Patents

Literature

117results about How to "Good defluoridation effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Defluorination absorbing material based on aluminum base composite oxides and its preparation method and use and special device of the preparation method

ActiveCN101507911AExcellent adsorption and defluorination performanceGood defluoridation effectOther chemical processesChemical reactionWater source

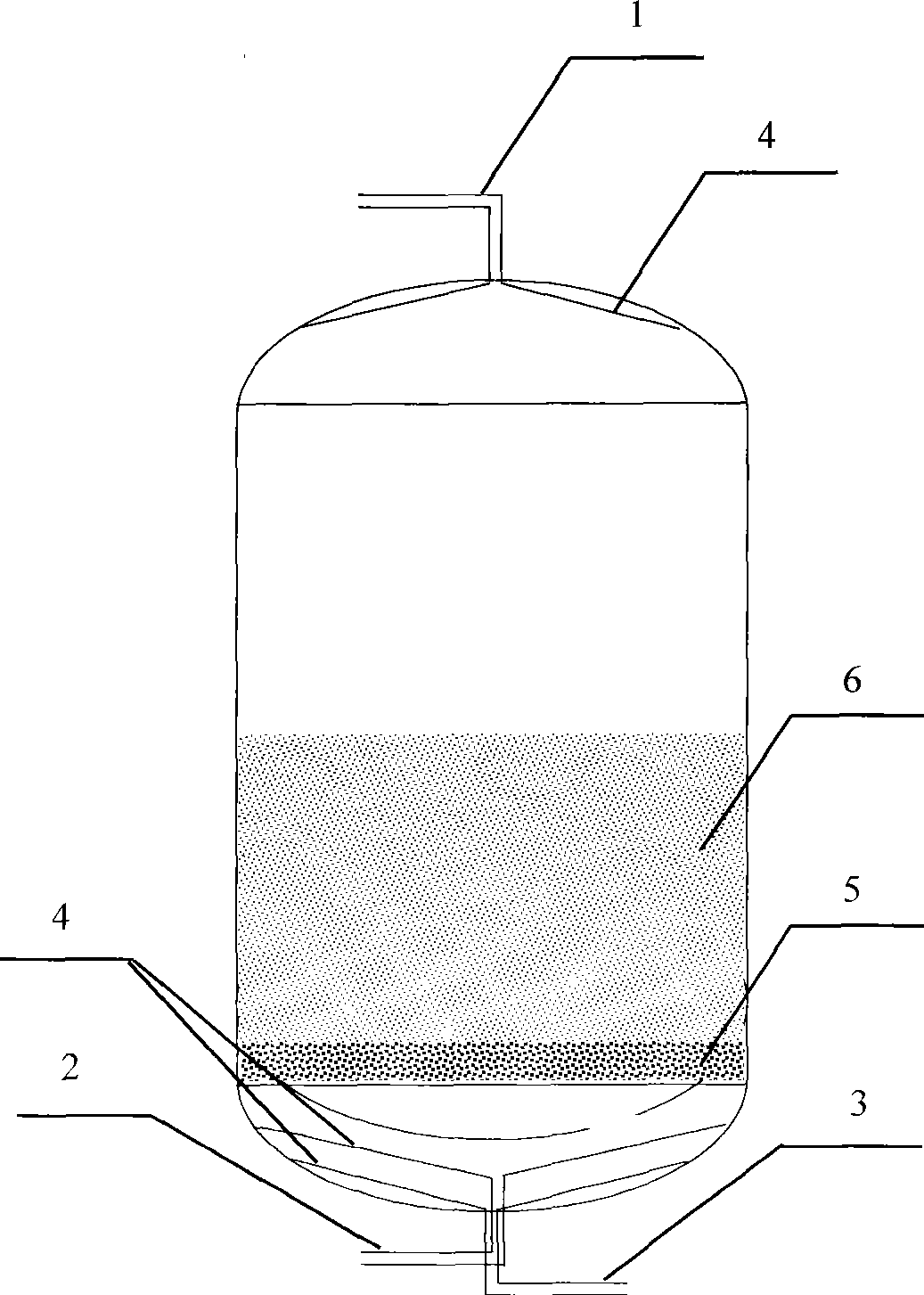

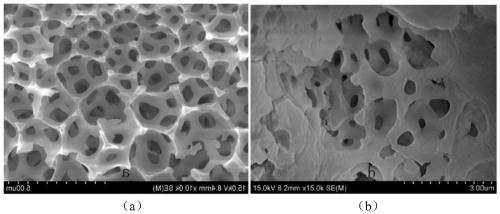

The invention belongs to the field of materials for removing fluorine in water, and in particular relates to a fluorine-removal adsorption material based on alanate and aluminum-based composite oxide, a preparation method and uses of the same, and a special device for the preparation method. The fluorine-removal adsorption material based on the aluminum-based composite oxide, which is prepared by a heterotopic preparation method or an in-situ preparation method, comprises two parts of an active composition and a porous supported substrate, wherein the active composition is the aluminum-based composite oxide prepared from an aluminum salt solution and an inorganic alkaline solution by chemical reaction; and the aluminum-based composite oxide is loaded on the surface of the porous supported substrate by an in-situ loading method, and the mass ratio of the aluminum-based composite oxide to the porous supported substrate is 0.25-25:100. The fluorine-removal adsorption material based on the aluminum-based composite oxide can be used for the adsorption of fluorine pollutants in the water and particularly common fluorine in underground drinking water sources. In addition, the material can also be used for removing pollutants such as arsenic, iron, manganese, phosphate, and the like in the water.

Owner:清华苏州环境创新研究院

Preparing and applications of ferric oxide-alumina compound nanophase defluoridation material

InactiveCN101229504AReduce dosageImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionSorbentAlumina composite

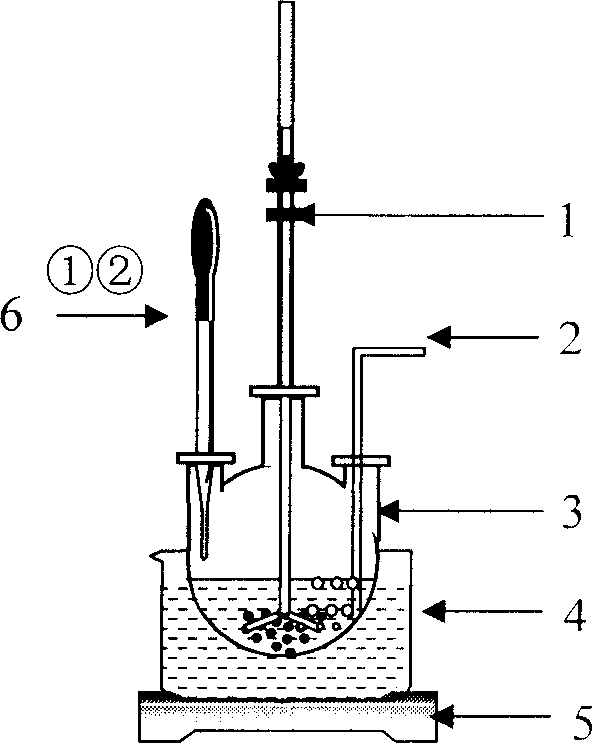

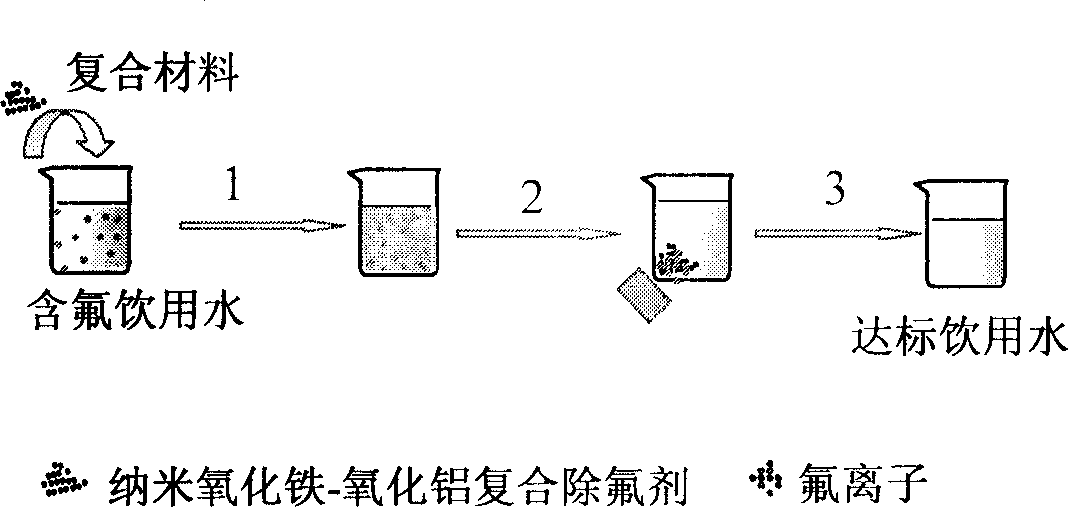

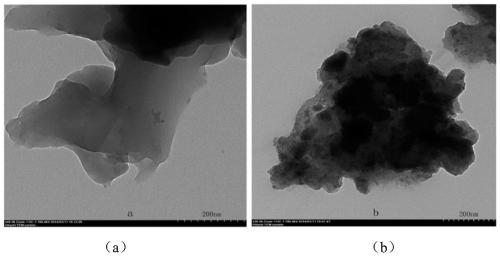

The invention pertains to the field of chemical analysis test equipment, relating to a novel composite material of nano iron oxide-alumina which is used as an sorbent for removing fluoride from water to remove the fluoride from the large amount of drinking water; the fluorin content after the treatment is lower than the content of national standard; compared with the traditional defluorinating agent, the invention has the advantages of simple structure, low cost, high sorption capacity and fast removing speed. As a novel magnetic nano material, the defluorinating agent can realize the separation of extraction agent and base solution under the condition of external magnetic field. The surface of the nano iron oxide is coated with a layer of Al(OH)3; F<-> and Al<3+> in the water to form a complex compound which settles down to realize the effect of defluorination; 1L of water sample only consumes the defluorinating agent of 0.1g; to high fluorin content water with concentration of 20mg / L, the concentration after defluorination can be less than 1mg / L, which can well meet requirement with the reproducibility of analysis result RSD being less than 7 percent.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Brackish water desalination device

InactiveCN101381126AMeet water requirementsIncrease permeation flux per unit areaGeneral water supply conservationWater/sewage treatment bu osmosis/dialysisUltrafiltrationFiltration

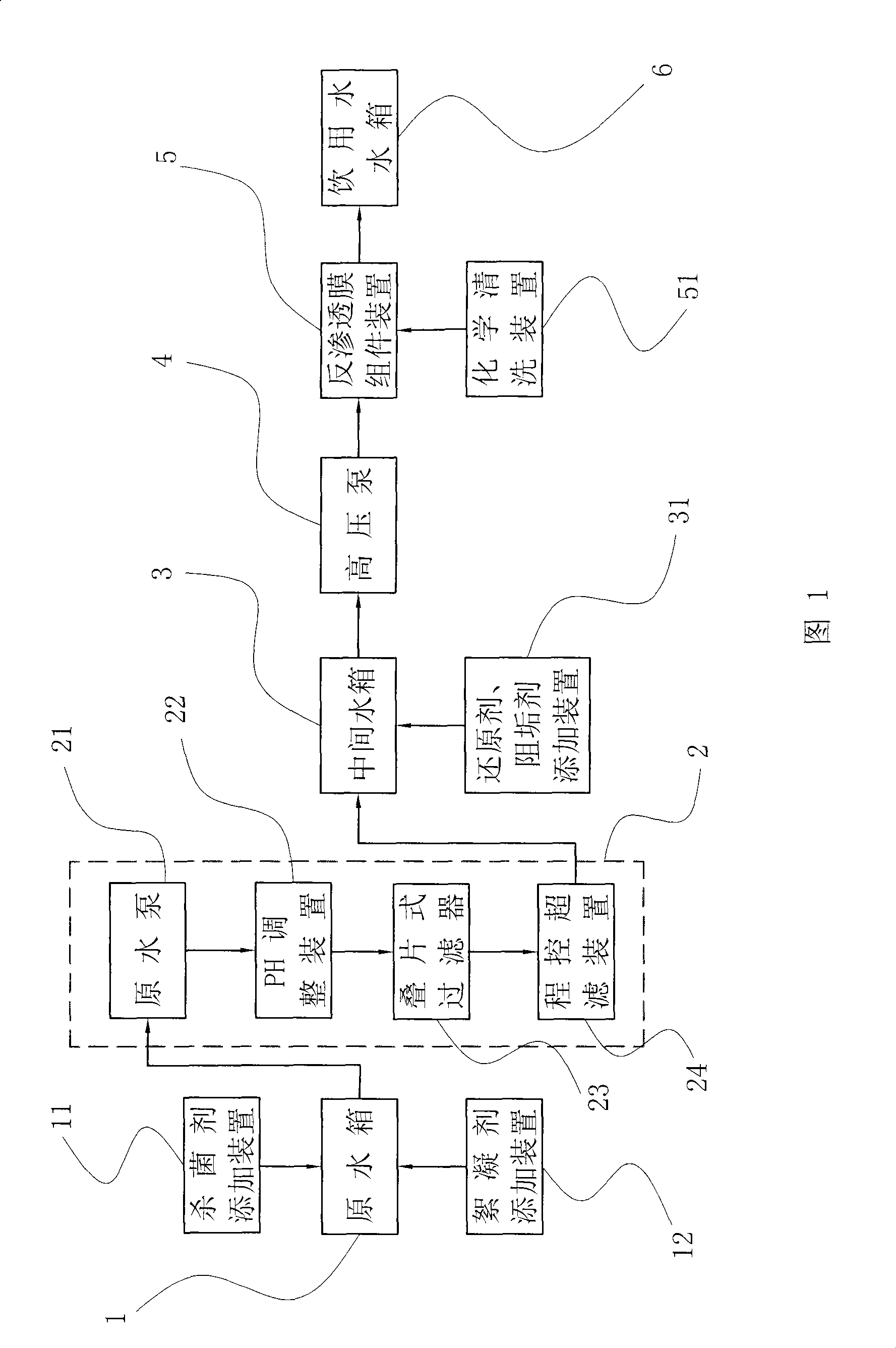

The invention discloses bitter saline water desalination equipment, which comprises a raw water tank, and a high pressure pump, a reverse osmosis membrane component and a drinking water tank which are sequentially connected. The bitter saline water desalination equipment further comprises a physical-chemical program controlled composite coupling preprocessor consisting of a raw water pump, a laminated filter and a program controlled ultrafiltration device which are sequentially connected. The bitter saline water desalination equipment has the advantages that the process of physical-chemical program controlled composite coupling preprocessing filtration is adopted so that the raw water with different types and different qualities can be pretreated to meet the inlet water requirement for the reverse osmosis membrane component, thus the inlet water quality for the reverse osmosis desalination is improved, the rubber body pollution and the microorganism pollution to membrane elements in the reverse osmosis membrane component are prevented, the unit area permeation flux of the reverse osmosis membrane component is improved, and the protection of the reverse osmosis membrane elements is increased; at the same time, the chemical cleaning frequency of the reverse osmosis membrane elements is reduced, the service life of the membrane elements is prolonged, the operating cost is reduced, and the production efficiency is improved.

