Patents

Literature

487results about How to "Stainless" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

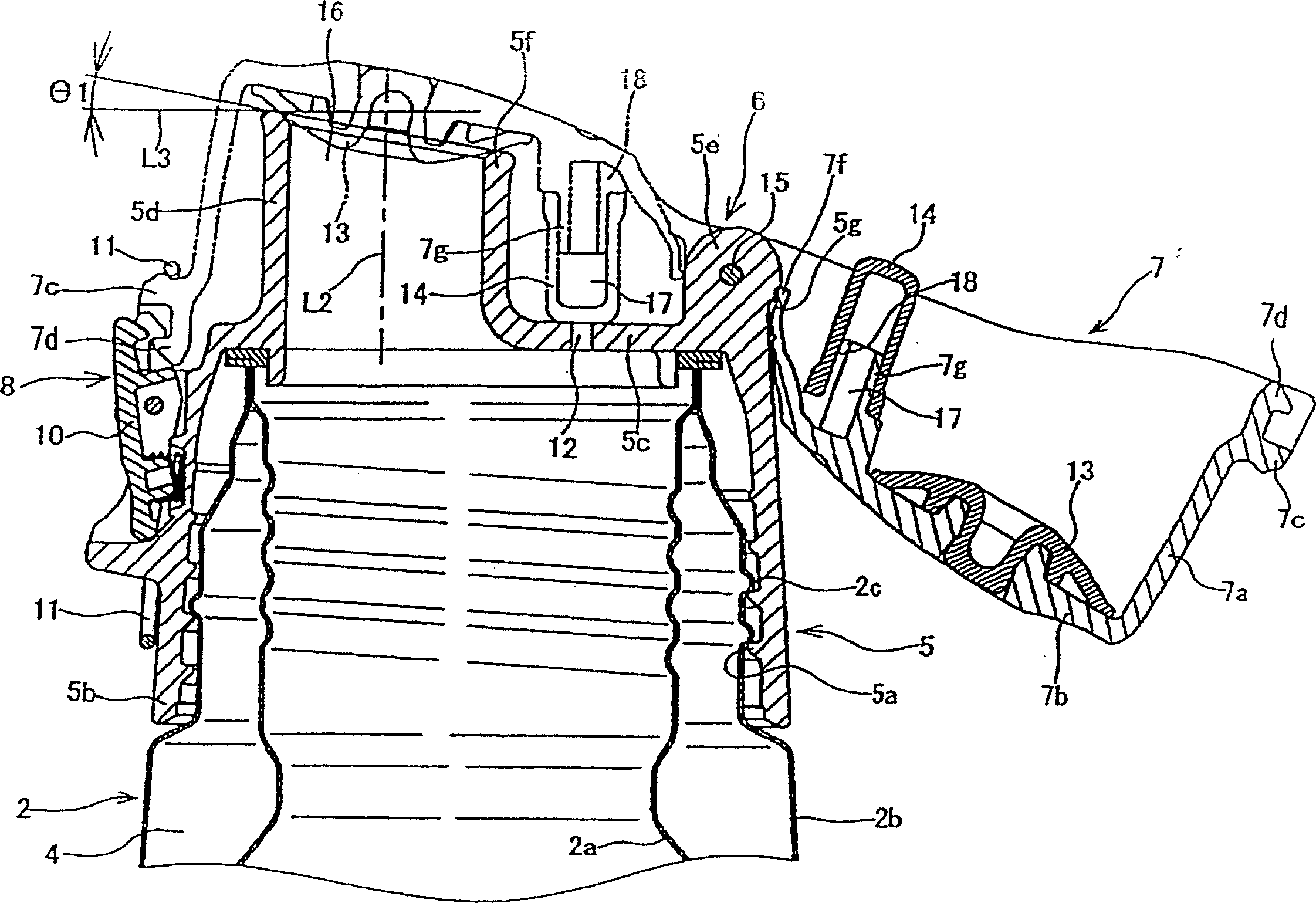

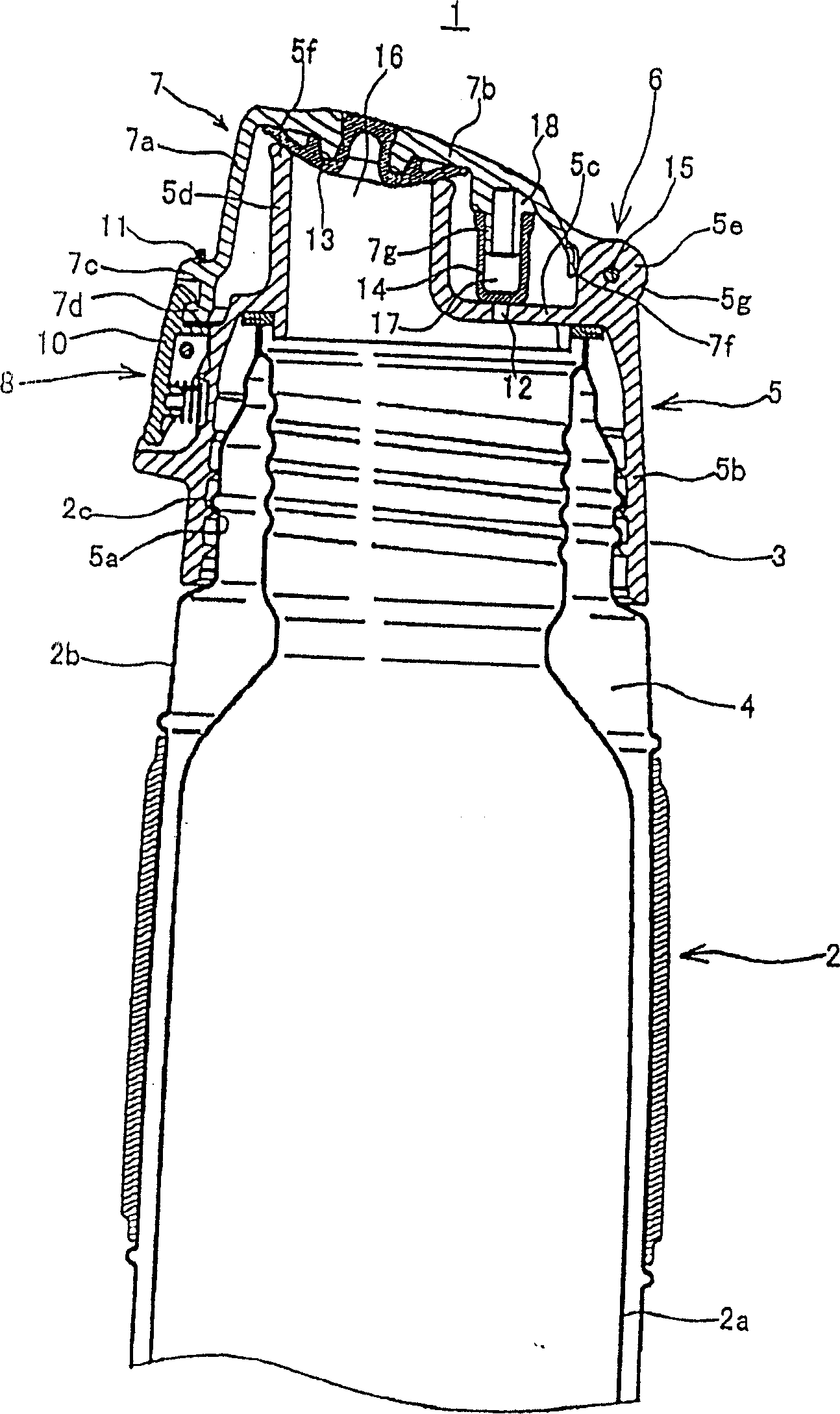

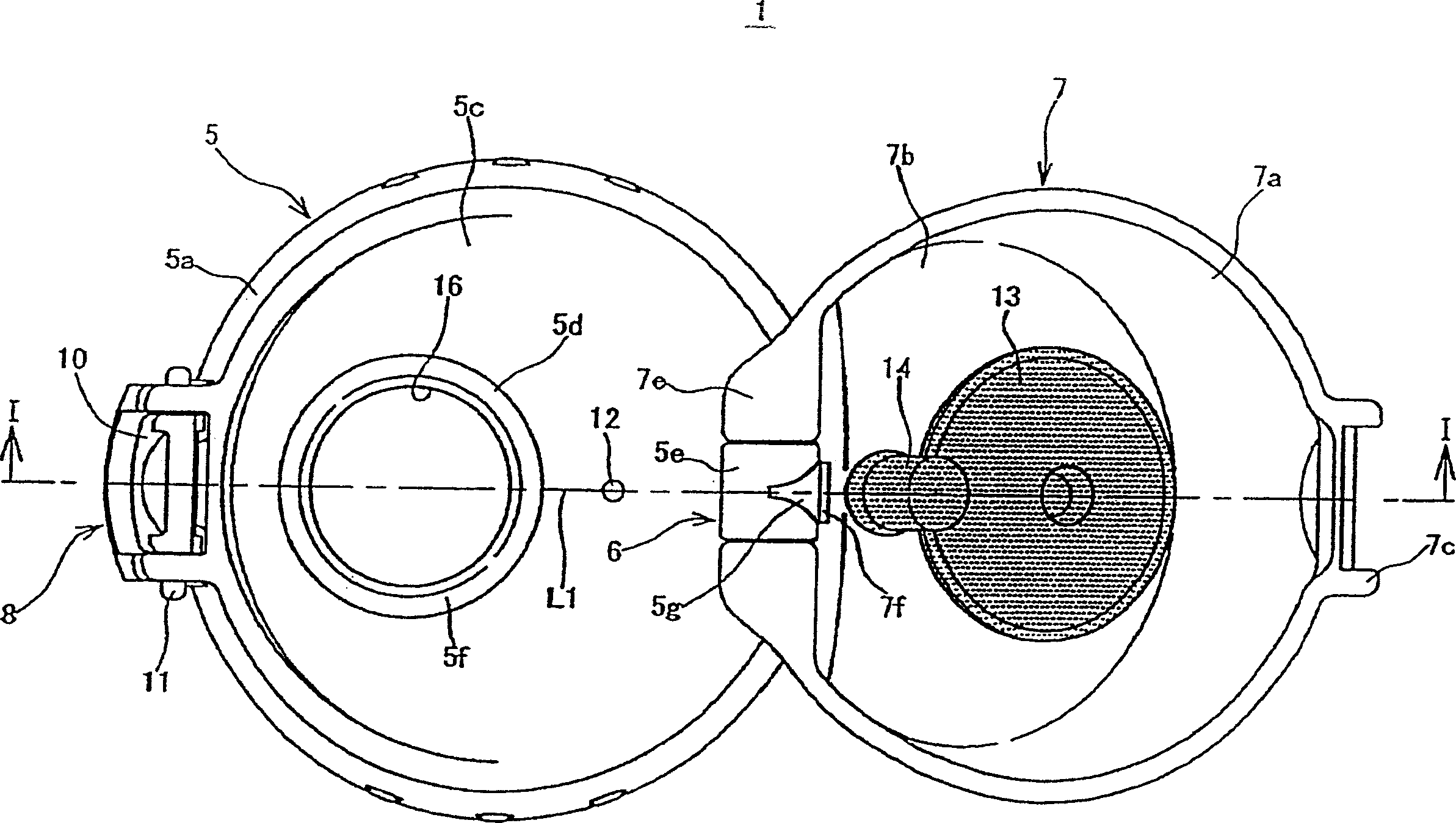

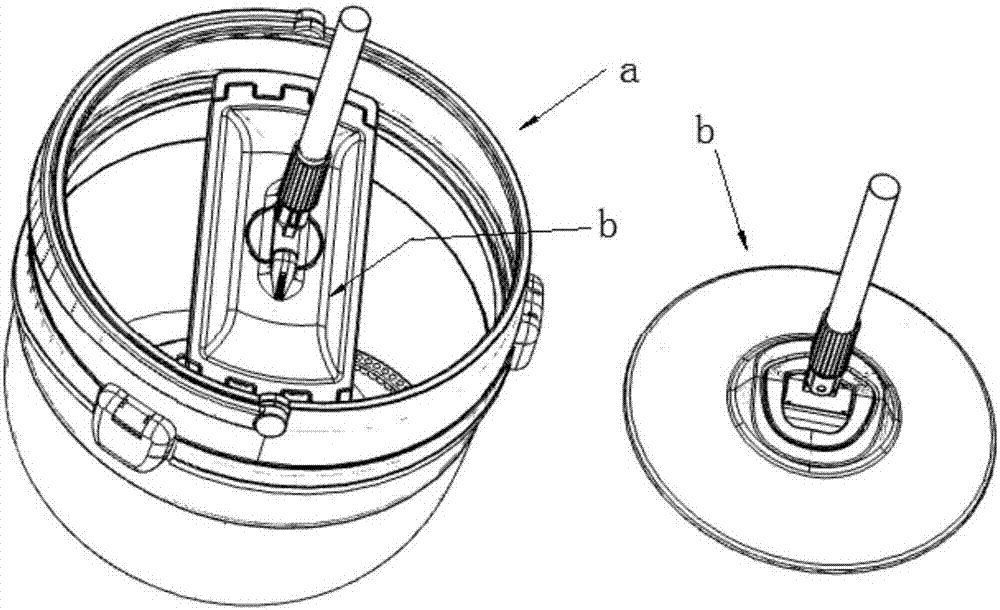

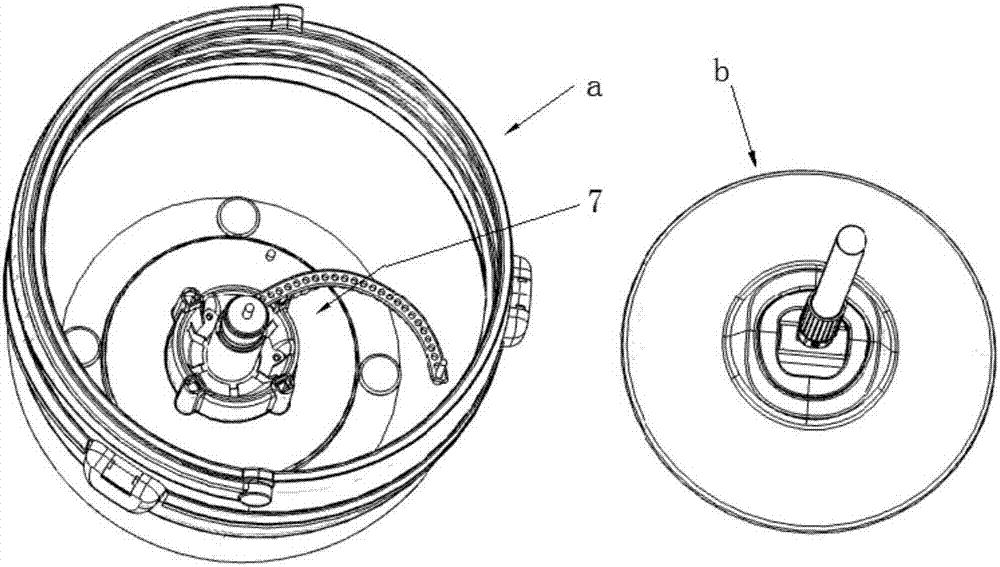

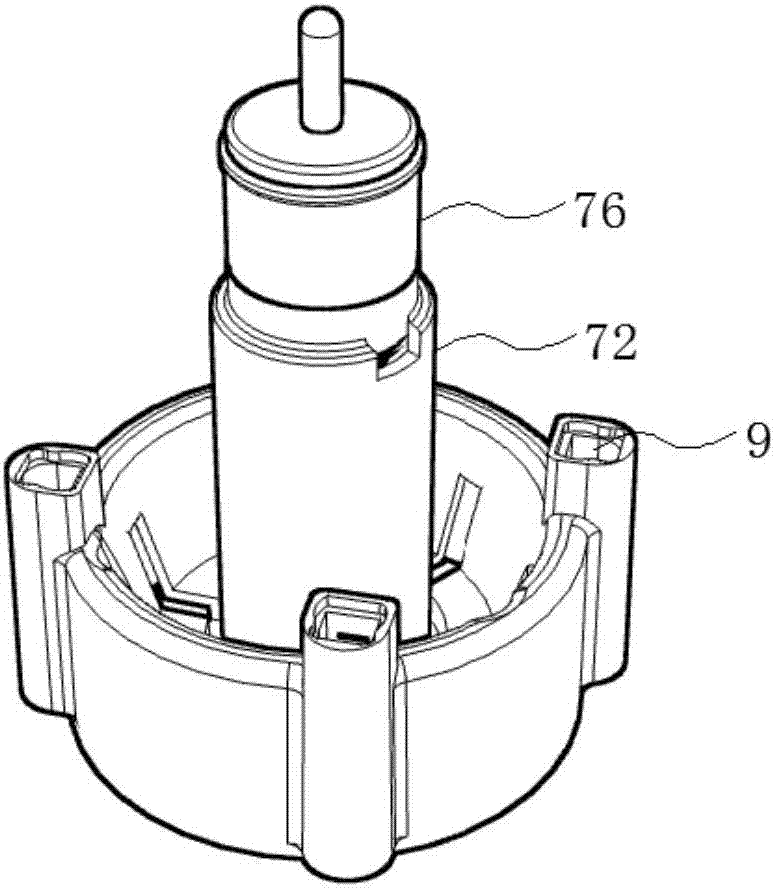

Middle bolt of beverage container

Owner:THERMOS LLC

Formula and preparation technology of machine tool working solution

InactiveCN103242946ALong effective timeImprove efficiencyLubricant compositionSodium phosphatesAlkylphenol

The invention discloses a formula and a preparation technology of a machine tool working solution. The formula of the machine tool working solution is characterized by comprising the following materials: 10-20 parts of dodecenylsuccinic acid, 5-10 parts of petroleum sodium sulfonate, 5-7 parts of alkylphenol ethoxylates, 2-6 parts of edible calcium benzoate, 5-7 parts of polyethylene glycol, 2-7 parts of sodium phosphate, 5-10 parts of barium petroleum sulfonate, 5-8 parts of tricthanolamine, 5-8 parts of sodium dodecyl sulfate, 2-4 parts of ethylenediamine tetraacetic acid, 1-3 parts of rosin, 1-2 parts of defoaming agent and the balance of deionized water. According to the preparation technology of the machine tool working solution, the machine tool working solution is prepared from the materials through three steps. The technical problem to be solved by the invention is to provide the formula and the preparation technology of the machine tool working solution; and the cutting solution provided by the invention does not contain sodium nitride, machine oil or heavy metals, is harmless to hands and does not cause the falling of paint.

