Patents

Literature

46results about How to "Guaranteed activation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Semi-conductor lead framework production process

ActiveCN103928351AExact widthAdequate heat dissipationSemiconductor/solid-state device manufacturingMechanical engineeringSemiconductor

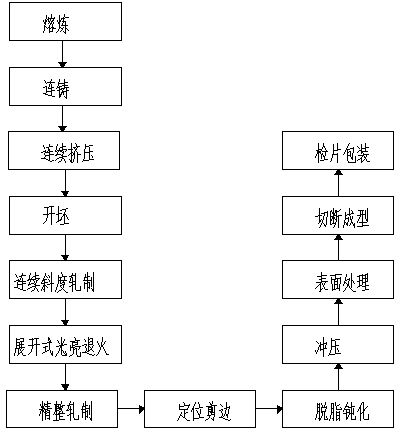

The invention relates to a semi-conductor lead framework production process which includes the steps of smelting, continuous casting, continuous extrusion, cogging, severe convection annealing, continuous inclination rolling, spreading-type bright annealing, finishing rolling, positioning-type edge shearing, degreasing passivation, stamping, surface processing, cutting forming and detection piece packaging. The production process is characterized in that the two work procedures of finishing rolling and positioning-type edge shearing are provided with continuous grooving procedures, when continuous grooving is carried out, precise grooving processing is carried out through a grooving machine, the rotation speed of the grooving machine is 1800-2000 r / min, the flow of cooling liquid is 45-50 L / min, and dovetail groove forming achieving through the process cannot cause strip width changes after forming, and the size of a formed semi-conductor lead framework is accurate.

Owner:SICHUAN JINGJIAN ELECTRONICS MATERIAL

Surface treatment method for bismuth telluride base thermoelectric material wafer

InactiveCN107227475AEasily brokenMany conversion linksSemiconductor devicesBismuth tellurideRoom temperature

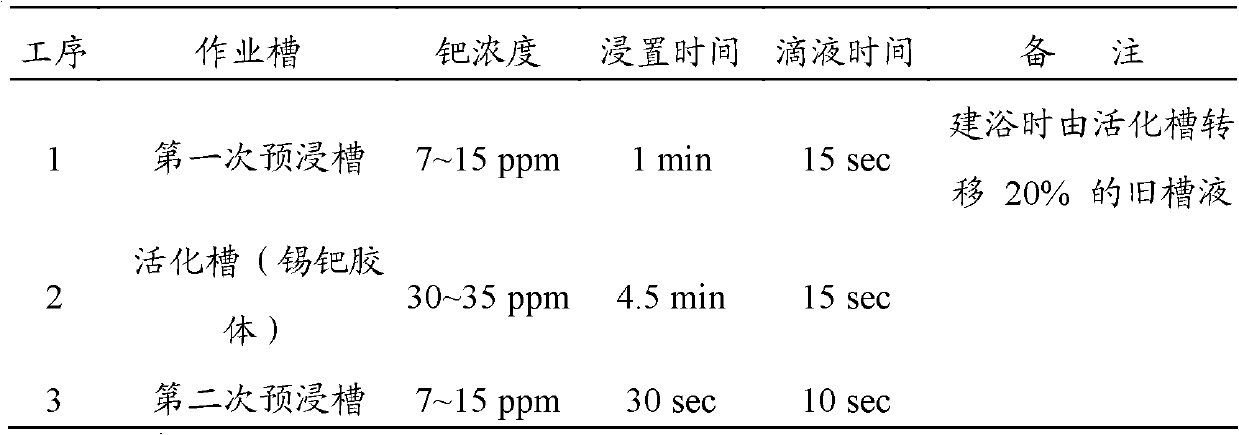

The invention discloses a surface treatment method for a bismuth telluride base thermoelectric material wafer. The surface treatment method includes the following steps that the wafer is put into oil removing liquid for oil removing, and cold water is used for thorough flushing; activating liquid is firstly used for conducting room-temperature activating; then an electrolyte the same as the oil removing liquid is used for treatment; finally, pre-nickel-plating activating liquid is used for treatment; nickel plating liquid is used for electroplating, the wafer is taken out after nickel plating, and cold water is used for thorough flushing; and tin bismuth plating liquid is used for electroplating, the wafer is taken out after tin bismuth plating is over, cleaning and drying are conducted, and surface treatment of a bismuth telluride base thermoelectric material is completed. By means of the surface treatment method, a multi-step activating treatment process is adopted for ensuring the activating effect of the surface of the wafer, and the plating combining strength is high.

Owner:GUANGDONG INST OF RARE METALS

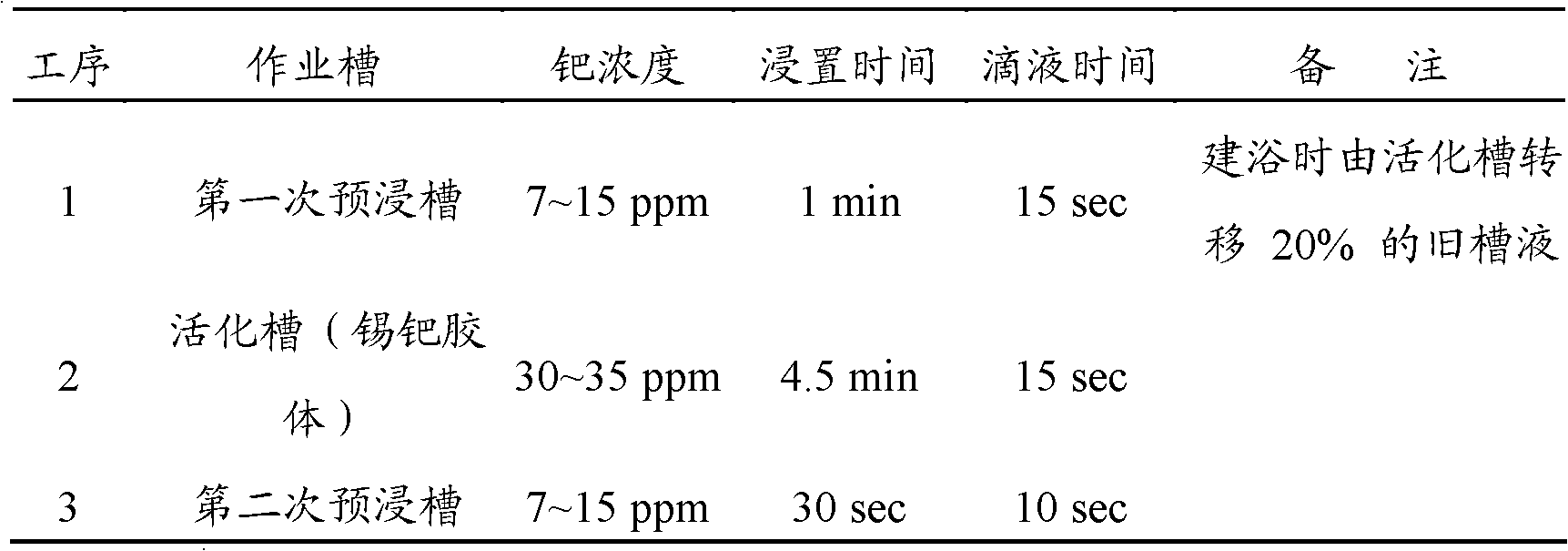

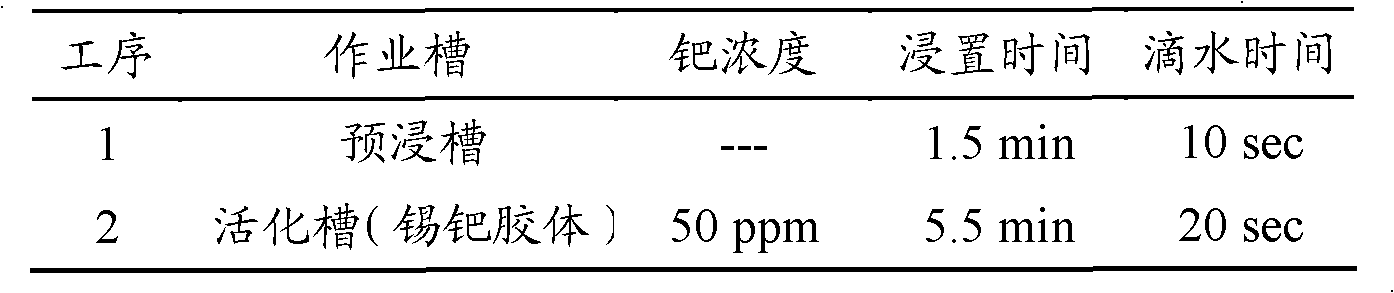

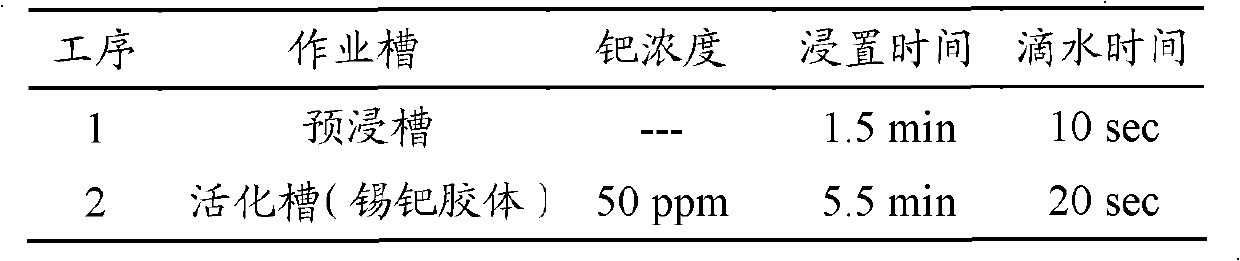

Surface activation method for nonmetal material

InactiveCN102321878AGuaranteed activation effectReduce wasteLiquid/solution decomposition chemical coatingHigh concentrationActivation method

The present invention discloses a surface activation method for a nonmetal material. The method comprises the following steps: adding tin palladium colloid to a pre-immersion solution to obtain a mixed solution; immersing a nonmetal substrate in the mixed solution; immersing the processed nonmetal substrate in a first activation solution, and then immersing the nonmetal substrate in the mixed solution. According to the present invention, the nonmetal substrate processed by the first activation solution is immersed in the mixed solution, such that the first activation solution absorbed on the surface of the nonmetal substrate, in the inner holes of the nonmetal substrate, and in the skeleton gaps of the nonmetal substrate are taken out and can be completely released in the mixed solution so as to reduce the waste of the noble metal palladium; the nonmetal substrate is respectively subjected to the low concentration activation treatment, the high concentration activation treatment and the low concentration activation treatment so as to provide the three activation functions at different concentrations for the nonmetal substrate, to enable adsorption of the activator, and the completeness and the compactness of the plating coat, to reduce specific consumption of the noble metal palladium, and to ensure the activation effect of the nonmetal material.

