A biomass material carbonization-activation integrated device

A biomass material and carbonization technology, applied in the fields of carbon compounds, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of high energy consumption, low efficiency of carbonization activation devices, and difficult control of activation process, so as to ensure the activation effect and reduce The effect of steam consumption, reduction of additional energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

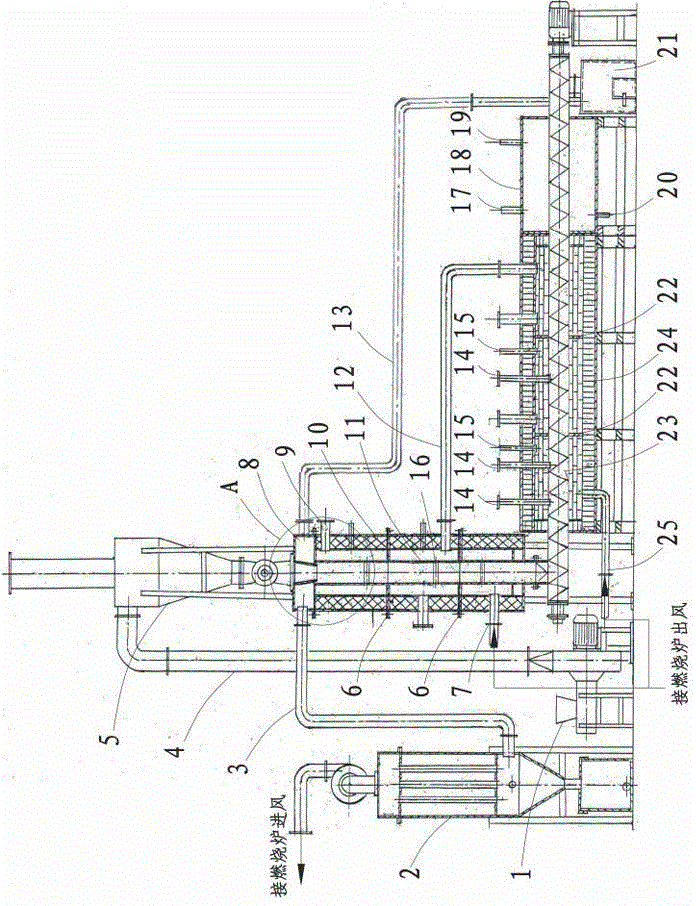

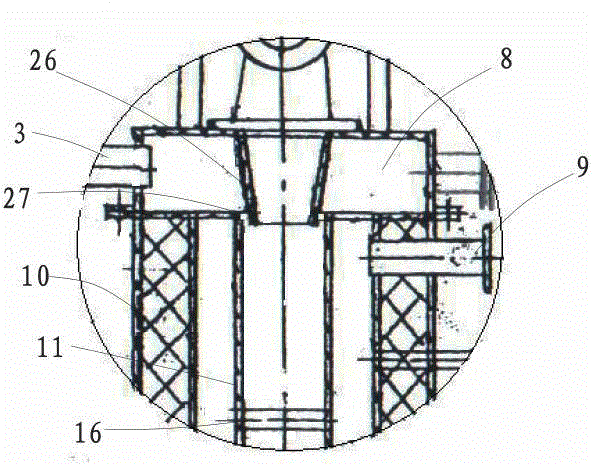

[0020] Embodiment: a kind of biomass material carbonization and activation integrated device, such as figure 1 , 2 shown. The device comprises a vertical carbonization furnace 10 and a horizontal activation furnace 24. A vertical carbonization cylinder 11 is arranged in the carbonization furnace. The activation auger 23 passes through the two ends of the activation furnace transversely. connected at the head end. The outer side of the carbonization cylinder is the gas chamber of the carbonization furnace, and the outer side of the gas chamber of the carbonization furnace is provided with an insulating interlayer, and the interlayer is filled with insulating materials. The activation furnace is built with refractory bricks, and the outside of the activation auger is the gas chamber of the activation furnace. Carbonization furnace and activation furnace use combustion furnace to supply hot air.

[0021] Such as figure 1 As shown, the air inlet 7 of the carbonization furnace...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com