Owner:CHANGSHA HAODI ELECTROMECHANICAL TECH

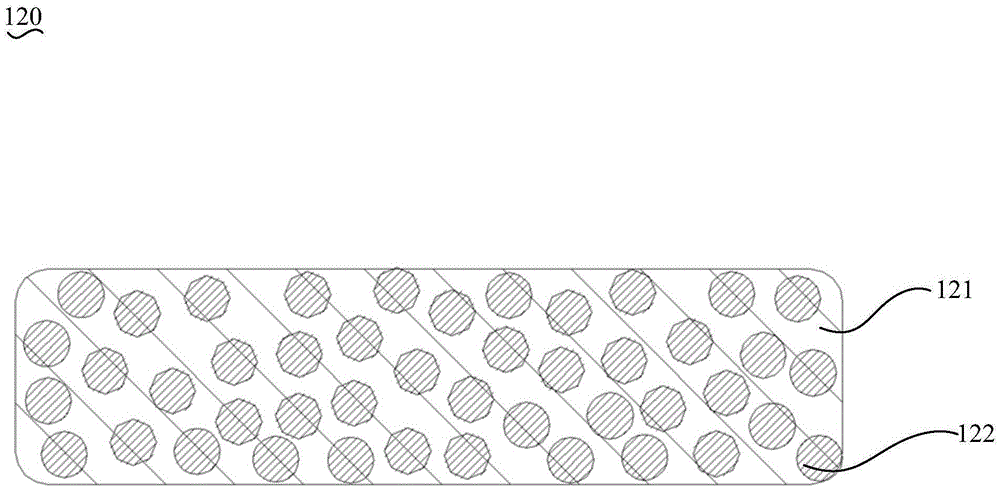

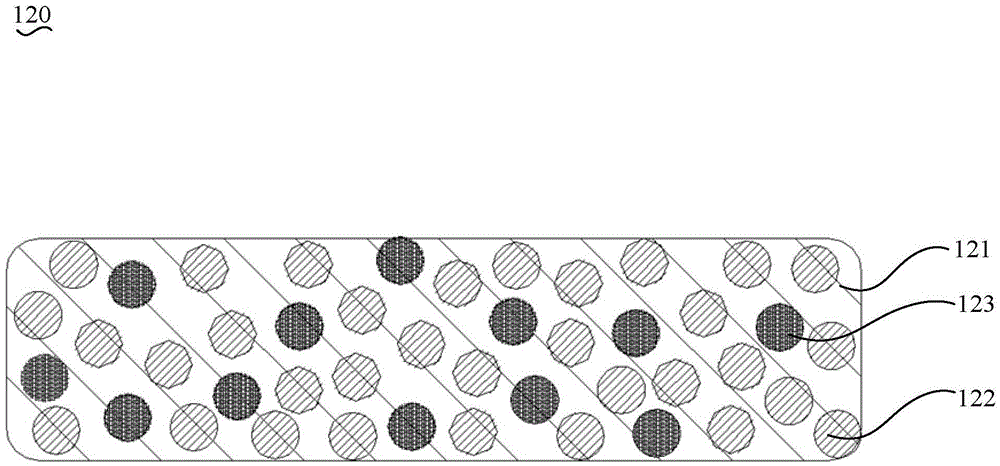

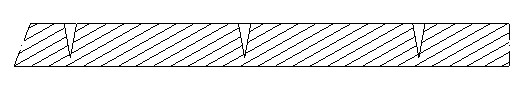

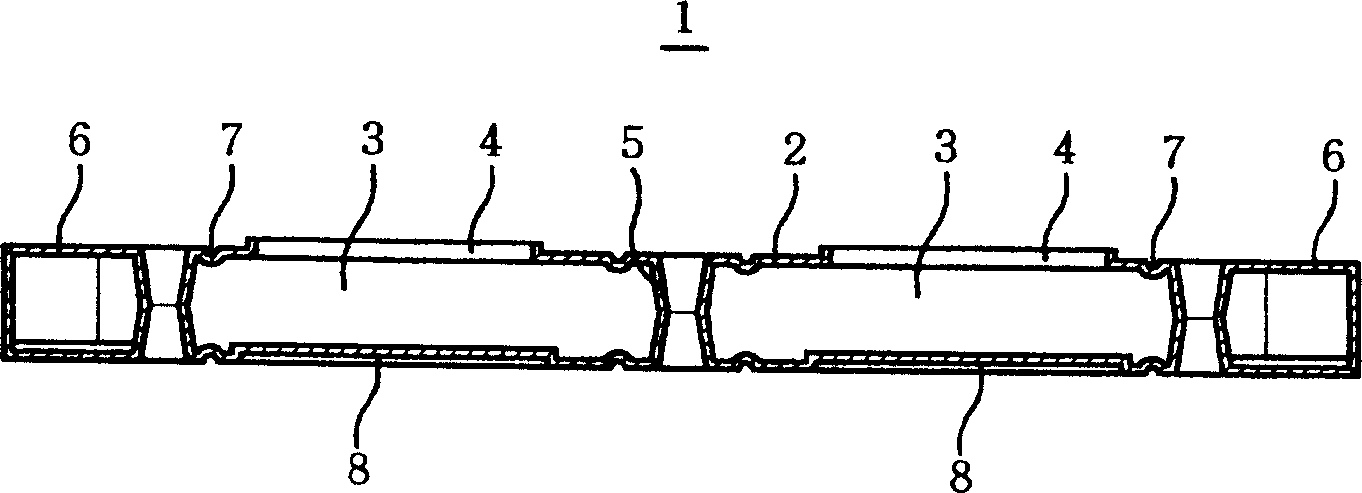

Elevator traction belt and elevator

InactiveCN105672009AHigh tensile strengthReduce weightRope making machinesElevatorsResin matrixEngineering

The invention discloses an elevator traction belt and an elevator with the traction belt. The traction belt comprises a wrapping layer and at least one bearing body sleeved with the wrapping layer. Each bearing boy comprises basalt fibers and a resin matrix which are compounded together. The basalt fibers comprise multiple parallel basalt fiber filaments. Due to the fact that density of the basalt fibers and the density of the resin are both smaller than that of a steel wire, the weight of the traction belt is effectively reduced, the traction belt can be easily used on the elevator with superlarge lifting height, and the range of an existing maximum elevator lifting height can be widened. Meanwhile, the basalt fibers have a good sound absorption effect, the traction belt is made from the basalt fibers, noise generated during operation of the traction belt can be effectively lowered, and elevator taking comfort is improved. The basalt fiber filaments are arranged in the resin matrix in parallel, friction force among the fiber mono-filaments is reduced, the traction belt has the advantages of being free of twisting, resistant to abrasion, resistant to fatigue and the like, the traction performance of the traction belt is improved, and the service life of the traction belt is prolonged.

Owner:HITACHI ELEVATOR CHINA

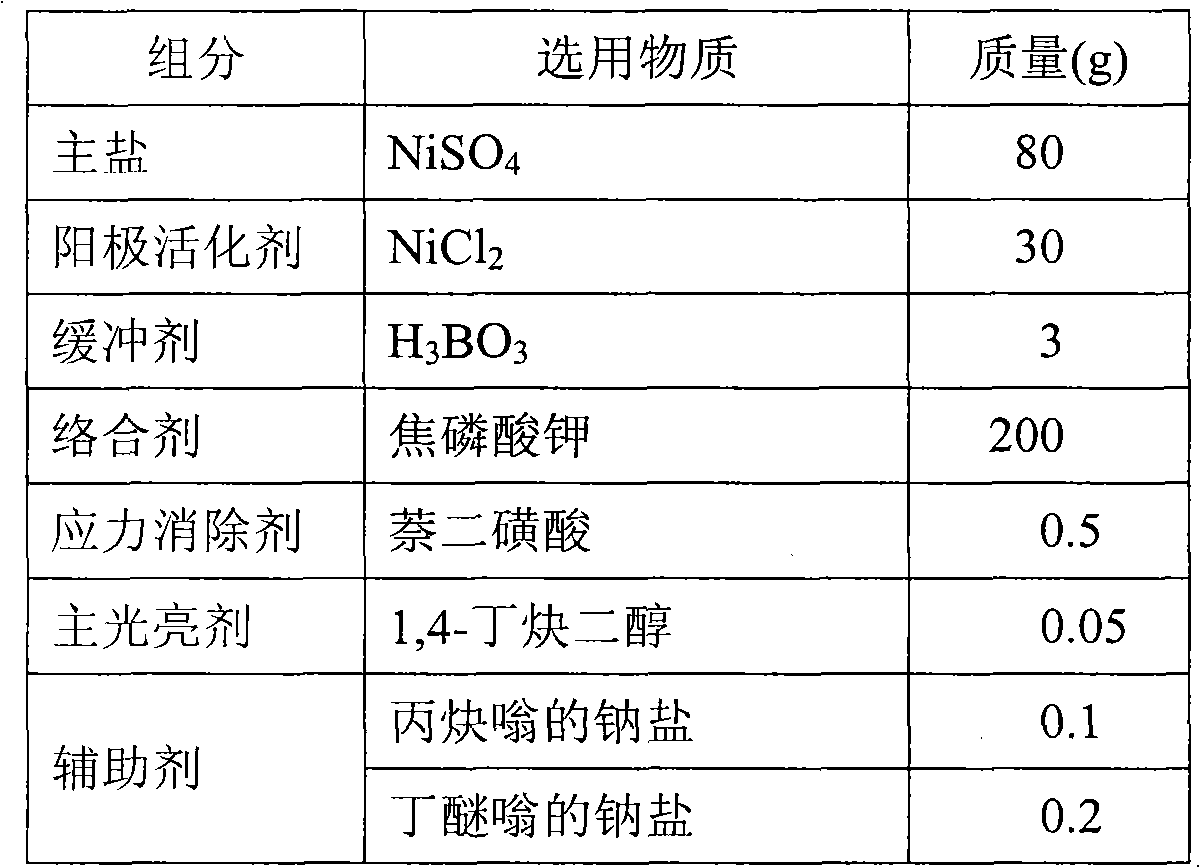

Plating solution for tumble-plating and tumble-plating method of steel battery shell

The invention relates to a treatment process of a carrier of a device which is used to directly change chemical energy to electrical energy, in particular to a plating solution for tumble-plating and a tumble-plating method of a steel battery shell. The plating solution comprises the following components in parts by weight: 80-120 or 200-350 parts of main salt, 30-100 parts of anode activator, 3-60 parts of buffering agent, 20-30 or 180-250 parts of complexant, 0.5-2.5 parts of stress reducer, 0.005-0.1 part of main brightener and 0.3-1.0 part of auxiliary agent and is prepared by dissolving the components in water. The tumble-plating method of the invention comprises the following steps in turn: degreasing, tumble-plating and bleaching, wherein during tumble-plating, the pH value of the plating solution is 4.0-4.6 or 6.5-8.5, the temperature is 40-70 DEG C, the current density is 0.2-3A / dm<2>, the rotational speed of the drum is 4-12rpm, and the tumble-plating time is 180-300 minutes. The coating of the invention has write and bright appearance, high luminance brightness and powerful corrosion resistance.

Owner:上海金杨金属表面处理有限公司

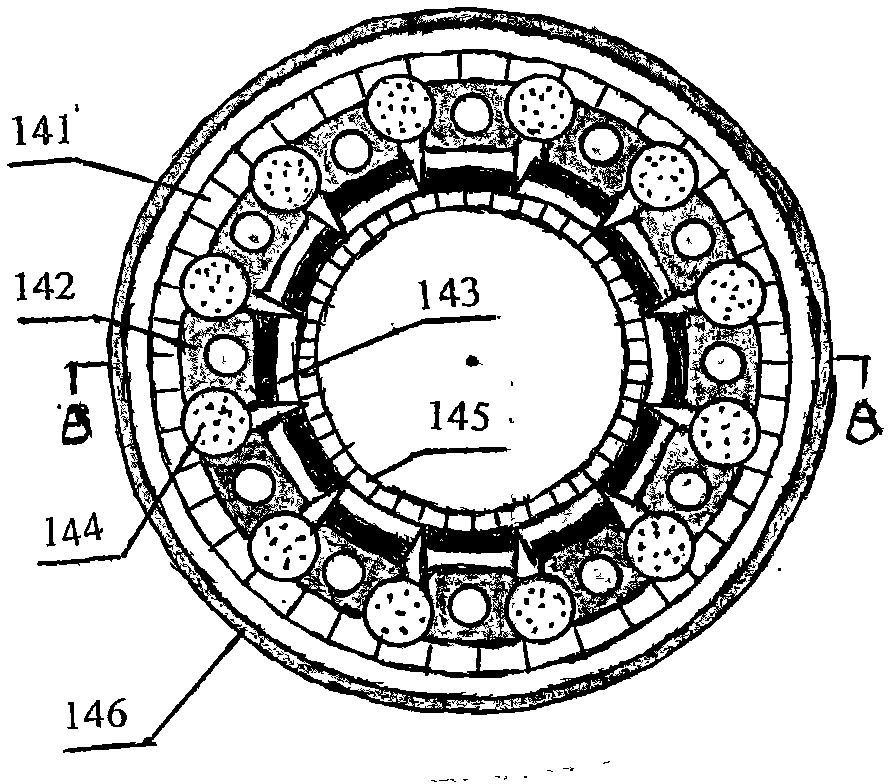

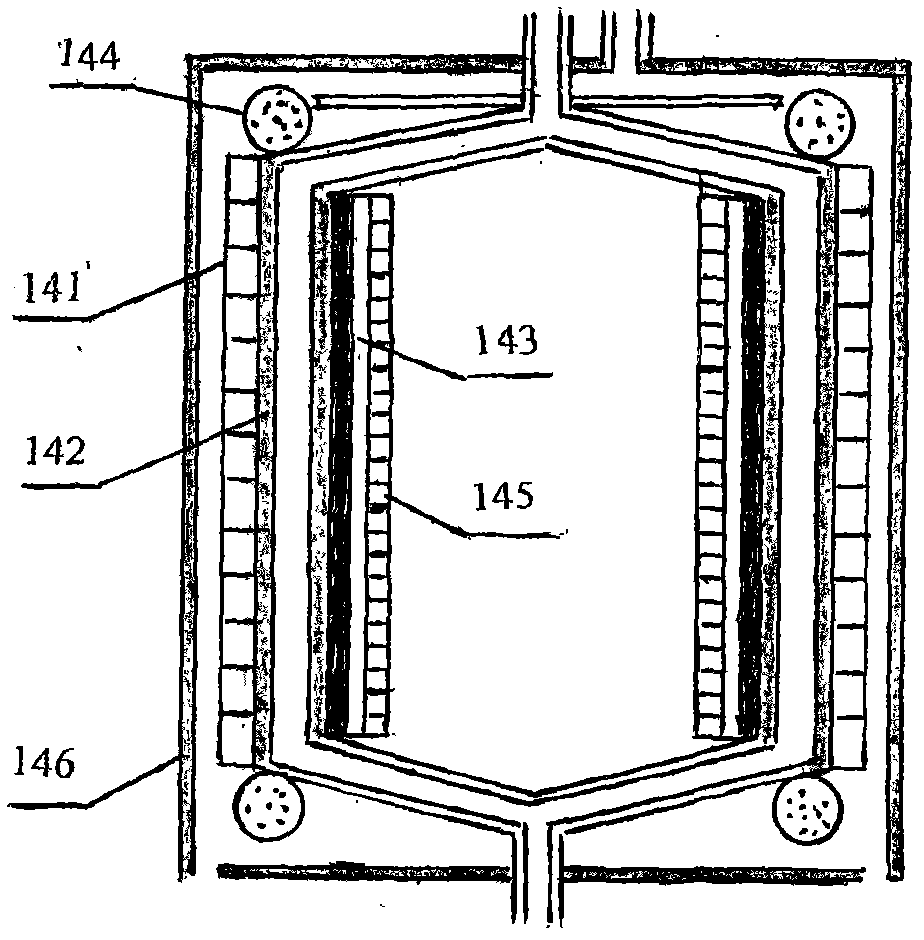

Power generating device by waste heat of automobiles

ActiveCN102510243AImprove pressure resistanceAccelerated corrosionInternal combustion piston enginesEngine componentsNon magneticAlternating current

The invention discloses a power generating device by waste heat of automobiles. A plurality of novel alloy bars are attached to the inner side of a circular iron hose of a power generator, coils are mounted between adjacent novel alloy bars and arranged in coil slots formed by adjacent novel alloy bars in a surrounded manner, heat and cold exchange holes are arranged on the novel alloy bars, an elongated rare earth magnet is attached on an outer face side of each alloy bar, magnetic polarities of the rare earth magnets on the face sides of the adjacent novel alloy bars are opposite, the other magnetic polarity surfaces of the rare earth magnets are wrapped on steel pipes, and the power generator is provided with an outer casing. The novel alloy bars are non-magnetic substances at a certain low temperature while are magnetic substances at a certain high temperature. When the rare earth magnets are close to the novel magnetic alloy bars, magnetism of the novel magnetic alloy bars is doubled. The novel alloy bars have magnetism after being heated by tail gas or a heat medium liquid in a cylinder liner of an automobile and have no magnetism after being cooled by cold air with water mist or refrigerant liquid, and high alternating current can be produced in the coils by repeating the above steps and can be used as power force for electric automobiles.

Owner:张英华

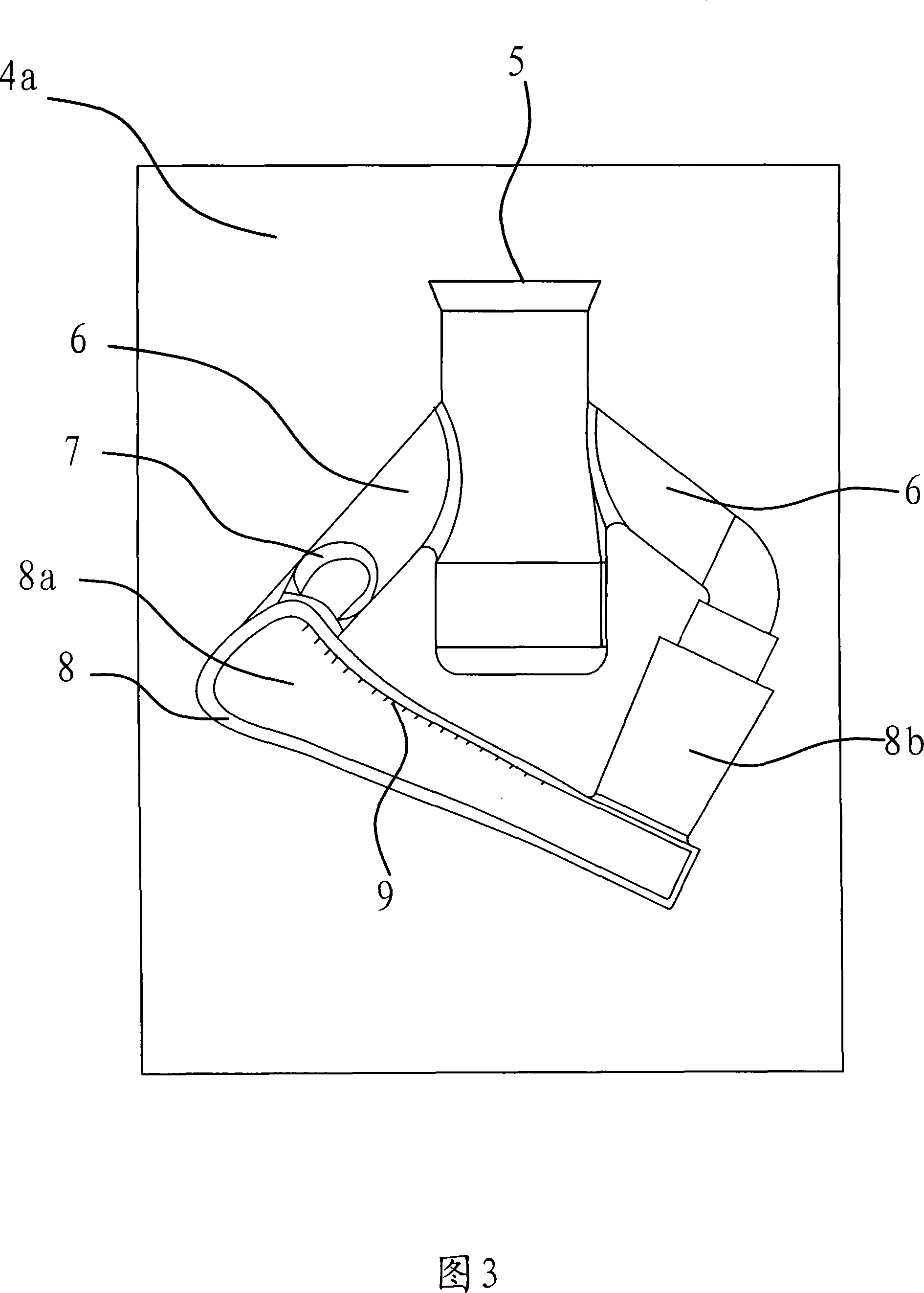

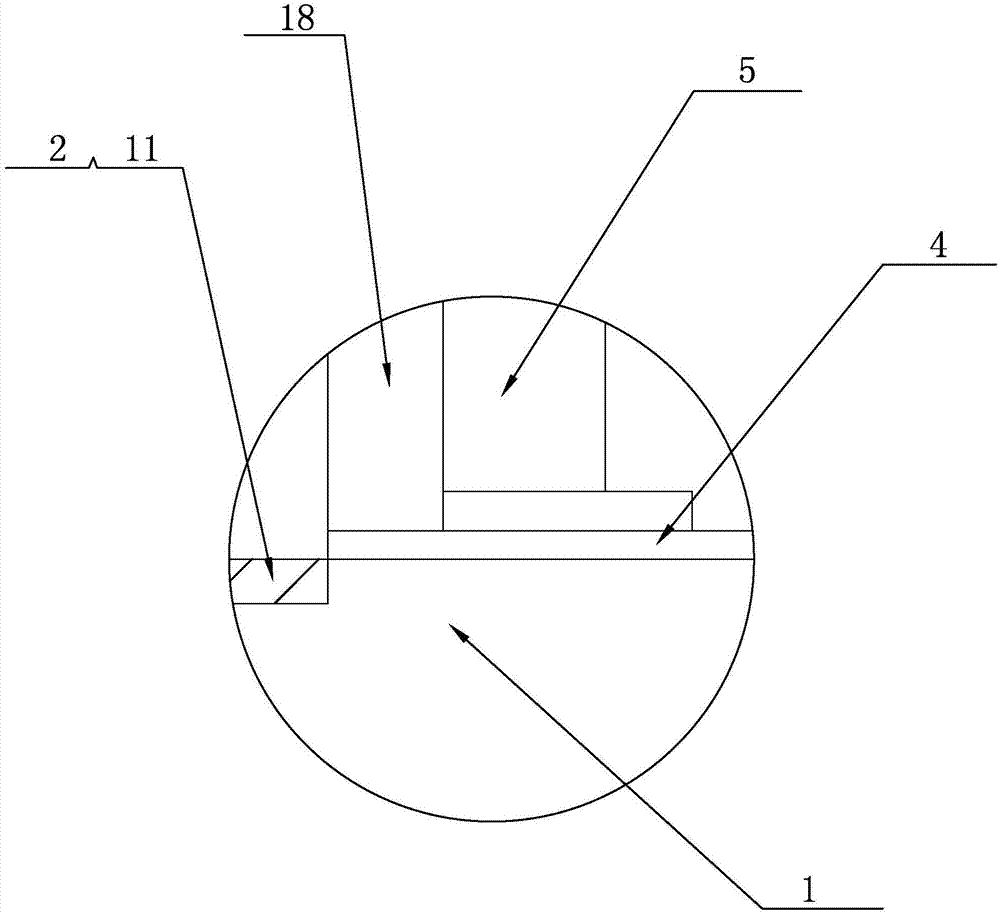

Cleaning tool

ActiveCN107997708ASimple structureEasy to manufactureCarpet cleanersFloor cleanersEngineeringMechanical engineering

The invention discloses a cleaning tool. The cleaning tool comprises a mop bucket and a mop. The mop comprises a mop rod, a bottom board and a rotation joint. The mop rod comprises an outer rod body and an inner rod body. The rotation joint comprises a first rotation part and a second rotation part. The bottom of the mop bucket is provided with a lifting mechanism. The lifting mechanism comprisesa fixing column fixed at the bottom of the mop bucket, a moving tube and a positioning rod. The moving tube is sheathed outside the fixing column. The positioning rod passes through the moving tube and is inserted in an inserting hole at the center of the fixing column, and the positioning rod is rotated relative to the fixing column. The lifting structure of the cleaning tool is simplified, and the operation is convenient, so the washing and dewatering functions of the mop are combined and coaxially performed, and the volume of the mop bucket can be reduced. The locking structure of the mop rod is simplified, and the angle between the mop rod and a faceplate can be conveniently adjusted and positioned. The locking structure is suitable for the mop or other cleaning tools with the similardemand. In addition, wiping cloth is effectively fixed on a bottom plate of the mop through a fixing claw by the lower faceplate, so the service life of the mop is prolonged.