Owner:SHENZHEN FARCIEN APPLIED MATERIALS

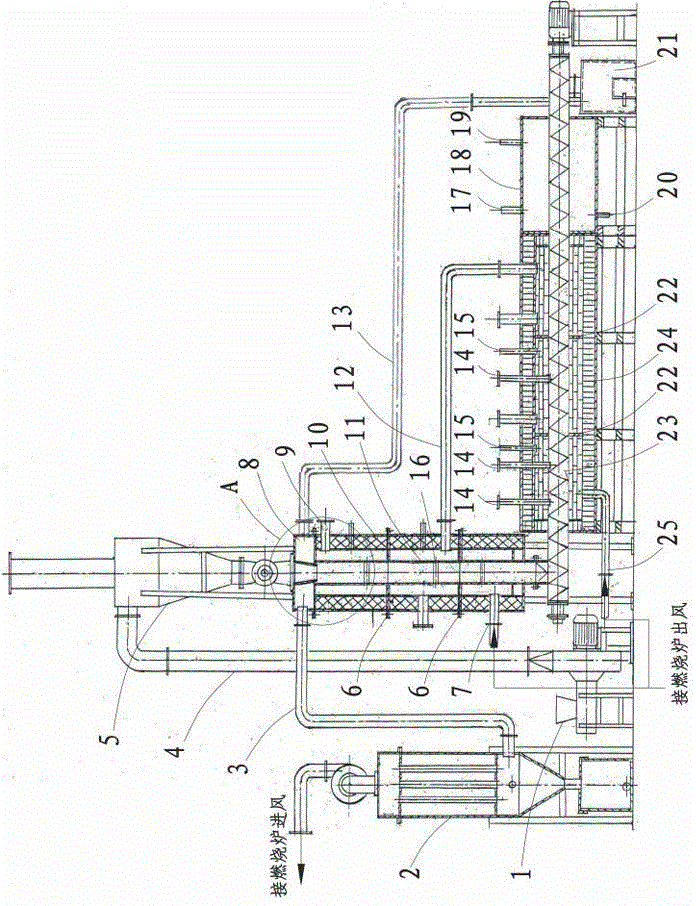

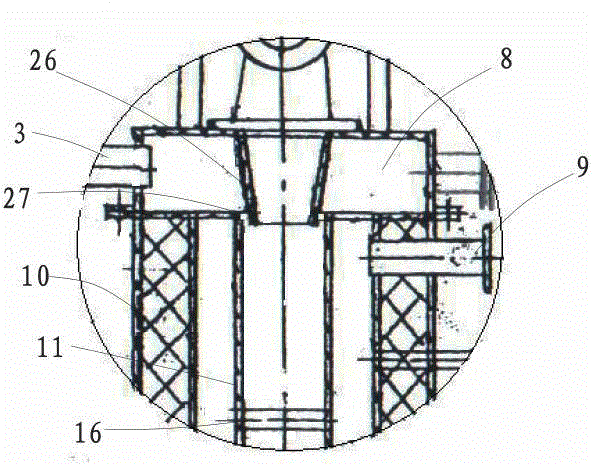

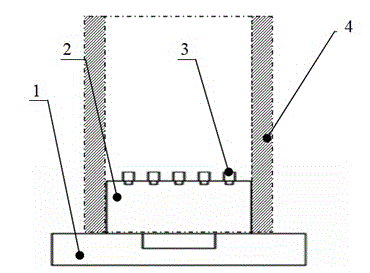

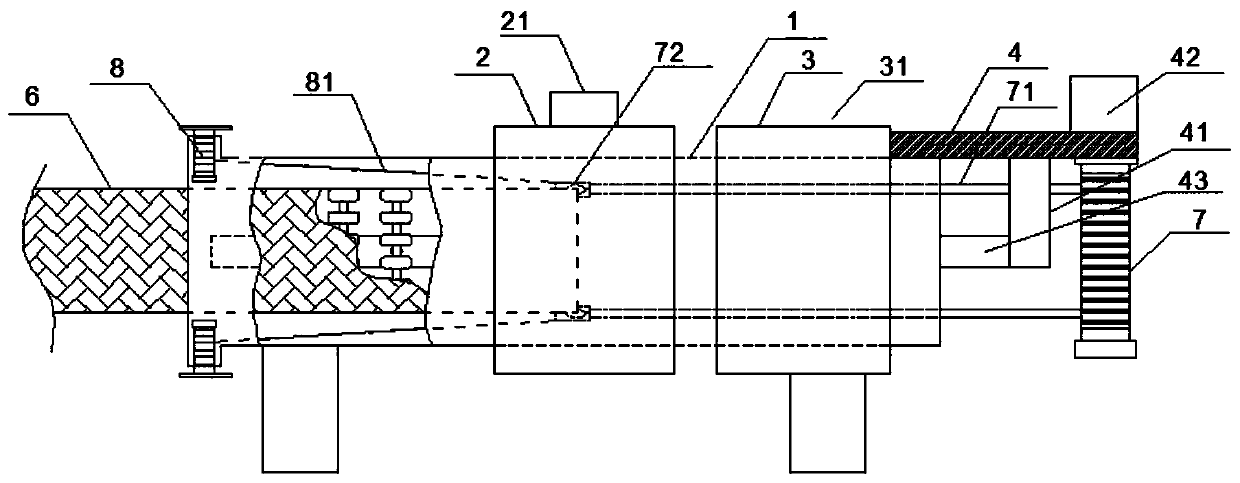

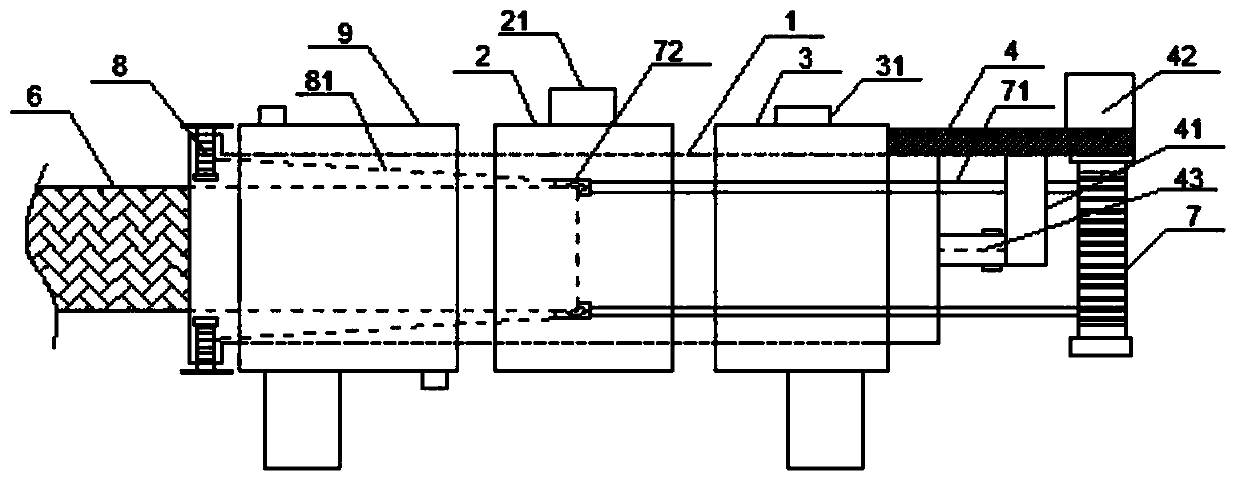

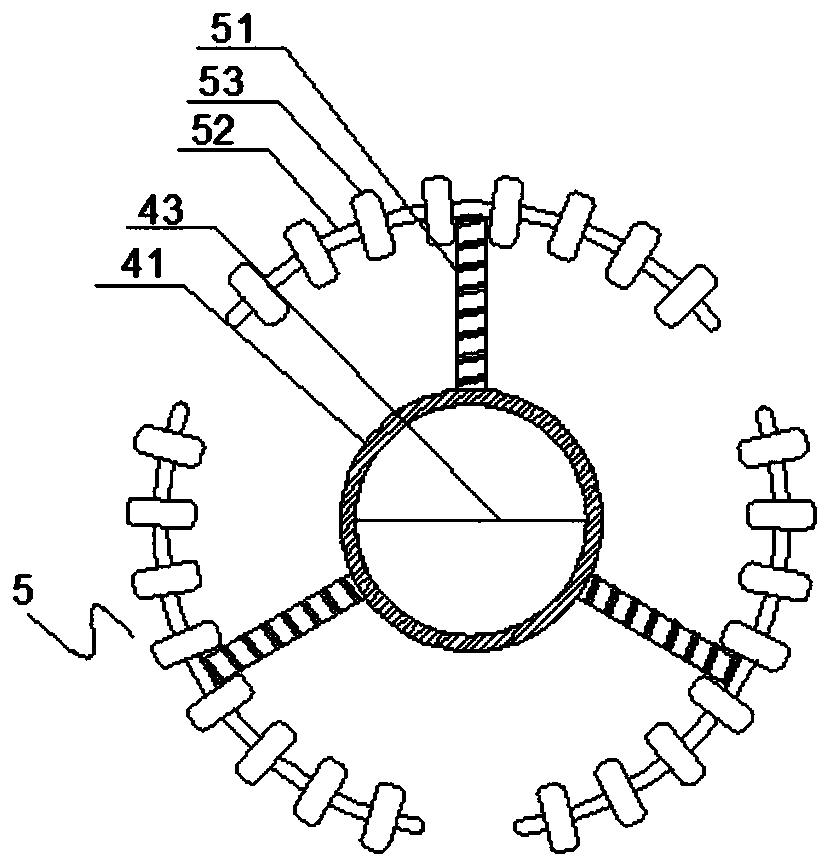

A biomass material carbonization-activation integrated device

The invention relates to a biomass material carbonization-activation integrated device, and overcomes the problems of carbonization-activation devices at present, namely a low efficiency, controlling difficulty of activation processes and high energy consumption. The device comprises a vertical carbonization furnace and a horizontal activation furnace. A vertical carbonization cylinder is disposed in the carbonization furnace. An activation spiral conveyer transversally penetrates the activation furnace. The lower end of the carbonization cylinder is connected to the initial end of the activation spiral conveyer. The carbonization furnace is also provided with steam spraying tubes communicating with the activation spiral conveyer and spraying steam to the inside of the activation spiral conveyer. The steam spraying tubes penetrate the furnace wall of the carbonization furnace. Both the activation furnace and the carbonization furnace are provided with a gas inlet and a gas discharging port. The gas inlets of the activation furnace and the carbonization furnace are connected to a combustion furnace. According to the device, steam activation has no influence on carbonization. An activation process adopts the steam spraying tubes to spray the steam, and the activation spiral conveyer is cooperated for control, thus effectively controlling the using amount of the steam, ensuring full contact between the steam and a carbon layer, ensuring activation effects, and reducing the using amount of the steam. The heat of the activation itself can be utilized to heat the steam in the steam spraying tubes, thus reducing extra energy consumption for heating steam.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

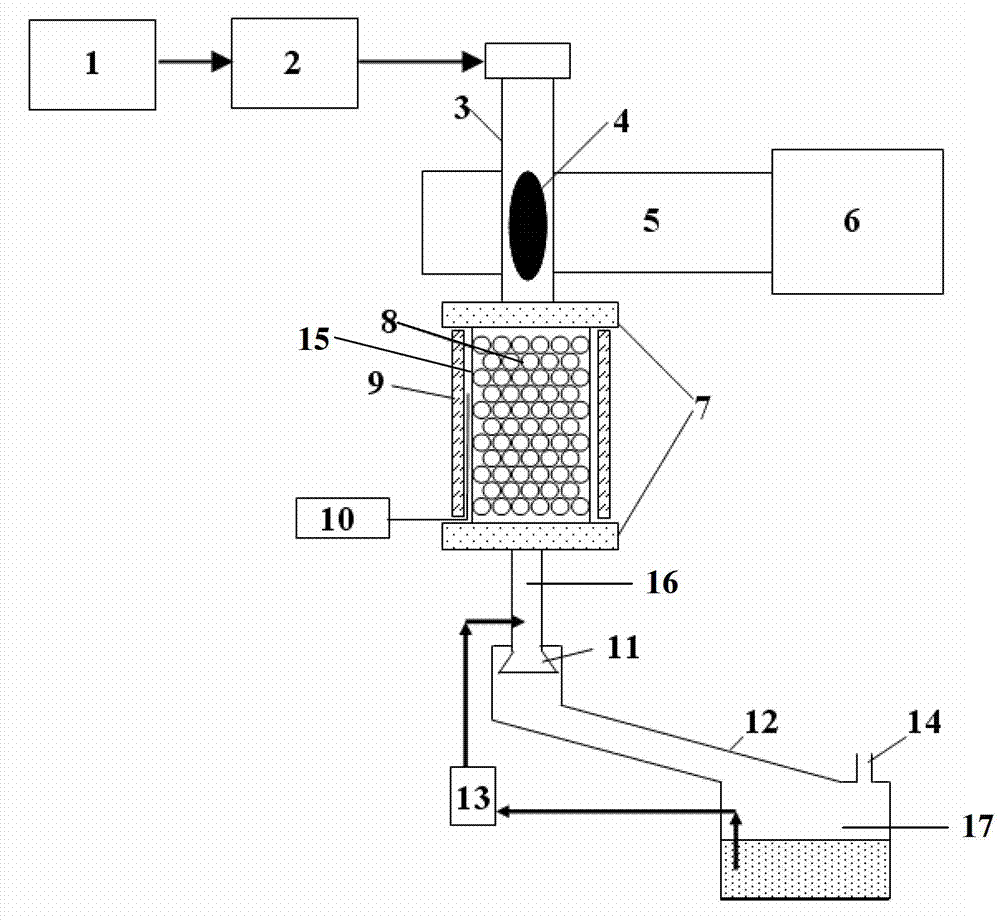

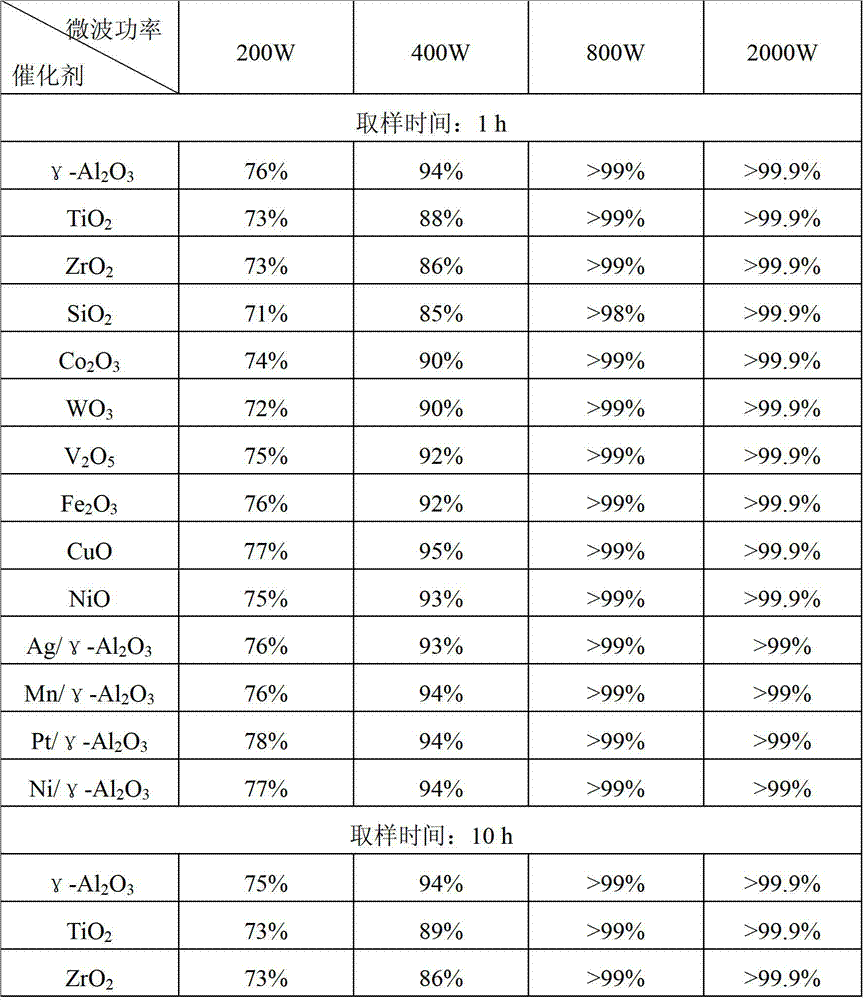

System and method for simultaneously removing carbon tetrafluoride (CF4) and concomitant nitrogen oxide (NOx) gases

InactiveCN102824829AImprove utilization efficiencyEasy to replaceDispersed particle separationMixed gasPollution

The invention provides a system and a method for simultaneously removing carbon tetrafluoride (CF4) and concomitant nitrogen oxide (NOx) gas. The system comprises a flow controller, a plasma reaction device, a catalytic reaction device and a tail gas processing device, wherein the catalytic reaction device is connected between the plasma reaction device and the tail gas processing device through a flange or a screw, so that the catalytic reaction device can be replaced; the catalytic reaction device comprises a silica tube; the silica tube is internally filled with a catalyst bed layer; the outer wall of the silica tube is coated with an insulating layer; the tail gas inlet of the tail gas processing device is connected with an absorption chamber through an inclined pipeline; and the top of the absorption chamber is provided with a tail gas outlet. The method for simultaneously removing CF4 and concomitant NOx gases by virtue of the system is as follows: performing microwave ignition in a quartz tube reactor and carrying out continuous processing on to-be-processed gases; reprocessing the processed mixed gas by virtue of a catalyst; and performing heat preservation on the catalyst by virtue of the insulating layer, thereby simultaneously removing the CF4 and concomitant NOx gases. The system and the method have the characteristics of high CF4 removal efficiency, low energy consumption and no secondary pollution.

Owner:DALIAN MARITIME UNIVERSITY

Method for preparing catalysts for preparing benzenetetracarboxylic anhydride

InactiveCN107649156AGuarantee full expressionGuaranteed activation effectOrganic chemistryCatalyst activation/preparationGas phasePhosphate

The invention discloses a method for preparing catalysts for preparing benzenetetracarboxylic anhydride from durene by means of gas-phase catalytic oxidation. The catalysts comprise spray liquid and carriers. The spray liquid mainly comprises, by weight, 3-5 parts of ammonium metavanadate, 11.2-11.4 parts of oxalic acid, 0.2-0.4 part of diammonium hydrogen phosphate, 0.1-0.3 part of trisodium phosphate anhydrous, 0.18-0.2 part of antimony oxide, 1.1-1.3 parts of ammonium molybdate, 0.98-1 part of potassium hydroxide, 0.6-0.8 part of sodium dihydrogen phosphate, 0.18-0.2 part of potassium carbonate, 0.68-0.7 part of potassium dihydrogen phosphate, 1.16-1.18 parts of potassium phosphate and 8.6-8.8 parts of titanium dioxide powder; the carriers are 78.5-78.7 parts of porcelain rings. The method includes four steps of weighing, liquid preparing, spraying and calcining. The method has the advantages that the catalysts prepared by the aid of the method are good in activity, high in selectivity, low in hotspot reaction temperature and long in service life when applied, and partial energy consumption can be reduced when the catalysts are applied.

Owner:RUGAO CITY LEHENG CHEM COMPANY

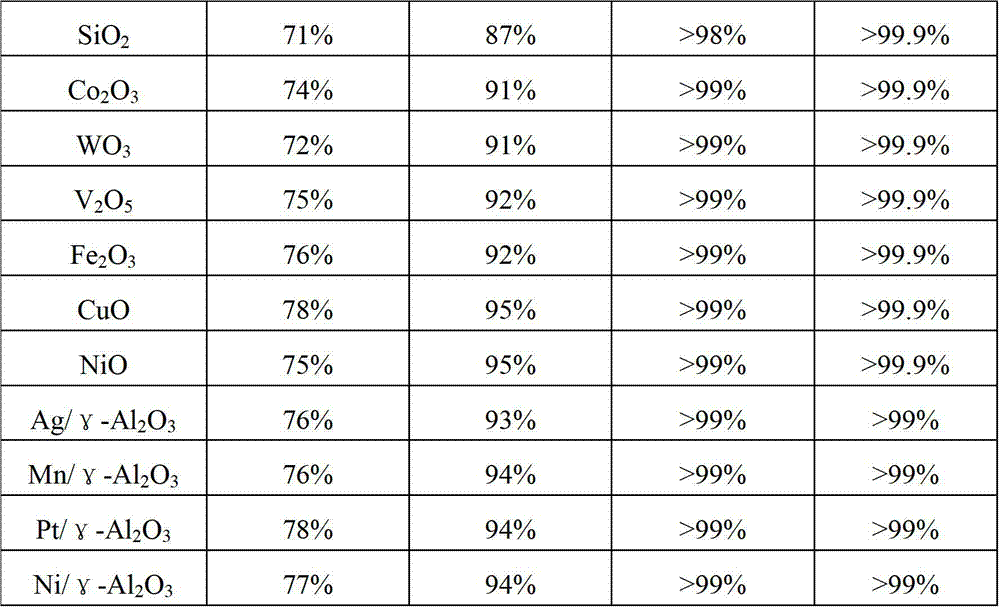

T cell activated by bispecific antibody as well as preparation method and application thereof

ActiveCN105296421AQuality improvementAvoid missingMammal material medical ingredientsAntibody ingredientsAntigenSerum free

The invention relates to a T cell activated by a bispecific antibody as well as a preparation method and an application thereof. The preparation method comprises the following steps: S1, taking peripheral blood for centrifugation, separating cells and blood plasma, inactivating complements in blood plasma, collecting cells and blood plasma for standby; S2, diluting the obtained cells to a suspension, separating mononuclear cells, and washing mononuclear cells for standby; S3, adding the obtained mononuclear cells into a serum-free nutrient solution, adding a bispecific antibody, a target cell, a cytokine and blood plasma, carrying out an incubation and cultivation according to a conventional method, collecting cultivated cells, carrying out centrifugal washing with normal saline for obtaining the T cell activated by the bispecific antibody; the bispecific antibody has a function for activating the T cell, the dissociation coefficient between the bispecific antibody and a T cell surface antigen is higher than 1x10<-7>, and the dissociation coefficient between the bispecific antibody and the target cell surface antigen is lower than 1x10<-9>; the molecular weight of the bispecific antibody is less than 50KD; the T cell activated by the bispecific antibody is obtained by the preparation method.

