Patents

Literature

113results about How to "Won't pull" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semiconductor lead frame manufacturing technology

ActiveCN103928302AQuality improvementStrong adhesionSemiconductor/solid-state device detailsSolid-state devicesManufacturing technologyCopper plating

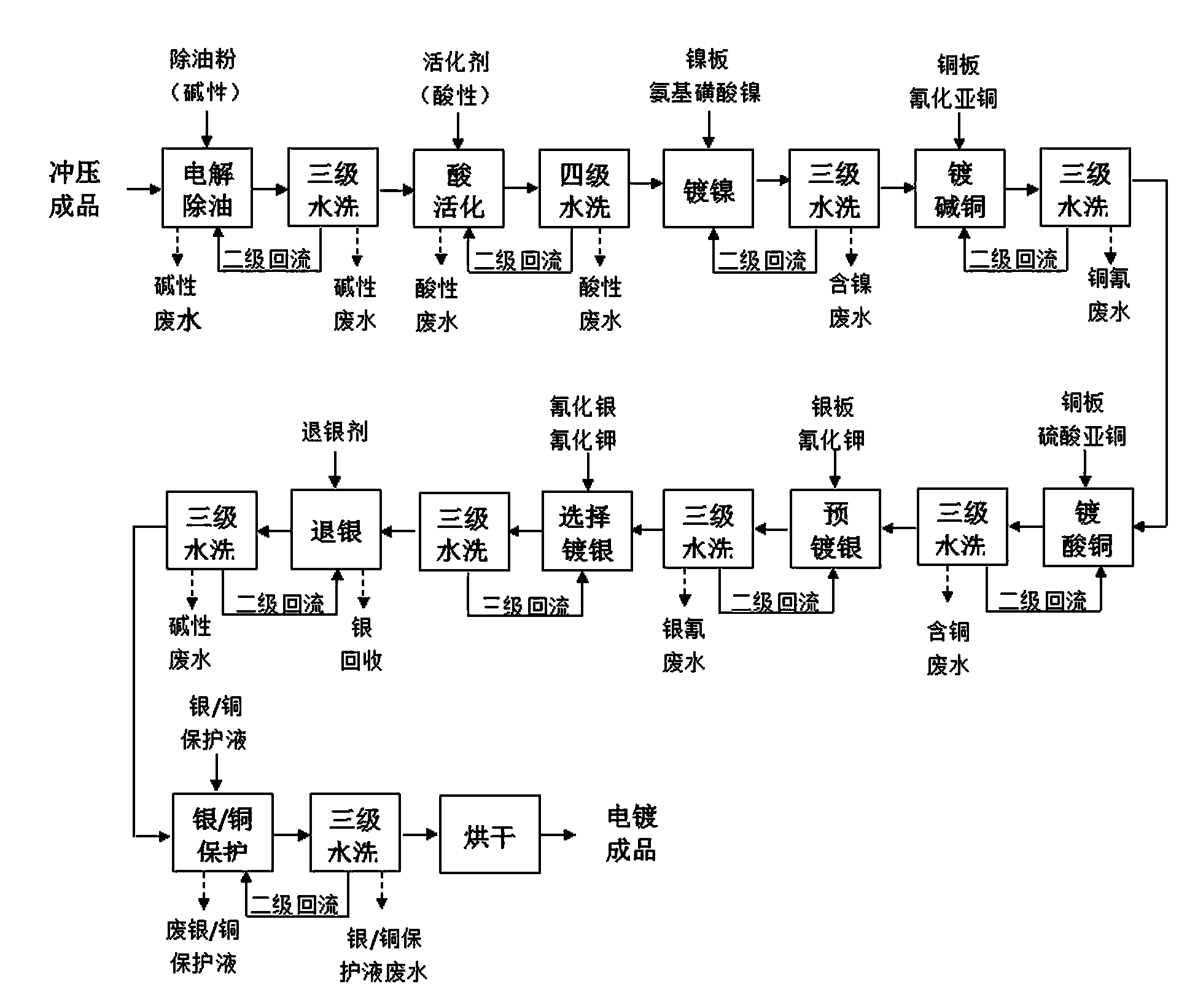

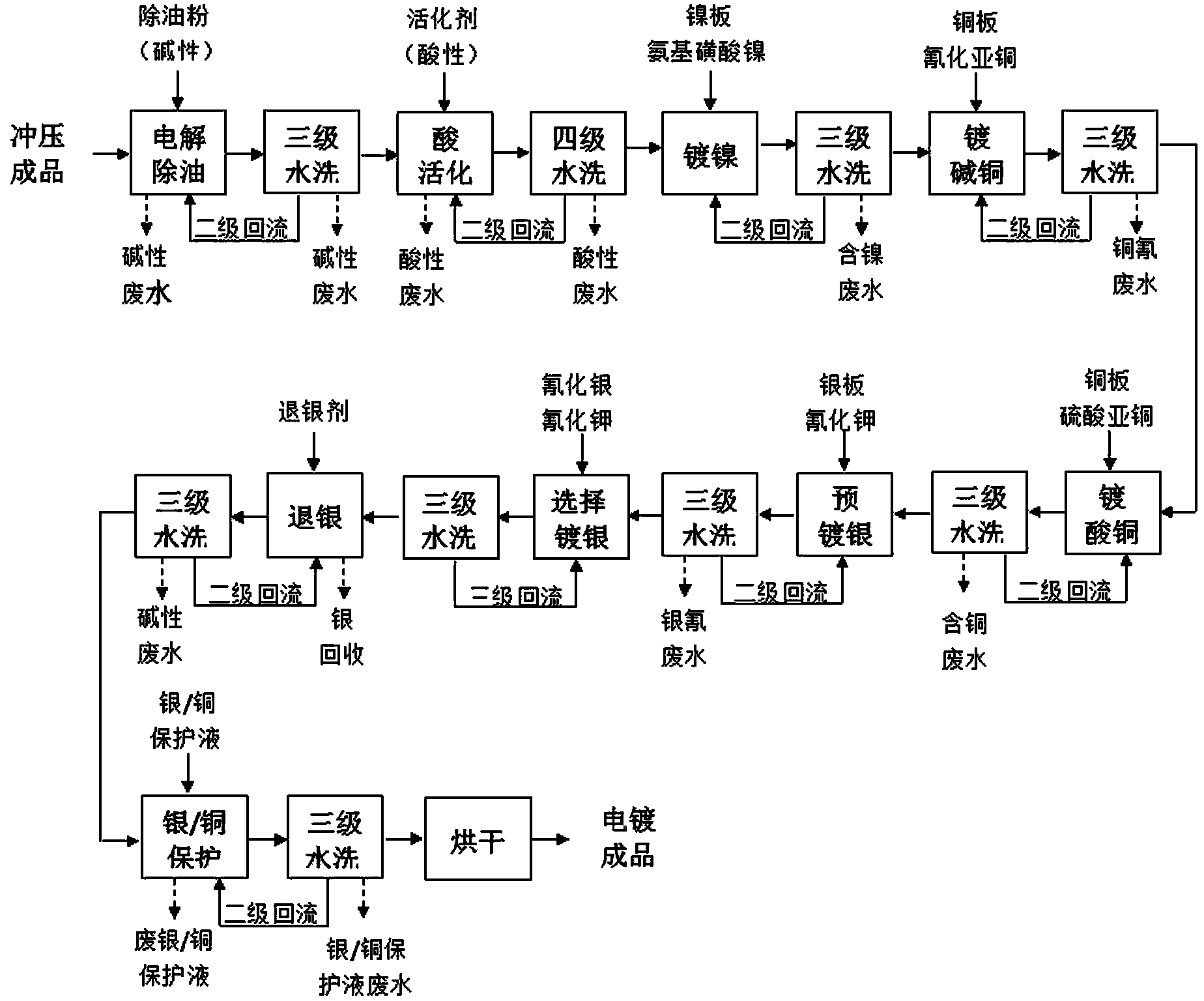

The invention relates to a semiconductor lead frame manufacturing technology which comprises the steps of stamping, surface treatment and cut-forming. The technology is characterized in that the surface treatment process specifically comprises the steps of electrolytic degreasing, washing, acid activation, washing, nickel plating, washing, alkaline copper plating, washing, acid copper plating, washing, silver preplating, washing, silver plating, silver removing, washing, protective solution plating, washing and drying. Plated layers of a semiconductor lead frame manufactured with the method are high in adhesive force and do not fall off easily. Meanwhile, the semiconductor lead frame is free of deformation and oversize, high in quality, and long in service life.

Owner:SICHUAN JINWAN ELECTRONICS

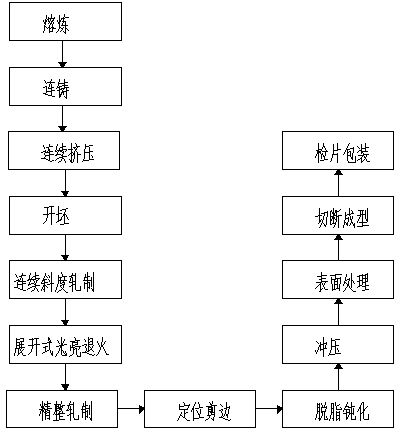

Semi-conductor lead framework production process

ActiveCN103928351AExact widthAdequate heat dissipationSemiconductor/solid-state device manufacturingMechanical engineeringSemiconductor

The invention relates to a semi-conductor lead framework production process which includes the steps of smelting, continuous casting, continuous extrusion, cogging, severe convection annealing, continuous inclination rolling, spreading-type bright annealing, finishing rolling, positioning-type edge shearing, degreasing passivation, stamping, surface processing, cutting forming and detection piece packaging. The production process is characterized in that the two work procedures of finishing rolling and positioning-type edge shearing are provided with continuous grooving procedures, when continuous grooving is carried out, precise grooving processing is carried out through a grooving machine, the rotation speed of the grooving machine is 1800-2000 r / min, the flow of cooling liquid is 45-50 L / min, and dovetail groove forming achieving through the process cannot cause strip width changes after forming, and the size of a formed semi-conductor lead framework is accurate.