Owner:陆惠民

Method for treating acidic fluorine-containing waste water

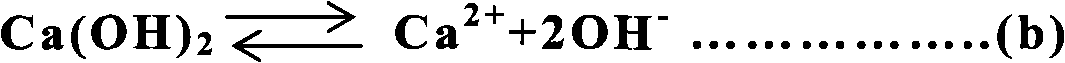

ActiveCN101823799AGood defluoridation effectNo secondary pollutionWater contaminantsMultistage water/sewage treatmentCalcium hydroxideSludge

The invention relates to a method for treating acidic fluorine-containing waste water. The method comprises the following steps sequentially: (1) adding calcium-containing substance into the fluorine-containing waste water to be treated and adjusting the pH value of the waste water to be about 4.0 to 9.0; and (2) adding water-soluble gamma-polyglutamic acid serving as a biologic capturing agent into the mixture, fully stirring and standing the mixture, separating the supernatant and collecting the precipitated sludge after the mixture is precipitated and demixed, wherein the calcium-containing substance at least comprises one of calcium hydroxide, calcium oxide or calcium salt. The method overcomes the technical disadvantages in the prior art; the high molecular water-soluble gamma-polyglutamic acid with a molecular weight between 500,000 and 1,500,000 is used in the treatment of the acidic fluorine-containing waste water; and repeated experiments show that the fluorine removing effect is excellent and the treated waste water can meet the national first-class discharge standard; moreover, the method has the advantages of low treatment cost, high efficiency for the treatment process, environment friendliness and no secondary pollution.

Owner:江西爱地生生物高分子材料有限公司

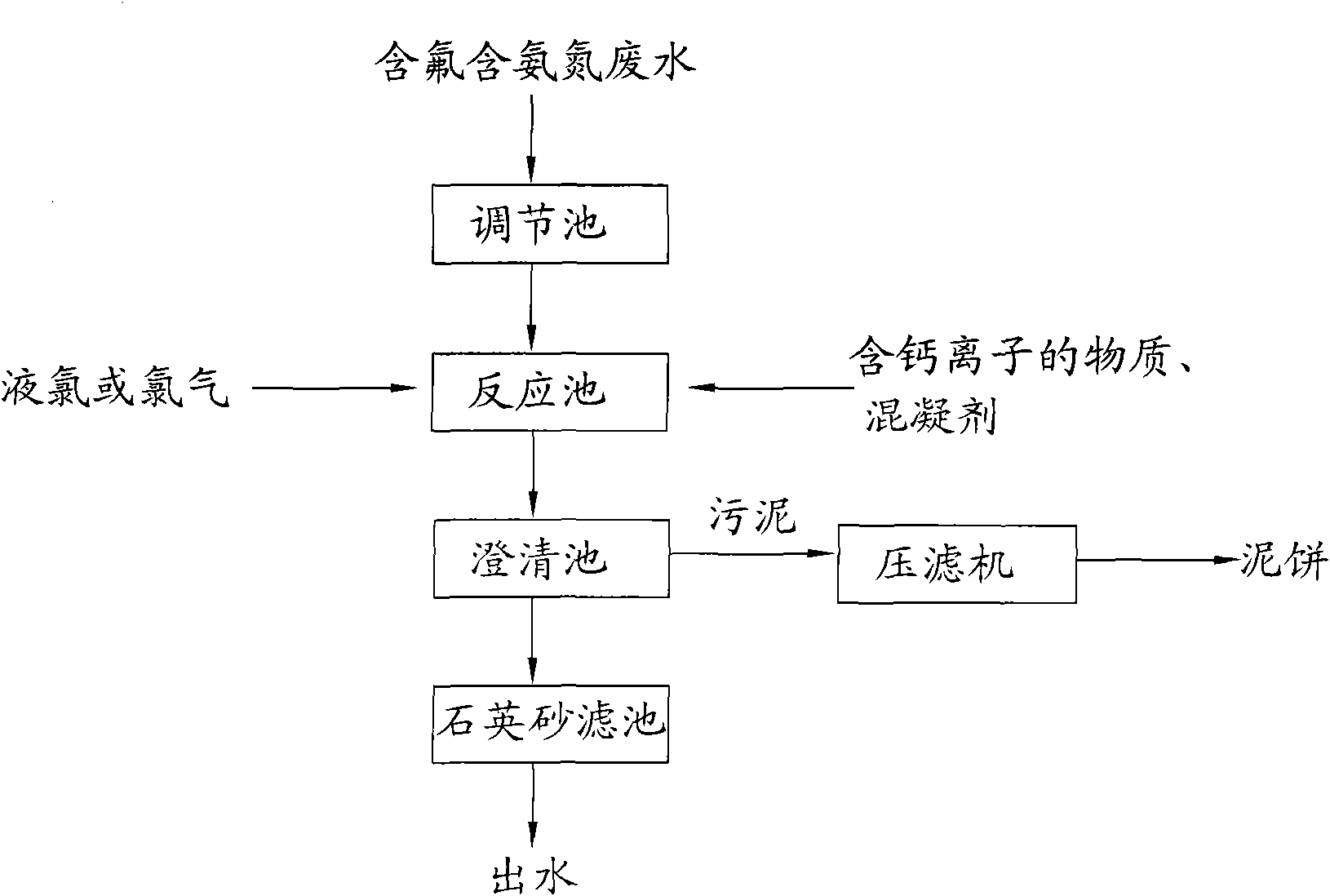

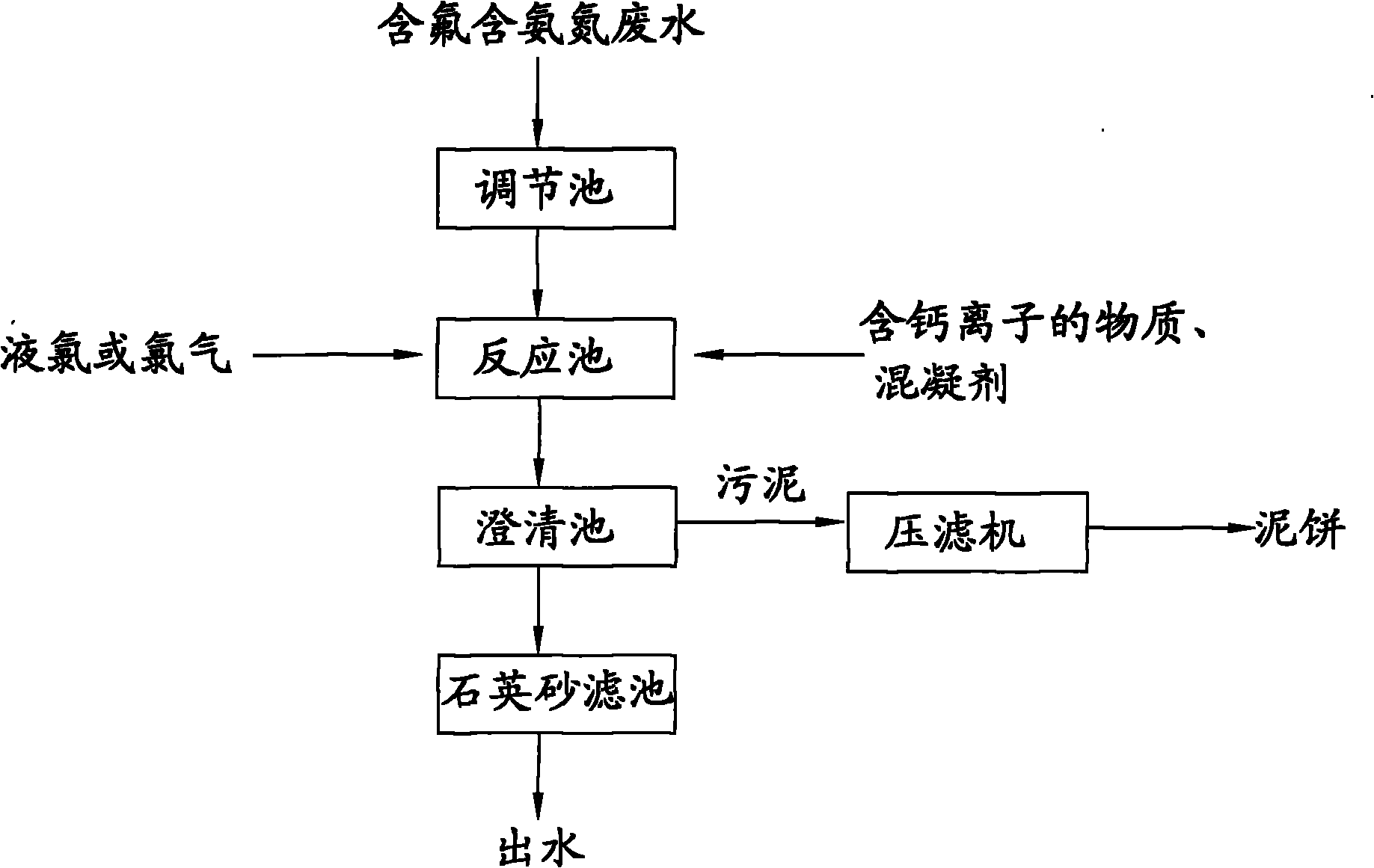

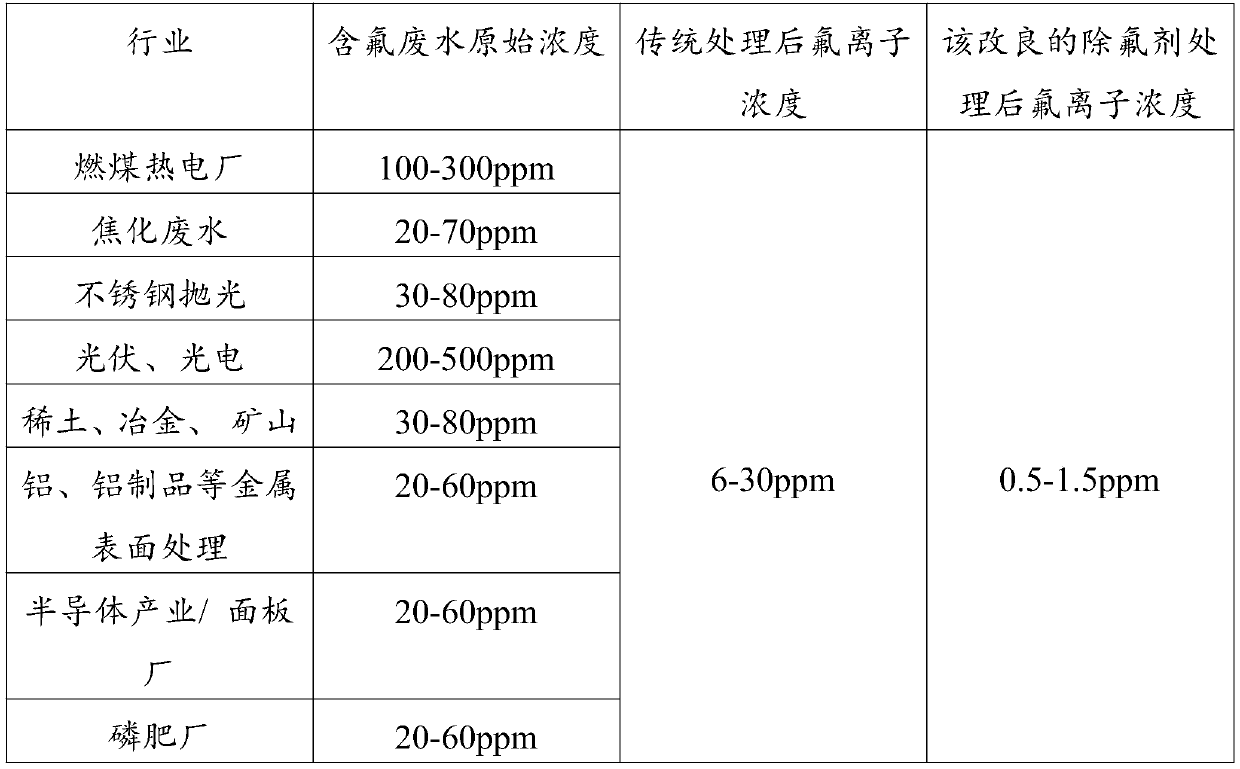

Method for treating fluorine-containing and ammonia nitrogen-containing waste water in electronic industry

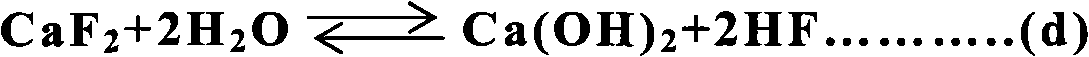

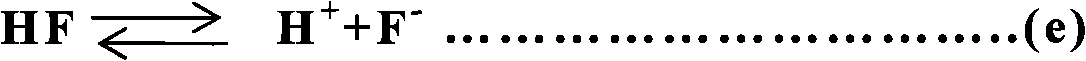

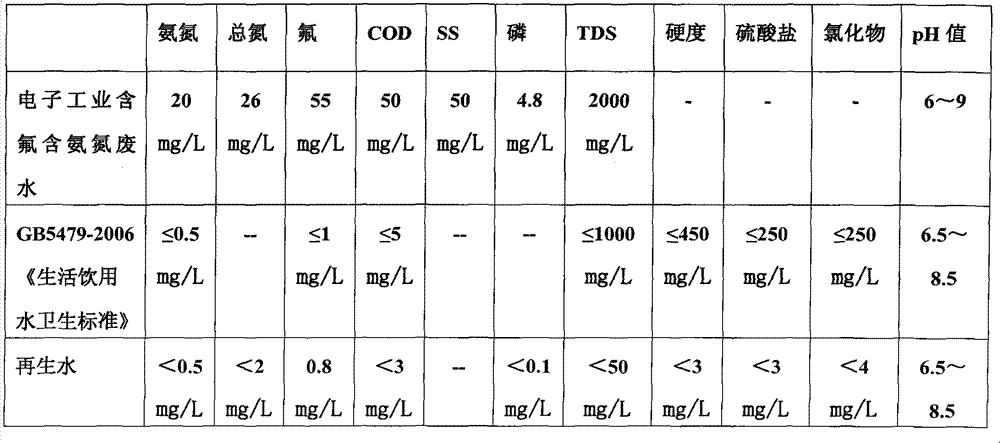

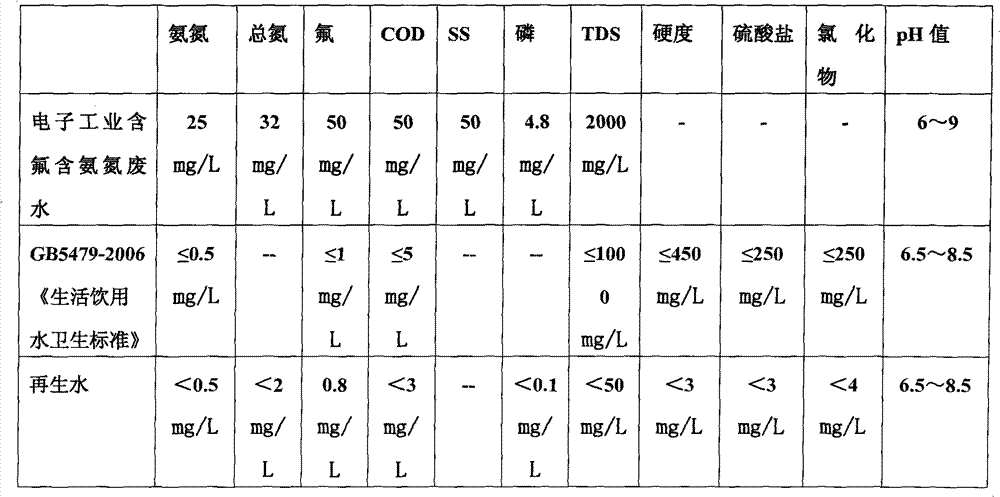

ActiveCN102126799AReduce ammonia nitrogen contentTo achieve the treatment effectWater contaminantsMultistage water/sewage treatmentIon contentChemical reaction

The invention relates to a method for treating fluorine-containing and ammonia nitrogen-containing waste water in electronic industry. The method comprises an ammonia nitrogen removal procedure and a fluorine removal procedure, wherein the ammonia nitrogen removal procedure is as follows: Cl2 is added into waste water, wherein 7.6-8.0mg of Cl2 is added into every one liter of waste water containing 1mg of ammonia nitrogen, and the Cl2 is added in two batches; the addition amount for the first batch is 65-75%, and the addition amount for the second batch is the rest; after the first batch of Cl2 is added, alkali equivalent to the added Cl2 for the first batch is added to neutralize hydrochloric acid produced by the reaction of the Cl2 and ammonia nitrogen, and then, the second batch of Cl2 is added; and the fluorine removal procedure combines chemical reaction precipitation and coagulative precipitation separation. By firstly removing ammonia nitrogen and then removing fluorine, the invention achieves the advantages of stable and favorable treatment effect, high efficiency and high speed. The fluorine ion content and ammonia nitrogen content in the waste water treated by the invention are effectively reduced, and the waste water can be discharged or be subjected to further reclamation treatment to be reclaimed according to different environmental protection requirements.