Owner:高岱清 +1

Activating method for nonmetallic base material surface chemical coated metal

InactiveCN1644758AReduce dosageReduce manufacturing costLiquid/solution decomposition chemical coatingBiological activationSurface chemical

The invention was about a technology of Ag-Pa compound activation, the non-metal material was activated by Ag and Pa, the other metal was plating the surface of it. Ag concentration of activate solution was 0.06-2g / L, Pa concentration of activate solution was 0.006-0.06g / L, the activate time was more than 10 seconds while the material activated in the Ag activate solution, more than 20 seconds in the Pa activate solution, the activate temperature was 40-60 deg.C. Its advantages include good activation, saving the use level of metal; fit for a lot of material; suit for the technology plating in the later process; fit for commercial production.

Owner:HUNAN CORUN NEW ENERGY CO LTD

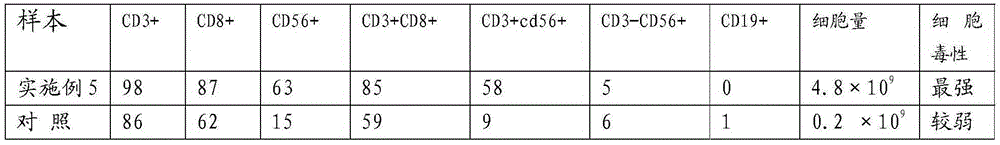

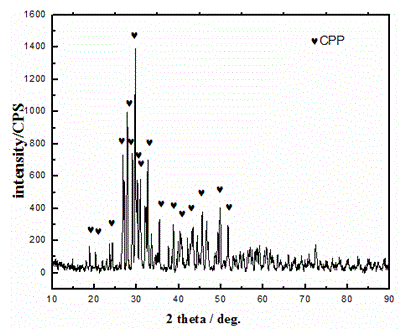

Titanium alloy / calcium pyrophosphate surface bio-composite material and preparation method thereof

ActiveCN104857562AEvenly distributedGuaranteed activation effectCoatingsProsthesisNiobiumLayer thickness

The invention discloses a titanium alloy / calcium pyrophosphate surface bio-composite material and a preparation method thereof, and belongs to the field of biomedical materials. The surface composite material uses as titanium alloy as the matrix, and calcium pyrophosphate and zirconium as a bio-ceramic layer. The process comprises the steps of: subjecting the titanium, niobium and zirconium powder to mechanical alloying for 6-8h and drying to obtain a titanium alloy mixed powder; milling and mixing the calcium pyrophosphate with the zirconium powder for 1-2h and drying to obtain a mixed calcium pyrophosphate powder; and respectively filling the titanium alloy mixed powder and calcium pyrophosphate mixed powder into an upper layer and a lower layer of a graphite mold by means of an auxiliary device, compacting, and sintering in a plasma sintering furnace to obtain the titanium alloy / calcium pyrophosphate surface bio-composite material. The surface composite material prepared by the invention has good interface combination, suitable strength and excellent surface biological activity, reaches composite layer thickness of 10mm, and can be used in human hard tissue replacement and repair. The manufacturing process is clean, simple in process, low in cost, and easy to achieve industrialization production.

Owner:KUNMING UNIV OF SCI & TECH

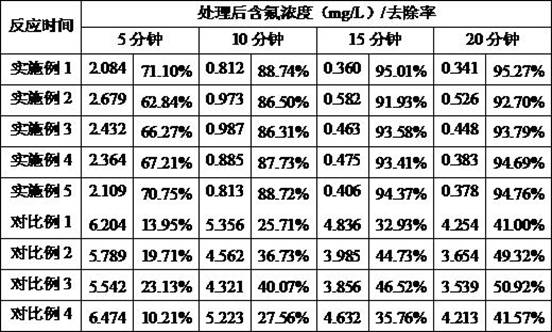

Water treatment defluorination agent and preparation method thereof

PendingCN113401996AHigh fluoride removal rateGood defluoridation effectWater contaminantsWater/sewage treatment by flocculation/precipitationCelluloseAluminium chloride

The invention discloses a preparation method of a water treatment defluorination agent. The preparation method is characterized by comprising the following steps: step 1, preparing a sodium silicate solution, and adding a diluted hydrochloric acid solution for activation to obtain a solution A; step 2, weighing a first fixed amount of aluminum chloride hexahydrate solid, adding the aluminum chloride hexahydrate solid into the solution A, stirring for 10-30 minutes, continuously weighing a second fixed amount of ferric chloride hexahydrate solid, slowly adding the ferric chloride hexahydrate solid into the solution until the color of the solution becomes dark and turbid, continuously stirring, gradually clarifying the solution, and finally turning into a reddish brown transparent solution, so as to obtain a solution B; step 3, preparing a sodium carboxymethyl cellulose solution, namely a solution C; and step 4, placing the prepared solution B and the solution C in a constant-temperature water bath kettle according to the proportion, fully mixing and reacting in a high-speed stirring and heating state, and after the reaction is finished, obtaining the final defluorination agent solution. The fluorine removal rate of the deep defluorination agent can reach 95% or above, the fluorine removal rate is high, the fluorine removal effect is obvious, and deep fluorine removal of fluorine-containing wastewater can be achieved.

Owner:神美科技有限公司

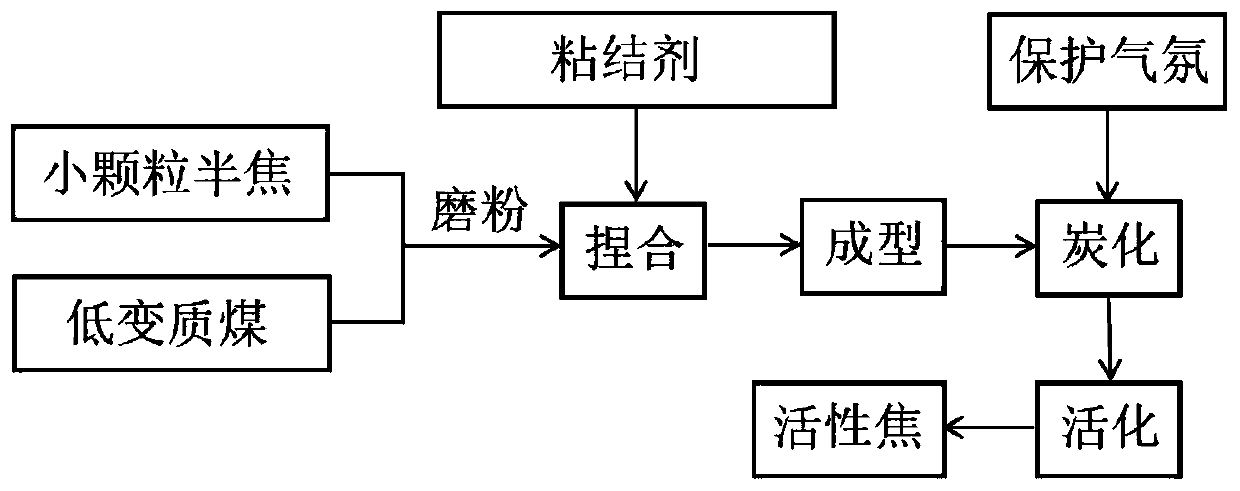

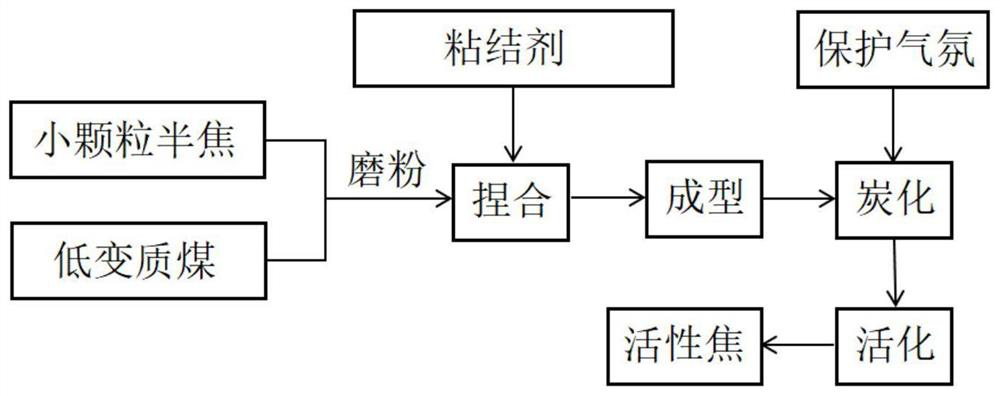

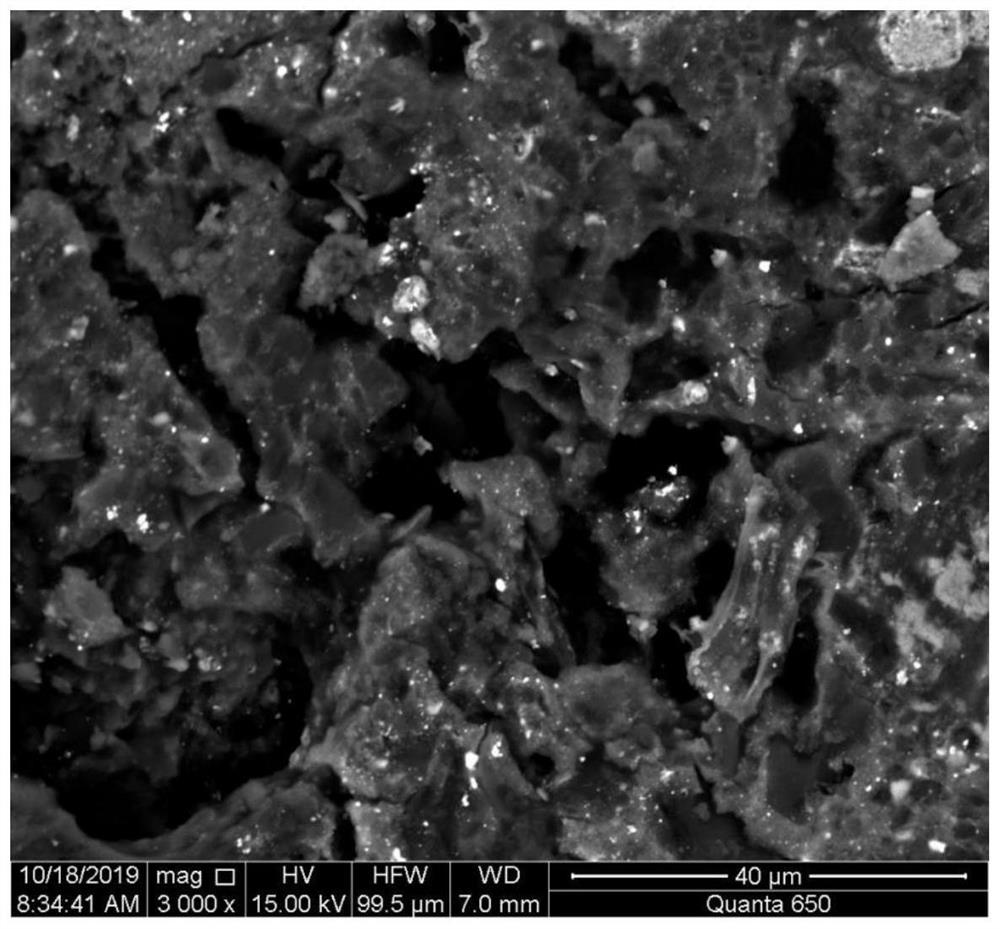

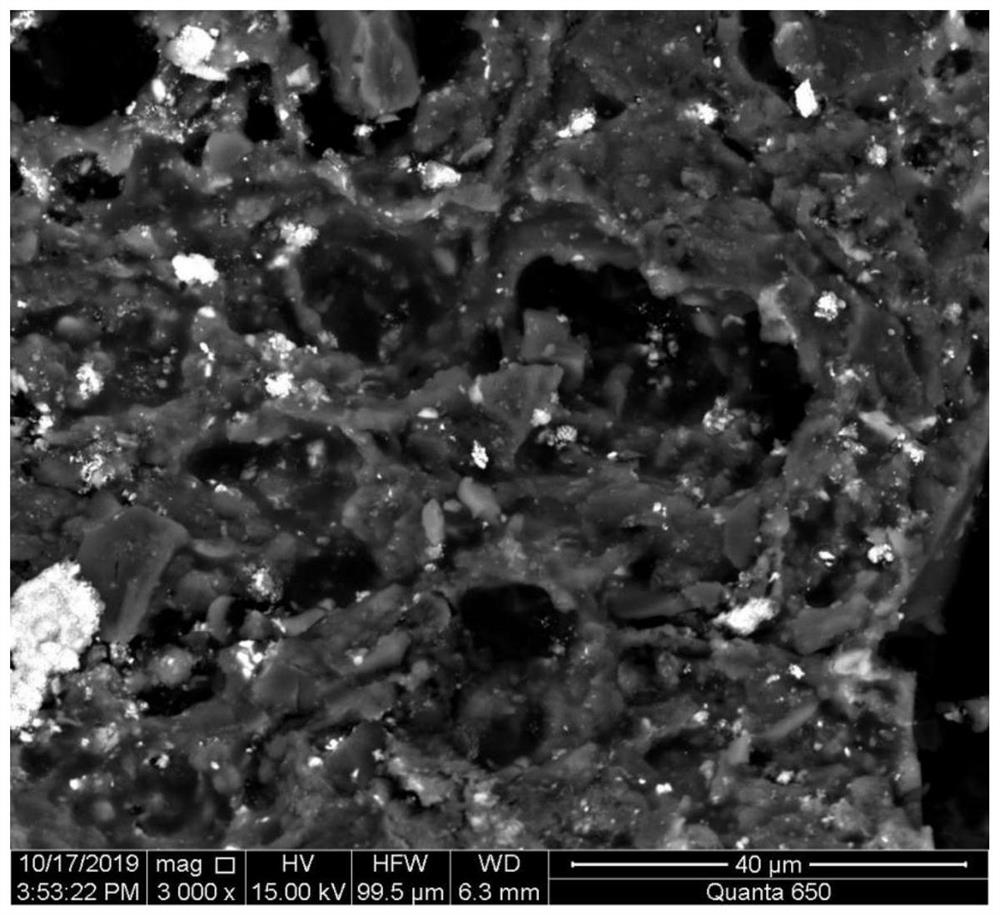

Active coke for flue gas desulfurization, and preparation method thereof

ActiveCN111054310AImprove adsorption capacityReduce manufacturing costGas treatmentCarbon compoundsSodium BentoniteCoal

The invention belongs to the technical field of comprehensive utilization of resources, and relates to an active coke for flue gas desulfurization, and a preparation method thereof. The preparation method comprises the following steps: mixing low metamorphic pulverized coal, semicoke powder, phenolic resin, sodium humate and sodium bentonite to obtain a mixture A, wherein the mixture Acontains, bymass, 35-42.5% of the low metamorphic pulverized coal, 35-42.5% of the semicoke powder, 5-15% of the phenolic resin, 5-15% of sodium humate and 5-15% of sodium bentonite; adding an ethanol solution of which the solute mass is 8-10% and deionized water into the mixture, uniformly mixing, and performing compression molding under the pressure of 5-7 MPa to obtain formed material strips; drying the formed material strips; carbonizing and activating the dried formed material strips in a protective atmosphere; and carrying out activation treatment to obtain the active coke material for flue gas desulfurization. The method is simple in process and low in cost, and opens up a new development and application way for high-added-value utilization of the low-rank coal.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +1