Owner:SICHUAN JINGJIAN ELECTRONICS MATERIAL

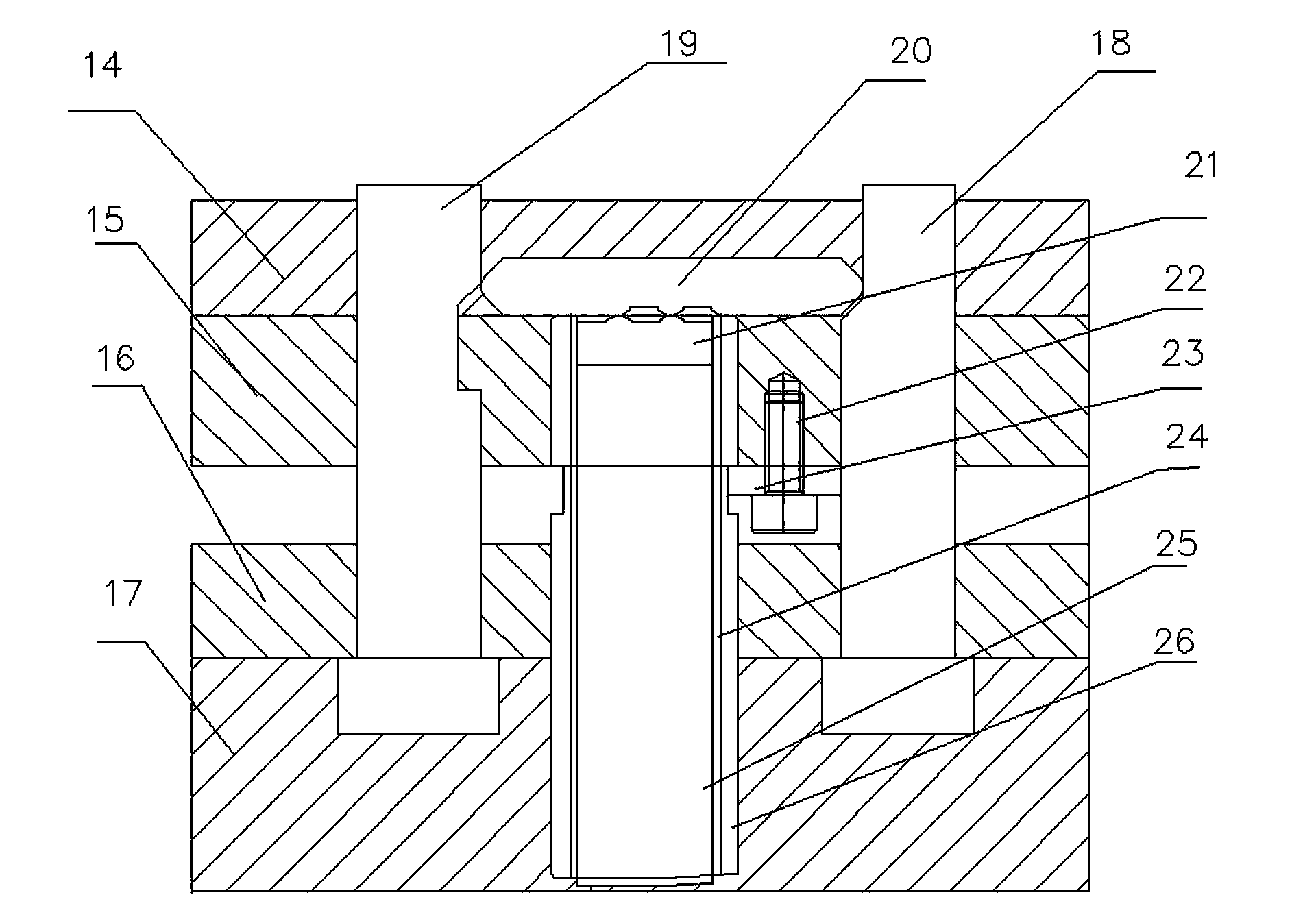

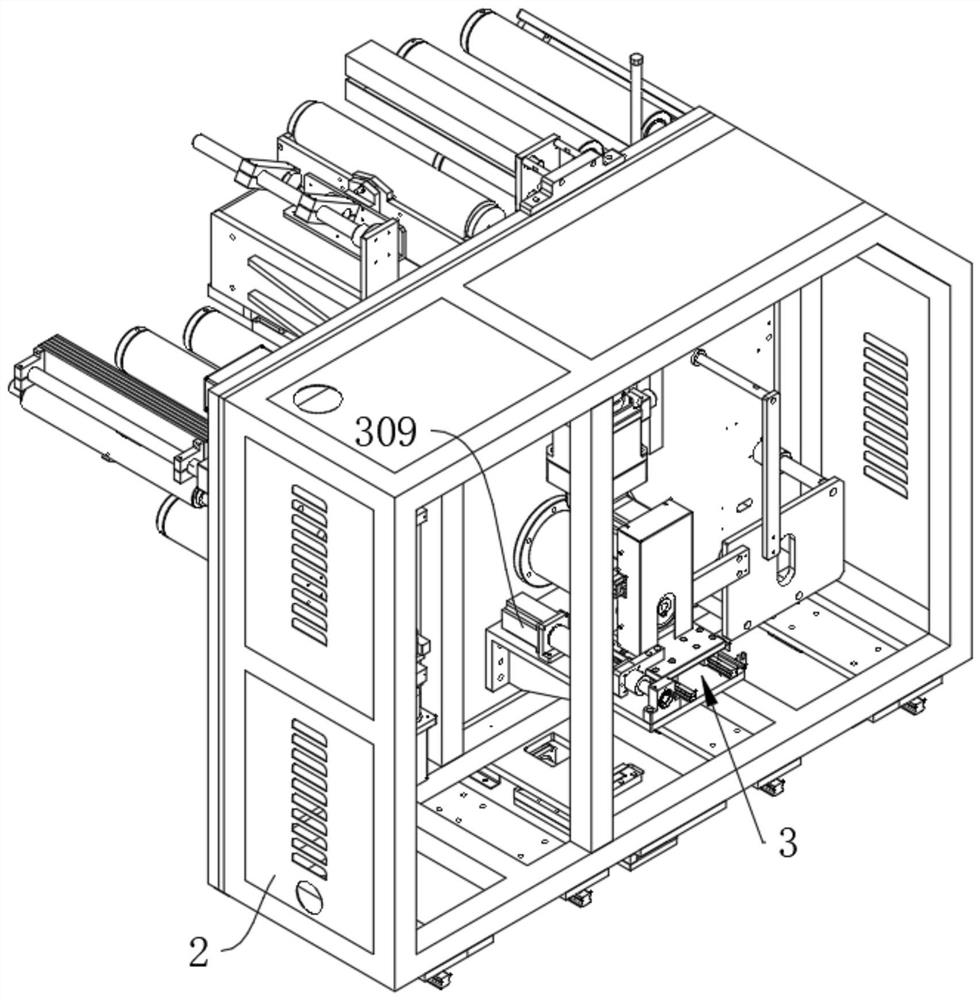

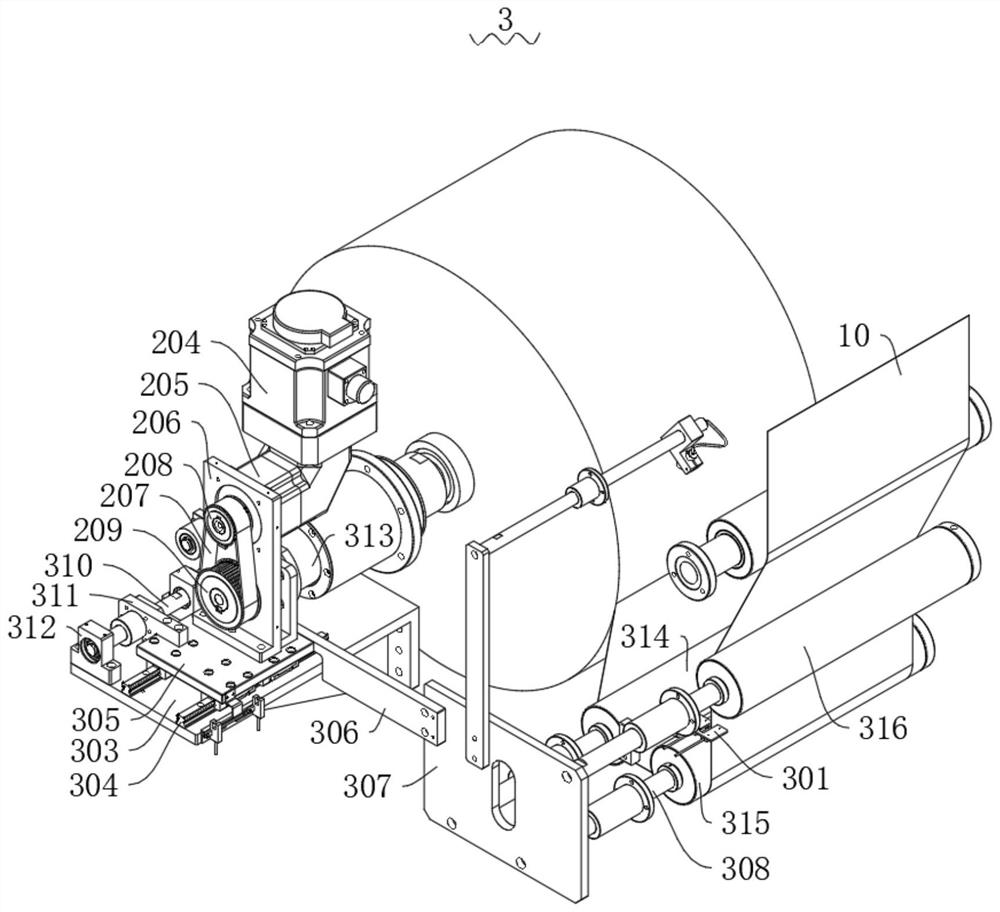

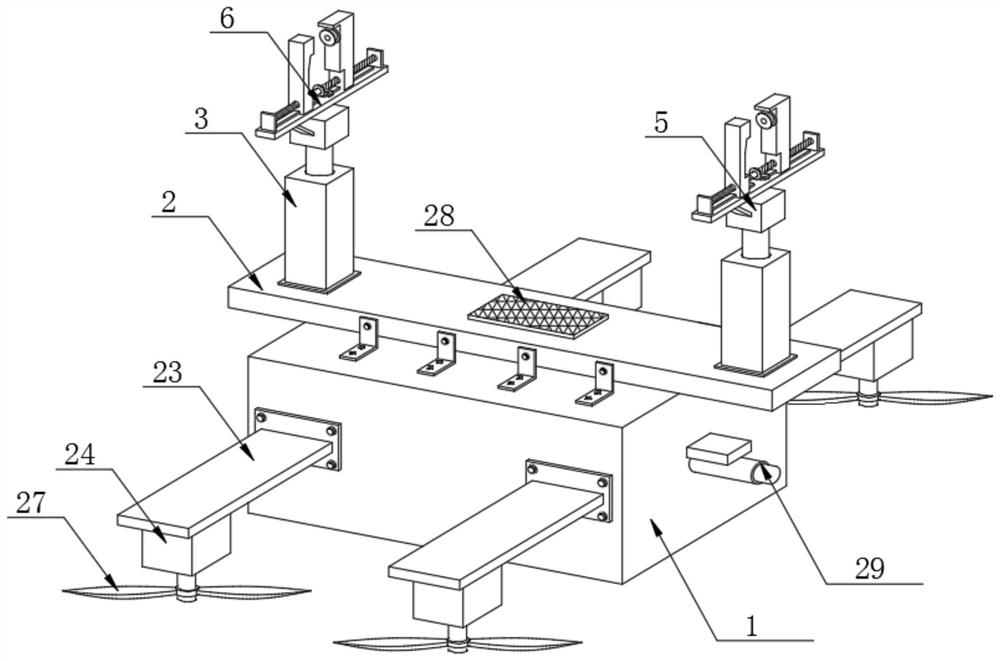

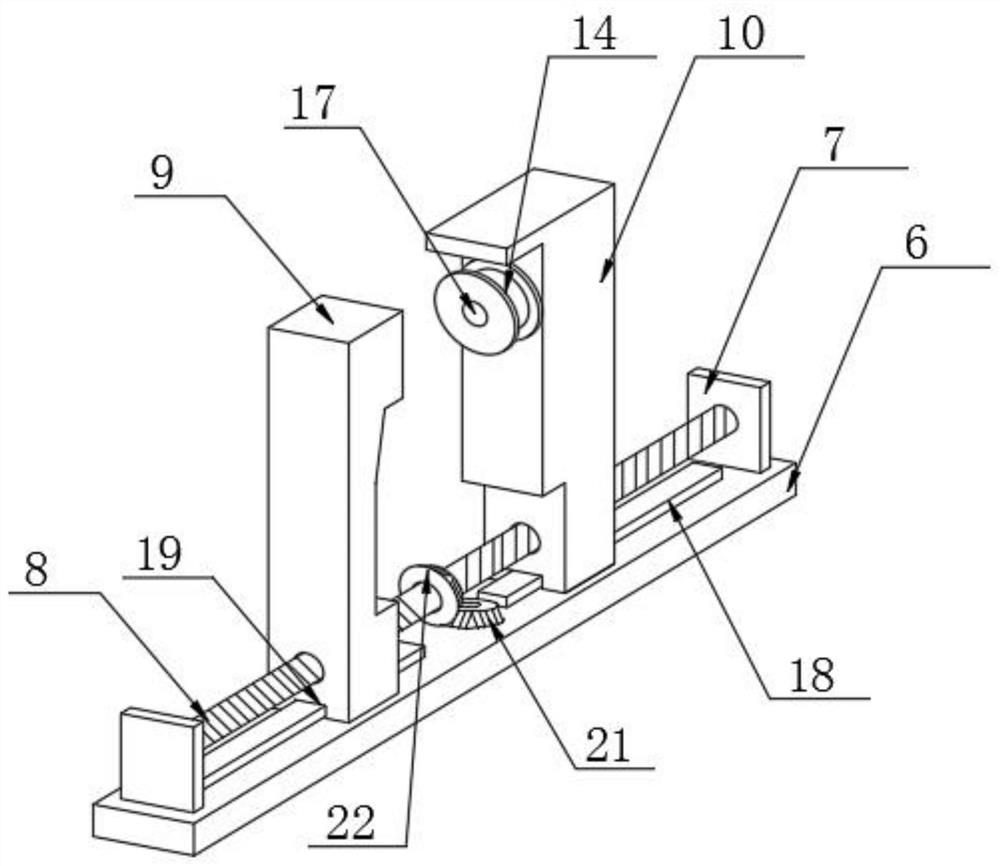

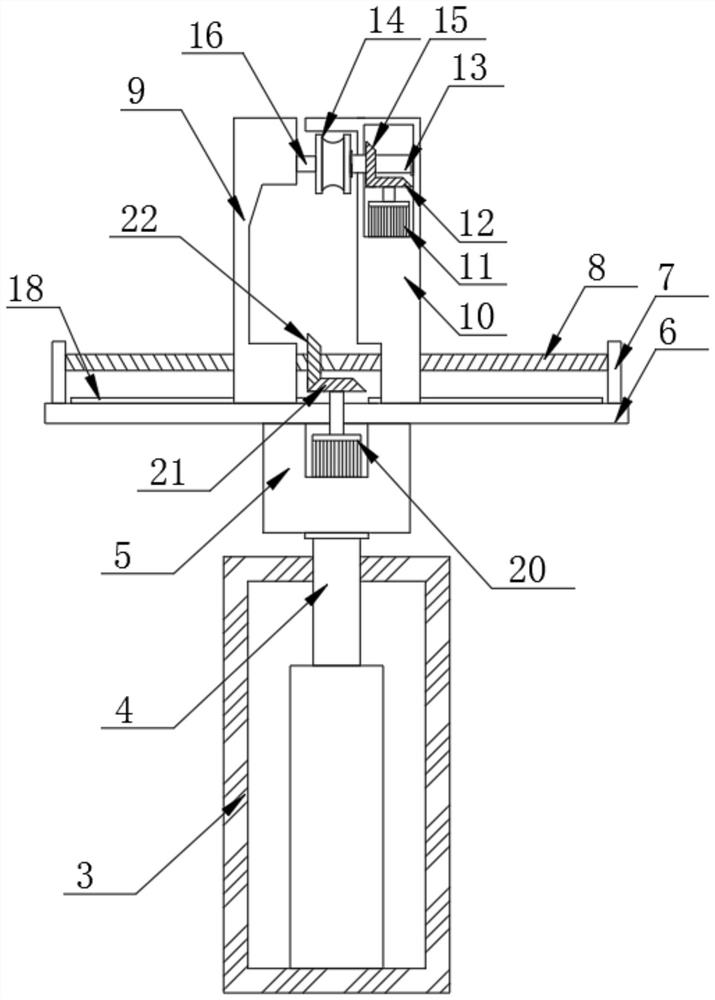

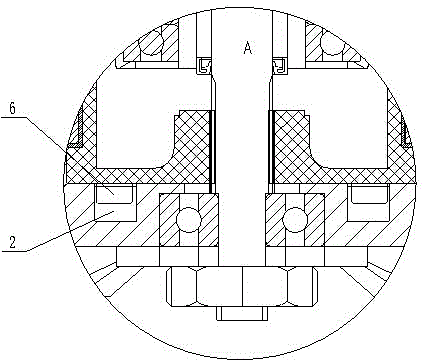

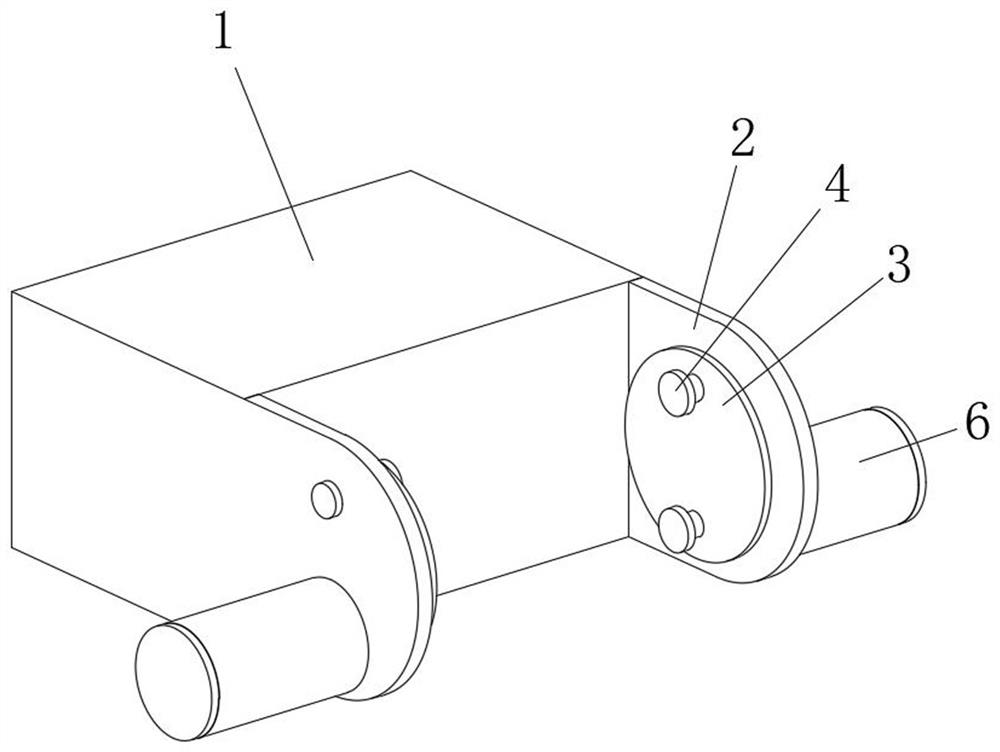

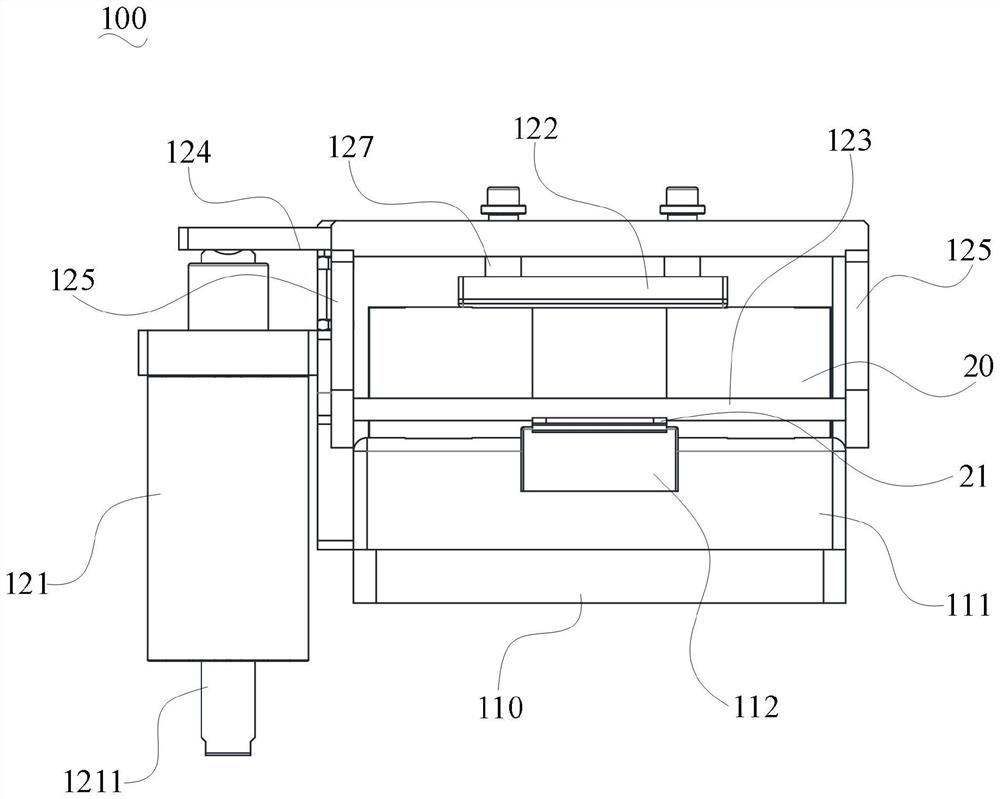

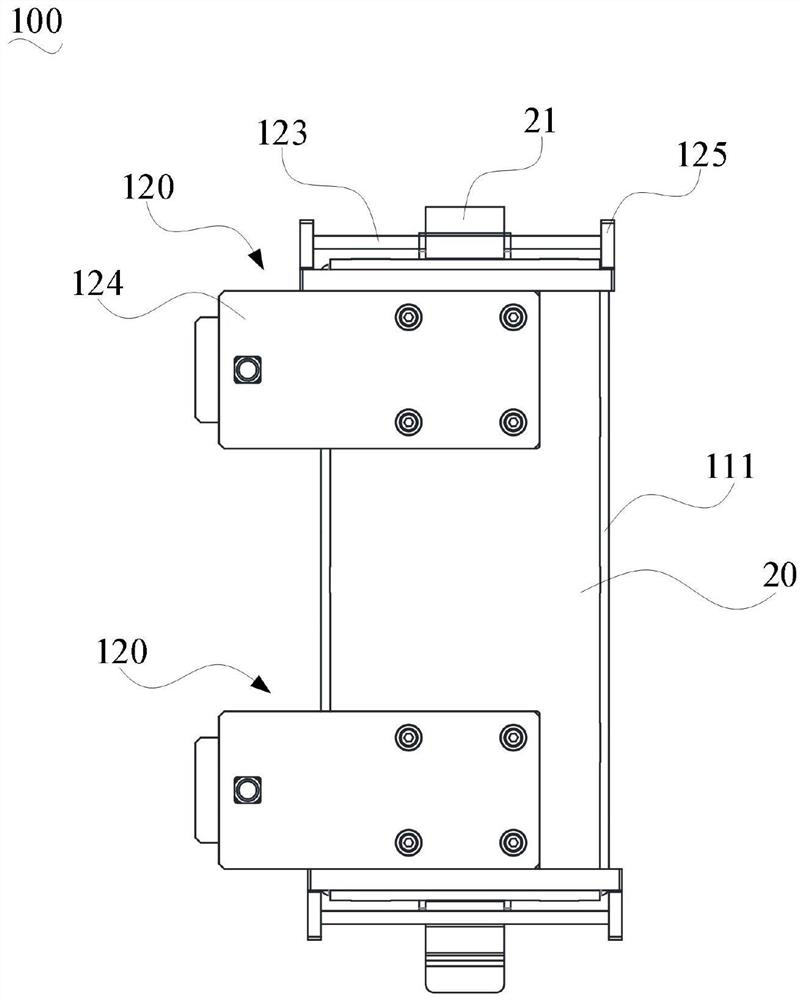

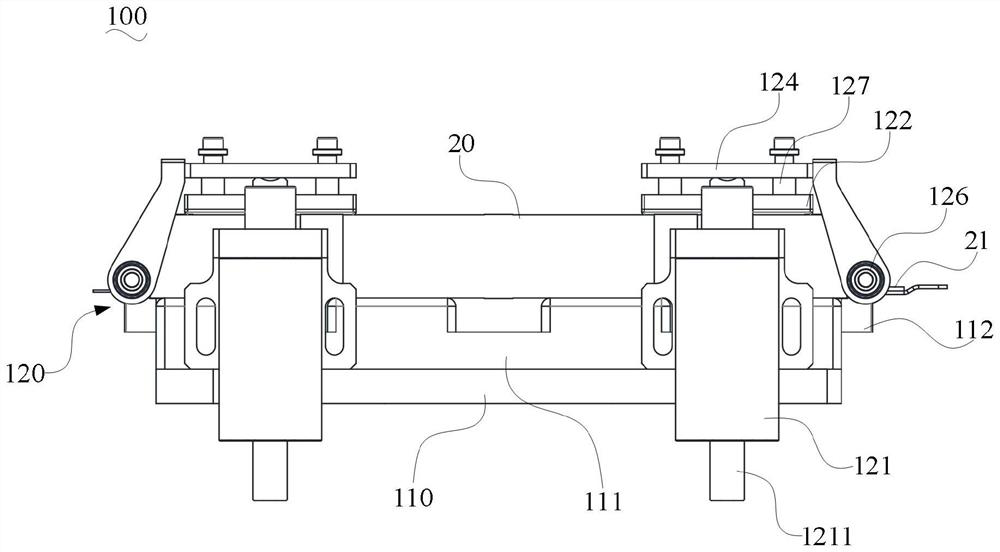

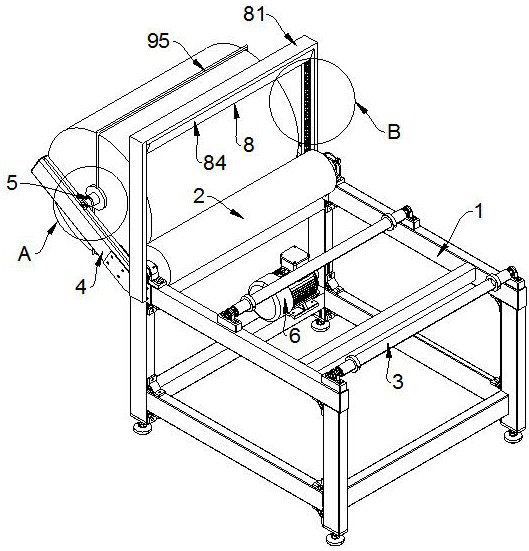

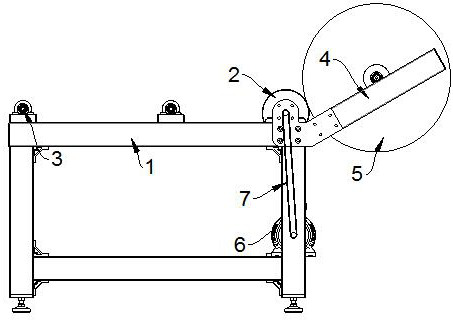

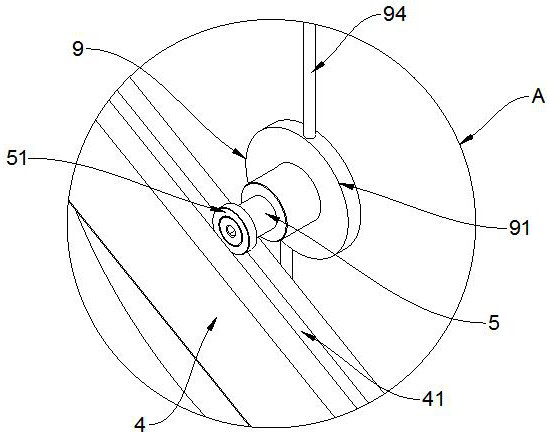

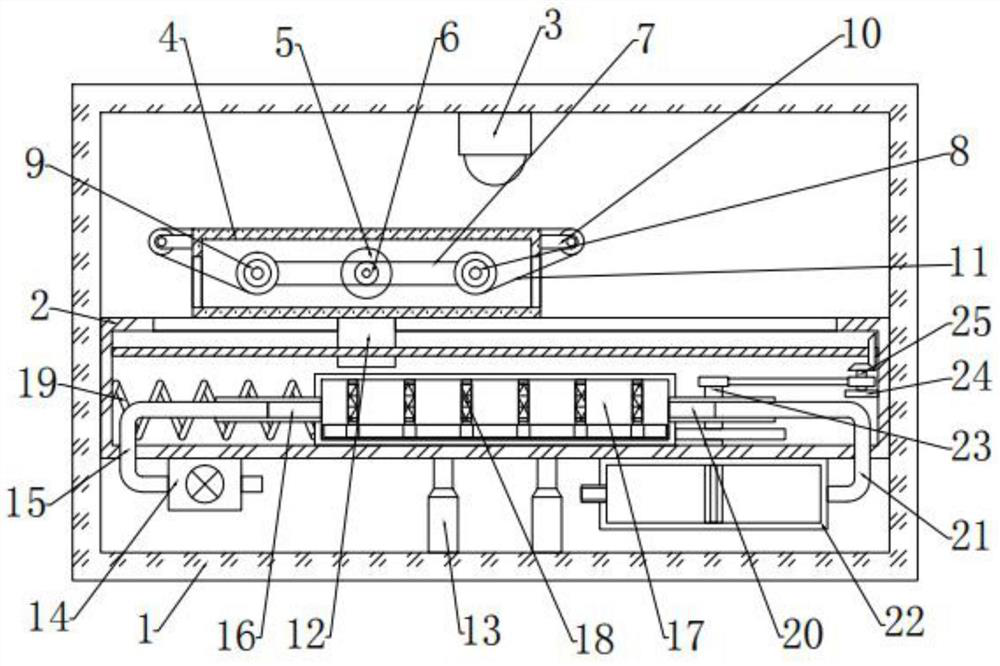

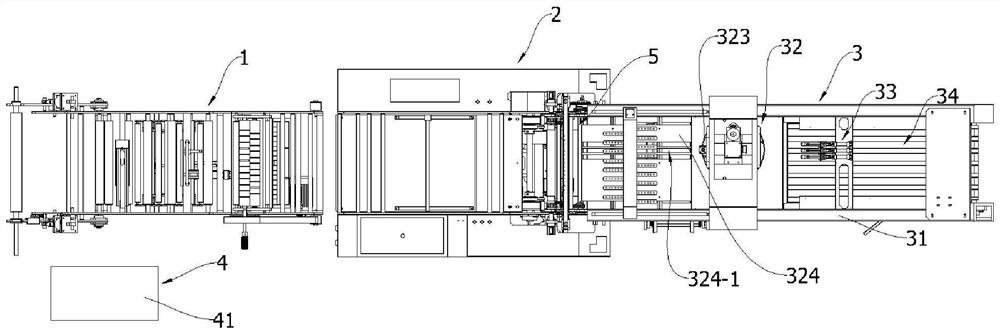

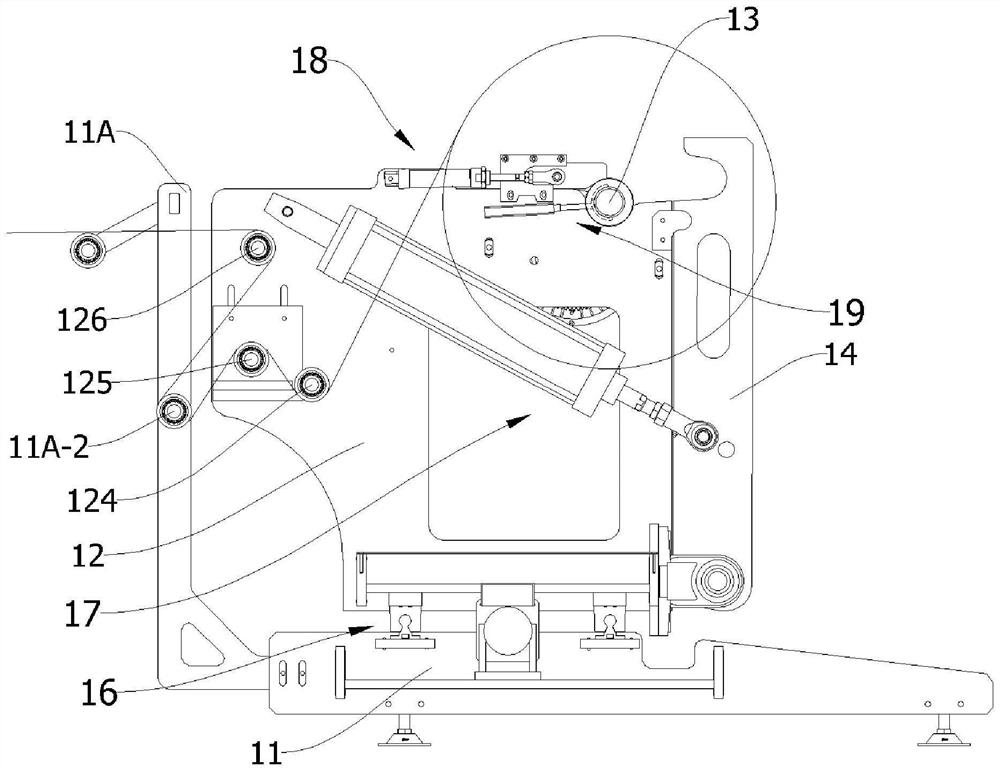

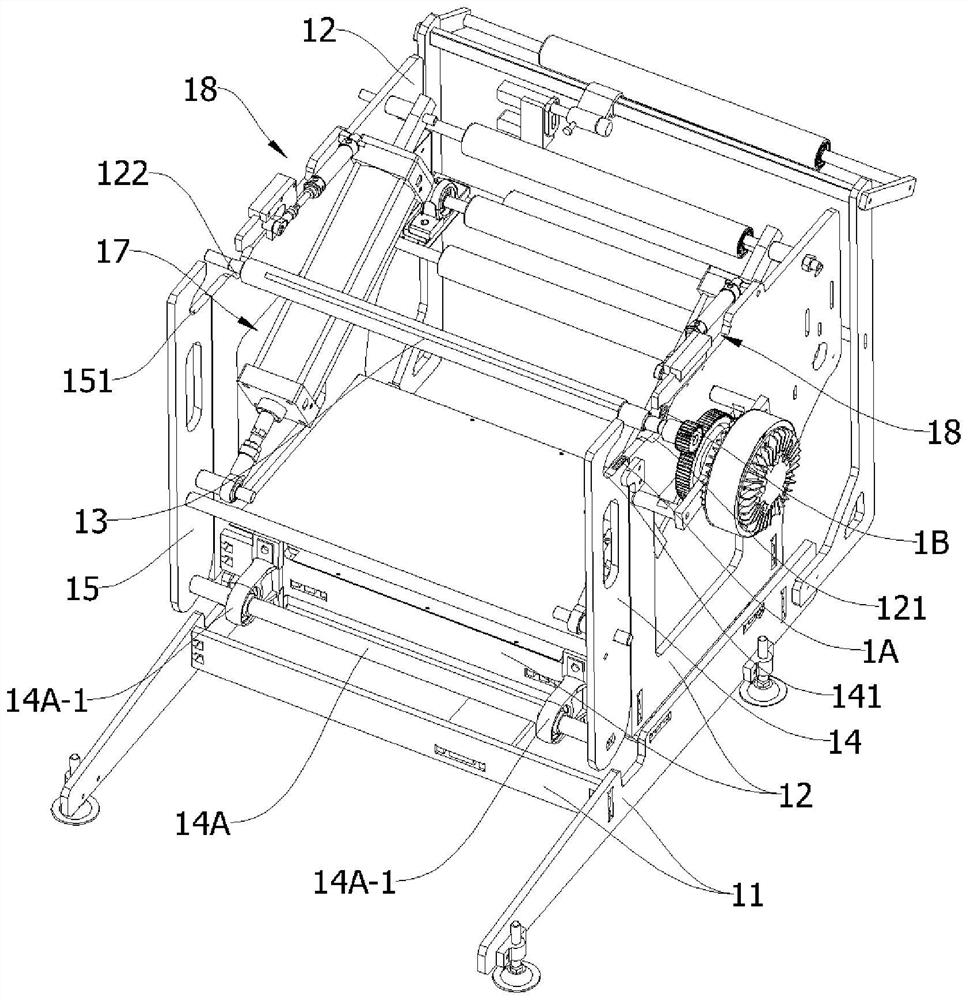

Unwinding mechanism

PendingCN111702032AHigh precisionQuality assuranceMetal-working feeding devicesMetal working apparatusStructural engineeringPole piece

The invention discloses an unwinding mechanism, and belongs to the field of pole piece die-cutting machines. The unwinding mechanism comprises a large plate, an unwinding frame arranged on the large plate, an air expansion shaft connected to the unwinding frame in a sliding manner along the axis direction, and an unwinding assembly for driving the air expansion shaft to wind out a pole piece, theunwinding frame is provided with a first deviation rectifying device, a second deviation rectifying device and a third deviation rectifying device, and the pole piece is conveyed to a die cutting mechanism after being rectified by the first rectifying device, the second rectifying device and the third rectifying device in sequence. According to the unwinding mechanism, the problems that a two-stage deviation rectifying mechanism is adopted in a traditional die-cutting machine, due to the fact that part machining errors and assembly errors exist in a passing roller or a temporary storage roller, the position of the pole piece cannot be quite accurate before the pole piece enters a die, large deviation of the appearance size of a finished pole piece is caused, and risks of battery explosionand like are increased are solved.

Owner:JIANGSU KATOP AUTOMATION CO LTD

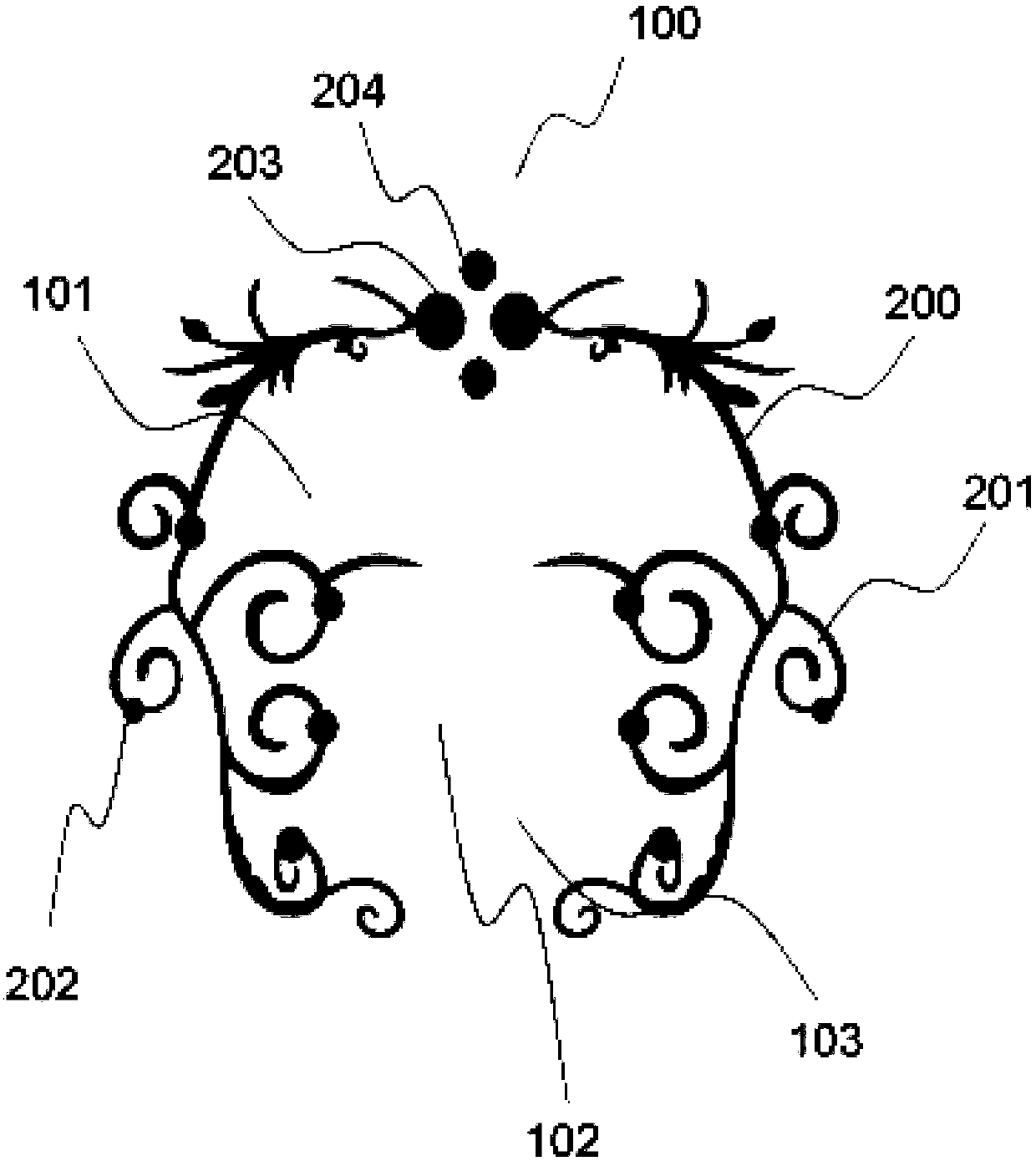

Taiji mineral wool-based intelligent mask

PendingCN109675186AImprove conductivityPromote absorptionCosmetic preparationsElectrotherapyFiberSilver paste

The invention relates to a taiji mineral wool-based intelligent mask. The intelligent mask comprises a mask base cloth, a pulse conducting layer and an intelligent main engine, wherein the mask base cloth is soaked with a skincare product essence; the pulse conducting layer is adhered to the mask base cloth; the pulse conducting layer comprises conducting circuits which are respectively arranged on left and right sides of the mask base cloth and are made from silver paste and graphene; the conducting circuits are used for conducting low-frequency pulse; the conducting circuits have a dendriticstructure; a plurality of arc-shaped branches are arranged on the conducting circuits; the intelligent main engine is connected with the pulse conducting layer; a pulse output electrode, a skin detecting electrode and a heating output electrode are arranged on the intelligent main engine. The intelligent mask provided by the invention is capable of transmitting low-frequency pulse and heating current to the whole face, so as to achieve the functions of vibration massage and hot compress, boost the absorption of skin for essence and achieve a phototherapy function and a control function of a mobile intelligent terminal.

Owner:TAICHI STONE TECH CO LTD

Line patrol robot

InactiveCN113022869AWon't pullAffect sagAircraft componentsClosed circuit television systemsStructural engineeringMechanical engineering

The invention provides a line patrol robot which comprises a box body, a top plate is fixedly connected with the top of the box body, top boxes are fixedly connected with the two sides of the top of the top plate, electric telescopic rods are fixedly connected with the bottoms of the inner walls of the top boxes, the output ends of the electric telescopic rods penetrate through the top boxes and extend to the tops of the top boxes, the end, extending to the top of the corresponding top box, of the output end of each electric telescopic rod is fixedly connected with a fixed box. The invention relates to the technical field of circuit inspection. According to the power transmission line inspection equipment, the top of the box body is fixedly connected with the top plate, automatic walking can be achieved, hanging of different split conductors is facilitated, meanwhile, when encountering an obstacle, the whole equipment can be driven to move through a flying device, and the quality of power transmission line inspection work is guaranteed; the equipment can be remotely controlled and can be widely applied to inspection work of power transmission lines.

Owner:ZHENGZHOU UNIV OF IND TECH

Anti-wrinkling structure of sewing machine

InactiveCN102733106AAvoid deformation and wrinklingWon't pullWork-feeding meansConveyor beltFriction force

The invention relates to an anti-wrinkling structure of a sewing machine. The anti-wrinkling structure comprises a frame, and a bedplate and a driving device which are arranged on the frame, wherein a headpiece is arranged on the bedplate; a machine needle is arranged on the headpiece; a needle plate is arranged below the machine needle; conveying devices are arranged on two sides of the needle plate on the bedplate; and tip-shaped bulges are arranged on the conveying devices. The anti-wrinkling structure is simple in structure; when a cloth material is placed on conveyor belts, the tip-shaped bulges on the conveyor belts are buckled into small holes of the cloth material, the friction force is increased, the cloth material is pulled by a pull force, so that the cloth material is prevented from deforming and wrinkling during sewing, the sewing quality is good, the cloth material is attractive in appearance, and simultaneously the conveyor belts can drive the cloth material to move forwards and the cloth material is not pulled; and the anti-wrinkling structure has great application and promotion values.