Owner:WUXI DEPPEL WATER INVESTMENT

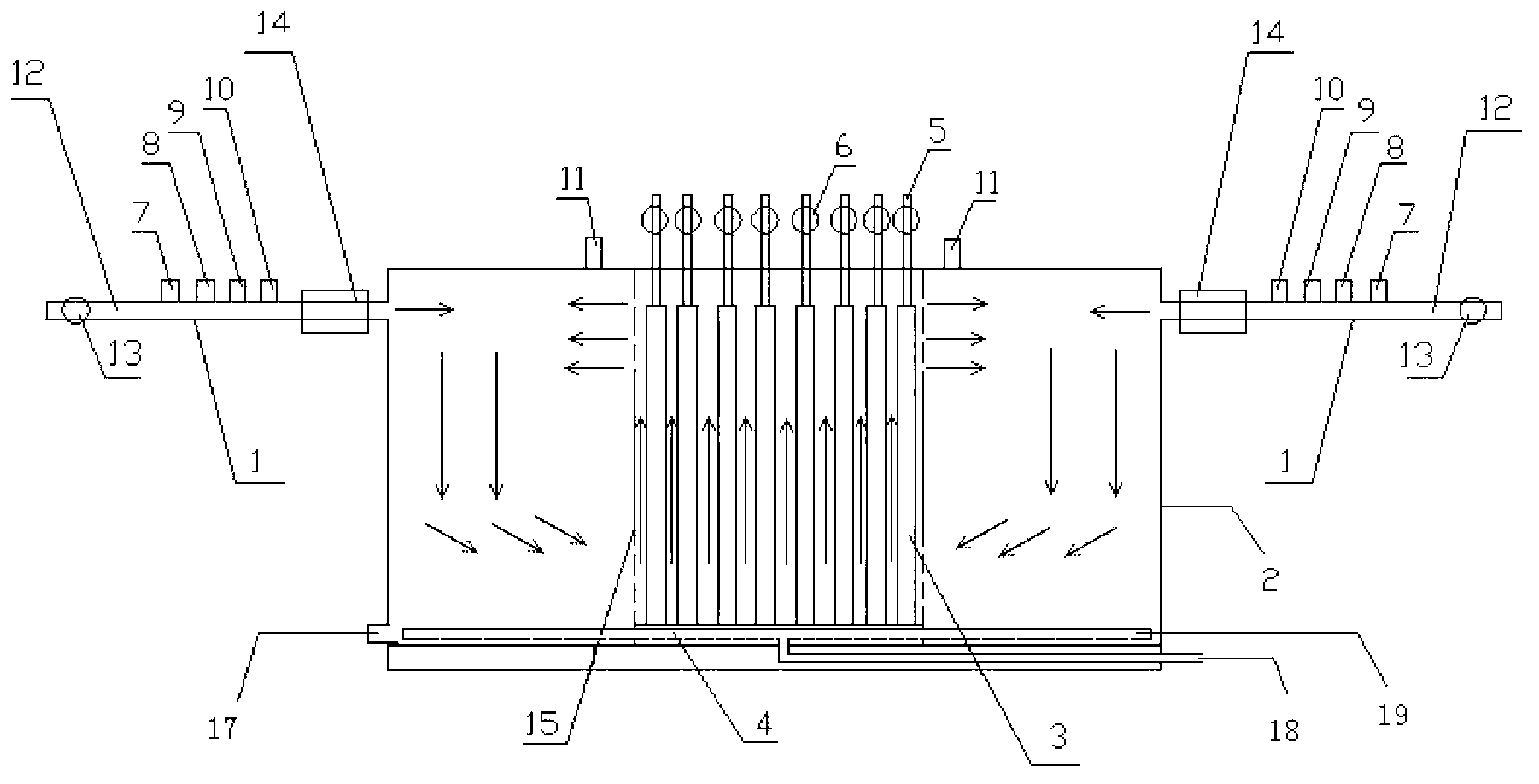

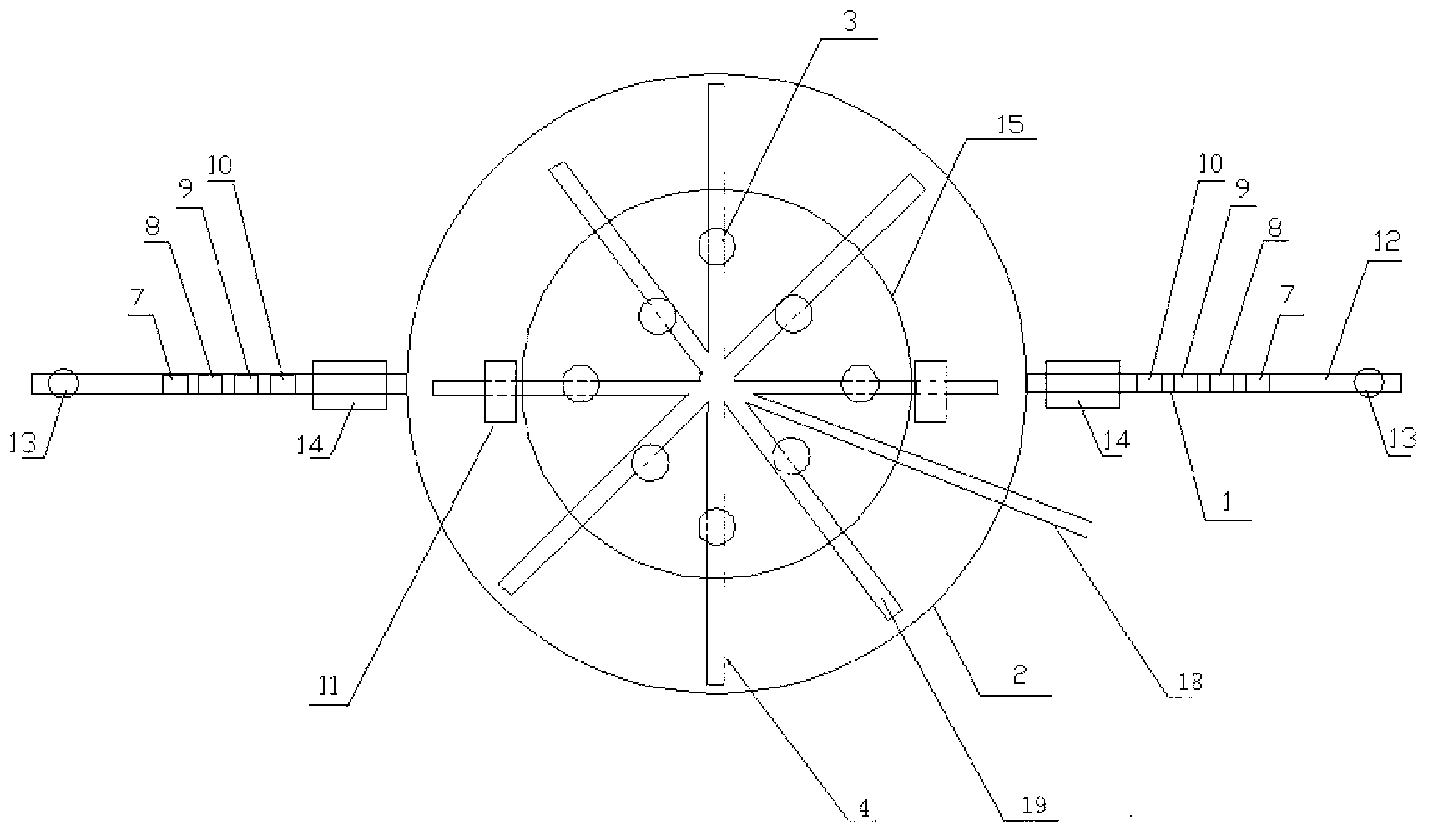

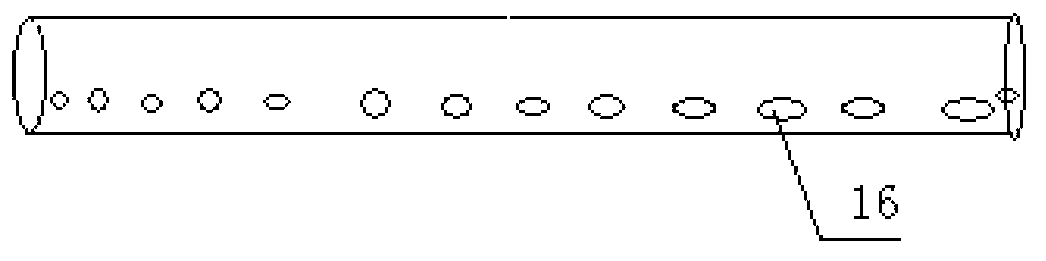

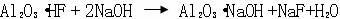

Device and method for removing fluorine ions in groundwater

ActiveCN102838199ASimple structureEasy to useWater contaminantsWater/sewage treatmentFiltrationWater quality

The invention provides a device for removing fluorine ions in groundwater, which comprises water inlet devices (1), a reaction device (2), ultra-filtration devices (3) and aeration devices (4), wherein the water inlet devices (1) are arranged on the reaction device (2) and are provided with material feed devices; the ultra-filtration devices (3) are arranged in the reaction device (2); the aeration devices (4) are arranged at the bottom of the reaction device (2) and aerate by aeration holes (16) on the aeration devices (4); the ultra-filtration devices (3) are provided with outlet pipes (5); and first water pumps (6) are arranged on the outlet pipes (5). The invention further provides a method for removing fluorine by the device for removing fluorine ions. The device for removing fluorine ions in groundwater has the characteristics of simple structure, convenient use, low cost, good fluorine removing effect, and high effluent quality.

Owner:HOHAI UNIV

Defluorination material and preparation and application thereof

InactiveCN106975456AImprove stabilityGood defluoridation effectOther chemical processesWater contaminantsSulfateMetal-organic framework

The invention discloses a defluorination material, which comprises a metal organic framework material, wherein metal hydroxide is dispersed on the surface of the metal organic framework material and / or in holes; the metal hydroxide is at least one of Mg(OH)2, M(OH)3 and Zr(OH)4; and M is a trivalent metallic element. The invention further discloses the defluorination material which is obtained through activating the metal organic framework material at 180-260 DEG C, putting the metal organic framework material into a solution into which a water-soluble salt of magnesium, a water-soluble salt of M and a water-soluble salt of zirconium are dissolved, regulating the pH of a system to be 8.0-9.5 by using a fixing agent, carrying out stirring reaction, carrying out solid-liquid separation, washing and drying. In addition, the invention further discloses an application of the defluorination material in defluorination of a zinc sulfate solution. The preparation method of the defluorination material is simple, and the prepared material has large specific surface area and uniformly dispersed metal groups, has good compatibility on fluorin ions and has very high selectivity and high defluorination efficiency.

Owner:CENT SOUTH UNIV

High performance agent for removing fluorin, preparation method, and application

InactiveCN101091903ARaise the pHGood defluoridation effectOther chemical processesWater/sewage treatment by sorptionBrickSorbent

The invention relates to a fluorine-removing agent with high efficiency and its preparation method and application. The invention includes the raw material agitation, the formation and the roasting which contains laterite, the aluminum salt, of which the weight dosage of the aluminum salt is 0-30% according to the gross weight of the raw material, the fluorine-removing agent can widely used in the profession of the fluorine sewage treatment, the high fluorine surface water purification. The invention is simple craft, and operation.

Owner:INST OF GEOGRAPHICAL SCI & NATURAL RESOURCE RES CAS

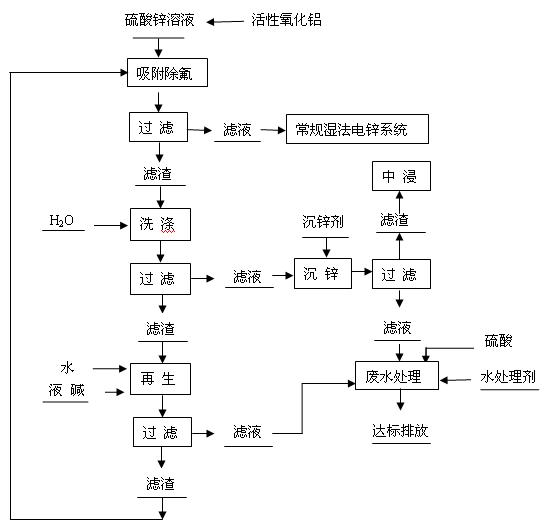

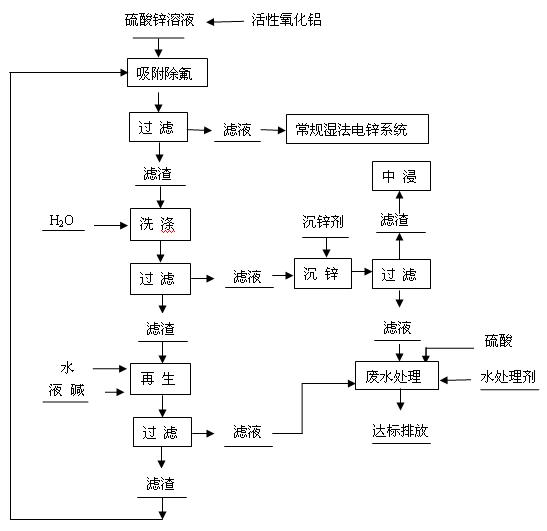

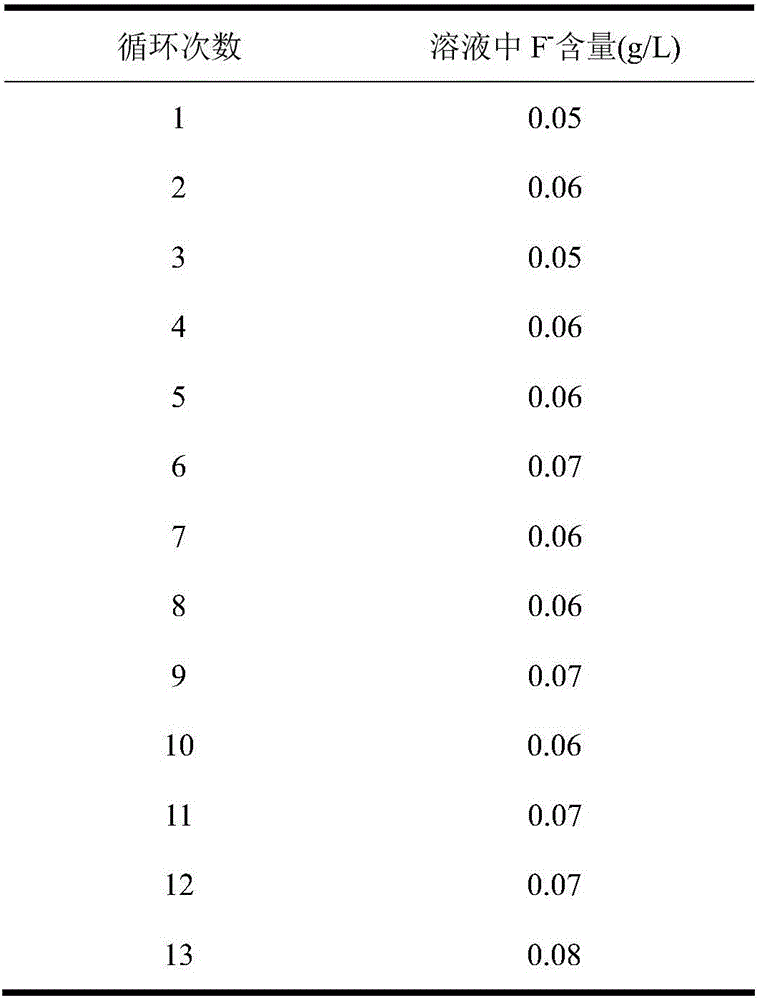

Method for removing fluorine from zinc sulfate solution with active alumina

InactiveCN102228746AImprove wear resistanceHighly corrosiveIon-exchange process apparatusPhotography auxillary processesSulfate zincProcess engineering