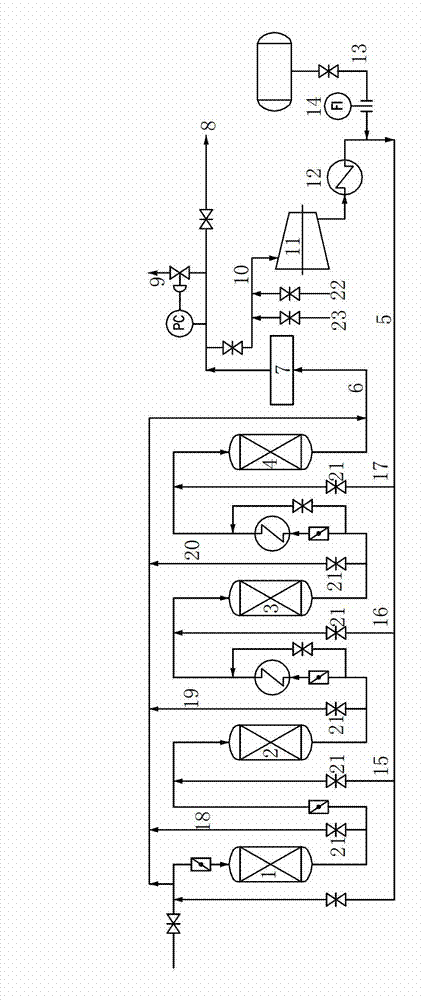

Individual activating process for catalysts in converting furnaces of CO (carbon oxide) sulfur-resistant converting device

The invention relates to an individual activating process for catalysts in converting furnaces of a CO (carbon oxide) sulfur-resistant converting device. The activating process is characterized in that: a heating vulcanization line is arranged at an inlet of each of the converting furnaces, and an emptying line is arranged at an outlet of each of the converting furnace, so that after the catalyst in each converting furnace is changed, the converting furnace can be separated from a system, and then, the converting furnace can be heated and vulcanized individually. In comparison with the prior art, the individual activating process for the catalysts in the converting furnaces of the CO sulfur-resistant converting device, disclosed by the invention, effectively improves production efficiency and reduces activation cost of the catalysts; in addition, a supplement position of a vulcanizer is arranged at an outlet of a heater, so that the vulcanizer can be guaranteed to be vaporized sufficiently to be mixed with nitrogen sufficiently and uniformly, and further, the activation effect is guaranteed.

Owner:CHINA PETROCHEMICAL CORP +2

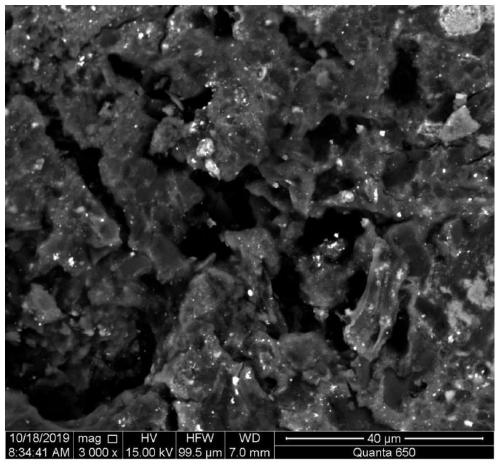

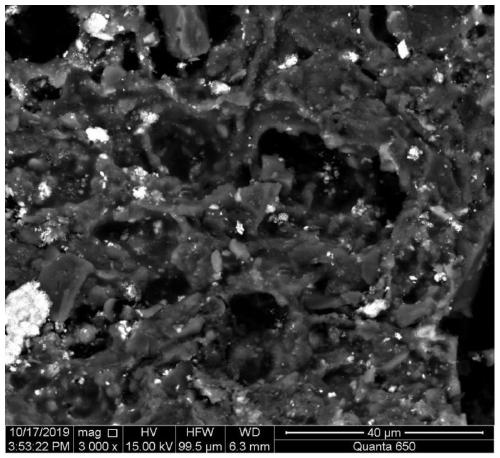

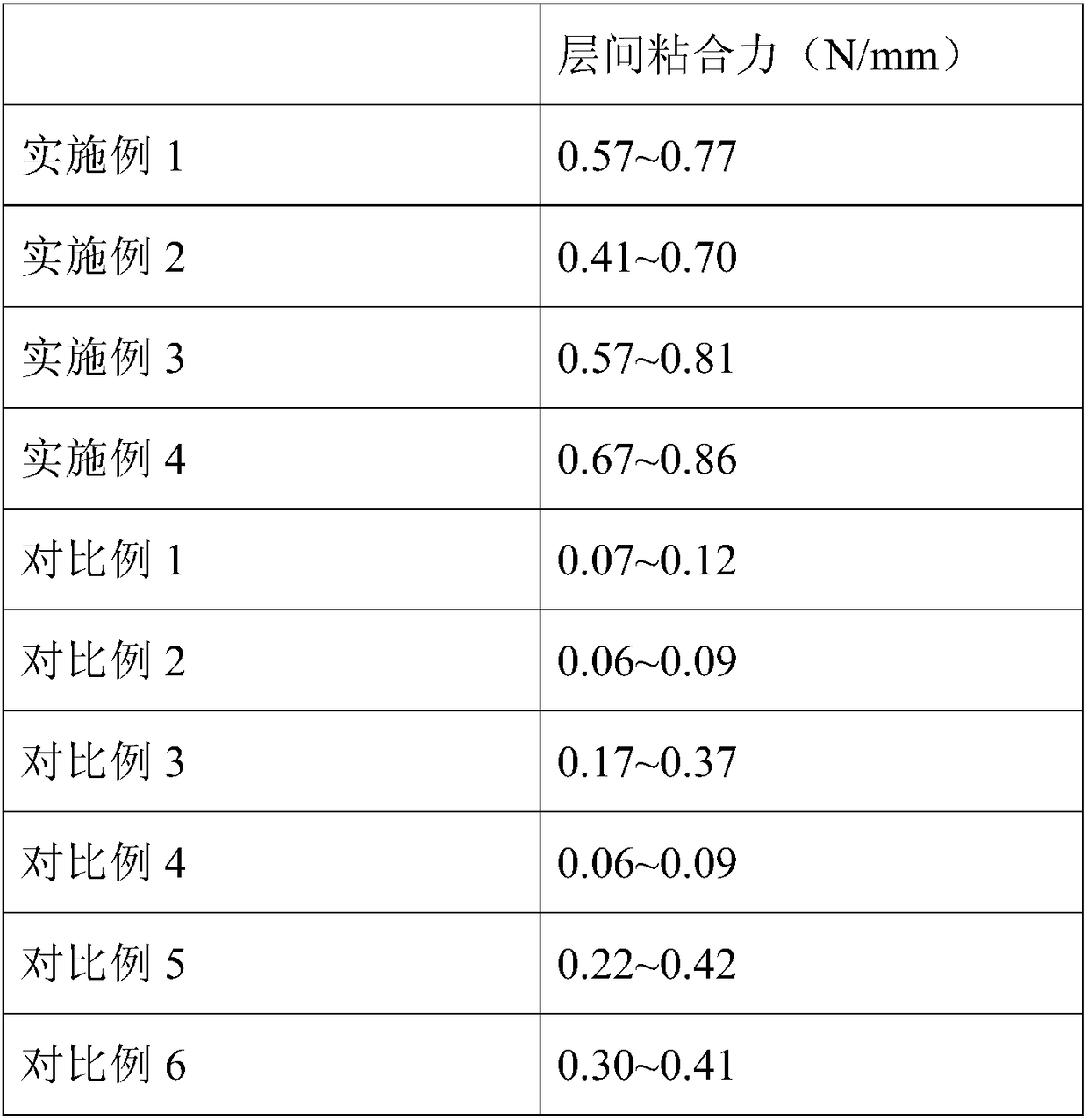

Manufacturing method of PTFE-containing multilayered PCB

InactiveCN108449890AGuaranteed activation effectMultilayer circuit manufactureEtchingPhysical chemistry

The invention relates to a manufacturing method of a PTFE-containing multilayered PCB. The manufacturing method comprises the following steps of (1) providing a PTFE substrate adopting an RTF copper coil; (2) performing circuit etching, and not forming a brown line on the circuit-etched PTFE substrate; (3) performing plasma surface plasma activation treatment on the surface of the etched PTFE substrate; (4) performing a laminating procedure, and controlling the residence time before lamination to be within 4h; and (5) completing lamination to obtain the PTFE-containing multilayered PCB. By adjusting the PCB design, the technological flows and the involved parameters, the interlayer adhesive force between PP and the substrate is increased to the maximum degree, thereby solving the problem of adhesive force between the PTFE multilayered board and PP.

Owner:GUANGDONG SHENGYI SCI TECH

Benzene tetramethyl acid dianhydride catalyst and preparation method thereof

InactiveCN106423237AActiveHigh selectivityOrganic chemistryPhysical/chemical process catalystsAntimony oxideBenzene

The invention relates to a tetramethyl benzene catalytic oxidation prepared benzene tetramethyl acid dianhydride catalyst, including a spray solution and a carrier, the spray solution comprises by weight of 3-5 parts of partial ammonium vanadate, 11.2-11.4 parts of oxalic acid, 0.2-0.4 part of diammonium hydrogen phosphate, 0.1-0.3 part of sodium phosphate, 0.18-0.2 part of antimony oxide, 1.1-1.3 parts of ammonium molybdate, 0.98-1 part of potassium hydroxide, 0.6-0.8 part of sodium dihydrogen phosphate, 0.18-0.2 part of potassium carbonate, 0.68-0.7 part of potassium dihydrogen phosphate, 1.16-1.18 parts of potassium phosphate and 8.6-8.8 parts of titanium dioxide; the carrier is a 78.5-78.7 parts of ceramic ring; and the catalyst is prepared through the four steps of weighing, apportioning, spraying and roasting. The advantages of the provided catalyst are characterized in that when applying, the catalyst has relatively good activity, high select ability, low heat point reaction temperature, long service life, low energy consumption for certain resources.

Owner:RUGAO CITY LEHENG CHEM COMPANY +1

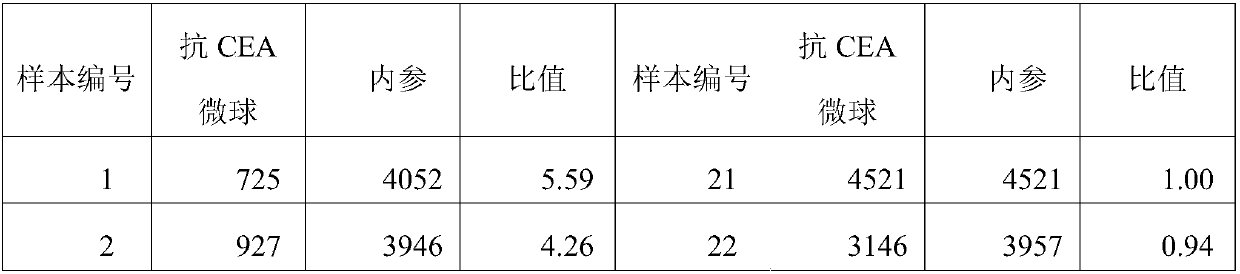

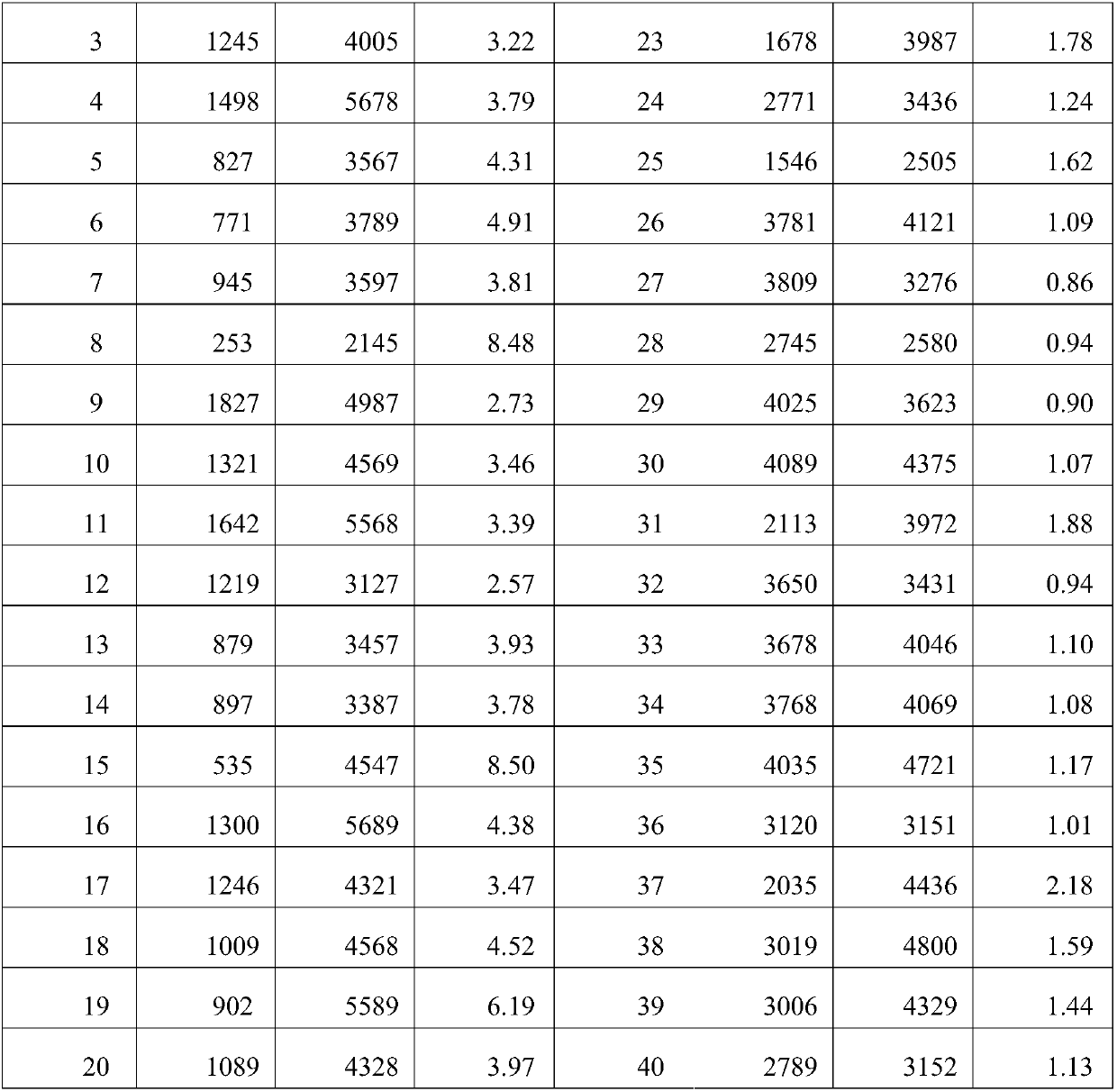

Tumor detection sample, preparation method therefor and application thereof

The invention relates to the field of molecular biology, and particularly discloses a tumor detection sample, a preparation method therefor and an application thereof. The detection sample is a "magnetic bead-secondary antibody-antigen-capture antibody-microsphere" penta-complex. The preparation method of the tumor detection sample comprises: preparing a "secondary antibody-magnetic bead" complex;coupling the secondary antibody with superparamagnetic nanospheres; corresponding the secondary antibody to the antigen and the capture antibody respectively; and binding with the capture antibody ondifferent epitopes of the antigen respectively. The tumor detection sample of the invention is mainly applied to quantitatively detect a tumor marker and at the same time, quantitatively detect different antigens, and solves problems that a fluorescent reporter molecule in the prior art is easy to quench, photosensitivity is low, there is no accurate basis for a quantitative analysis, and detection flux has a certain limitation.

