Fixed part and its manufacturing method, combination of radiating devices using the fixed part

A technology for fixing parts and heat sinks, which is applied in semiconductor/solid-state device components, electric solid-state devices, electrical components, etc., and can solve problems such as rust, deformation of fixing rings, and falling off rods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

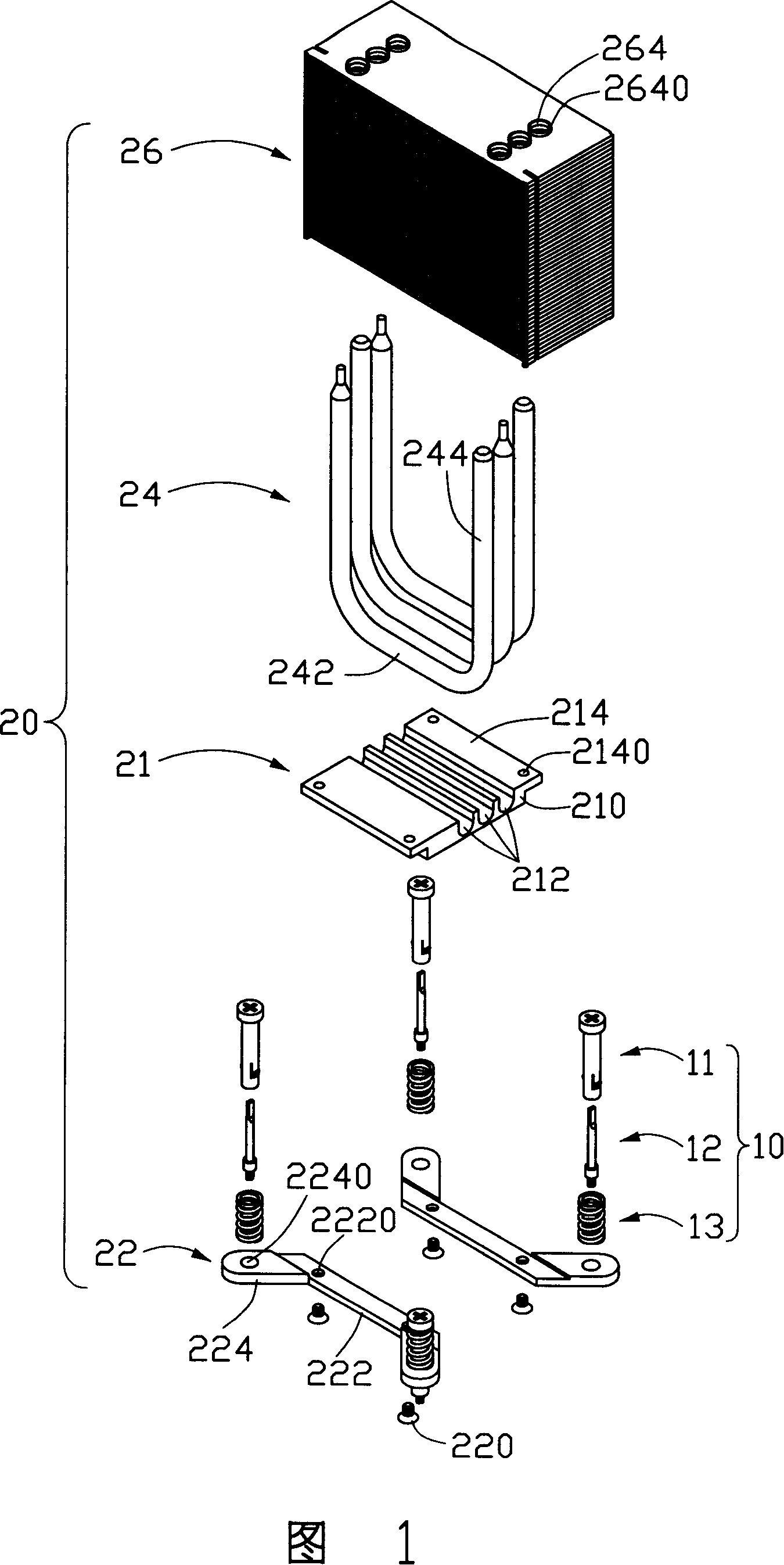

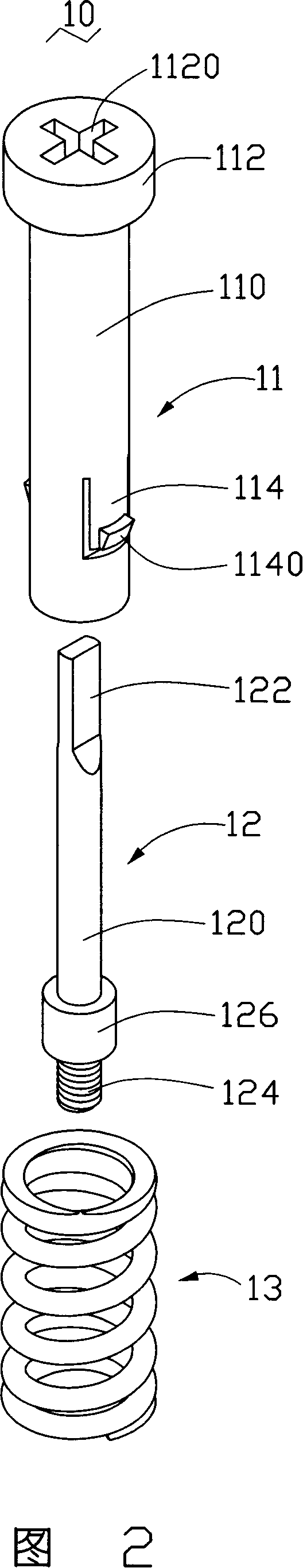

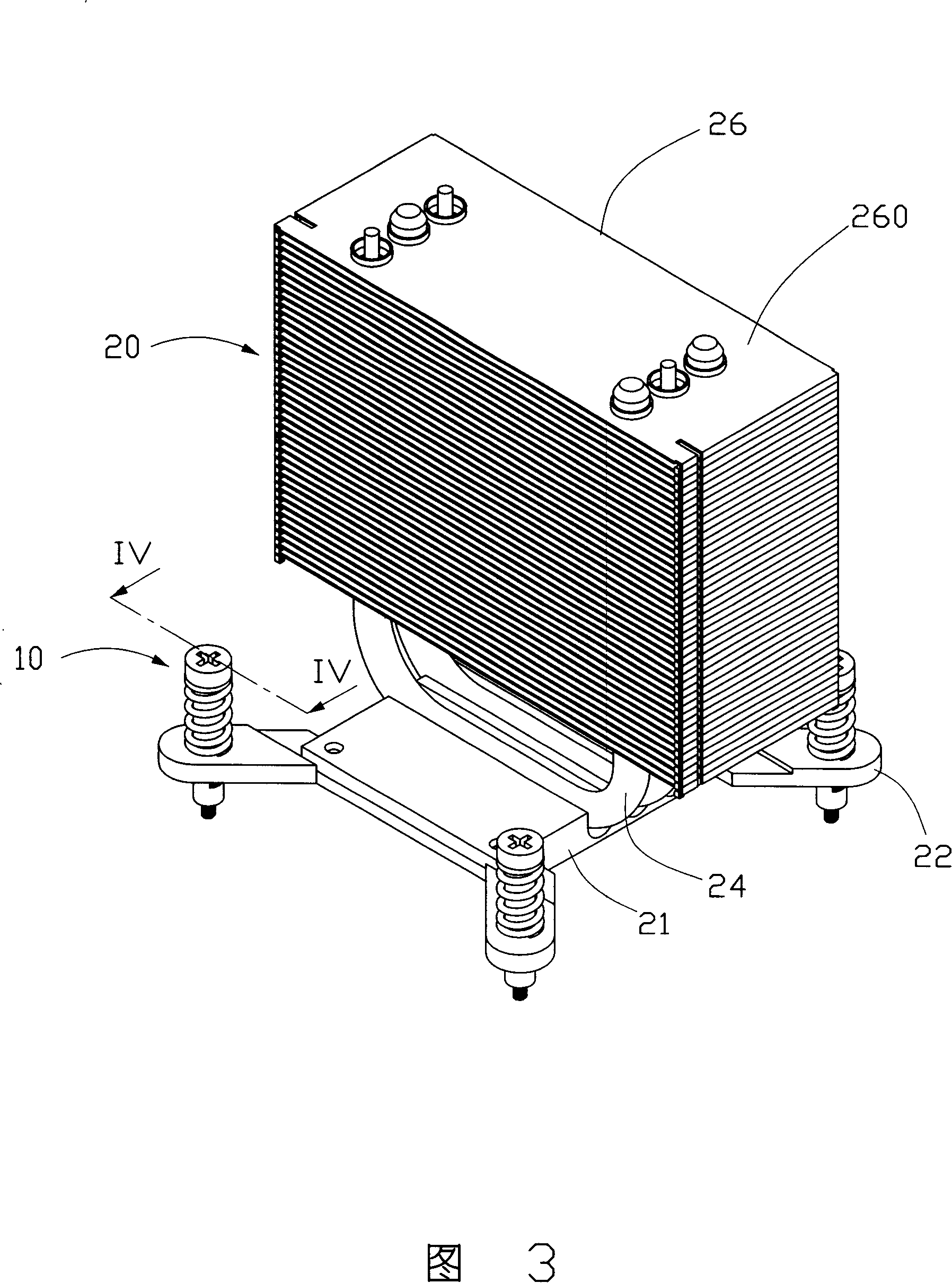

[0015] Please refer to FIG. 1 , a fixing member according to a preferred embodiment of the present invention includes several fixing members 10 . Taking the fixing of the heat sink 20 on the circuit board (not shown) as an example, the fixing device of the preferred embodiment of the present invention will be described in detail below.

[0016] The heat sink 20 includes a base 21 that is attached to the electronic components on the circuit board to absorb heat, a number of heat sinks 26 that are fastened together, three heat pipes 24 that are thermally connected together with the heat sink 26 and the base 21, and a power supply. The fixing member 10 passes through to fix the heat sink 20 to two fixing feet 22 on the circuit board.

[0017] The base 21 has a body 210, which is provided with a straight groove 212 corresponding to the heat pipe 24, and a flange extends horizontally outward from the upper half of the side edges of the body 210 parallel to the groove 212. 214 , th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com