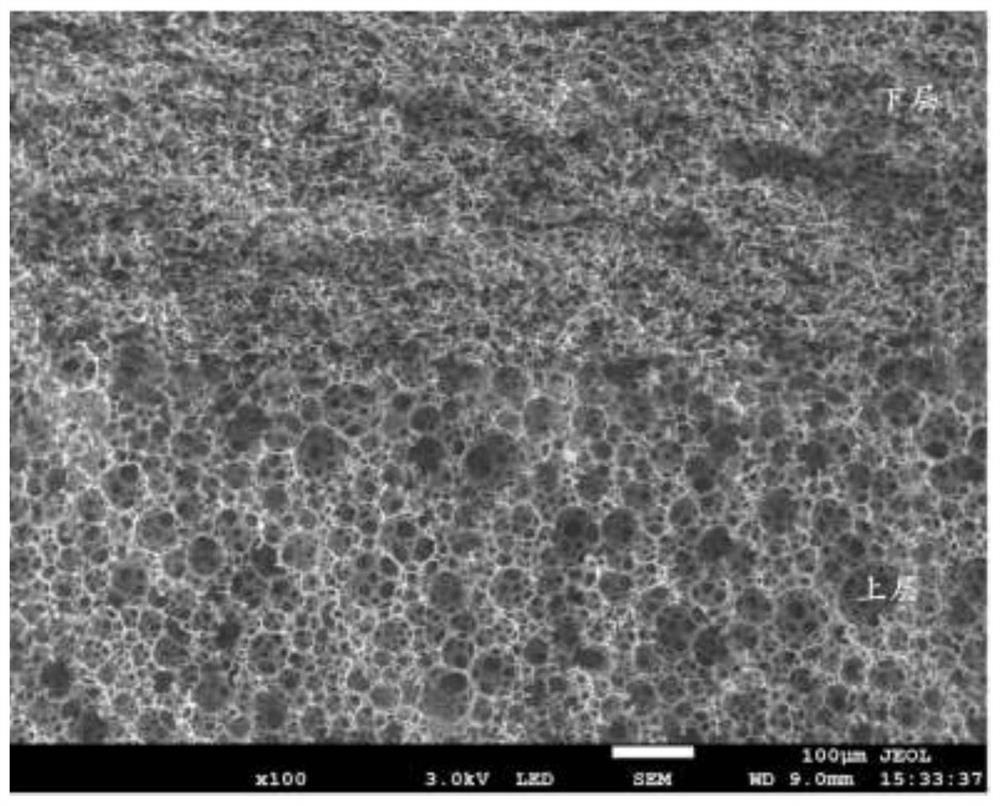

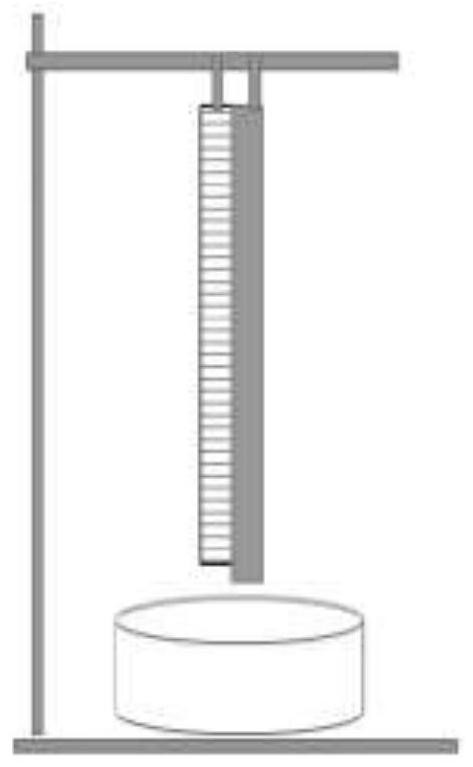

Method used

Image

Examples

Embodiment 1

[0137] A) Preparation of lower HIPE emulsion

[0138] Calcium chloride (60.0 grams) was dissolved in 1000 milliliters of deionized water to obtain an aqueous phase, which was maintained at 70° C.; mixed isooctyl acrylate (13.5 grams), styrene (6.0 grams), ethylene glycol dimethyl Acrylate (5.0 g) was uniformly dispersed with Span20 (2 g), Span 80 (3.5 g), and 1173 (1.9 g) to obtain a uniform oil phase.

[0139] The resulting oil phase is placed in a 2-liter volume stainless steel interlayer insulation dispersing tank, and the oil phase is stirred using a disperser with a diameter of 8 cm. The oil phase is stirred at a speed of 300 rpm at the beginning, and at the same time, the oil phase is stirred for 10 minutes. Add all the water phase within a certain period of time. During the addition of the water phase, the dispersion tank has been kept at 70°C. With the addition of the water phase, the stirring speed gradually increases. Layered high internal phase emulsion.

[0140] ...

Embodiment 2

[0148] A) Preparation of lower HIPE emulsion

[0149] Calcium chloride (40.0 grams), photoinitiator 2959 (purchased from Bailingwei, 0.1 grams) were dissolved in 600 milliliters of deionized water to obtain an aqueous phase, and the aqueous phase was maintained at 70°C; mixed isooctyl acrylate (20.0 grams), Divinylbenzene (55%, 5.0 g) was stirred and dispersed with Cithrol DPHS (PEG-30 dipolyhydroxystearate, purchased from CRODA, 5.0 g) to obtain a uniform oil phase.

[0150] The resulting oil phase is placed in a 2-liter volume stainless steel interlayer insulation dispersing tank, and the oil phase is stirred using a disperser. Add all the water phase within a certain period of time. During the addition of the water phase, the dispersion tank has been kept at 65°C. With the addition of the water phase, the stirring speed gradually increases. Layered high internal phase emulsion.

[0151] B) Preparation of upper HIPE emulsion

Embodiment 3

[0159] A) Preparation of lower HIPE emulsion

[0160] Calcium chloride (10.0 grams) was dissolved in 500 milliliters of deionized water to obtain an aqueous phase, which was maintained at 80° C.; mixed with isooctyl acrylate (25.0 grams), trimethylolpropane trimethacrylate (2.0 grams ) and diglycerin fatty acid ester (purchased from McLean, 3.0 g) to obtain a homogeneous oil phase.

[0161] The resulting oil phase is placed in a 2-liter volume stainless steel interlayer insulation dispersing tank, and the oil phase is stirred using a disperser. Add all the water phase within a certain period of time. During the addition of the water phase, the dispersion tank has been kept at 80°C. With the addition of the water phase, the stirring speed gradually increases. Layered high internal phase emulsion.

[0162] B) Preparation of upper HIPE emulsion

[0163] Calcium chloride (100.0 grams) was dissolved in 650 milliliters of deionized water to prepare an aqueous phase, which was mai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com