Owner:ARMY MEDICAL UNIV

Nickel pre-plating process suitable for battery shell steel

InactiveCN106567113AImprove the quality of nickel platingGuaranteed bonding strengthStrip steelBiological activation

The invention relates to a nickel pre-plating process suitable for battery shell steel. The nickel pre-plating process suitable for the battery shell steel comprises the following process steps: 1) chemical deoiling; 2) electrolytic deoiling; 3) washing with water; 4) primary activation; 5) secondary activation; and 6) pre-plating. Through the process method, the activation effect can be guaranteed, over corrosion can also be prevented, the bonding strength of a pre-plating layer and the surface of strip steel can be guaranteed, and the quality of a finished nickel plated battery shell steel product is improved.

Owner:JIANGSU JIUTIAN PHOTOELECTRIC TECH CO LTD

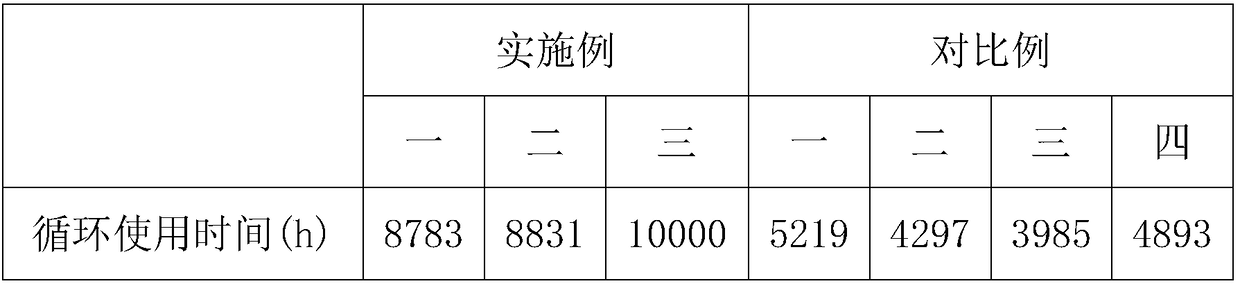

Activating method for high-nickel catalyst

InactiveCN108816295ALow costEfficient removalCatalyst regeneration/reactivationNickel catalystDistillation method

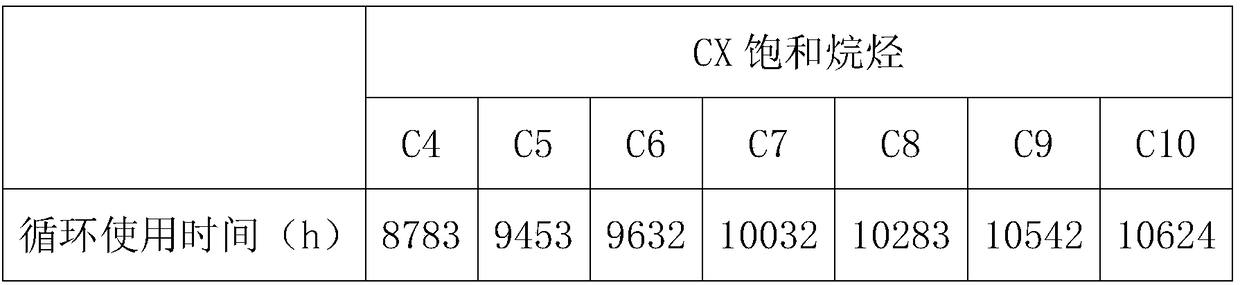

The invention provides an activating method for a high-nickel catalyst. The activating method comprises following steps: S1, regeneration of the high-nickel catalyst: the high-nickel catalyst enteringthe last stage is added to a reaction kettle, temperature and pressure of the reaction kettle are controlled, an activating agent is introduced into the reaction kettle, the introduction time is notshorter than 36 h, the high-nickel catalyst is activated, after the activation is finished, the activating agent and the high-nickel catalyst are separated, the activated high-nickel catalyst and theused activating agent are obtained, and the activated high-nickel catalyst can be used again after vacuum drying; S2, regeneration of the activating agent: the used activating agent obtained by separation in the step S1 is regenerated with a distillation method, and the regenerated activating agent is applied to the regeneration of the high-nickel catalyst. The activating method has good activating effect on the high-nickel catalyst, molecular crystal form of the activated high-nickel catalyst is not changed obviously, pore channels have no apparent collapse, and the high-nickel catalyst can be continuously recycled for 8000-10000 h.

Owner:濮阳市联众兴业化工有限公司

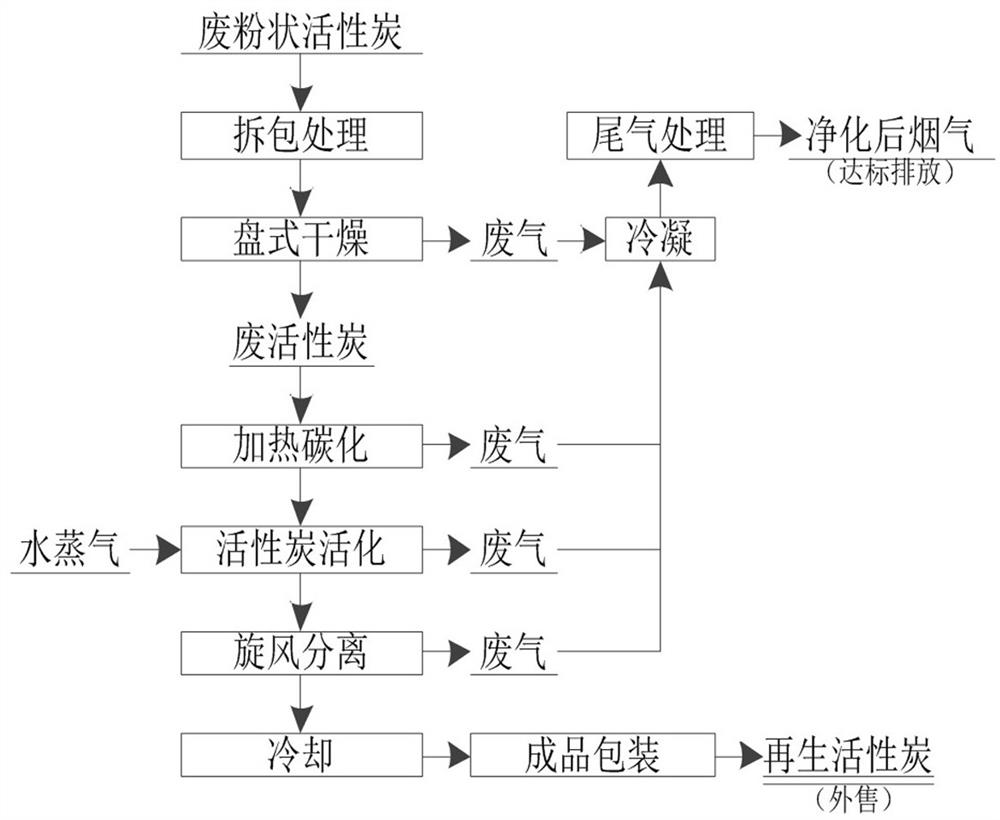

Regeneration method of waste powdered activated carbon

PendingCN111617751ACompletely decompose and removeSolve problems such as sticking and bad smellOther chemical processesCombustible gas purificationActivated carbonCarbonization

The invention discloses a regeneration method of waste powdered activated carbon. Waste activated carbon is fully recycled; resource waste and environmental pollution are avoided; the regeneration method conforms to circular economy principle; the positive effects of energy conservation and emission reduction are achieved; an indirect heating carbonization and activation two-step method is adopted; organic matters can be thoroughly removed from the source; the waste activated carbon can be fully activated, so that the quality of the waste activated carbon is guaranteed; the whole production process is in an oxygen-free environment, so that the organic matters are fully carbonized to finally form fixed carbon to be adhered to the activated carbon, the effective activated carbon is preventedfrom being burnt and wasted, meanwhile, fixed carbon after carbonization of the organic matters is collected, the waste is fully utilized, and meanwhile, the risk of dust explosion is also avoided due to the oxygen-free atmosphere.

Owner:江苏双优环境科技有限公司

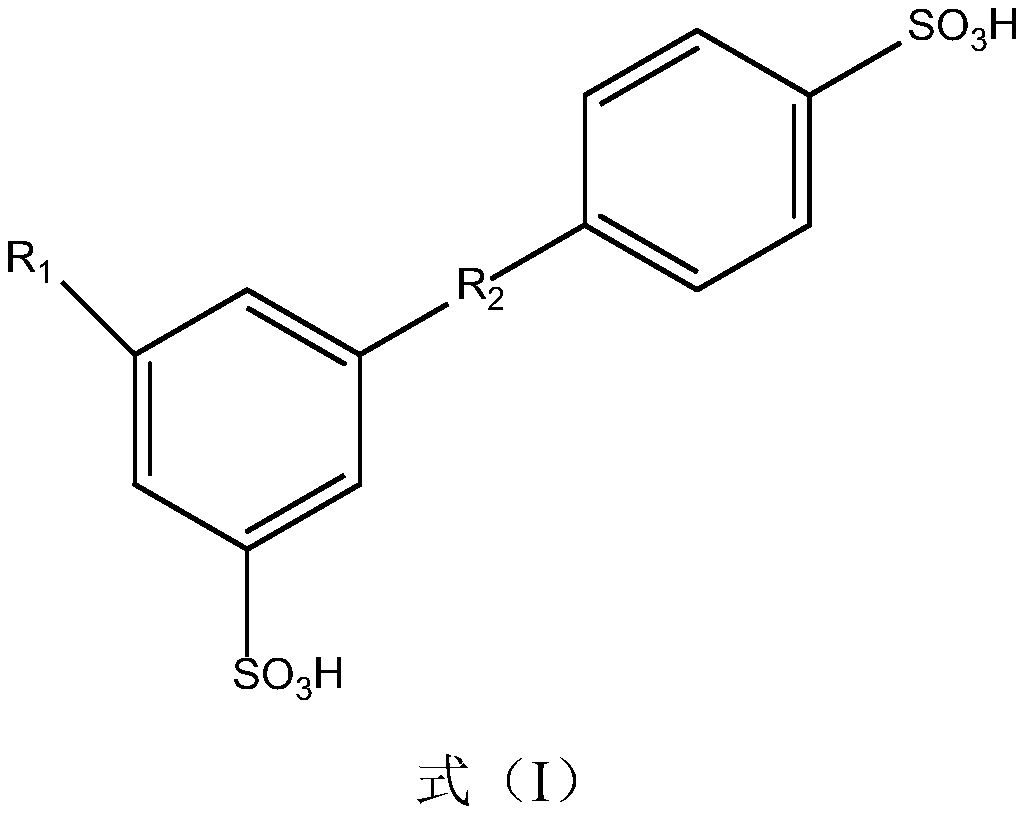

Novel application of sulfonic acid group aromatic compounds

ActiveCN110042372ALarge adsorption capacityGuaranteed adsorption effectLiquid/solution decomposition chemical coatingChemistryCopper plating

The invention relates to a novel application of sulfonic acid group aromatic compounds, and in particular relates to the sulfonic acid group aromatic compounds with the structure in the formula (I) orapplication of salt of the sulfonic acid group aromatic compounds in electroless copper plating on surface of non-metal base materials substrate; pre-immersion liquid treatment of the non-metal basematerials using sulfonic acid group aromatic compounds with the structure in the formula (I), and after the activation step, enabling the palladium ions to be more uniformly adsorbed on the base materials, the adsorption amount is large. The adsorption amount of the palladium can be ensured even in an activation solution with relatively low concentration of the palladium ions.

Owner:GUANGDONG TONESET SCI & TECH

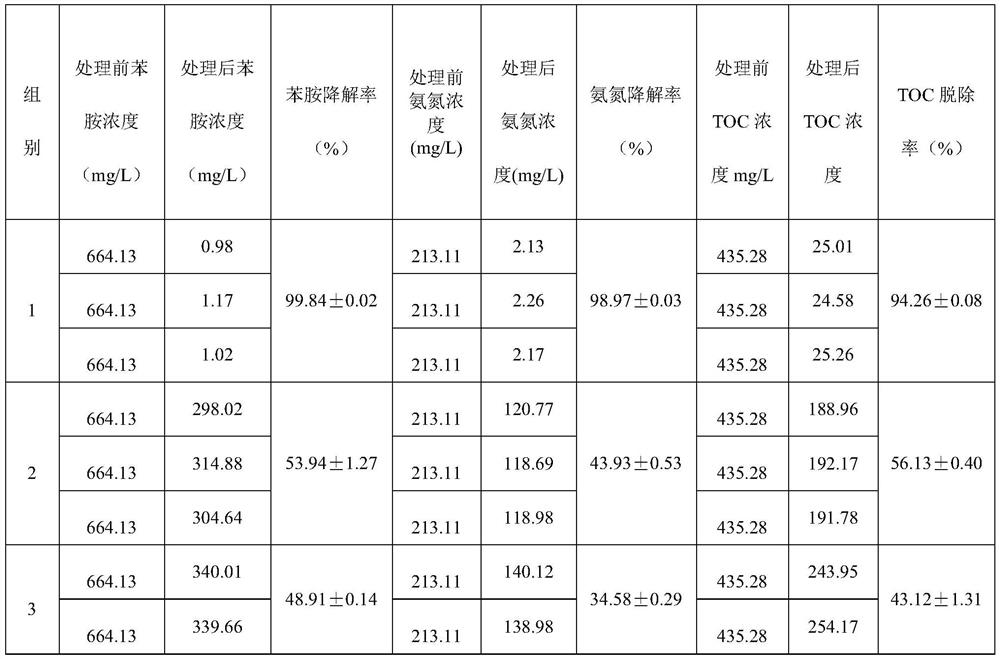

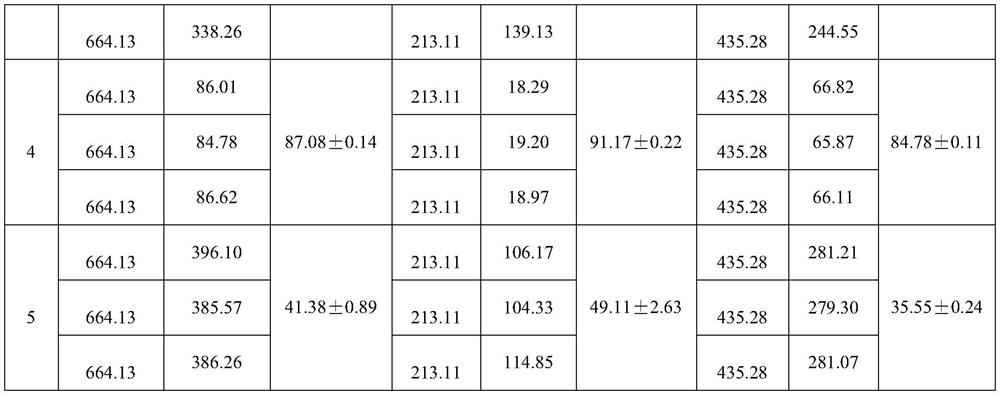

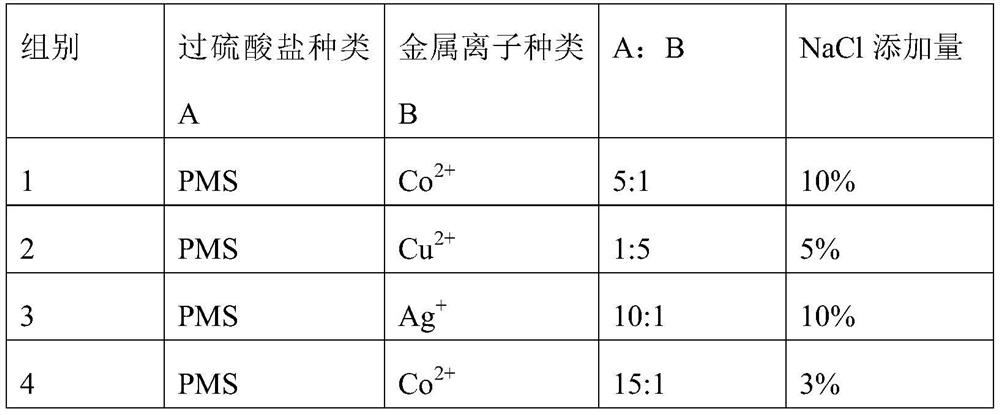

Wastewater treatment preparation and preparation method thereof

PendingCN114656041AGuaranteed activation effectGuaranteed treatment effectWater contaminantsBiological water/sewage treatmentPoly ethyleneSewage treatment

The invention relates to the field of sewage treatment, and discloses a wastewater treatment preparation and a preparation method thereof.The wastewater treatment preparation is prepared from, by mass, 12-15 parts of stearoyl glutamate, 10-15 parts of glucose, 15-20 parts of silica gel powder, 3-5 parts of persulfate, 1-5 parts of polyvinylpyrrolidone and 10-30 parts of complex microbial inoculants; the persulfate is subjected to metal ion activation treatment; the composite microbial agent comprises a carrier and a composite microbial agent, wherein the composite microbial agent comprises 3-5 parts of bacillus, 3-5 parts of pseudomonas putida, 5-10 parts of candida mycoderma bacteria, 1-3 parts of nitrosobacteria, 3-5 parts of nitrifying bacteria and 1-5 parts of denitrifying bacteria. The method provided by the invention has an outstanding degradation effect on aniline in wastewater, has excellent flocculation and ammonia nitrogen degradation effects, and has very high popularization and application values.