Owner:HEBEI JIESHIBAO DAILY PLASTIC PROD CO LTD

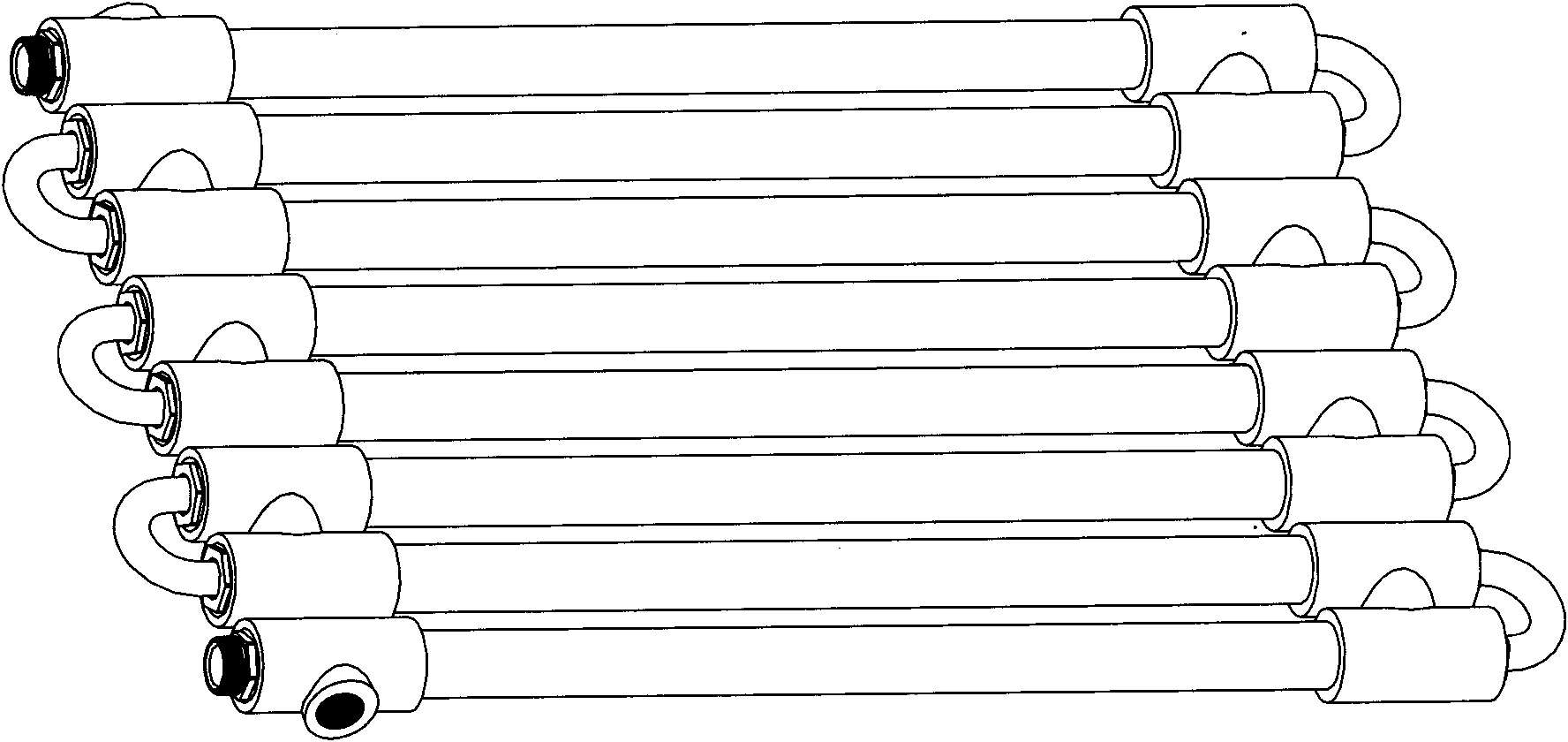

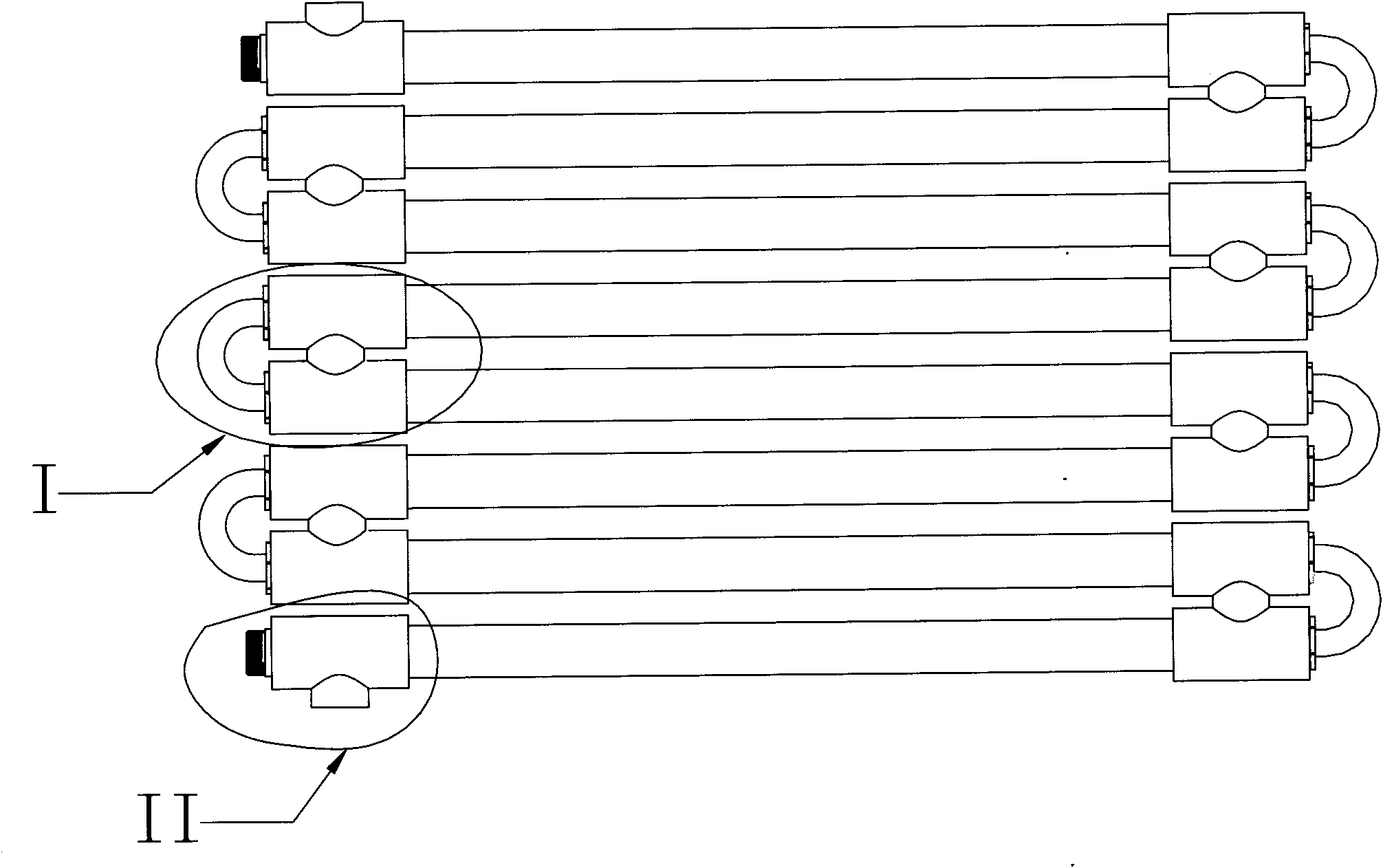

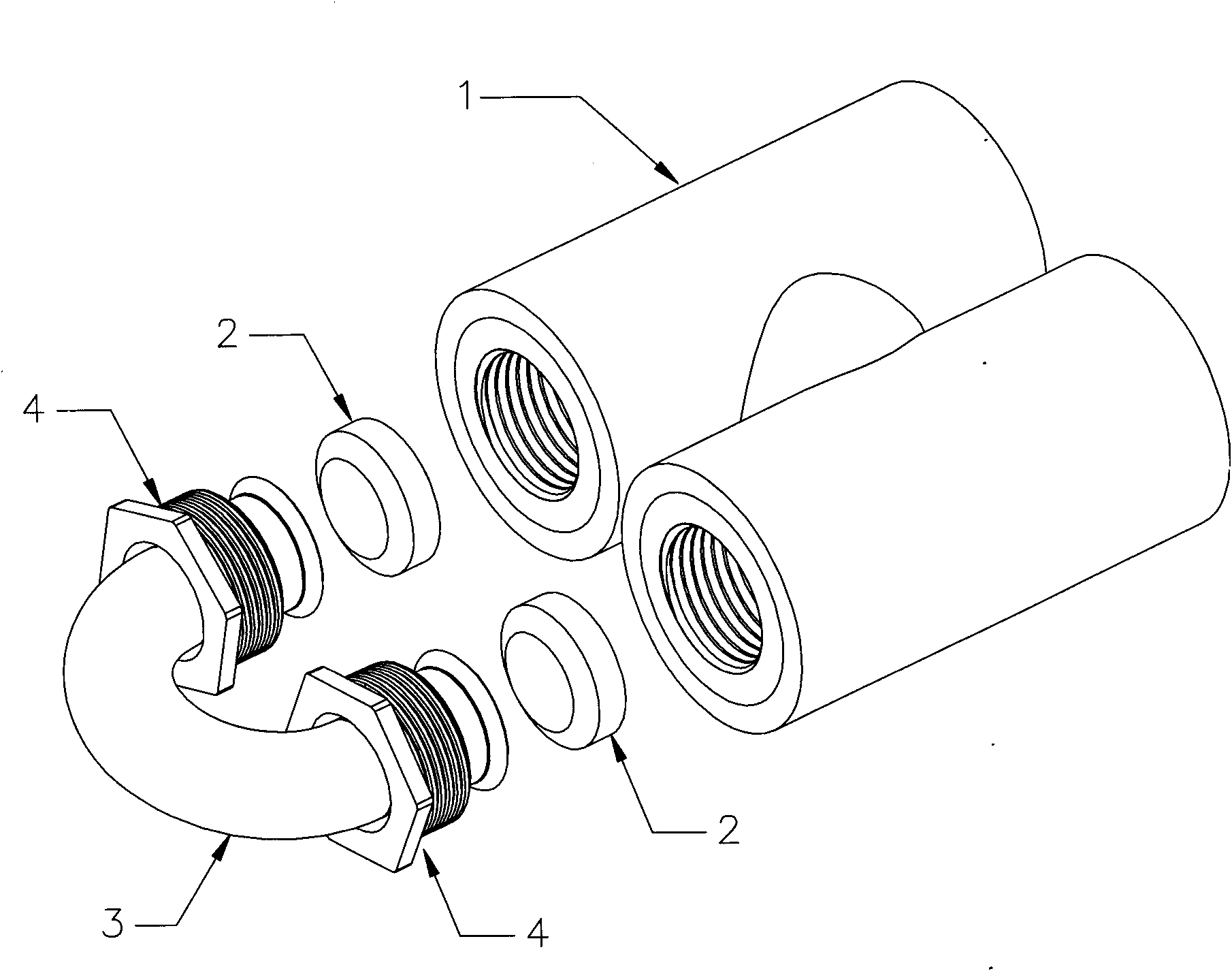

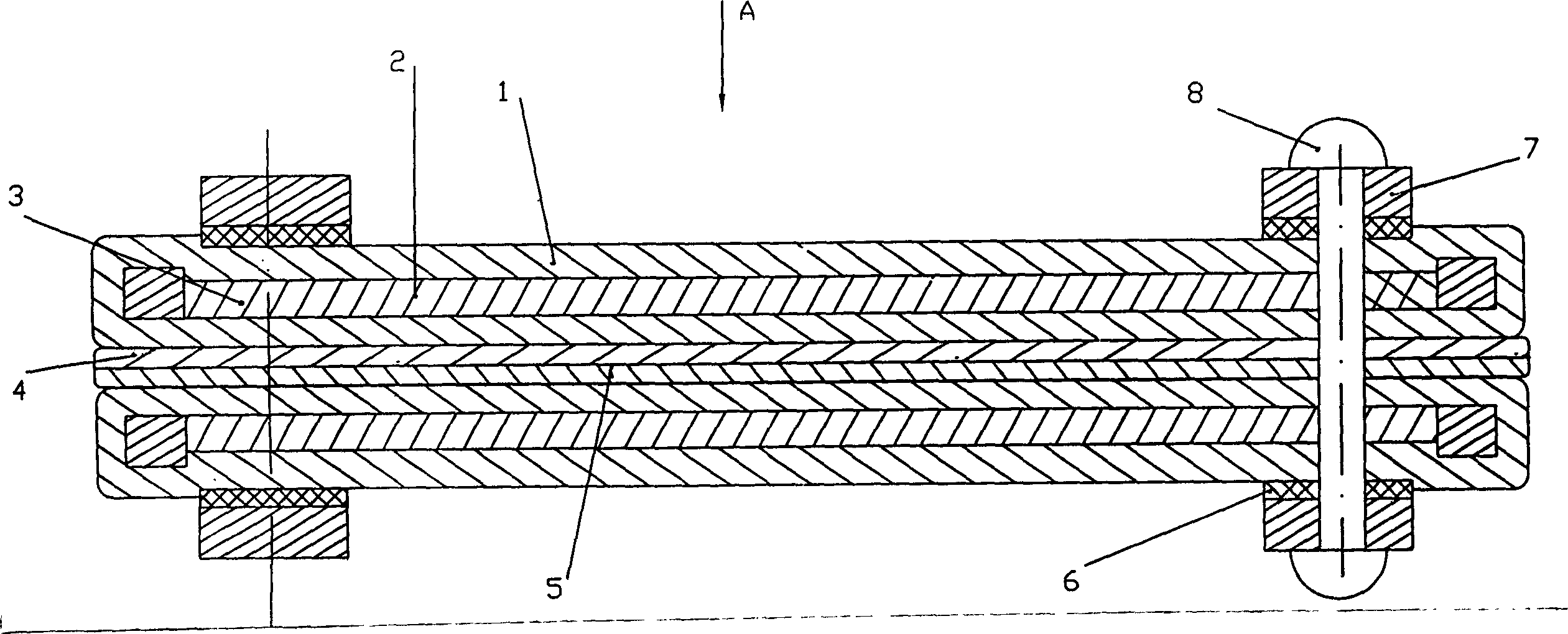

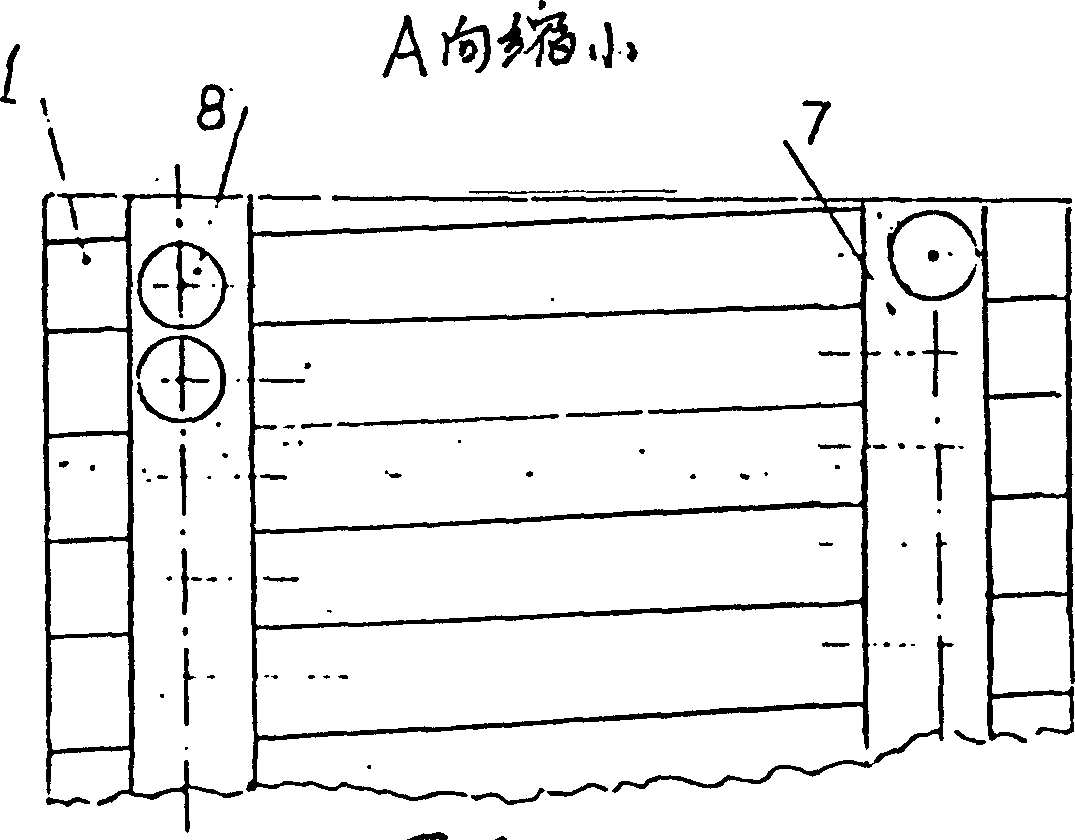

Double-pipe heat exchanger

InactiveCN101776405AReduce lossesImprove heat transfer effectHeat exchanger casingsStationary tubular conduit assembliesPlate heat exchangerScrew thread

The invention discloses a double-pipe heat exchanger which is characterized in that an outer pipe is a plastic pipe and an inner pipe is a metal pipe; the two pipes are spliced through a U-shaped pipe with movable adapters, a rubber sealing ring and a plastic H-shaped four-way joint; and the two ports of the heat exchanger are separated and led out through a plastic T-shaped tee joint, an annular rubber sealing ring and a metal straight-through joint. Both the plastic T-shaped tee joint and the plastic H-shaped four-way joint are provided with ports which are provided with metal inserts, and round holes just for the inner pipe to pass through are arranged at the bottoms of the inserts. Two parallel straight pipe sections with equal length are respectively arranged at the two ends of the U-shaped pipe, two tubular threaded moveable adapters are respectively sleeved at the outsides of the two ends of the U-shaped pipe, and trumpet-shaped flarings are arranged at the ports of the two ends of the U-shape pipe. The heat exchanger is convenient to install, can be dismantled for cleaning and is low in cost.

Owner:SHANGHAI CHUNHUA ELECTRONICS

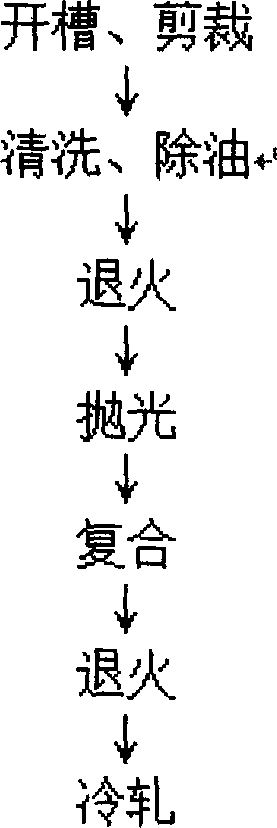

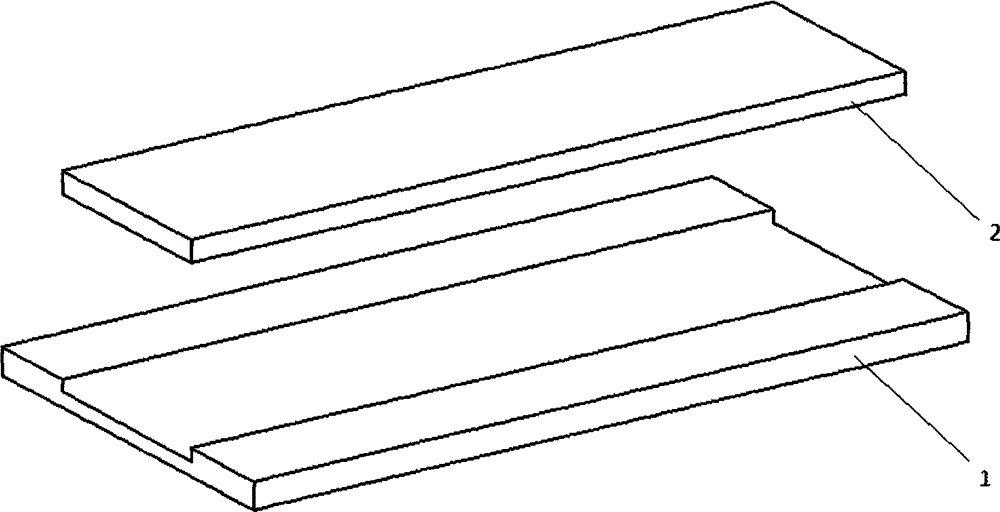

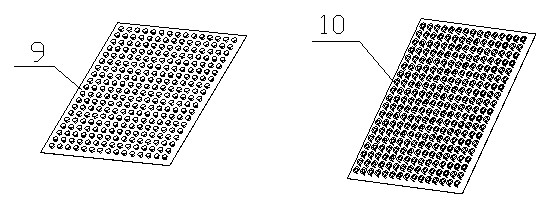

Conductive composite metal sheet between lugs in batteries or batteries and machining method

The invention discloses a machining method for a conductive composite metal sheet between lugs in batteries or the batteries. According to the conductive composite metal sheet located between the lugs in the batteries or the batteries and produced through the method, the thickness of a nickel metal layer on the surface of the metal sheet is much larger than the thickness of an electroplated coating, so that the welding strength is high, the welding difficulty is low, and a cold solder joint is not prone to being generated; and the binding strength between the nickel metal layer and a copper belt is higher, and the performance of a whole battery set is ensured. The method is characterized by comprising the following steps of conducting grooving and tailoring on a copper belt and a nickel belt, conducting cleaning and oil removal on the copper belt and the nickel belt, conducting annealing on the copper belt and the nickel belt, polishing of the surfaces of the copper belt and the nickel belt, compositing, annealing and cold rolling finally.