The invention relates to a method for removing fluorine from a zinc sulfate solution with active alumina. The method comprises the following steps: A, removing fluorine through adsorption: adding active alumina to the zinc sulfate solution, removing most fluorine through adsorption to the content of fluorine in the solution of less than 0.1 g / L, filtering, allowing the low fluorine zinc sulfate solution to enter into a zinc hydrometallurgy process, and allowing a filter residue to enter into a washing process; B, washing: adding water to the filter residue obtained in step A, washing, filtering, allowing a filtrate to enter into a zinc precipitation process, and allowing a filter residue to enter into a regeneration process; C, regenerating: adding water and caustic soda to the filter residue obtained in step B, regenerating, filtering, allowing a filtrate to enter into a waste water processing process, allowing a filter residue to enter into an adsorption fluorine removal process to obtain active alumina for removing fluorine from a next zinc sulfate solution; D, precipitating zinc: adding a zinc precipitant into the filtrate obtained in the step B, precipitating zinc, filtering,allowing a filtrate to enter into the waste water processing process, and allowing a filter residue to enter into the zinc hydrometallurgy process; and E, processing waste water: adding sulfuric acidand a water processing agent into the filtrates obtained in step C and step D, and discharging when standards are reached. The method has the characteristics of simplicity and easy operation, low cost, environmental protection, good fluorine removal effect, remarkable economic benefit and the like.

Owner:孙位成

Rare-earth electrolysis fume cleaning system and method

ActiveCN105603459AFast adsorptionGood defluoridation effectElectrolysis componentsElectrolysisRare earth

The invention relates to a rare-earth electrolysis fume cleaning system and method. The rare-earth electrolysis fume is treated by a two-stage cleaning technique, wherein the first stage is dry-process adsorption for defluorination, and the second stage is wet-process treatment for SO2 removal. The dry-process adsorption adopts special oxides for adsorption. The method has the advantages of high adsorption rate for fluorides and favorable defluorination effect, can recover fluorides in the fume, can remove SO2 in the fume, reduces the discharge of acidic gas, and is friendly to the environment. The system can recover fume waste heat, has the characteristics of high heat utilization ratio, low operating cost, high automation level and the like, and is simple to operate.

Owner:CENT SOUTH UNIV

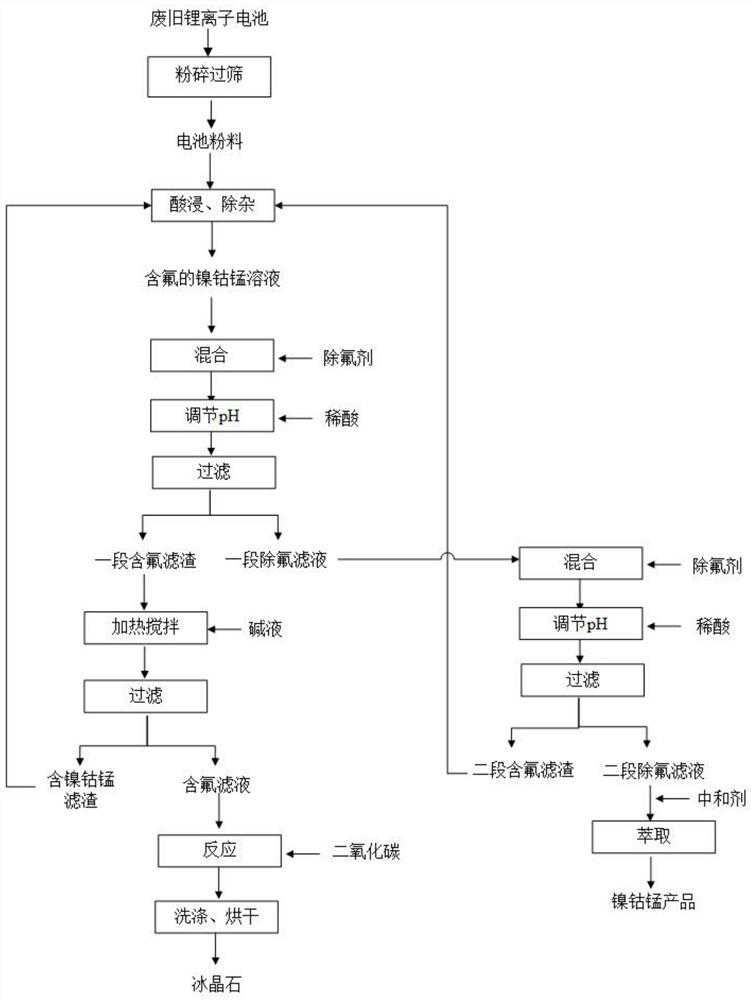

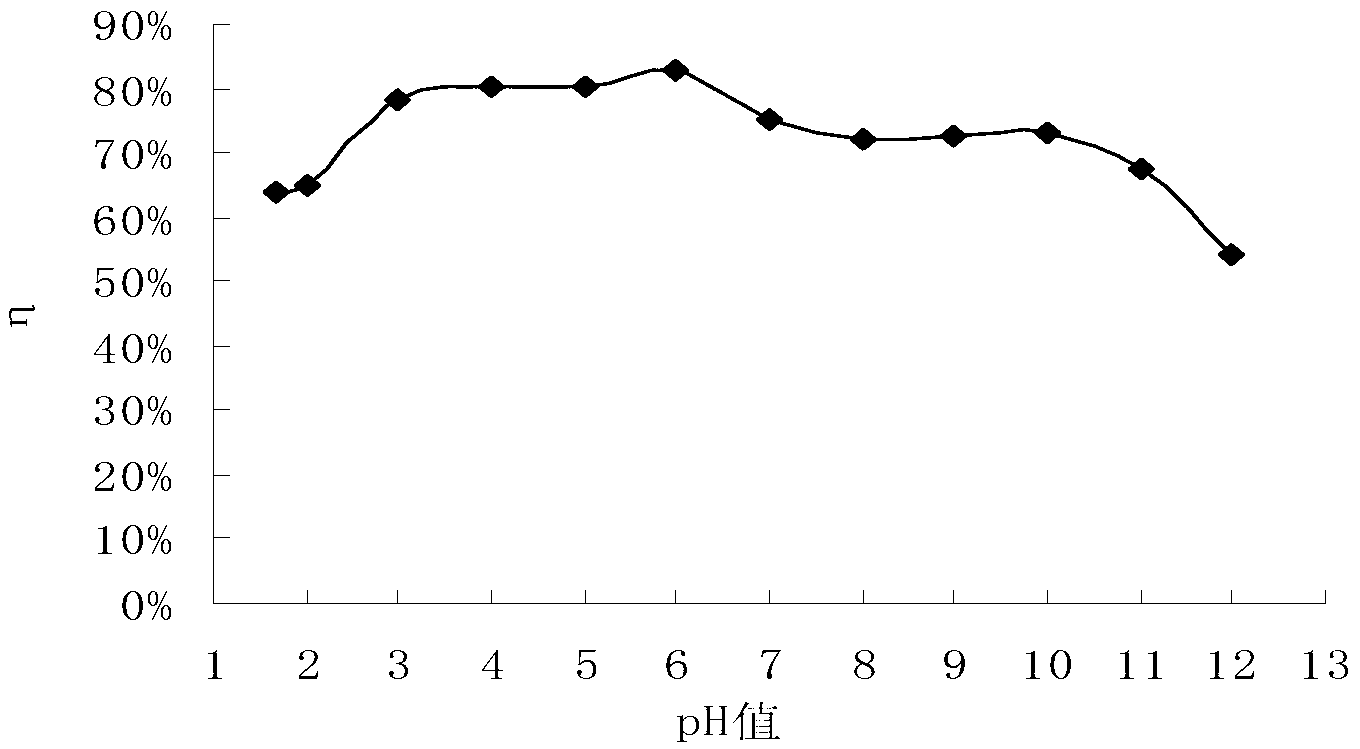

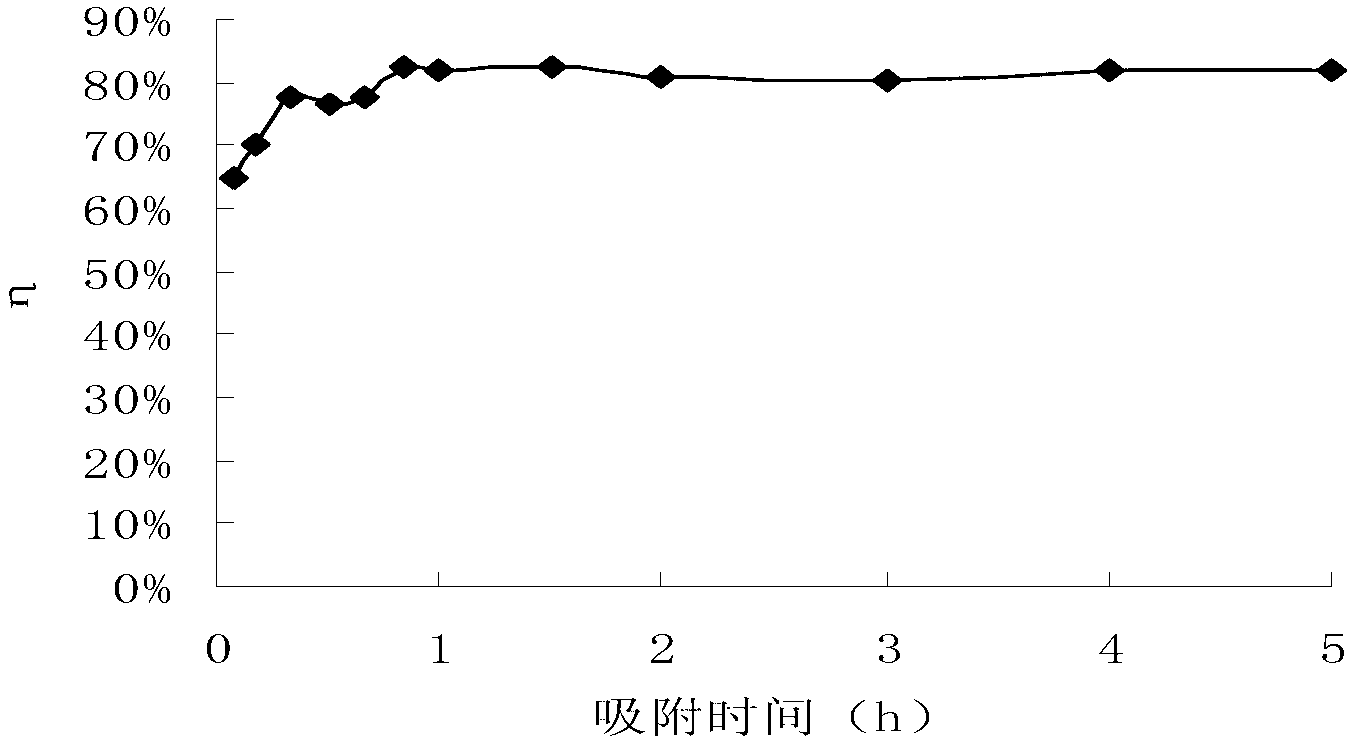

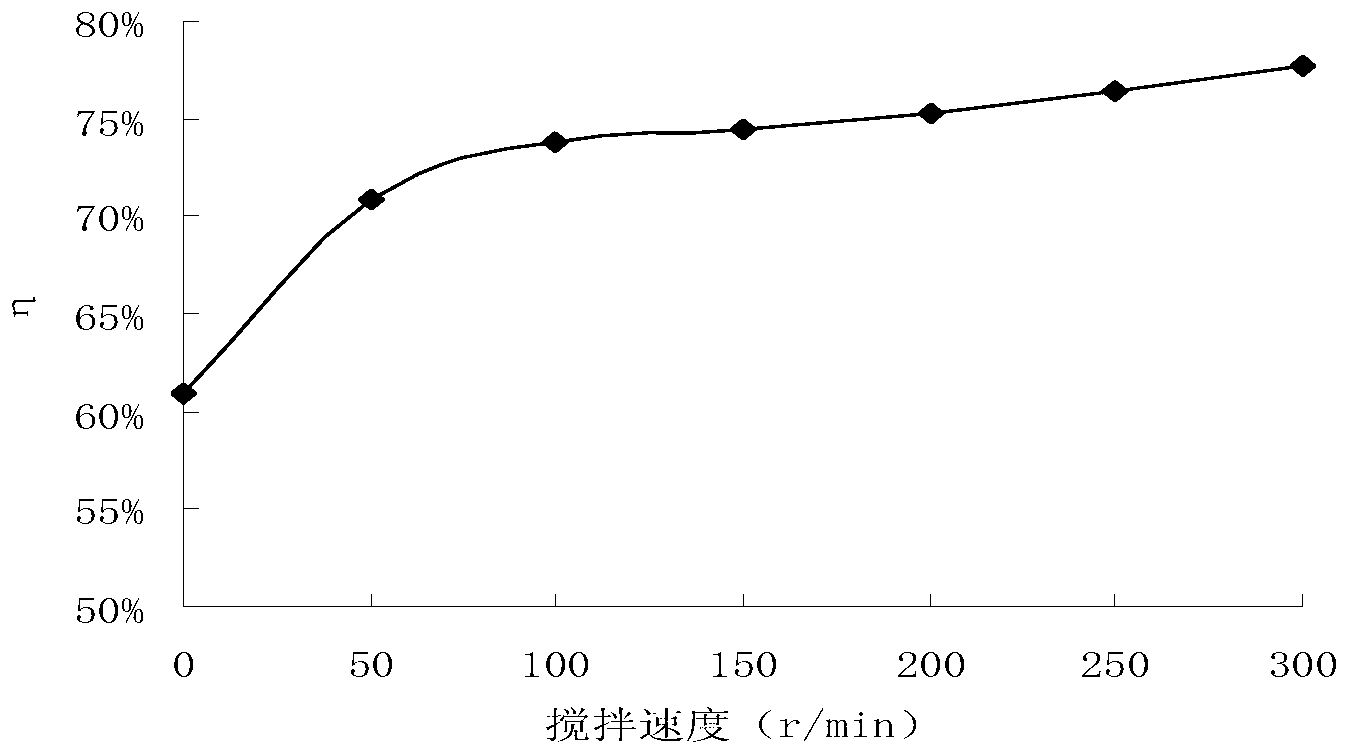

Recovery method for removing fluorine from nickel-cobalt-manganese solution

InactiveCN112079371AReduce lossesIncrease added valueWaste accumulators reclaimingAluminium fluoridesPhysical chemistryManganese

The invention relates to a recovery method for removing fluorine from a nickel-cobalt-manganese solution. The method comprises the following steps of: carrying out acid leaching and impurity removal on battery powder to obtain a fluorine-containing nickel-cobalt-manganese solution; mixing the obtained fluorine-containing nickel-cobalt-manganese solution with a fluorine removal agent to obtain a mixed slurry; adjusting the pH value of the obtained mixed slurry to 2-5, and performing filtering to obtain a first-stage defluorination filtrate and a first-stage fluorine-containing filter residue; washing the first-stage fluorine-containing filter residue, adding the washed first-stage fluorine-containing filter residue into alkali liquor, performing heating and stirring, and conducting filtering to obtain fluorine-containing filtrate and nickel-cobalt-manganese-containing filter residue. The method disclosed by the embodiment of the invention has a good fluorine removal effect in the front-section nickel-cobalt-manganese solution, meanwhile, other impurities are not introduced, the obtained fluorine-containing filter residue can meet the requirements of industrial cryolite products after being purified, and the method has great economic benefits.