Owner:WUJIANG XIAOYU JET WEAVING

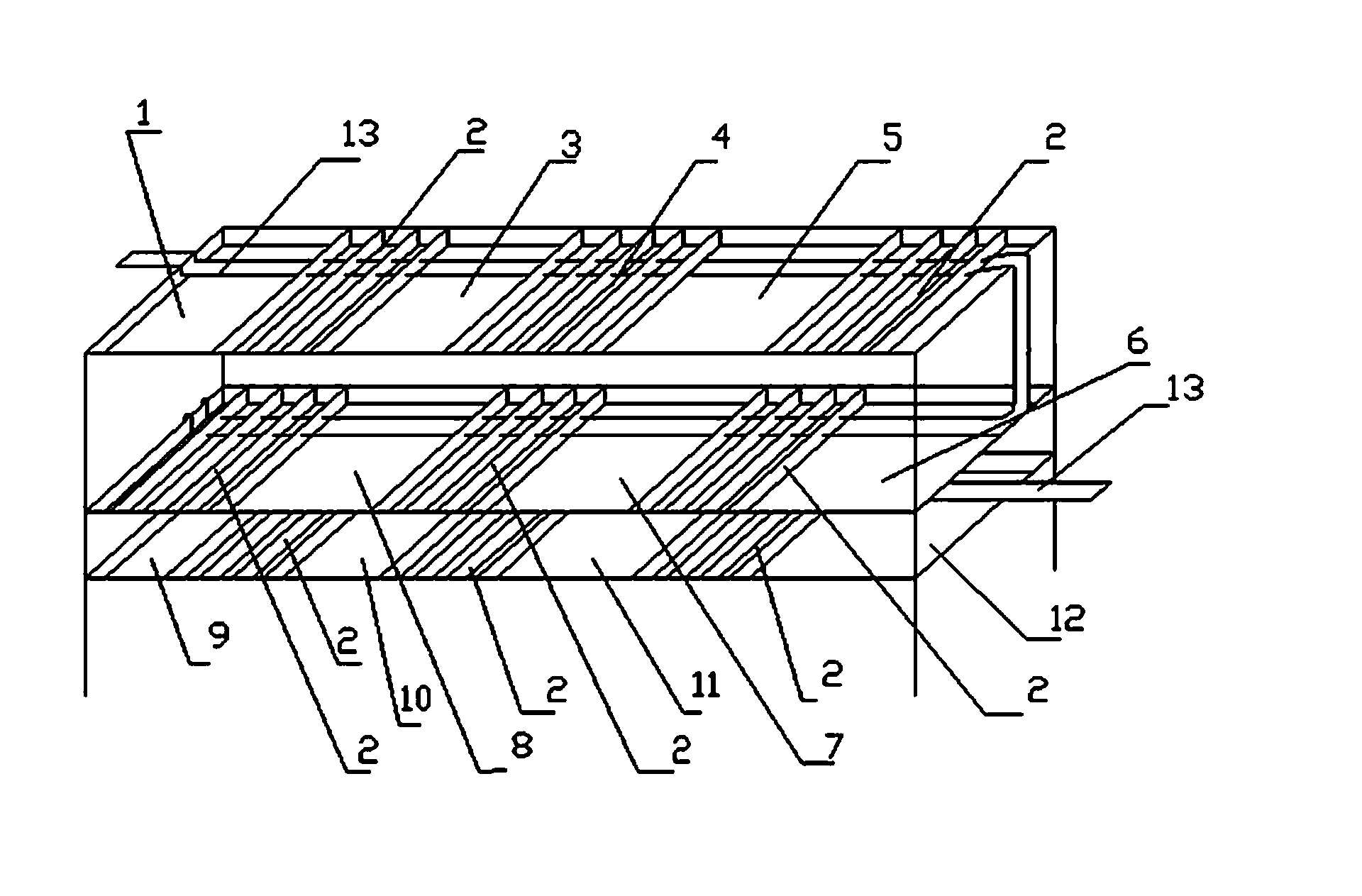

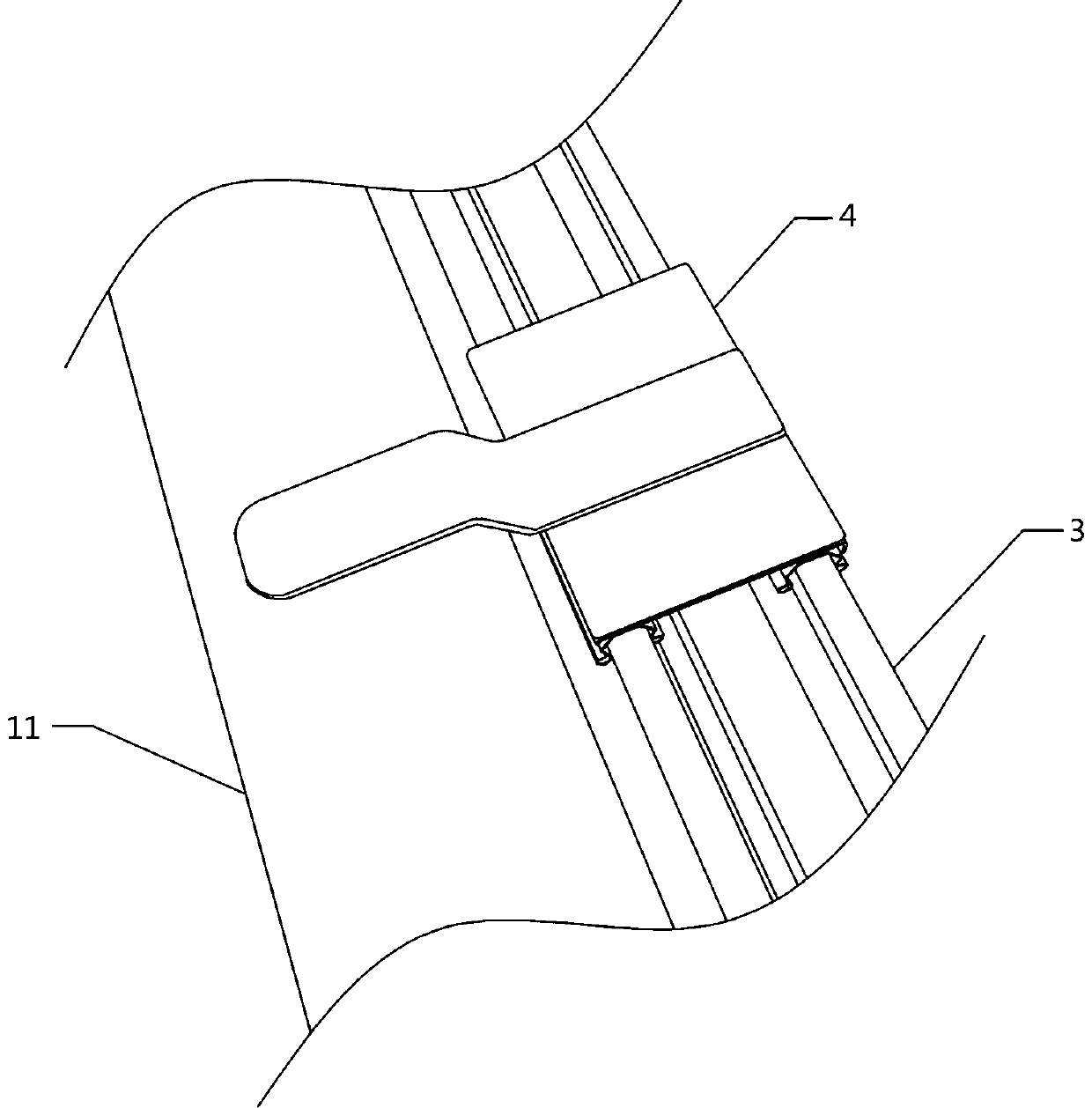

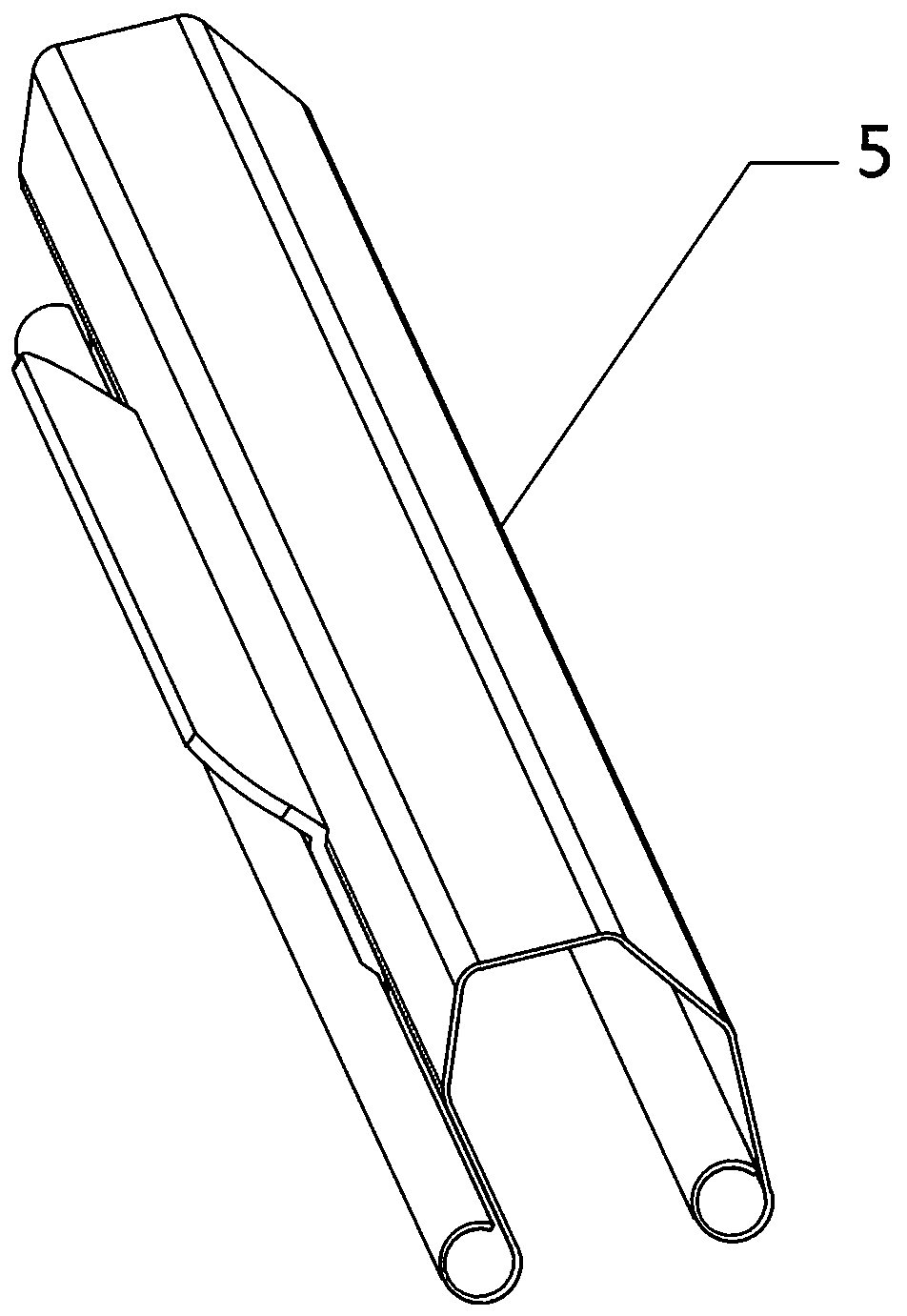

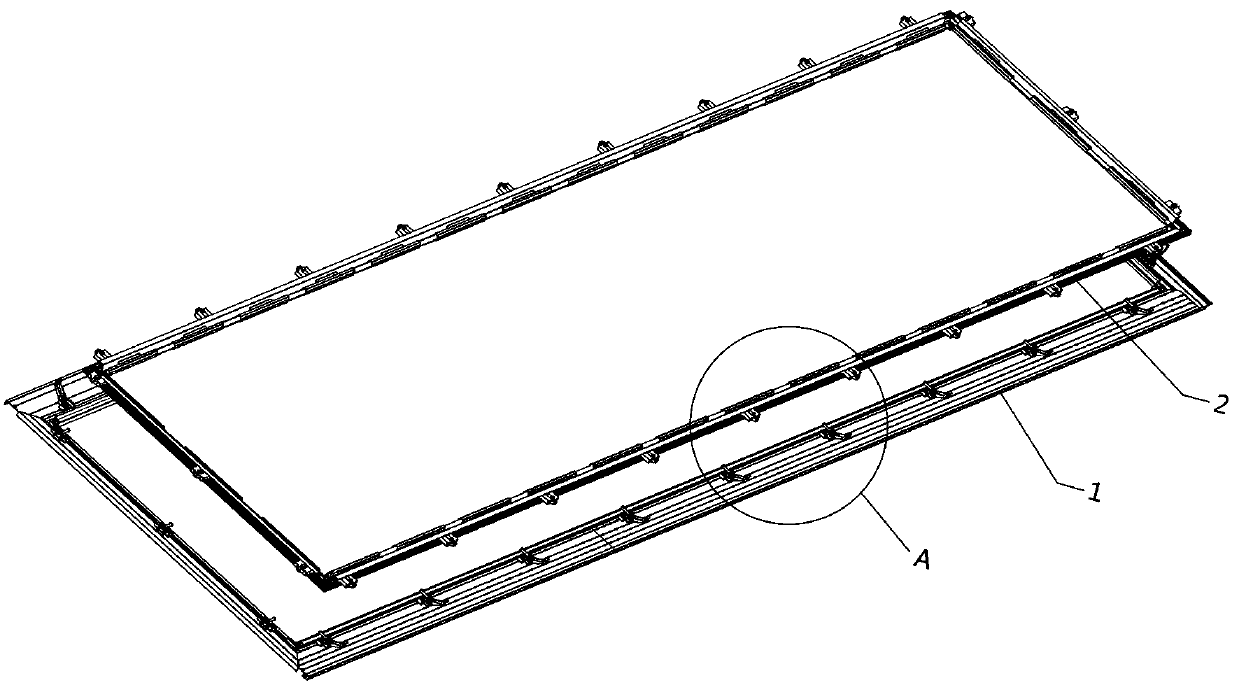

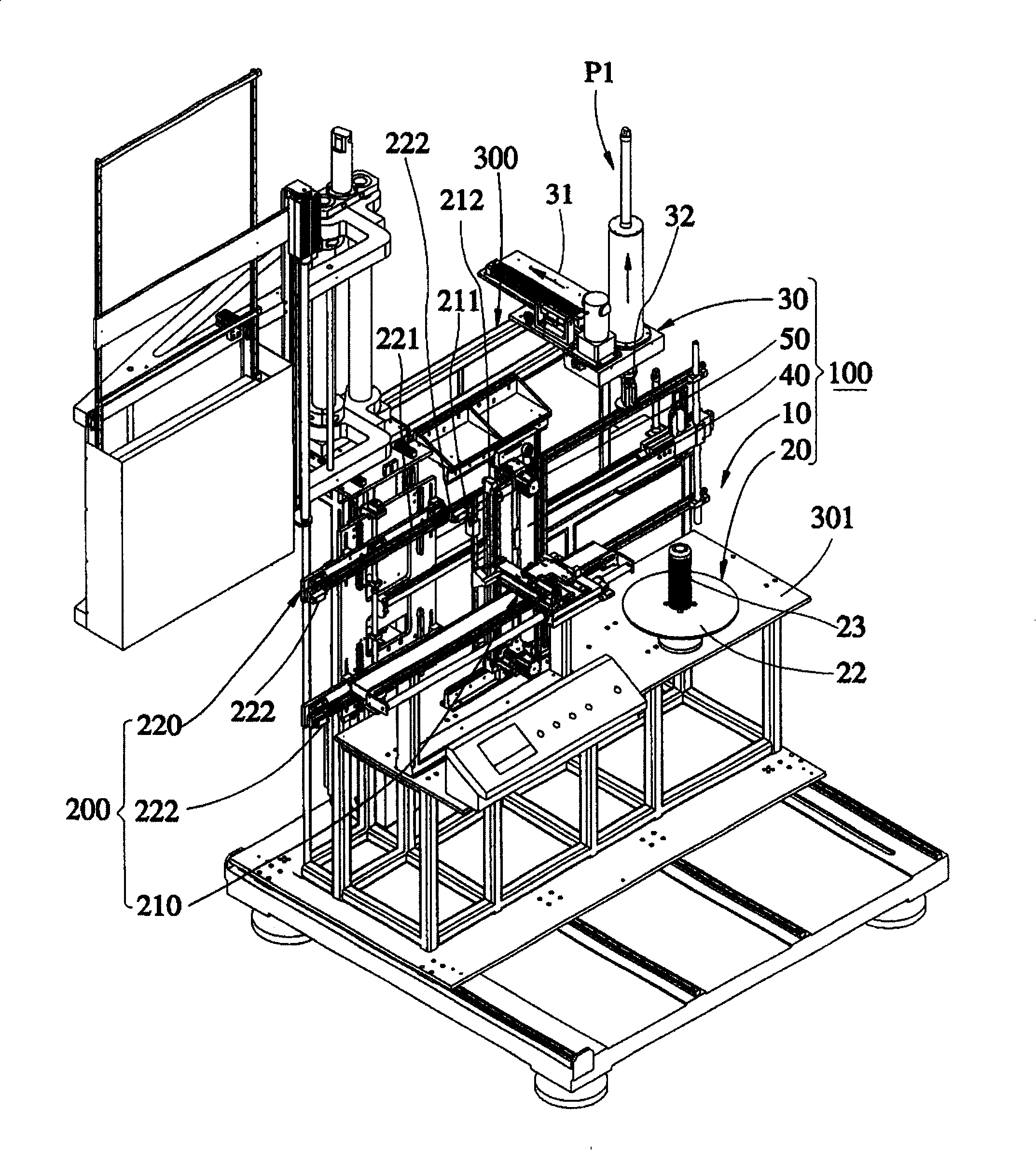

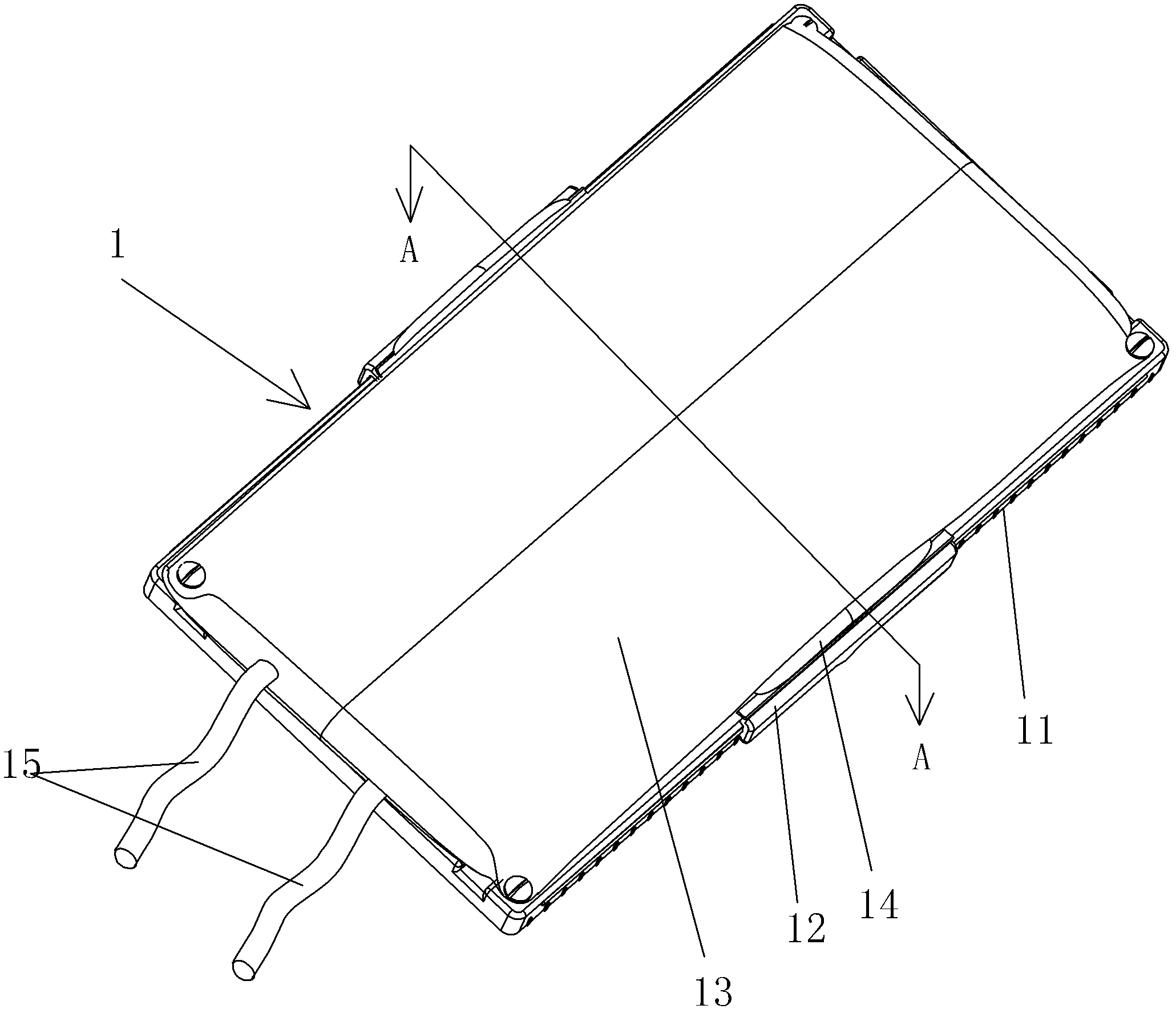

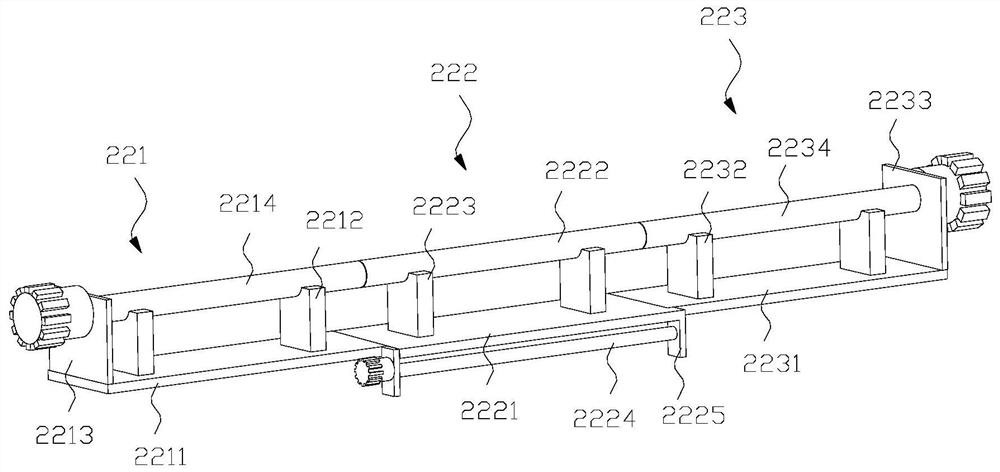

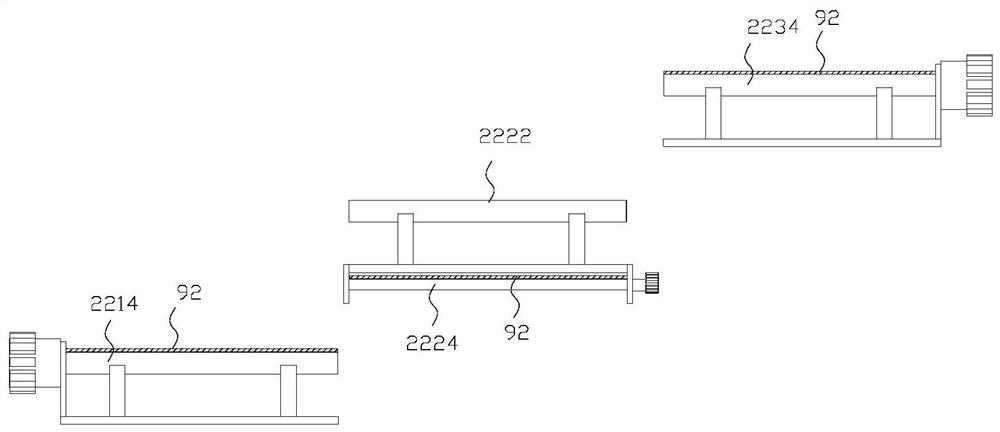

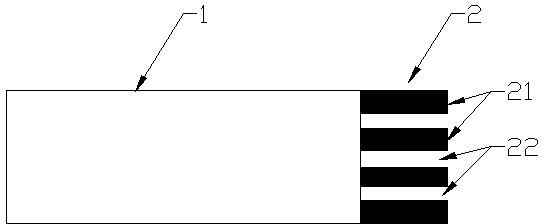

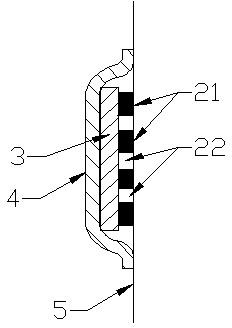

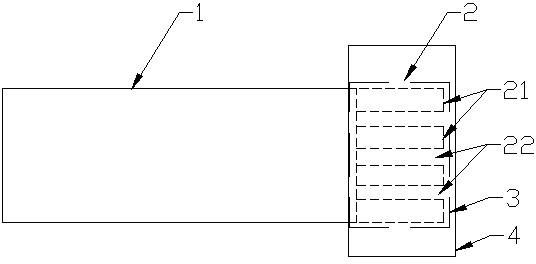

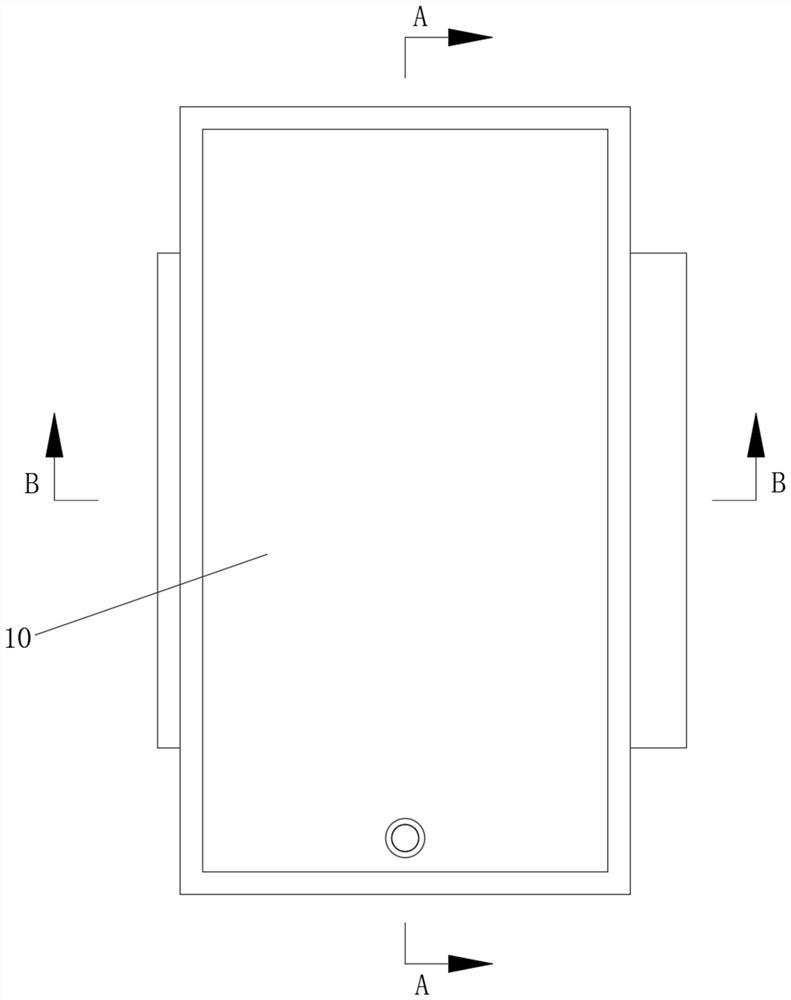

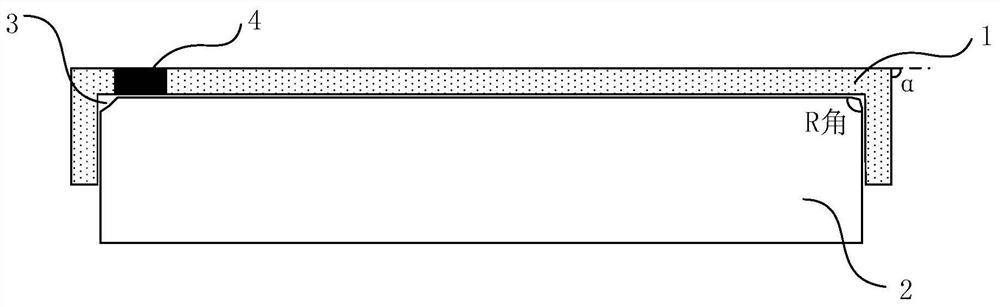

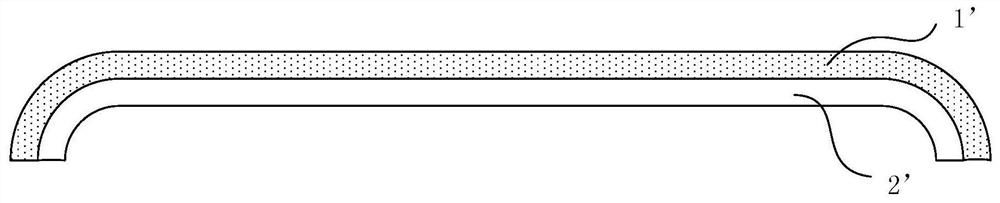

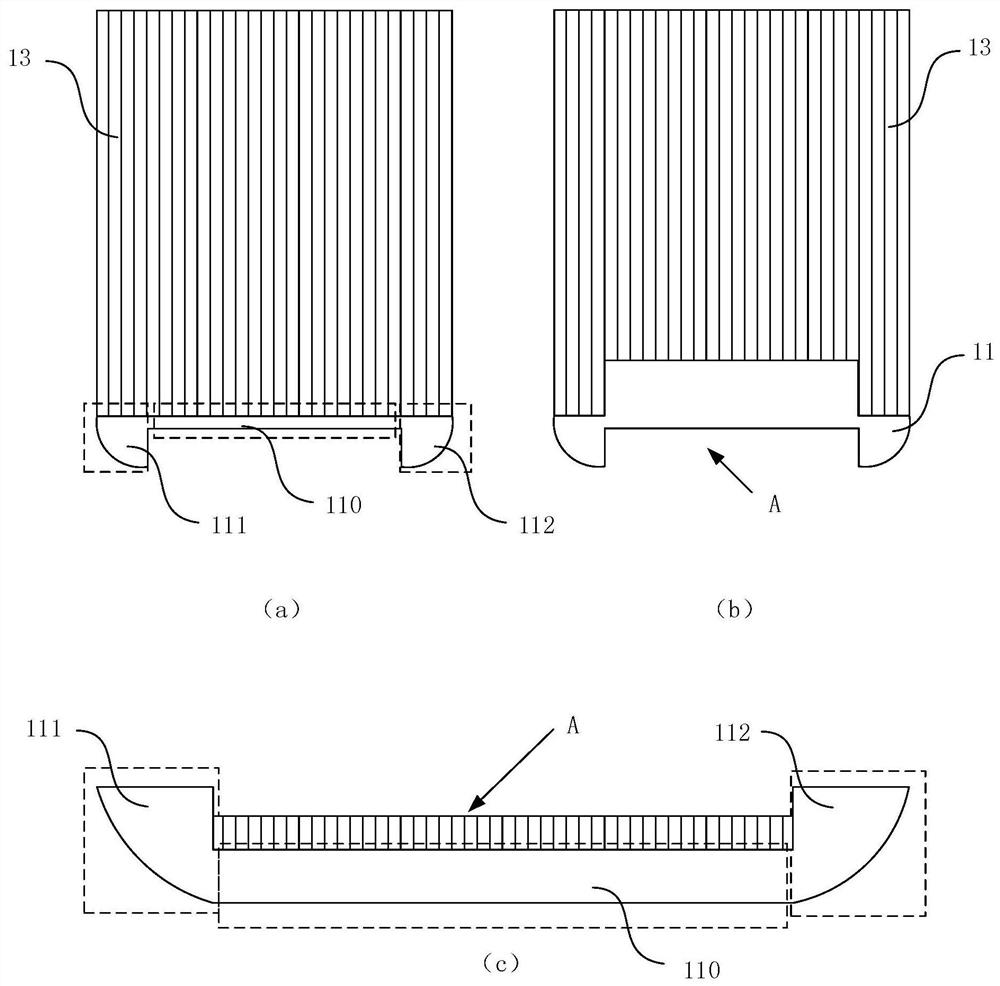

Embroidered material clamping frame system applied to multi-layer embroidery

The invention discloses an embroidered material clamping frame system applied to multi-layer embroidery. The embroidered material clamping frame system comprises an embroidery frame, and further comprises an auxiliary clamping part and a tensioning assembly; an embroidery frame inner side clamping face is arranged on the embroidery frame; a front side embroidered material clamping face and a rearside embroidered material clamping rung are arranged on the auxiliary clamping part, the front side embroidered material clamping face is used for tightly fitting the embroidery frame inner side clamping face to clamp an embroidered material, and the rear side embroidered material clamping rung is used for cooperating with an embroidered material clamp to clamp the embroidered material; the embroidery frame and the cooperating auxiliary clamping part correspond to the tensioning assembly, and the auxiliary clamping part is pulled by the tensioning assembly to the embroidery frame until the auxiliary clamping part is tightly attached and fixed to the embroidery frame. The embroidered material clamping frame system is simple in structure and convenient to use, can well complete single-layeror multi-layer embroidery, is simple and convenient to disassemble and assemble and effortless, lowers the operation difficulty of workers, has good tautness and stationarity, cannot rub and damage the embroidered material, has a good positioning effect, improves the operation efficiency of the workers and the quality of obtained embroidery products, and is extremely worthy of application and promotion in the field.