Owner:谢振华

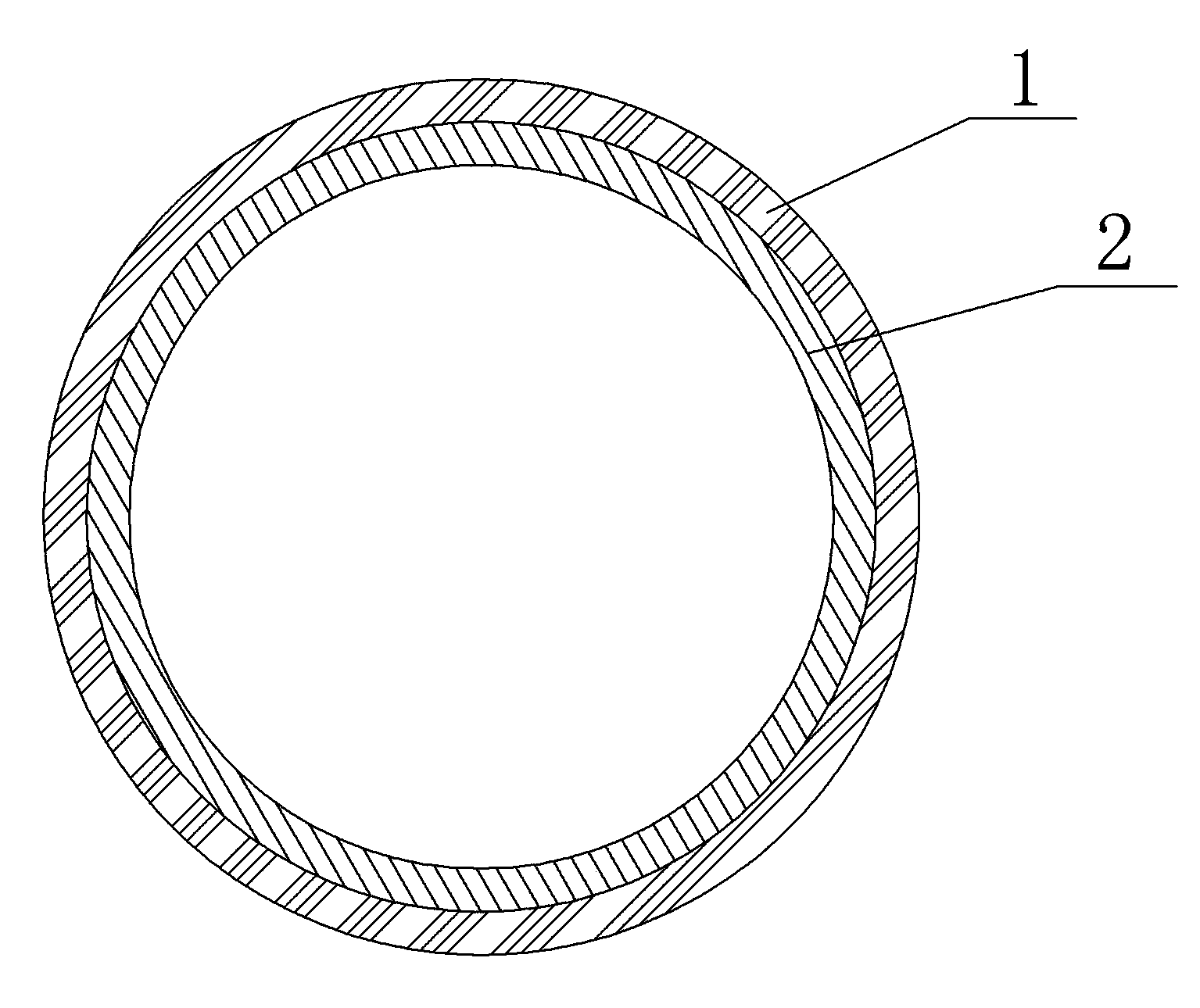

Double-layer composite tube and manufacturing method thereof

ActiveCN104019298AImprove stress resistanceFlow fastFlexible pipesLow-density polyethyleneWater quality

The invention discloses a double-layer composite tube and a manufacturing method thereof. The double-layer composite tube and the manufacturing method aim to solve the technical problems that black pigment is added into traditional HDPE tubes, accordingly inner walls are not smooth, water scale is prone to being generated, bacteria grow, and secondary pollution of water is caused. The double-layer composite tube comprises an inner layer and an outer layer, the inner layer is made of ultrahigh molecular weight polyethylene and ethylene-vinyl alcohol copolymers or low-density polyethylene, and the outer layer is made of high-density polyethylene, ethylene-vinyl alcohol copolymers and special melanin particles C of PE. The method includes the following steps of material proportioning and dehumidifying, material plastifying, material forming, vacuum sizing and spraying and cooling. The double-layer composite tube has the advantages of being good in toughness and flexibility, high in chemical stability, good in corrosion resistance, good in sealing performance, large in distribution power, long in service life, high in low temperature resistance, hygienic, free of toxin and the like. The manufacturing method is simple, easy to operate and capable of achieving integral production of the double-layer composite tube.

Owner:菏泽三垒塑业股份有限公司

Manufacturing method of thermoplastic composite vehicle door

ActiveCN102476455ALight in massReduce weightDomestic articlesCooking & bakingThermoplastic composites

The invention relates to a manufacturing method of a thermoplastic composite vehicle door, comprising the following steps of: piling up a composite material until its thickness reaches 5-8mm, heating the material in a baking oven to fuse matrix resin in the composite material, transferring the fused composite material into a vehicle door die, controlling the temperature of the die within 40-120 DEG C for die locking, maintaining the die pressure at 2-40MPa, maintaining the pressure for 1-5 minutes, performing cooling setting, taking out and trimming to obtain a thermoplastic composite vehicle door main body, and fixedly connecting the vehicle door main body with a handle to obtain the thermoplastic composite vehicle door. In comparison with the prior art, the vehicle door obtained in the invention is light in weight, has more excellent deformation resistance and better endurance, will not deform permanently, has good weatherability and corrosion resistance, and is convenient to maintain.

Owner:SHANGHAI GENIUS ADVANCED MATERIAL (GRP) CO LTD

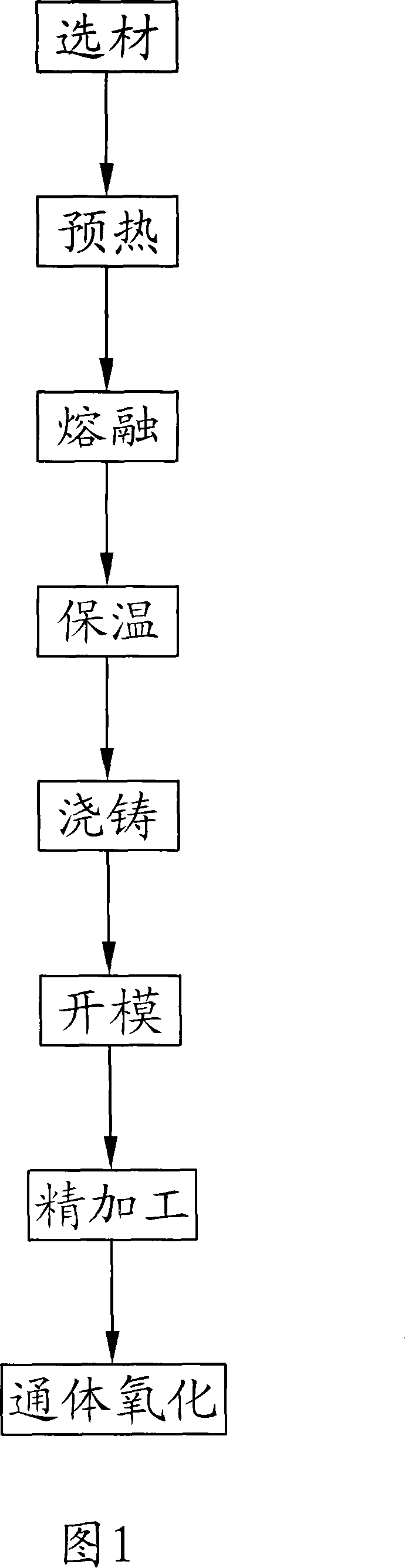

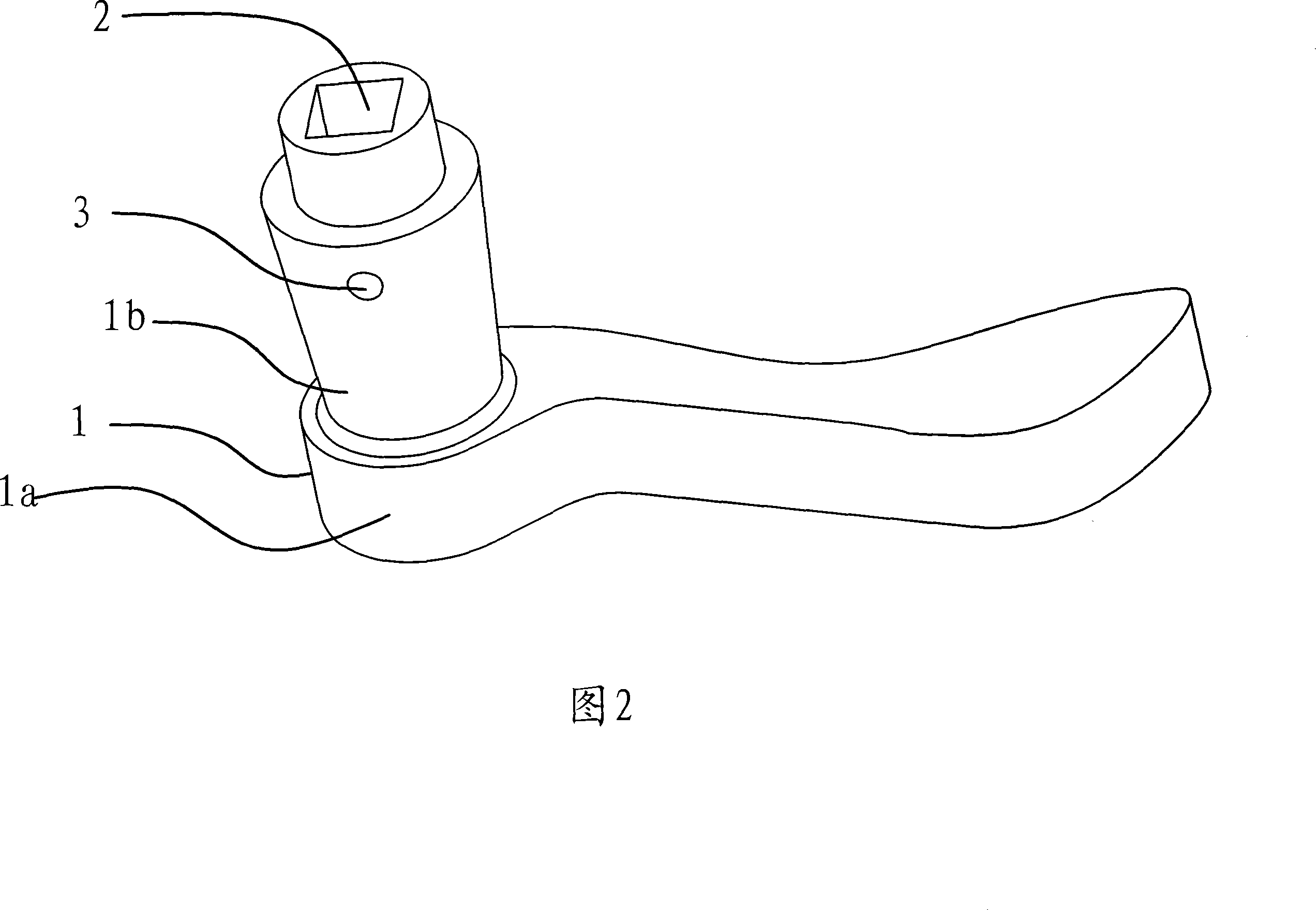

Manufacturing method of stainless aluminum handle, product and module thereof

InactiveCN101224539AImprove mechanical propertiesGood appearanceWing handlesFoundry mouldsMachiningMaterials science

The invention provides a manufacturing method of a stainless aluminium handle, a product and a die thereof, which belongs to the mechanical technical field. The manufacturing method of the stainless aluminium handle comprises the steps of material selection, melting, pouring, finish machining, oxidation, etc. The invention also provides a handle which is fabricated by the manufacturing method and a die used for fabricating the handle; the manufacturing method of the stainless aluminium handle has simple process flow and reasonable design; the fabricated product has good tensile strength and beautiful appearance; the die has long service life and is not easy to damage.