Owner:HUNAN BRUNP RECYCLING TECH +2

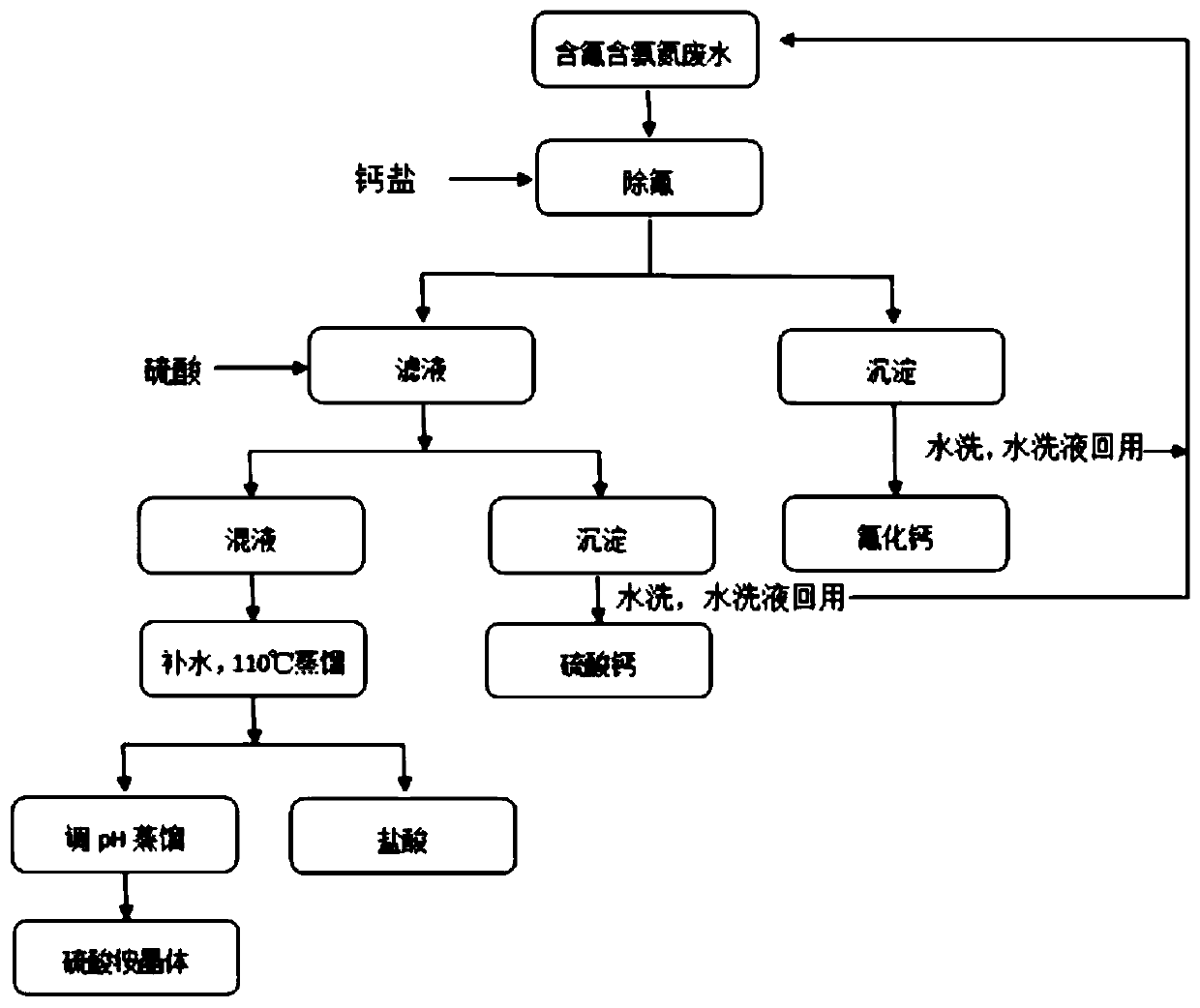

Chitosan/natural zeolite material for removing fluorine in water

InactiveCN103191700AEasy to manufactureLow costOther chemical processesWater/sewage treatment by sorptionPre treatmentAcetic acid solution

The invention discloses a chitosan / natural zeolite material for removing fluorine in water. The chitosan / natural zeolite material is a particle which is prepared by enveloping the surface of the natural zeolite by using the chitosan, wherein the mass of the chitosan is 0.1-16.7% of the total mass of the particle, and the average particle size of the particle is 1-2mm. The preparation method of the chitosan / natural zeolite material comprises the following steps of: firstly calcining the screened natural zeolite in a muffle furnace at the temperature of 450-550 DEG C for 1-2 hours, adding glacial acetic acid into deionized water to prepare the glacial acetic acid solution at the concentration of 0.5-10%, and adding the chitosan and the natural zeolite which is pretreated by calcination into the glacial acetic acid solution while stirring to obtain the chitosan / natural zeolite material. The chitosan / natural zeolite material is fast in fluorine removal speed, large in fluorine removal volume, stable in fluorine removal effect, simple and easy in implementation of the preparation process, easy in storage, low in preparation cost, applicable to the in-site fluorine removal for ground water, and suitable for the fluorine removal for the ground water with high Cl- and HCO3- content.

Owner:BEIJING ZHONGDI HONGKE ENVIRONMENT SCI & TECH

Cerium/aluminum modified montmorillonite fluoride removal adsorbing agent and preparation method thereof

InactiveCN106824058ALow costGood defluoridation effectOther chemical processesWater contaminantsSorbentCerium

The invention discloses a cerium / aluminum modified montmorillonite fluoride removal adsorbing agent and a preparation method thereof. The adsorbing agent comprises a montmorillonite carrier and active ingredients of the carrier: cerium and aluminum. The preparation method comprises the following preparation processes: sodium treatment of montmorillonite, preparation of pillar liquid, pillar modification of the montmorillonite, calcination, smashing and sieving of modified montmorillonite solids and the like. According to the fluoride removal adsorbing agent, a synergistic effect can be achieved between the active ingredients and the montmorillonite, so that the adsorbing agent is good in adsorption capacity and wide in applicable pH range; the defect of high cost of fluoride removal by adsorption with a single rare-earth metal or rare-earth metal modified montmorillonite is overcome, so as to lower the cost of fluoride removal; in addition, secondary pollution is not caused, so that the adsorbing agent can be used for treating high fluorine drinking water.

Owner:HEFEI UNIV OF TECH

Novel liquid defluorination agent as well as preparation method and application thereof

ActiveCN111302465AGood defluoridation effectPlay the role of adsorption and flocculationGeneral water supply conservationWater contaminantsAluminium chlorideAluminium chlorohydrate

The invention discloses a novel liquid defluorination agent as well as a preparation method and application thereof, and belongs to the technical field of fluorine-containing wastewater treatment. Theliquid defluorination agent is prepared from the following components in percentage by mass: 25% of polyaluminum chloride, 17% of polyaluminum ferric chloride, 9% of magnesium sulfate, 6% of N, O-carboxymethyl chitosan, 3% of a coagulant aid and 40% of purified water. When the defluorination agent disclosed by the invention is used for treating low-concentration fluorine-containing wastewater, the fluorine ion concentration of effluent can be less than or equal to 1.0 mg / L, and the fluorine removal effect is good.

Owner:山东环瑞生态科技有限公司

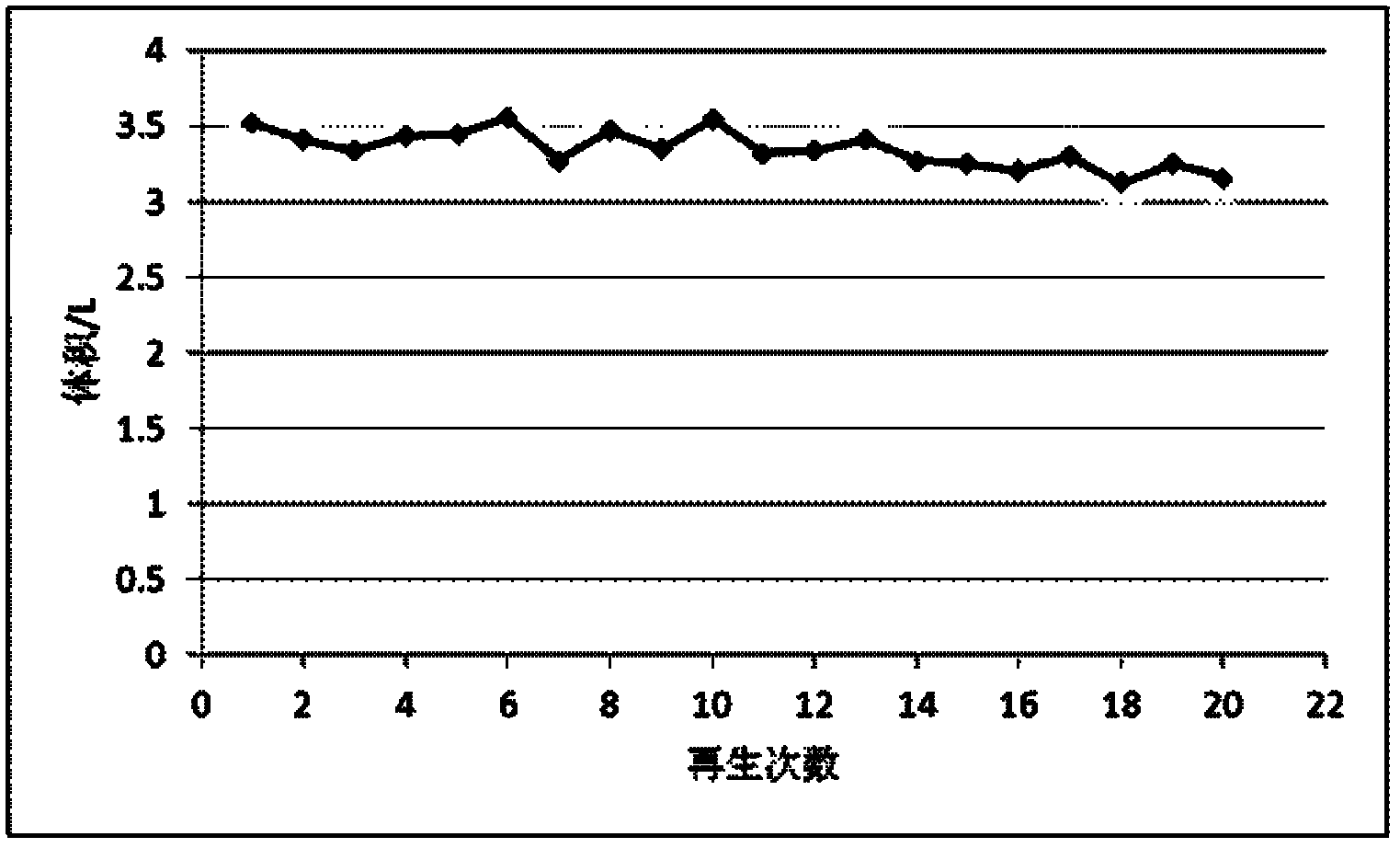

Preparation and regeneration method of water treatment defluoridation material

ActiveCN102489241ALow priceGood defluoridation effectOther chemical processesWater contaminantsChemistryMagnesium

The invention discloses a preparation and regeneration method of a water treatment defluoridation material. The method comprises the following steps of: A, selecting raw materials: selecting natural calcium and magnesium minerals as the raw materials; B, crushing and sieving the raw materials; C, not calcining or calcining particles in a furnace; D, closing a heating device, cooling and taking the raw materials; E, placing the calcined raw materials into a container or directly placing the non-calcined raw materials into the container after the process B, adding phosphoric acid or a mixed solution of phosphoric acid and calcium hydrophosphate to soak the raw materials, and removing acid liquor after the treatment is completed; F, soaking the raw materials by using sodium hydroxide or a potassium hydroxide solution, cleaning by using clear water after the solution is removed, and drying to obtain a defluoridation filter material; and G, regenerating the saturated filter material by using sodium hydroxide or white alum. The preparation and regeneration method of the water treatment defluoridation material, provided by the invention, has the advantages of low cost, simple production cost, wide application range of the filter material about water quality and pH, convenience for use, large absorption capacity and free secondary pollution; furthermore, the water treatment cost is reduced greatly, and the treated water is good in taste, stable in water quality and high in safety, and can be regenerated for many times.

Owner:徐彬清

Composite fluorine removal agent and preparation method thereof

InactiveCN108911091AIncrease profitEffective control of fluorine contentWater contaminantsWater/sewage treatment by flocculation/precipitationIron saltsFree cooling

The invention discloses a composite fluorine removal agent and a preparation method thereof. The composite fluorine removal agent is prepared from the following components: in percent by mass, 70.00%of calcium salts, 15.80% of water, 5.5% of water glass, 2.00% of acids, 1.5% of iron salts, 5.00% of aluminum salts and 0.20% of polydimethyldiallyl ammonium chloride, and the preparation method comprises the steps: injecting the calcium salts into an enamel reaction kettle, adding water, and performing full and even mixing; then adding the acids to the reaction kettle, and performing full mixing;continuously inputting the iron salts, performing full dissolution, adding the aluminum salts continuously, and performing full dissolution; slowly adding the water glass at an adding speed of 275 kg / h for an adding period of 1 h, adding the acids, and performing guarantee of a constant temperature; adding the polydimethyldiallyl ammonium chloride slowly and uniformly under the conditions of theconstant temperature and stirring, performing stirring for polymerization for 3 hours, transferring the polymerized product to a finished product barrel, and performing natural cooling to normal temperature so as to obtain the target product. The composite fluorine removal agent has the advantages of a good fluorine removal effect, a high utilization rate and the like.

