White light LED and manufacturing method

A technology of LED chips and white light, which is applied in the direction of semiconductor devices, electrical components, circuits, etc., can solve the problems of derivation, high temperature of white light LEDs, and reduction of luminous efficiency and life of white light LEDs, so as to improve thermal conductivity, small absorption effect, and improve Effect of Optical Stability and Lifetime

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

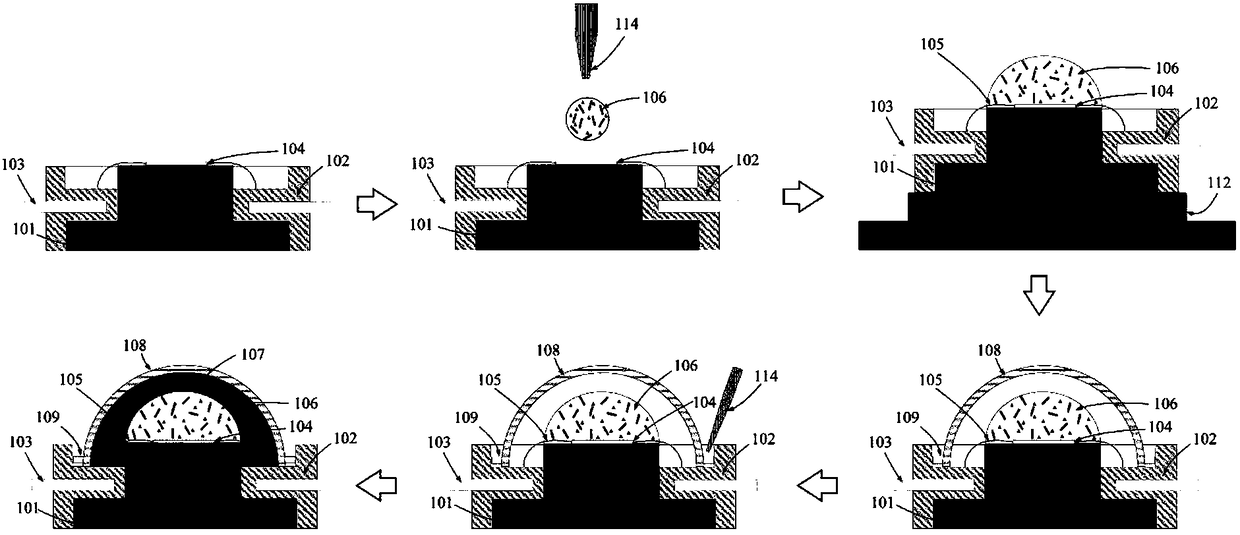

[0044] Such as figure 2 As shown, the present invention also provides a preparation method of the white light LED, comprising the following steps:

[0045] S1. Install the LED chip 104 on the upper surface of the substrate 115, and then apply the fluorescent colloid mixed with the colloid matrix, fluorescent powder and quantum dot composite material on the top of the LED chip, and heat and cure at a heating temperature of 100°C to 150°C;

[0046] S2. Nesting the light-transmitting housing 108 above the LED chip and the fluorescent colloid to seal the LED chip and the fluorescent colloid;

[0047] S3. Fill the gap between the fluorescent colloid and the light-transmitting shell with encapsulation glue, and prepare a white light LED after curing.

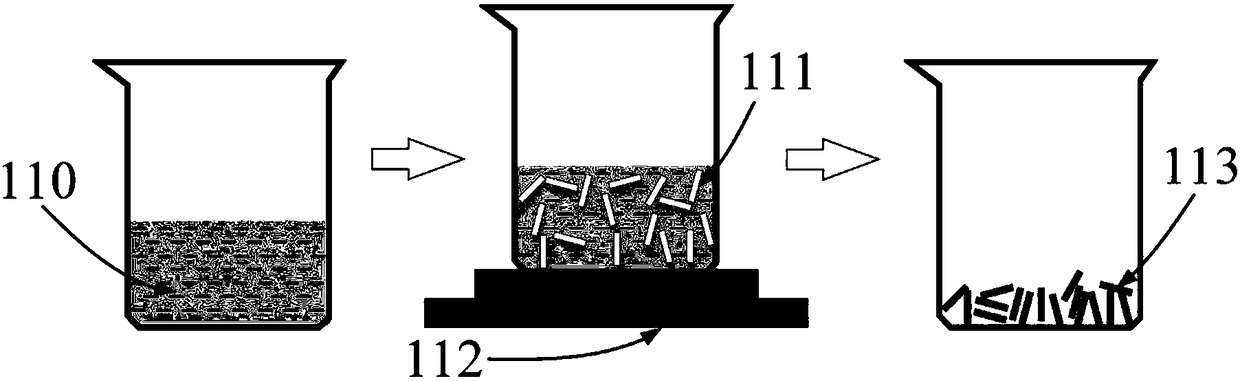

[0048] Among them, such as figure 1 As shown, the quantum dot composite material is prepared by the following steps:

[0049] S11. When configuring the quantum dot particle solution, metal cations are placed on the surface of the ...