Owner:浙江镨美科智能刺绣设备有限公司

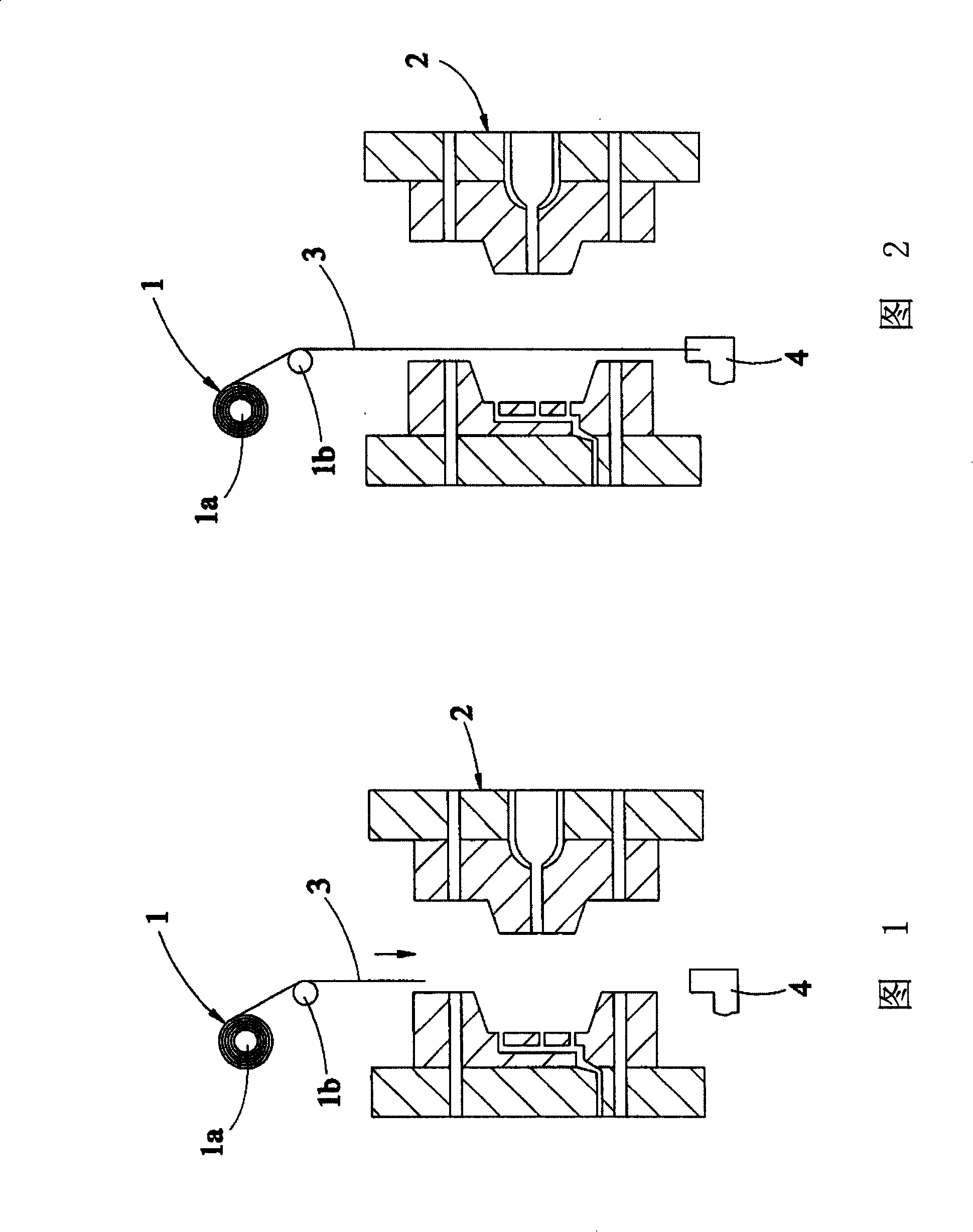

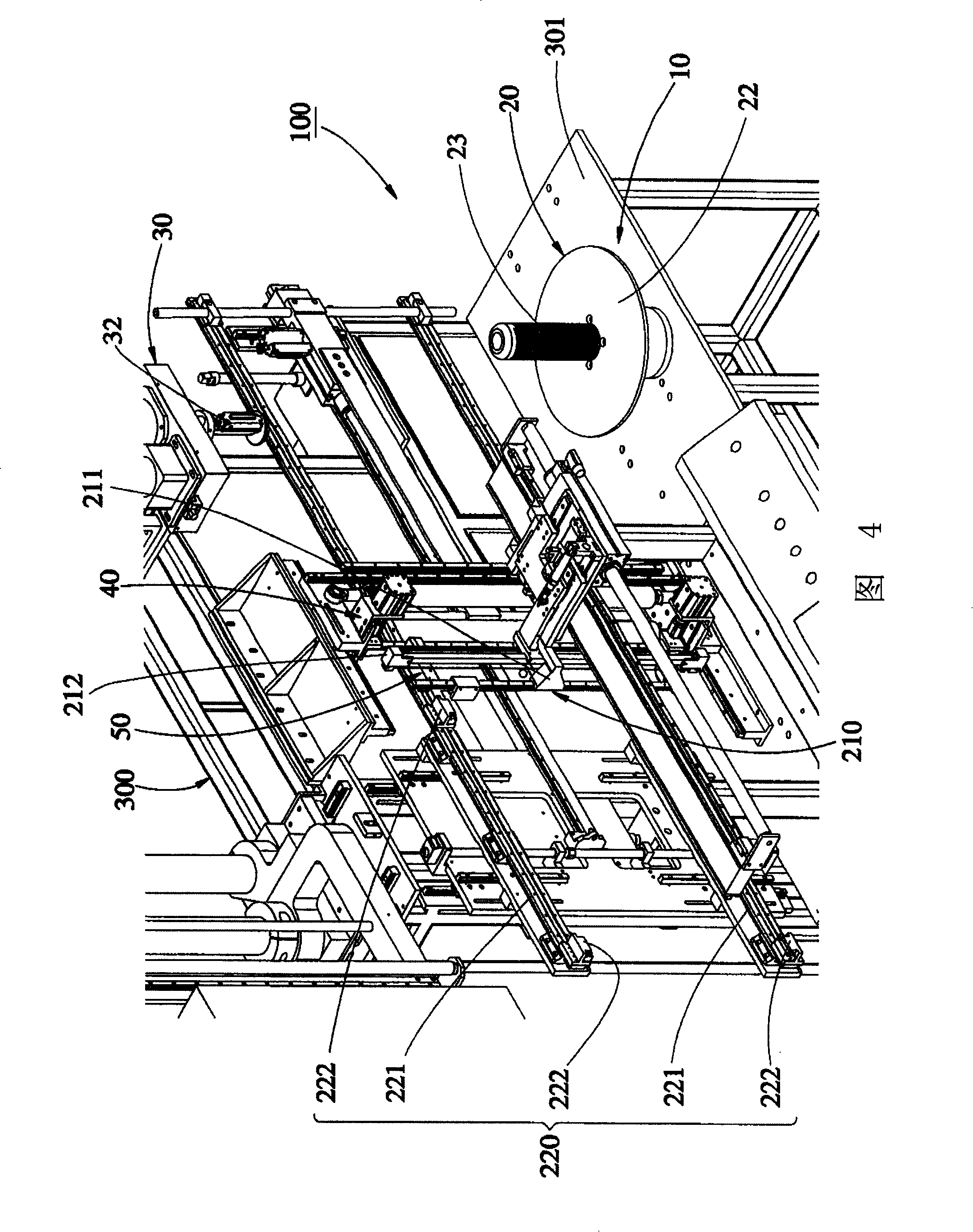

Vertical film lifting mechanism

InactiveCN101219738AWon't pullEasy to replaceArticle deliveryWebs handlingEngineeringMechanical engineering

The invention relates to an upright filming mechanism, which outputs a coiled film in an upright state; the filming mechanism is arranged on a frame which is provided with a platform; the upright filming mechanism comprises a film base group which is arranged on the frame; the film base group has a supporting component, a compressing component and a driving and rotating component; the supporting component supports the coiled film to be arranged vertical to the platform; the compressing component is arranged above the supporting component, and the compressing component can generate radial movement of expansion and contraction; the driving and rotating component is connected with the compressing component so as to drive the compressing component to rotate; the invention also comprises a rotating group which is arranged on the platform and behind the film base group; the rotating group has at least two rotating shafts vertical to the platform; the coiled film is pulled on the film base group and then wound between the rotating shafts. The invention can combine with a film pulling mechanism for inputting upright films parallelly into a die, ensure that the coiled film is not subject to pulling due to direction change, and facilitate each work item of the film (such as replacement of the entire film coil or part film treatment).

Owner:翔渝实业股份有限公司

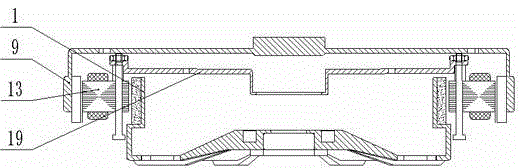

Power device of dual-drive washing machine

ActiveCN105780373AEasy to switchWon't pullOther washing machinesWashing machine with receptaclesImpellerLaundry washing machine

The invention discloses a power device of a dual-drive washing machine.The power device comprises a direct drive motor, the direct drive motor comprises a stator, an inner rotor mounted at the inner side of the stator and an outer rotor mounted at the outer side of the stator, the power device of the dual-drive washing machine further comprises a dehydration shaft fixedly connected with the outer rotor, an impeller shaft connected with the inner rotor and a slide block arranged between the impeller shaft and the inner rotor; the power device is characterized in that the impeller shaft is sleeved with the slide block, one or more pairs of key groove structures are arranged between the slide block and the impeller shaft enable the slide block to slide in the axial direction of the impeller shaft and can drive the impeller shaft to rotate along the axis of the impeller shaft, a protruding block is arranged on the slide block, and a groove in occlusion with the protruding block is formed in the inner rotor.The power device is low in noise, low in energy consumption, simple in structure and capable of achieving switching between washing and spinning-drying easily and conveniently, and clothes are protected from drawing in spinning-drying operation.

Owner:NINGGUO JULONG IND

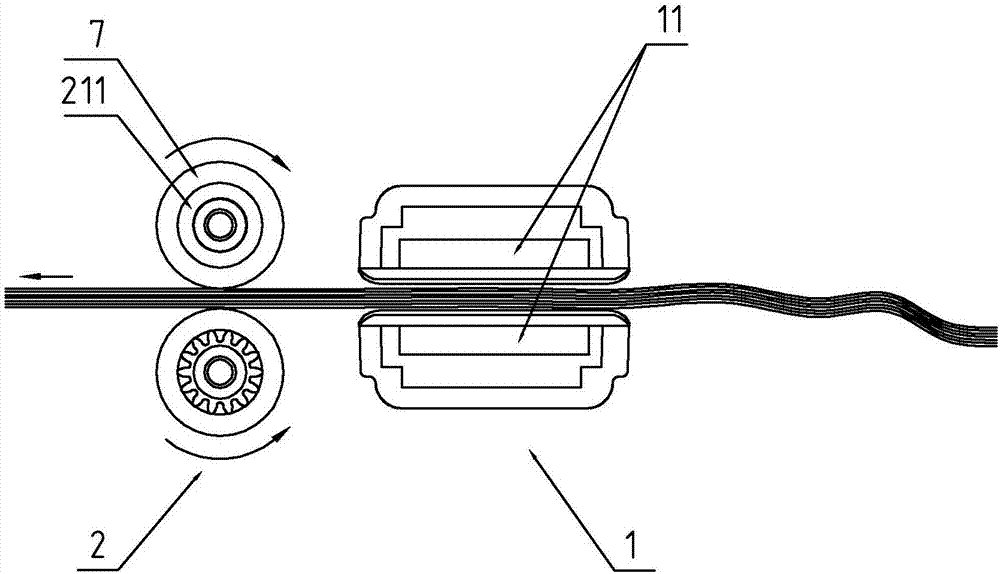

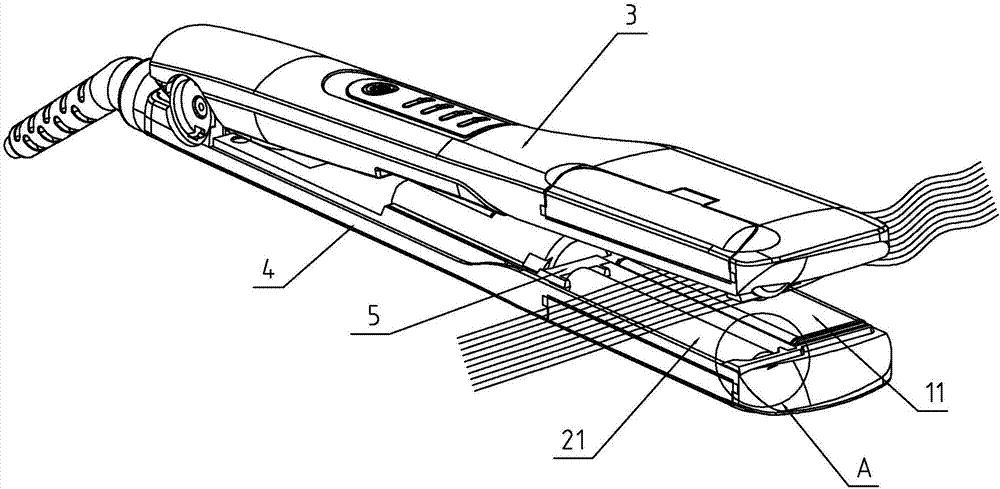

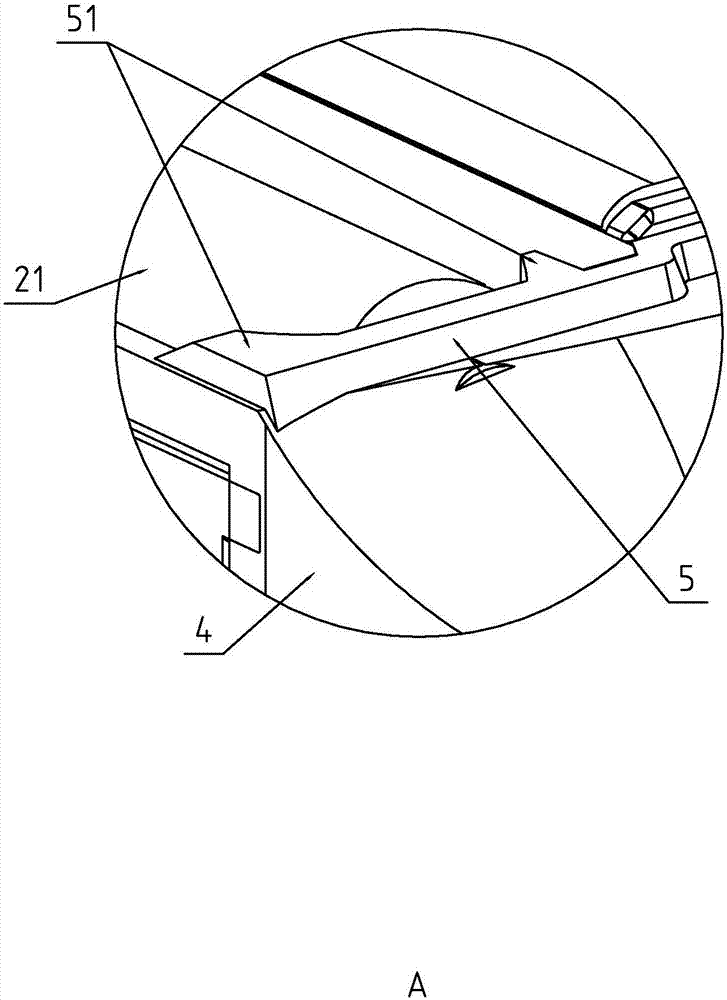

Wave hair styling assembly

The invention discloses a wave hair styling assembly. The wave hair styling assembly is characterized in that the assembly comprises a wave hair mechanism and a power mechanism; the wave hair mechanism comprises two wave hair plates, wherein the end surfaces of the wave hair plates are capable of fitting with each other; the power mechanism comprises two rotating rollers capable of fitting with each other, and the two rotating rollers are parallel to each other while fitting, and at least one rotating roller is provided with an elastic mechanism which generates a flexible clamping force to hairs when the rotating roller is fitted with the other rotating roller; the power mechanism further comprises a motor which drives the two rotating rollers in the fitted state to rotate; when the two rotating rollers rotates in a fitted mode, the hairs held between the two wave hair plates can be pulled towards one side of the rotating roller. The implementation way is labor-saving, and the speed that the motor drives the rotating rollers to pull the hairs is more even to avoid the problems that the wave hair is uneven and wave hair effect is poor; the traction direction of the power mechanism is the direction of from hair tip to hair root, thus there is no pulling force on the hair root, therefore the scalp is not pulled.

Owner:叶伙荣

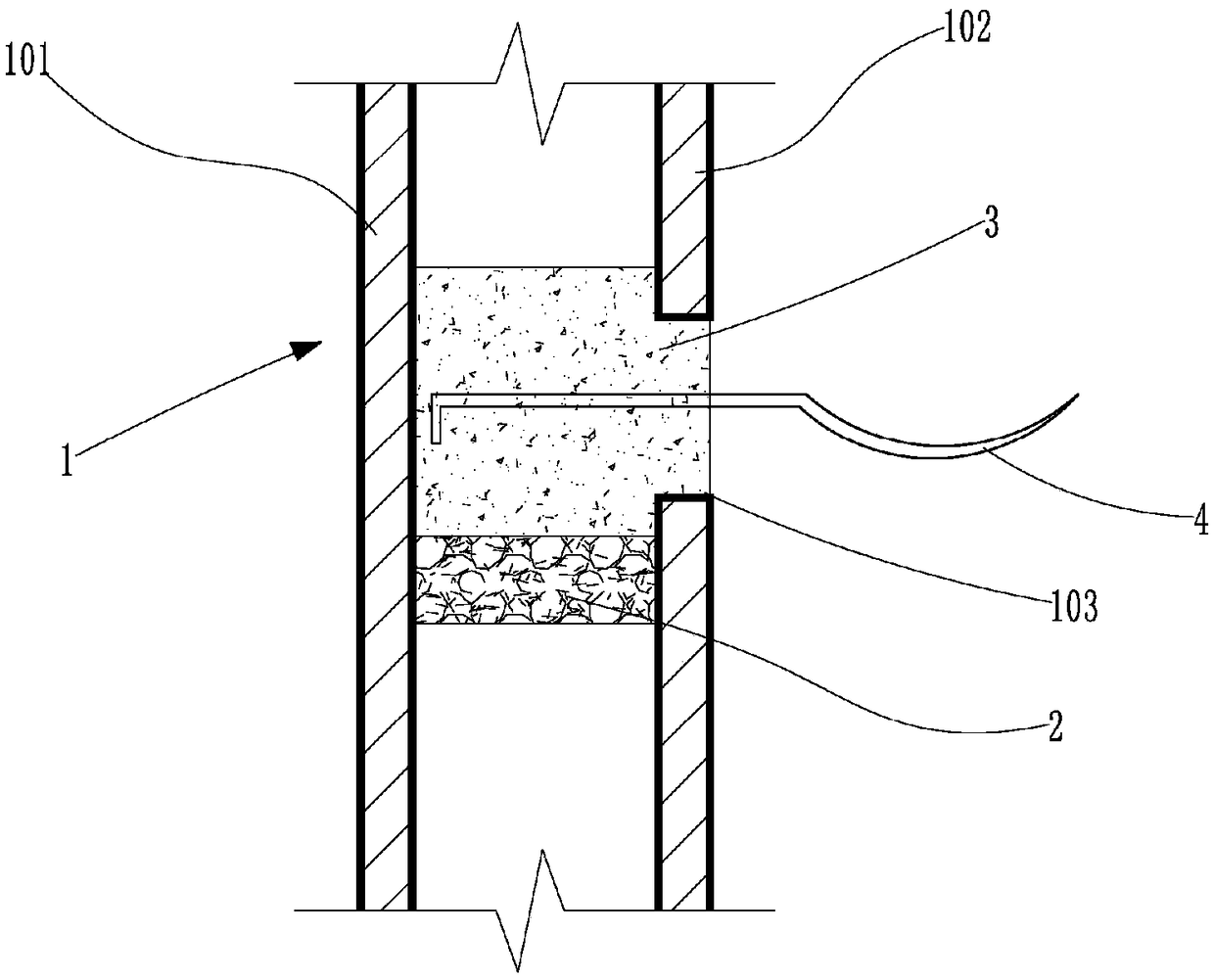

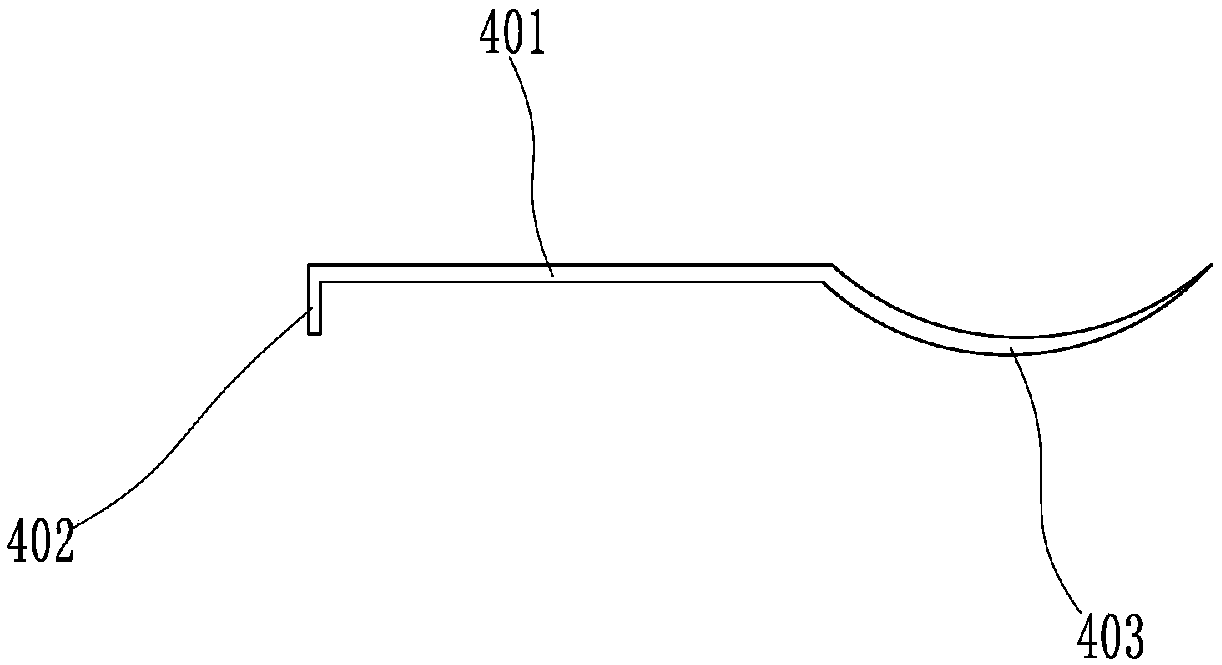

Weight hanging structure of prefabricated inner partition wall board and construction technology thereof

InactiveCN108818879AImprove connection strengthEasy to hangCeramic shaping apparatusBuilding componentsEngineeringUltimate tensile strength

The invention discloses a weight hanging structure of a prefabricated inner partition wall board. The weight hanging structure comprises the prefabricated inner partition wall board, wherein the prefabricated inner partition wall board comprises an external wall board and an internal wall board which are prefabricated and connected integrally. A through hole communicating with the interior is formed in the internal wall board, and a blocking hole core located below the through hole is arranged between the external wall board and the internal wall board in a clamped mode, wherein a concrete block covering the through hole is arranged on the blocking hole core, and a hanging hook penetrating through the through hole is arranged in the concrete block in an embedded mode. The hanging hook comprises a connecting rod, wherein a limiting rod which is perpendicular to the connecting rod is fixedly connected to the end, extending into the concrete block, of the connecting rod, a hook rod of anarc-shaped structure is fixedly connected to the end, extending out of the through hole, of the connecting rod, and the center of a circle of the hook rod is located above the connecting rod. The cross-sectional area of the hook rod gradually decreases from one end of the connecting rod to the tail end of the hook rod, and the hanging structure is improved to enable the prefabricated inner partition wall board to have the intensity, stability and safety of hanging weights.