Owner:郑金星

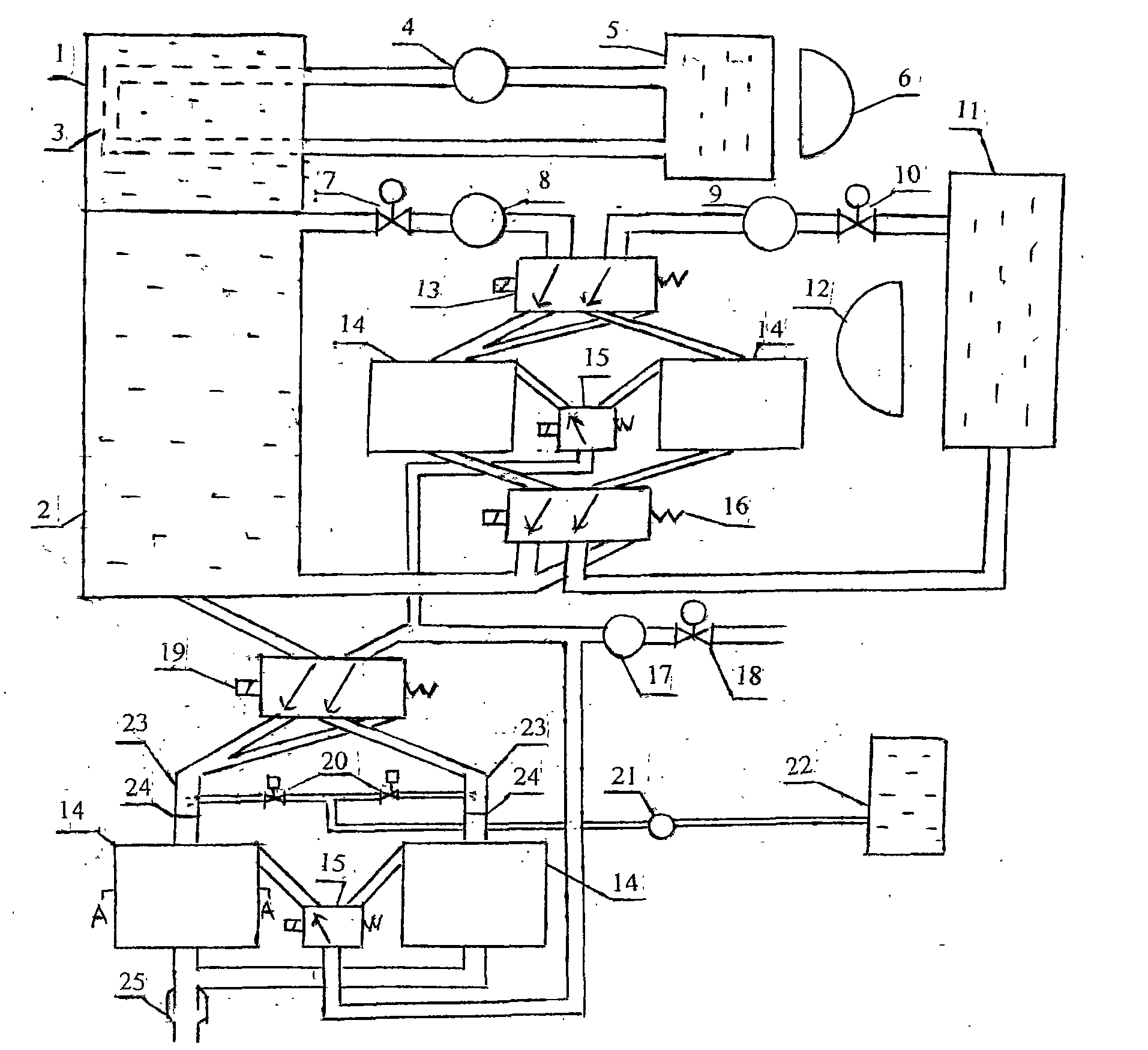

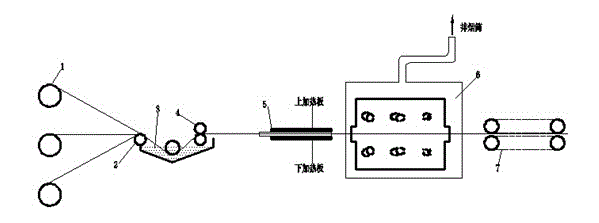

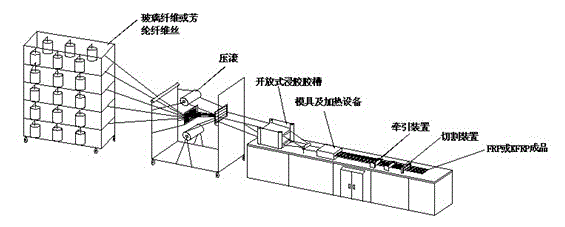

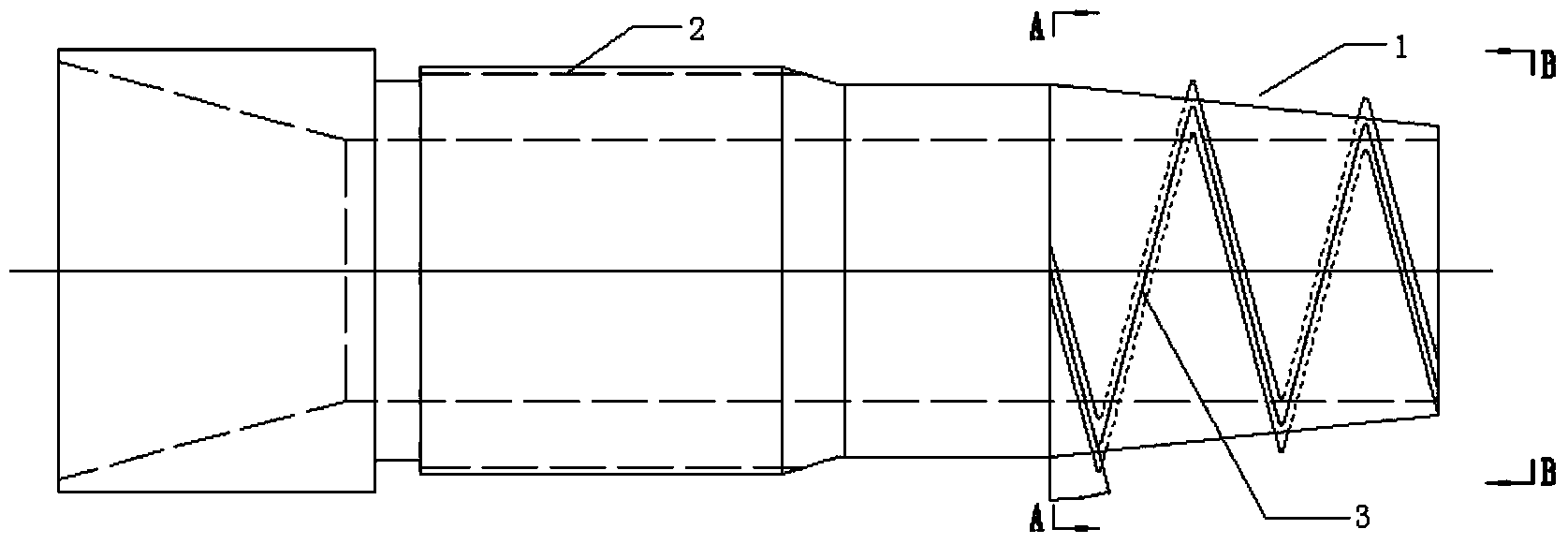

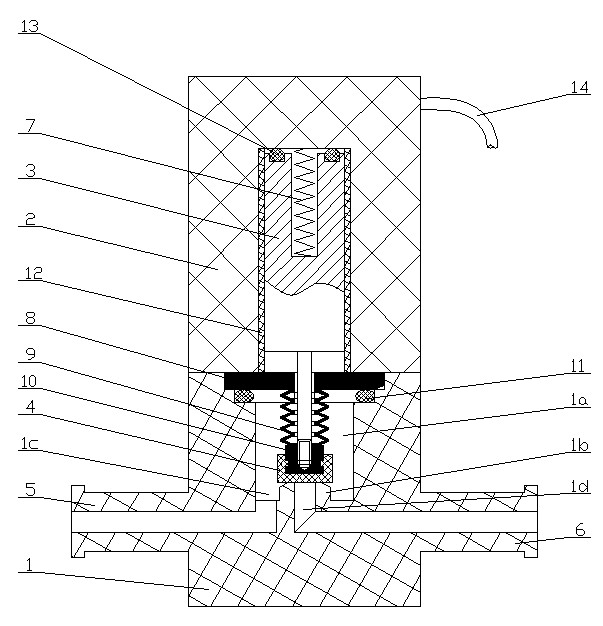

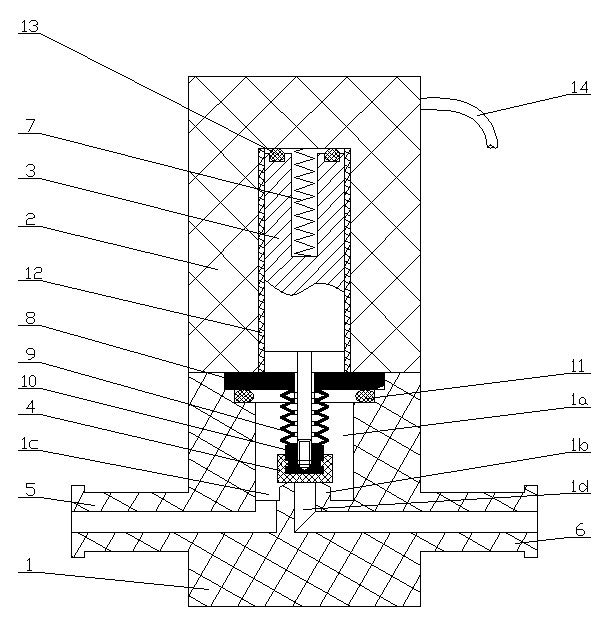

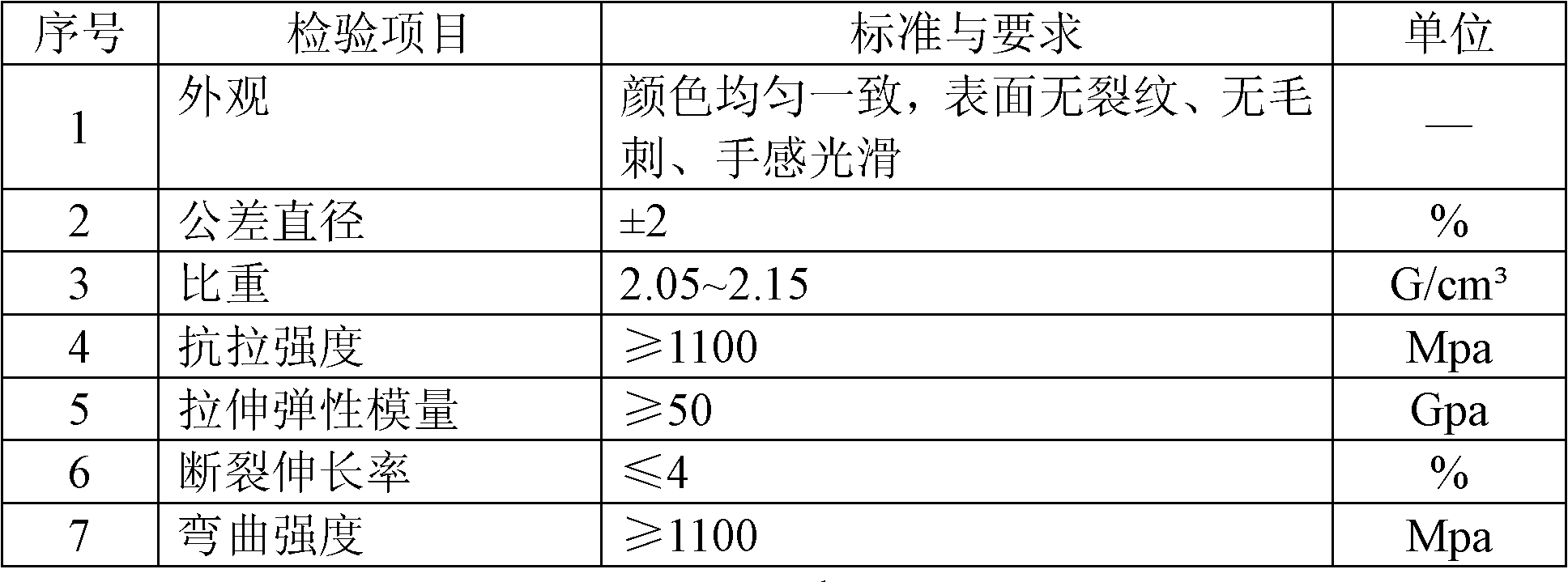

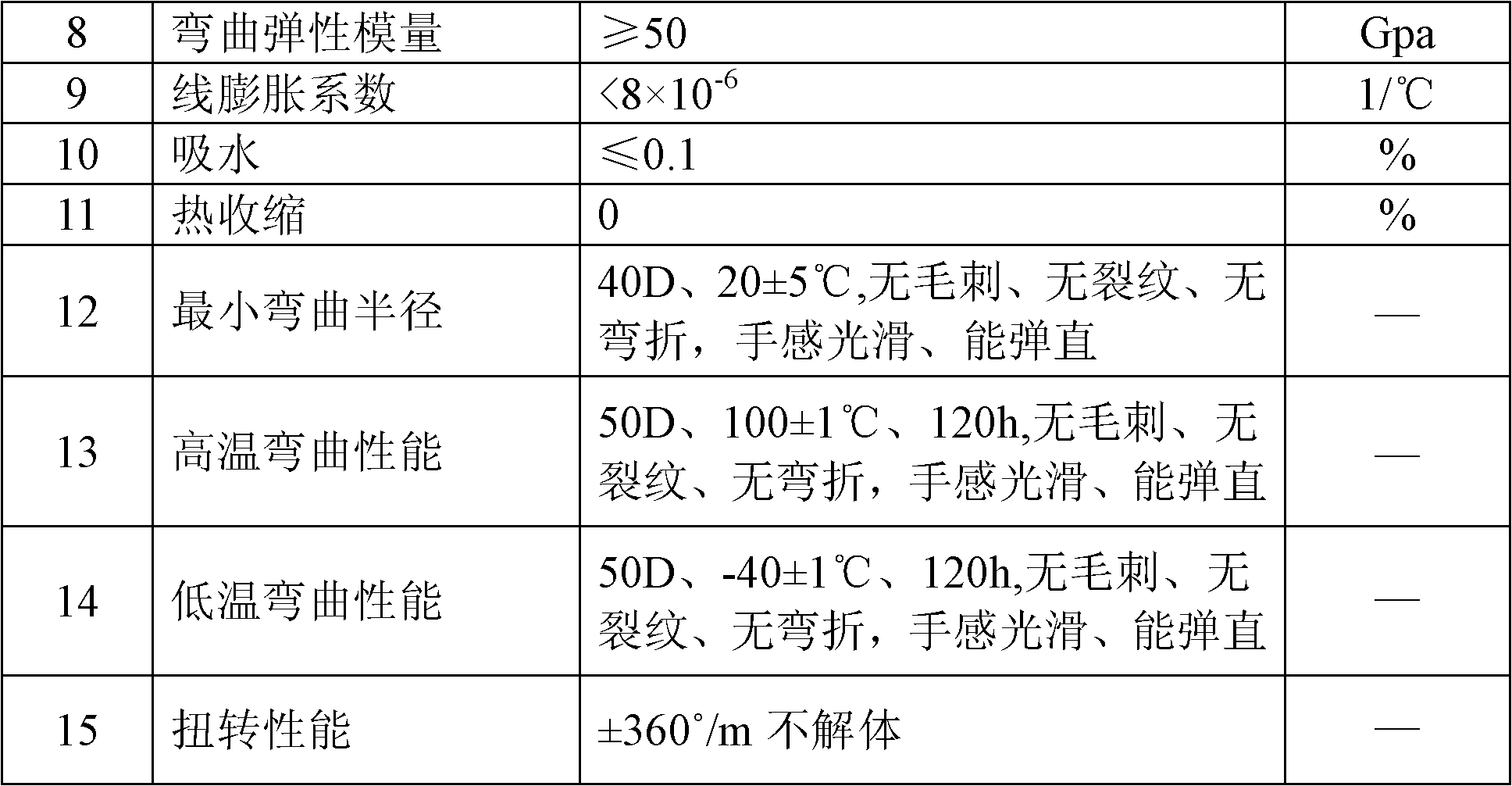

Sealing dipping pultrusion system device for producing optical fiber reinforced core and preparation method

The invention discloses a sealing dipping pultrusion system device for producing an optical fiber reinforced core and a preparation method. The device is characterized in that a heat moisture removing device, a seal pressure dipping device, a heat molding mold, a mechanical traction device and a rolling reel device are arranged at the right side of a guide creel in sequence, the upper end of a transparent sealing glue storage tank is connected with a glue inlet through a 1# valve and a pipeline; the lower end of the transparent seal glue storage tank is connected with the seal pressure dipping device through a 2# valve and a pipeline; the bottom of the seal pressure dipping device is connected with a glue outlet through a 3# valve and a pipeline; and the tail end of the seal pressure dipping device is connected with a vacuum pump through a 4# valve and a pipeline. The device provided by the invention is simple in structure, pollution-free for atmosphere, harmless for bodies of workers, and the harmful gases in glue material cannot be volatized; the product is strong in corrosion resistance, resistant to rust, free from nitrogen damage, does not affect the signal propagation performance of optical fiber, is insensitive to electric shock and long in service life. The product has no air gap, is large in density, high in strength and excellent in performance, thus, the device can be widely used for the manufacturing industry of optical fiber communication.

Owner:西安永兴科技发展有限公司

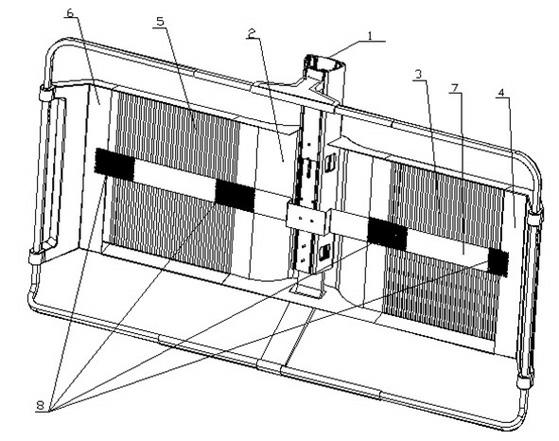

Rear protective cover for integral suspension system of multiple medical displays

InactiveCN102497757AEasy to assemble and disassembleEasy to disassembleCasings/cabinets/drawers detailsDisplay deviceEngineering

The invention relates to a rear protective cover for an integral suspension system of multiple medical displays, which comprises a suspension cantilever bracket. The rear protective cover is characterized in that a rear suspension cantilever cover is arranged behind the suspension cantilever bracket, a first protective cover is arranged on the left side of the suspension cantilever bracket, a left sleeve rod connector is arranged on the left side of the first protective cover, a second protective cover is arranged on the right side of the suspension cantilever bracket, a right sleeve rod connector is arranged on the right side of the second protective cover, a support plate is arranged in the front of the suspension cantilever bracket, and nylon hoop-and-loop fastener plates are arranged among the support plate and the rear suspension cantilever cover, the first protective cover, the left sleeve rod connector, the second protective cover and the right sleeve rod connector. During mounting, only hoop plates and loop plates are fastened, the first protective cover and the second protective cover can be mounted successfully, and detachment tools are omitted when connection is realized by the nylon hoop-and-loop fastener plates, so that the rear protective cover is convenient, simple and fast in mounting. Further, since the surfaces of the first protective cover and the second protective cover are provided with V-shaped grooves, the protective cover can be divided into units in required size by bending, is convenient, fast and simple in operation and is more convenient in cleaning due to no screws.

Owner:MAQUET SUZHOU

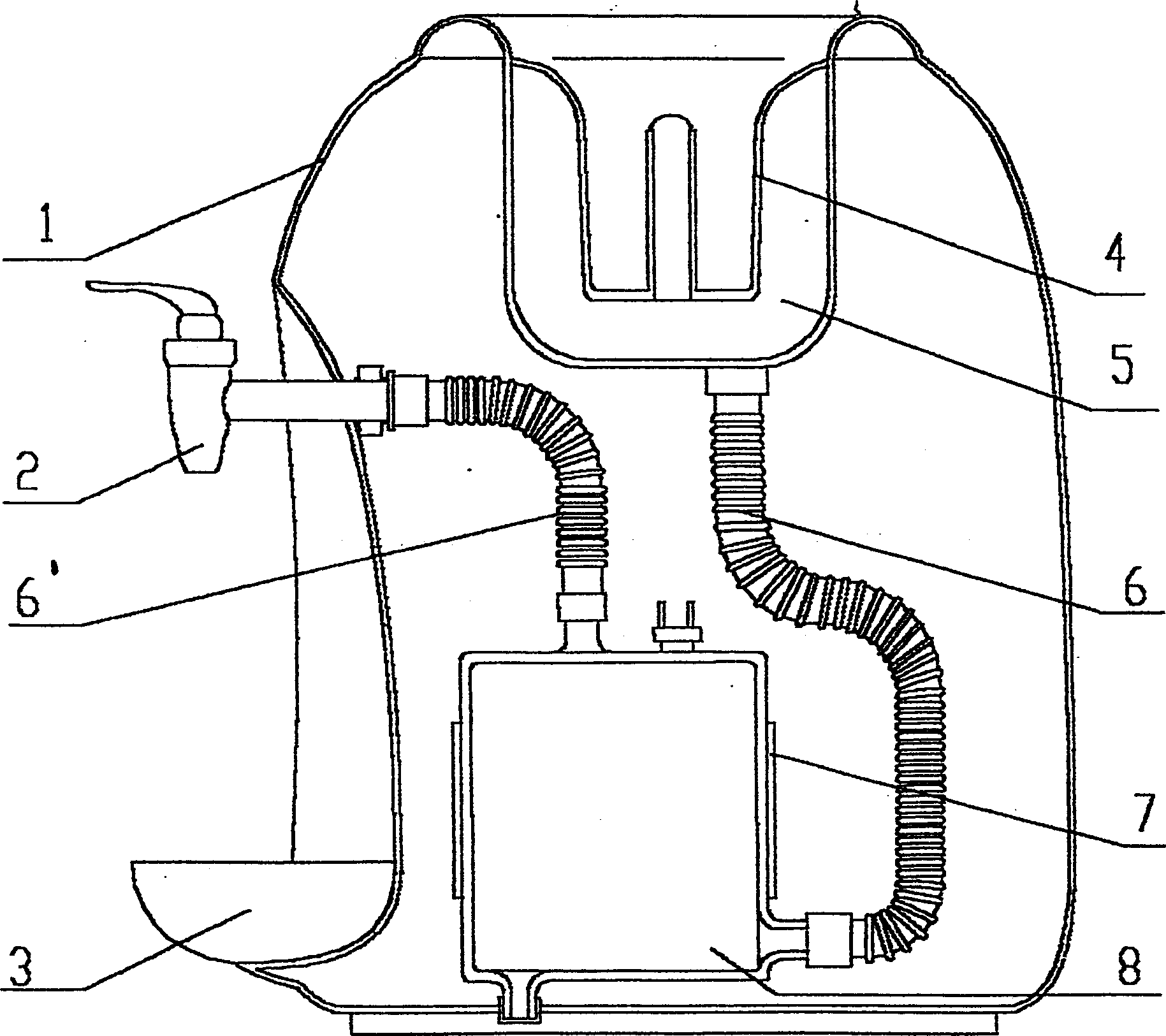

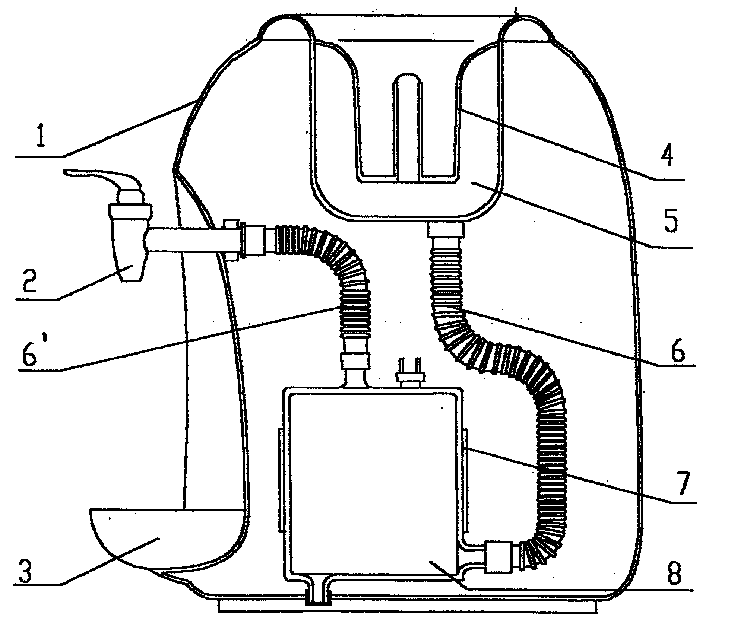

Health type drinking water machine

InactiveCN1408307AComply with hygienic standardsHas a health effectCooking vesselsBeverage vesselsTrace elementPhysical well being

The health type drinking water machine includes casing, water tap, clever seat, cold water tank, water inlet pipe, water outlet pipe, heater and heating tank. The heating tank is made of ceramic, which leaches some trace elements needed by human body and produces no harmful matter and no rust. The electrothermal film for the heater is mounted outside the heating tank without contact with water and this prevents scaling. The water inlet pipe and the water outlet pipe are flexible corrugated pipes and this can prevent leakge. Therefore, the drinking water machine is hygienic, safe and reliable and has no excessive phenol.

Owner:MIDEA GRP CO LTD

Iron-based magnetic alloy powder containing rare earth element, method for producing same, resin composition for bonded magnet obtained from same, bonded magnet, and compacted magnet