Owner:湖北蓝钴环保科技有限公司

Preparation method of magnetic composite adsorbing material for Antarctic krill protein enzymolysis solution defluorination

InactiveCN104815627AImprove magnetic propertiesEasy to separateOther chemical processesWater/sewage treatment by sorptionFiltrationApatite

The invention discloses a preparation method of a magnetic composite adsorbing material for Antarctic krill protein enzymolysis solution defluorination, which comprises the following steps: 1. adding Fe3O4 into a chitosan acetic acid solution, and carrying out ultrasonic dispersion; 2. adding the solution into a Ca(NO3)2 solution, and stirring; 3. under stirring conditions, slowly and dropwisely adding the solution into a (NH4)2HPO4 solution while keeping the Ca / P mole ratio at 1.60-1.80 and regulating the pH value at 10-11, and standing; and 4. carrying out vacuum filtration on the solution, repeatedly washing with deionized water and anhydrous ethanol until the solid becomes neutral, carrying out vacuum drying, pulverizing the dried product into powder, and screening to obtain the magnetic hydroxyapatite / chitosan (HA / CS) composite adsorbing material. The saturation magnetization of the magnetic composite adsorbing material is 18.0-20.0 emu / g. When the magnetic composite adsorbing material is used for defluorinating the Antarctic krill protein enzymolysis solution, the water-soluble fluorine removal rate can reach 90% above; and the adsorbing material after defluorination is more convenient for separation, recovery and regeneration due to the magnetism of the adsorbing material.

Owner:DALIAN POLYTECHNIC UNIVERSITY

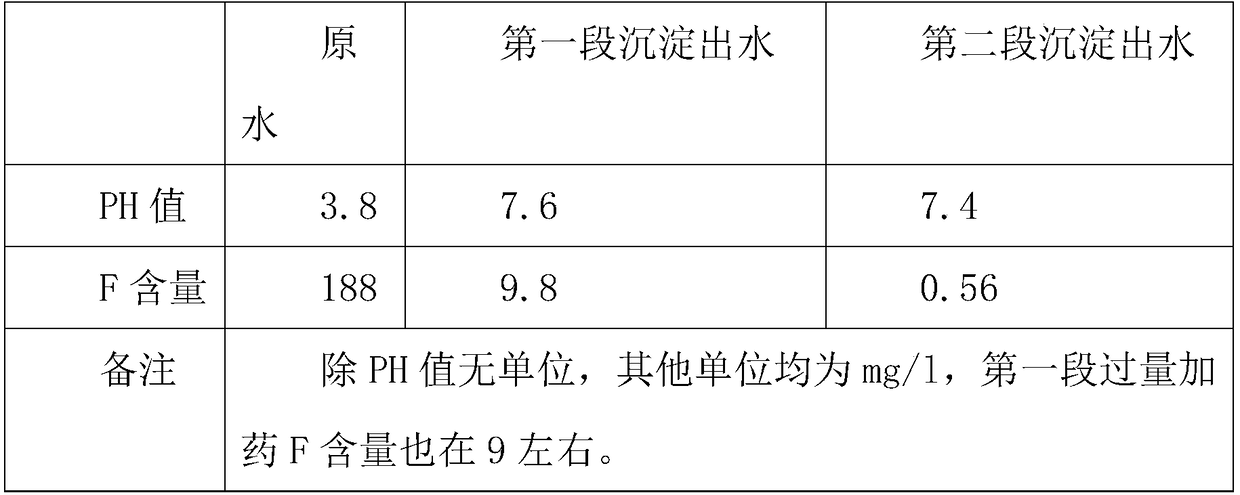

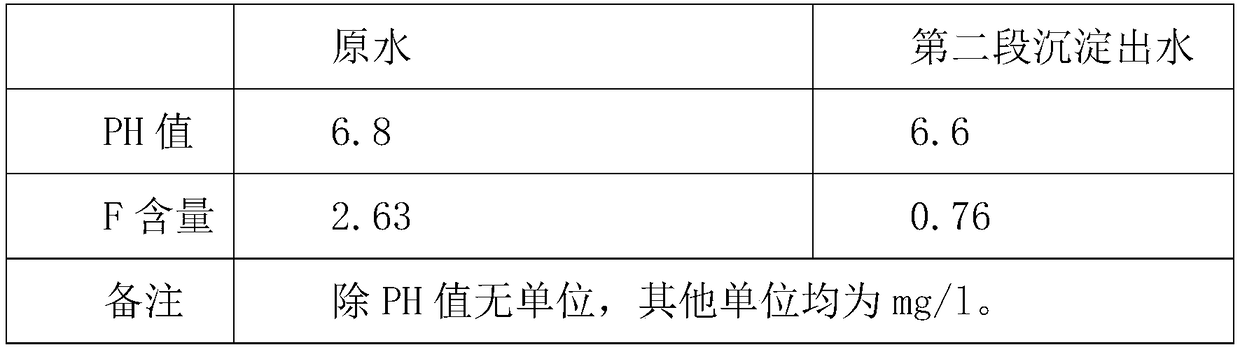

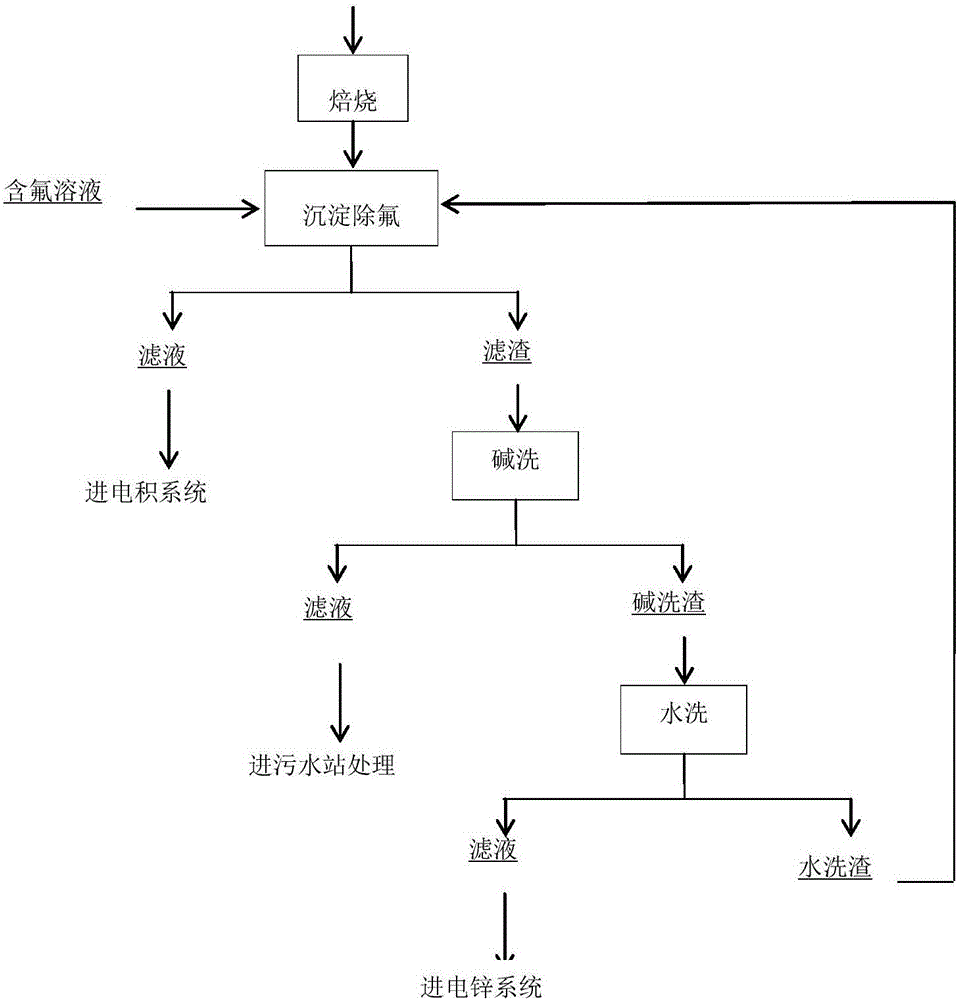

Method for removing fluorine from zinc sulfate solution after roasting of zinc smelting silicon residues

InactiveCN106756010AImprove the utilization rate of fluorine removalReduce manufacturing costPhotography auxillary processesElectrolysis componentsSulfateRoom temperature

The invention discloses a method for removing fluorine from a zinc sulfate solution after roasting of zinc smelting silicon residues. The method comprises the following steps that A, the silicon residues are prepared, specifically, the silicon residues generated in the zinc hydrometallurgy process are roasted under the condition of 300-650 DEG C; B, sediment defluorination is conducted, specifically, the roasted silicon residues obtained in the step A are added into the zinc sulfate solution with the pH value no larger than 5.0 and washed at a room temperature till the concentration of fluorine ions in the solution is decreased to 60-80%; C, the sediment residues are subjected to alkaline cleaning, specifically, the residues obtained in the step B are subjected to alkaline cleaning, and the fluorine ions adsorbed to the silicon residues are desorbed; and D, alkaline cleaning residues are washed, specifically, the alkaline cleaning residues obtained in the step C are washed through clear water to enable zinc in the residues enter an aqueous solution to be recycled, and the washed residues are continuously defluorinated. By adoption of the method, the number of cyclic times can reach 40 or above, and the defluorination effect can still be kept at 50% or above. The method has the advantages of being extensive in raw material resource, short in technological process, easy to operate, high in defluorination rate, low in operation cost, remarkable in economic benefit and the like.

Owner:CHENZHOU FENGYUE ENVIRONMENTAL PROTECTION TECH

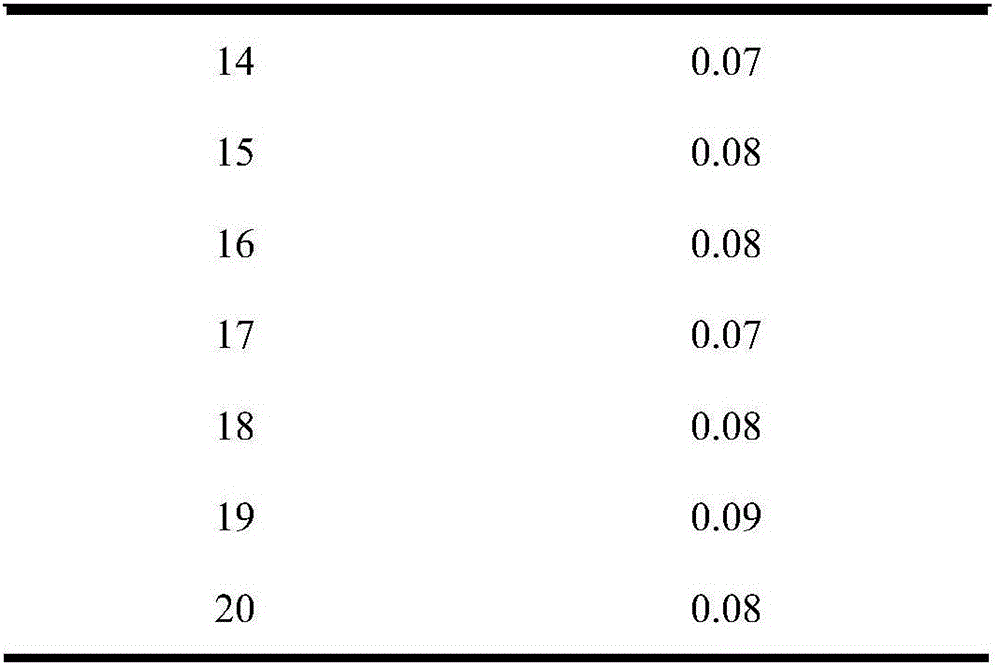

Water treatment method for fully utilizing resources in high-fluorine and high-ammonia nitrogen wastewater

ActiveCN110092521AGood defluoridation effectReduce residualChlorine/hydrogen-chloride purificationWater contaminantsFiltrationDistillation

The invention discloses a water treatment method for fully utilizing resources in high-fluorine and high-ammonia nitrogen wastewater. The treatment method comprises the following steps: (1) adding a calcium salt to the wastewater, performing stirring and uniform mixing to form a calcium fluoride precipitate, and filtering the obtained solution; (2) adding sulfuric acid to a filtrate obtained through filtration in step (1), performing stirring and uniform mixing to form a calcium sulfate precipitate, and filtering the obtained solution; (3) continuously adding water to a filtrate obtained by filtration in step (2), carrying out reduced pressure distillation, and cooling and refluxing the obtained distillate to recover hydrochloric acid; and (4) adding ammonia water to a remaining solution obtained after distillation in step (3) to adjust the pH value, carrying out reduced pressure distillation, and collecting obtained ammonium sulfate crystals. The method has the advantages of easinessin control of conditions, mature process, no secondary waste, high economic values of the product, and realization of complete recycling and full utilization of ammonia nitrogen and fluorine in the wastewater.

Owner:盛隆资源再生(无锡)有限公司

Method for removing fluoride in drinking water by complexation-coacervation-adsorption with defluorination adsorption material based on aluminium base composite metal oxide

ActiveCN103274539AImprove the effect of fluoride removalReduce the cost of defluoridation treatmentWater contaminantsMultistage water/sewage treatmentParticulatesFree form

The invention relates to a method for removing fluoride in drinking water by complexation-coacervation-adsorption with defluorination adsorption material based on aluminium base composite metal oxide. Firstly free form fluorine in water is converted into complexation state fluorine by controlling appropriate pH value condition, aluminium salt form and throwing amount or the like; calcium hydrate and aluminium salt are introduced for realizing coacervation process and providing active adsorption sites with abundant surface hydroxies, thereby the dissolved state fluorine in water is converted into particulate type fluorine by coacervation and absorption effects; dissolved state fluorine is further removed after water flows though an absorption fixed bed reactor filled with defluorination adsorption material based on aluminium base composite metal oxide; finally, water flows through a filter reactor, and colloid, particle and other impurities contained in the absorption fixed bed reactor water outlet are removed. Fluorine in the drinking water is removed by using the method provided by the invention, and the processed water can reach the WHO, USEPA and other related standards and national drinking water standard (GB5749-2006).

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

Spherical hydroxyapatite fluoride-removing material regenerated powder and application thereof

InactiveCN103349974AReduce the cost of defluoridationEnsure water quality safetyOther chemical processesWater contaminantsParticulatesWastewater

The invention provides spherical hydroxyapatite fluoride-removing material regenerated powder comprising natural particles and inorganic aluminum salt. The invention also provides a method for removing fluoride from underground water by using the regenerated powder. The spherical hydroxyapatite fluoride-removing material regenerated powder provided by the invention has the advantages of scientific formula, wide raw material source, and low cost. An underground water fluoride-removing method provided by the invention has the advantages of simple technology, convenient application, low cost, good fluoride-removing effect, high outlet water quality, no need of periodic regeneration, low wastewater production, low processing cost, and good popularization and application prospect.