Owner:CHONGQING UNIV

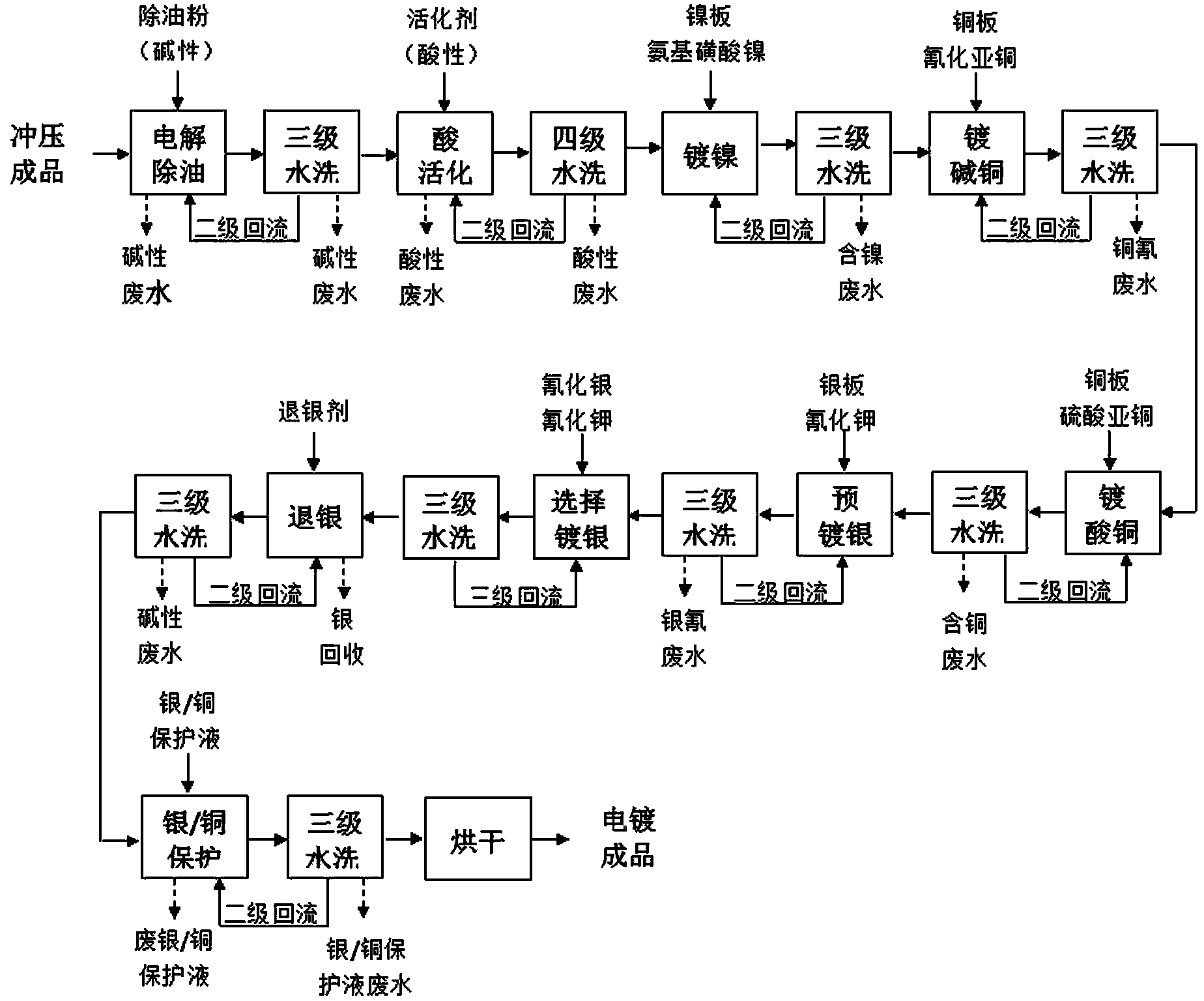

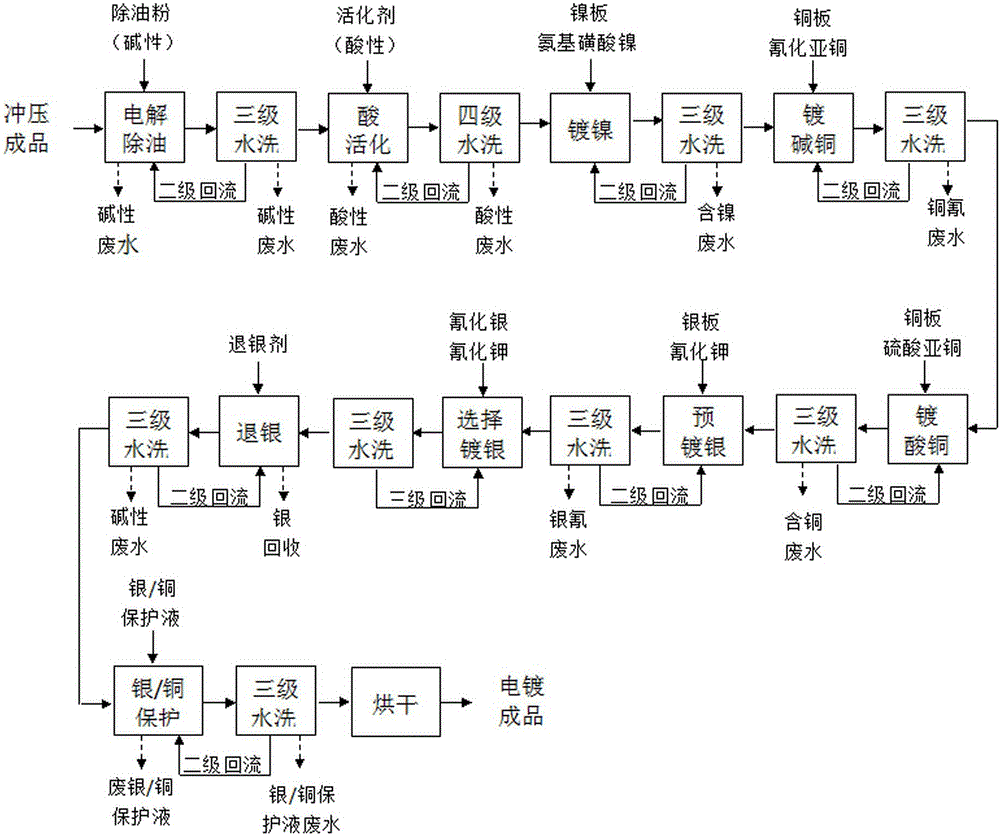

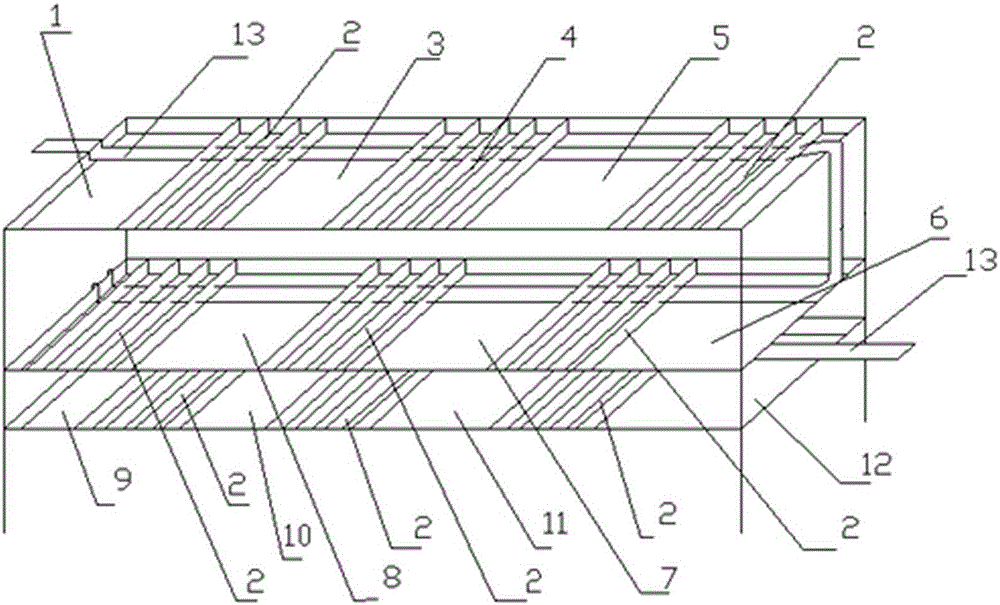

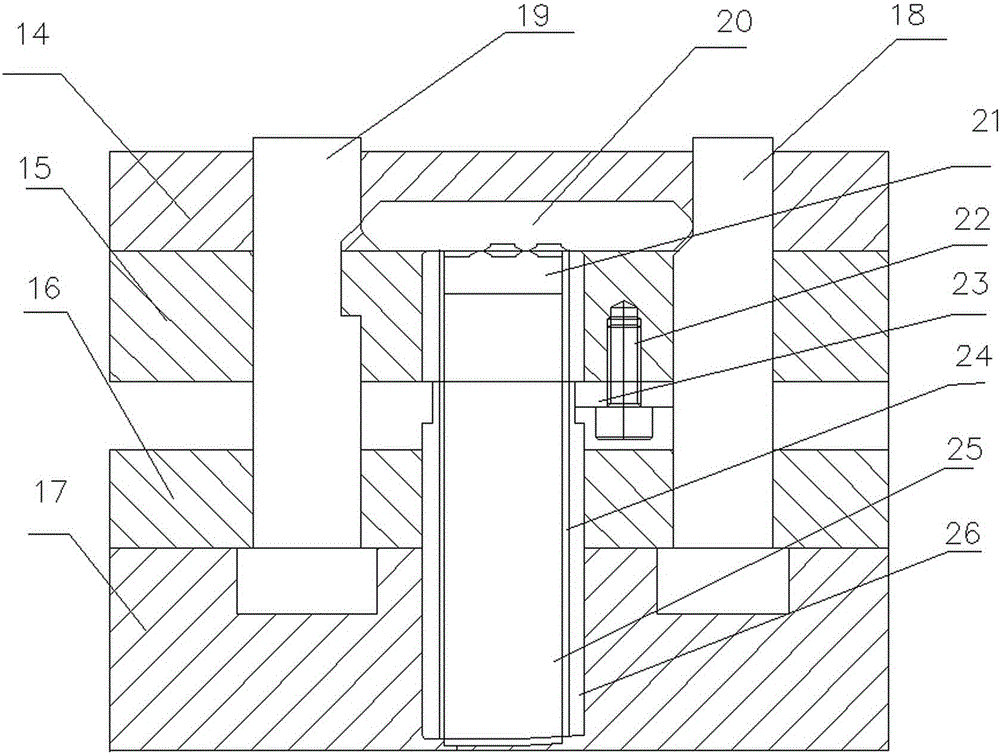

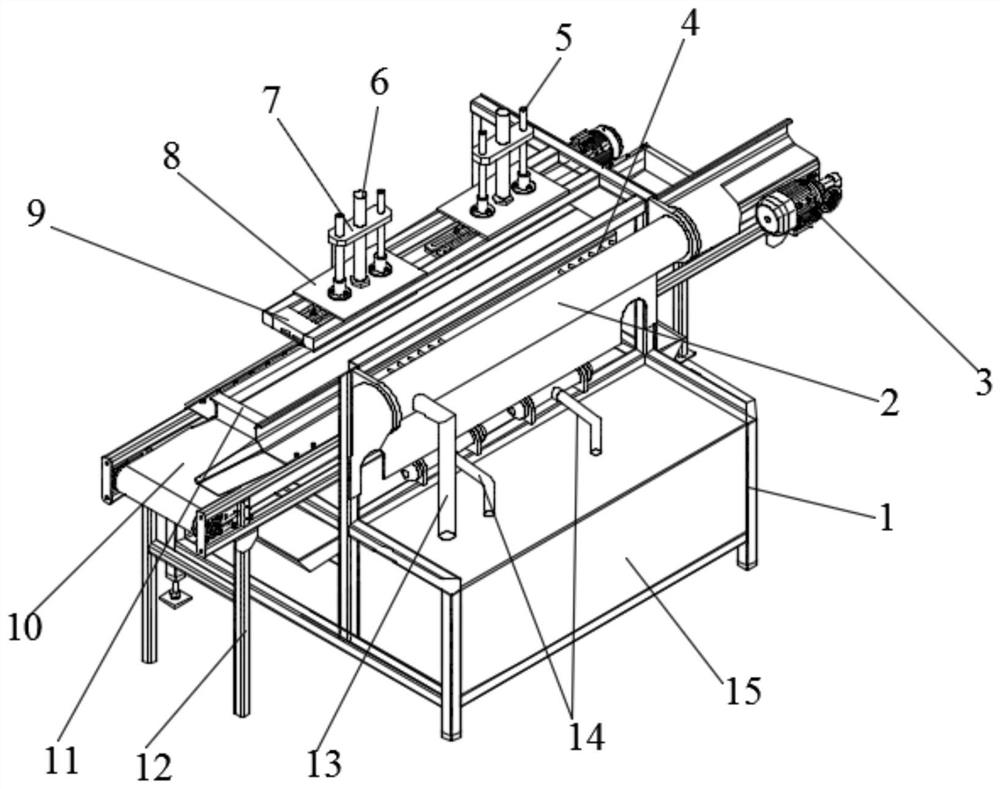

A kind of semiconductor lead frame manufacturing process

ActiveCN103928302BQuality improvementStrong adhesionSemiconductor/solid-state device detailsSolid-state devicesManufacturing technologyCopper plating

The invention relates to a semiconductor lead frame manufacturing technology which comprises the steps of stamping, surface treatment and cut-forming. The technology is characterized in that the surface treatment process specifically comprises the steps of electrolytic degreasing, washing, acid activation, washing, nickel plating, washing, alkaline copper plating, washing, acid copper plating, washing, silver preplating, washing, silver plating, silver removing, washing, protective solution plating, washing and drying. Plated layers of a semiconductor lead frame manufactured with the method are high in adhesive force and do not fall off easily. Meanwhile, the semiconductor lead frame is free of deformation and oversize, high in quality, and long in service life.