Owner:四川时宇建设工程有限公司

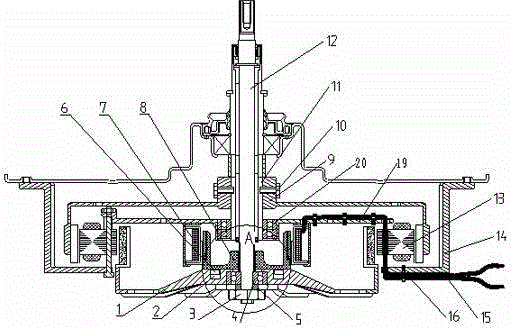

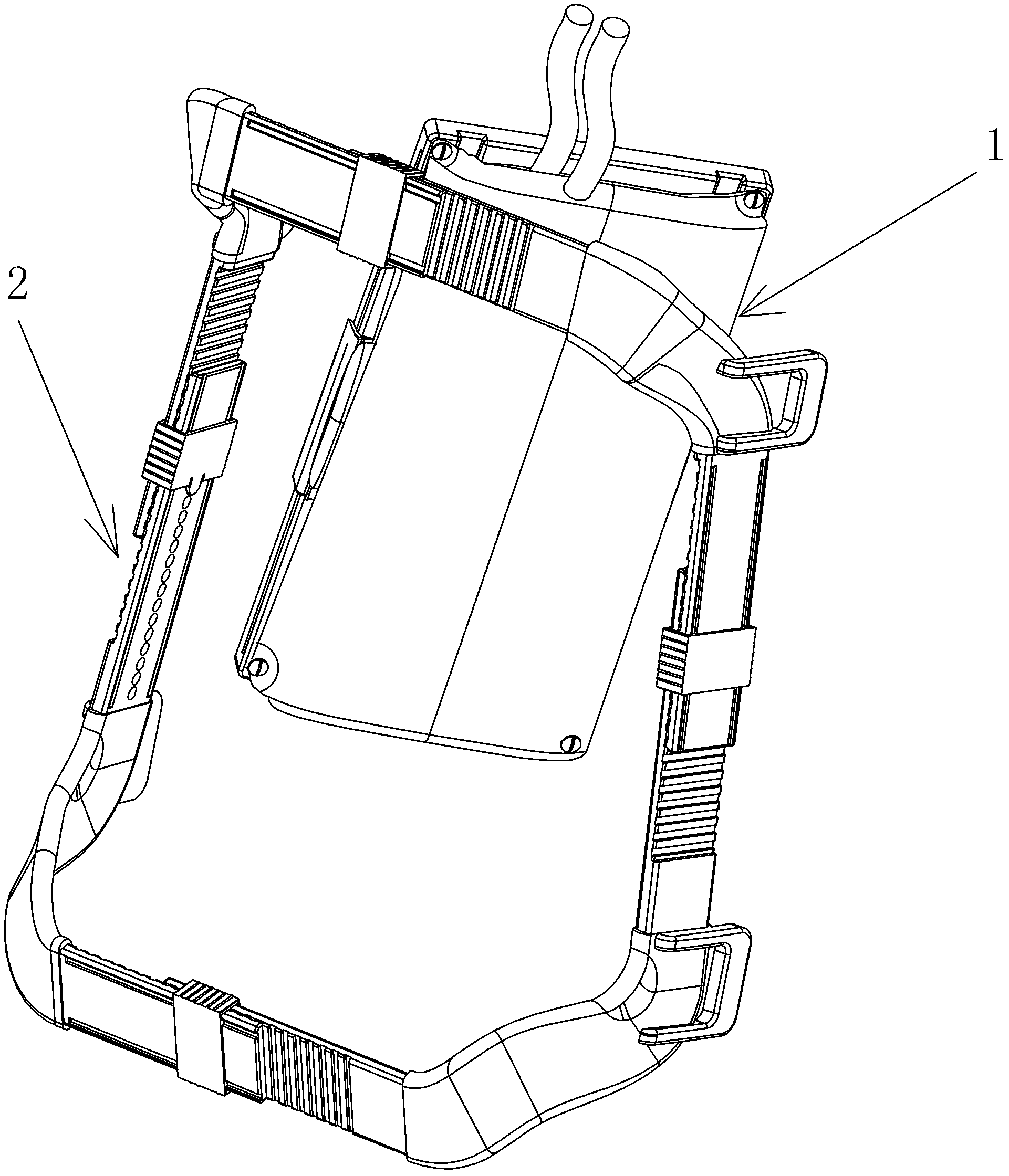

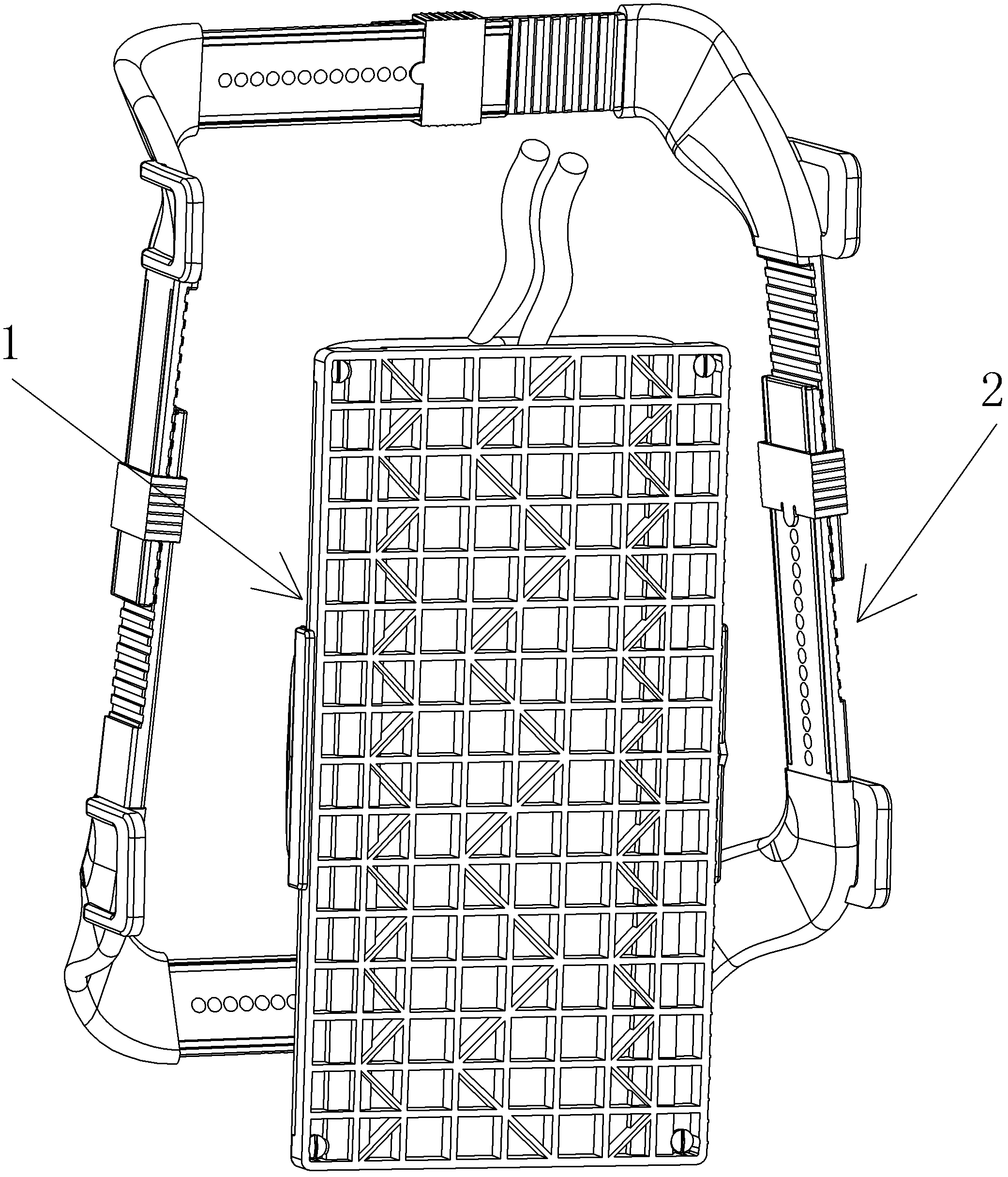

Thoracolumbar fracture reduction orthopaedic outer fixer for effectively fixing thoracolumbar bone

ActiveCN102247234AImprove the reset success rateRestore physiological heightFractureThoracolumbar spineHuman body

The invention discloses a thoracolumbar fracture reduction orthopaedic outer fixer for effectively fixing thoracolumbar bone, comprising an orthopaedic airbag and an orthopaedic outer fixing brace connected with the orthopaedic airbag through a connecting member, wherein the orthopaedic airbag comprises a support plate; a moving plate is slidably arranged on the support plate; an outer airbag is arranged on the support plate; an inner airbag capable of supporting against the outer airbag and adjusting the height of the outer airbag is arranged on the moving plate; and respective ventilation pipes are correspondingly arranged on the outer airbag and the inner airbag. The orthopaedic outer fixing brace comprises waistline support plates at the left side and the right side; upper chest circumference fixing plates matched with the oxter and the colpus of human body in shape are arranged at the upper ends of the two waistline support plates; and lower crista iliaca fixing plates matched with crista iliaca of human body in shape are arranged at the lower ends of the two waistline support plates. The two waistline support plates, the upper chest circumference fixing plates and the lower crista iliaca fixing plates encircle to form a frame-shaped body capable of framing the part from the chest below oxter of human body to the abdomen of the crista iliaca part.

Owner:中山市智达合众医疗器械有限公司

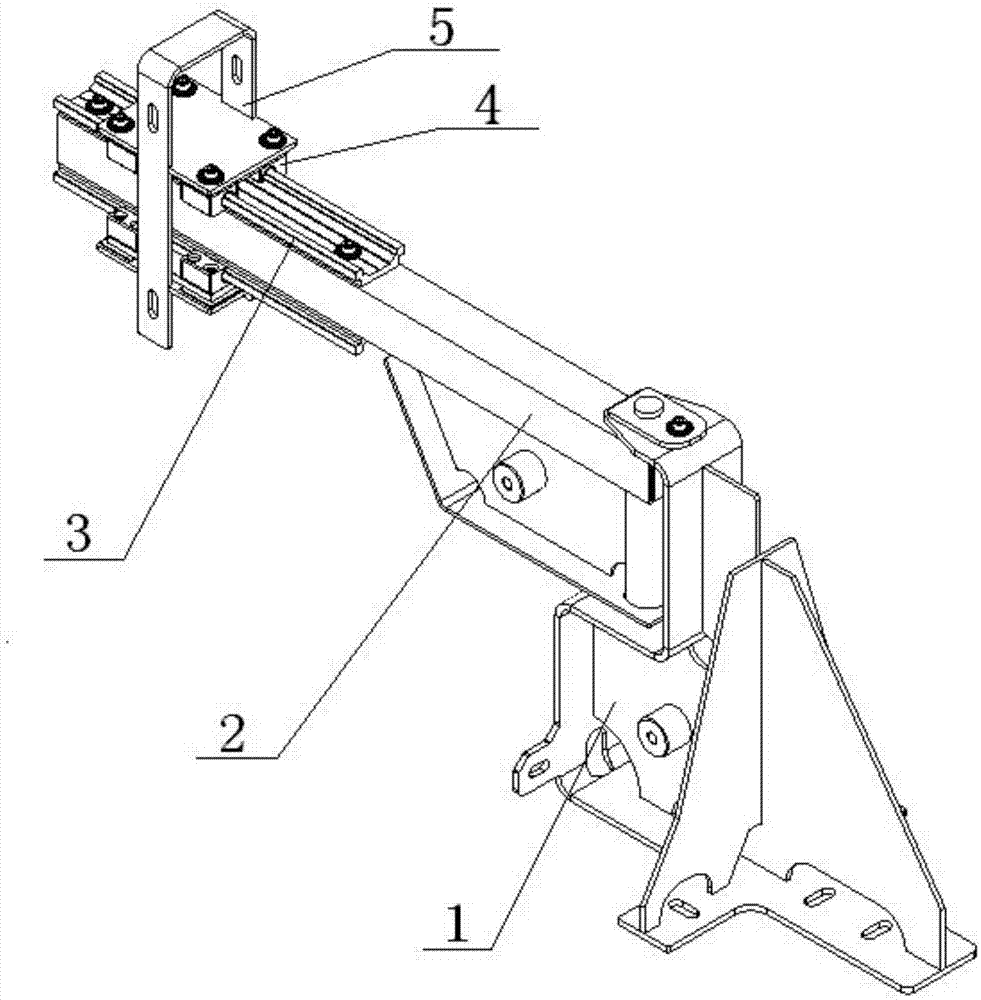

Passive sliding-swinging cable passing bridge device

InactiveCN107196251APrevent pulling or pulling the plug looseSwing freeElectrical apparatusEngineeringMechanical engineering

The invention discloses a passive sliding-swinging cable passing bridge device. The cable passing bridge device comprises a base, a swing arm, a guide rail, a slide block and a cable bracket, wherein the base is used for fixing the cable passing bridge device on a carriage; the swing arm is arranged on the base, and can swing freely relative to the base; the guide rail is arranged on the swing arm; the slide block is arranged on the guide rail, and connected with the guide rail in a matching way; and the cable bracket is used for supporting and fixing a cable, is connected integrally with the slide block, and can slide freely along the guide rail along with the slide block. The sliding and swinging of the passive sliding-swinging cable passing bridge device provided by the invention are passive sliding and swinging due to cable deformation, so that the passive sliding-swinging cable passing bridge device can adapt to the change of the cable without dragging the cable. Moreover, a motion combination of sliding and swinging perfectly adapts to optional linear or nonlinear change of the cable in a fan-shaped working region, thereby preventing damage to the cable or loosening of a plug caused by dragging.

Owner:CHENGDU XINZHU ROAD & BRIDGE MASCH CO LTD

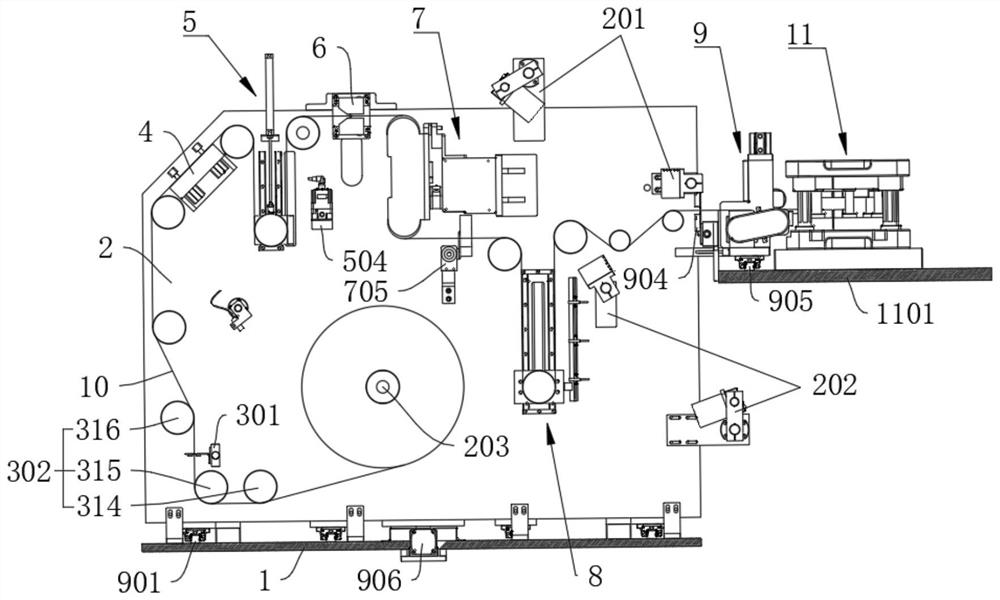

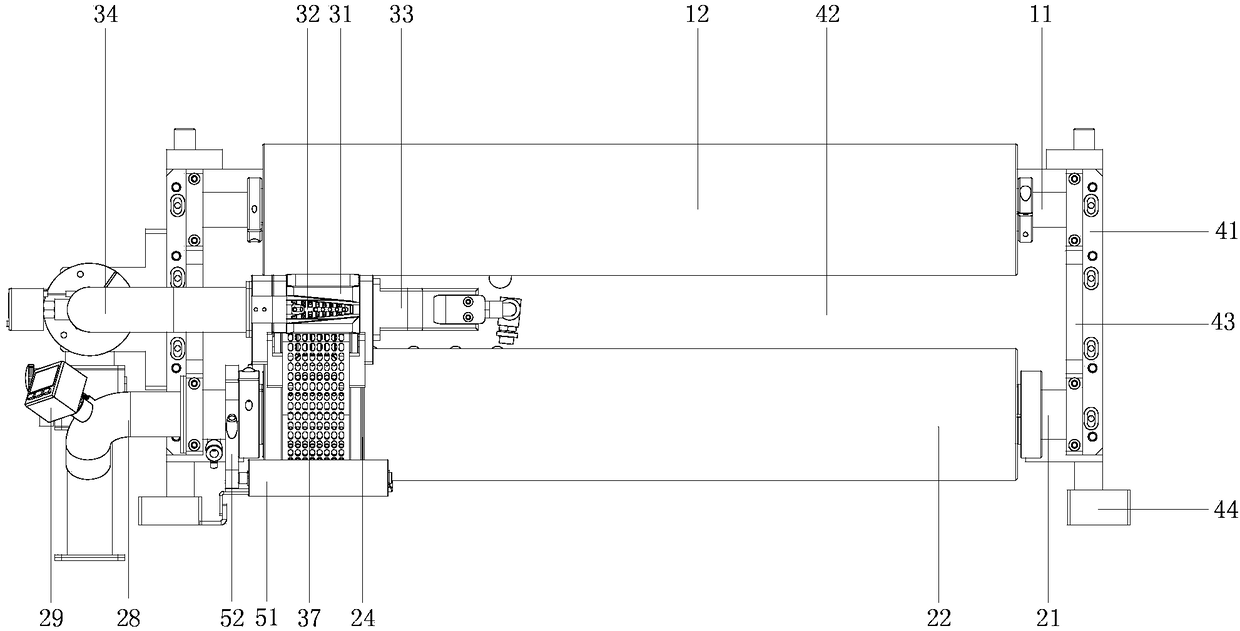

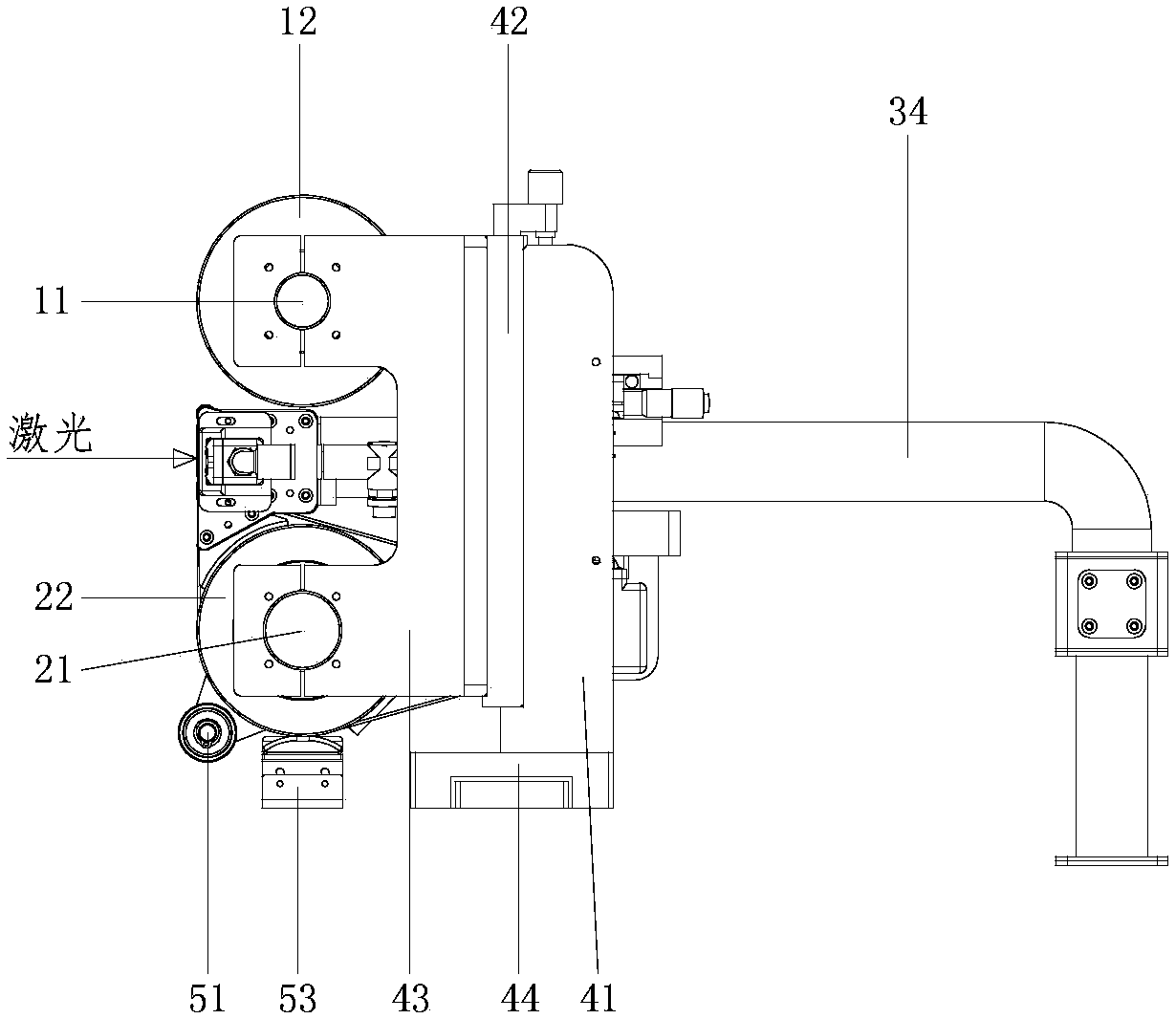

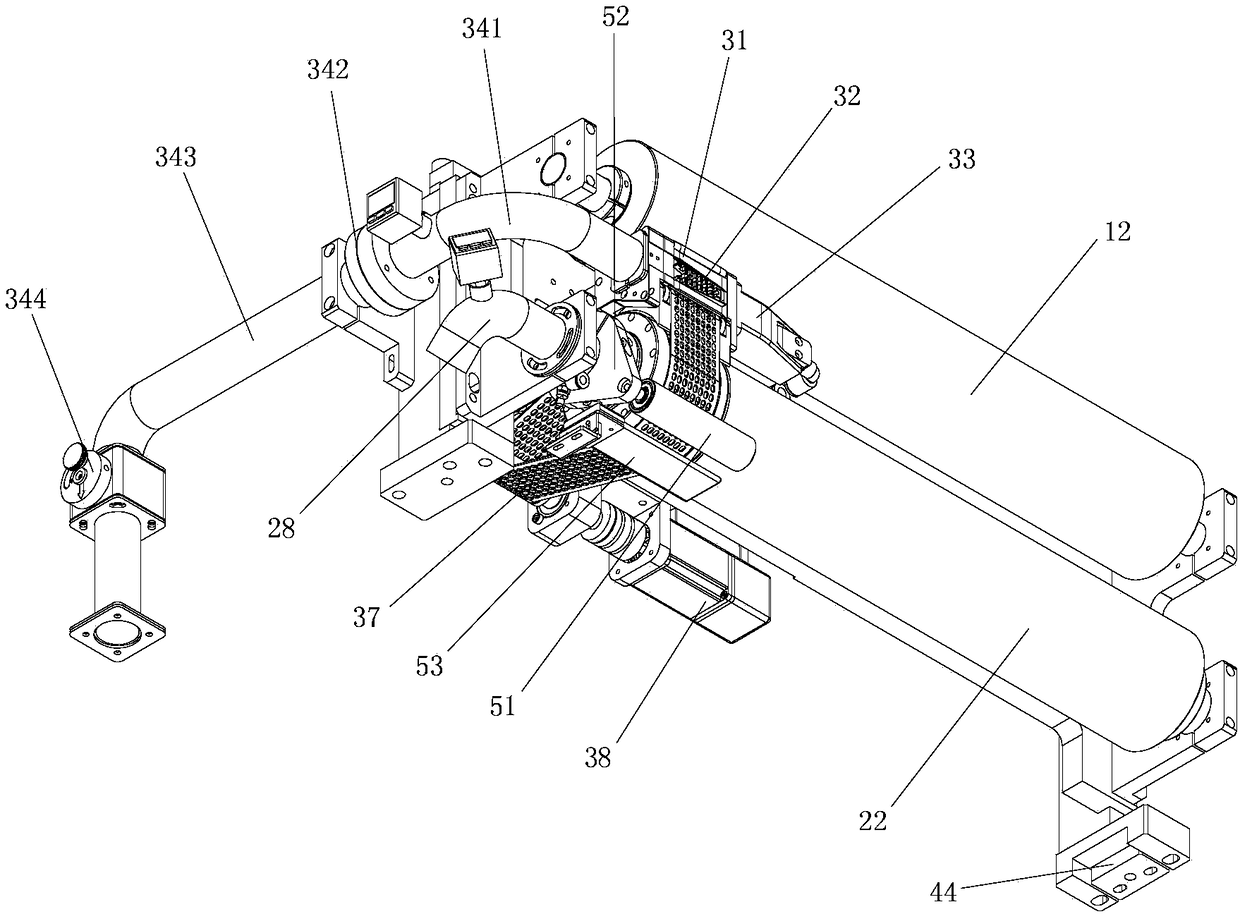

Laser trimming tab device

PendingCN108393597AMeet cutting quality requirementsKeep it flatWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a laser trimming tab device. The laser trimming tab device comprises a bracket assembly, an upper roller assembly, a separation roller assembly and a cutting assembly, whereinthe upper roller assembly and the separation roller assembly are arranged on the bracket assembly in parallel up and down. The separation roller assembly is provided with two separate independent-moving rollers, namely, a non-vacuum separation roller and a vacuum separation roller which are rotatably installed with a second central shaft correspondingly. The cutting assembly is located between theupper roller assembly and the vacuum separation roller. The laser trimming tab device provides support, waste derivation and cutting dust treatment for tab cutting, the flat state of tab cutting areaof a battery plate electrode is kept, the vibration of the tab cutting area is avoided, and the quality requirement of tab cutting is required.