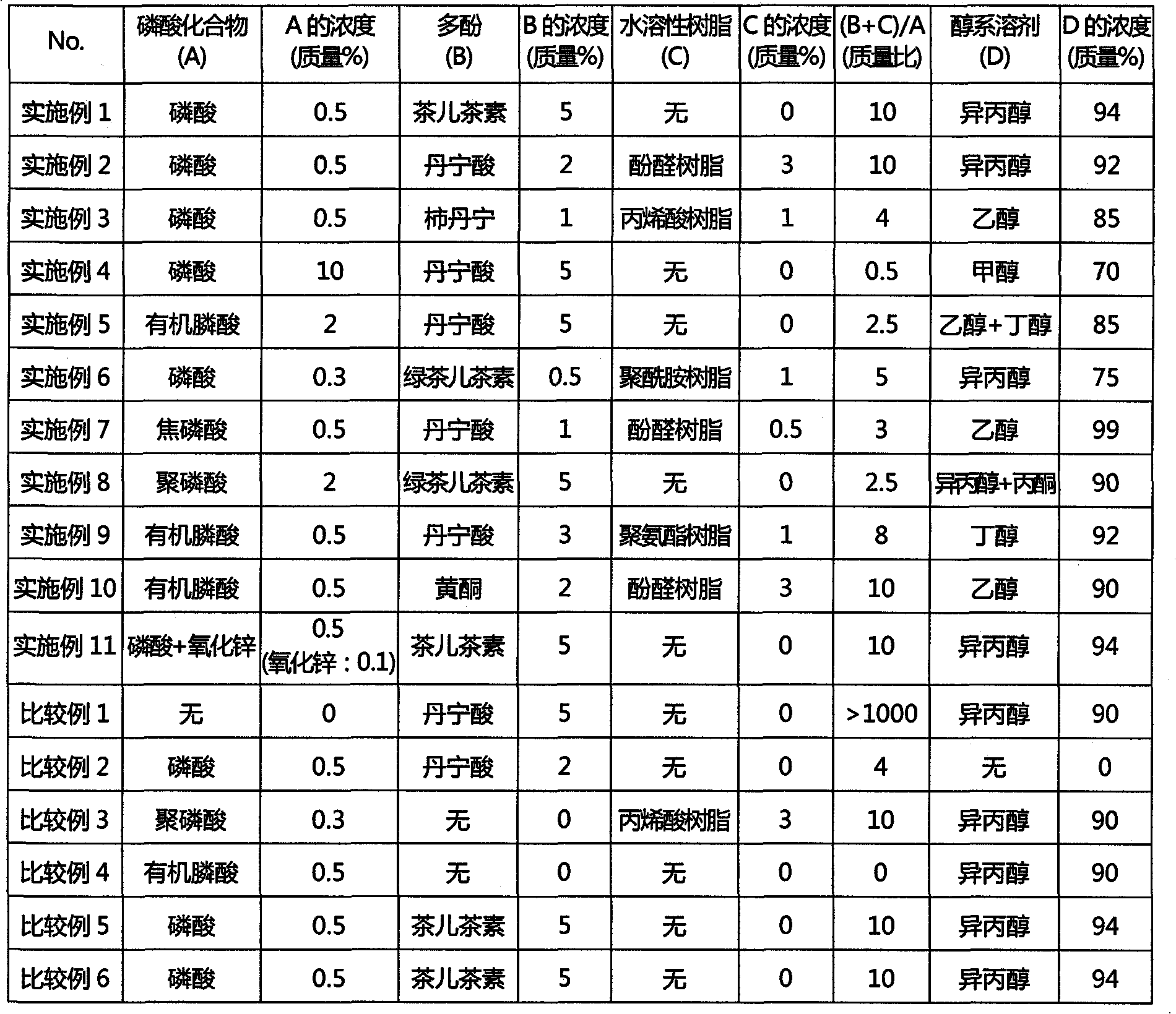

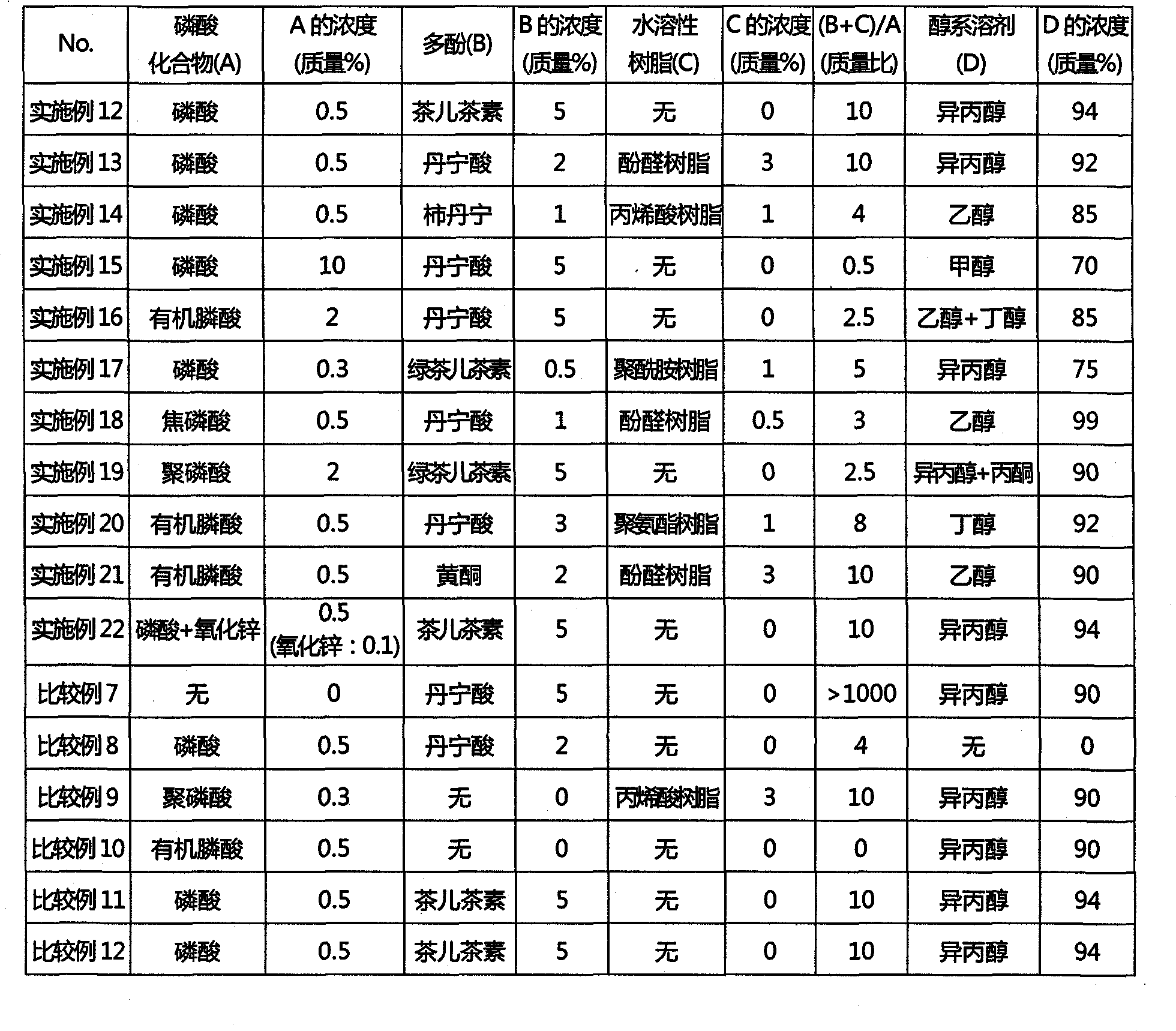

ActiveCN102076448AImprove corrosion resistanceHigh mechanical strengthTransportation and packagingMetal-working apparatusRare-earth elementPhosphate

Disclosed is a magnetic alloy powder containing a rare earth element, which has a surface covered with a strong coating film and does not rust even in a corrosive environment, while exhibiting excellent corrosion resistance and resin adhesion. Also disclosed are: a method for producing the magnetic alloy powder containing a rare earth element; a resin composition for bonded magnets using the magnetic alloy powder and having excellent mechanical strength; a bonded magnet; and a compacted magnet. Specifically disclosed is an iron-based magnetic alloy powder containing a rare earth element, wherein an inorganic-organic composite coating film is uniformly formed on the surface of the magnetic powder, said coating film being composed of a complex metal phosphate that contains iron phosphate and a rare earth metal phosphate, and an organic compound that contains a polyphenol. Also specifically disclosed is a compacted magnet or bonded magnet which is characterized in that an inorganic-organic composite coating film is formed on the surface of a molded body which is obtained by molding an iron-based magnetic alloy powder containing a rare earth element, or molding a resin composition containing an iron-based magnetic alloy powder containing a rare earth element and a resin binder, said coating film being composed of a complex metal phosphate that contains iron phosphate and a rare earth metal phosphate, and an organic compound that contains a polyphenol.

Owner:SUMITOMO METAL MINING CO LTD

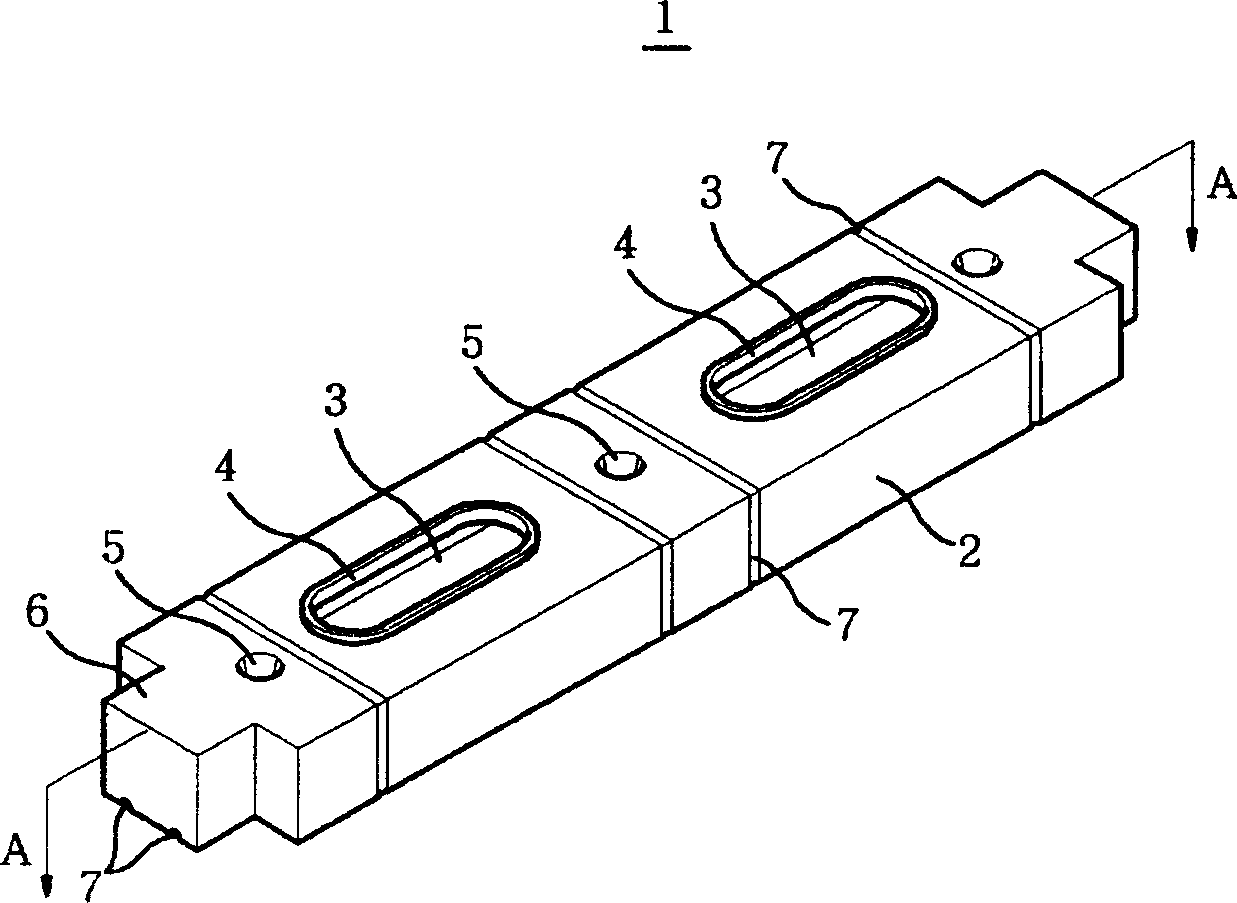

Weight of elevator

InactiveCN1824598AStainlessBroad interpretationSheet joiningFriction grip releasable fasteningsEngineeringMechanical engineering

The invention relates to a lifter weighting block, especially used in the lifter with up and down operations, wherein said weighting block comprises: a frame filled with cement mixture and in long shape; a inlet on the upper side surface of frame to fill the cement mixture; a support inside the frame to hold the chamber that filled with cement mixture; and the protrusions from on two ends of frame inserted into the guide device of lifter; when several frames are carried to the lifter on-site to be layered, and filled with cement mixture. The invention can avoid directly move weight block.

Owner:京旻重块株式会社

Nickel-chromium alloy powder-coated steel bar manufacturing method

ActiveCN103643086AHigh strengthImprove safety and reliabilityMolten spray coatingNickel Chromium AlloysHeating furnace

The present invention discloses a nickel-chromium alloy powder-coated steel bar manufacturing method, which is characterized in that (1) the chemical components of the nickel-chromium alloy powder comprise, by weight, 0.2-3.3% of Re, 45-55% of Ni, 16-33% of Cr, 1.5-5.0% of Si, 0.25-0.5% of S, 0.2-1.5% of C, 10-16% of Fe, 0.8-10% of Mn, and 1-2% of composite rare earth; (2) the smelted steel bar is conveyed into a heating furnace to heat to achieve a temperature of 900-1000 DEG C; (3) the nickel-chromium alloy powder mixed according to a certain ratio is uniformly sprayed on the steel bar surface through a spraying gun; (4) the heated steel bar is conveyed into a quenching device; (5) the quenched steel bar is heated through a tempering heating furnace to achieve a temperature of 450-480 DEG C; and (6) the tempered steel bar is naturally cooled to achieve a room temperature. According to the invention, the nickel-chromium alloy is coated the steel bar surface so as to increase the wear resistance.

Owner:TIANSHUN GROUP

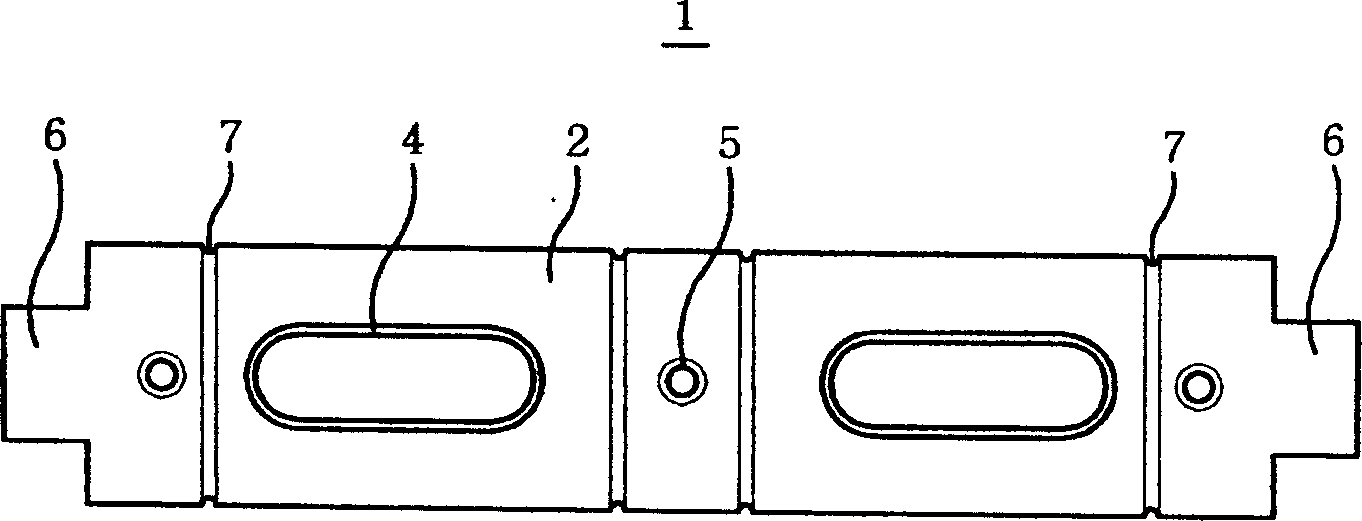

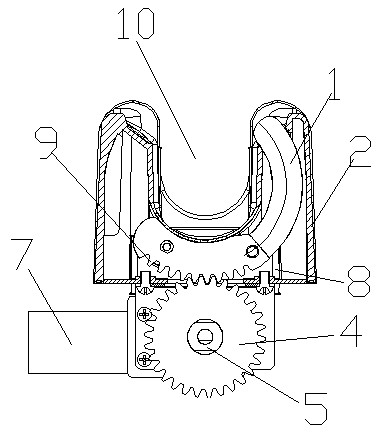

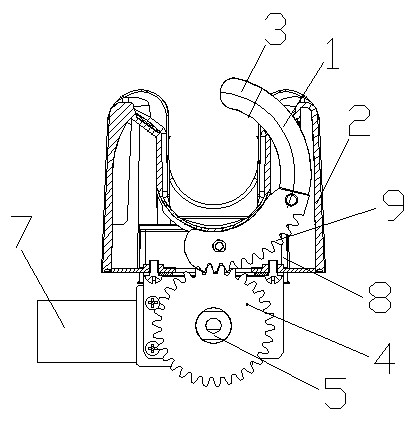

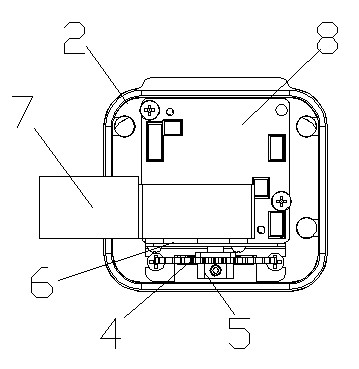

Public bicycle lock

InactiveCN102116116AStainlessAnti-prying performance is goodBicycle locksNon-mechanical controlsControl signalElectric power

The invention relates to a public bicycle lock, in particular to an electronic automatic public bicycle lock with anti-picking function. The lock comprises a lock shell, a lock tongue, a lock tongue gear, a motor, a motor gear and a control box, wherein a front fork nick matched with a bicycle front fork is arranged on the lock shell; the lock tongue and the lock tongue gear fixedly connected with the lock tongue are movably arranged in the lock shell; the lock shell is fixedly connected with the motor; the motor is fixedly connected with the motor gear; the motor gear is engaged with the lock tongue gear; the control box is arranged in the lock shell; and the control box is provided with a driving circuit device for providing electric power to the motor and controlling signals and a chipsensor matched with the bicycle. The lock has the advantages of reasonable design, low cost, low possibility of being damaged, safety and reliability.

Owner:杭州艾动工业产品设计有限公司

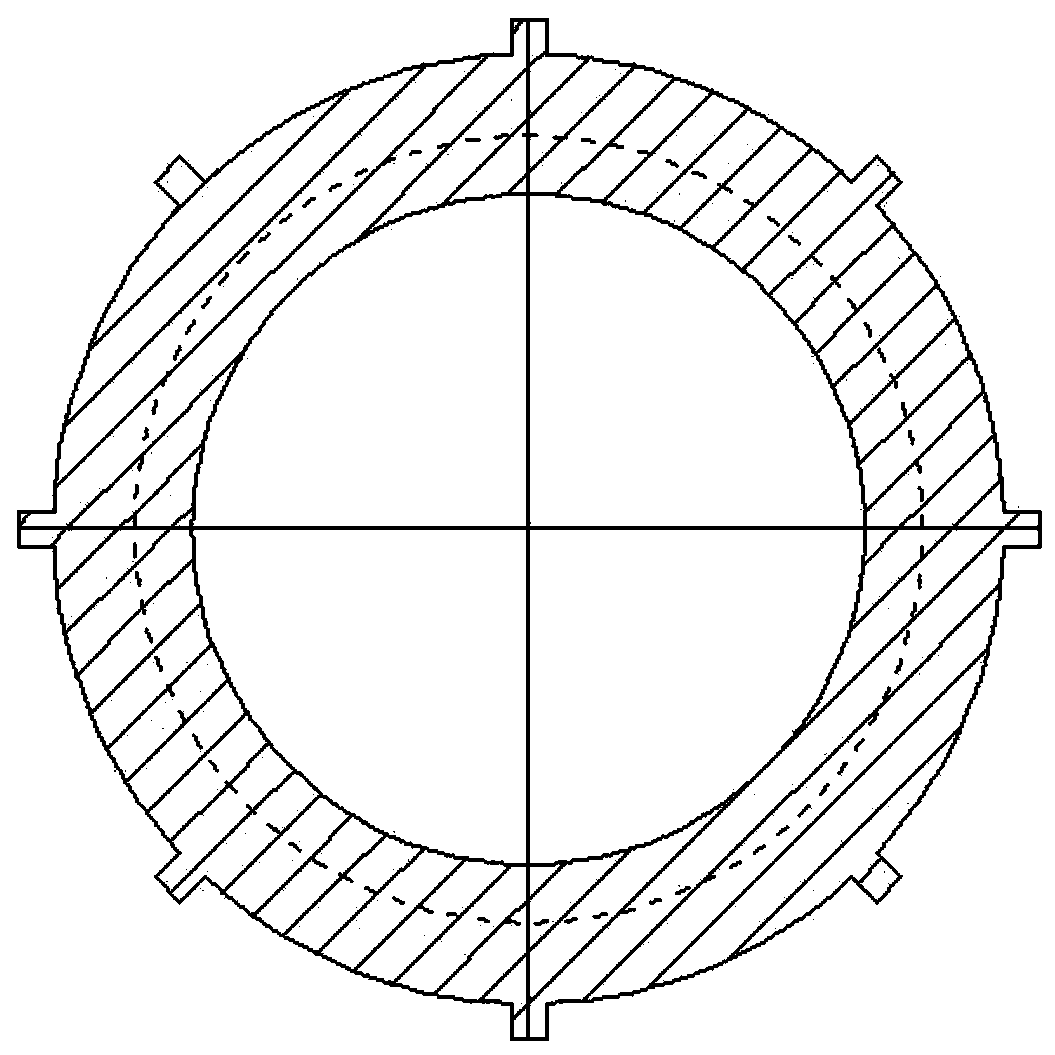

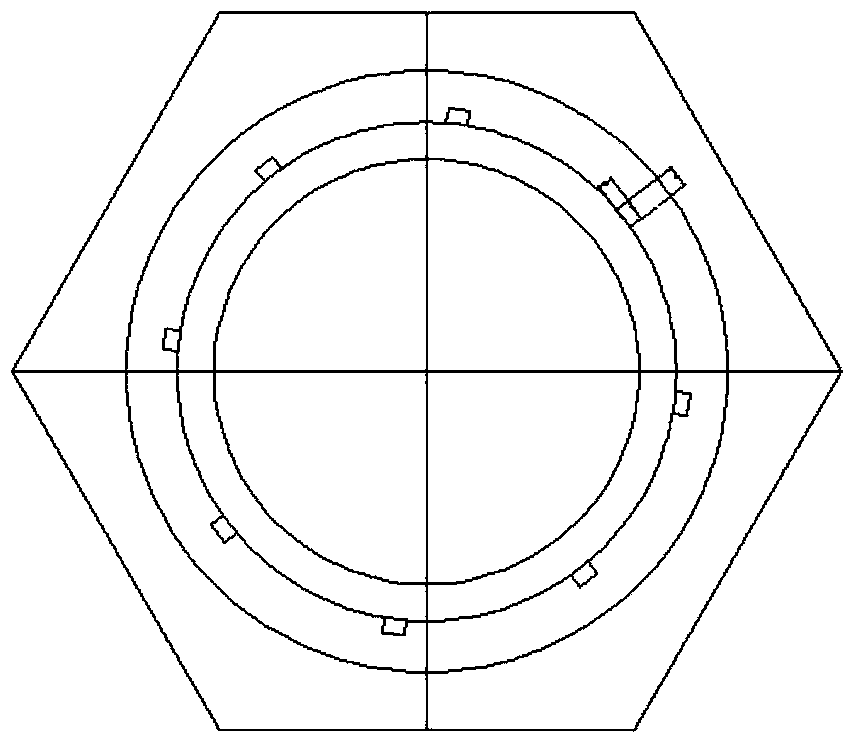

Spiral nozzle used in controlled rolling and controlled cooling technology and spiral type water feeding method

InactiveCN104107767AFast heat exchangeImprove wear resistanceSpray nozzlesWork cooling devicesSpray nozzleEngineering

The invention relates to a spiral nozzle used in controlled rolling and controlled cooling technology and a spiral type water feeding method. A water feeding chamber and a turbulence pipe are matched for use. The spiral nozzle comprises a nozzle body and an adjustable spiral type circular seam which is arranged in the periphery direction of the outer wall of the nozzle body. Cooling media are sprayed into the turbulence pipe in the adjustable spiral type circular seam direction through fixed tangent kinetic energy. Through the adjustable spiral type circular seam, the cooling media enter the turbulence pipe under large pressure in the adjustable spiral type circular seam direction through large tangent kinetic energy. By tangent flowing of the cooling media, heat exchanging speed of the cooling media and high-temperature rolled pieces is greatly improved, steel surfaces and core part grain growth can be effectively avoided, the strength is improved, and meanwhile other performance is obviously improved. Meanwhile, the spiral nozzle is small, energy consumption is lowered, cooling capacity is improved, a corrosion resistant coating layer is sprayed on the surface of the nozzle, and the corrosion resistance of the nozzle is improved.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

