Surface activation method for nonmetal material

A non-metallic material and surface activation technology, which is applied in the field of surface activation of non-metallic materials, can solve the problems of large unit consumption of activation solution and waste of precious metal palladium, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] In the preparation process of printed circuit boards, the pre-dip solution is a sacrificial solution. Its main function is to reduce pollutants or copper ions from being brought into the activation tank. In the activation solution, ensure the necessary base content (specific gravity) and acidity in the activation solution, maintain the stability of the activation solution, and avoid the hydrolysis of the tin-palladium colloid in the activation solution. The pre-dipping solution used in the present invention can be prepared according to methods well known to those skilled in the art. Preferably, the pre-dipping solution includes sodium chloride, inorganic acid, stabilizer and antioxidant. In the present invention, tin-palladium colloid is firstly added to the pre-dipping solution, so that the obtained mixed solution has a certain palladium concentration while functioning as the original pre-dipping solution, thereby having a certain activation effect on the non-metallic s...

Embodiment 1

[0041] The tin-palladium colloidal activator used in this embodiment is the tin-palladium colloidal activator of model CA-230 produced by Shenzhen Huaxun Applied Materials Co., Ltd.

[0042] Be that the stock solution of palladium concentration is 1650ppm with 2% matching tank, the palladium concentration of activation tank matching tank is 33ppm, collocation 200g / L composition is sodium chloride presoaker A and 70ml / L contain sulfuric acid, stabilizing agent, anti Pre-dipping agent B of the oxidizing agent builds a bath, and transfers 20% of the activation solution from the activation tank to the pre-dipping tank to establish the initial palladium concentration to obtain a mixed solution;

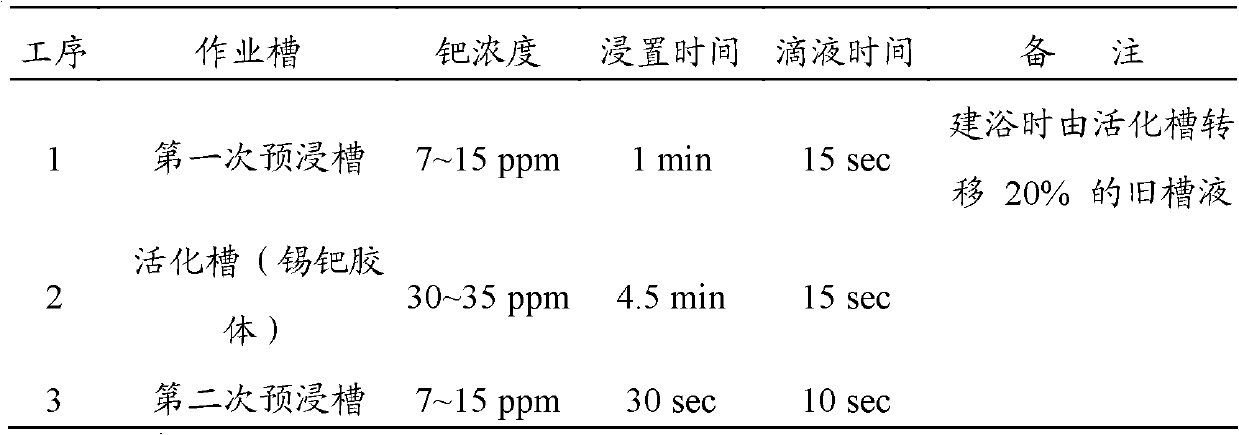

[0043] According to the experimental parameters shown in Table 1, adjust the production line crane program time, the immersion time and dripping time of each operation tank, etc.;

[0044] The process parameter that table 1 embodiment 1 adopts

[0045]

[0046] The test was carried out...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com