Manufacturing method of PTFE-containing multilayered PCB

A technology of PTFE and its production method, which is used in multilayer circuit manufacturing, printed circuit manufacturing, electrical components, etc., can solve the problem of inability to effectively solve the problem of bonding force between PTFE multilayer boards and PP layers, increase the surface chemical activity of PTFE substrates, and cannot Better realize the combination of PTFE and adhesive sheet, etc., to save browning time, reduce residence time, and protect activity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

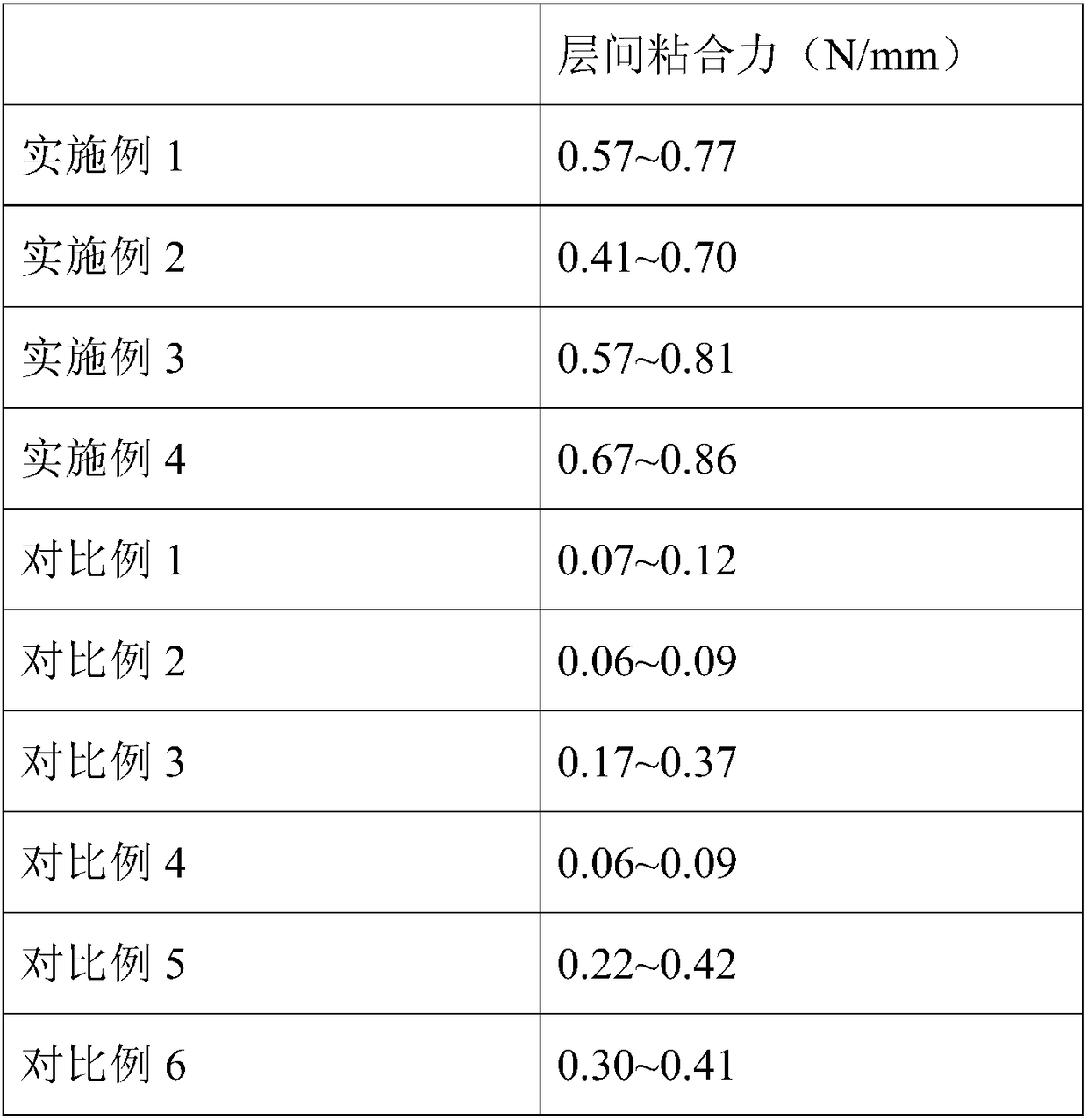

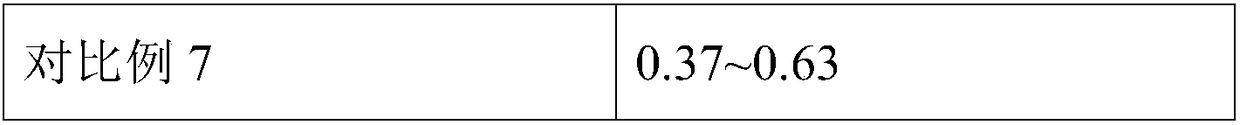

Examples

Embodiment 1

[0044] A kind of manufacture method that contains the multilayer PCB of PTFE, it comprises the following steps:

[0045] (1) Provide PTFE substrate with RTF copper foil, without any form of grinding and micro-etching after cutting;

[0046] (2) Etching the circuit, the PTFE substrate after etching the circuit is not browned;

[0047] (3) do plasma surface plasma activation treatment on the PTFE substrate surface after etching, the temperature of said plasma surface plasma activation treatment is controlled at 50 ℃, and the time is controlled at 1h;

[0048] The plasma surface activation treatment of the plasma is specifically: the first step adopts O 2 , N 2 and H 2 The gas is treated with a volume ratio of 10:10:20, under the pressure of 250 Torr, and the plasma gas flow rate is 2.5LT / min for 15 minutes; the second step uses N 2 and H 2 The gas was treated for 45 minutes at a volume ratio of 20:80 under a pressure of 250 Torr and a plasma flow rate of 2.5 LT / min;

[004...

Embodiment 2

[0052] A kind of manufacture method that contains the multilayer PCB of PTFE, it comprises the following steps:

[0053] (1) Provide PTFE substrate with RTF copper foil, without any form of grinding and micro-etching after cutting;

[0054] (2) Etching the circuit, the PTFE substrate after etching the circuit is not browned;

[0055] (3) do plasma surface plasma activation treatment on the PTFE substrate surface after etching, the temperature of described plasma surface plasma activation treatment is controlled at 40 ℃, and the time is controlled at 50min;

[0056] The plasma surface activation treatment of the plasma is specifically: the first step adopts O 2 , N 2 and H 2 The gas is treated for 15 minutes at a volume ratio of 10:10:20 under a pressure of 220 Torr and a plasma gas flow rate of 3LT / min; the second step uses N 2 and H 2 The gas was treated for 35 minutes at a volume ratio of 20:80 under a pressure of 250 Torr and a plasma flow rate of 2.5 LT / min;

[0057]...

Embodiment 3

[0060] A kind of manufacture method that contains the multilayer PCB of PTFE, it comprises the following steps:

[0061] (1) Provide PTFE substrate with RTF copper foil, without any form of grinding and micro-etching after cutting;

[0062] (2) Etching the circuit, the PTFE substrate after etching the circuit is not browned;

[0063] (3) do plasma surface plasma activation treatment on the PTFE substrate surface after etching, the temperature of said plasma surface plasma activation treatment is controlled at 30 ℃, and the time is controlled at 40min;

[0064] The plasma surface activation treatment of the plasma is specifically: the first step adopts O 2 , N 2 and H 2 The gas was treated for 10 minutes at a volume ratio of 10:10:40 under a pressure of 250 Torr and a plasma flow rate of 3LT / min; the second step was to use N 2 and H 2 The gas was treated for 30 minutes at a volume ratio of 20:40 under a pressure of 220 Torr and a plasma flow rate of 2.5 LT / min;

[0065] (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com