Embodiment 1

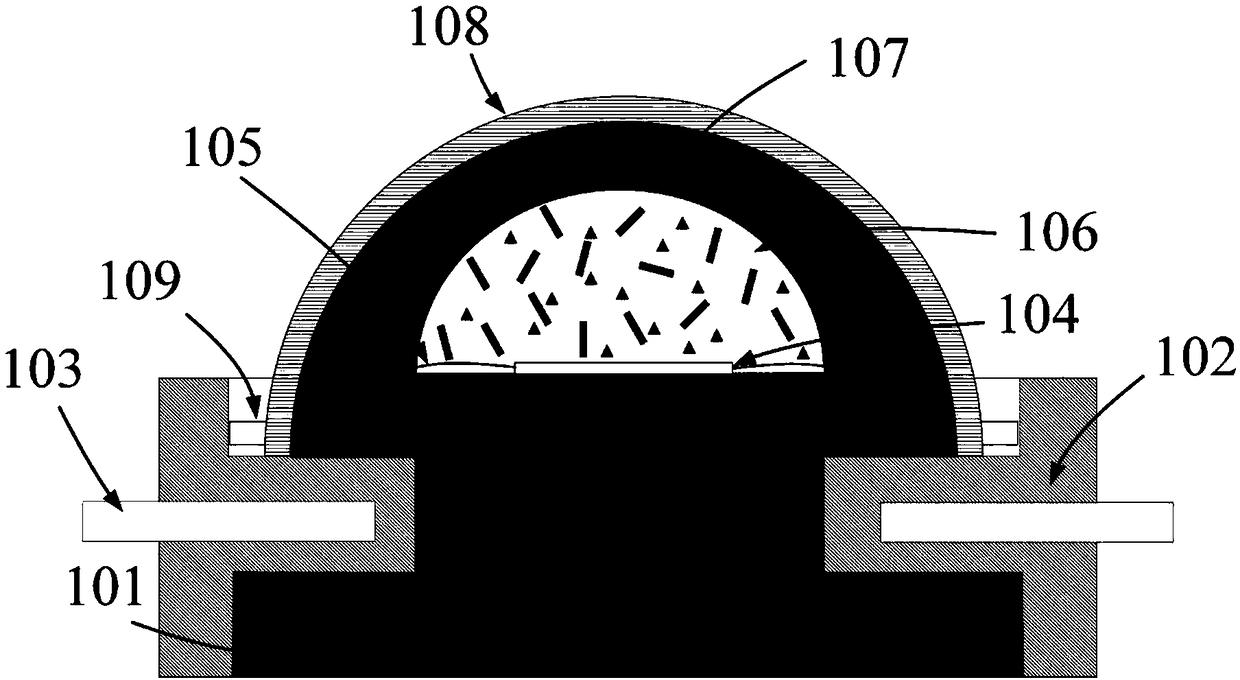

[0054] see image 3 , in this embodiment, the LED chip is a horizontal electrode chip, its substrate is sapphire, the material of the light-transmitting shell is polymethyl methacrylate, and its light transmittance is 95%, and the shape of the light-transmitting shell is hemispherical. shape, the diameter of the inner surface is 6mm, the height of the inner surface is 6mm, and the encapsulation glue is heat-curing silicone.

[0055] First, prepare the quantum dot composite material, including the following steps:

[0056] S1. When synthesizing the solution of quantum dot particles, make the surface of quantum dot particles positively charged, the core compound of quantum dot particles is CdSe, the shell compound is ZnS, and the surface ligand is oleic acid with metal cations to obtain surface bands Positively charged quantum dot solution 110; the specific steps for synthesizing the quantum dot particle solution are:

[0057] S11. Preparation of precursor: 0.26g CdO was disso...

Embodiment 2

[0068] see Figure 4 , repeating Example 1 with the same steps as described, the difference is that in the fluorescent colloid, the mass fraction of the phosphor powder accounting for the fluorescent colloid is 15%, the quantum dot composite material accounts for 15% of the mass fraction of the fluorescent colloid, and the dispensing of the fluorescent colloid The volume is 20 μL.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Luminous wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com