Owner:SHENZHEN HYMSON LASER INTELLIGENT EQUIP CO LTD

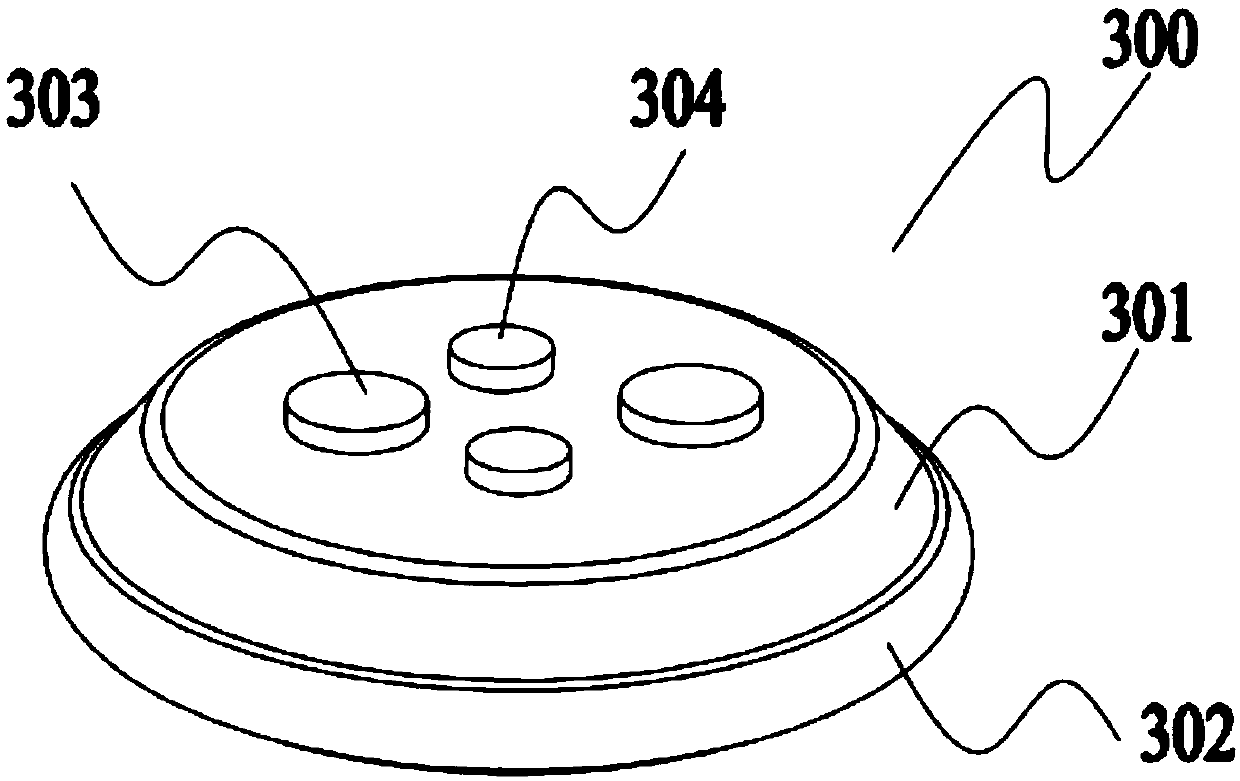

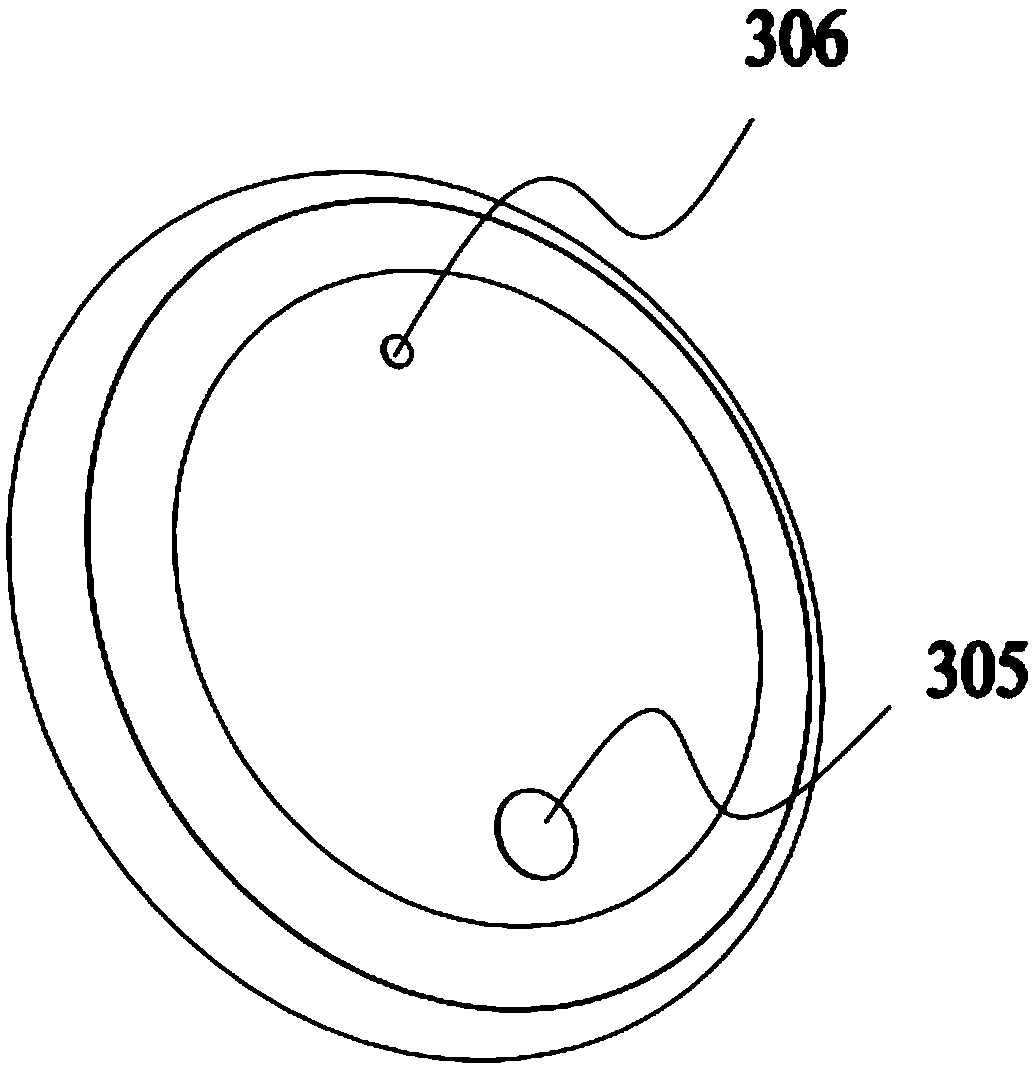

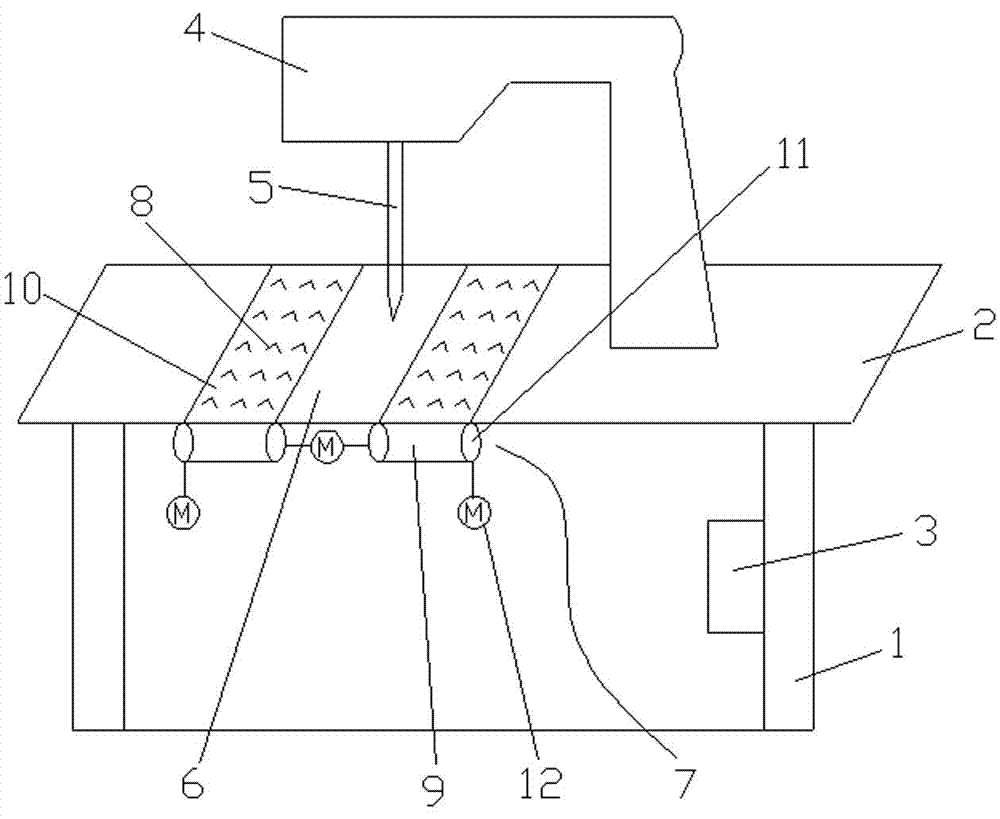

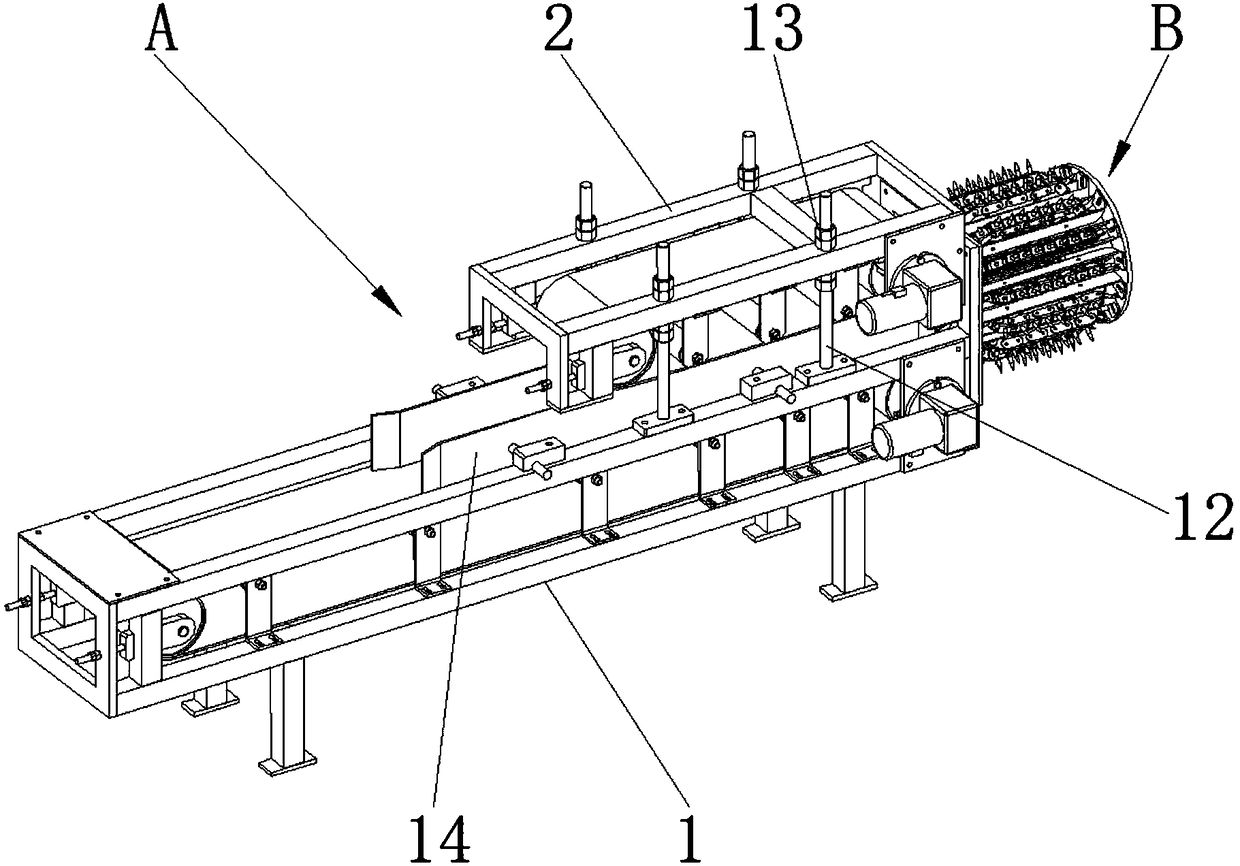

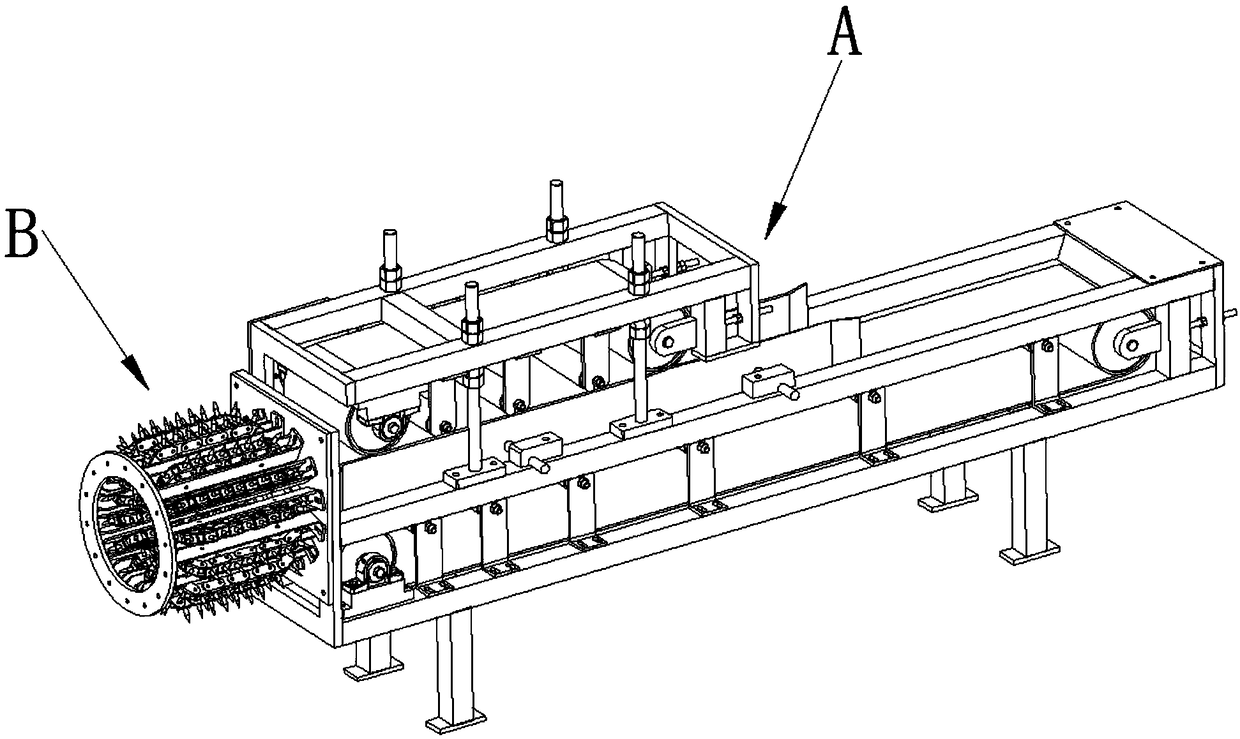

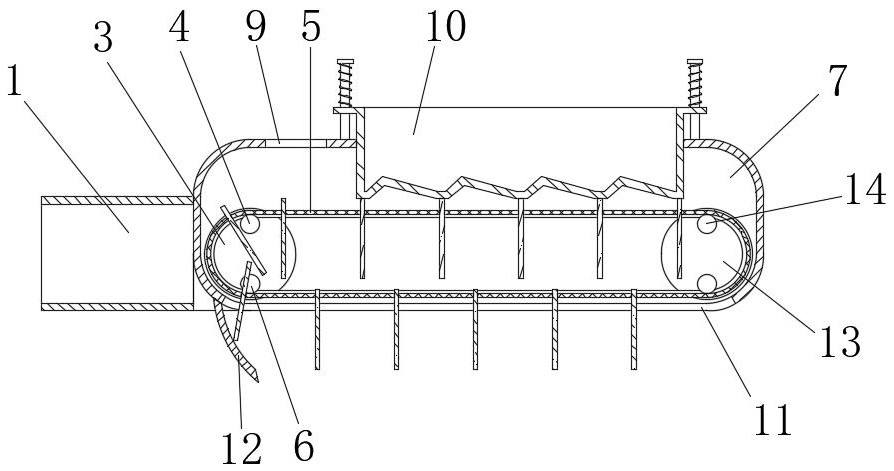

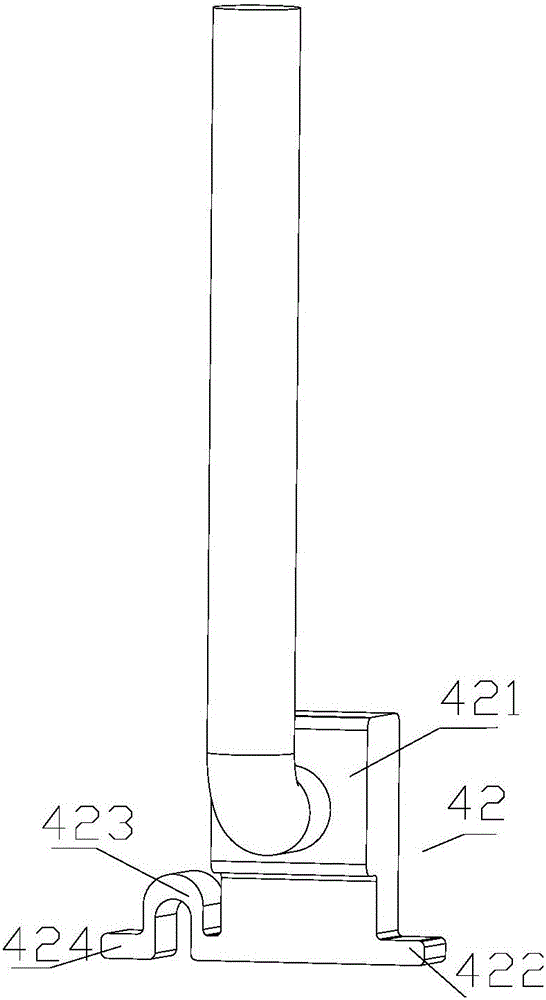

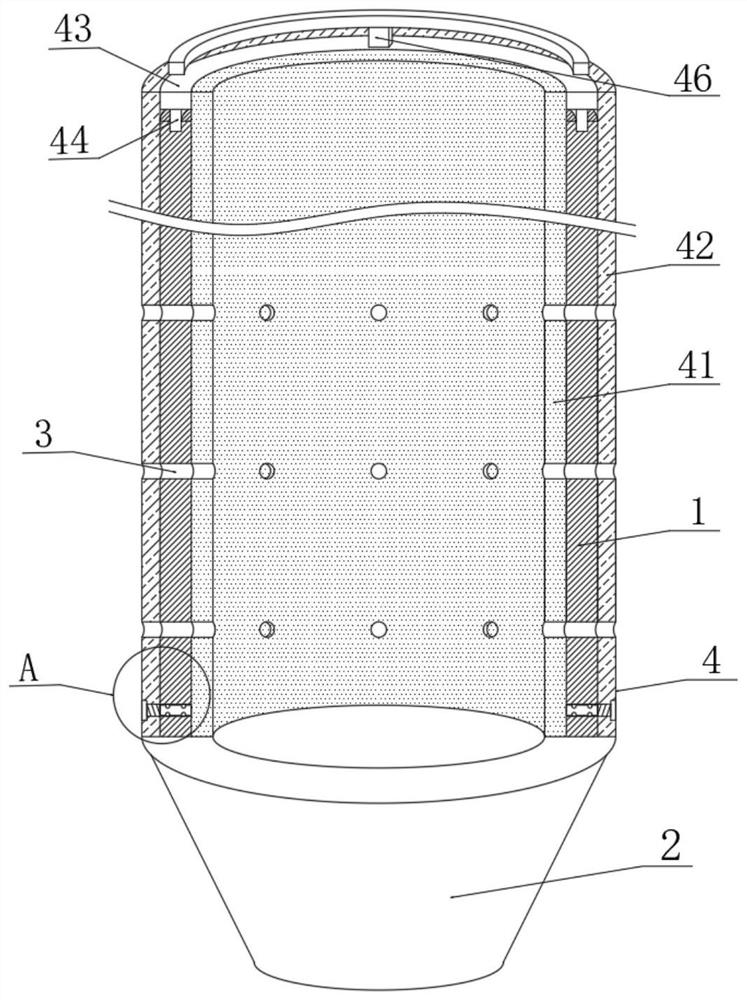

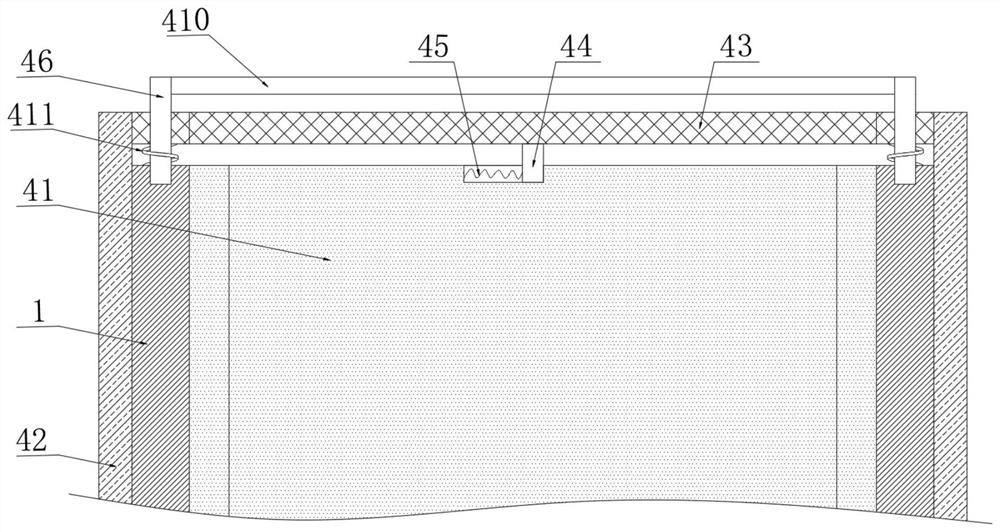

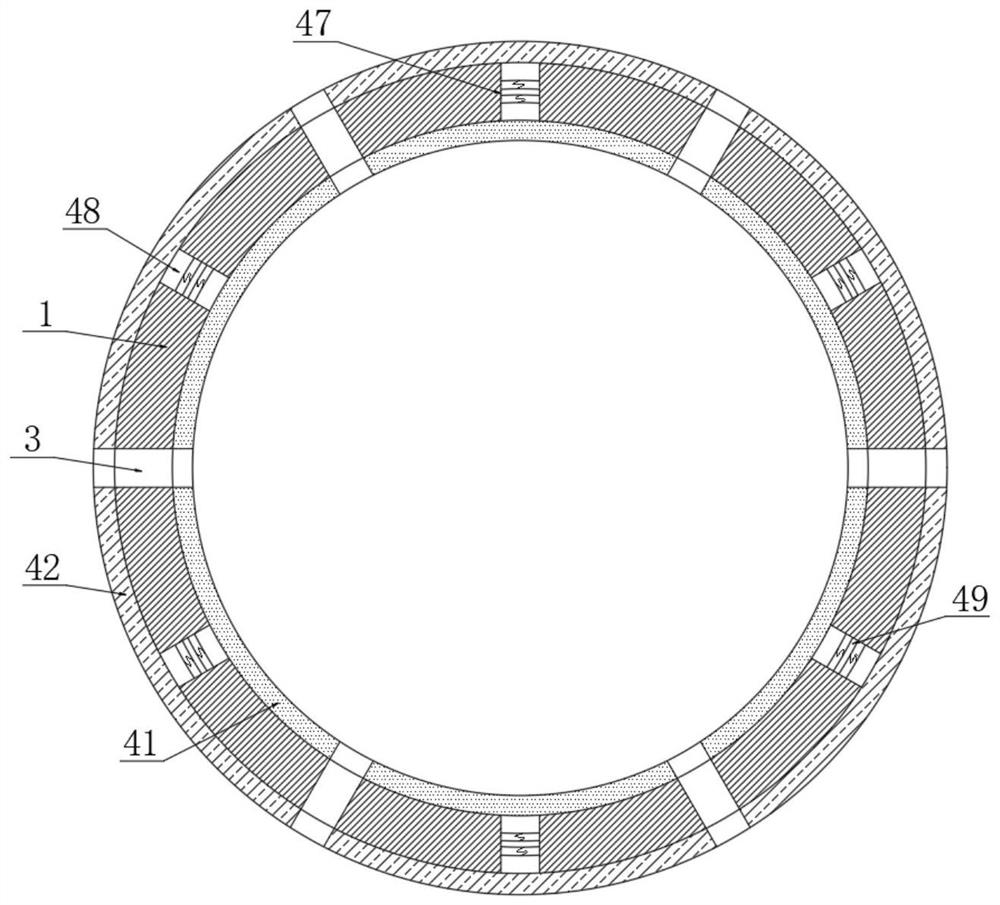

Fungus cultivating bag punching device

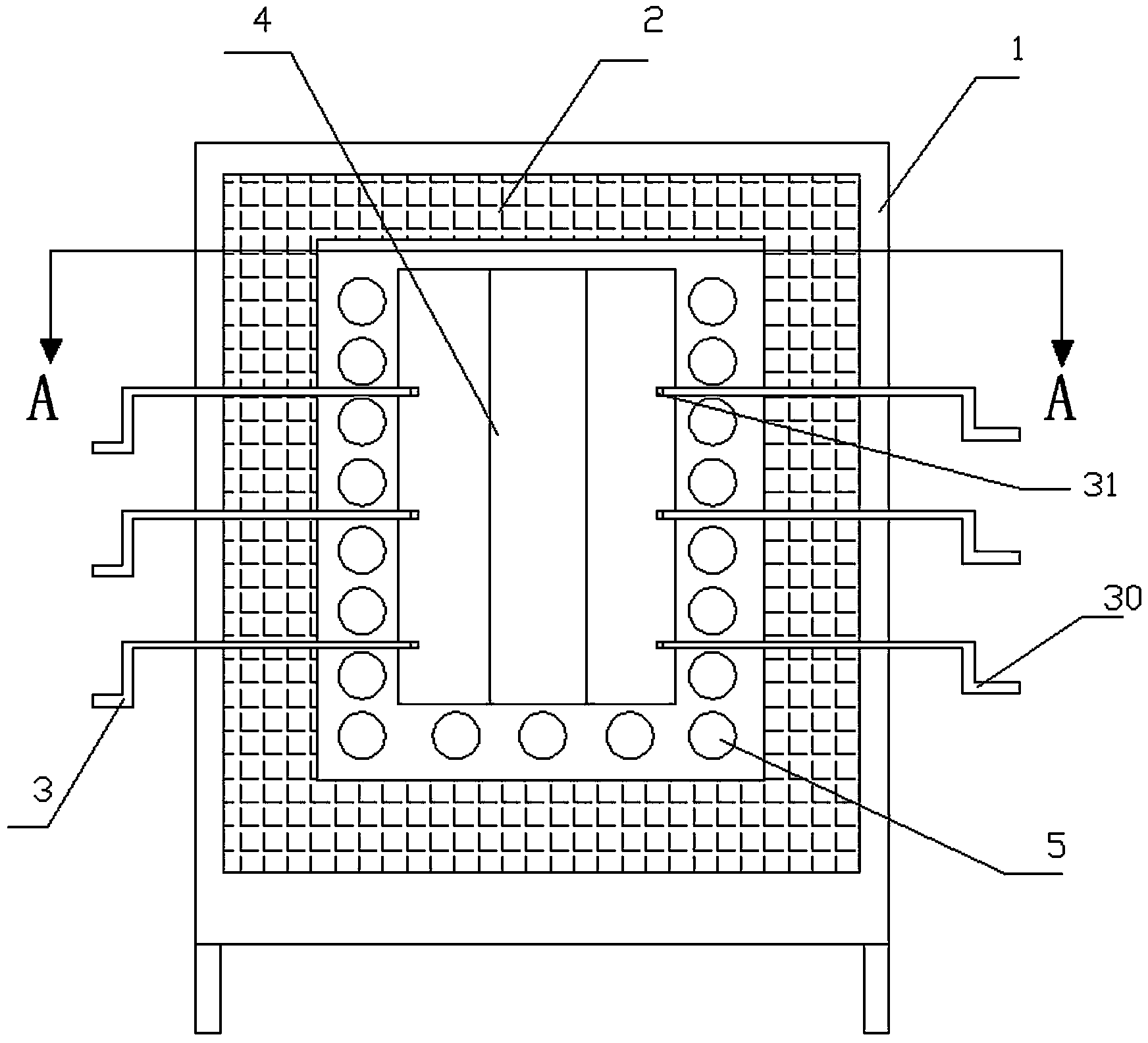

PendingCN108432558AEvenly punchedThe treatment effect is stableCultivating equipmentsMushroom cultivationMushroomTreatment effect

The invention provides a fungus cultivating bag punching device. The fungus cultivating bag punching device comprises a connecting plate 3 of which the middle is provided with a round hole structure,and several punching units 4 which are distributed around the circumference of the round hole structure are arranged on the connecting plate 4; the circumferential distribution center of the punchingunits 4 is coaxial to the axis of the round hole structure of the connecting plate 3; each punching unit 4 comprises a mounting support 5, guide wheels 6 which are movably connected with each mountingsupport are arranged at the two ends of each mounting support respectively, an annular connecting belt 7 is arranged to be connected with the corresponding guide wheels 6, and several conical barns 8perpendicular to the annular connecting belts 7 are arranged at the outer sides of the annular connecting belts 7. The fungus cultivating bag punching device is used for punching the peripheries of cultivating bags after inoculation of cultures like auricularia fuscosuccinea or some mushrooms, punching is uniform, the treatment effect is stable, and the bag bodies cannot be torn expect for punching. After the fungus cultivating bag punching device is properly applied, the labor intensity can be low, the high-quality processing effect and high-efficiency production efficiency are obtained, andthus the economic benefit of enterprises is increased.

Owner:贵州大秦农业科技有限公司

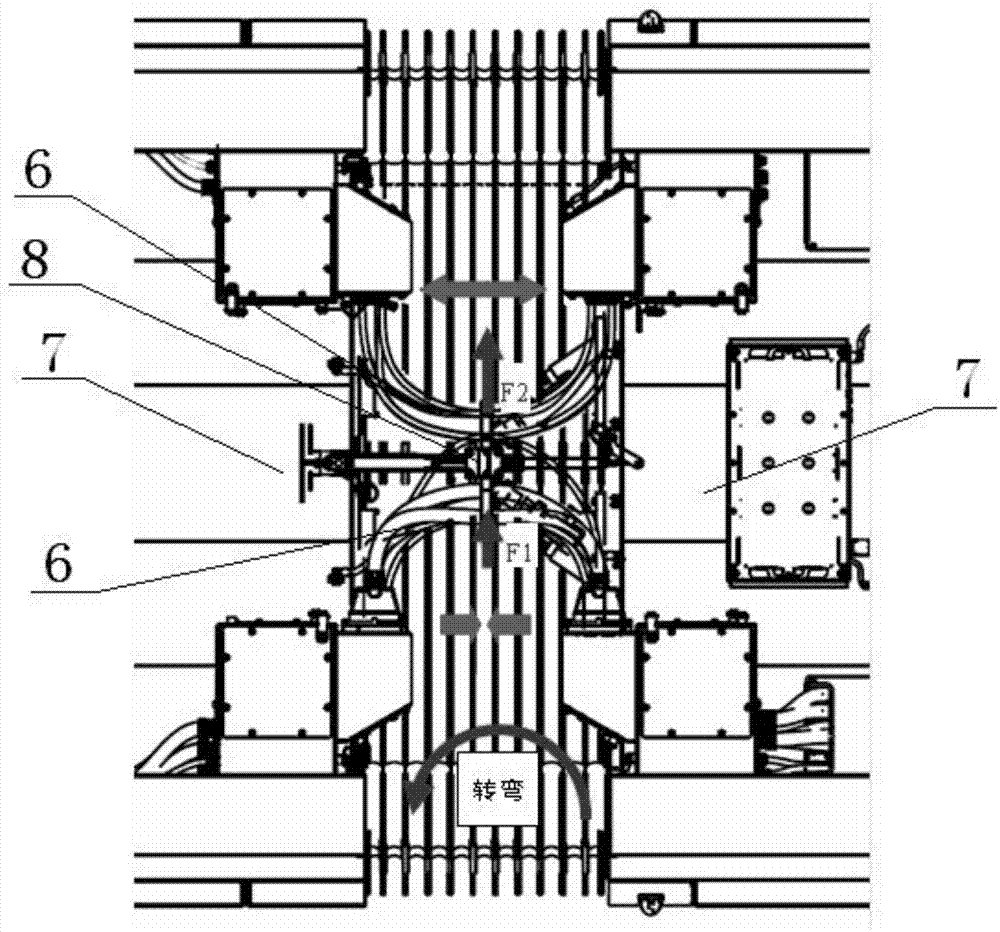

Guide device capable of implementing spatial dislocation conveying and non-woven fabric forming machining mechanism

ActiveCN112758746AImprove operational collaboration efficiencySmall footprintArticle deliveryWebs handlingEngineeringHeight difference

The invention discloses a guide device capable of implementing spatial dislocation conveying. In the process that a driving device drives adjacent guide devices to generate a height difference, a pressing roller can be linked to move downwards to press on a sub-material strip, and the pressing roller can be linked to move upwards in sequence; after the pressing roller is lifted, different sub-material strips slit by a slitting knife can sequentially pass through a gap between the pressing roller and a slitting platform and different guide devices; when the driving device drives guide rollers in the adjacent guide devices to be mutually horizontal, the guide rollers in the adjacent guide devices are in end-to-end contact to form an integral guide roller structure; and materials can sequentially pass through the gap between the pressing roller and the slitting platform and the integral guide roller structure. The invention further discloses a non-woven fabric forming machining mechanism. The device has the advantages that different post-treatments are carried out on the same blank in the same machining production line to improve the device integration and the process collaboration.

Owner:福建宇邦纺织科技有限公司

Adhesive adhering structure and adhesive adhering method for hollowed-out goldfinger of flexible circuit board

ActiveCN102595777AConvenient stickersWon't pullPrinted circuit manufactureElectrical connection printed elementsFlexible circuitsAdhesive

The invention discloses an adhesive adhering structure and an adhesive adhering method for a hollowed-out goldfinger of a flexible circuit board. Hollowed-out areas are formed among all terminal in a goldfinger area, and a cushion layer covers on the entire goldfinger area; and an adhesive layer covers the goldfinger area by being spaced by the cushion layer and is adhered onto the flexible circuit board or a part on which the adhesive layer can be adhered. According to the adhesive adhering structure and the adhesive adhering method for the hollowed-out goldfinger of the flexible circuit board, disclosed by the invention, adhesive adhering and adhesive stripping are more convenient and quicker and are free from the limitation from adhesiveness, the goldfinger cannot be pulled through stripping when the adhesiveness is high, a chemical liquid cannot permeate to influence an adherence part when the adhesiveness is low, and thus, the goldfinger is protected effectively.

