Semiconductor lead frame manufacturing technology

A technology of lead frame and manufacturing process, which is applied in the field of semiconductor lead frame manufacturing technology, can solve the problems of poor quality of lead frame and large amount of precious metals, etc., and achieve the effects of strong coating adhesion, reasonable arrangement of process steps, and strong protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0061] This embodiment provides a manufacturing process of a semiconductor lead frame, which is an improved process for manufacturing a semiconductor lead frame by the existing die stamping method, and the main improvement of the process lies in the surface treatment process.

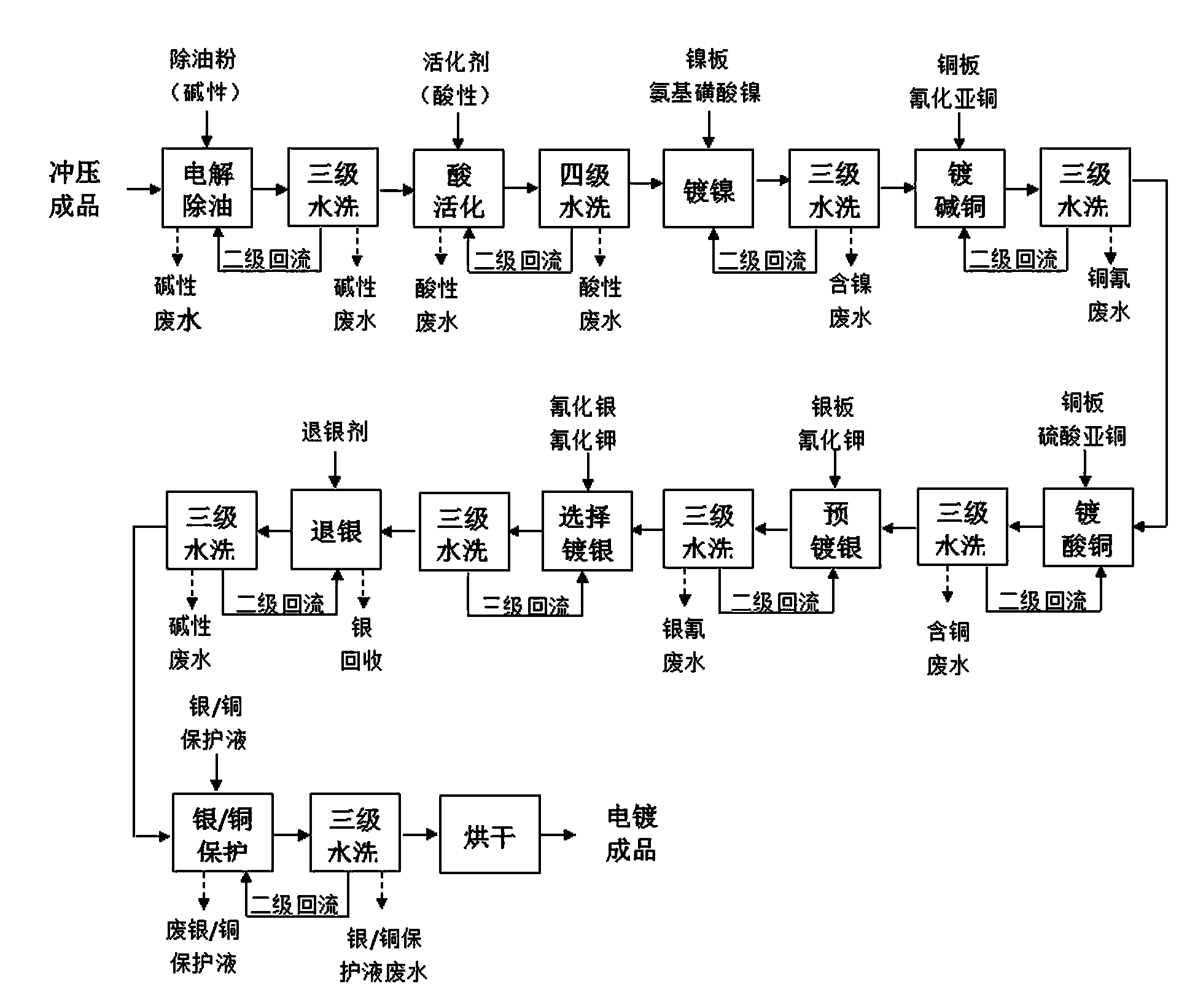

[0062] like figure 1 As shown, this embodiment includes stamping, surface treatment and cutting forming. The specific process steps of surface treatment are: electrolytic degreasing, water washing, acid activation, water washing, nickel plating, water washing, alkali copper plating, water washing, acid copper plating, Water washing, pre-silvering, water washing, silver plating, water washing, desilvering, water washing, plating protection solution, water washing and drying.