Owner:HOHAI UNIV +1

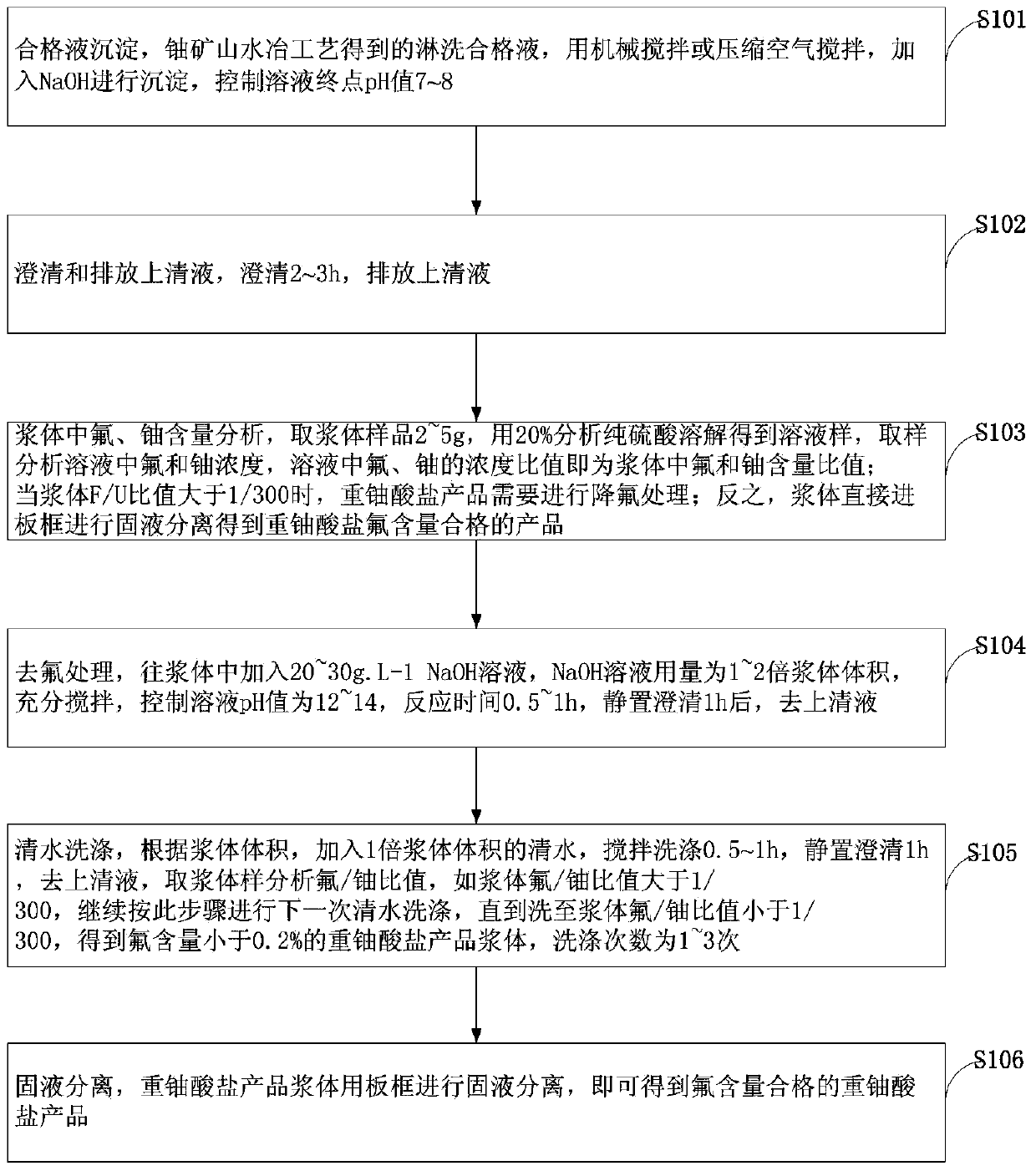

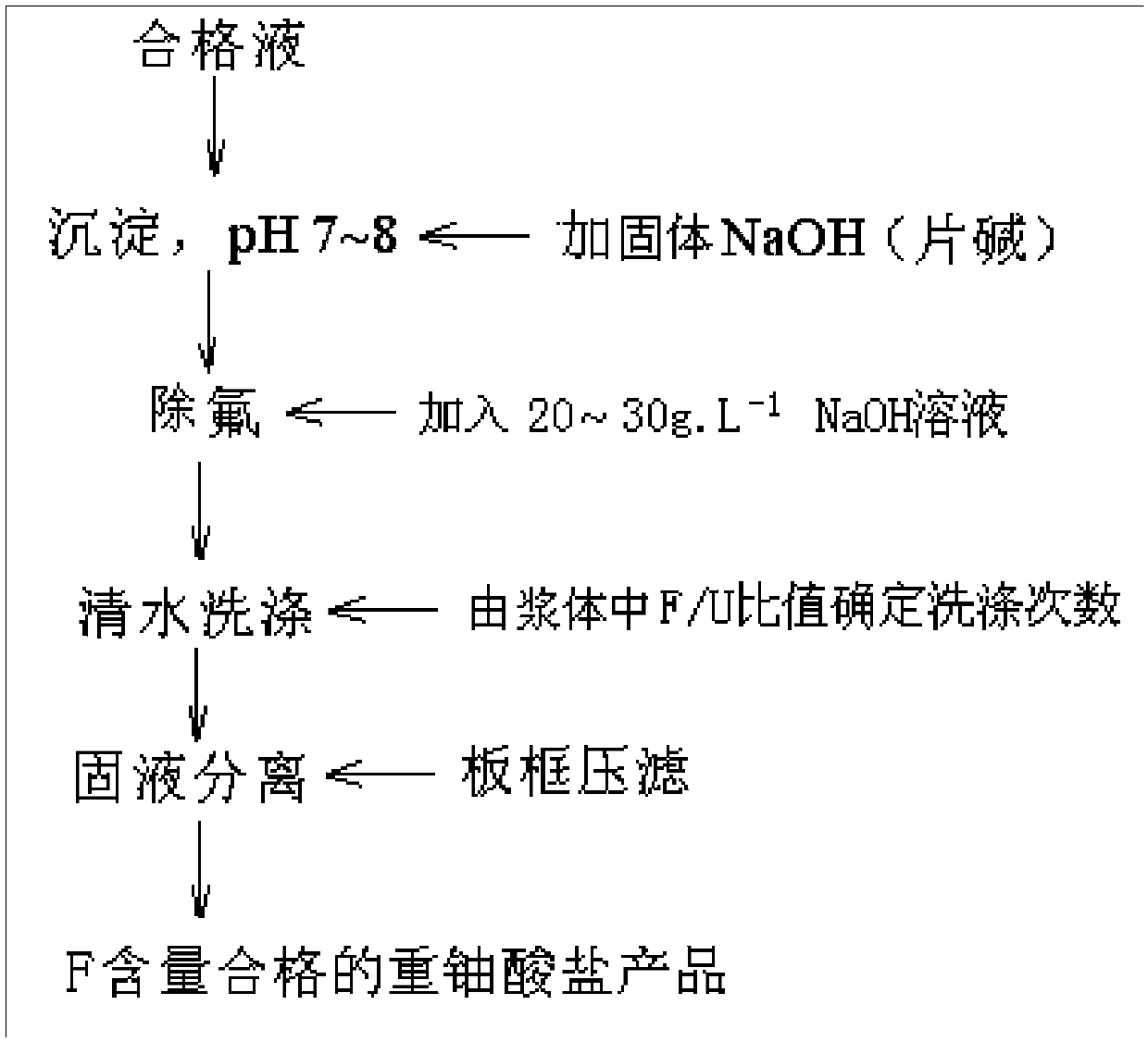

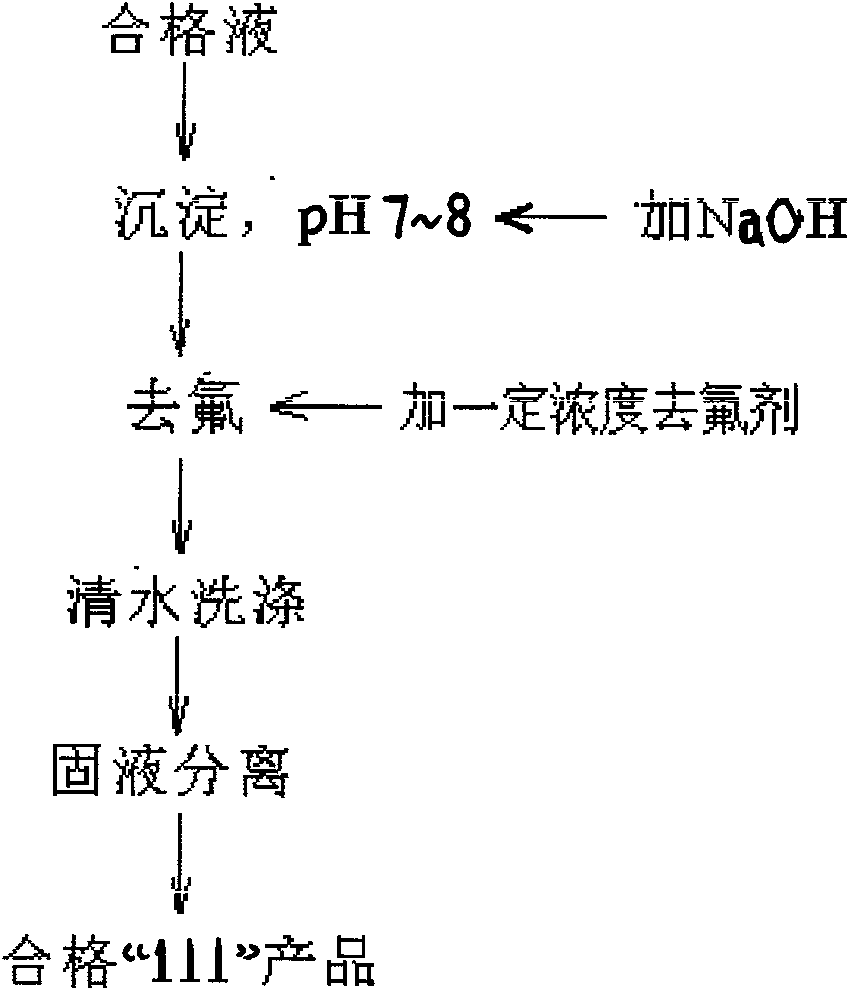

Diuranate product fluorine reduction technique

The invention discloses a diuranate product fluorine reduction technique which comprises the following steps: precipitating a qualified solution, and controlling the end pH value of the solution at 7-8; settling, and discharging the supernate; analyzing the contents of fluorine and uranium in the slurry; fluorine removal treatment: adding 1-2 times by volume of 20-30g.L<-1> NaOH solution into the slurry, sufficiently stirring to react for 0.5-1 hour while controlling the pH value of the solution at 12-14, standing to settle for 1 hour, and removing the supernate; and washing with clear water, and carrying out solid-liquid separation. The NaOH solution is added as the defluorinating agent to control the pH value and generate the precipitate, stirred and subjected to solid-liquid separation, 1-2 times volume of the tap water is used for washing the slurry, and the solid-liquid separation is carried out to obtain the diuranate product with qualified fluorine content. The technique is simple to operate, and has the advantages of low fluorine removal cost and favorable fluorine removal effect; and the fluorine content of all the treated diuranate product produced by the uranium ore enterprise satisfies the national standard of lower than 0.2%.

Owner:NANHUA UNIV +1

Zirconium loaded biological composite adsorbent used for removing fluorine in water, and regeneration method and applications thereof

InactiveCN110102265AImprove work efficiencyExpand application spaceOther chemical processesWater contaminantsSorbentZirconium oxychloride

The invention discloses a zirconium loaded biological composite adsorbent used for removing fluorine in water, and a regeneration method and applications thereof. The zirconium loaded biological composite adsorbent used for removing fluorine in water is prepared from zirconium oxychloride, artemia salina egg shell, sodium hydroxide, and ethanol, can be used for removing trace amount fluorinion inwater, and is capable of maintaining relatively large adsorption capacity and relatively high selectivity when there are other co-existing ions in water body. According to fluorine-containing sewage processed using the zirconium loaded biological composite adsorbent, when the discharged water fluorinion concentration is higher than 1.0mg / L, adsorption is stopped, and a mixed solution of NaOH and NaCl is adopted for regeneration of the zirconium loaded biological composite adsorbent. The zirconium loaded biological composite adsorbent is excellent in fluorine removing effect; production technology is easy to control; production cost is relatively low; the zirconium loaded biological composite adsorbent can be stored steadily for about 1 year, and can be used for processing of drinking water.

Owner:ZHEJIANG SHUREN UNIV

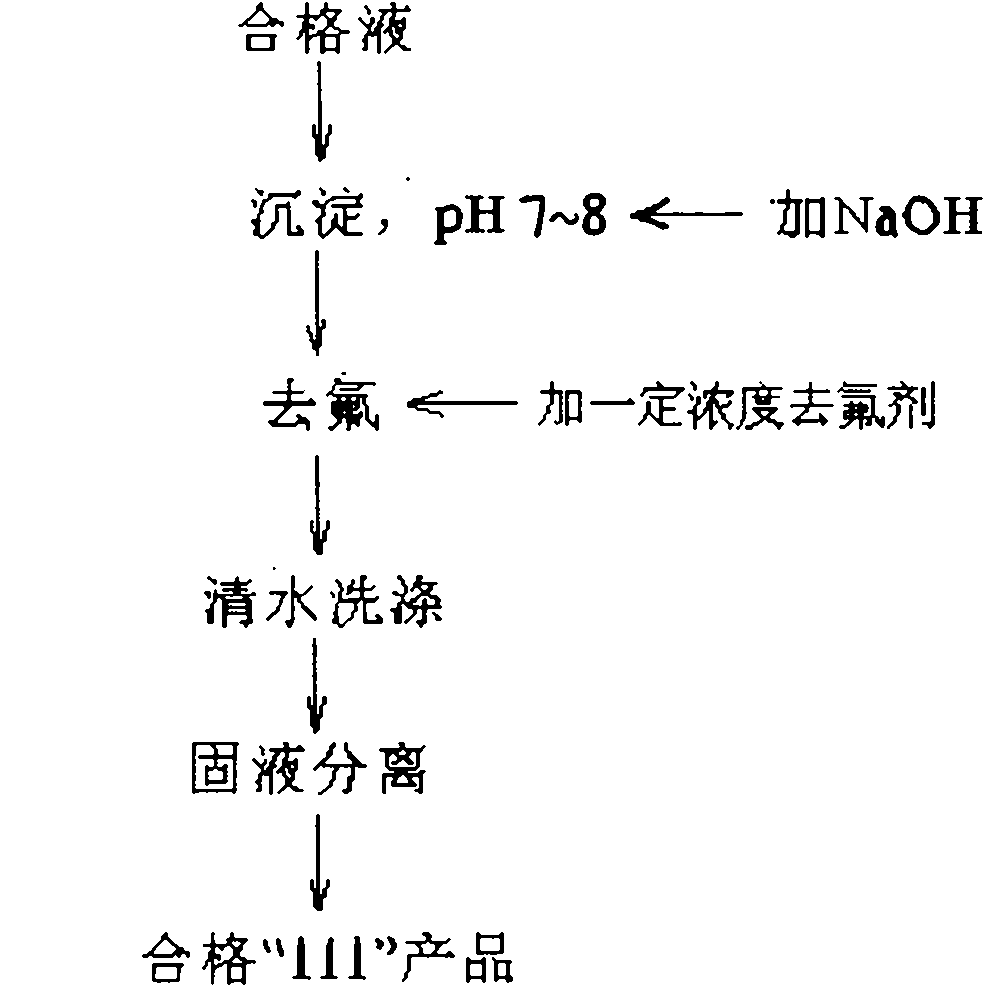

Process for reducing fluorine in biuranate product

InactiveCN101844812AEasy to operateLow cost of defluorinationUranium compoundsL&D processAnalysis method

The invention relates to a process for reducing fluorine in a biuranate product. The process comprises the following technical steps of: precipitating qualified liquid; analyzing the ratio of the percentage composition of fluorine (F) to that of uranium (U) in slurry by an analysis method; when the F / U ratio is more than 1 / 300, performing fluorine reducing treatment on the slurry; adding a fluorine-removing agent with a certain concentration into the treated slurry; washing the mixture with clear water; and separating solid from liquid. The process has the advantages of simple operation, low fluorine removing cost and good fluorine removing effect.