Owner:SICHUAN JINWAN ELECTRONICS

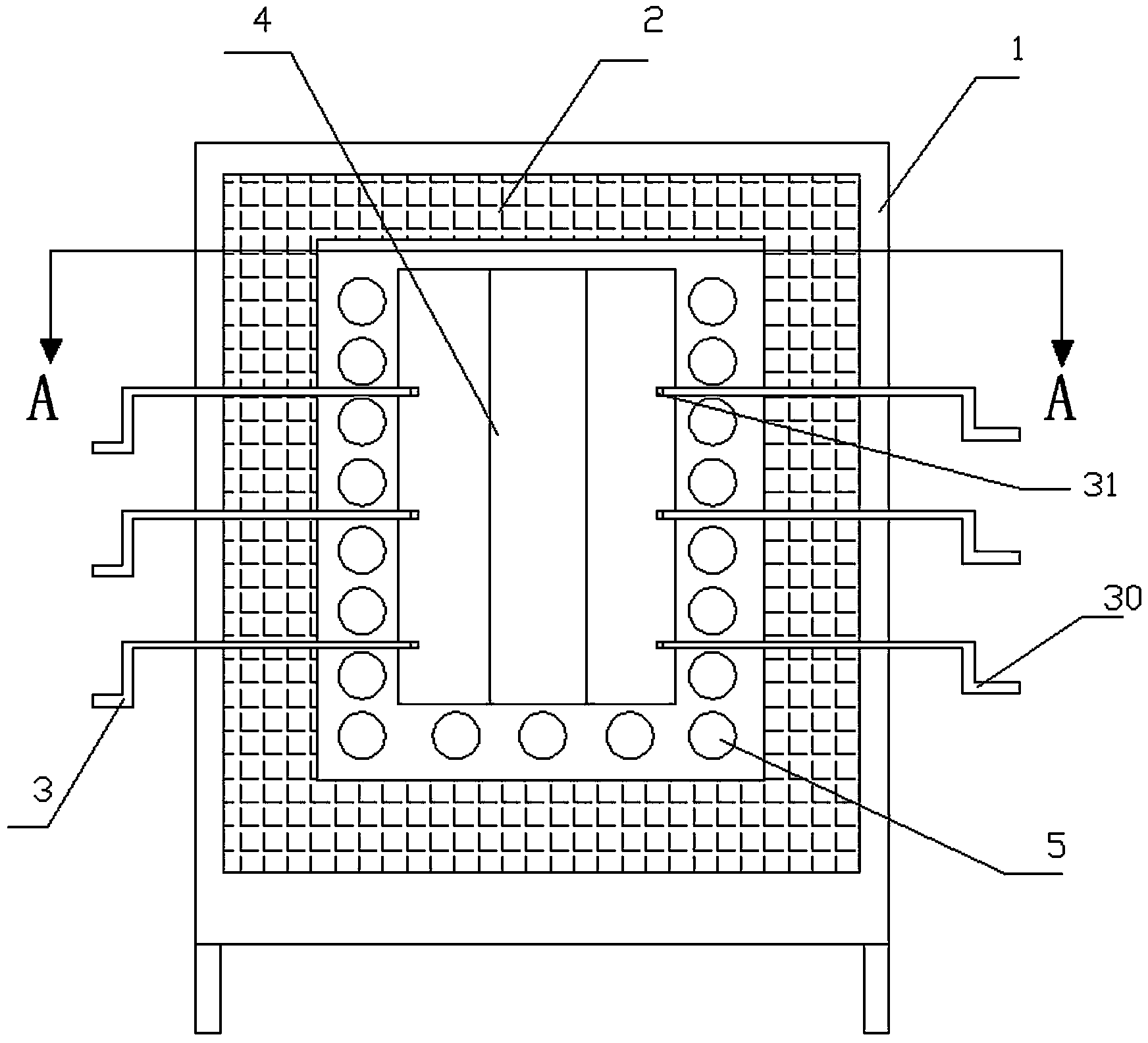

Purifying catalyst plate activating device for indoor air purification of high-rise resident

ActiveCN114272727AGuaranteed impactAvoid lostDispersed particle separationLiquid spraying apparatusHigh activationControl theory

The invention discloses a purification catalyst plate activation device for indoor air purification of high-rise residents, during activation, high-frequency oscillation of a voice coil motor and high-frequency oscillation of ultrasound are utilized to effectively improve the ability of an activation solution to permeate into a membrane and ensure the activation effect, and in addition, the combination of the voice coil motor and the ultrasound effectively exerts the oscillation advantages of the voice coil motor and the ultrasound, so that the activation effect is improved. A voice coil motor is further arranged at the upper end of the ultrasonic activation mechanism, the voice coil motor enables the ultrasonic activation mechanism to perform high-frequency oscillation in the vertical direction, the activation liquid is sprayed while oscillation is performed, and therefore the activation performance is improved, the impact capacity of the activation liquid on a film is guaranteed, and the activation permeability is further improved. The high-frequency jet activation liquid effectively ensures the kinetic energy of activation, improves the activation effect and efficiency, has a better effect than the effect of simply arranging an ultrasonic generator in water, effectively solves the problem of ultrasonic momentum loss caused by water when the ultrasonic generator is simply arranged in water, and improves the activation effect and the ultrasonic utilization rate.

Owner:长春电子科技学院

Activating method for nonmetallic base material surface chemical coated metal

InactiveCN1325695CReduce dosageReduce manufacturing costLiquid/solution decomposition chemical coatingBiological activationSurface chemical

The invention was about a technology of Ag-Pa compound activation, the non-metal material was activated by Ag and Pa, the other metal was plating the surface of it. Ag concentration of activate solution was 0.06-2g / L, Pa concentration of activate solution was 0.006-0.06g / L, the activate time was more than 10 seconds while the material activated in the Ag activate solution, more than 20 seconds in the Pa activate solution, the activate temperature was 40-60 deg.C. Its advantages include good activation, saving the use level of metal; fit for a lot of material; suit for the technology plating in the later process; fit for commercial production.

Owner:HUNAN CORUN NEW ENERGY CO LTD

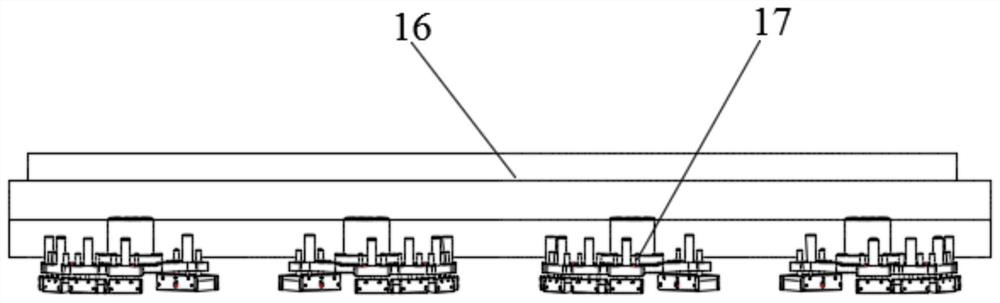

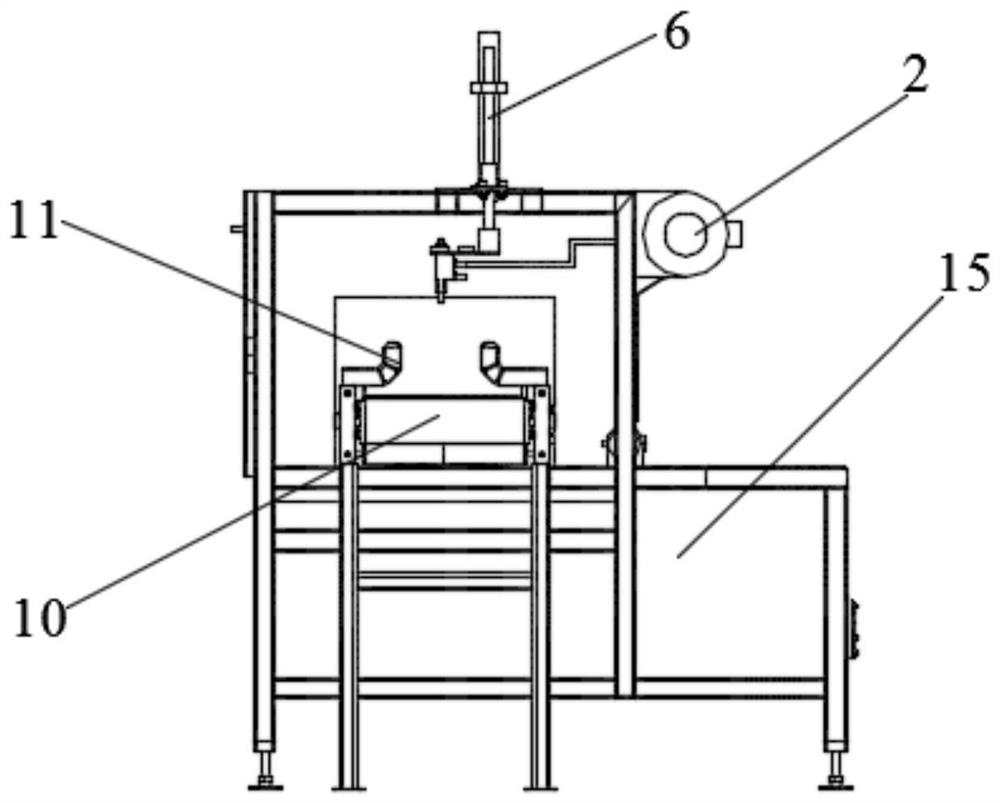

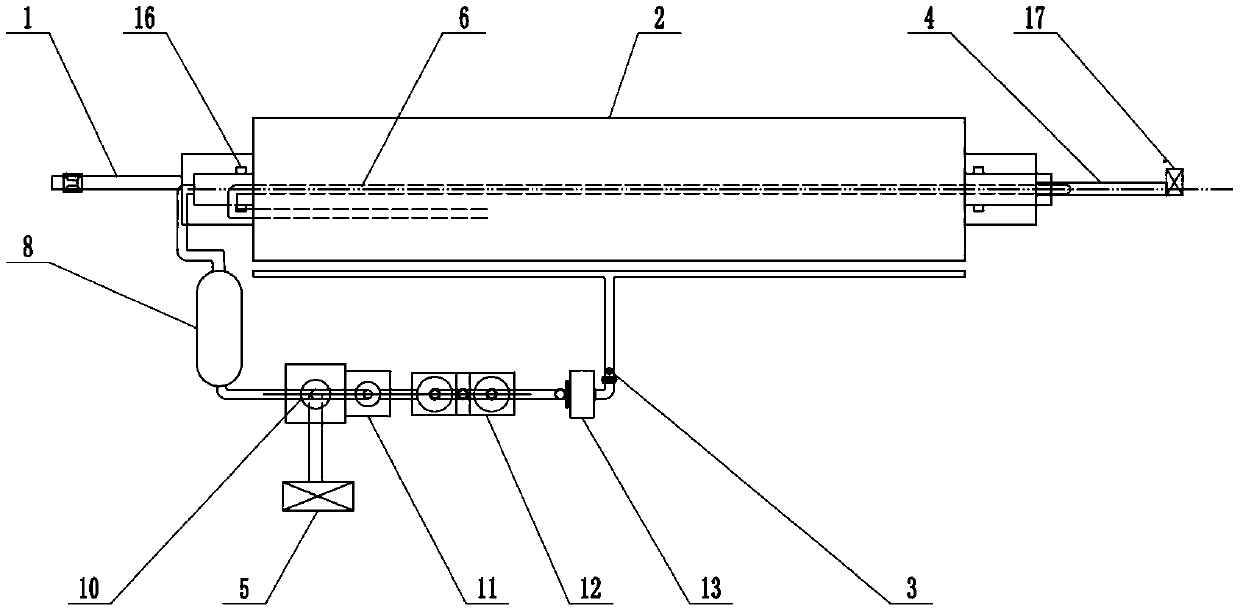

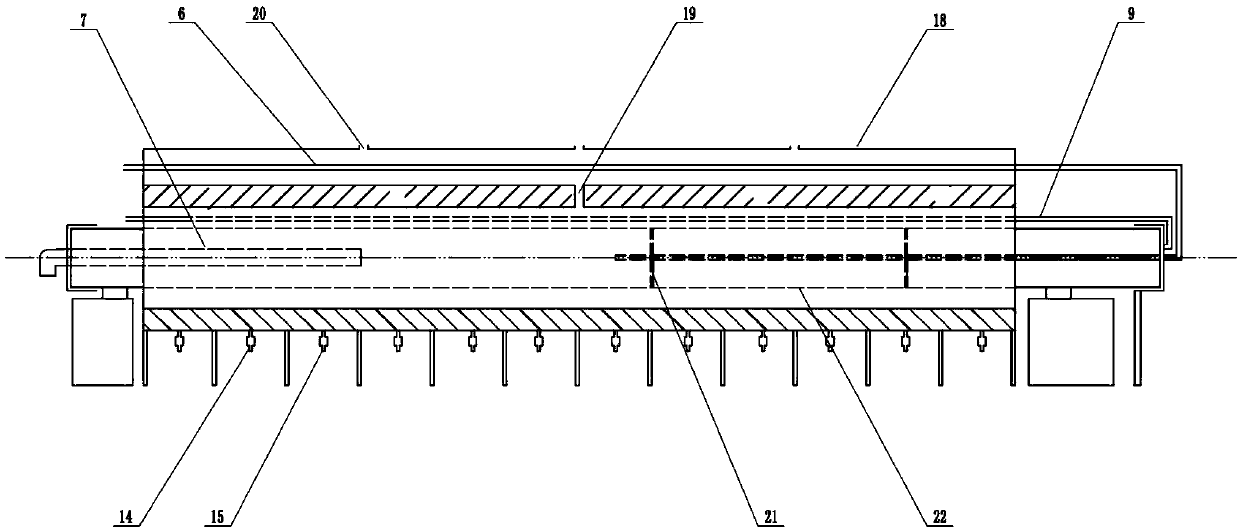

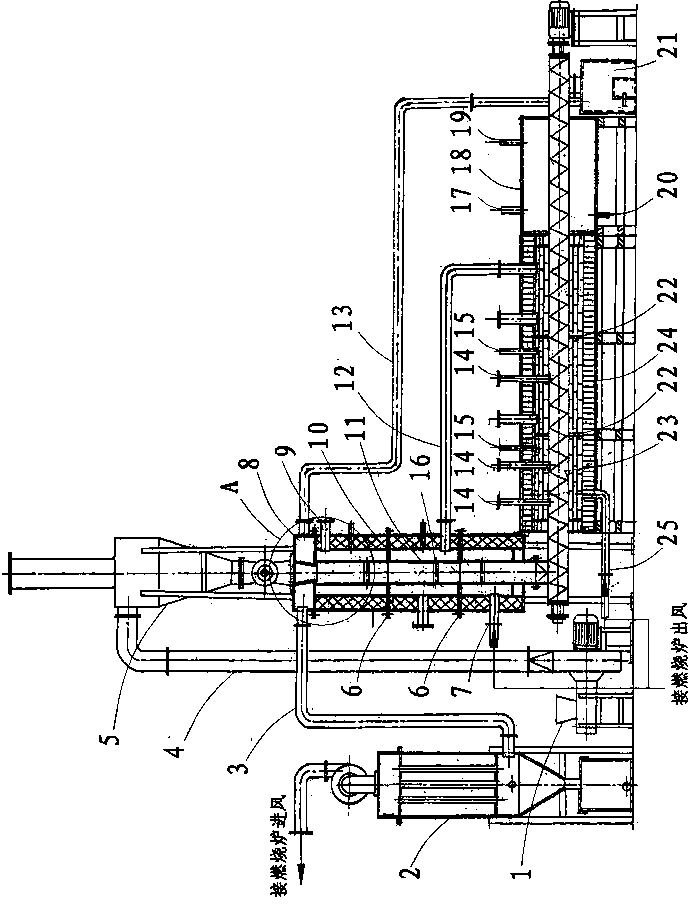

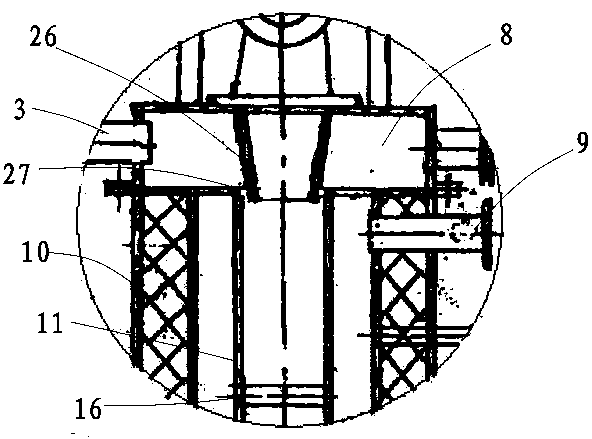

External heat rotary activated carbon high-efficiency and energy-saving production device

ActiveCN106946252BIncrease temperatureImprove activation efficiencyCarbon compoundsEnergy inputActivated carbonProcess engineering

The invention discloses an external heat rotary type activated carbon efficient energy-saving production device which comprises an activating rotary furnace, a main steam generating system and a main heating system. A rotary pipe of the activating rotary furnace comprises a feeding end, a heating region, a high-temperature activating region, a cooling discharging region and a discharging end. The device also comprises a waste heat exchange water steam generating system and a second heating system; a normal temperature circulating water indirect heat-exchange pipeline is connected behind the discharging end; the main steam generating system comprises a biomass steam generator and a main steam pipe; the waste heat exchange water steam generating system comprises a suction pipe, a waste heat exchange water steam generator and a waste heat exchange steam pipe; the second heating system comprises a suction pipe, a waste heat exchange water steam generator, a cyclone dust removal device, a spray water device, a cooling water gas condensing device, a high pressure induced draft fan and a self-sucking open fire fan nozzle. The external heat rotary type activated carbon efficient energy-saving production device disclosed by the invention not only guarantees the activating effect, but also greatly reduces the production energy consumption, and is simple to operate and convenient to maintain and repair.