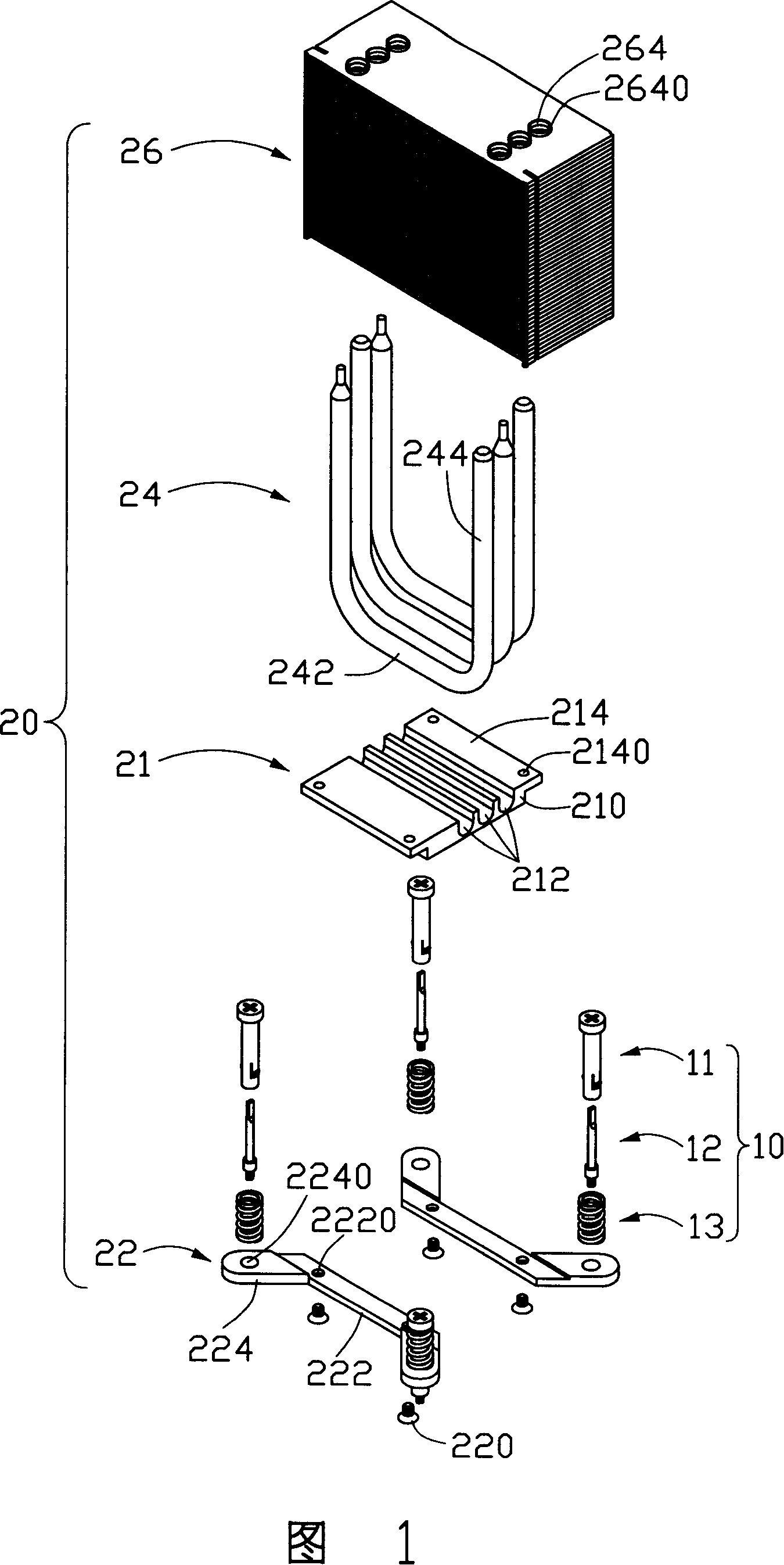

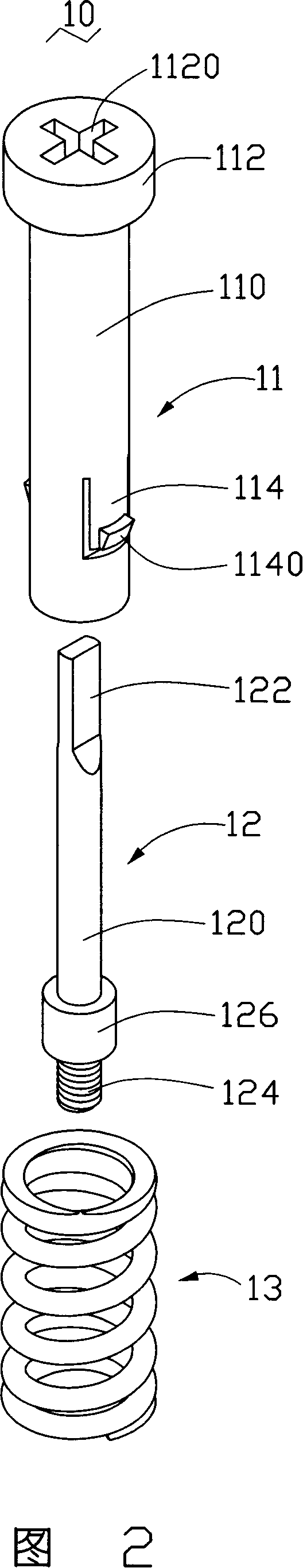

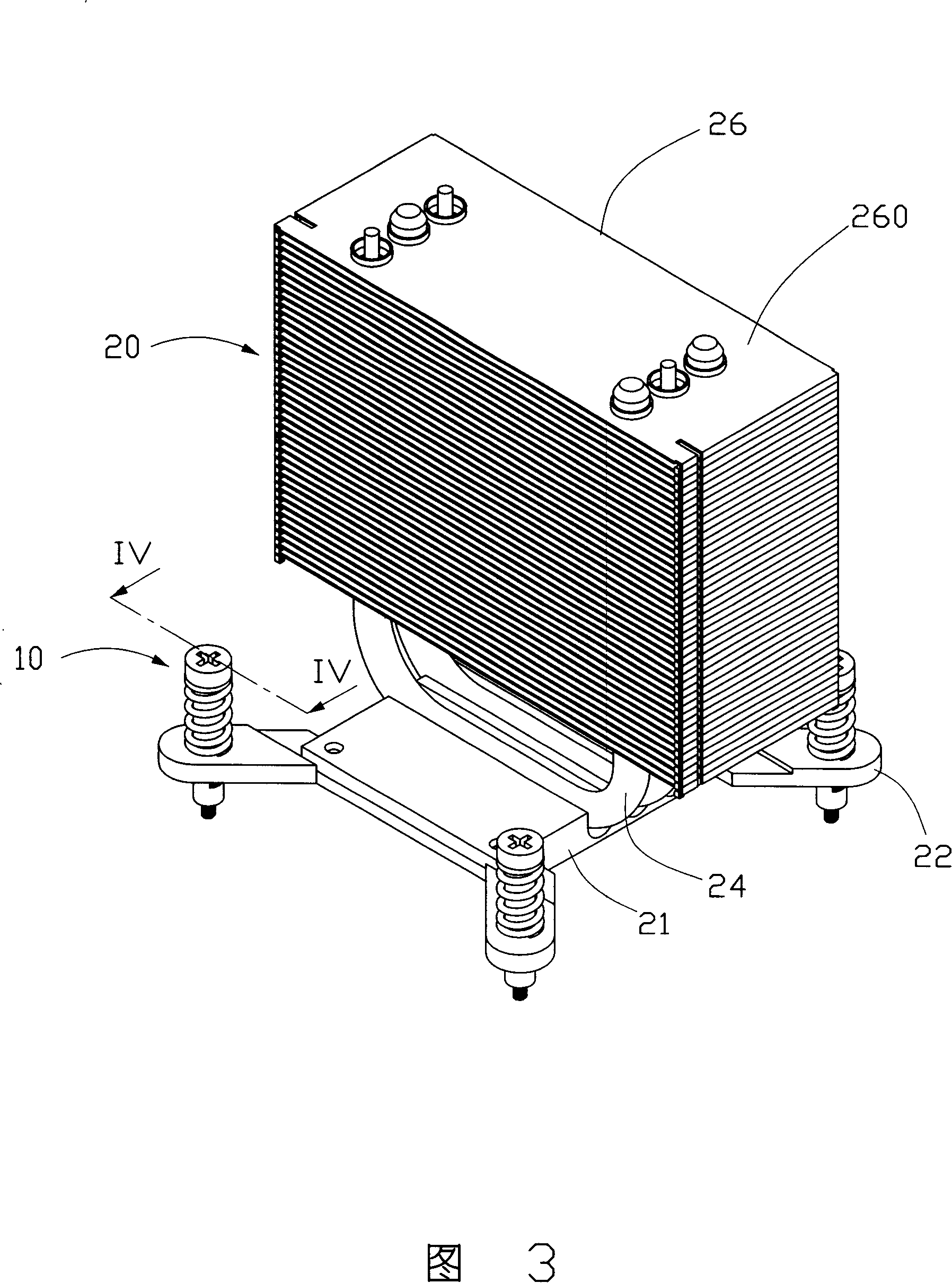

Fixed part and its manufacturing method, combination of radiating devices using the fixed part

InactiveCN101132682ANo risk of falling offStainlessDigital data processing detailsSemiconductor/solid-state device detailsEngineeringMechanical engineering

Owner:FU ZHUN PRECISION IND SHENZHEN +1

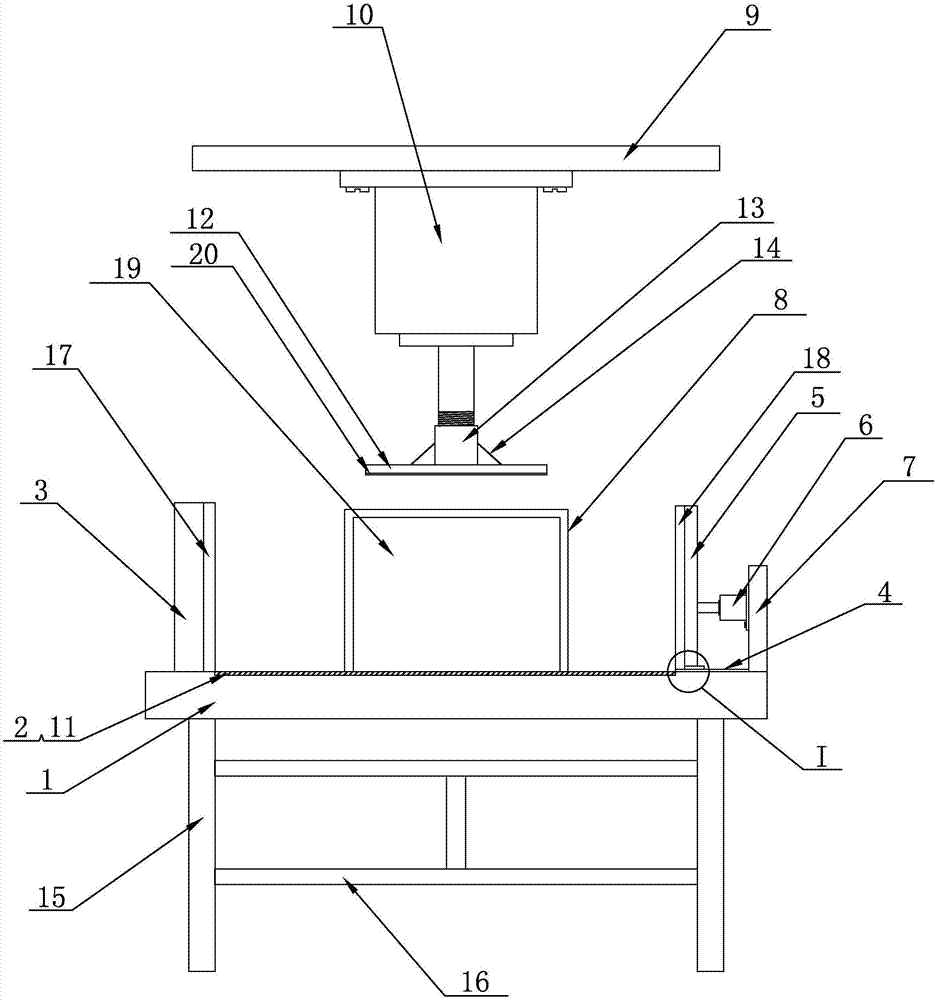

Bag and suitcase positioning device for bag and suitcase production

PendingCN107186640AReasonable structural designSimple structureWork holdersEngineeringPulp and paper industry

The invention discloses a bag and suitcase positioning device for bag and suitcase production. The bag and suitcase positioning device comprises a worktable, wherein a rectangular storage groove is formed in the upper end surface of the worktable; a hard alloy plate is fixedly arranged in the storage groove; a first positioning plate is arranged at the left end of the storage groove; a positioning slide rail is transversely arranged at the right end of the storage groove; a second positioning plate is arranged on the positioning slide rail; a driving device is arranged at the right end of the second positioning plate and comprises a first cylinder and a cylinder frame; a piston rod of the first cylinder is connected with the second positioning plate and stretches out and draws back to drive the second positioning plate to move leftwards or rightwards; a third positioning plate is arranged at the rear end of the worktable; the lower end of the third positioning plate is fixedly welded with the rear end surface of the worktable; and a lift-type positioning mechanism is arranged above the worktable. According to the technical scheme, the bag and suitcase positioning device is reasonable in structural design, simple in structure, convenient to operate, reliable in positioning, stable in operation and convenient to maintain.

Owner:平湖智铂自动化设备股份有限公司

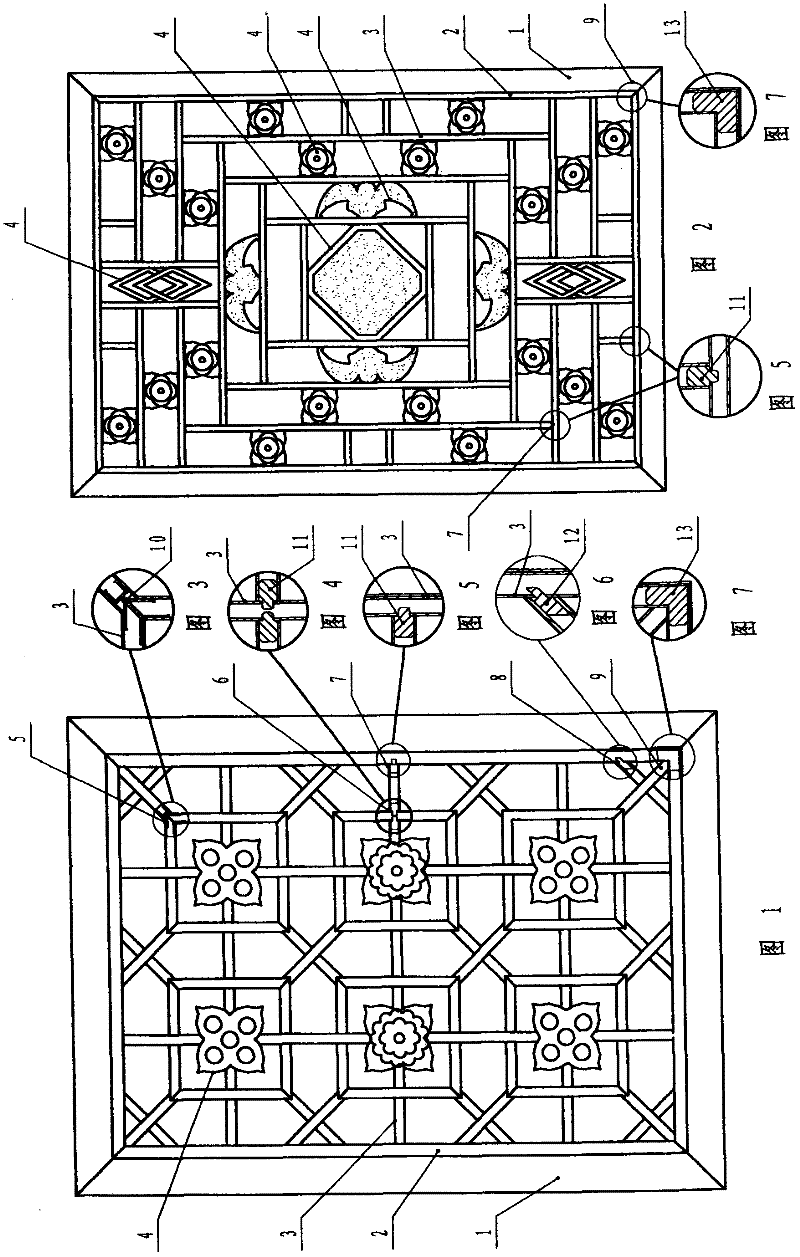

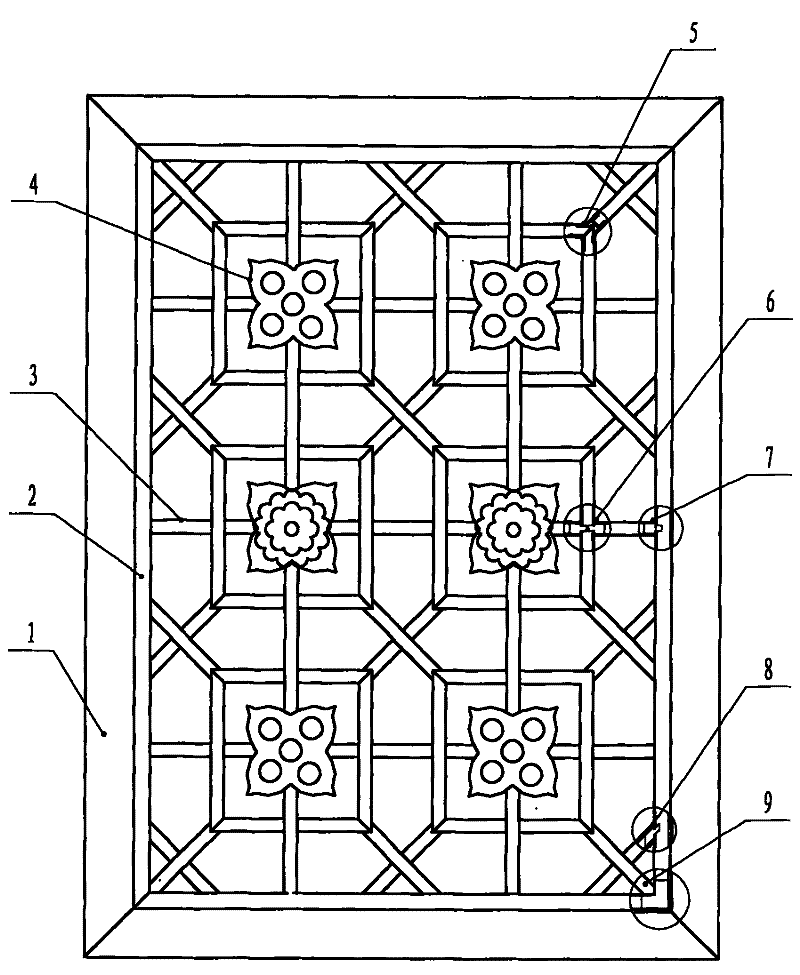

Archaistic aluminum alloy window

InactiveCN102536077AStainlessReduce weightFixed grillesOrnamental structuresEngineeringAluminium alloy

The invention discloses an archaistic aluminum alloy window. An external frame is square and is provided with an internal frame, decorative strips are arranged in the internal frame in a staggered and are connected to form a polygonal geometrical decorative pattern. The connecting points of the decorative strips are ''T''-shaped, ''Cross''-shaped or trifurcate. The connecting points between the decorative strips and the internal frame are ''T''-shaped or inclined. The connecting points between the internal frame and four corners of the internal frame are ''L''-shaped. Decorative flowers are arranged on the decorative strips. The external frame, the internal frame and the decorative strips of the archaistic window are made of aluminum alloy section bars which are hollow strip-shaped aluminum tubes. With adoption of the technical scheme, the external frame, the internal frame and the decorative strips used by the archaistic window are subjected to hot extrusion molding by aluminum materials. The surface of the materials can be colored by electroplating or spraying. The materials prepared can be laid off and used only according to the length. During installation, the decorative strips can be installed vertically, obliquely or in a trifurcate way by matching with fixed joints of various types so as to form various archaistic patterns.

Owner:陈宝贵

Riveted rolled plate type long large hose

A riveted rolling-piece type long flexible pipe is adapted for flow guiding. It is made of cheap plastic and cloth and riveted to a long flexible pipe according to the need. It is also riveted to a large circumferential tank for storing oil-gas. The invention can be floating anchored on the water surface so that ití»s easy to find the fault.