Owner:NANHUA UNIV +1

Preparation method of industrial water fluorine removal agent

ActiveCN104085973AGood defluoridation effectHigh fluoride removal efficiencyWater/sewage treatmentEthylenediamineSodium hydroxide

The invention discloses a preparation method of an industrial water fluorine removal agent, and belongs to the technical field of industrial water fluoride removal. The industrial water fluorine removal agent is prepared from the following synthetic raw materials: acrylic acid, de-ionized water, acrylamide, urea, sodium carbonate, ferrous hydroxide, aluminum hydroxide, 10%-30% sodium hydroxide, active carbon, 10% ethylenediamine, nitrilo, ammonium persulfate, sodium hydrogen sulfite and calcium chloride. The preparation method comprises the following steps: preparing the synthetic raw materials, polymerizing and mixing to prepare the industrial water fluorine removal agent. The preparation method has the advantages that the prepared fluorine removal agent is high and stable in fluorine removal efficiency, and has a good fluorine removal effect on low-fluorine water with fluoride content of 20-50mg / L; a medicament preparation process is simple.

Owner:SHOUGANG CORPORATION

Composite fluorine removal agent and preparation method thereof

ActiveCN113651407AEffective scaling controlExtended cleaning cycleWater contaminantsWater/sewage treatment by flocculation/precipitationCoking wastewaterMetallurgical coke

The invention belongs to the technical field of water treatment agents, and relates to a composite fluorine removal agent. The composite fluorine removal agent is prepared from the following raw materials in parts by weight: 10 to 15 parts of a polyaspartic acid-sulfonated styrene copolymer, 5 to 8 parts of zinc salt, 8 to 10 parts of acid, 25 to 35 parts of ferric salt, 3 to 5 parts of cationic starch ether quaternary ammonium salt and 27 to 49 parts of water. The invention also discloses a preparation method of the composite fluorine removal agent. Compared with the prior art, the composite fluorine removal agent has the following advantages that the composite fluorine removal agent mainly aims at chemical deep fluorine removal of industrial wastewater such as coal metallurgy coking wastewater, glass manufacturing wastewater, polycrystalline silicon, semiconductor wastewater and pharmaceutical wastewater, is a reddish brown liquid in appearance, mainly utilizes the strong coagulation and flocculation functions of cationic starch ether quaternary ammonium salt, utilizes the adsorption and complexation capabilities of zinc salt and iron salt to the fluorine ions, controls fluorine ions in effluent to be 2 mg / L or below, and has good fluorine removal effect; and the polyaspartic acid copolymer can effectively control the scaling of calcium salt, prolong the cleaning period of a pipeline and improves the utilization rate of lime.

Owner:SCI GREEN SHANDONG ENVIRONMENT TECH CO LTD

Improved fluorine removal agent

InactiveCN110835153AImprove precipitation effectLow concentration of F ionsWater contaminantsWater/sewage treatment by flocculation/precipitationSulfateEnvironmental engineering

The invention discloses an improved fluorine removal agent, and a preparation method and a use method thereof. The fluorine removal agent comprises ferrous sulfate, nonferrous alumina, water and a polymeric flocculant. The preparation method comprises the following steps: S1, putting ferrous sulfate, nonferrous alumina and water into a reaction kettle, heating the reaction kettle, and performing stirring to achieve complete dissolving in order to obtain a mixture; S2, taking and adding the polymeric flocculant into the mixture obtained in step S1; and S3, performing mixing and stirring, and adjusting the pH value of the obtained mixture to 3 with an acidic pH regulator after complete cooling is performed in order to obtain the improved fluorine removal agent. The use method comprises the following steps: S1, detecting the fluorine ion concentration of to-be-treated water; S2, adding the improved fluorine removal agent according to the detection result of the fluorine ion concentrationof the to-be-treated water; S3, controlling the pH value of the to-be-treated water to be 6.5-7.0; and S4, carrying out a standing reaction on the treated water obtained after the addition of the improved fluorine removal agent for 30 min or above. The improved fluorine removal agent prepared by the preparation method has a good fluorine removal effect after the use steps.

Owner:昆山欣余清环保材料有限公司

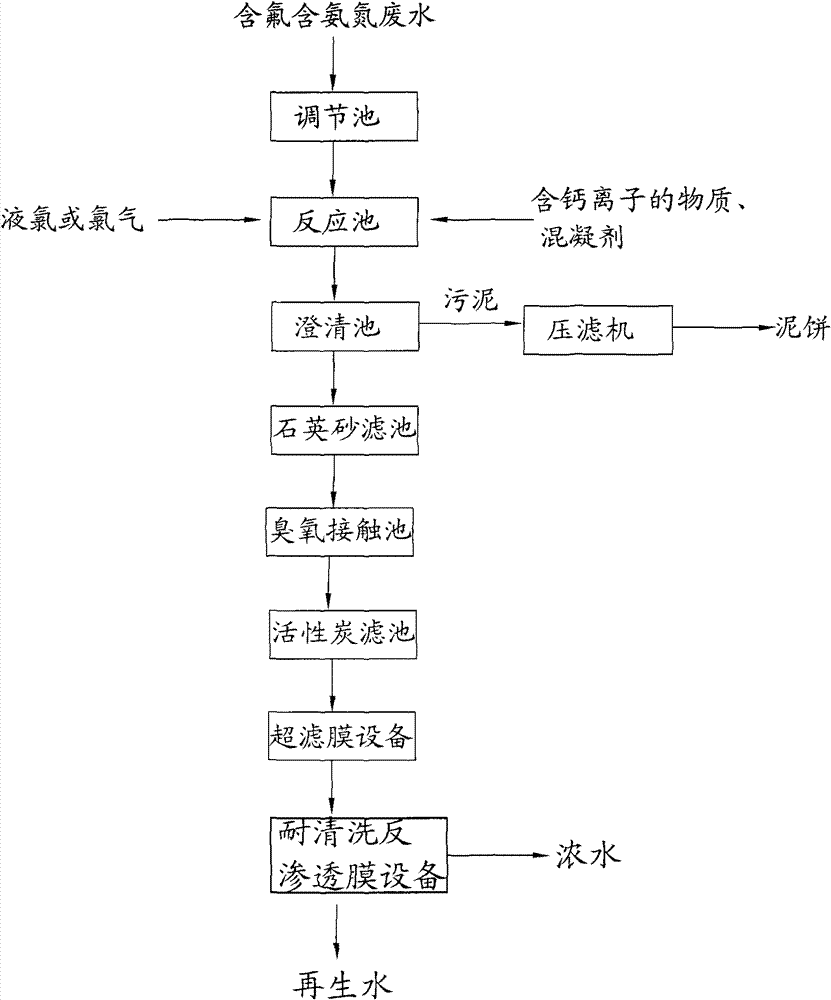

Method for reclaiming fluorine-containing and ammonia nitrogen-containing waste water in electronic industry

ActiveCN102126798BReduce ammonia nitrogen contentTo achieve the treatment effectWater contaminantsMultistage water/sewage treatmentDevice formUltrafiltration

The invention relates to a method for reclaiming fluorine-containing and ammonia nitrogen-containing waste water in electronic industry. In the method, waste water passes through a three-in-one integral device formed by the sequential series connection of a waste water treatment plant treating process, a water works treating process and a pure water treatment plant treating process to obtain reclaimed water. The device for implementing the waste water treatment plant treating process comprises a conditioning tank, a reaction tank and a clarifying tank; the device for implementing the water works treating process comprises a quartz sand filter tank, an ozone contact tank and an activated carbon filter tank; and the device for implementing the pure water treatment plant treating process comprises an ultrafiltration membrane device and a cleaning-resistant reverse osmosis membrane device, and thick water produced by the cleaning-resistant reverse osmosis membrane device can be reclaimed or not to obtain the reclaimed water according to the reclamation rate requirement and environmental impact assessment requirement of a reclamation customer. The reclaimed water treated by the invention has stable and favorable quality, meets and surpasses the leading indicators of GB5749-2006 Standards for Drinking Water Quality issued by China, and can be used as primary pure water for industrial production.

Owner:WUXI DEPPEL WATER INVESTMENT

Utilization method of phosphate ores

InactiveCN105692575ALow viscosityDimensionally stableCalcium/strontium/barium sulfatesPhosphoric acidCalcium phosphorusTri calcium phosphate

The invention discloses a utilization method of phosphate ores. The utilization method comprises the following steps: crushing and finely grinding the phosphate ores to obtain phosphate ore powder; stirring the phosphate ore powder and hydrochloric acid to react at a room temperature for 0.5 hour to 6 hours; carrying out solid-liquid separation; carrying out fluorine removal, impurity removal, calcium-phosphorus separation (sedimentation, filtering, extracting, drying and the like) on a liquid solution; furthermore, treating a residual calcium chloride solution; finally, obtaining products including fertilizer-grade calcium hydrogen phosphate, feed-grade calcium hydrogen phosphate, phosphorus-nitrogen composite flame retardant, tricalcium phosphate, calcium sulfate whiskers and the like, and also obtaining a diluted hydrochloric acid solution; rectifying and concentrating the diluted hydrochloric acid solution and returning the solution back to a phosphate ore powder acidolysis procedure. According to the utilization method, the used hydrochloric acid can be circularly utilized, and the hydrochloric acid can be generated; the obtained hydrochloric acid is used for decomposing the phosphate ores again and the acidolysis cost is low; meanwhile, the phosphorus chemical products including the fertilizer-grade calcium hydrogen phosphate, the feed-grade calcium hydrogen phosphate, the phosphorus-nitrogen composite flame retardant, the tricalcium phosphate, the calcium sulfate whiskers and the like can also be obtained, so that the comprehensive utilization efficiency of the phosphate ores is high and the economic benefits are good.

Owner:GUIZHOU INST OF METALLURGY & CHEM ENG

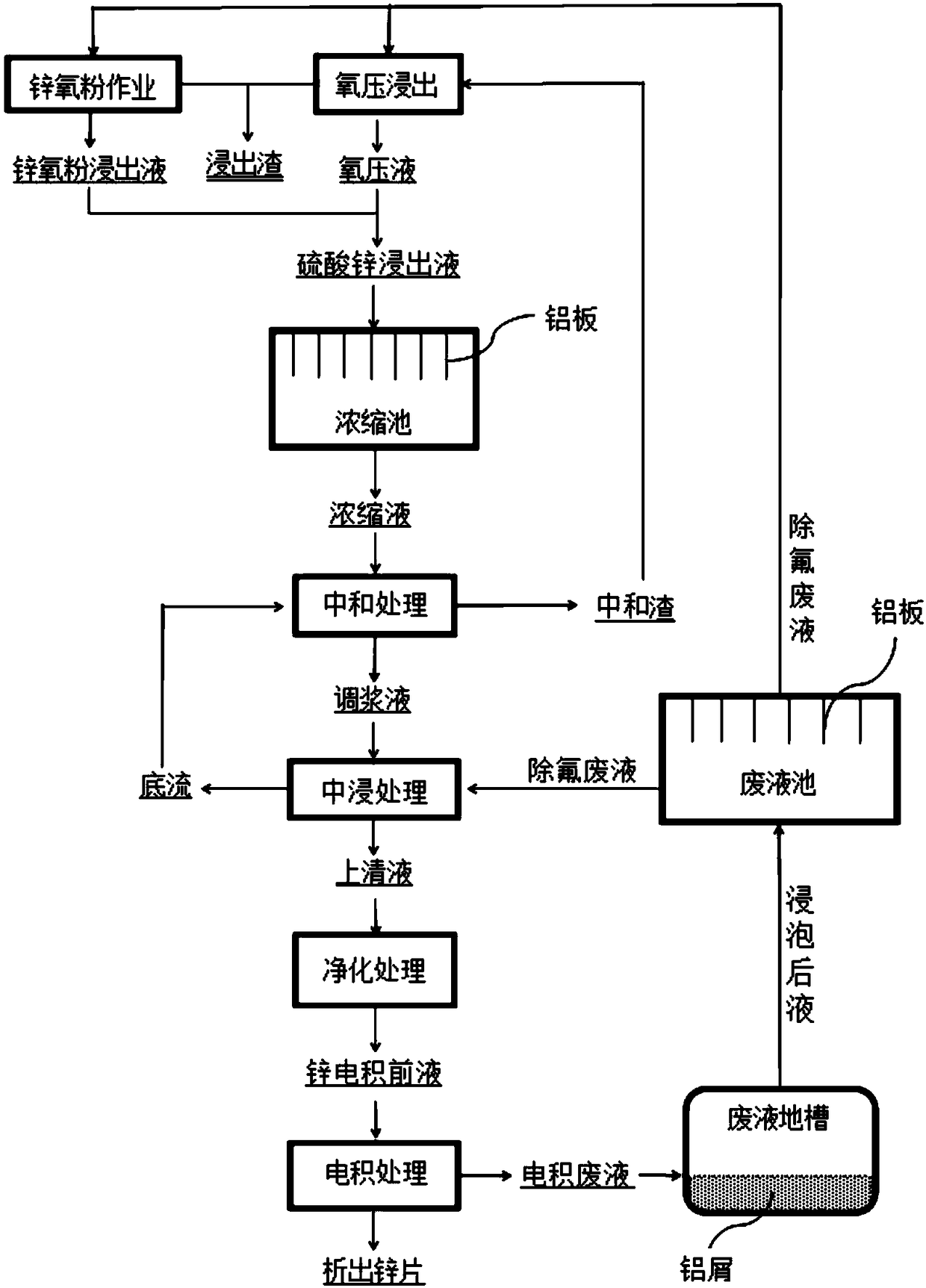

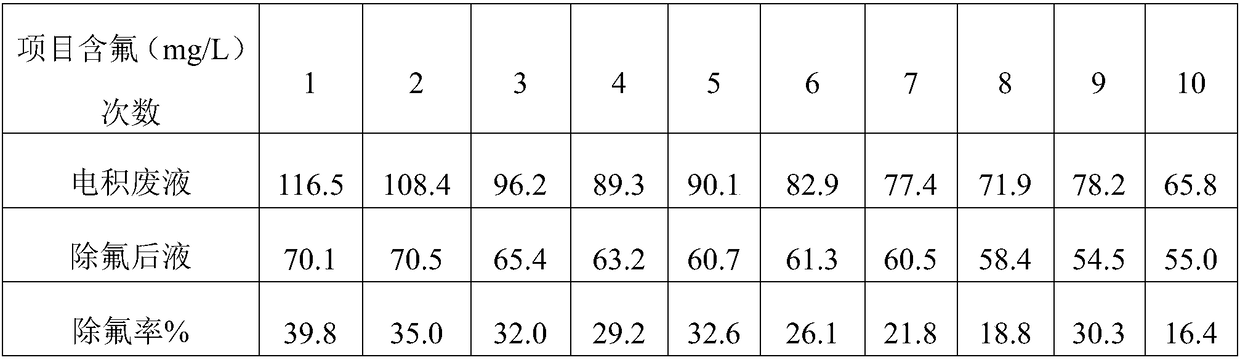

Method for removing fluorine in wet-method zinc smelting process

ActiveCN108977660AAvoid lostSimple processProcess efficiency improvementAluminum fluorideChemical reaction

The invention discloses a method for removing fluorine in a wet-method zinc smelting process. The method comprises the following steps: enabling a perchloric acid zinc sulfate solution and an aluminumplate or aluminum chippings to have chemical reaction, and removing the generated aluminum fluoride precipitates from a solution, so that the content of fluorine ions in the perchloric acid zinc sulfate solution can be reduced. According to the method, the fluorine ions in the perchloric acid zinc sulfate solution can be removed by adopting the aluminum plate or aluminum chippings, no special impurity removal process and device are not added, no novel chemicals and auxiliary materials are needed, the process is simple, the investment cost is low, the fluorine removal effect is good, the zincmetal loss caused by adding the impurity removal process can be effectively avoided, and the zinc electrodeposition can be continuously and normally performed.

Owner:云南永昌铅锌股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com