Owner:无锡市倍力耐工业设备有限公司

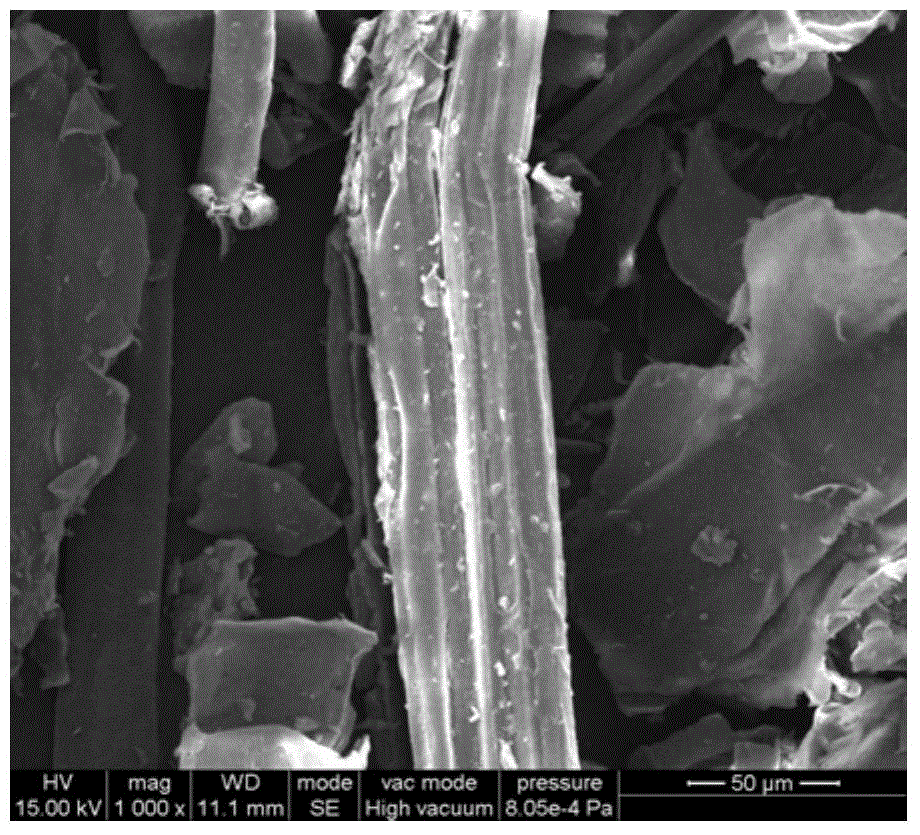

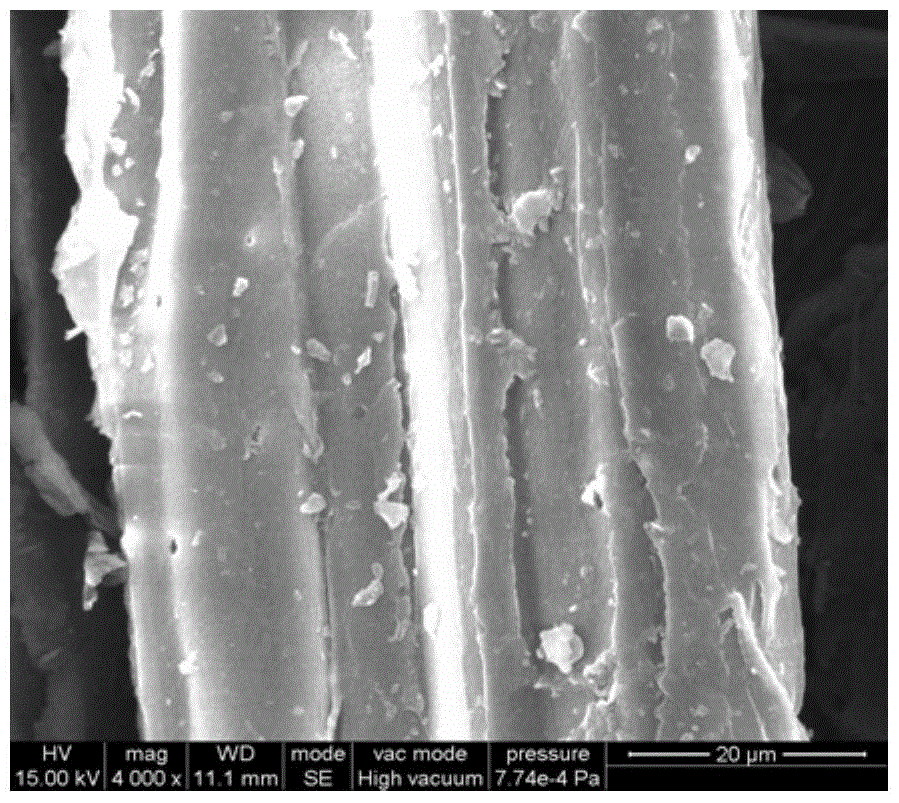

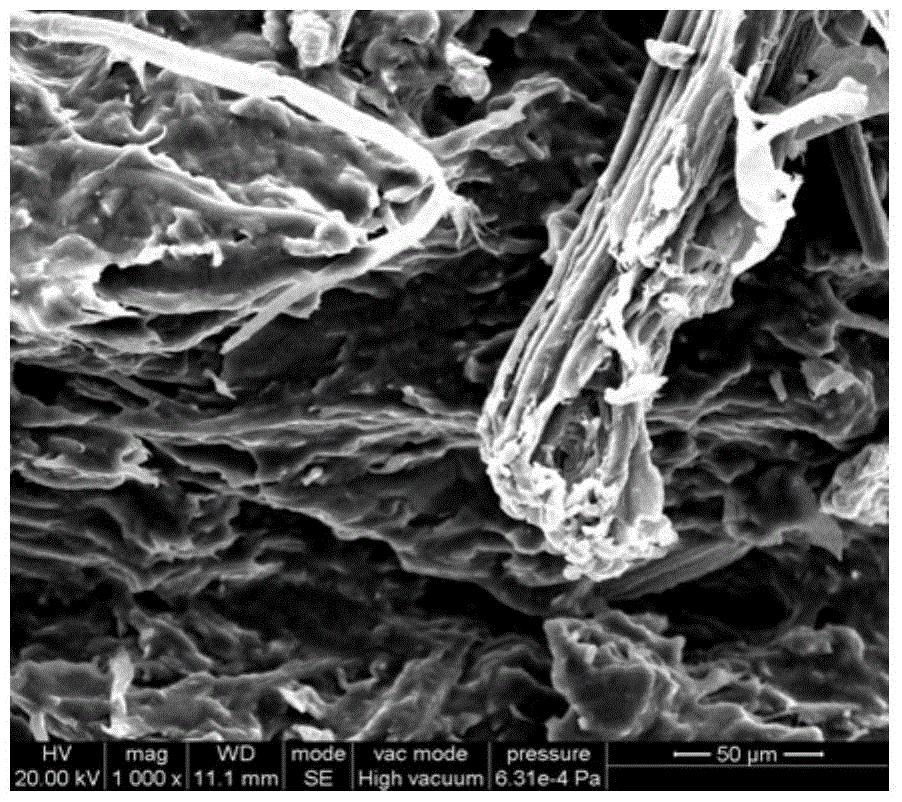

A kind of modified bagasse-plastic composite material and its preparation method and application

The invention belongs to the field of composite materials, and discloses a modified bagasse-plastic composite material and a preparation method thereof. The method comprises the following steps: putting dry bagasse fiber and a grinding medium into a ball mill, and activating the bagasse fiber in a mechanical activation mode; adding the activated bagasse fiber into a maleic anhydride-acetone solution, evenly stirring, and volatilizing; putting the dry bagasse into the ball mill while adding an initiator, heating to 80 DEG C, keeping the temperature, and reinforcing polymerization reaction by mechanical activation; extracting the product with acetone to obtain the modified bagasse fiber; premixing a resin matrix with a compound plasticizer, borax and processing assistants in a high-speed mixer until the material temperature is 50 DEG C, adding the modified bagasse fiber, and thoroughly mixing to obtain a premixture; and carrying out melt extrusion on the premixture to obtain the bagasse-plastic composite material. The modified bagasse-plastic composite material can be used for manufacturing various plastic products. The method is simple and easy to implement and low in cost, and has wide application prospects.

Owner:ZHONGKAI UNIV OF AGRI & ENG

Fire hose containing high-binding-force functional coating and coating spraying equipment

ActiveCN110513549AGood physical propertiesImprove bindingFlexible pipesGeneral functionEthylene-propylene-diene-monomer

The invention relates to a fire hose containing a high-binding-force functional coating and the coating spraying equipment. The fire hose comprises a rubber inner pipe, a fiber framework layer, an external protective layer and a functional coating layer which are coaxially sleeved from inside to outside in sequence, wherein the rubber inner pipe is made of a rubber / resin composite material; the fiber framework layer is made of a woven material formed by blending polyamide fibers, polypropylene fibers and brucite fibers; the external protective layer adopts composite silica micropowder / magnesium hydroxide / desulfurized rubber powder modified and doped ethylene propylene diene monomer rubber; and the functional coating layer adopts conventional functional coating or functional paint sold in the market. The fire hose containing a high-binding-force functional coating and the coating spraying equipment carry out targeted reasonable design on the multilayer structure material of the rubber inner pipe, greatly improve the physical and chemical properties of the fire hose, and obviously improve the bonding force of the coating on the outer layer by matching with corresponding coating spraying equipment, so that the comprehensive performance is more excellent.

Owner:扬州水龙消防器材有限公司

Biomass material carbonization and activation integrated device

The invention relates to a biomass material carbonization-activation integrated device, and overcomes the problems of carbonization-activation devices at present, namely a low efficiency, controlling difficulty of activation processes and high energy consumption. The device comprises a vertical carbonization furnace and a horizontal activation furnace. A vertical carbonization cylinder is disposed in the carbonization furnace. An activation spiral conveyer transversally penetrates the activation furnace. The lower end of the carbonization cylinder is connected to the initial end of the activation spiral conveyer. The carbonization furnace is also provided with steam spraying tubes communicating with the activation spiral conveyer and spraying steam to the inside of the activation spiral conveyer. The steam spraying tubes penetrate the furnace wall of the carbonization furnace. Both the activation furnace and the carbonization furnace are provided with a gas inlet and a gas discharging port. The gas inlets of the activation furnace and the carbonization furnace are connected to a combustion furnace. According to the device, steam activation has no influence on carbonization. An activation process adopts the steam spraying tubes to spray the steam, and the activation spiral conveyer is cooperated for control, thus effectively controlling the using amount of the steam, ensuring full contact between the steam and a carbon layer, ensuring activation effects, and reducing the using amount of the steam. The heat of the activation itself can be utilized to heat the steam in the steam spraying tubes, thus reducing extra energy consumption for heating steam.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

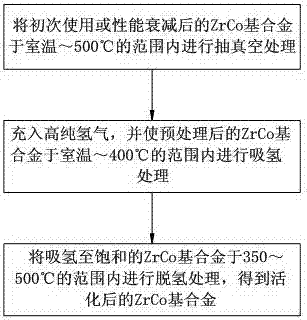

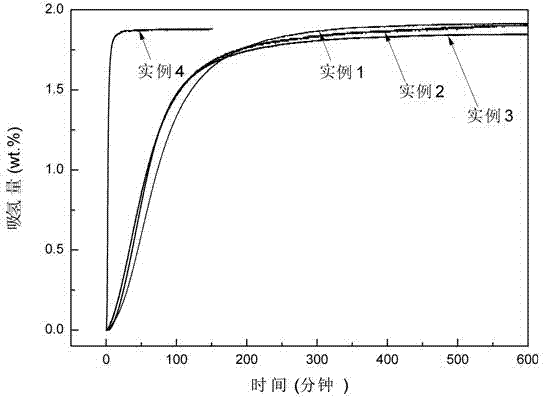

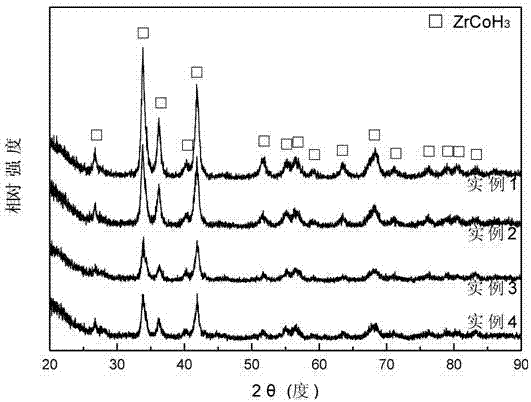

A method for rapidly and efficiently activating ZrCO-based hydrogen isotope storage materials

The invention discloses a method for rapidly and efficiently activating a ZrCo-based hydrogen isotope storage material. The method includes the steps that firstly, ZrCo-based alloy which is preliminarily used or attenuated in performance is subjected to vacuumizing pretreatment within the temperature range from the indoor temperature to 500 DEG C; secondly, 10 kPa to 500 kPa of high-purity hydrogen gas is injected and the pretreated ZrCo-based alloy is subjected to hydrogen absorption treatment within the temperature range from the indoor temperature to 400 DEG C; and thirdly, the ZrCo-based alloy absorbing hydrogen to be saturated is dehydrogenized within the temperature range from 350 DEG C to 500 DEG C, so that the activated ZrCo-based alloy is obtained. The method is simple and prominent in activating effect, the activating time of the ZrCo-based alloy in the actual application process can be effectively shortened, the ZrCo-based alloy has the brand-new hydrogen isotope storage activity after being preliminarily used or attenuated in performance, and the method has the important significance in promoting application and popularization of the ZrCo-based alloy in the hydrogen isotope storage field.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

Surface activation method for nonmetal material

InactiveCN102321878BGuaranteed activation effectReduce wasteLiquid/solution decomposition chemical coatingHigh concentrationPhysical chemistry

Owner:SHENZHEN FARCIEN APPLIED MATERIALS

Activated coke for flue gas desulfurization and preparation method thereof

ActiveCN111054310BImprove adsorption capacityReduce manufacturing costGas treatmentOther chemical processesSodium BentoniteFlue gas

The invention belongs to the technical field of comprehensive utilization of resources, and relates to an active coke for flue gas desulfurization and a preparation method thereof. The mixture is obtained by mixing low-modified pulverized coal, semi-coke powder, phenolic resin, sodium humate and sodium bentonite; In terms of percentage, the mixture A contains 35%-42.5% of low-modified pulverized coal, 35%-42.5% of semi-coke powder, 5%-15% of phenolic resin, 5%-15% of sodium humate, 5%- 15% sodium-based bentonite; add ethanol solution and deionized water with a solute quality of 8%-10% to the mixture, mix uniformly and press under a pressure of 5-7MPa to obtain a molding strip; dry the molding strip Carrying out carbonization and activation treatment on the dried molding strips under a protective atmosphere; obtaining the active coke material for flue gas desulfurization after the activation treatment. The invention has simple process and low cost, and opens up a new development and application path for the utilization of low-rank coal with high added value.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com