[0063] The water washing step between the electrolytic degreasing step and the acid activation step is three-stage water washing, and the first two stages of water washing are refluxed to the electrolytic degreasing step;

[0064]...

Embodiment 2

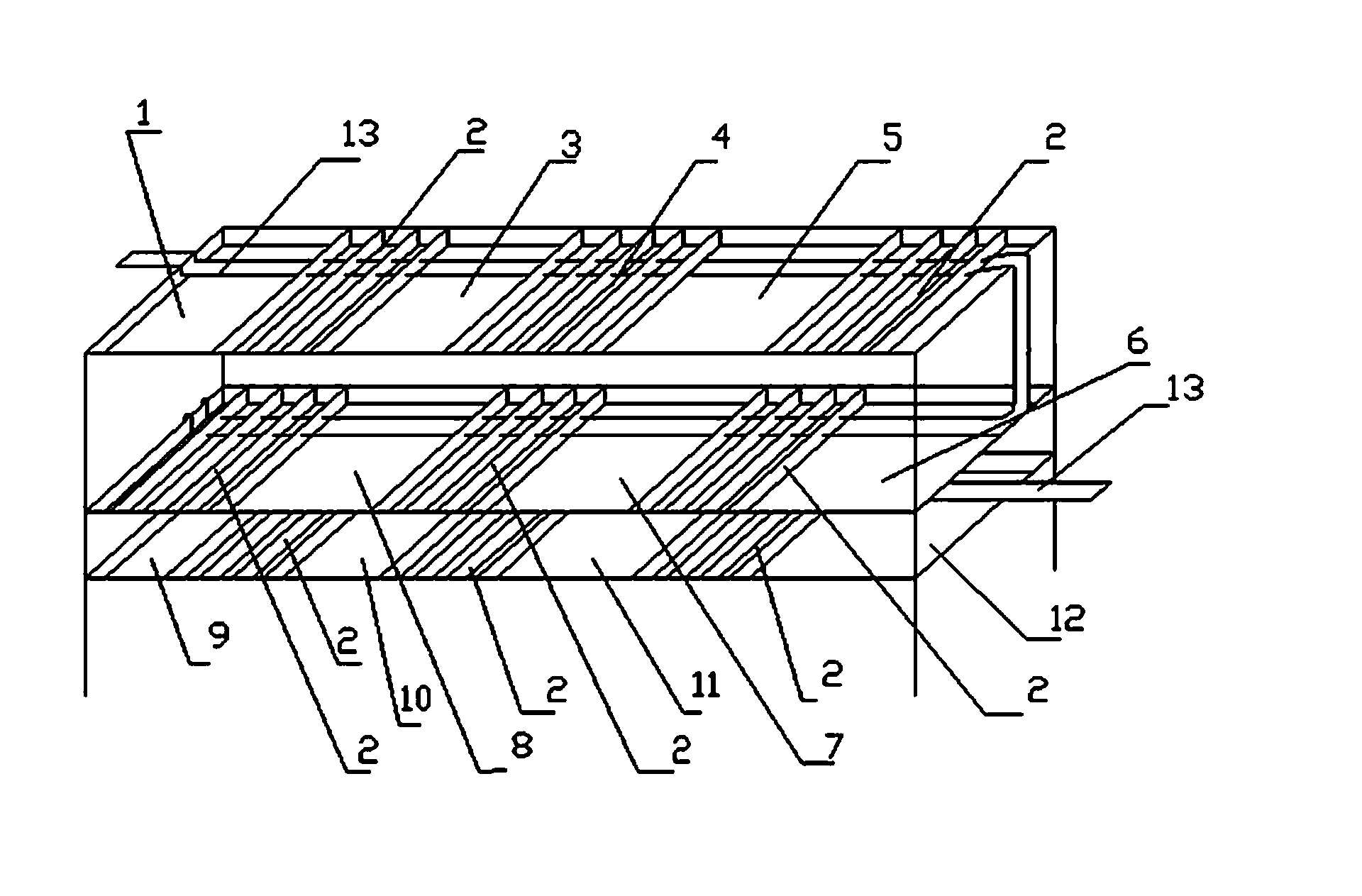

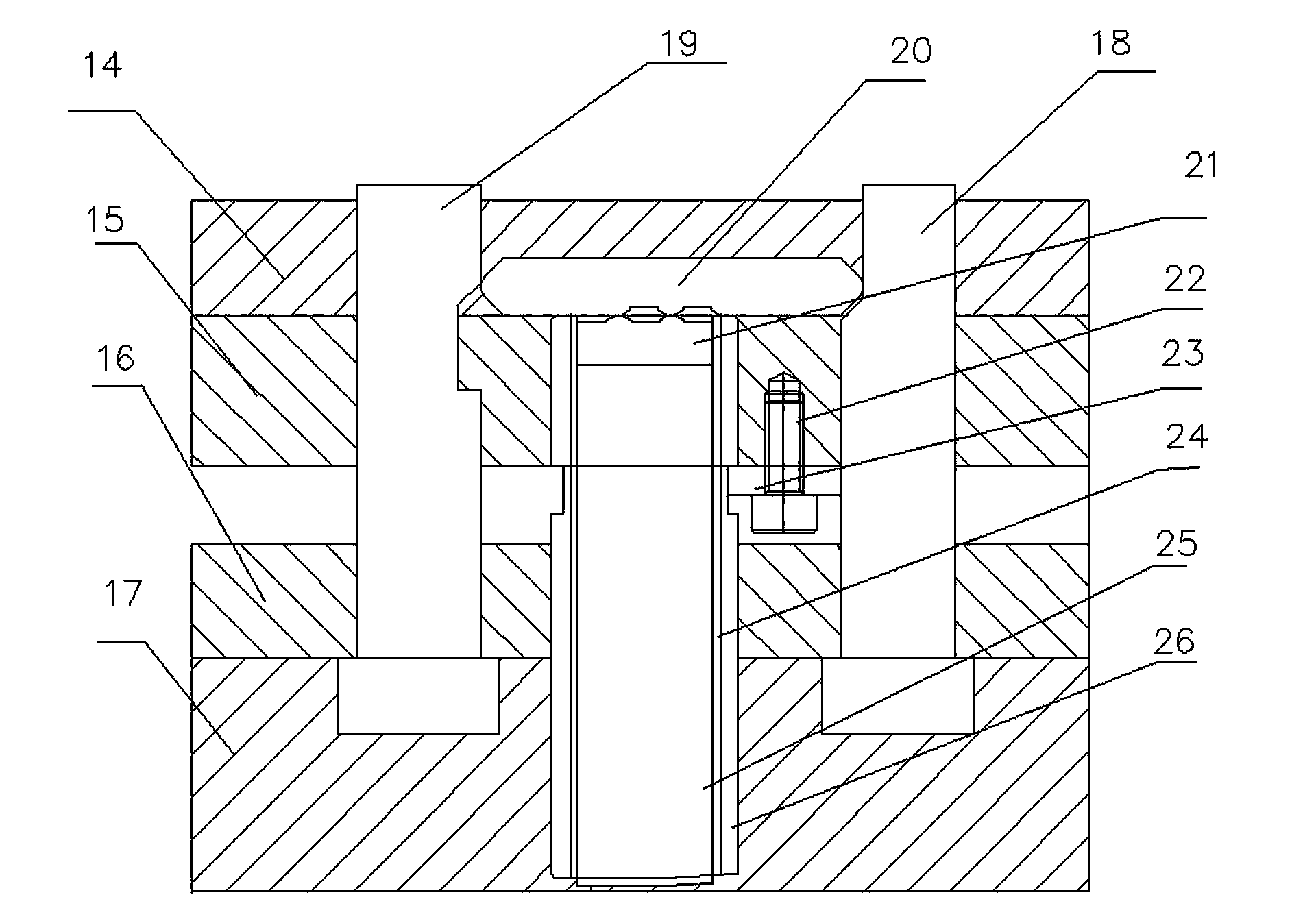

[0085] like Figure 3 to Figure 10 As shown, what this embodiment provides is a cutting and molding die for manufacturing semiconductor lead frames. This cutting and molding die combines the two processes of cutting and forming into one, and realizes these two processes on one mold, and at the same time does not The deformation of the semiconductor lead frame is caused, and the defect that the size of the semiconductor lead frame exceeds the standard error, that is, is out of tolerance, does not appear.

[0086] This cutting forming mold comprises upper mold, lower mold, cutting punch 25 and molding convex 26 molds, upper mold includes fixed backing plate 14 and fixing plate 15, and fixing backing plate 14 is positioned at the top of fixing plate 15, and lower mold includes unloading backing plate 16 and the unloading plate 17, the unloading backing plate 16 is located above the unloading plate 17, and is characterized in that: it also includes an upper slider 20, a lower slid...

Embodiment 3

[0097] In this implementation, the surface treatment process is the same as that of the embodiment, the cutting and forming mold is the same as that of the embodiment 2, and the others are the same as those of the prior art, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com