Owner:罗晓晖

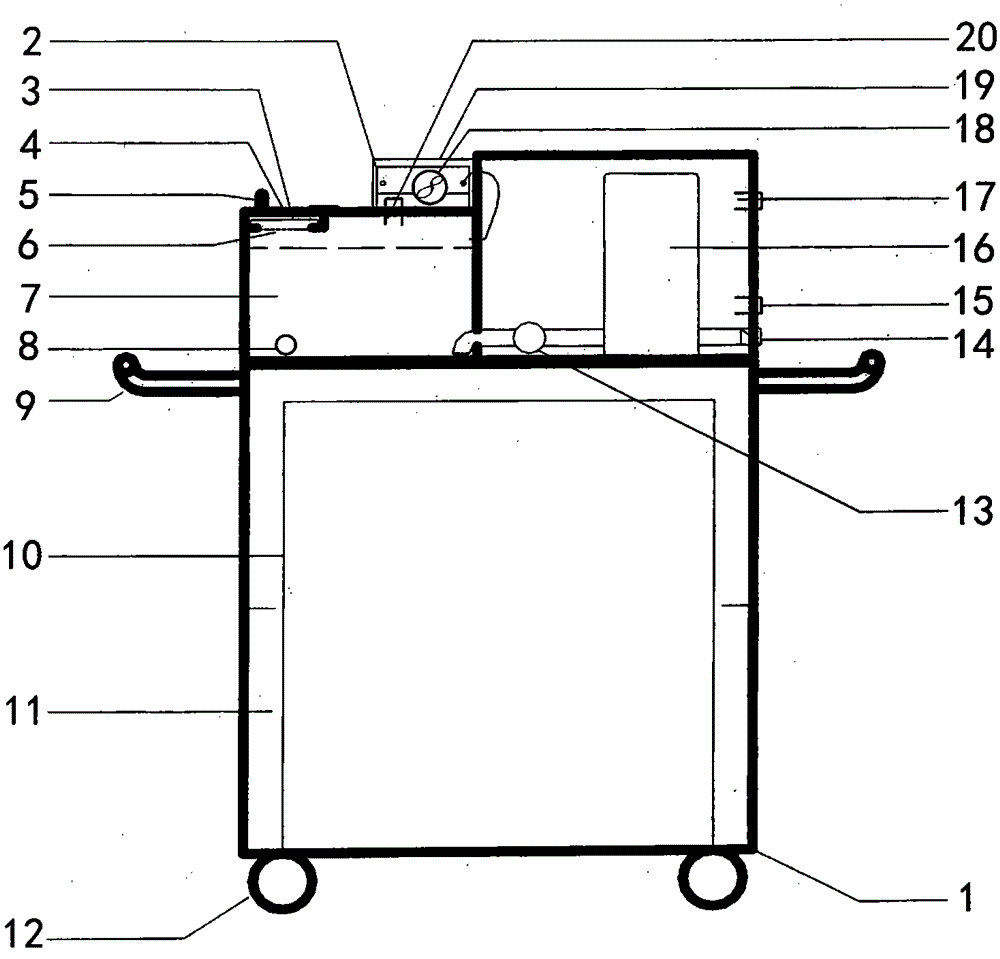

Movable argon arc welding machine and cooling platform

InactiveCN105033425ALarge capacityMeet support requirementsWelding/cutting auxillary devicesAuxillary welding devicesWater storage tankEngineering

The invention provides a movable argon arc welding machine cooling platform. The movable argon arc welding machine cooling platform comprises a cart type structure, a cooling water tank, a supporting bracket of the cooling water tank, a cooling water booster pump and a prefilter. The filter and the booster pump are connected through a valve and a water pipe. A manual water adding opening, a tap water adding opening, a cooling water outlet, a backflow water pipe inlet and a drain opening are formed in the tank body of a water storage tank. Cooling water in the water tank passes through the filter and then is pressurized by the booster pump, and then the cooling water is connected with a cooling water inlet in an argon arc welding handle; the cooling water is input to an argon arc welding machine via a water-cooling cable through a welding handle cooling water outlet, a high-temperature water outlet is connected to a cooling water return connector on the cooling platform through the cooling water outlet of the argon arc welding machine, and then the cooling water is cooled by a radiator and flows back into the water storage tank. The platform can be provided with the welding machine to be moved for use, the operating cost is low, operation is convenient, and the cooling platform can be used by a plurality of argon arc welding machines at the same time; the cooling water is recycled, so that water resources are saved, and energy consumption is lowered.

Owner:陈奕曼 +3

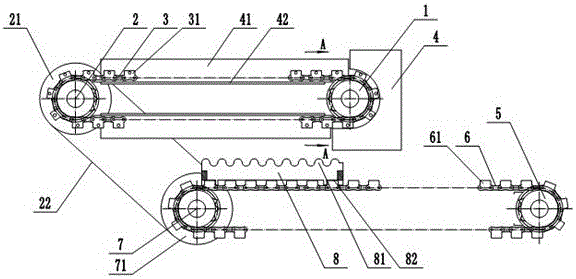

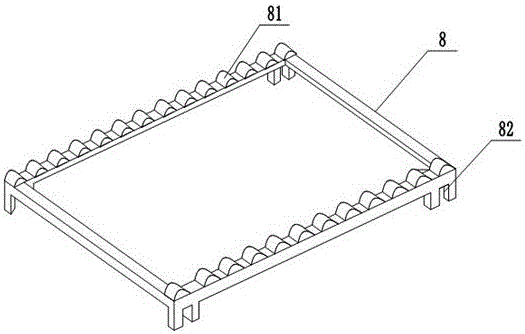

Soybean gluten stick conveying mechanism

The invention relates to the field of food processing and discloses a soybean gluten stick conveying mechanism.The mechanism comprises upper chain wheels, upper chains and upper rotating shafts, the two upper rotating shafts are arranged oppositely, the two ends of each upper rotating shaft are each connected with the corresponding upper chain wheel, the two upper chain wheels located at each same end of the two upper rotating shafts are matched with the corresponding upper chain, upper check blocks are arranged on chain bodies which are located on the upper chains at intervals, and a gap used for allowing for placing a soybean gluten stick therein is reserved between every two adjacent upper check blocks; the mechanism further comprises lower chain wheels, lower chains, lower rotating shafts and a tray, the two lower rotating shafts are arranged oppositely, the two ends of each lower rotating shaft are each connected with the corresponding lower chain wheel, the two lower chain wheels located at each same end of the two lower rotating shafts are matched with the corresponding lower chain, and the tray is detachably connected to the lower chains and provided with limiting teeth which are arranged uniformly.By means of the conveying mechanism, efficiency is improved, and meanwhile errors of manual operation is reduced; the tray is provided with the limiting teeth, so that the soybean gluten sticks are separated uniformly and automatically and arranged in order, it is convenient to air the soybean gluten sticks, and meanwhile time and labor are saved.

Owner:LIANGPING XINGYU BEAN PROD CO LTD

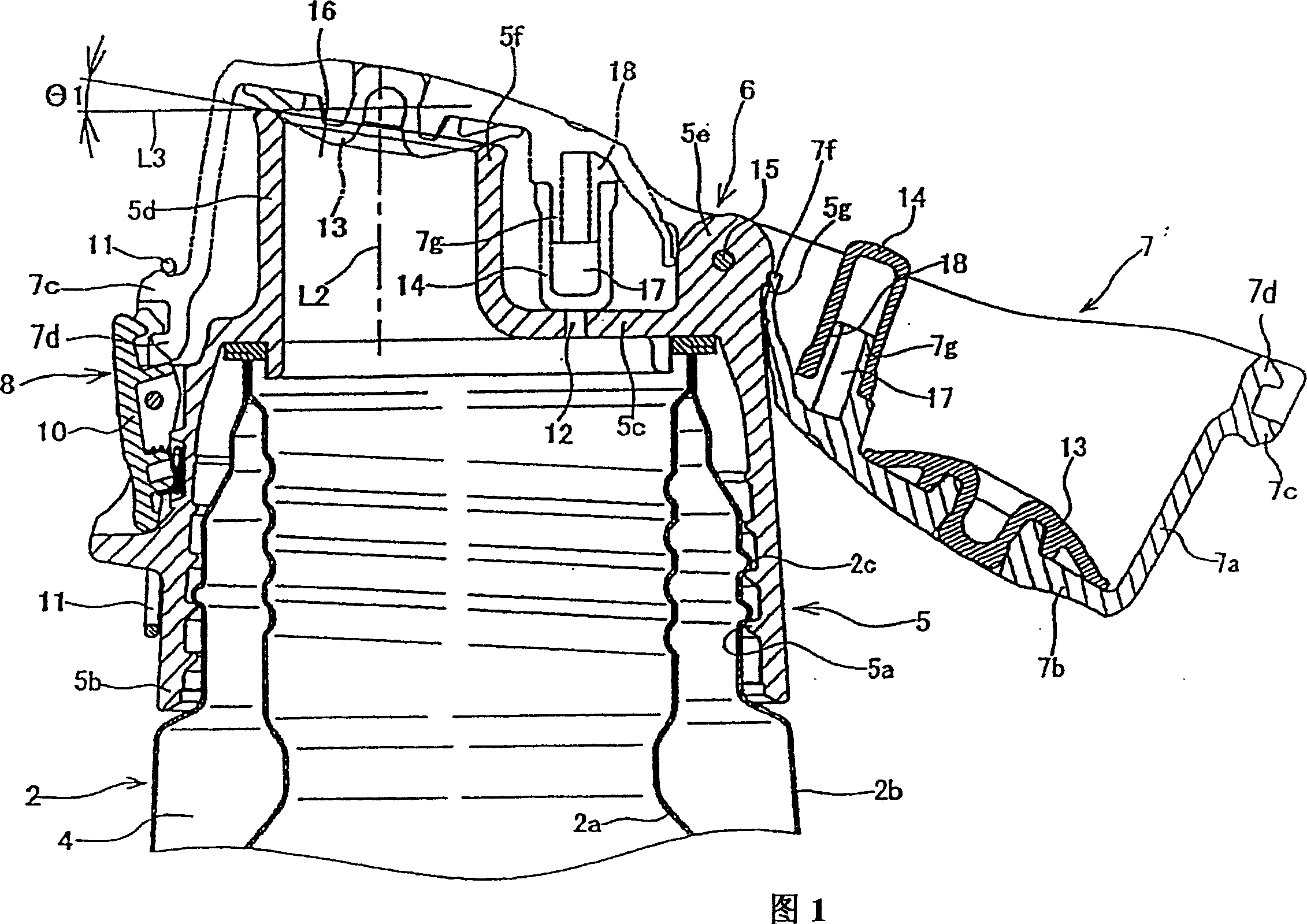

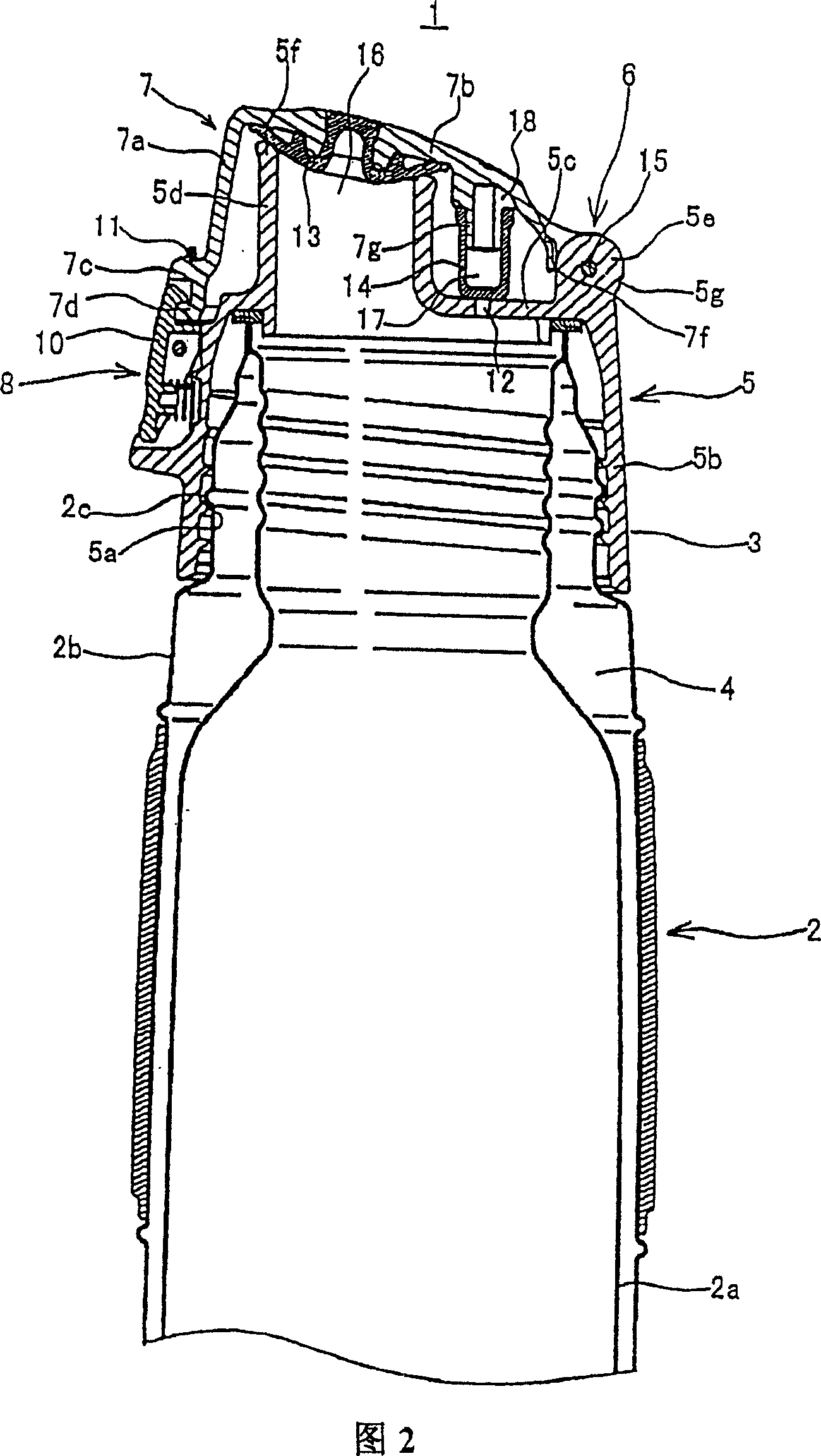

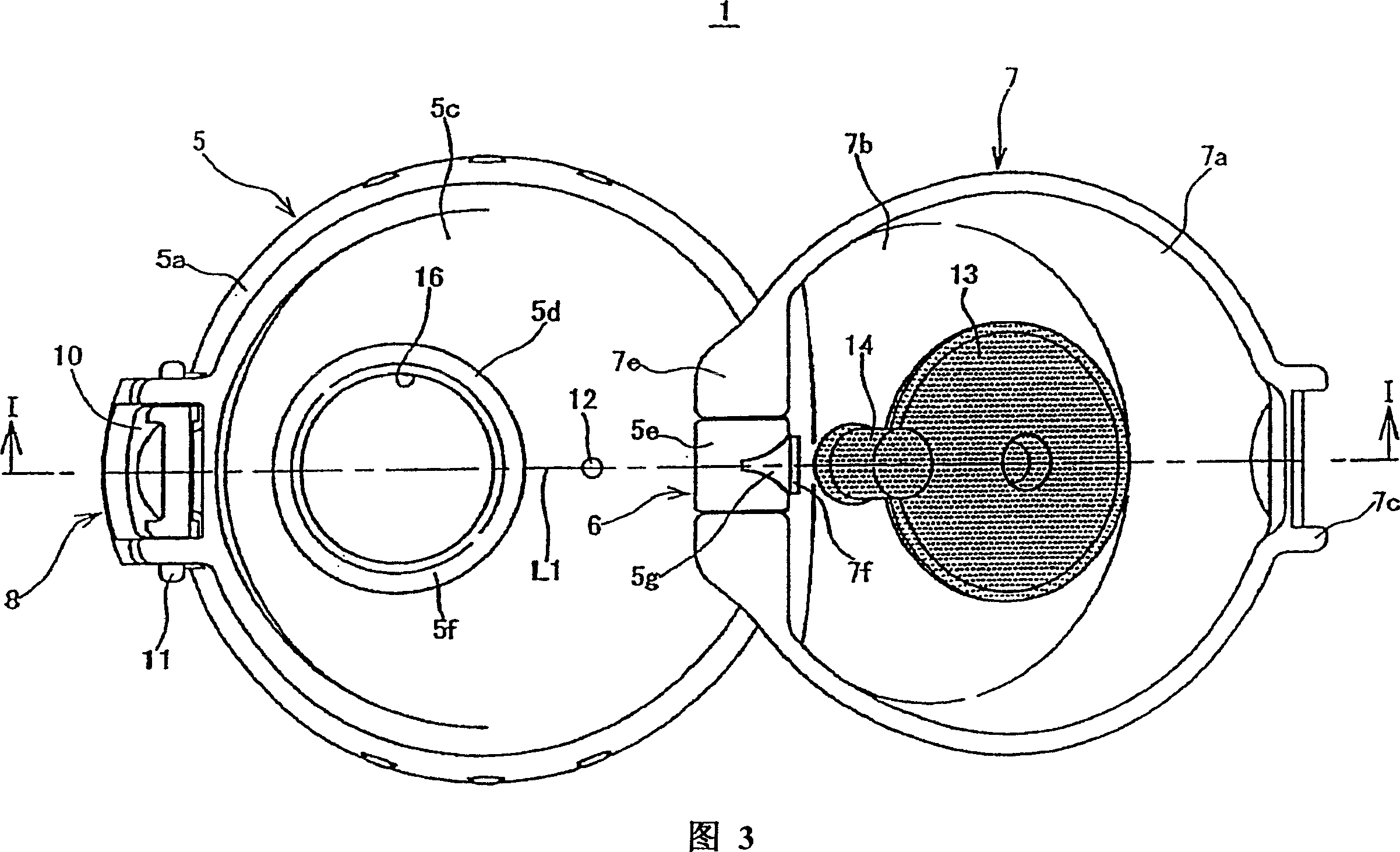

Plug of a container for holding beverage

Owner:THERMOS LLC

Electromagnetic valve for blood purification

ActiveCN102091381AGood biological propertiesStainlessDialysis systemsMedical devicesDisinfectantEngineering

The invention discloses an electromagnetic valve for blood purification. The bottom of the inner cavity of a valve body is provided with an annular boss; a seal gasket for sealing the central hole of the annular boss is positioned in the inner cavity of the valve body; the inner cavity of the valve body is provided with an elastic isolating piece, the upper end of the isolating piece is compressed tightly and fixed by a coil body, and the lower end of the isolating piece is fixedly connected with the seal gasket; the lower end of a slide iron core extends into an isolating body and is fixedly connected with the isolating body; and the inner hole at the upper end of the slide iron core is internally provided with a spring, and the upper end of the spring is connected with the coil body in a propping manner. The electromagnetic valve for blood purification provided by the invention has the advantages of good biology performance and high corrosion resistance, and can not rust, can not cause medium pollution, and can not be aged even if liquids with high corrosivity such as a disinfectant, acid liquor and the like are used; and the actions of the slide iron core are flexible and reliable, and the noise of the electromagnetic valve is lower during starting and closing.

Owner:SWS HEMODIALYSIS CARE CO LTD

Metal machining liquid and preparation method thereof

The invention relates to metal machining liquid and a preparation method thereof. The metal machining liquid is characterized by being prepared from the following raw materials in parts by weight: 1-1.2 parts of dodecyl sodium sulfate, 2-3 parts of simethicone, 2-2.4 parts of phenethyl phenol polyethenoxy ether, 1.2-1.4 parts of abietic acid polyoxyethylene ester, 1-1.3 parts of petroleum sodium sulfonate, 1.2-1.3 parts of phytic acid, 0.3-0.5 part of benzotriazole, 1.2-1.4 parts of a silane coupling agent KH550, 5-6 parts of a film auxiliary agent and 120-130 parts of water. The metal machining liquid is long in service life, environment-friendly and low in price.

Owner:CHANGLI FORGING

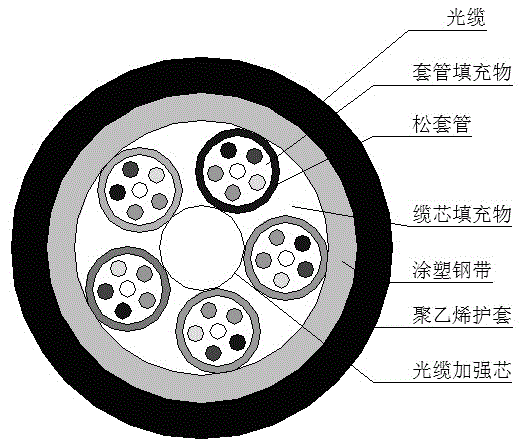

Cable reinforcement core and production method thereof

InactiveCN102608721ADoes not affect propagation performanceWon't happenFibre mechanical structuresEpoxyGlass fiber

The invention relates to a glass fiber reinforcement core used for increasing cable strength and a production method of the glass fiber reinforcement core, and belongs to the technical field of optical fiber. The production method comprises the following steps of: placing epoxy vinyl ester resin, curing agent BPO, curing agent TBPB, release agent PUL24 and fillers in a liquid tank, and uniformly stirring the components to obtain a resin mixed solution; heating a mould to be used, and stranding glass fibers to a necessary line diameter; and passing the stranded glass fibers through the liquid groove filled with the resin mixed solution, and passing the stranded glass fibers through the heated mould, demoulding, towing and winding the demoulded cable to obtain the cable reinforcement core. The cable reinforcement core provided by the invention is prepared with the glass fibers and the epoxy vinyl ester resin as main raw materials, so that the cable reinforcement core is non-conductive and is not affected by high pressure electricity or thunder and lightning. Therefore, the service life is long.

Owner:无锡市伟博通讯材料厂

Method for making non-ferrous metal alloy punching art decoration board

InactiveCN1944086AImprove bonding propertiesAdhesivelyOrnamental structuresSurface reaction electrolytic coatingSurface finishingAnode oxidation

The present invention relates to household goods making technology, and is especially process of making rolled and punched artistic decorative board of non-ferrous metal alloy for use to replace timber, artificial board, etc. in outdoor and indoor decoration. The making process of the punched artistic decorative board includes the following steps: smelting alloy, casting blank, rolling into board, ageing or quenching, punching artistic pattern and surface treatment including anode oxidation and electrostatic painting. The product has high quality and convenient installation, and is waterproof, fireproof, anticorrosive and environment friendly.

Owner:王其昌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com