Owner:KUSN YIFUDA ELECTRONICS

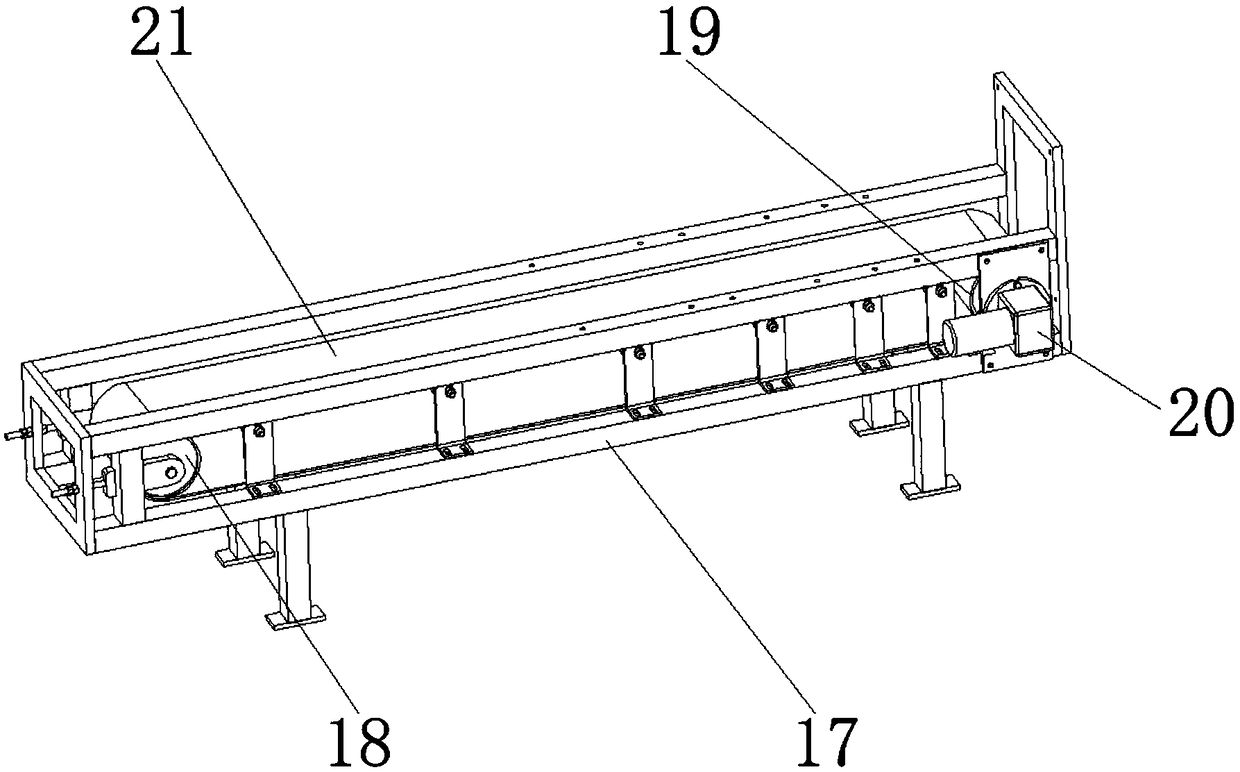

Angle-adjustable large-inclination-angle belt type totally-closed sample conveyor

ActiveCN113602765AWon't pullPrevent fallingConveyorsControl devices for conveyorsEngineeringTransportation technology

The invention relates to the technical field of belt type transportation, and discloses an angle-adjustable large-inclination-angle belt type totally-closed sample conveyor. The angle-adjustable large-inclination-angle belt type totally-closed sample conveyor comprises a driving machine, wherein a driving support is fixedly mounted on one side of the driving machine; a housing structure is movably connected to the outer surface of a fixed disc in a sleeving manner, and the driving machine can drive the housing structure to rotate; in the rotating process of the housing structure, the fixed disc is kept in a static state, and a rotating disc is connected with the housing structure in a movable sleeving manner, so that the plane where the axis of a guide wheel II is located is parallel to the plane where the axis of a guide wheel I is located and the plane where the axis of a power machine output shaft is located; and at the moment, the distance between the upper surface M and the lower surface N of a conveying belt is reduced, so that the rising length of an adjustable partition plate located at the M position is increased, the rising length of the adjustable partition plate used for separation in the process that the inclination angle of the device is increased is also increased, the problem that a sample rolls off under the action of a large inclination angle of the device is solved, and the limiting capacity of the device to the position of the sample is improved.

Owner:江苏德博利恩工业科技有限公司

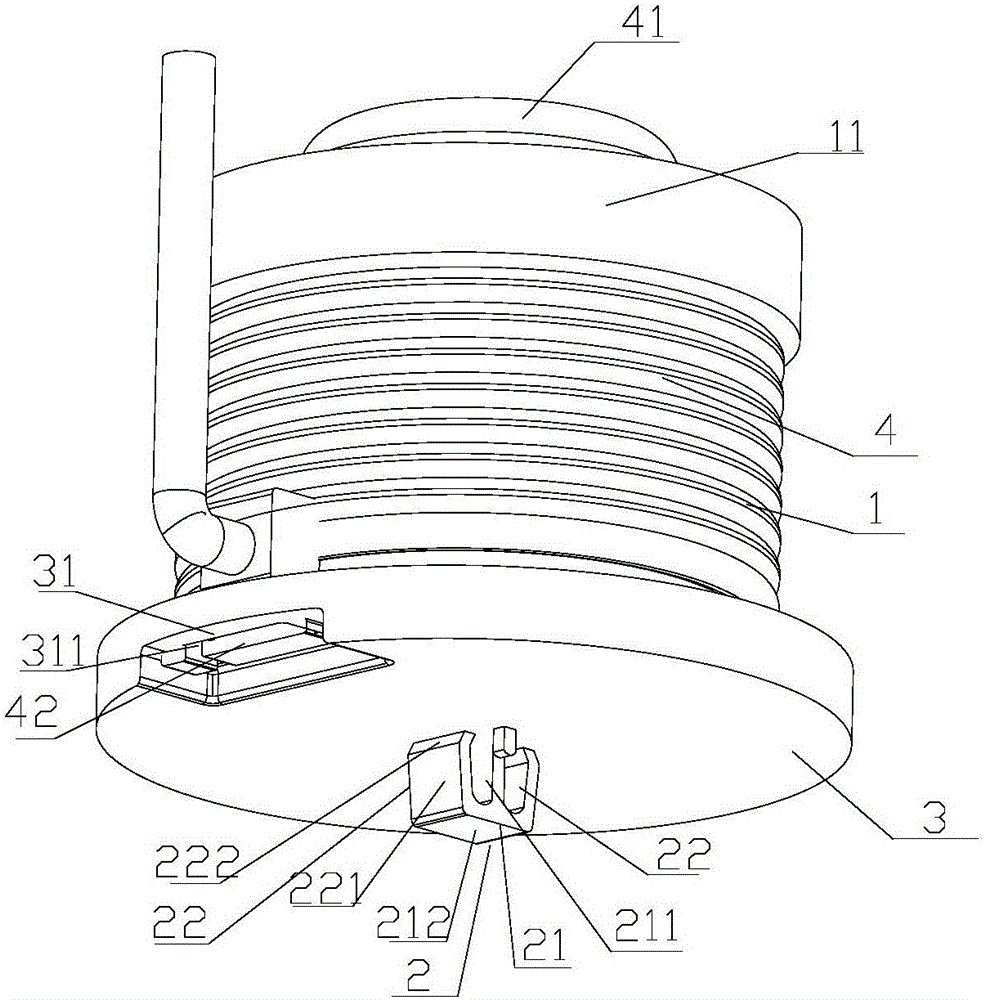

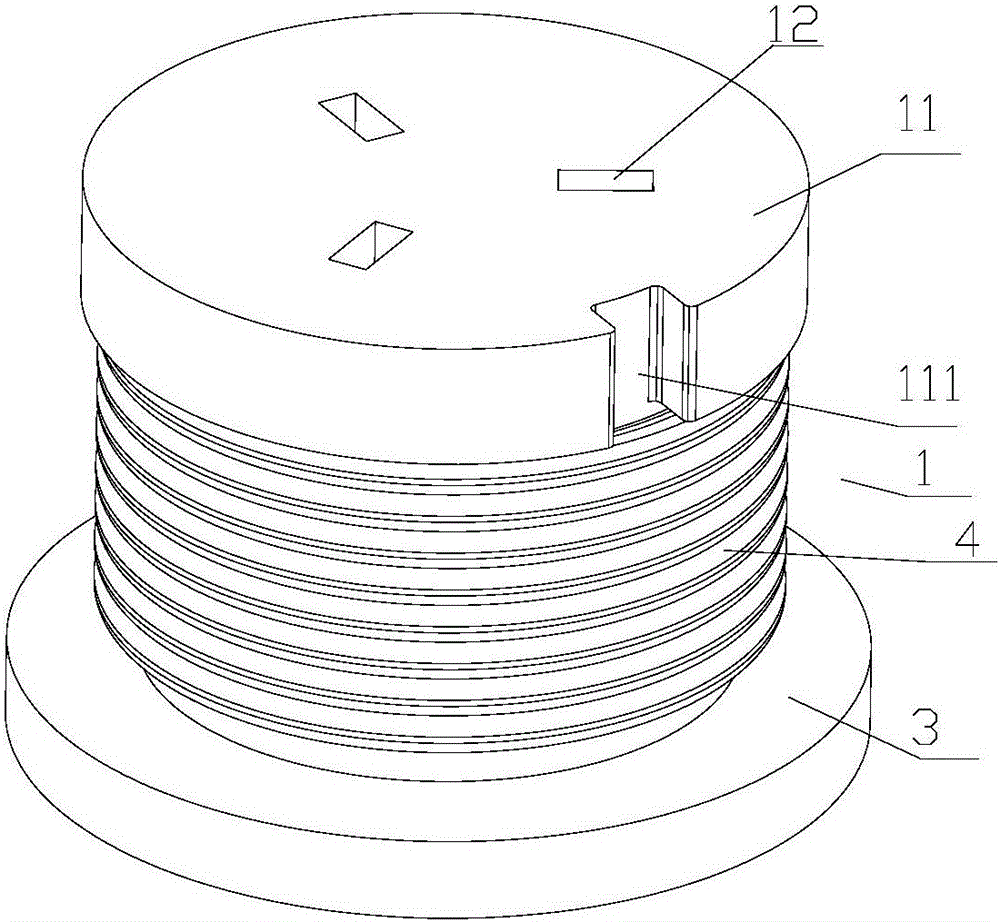

Power source line accommodating device and electric appliance

ActiveCN105826771ASmall footprintAvoid drops and abrasionsFlexible lead accommodationCable harnessElectrical equipment

Owner:宿松九点科技有限公司

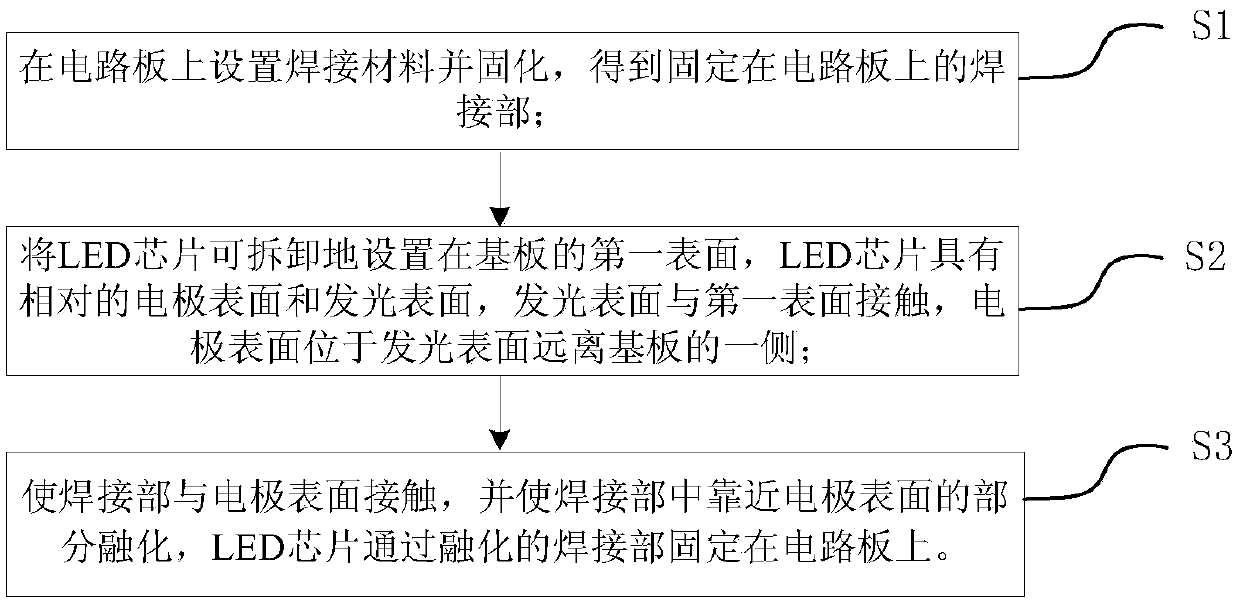

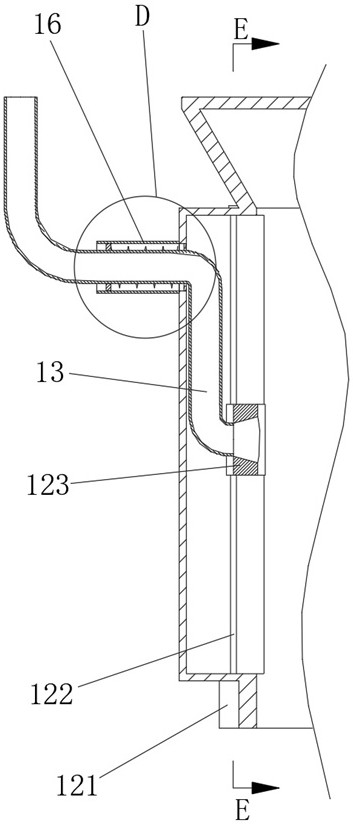

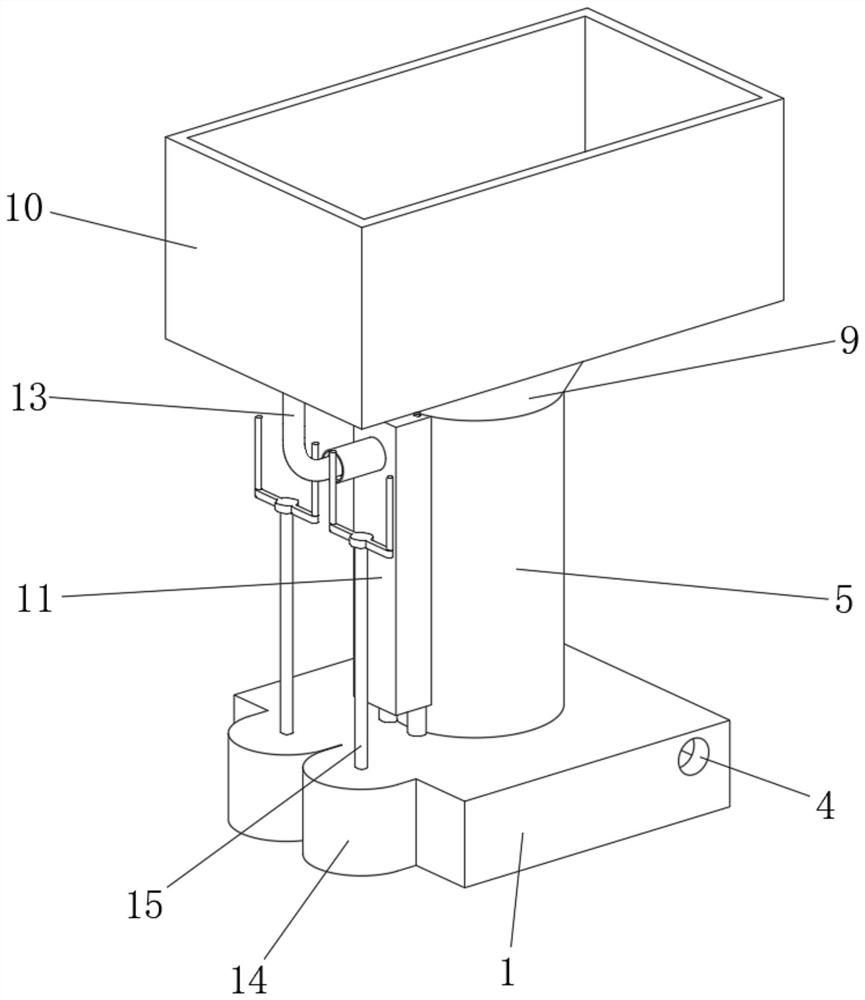

LED chip die-bonding method and package method of display module having same

ActiveCN109673110AImprove yieldWill not short circuitPrinted circuit assemblingIdentification meansElectrode ContactDie bonding

The invention provides a LED chip die-bonding method and a package method of a display module having the same. The LED chip die-bonding method comprises the steps of: S1, disposing a welding materialon a circuit board for curing to obtain a welding portion fixed on the circuit board; S2, detachably disposing a LED chip on the first surface of the substrate, wherein the LED chip has an electrode surface and a light emitting surface which are opposite, the light emitting surface is in contact with the first surface, and the electrode surface is located on one side, far away from the substrate,of the light emitting surface; and S3, making the welding portion and the surface of the electrode contact, and allowing the portion, close to the surface of the electrode, of the welding portion to be melted, and fixing the LED chip on the circuit board through the melted welding portion. The LED chip die-bonding method cannot pull the LED chip and cannot cause short-circuit of positive and negative electrodes so as to improve the yield of the die-bonding process; and compared to the prior art, the LED chip die-bonding method can perform die-bonding of hundreds of LED chips each time so as toimprove the die-bonding efficiency.

Owner:LEYARD

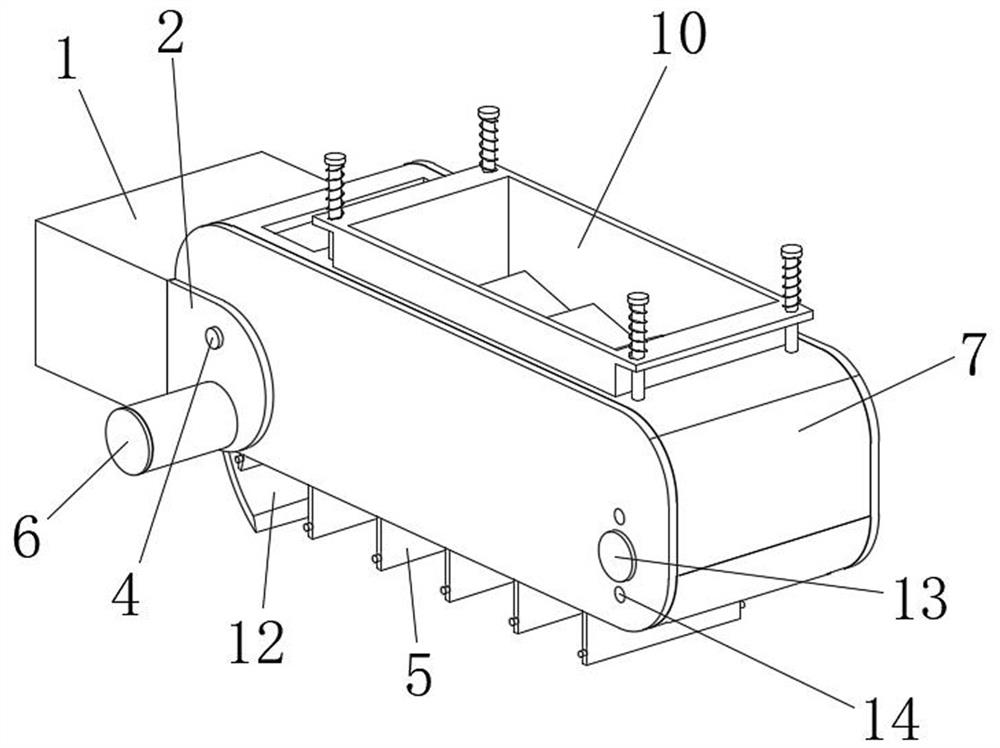

Particle feeding device for fishpond feeding

InactiveCN113951197ABig spaceImprove stabilityClimate change adaptationPisciculture and aquariaEngineeringMechanical engineering

The invention relates to the technical field of feeding, and discloses a particle feeding device for fishpond feeding, which comprises a feeding bin, a discharging bin is arranged at the top of the feeding bin and located in the center, a feeding channel is arranged in the feeding bin and located below the discharging bin, one end of the feeding channel communicates with the discharging bin, an annular air channel is formed in the position, located on the outer side of the discharging bin, in the feeding bin, and the screw pitch of a spiral conveying piece is continuously increased from top to bottom, so that materials in a storage bin enter the corresponding position of the spiral conveying piece through a conveying pipe and a conveying sliding block, in the process that a power machine drives the material conveying device to rotate, the materials can be driven to move downwards along the spiral shape of the spiral material conveying piece, the space where the materials are located is gradually enlarged, and the problems that the space is reduced, conveying is blocked and the attachment problem is gradually serious after the situation that sundries are attached to a traditional conveying piece due to the same screw pitch are avoided, and the stability of the device in the conveying process is improved.

Owner:何敏华

Battery cell clamping jig and battery cell processing device

PendingCN114639861AImprove machining accuracyWon't pullFinal product manufactureLi-accumulatorsPhysicsEngineering

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

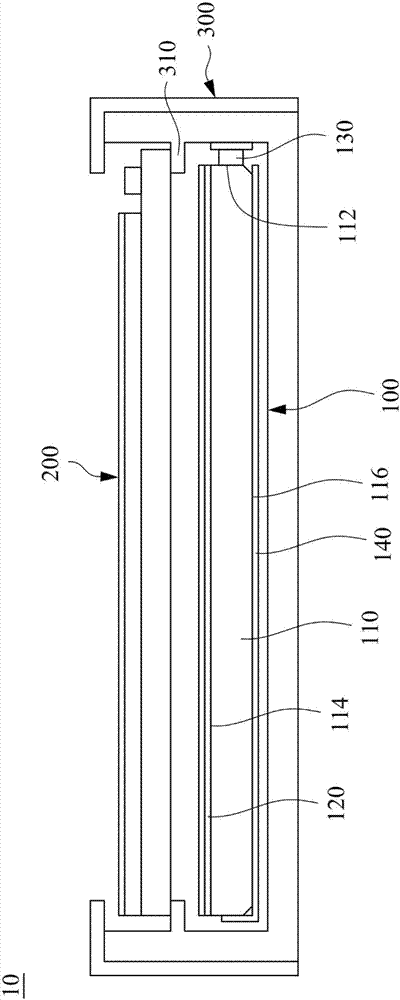

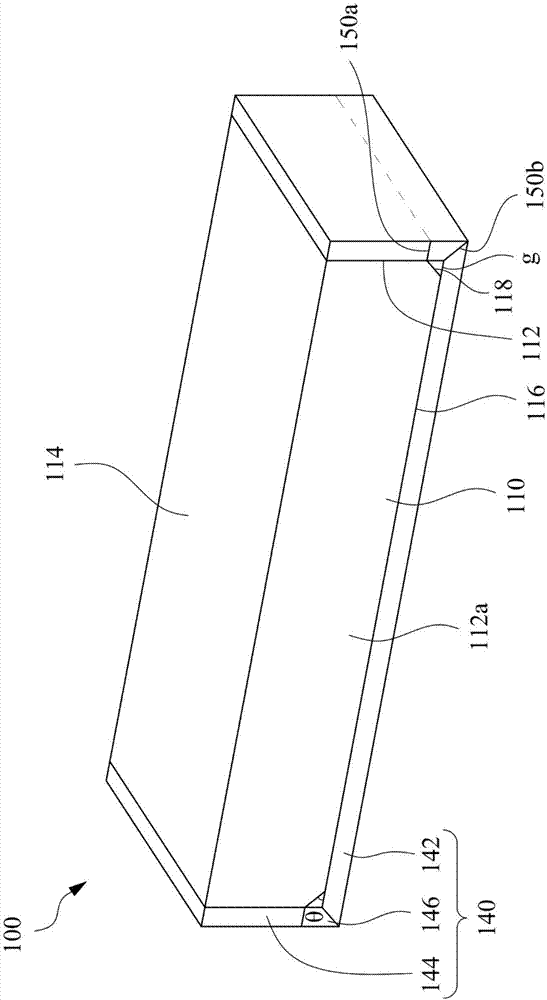

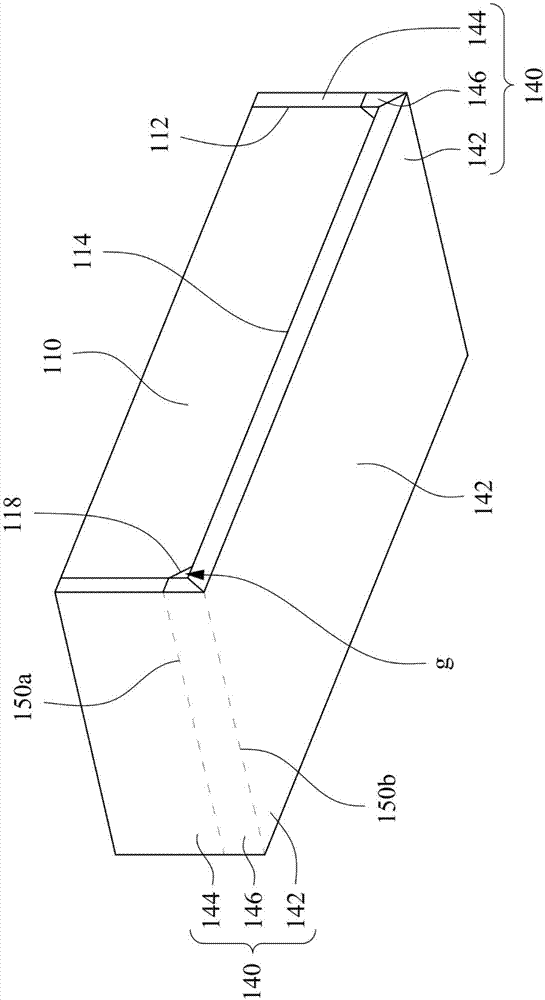

Backlight module

ActiveCN107340563AEasy to transformWon't pullOptical light guidesNon-linear opticsLight guideComputer science

The invention discloses a backlight module, and the backlight module comprises a light guide plate and a reflection piece. The light guide plate is provided with a first main surface and a second main surface, which are opposite to each other. The light guide plate is also provided with a plurality of side surfaces. The second main surface and the side surfaces are connected through inclined surfaces. The reflection piece comprises a negative film disposed on the second main surface, at least one fin disposed on the side surfaces, and buffering pieces disposed on at least one corresponding inclined surface, wherein there are spaces between the buffering pieces and the corresponding inclined surfaces. The reflection piece also comprises a first weakening structure which is connected with the fins and the buffering pieces, and a second weakening structure connected with the buffering pieces and the negative film.

