Plating solution for tumble-plating and tumble-plating method of steel battery shell

A battery steel shell and electroplating solution technology, applied in jewelry, etc., can solve the problems of low strength and poor corrosion resistance of battery steel shells, and achieve the effects of improving corrosion resistance, prolonging storage period, and small porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] A. Degreasing before plating:

[0015] i. Degreasing and degreasing:

[0016] Take the unplated steel shell used for LR6 alkaline zinc-manganese battery, put it in the degreasing tank, pour it into the degreasing liquid for washing, the degreasing liquid is based on the complete immersion of the steel shell, the mass of each component of the degreasing liquid The percentage concentration is as follows: 5% sodium hydroxide, 2% sodium silicate, 1% sodium carbonate, 2% sodium dodecylsulfonate, and the balance of tap water.

[0017] When washing, the temperature in the degreasing tank is 40°C, and the washing time is 20 minutes. After washing, it is cleaned with deionized water or tap water with a temperature of 40°C. The above washing-cleaning process is repeated twice.

[0018] ii pickling activation:

[0019] Pickle the steel case of the battery that has been degreased and degreased in step i with an acid solution at room temperature for 1 minute. The acid solution is...

Embodiment 2

[0028] A. Degreasing before plating:

[0029] i. Degreasing and degreasing:

[0030] The mass percent concentration of each component of the oil removal solution is as follows: 7% sodium hydroxide, 5% sodium silicate, 5% sodium carbonate, 3% sodium dodecylbenzenesulfonate, and the balance of tap water.

[0031] The temperature in the degreasing tank is 50°C, and the washing time is 30 minutes. After the washing is completed, it is cleaned with deionized water or tap water at a temperature of 50°C.

[0032] ii pickling activation:

[0033] Pickling for 2 minutes, the acid solution is 25% hydrochloric acid by mass percentage.

[0034] B. Barrel plating:

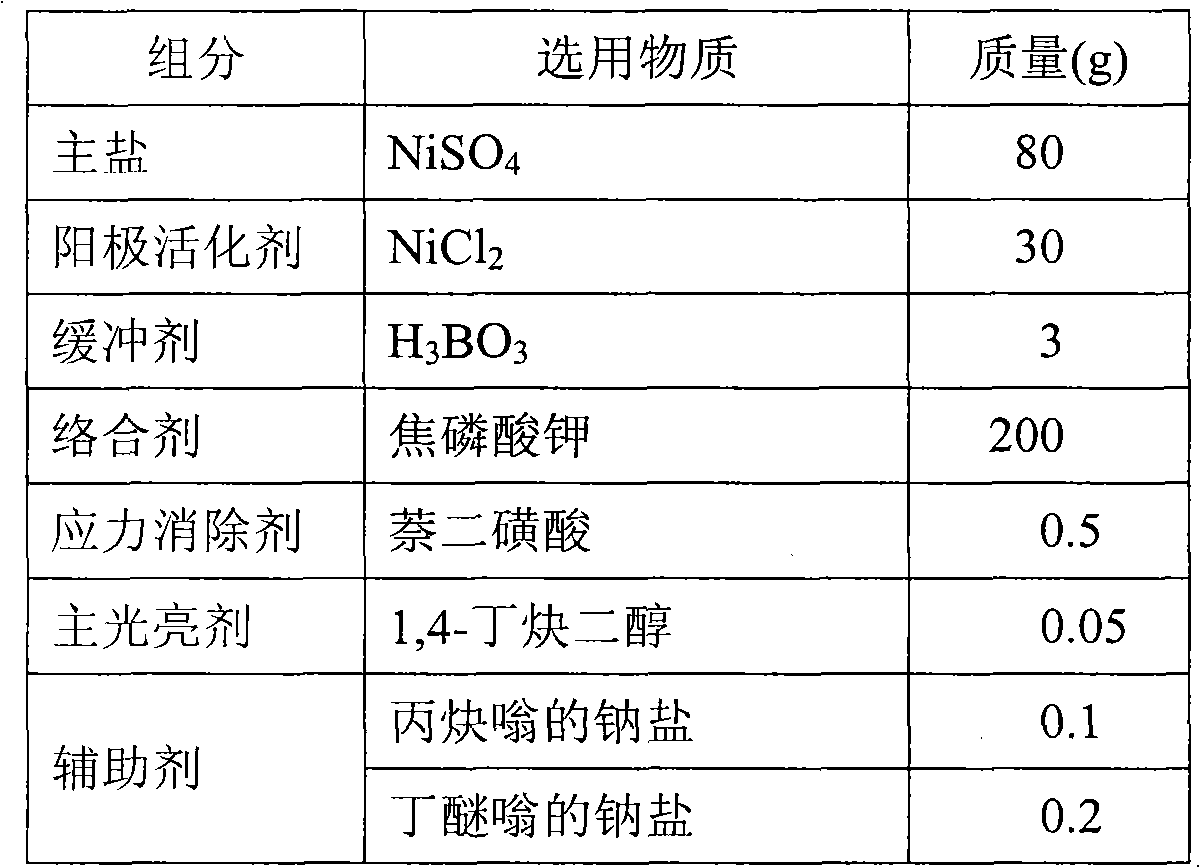

[0035] Put the steel shell that has completed the degreasing treatment before step A before plating into the barrel plating tank, pour the electroplating solution for barrel plating, and prepare the electroplating solution according to the following requirements:

[0036]

[0037]All the above components were dissolved i...

Embodiment 3

[0040] A. Degreasing before plating:

[0041] i. Degreasing and degreasing:

[0042] The mass percent concentration of each component of the oil removal solution is as follows: 10% sodium hydroxide, 8% sodium silicate, 10% sodium carbonate, 5% sodium dodecylsulfonate, and the balance of tap water.

[0043] The temperature in the degreasing tank is 60°C, and the washing time is 40 minutes. After washing, it is cleaned with tap water at a temperature of 60°C.

[0044] ii pickling activation:

[0045] Pickling for 3 minutes, the acid solution is 45% hydrochloric acid by mass percent.

[0046] B. Barrel plating:

[0047] Put the steel shell that has completed the degreasing treatment before step A before plating into the barrel plating tank, pour the electroplating solution for barrel plating, and prepare the electroplating solution according to the following requirements:

[0048]

[0049]

[0050] All the above components were dissolved in deionized water to form a sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com