Owner:AU OPTRONICS (XIAMEN) CORP +1

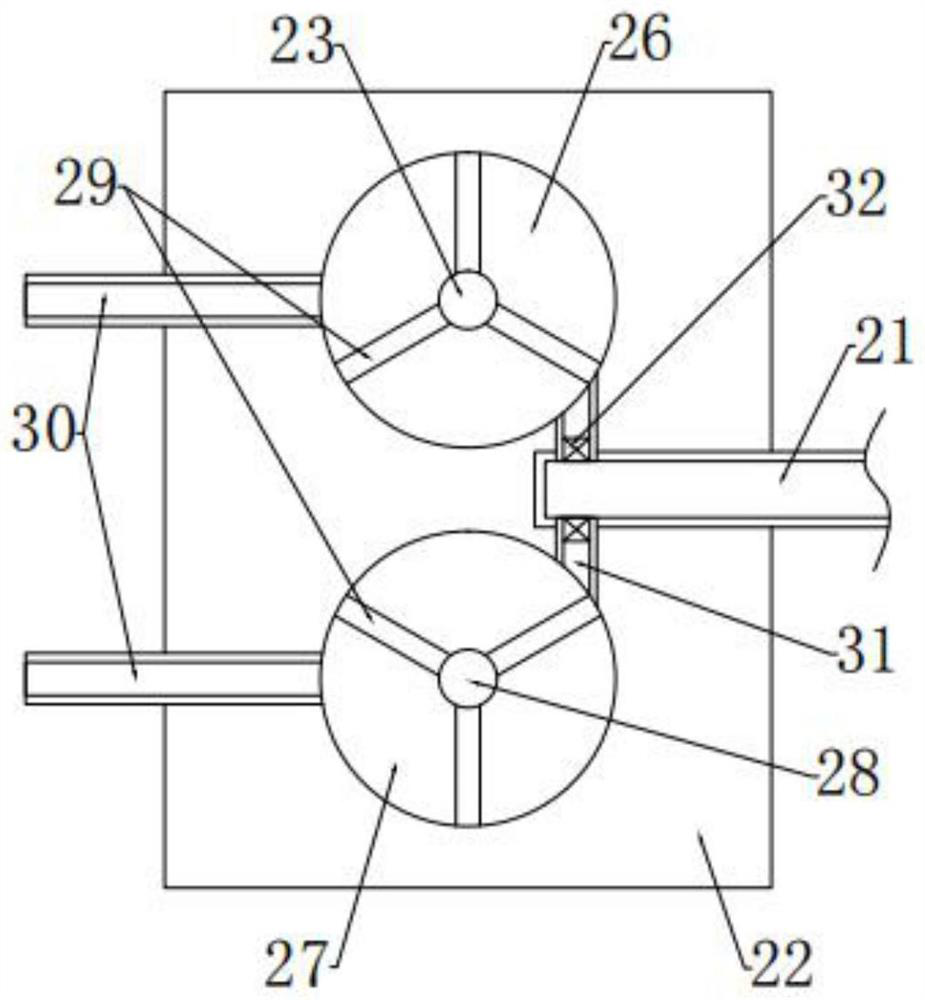

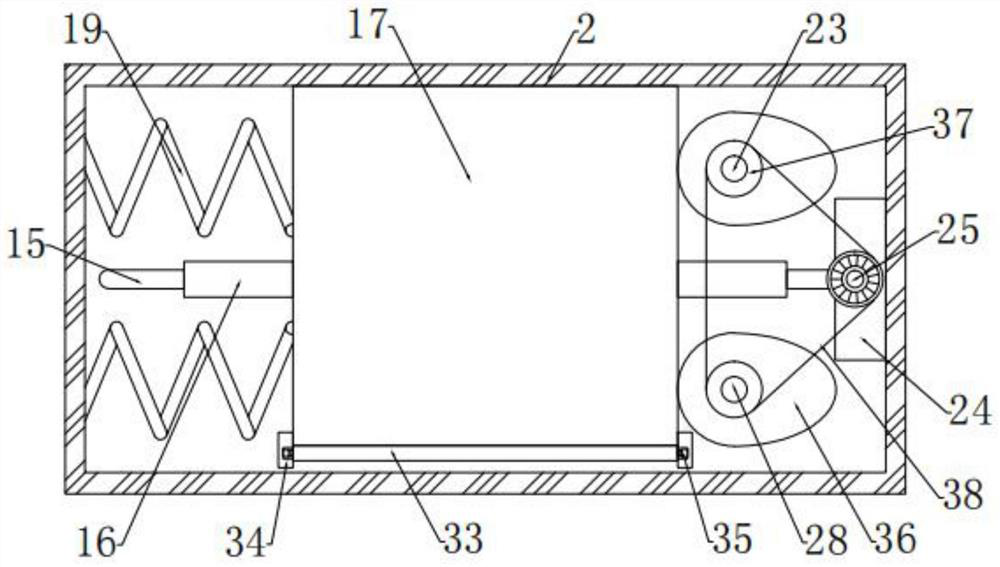

Recycled paper production winding equipment

ActiveCN114803615AWon't pullReduce the chance of damagePaper recyclingBundling machine detailsPaper recyclingPaper production

The invention relates to the field of paper recycling, in particular to recycled paper production winding equipment which comprises the following steps that S1, the end of paper penetrates through a smoothing roller to be fixed to the surface of a winding roller; s2, a motor is started, and a winding roller is driven to rotate through friction of a power roller to wind the paper; the recycled paper production winding equipment comprises a frame body, a power roller is rotationally connected to the left side of the upper end of the frame body, smoothing rollers are rotationally connected to the middle and the right side of the upper end of the frame body, side frames are fixedly connected to the front end and the rear end of the right side of the frame body, and the side frames are fixedly connected to the left side and the right side of the frame body. A winding roller is slidably connected between the two side frames and attached to the power roller, and a motor is fixedly connected to the left side of the lower portion of the frame body. According to the paper winding device, it can be guaranteed that paper is wound at a constant speed, damage to the paper is reduced, meanwhile, the winding roller can be replaced conveniently, and the paper winding efficiency is improved.

Owner:南通大豫纸业有限公司

Flexible display panel and flexible display device

ActiveCN112270890AWon't pullReduce stressPhotovoltaic energy generationIdentification meansSurface displayStructural engineering

The invention discloses a flexible display panel and a flexible display device. The flexible display panel comprises a supporting substrate and a flexible screen body arranged on the supporting substrate, wherein the supporting substrate comprises a non-bending area and a first bending area, and the first bending area is arranged on the outer edge of the non-bending area; the first bending area comprises a supporting part, a first protection part and a second protection part, the first protection part and the second protection part are located on the two sides of the supporting part respectively, a concave area is defined by the first protection part, the second protection part and the supporting part, and the concave area is used for containing the bending area of the flexible screen body. According to the scheme disclosed by the invention, while curved surface display of the flexible display panel is ensured, the stress of the flexible screen body during bending is reduced, and the product yield is improved.

Owner:HEFEI VISIONOX TECH CO LTD

Full-automatic coiled material exposure machine

PendingCN114355734ALittle impact on qualityEasy to movePhotomechanical exposure apparatusMicrolithography exposure apparatusDust controlEngineering

The invention relates to the technical field of exposure machines, in particular to a full-automatic coiled material exposure machine which comprises a shell and an exposure device fixedly connected to the inner side of the shell. The control mechanism is arranged on the inner side of the shell; the placing mechanism is arranged on the inner side of the shell and is connected with the control mechanism; wherein the control mechanism comprises a supporting assembly, and the supporting assembly is arranged on the inner side of the shell, connected with the placing mechanism and used for driving the placing mechanism to ascend and descend; the adjusting assembly is connected with the supporting assembly; the connecting assembly is arranged between the adjusting assembly and the placing mechanism, the control mechanism is arranged, and the adjusting assembly is matched with the connecting assembly, so that not only can the movement of the coiled material be realized, but also dust removal can be carried out on air, the exposure effect of the device is greatly improved, and the exposure quality is improved.

Owner:深圳市欣光辉科技有限公司

Equipment for reinforcing silty-fine sand foundation of passenger transport line and reinforcing method

InactiveCN112442980AAvoid destructionWon't pullTrack maintainenceBulkheads/pilesArchitectural engineeringStructural engineering

The invention discloses equipment for reinforcing a silty-fine sand foundation of a passenger transport line, and belongs to the technical field of foundation reinforcement. The equipment comprises atubular pile and a pile tip, the pile tip is movably connected with the outer wall of the bottom of the tubular pile through a buckle, holes are uniformly formed in the bottom of the outer wall of thetubular pile, and a rotating device sleeves the tubular pile. The rotating device comprises an inner pipe inserted into an inner cavity of the tubular pile, a connecting block sleeves the top end ofthe outer wall of the inner pipe, an outer pipe sleeves the outer wall of the connecting block, and open holes are evenly formed in the bottoms of the outer pipe and the outer wall of the inner pipe.The inner pipe and the outer pipe are rotated by rotating the rotating device, so that the open holes and the holes are staggered. The connection between the silty-fine sand pile inside the tubular pile and the silty-fine sand of the foundation outside the tubular pile is broken, and the connection between the silty-fine sand pile, the silty-fine sand of the foundation outside the tubular pile andthe silty-fine sand inside the holes is further broken, so that the silty-fine sand pile or the silty-fine sand foundation compacted outside is not pulled in the pipe pulling process, and the compacted reinforced foundation is prevented from being damaged.

Owner:王修亮

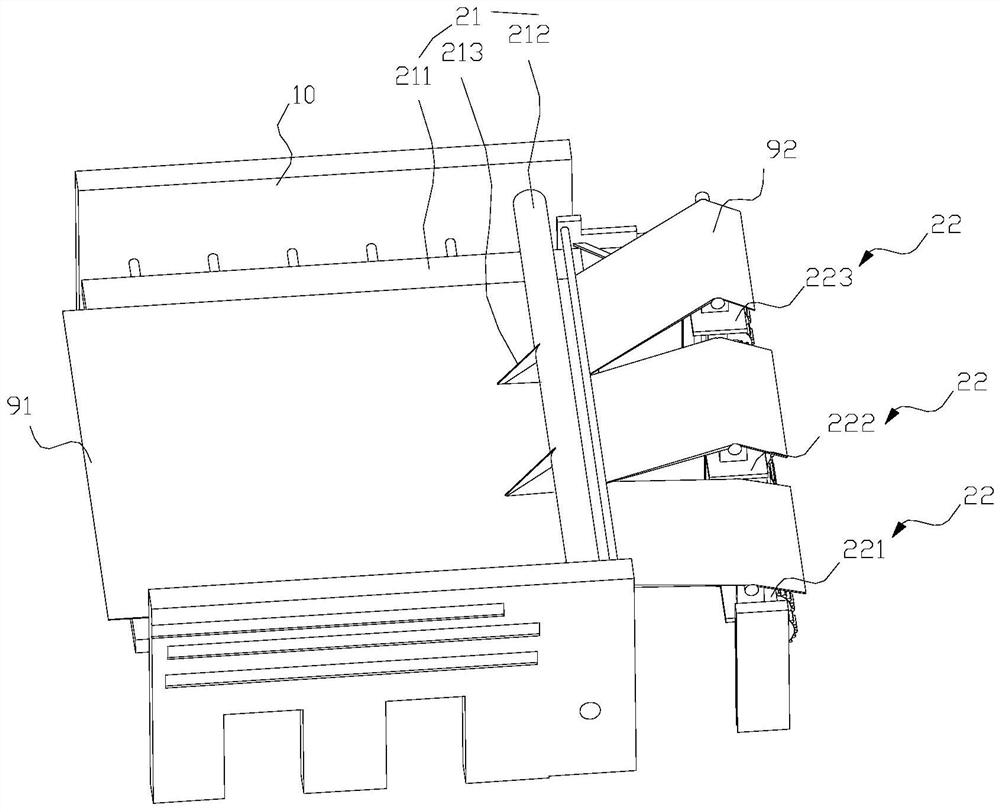

Novel packaging bag production line

PendingCN114347561AEasy maintenanceImprove work efficiencyBag making operationsPaper-makingProduction lineIndustrial engineering

The novel packaging bag production line comprises a feeding and film releasing mechanism, a traction sealing and cutting mechanism, a blanking and bag collecting mechanism and a centralized control module, the feeding and film releasing mechanism, the traction sealing and cutting mechanism and the blanking and bag collecting mechanism are sequentially arranged in the conveying direction of coiled packaging bags, and a bag folding device is arranged between the traction sealing and cutting mechanism and the blanking and bag collecting mechanism. The centralized control module is arranged on the outer side of the feeding and film releasing mechanism. Full-automatic intelligent feeding and discharging of the feeding shaft are achieved, the traction sealing and cutting mechanism and the blanking and bag collecting mechanism are high in working efficiency, high in machining precision and low in error rate, and the labor cost is greatly reduced.

Owner:JIEYANG QUNXING MACHINERY IND

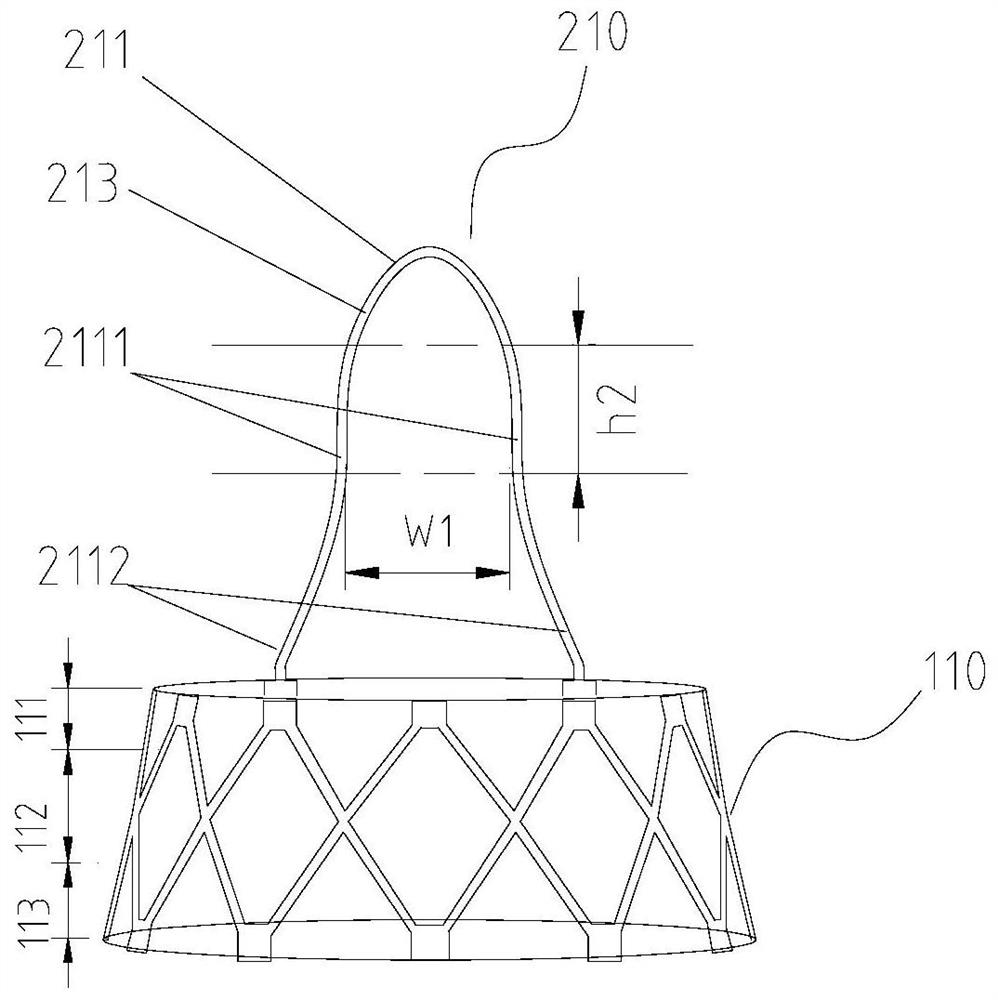

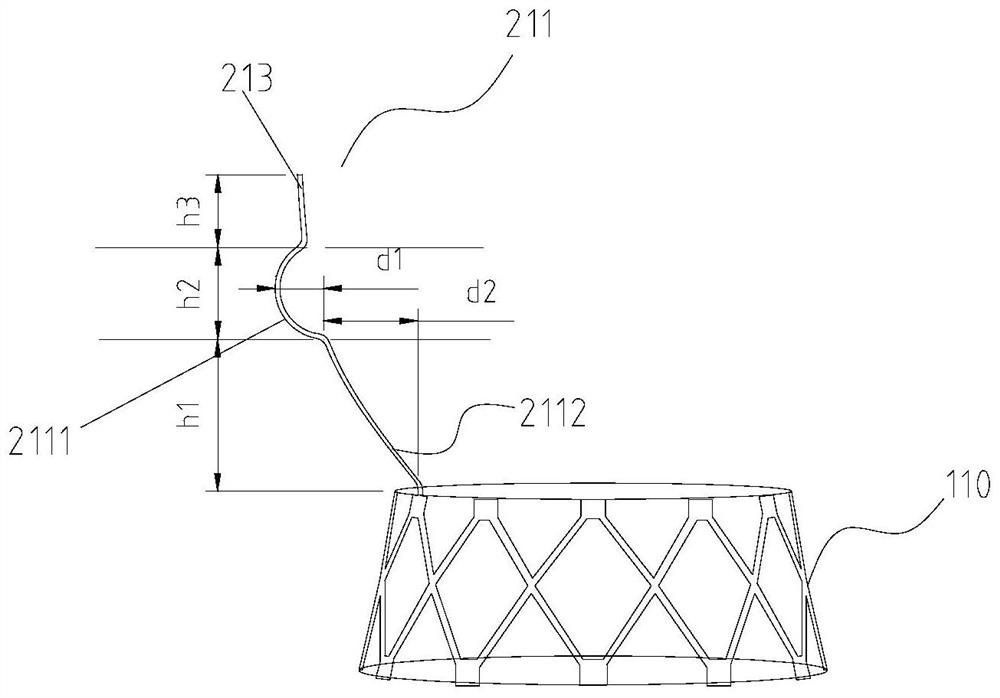

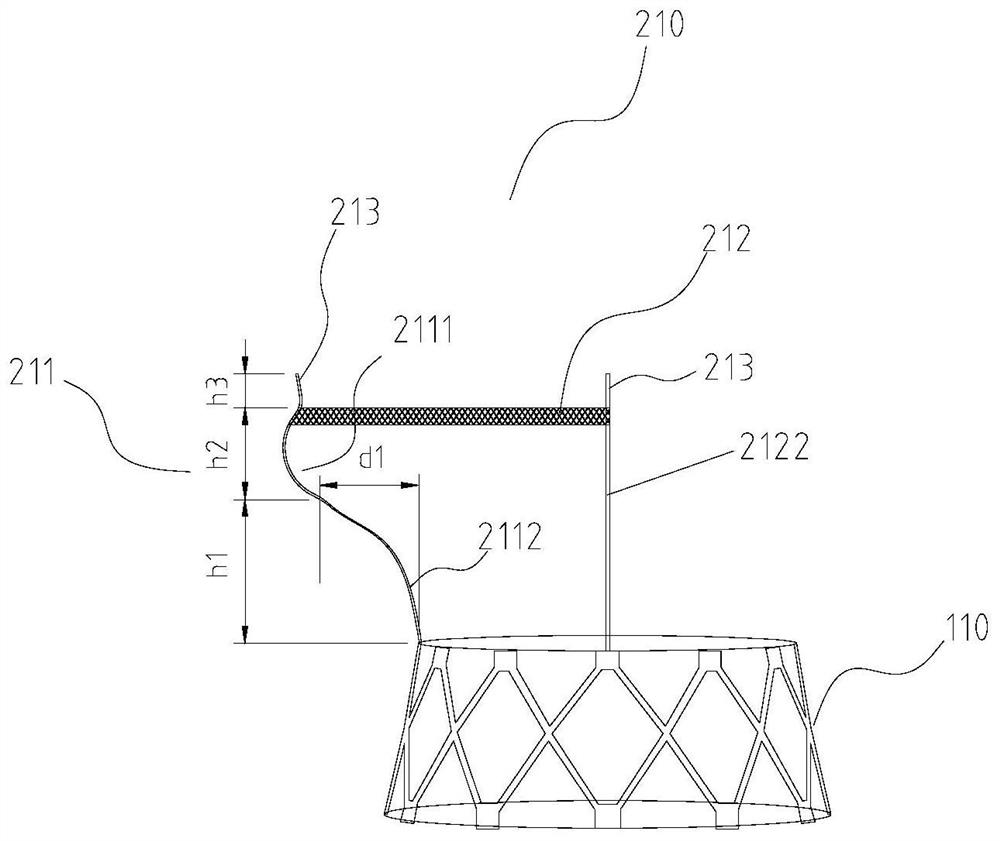

Tricuspid valve prosthesis

The invention discloses a tricuspid valve prosthesis. The tricuspid valve prosthesis comprises a stent main body implanted at a tricuspid valve ring and used for supporting an artificial valve leaflet; and an anchoring structure arranged above the stent main body and used for anchoring the stent main body at a native valve ring to prevent the stent main body from shifting. The anchoring structureis configured to be partially attached to the fossa ovalis of the atrial septum, retention force is formed by attaching the fossa ovalis, and therefore the anchoring effect on the valve prosthesis isachieved. Under the enlightenment of the original structure of the fossa ovalis, the concave structure of the fossa ovalis is fully utilized to partially clamp and fix the anchoring structure in the fossa ovalis, so that a certain retention force is provided, and the valve prosthesis is prevented from shifting during cardiac compression; and according to the anchoring structure, a traditional anchoring mode of clamping the valve leaflet or grabbing the valve leaflet is changed, and the chordae tendineae cannot be pulled or the valve leaflet cannot be damaged.

Owner:SHANGHAI TRULIVE MEDTECH CO LTD +1

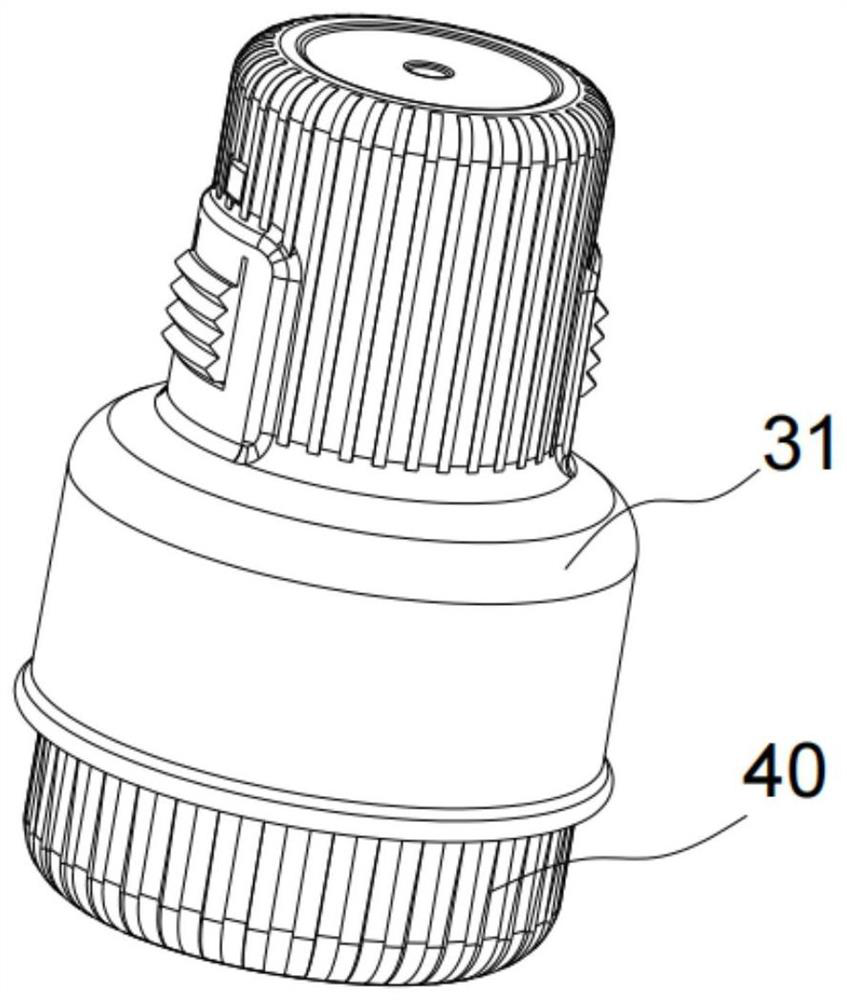

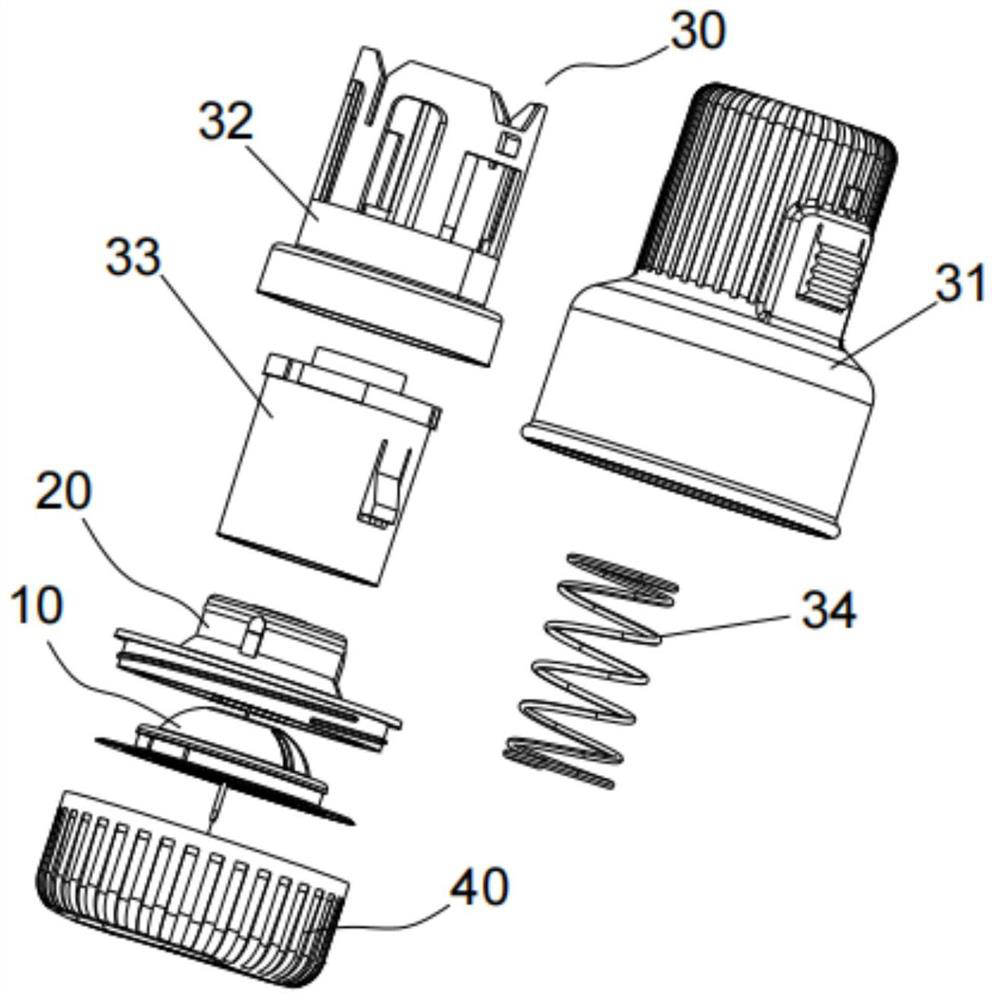

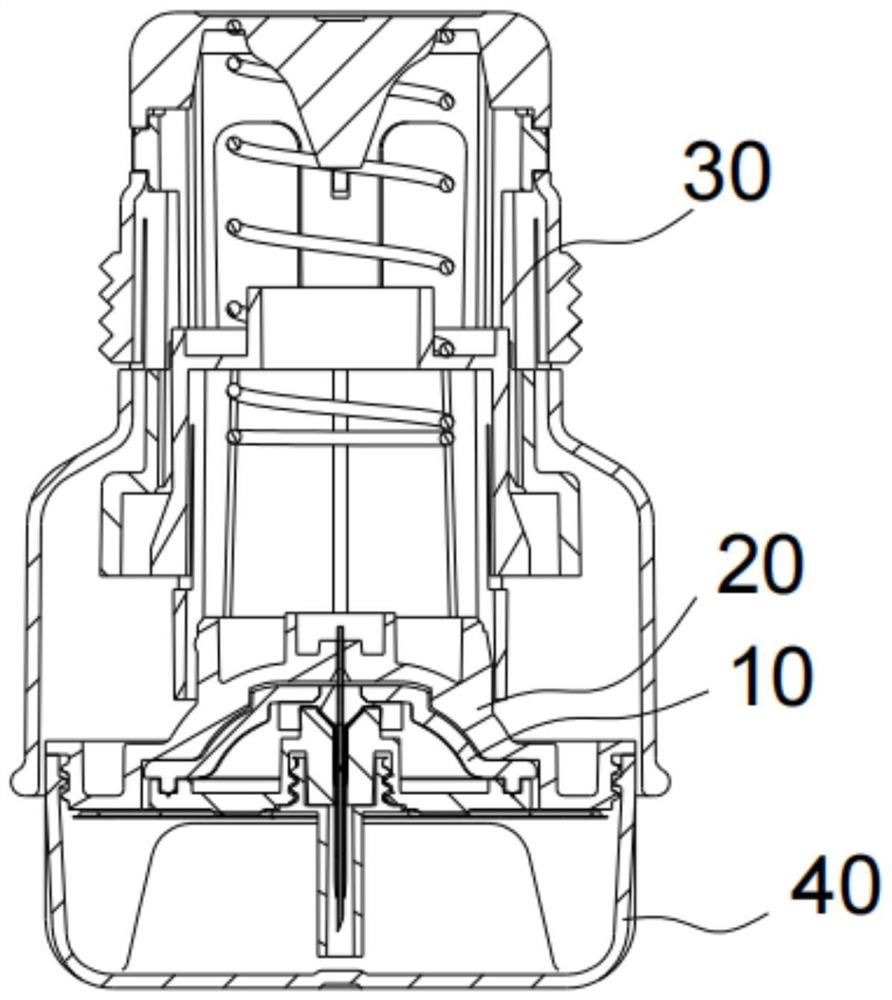

Patch type indwelling system

PendingCN114028648ADoes not cause separationWon't pullPressure infusionInfusion needlesAnatomyApparatus instruments

The invention relates to the field of medical instruments, and particularly discloses a patch type indwelling system. The system at least comprises a transmitting unit, a puncture unit and an patch type indwelling unit; wherein an accommodating cavity is formed in the bottom of the puncture seat, a plurality of elastic clamping arms are arranged on the side wall of the accommodating cavity, and convex parts are arranged at the free ends of the elastic clamping arms; an annular cavity is formed in the side, away from the containing cavity, of the puncture base; and an annular boss matched with the annular cavity is arranged in the transmitting unit. According to the structure, in the pre-emitting state, the elastic clamping arm deforms under the action of the convex part, the elastic clamping arm fixes the indwelling unit, and when the protective sleeve and the release paper are removed, the patch type indwelling unit cannot be separated from the puncture unit; at the puncture position, the elastic clamping arm is separated from the convex part and recovers to the initial state, and the elastic clamping arm and the indwelling unit are detached, so that the puncture unit and the patch type indwelling unit can be separated more easily without stretching skin through the patch type indwelling unit.

Owner:普昂(杭州)生命科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com