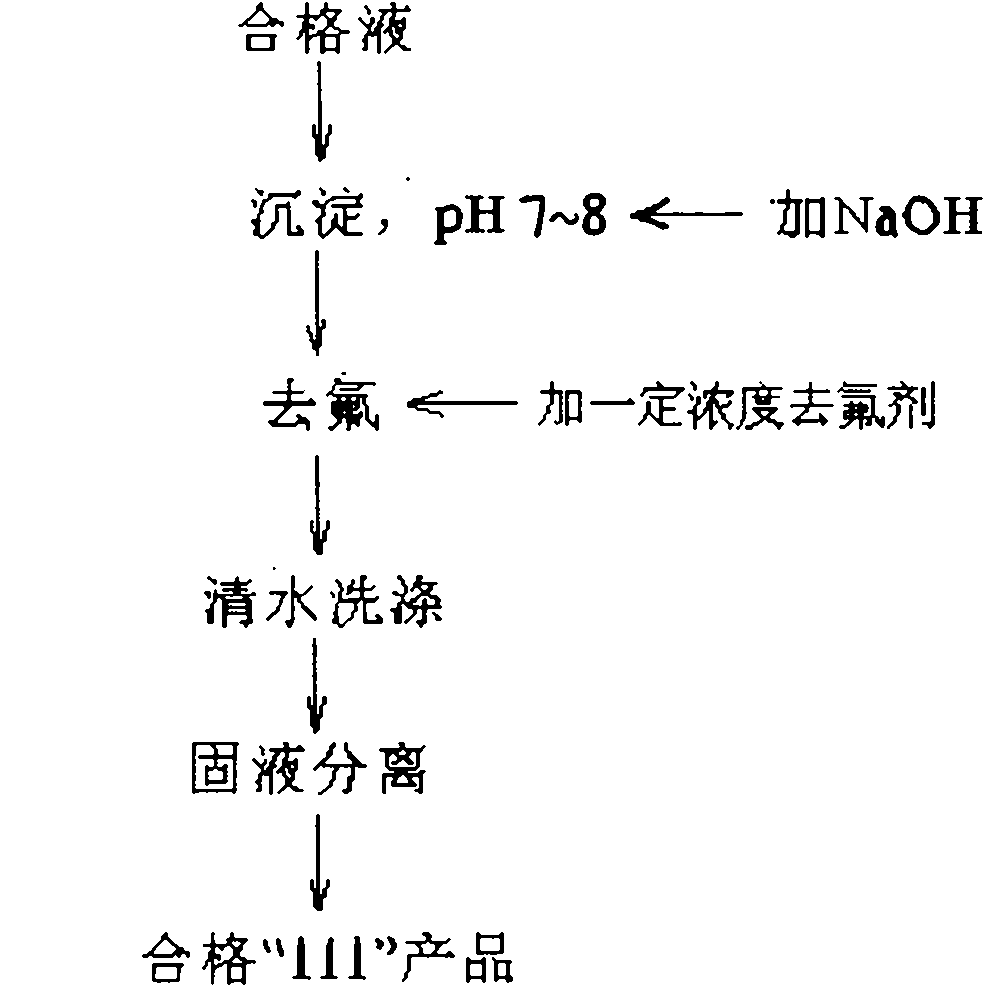

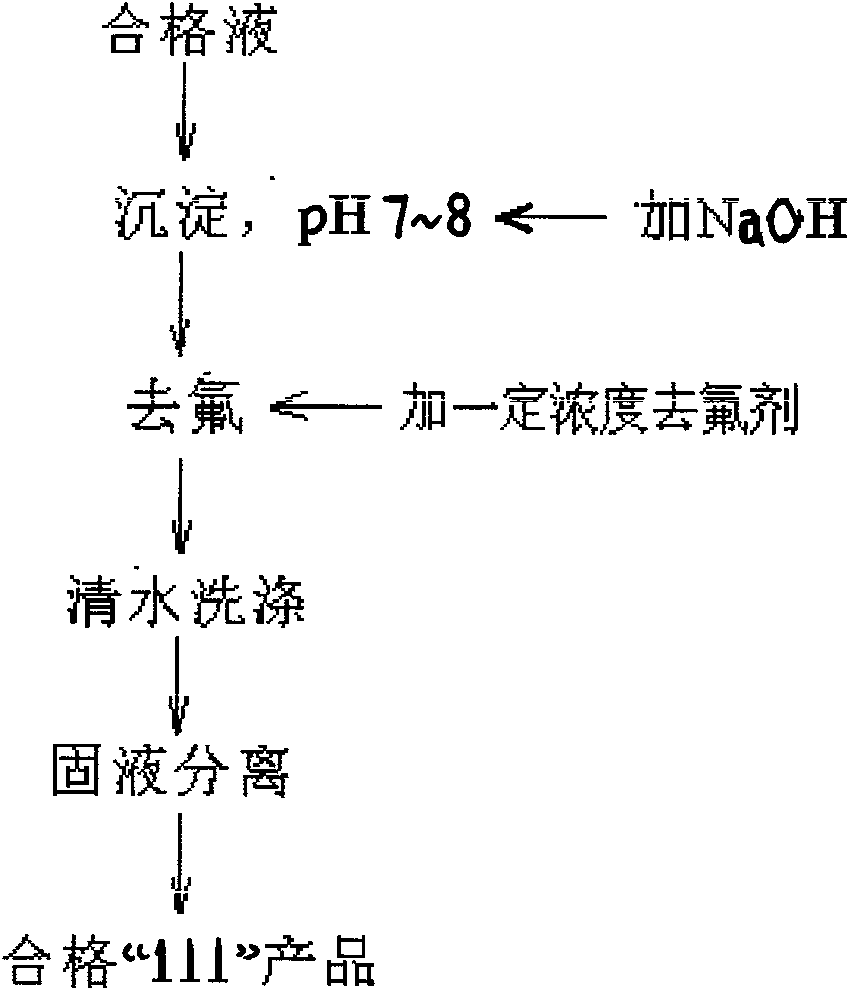

Process for reducing fluorine in biuranate product

A diuranate and fluoride reduction technology, which is applied in the fields of uranium compounds, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of purification treatment, increased treatment cost, and excessive fluorine content.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The specific implementation of defluorination technology for diuranate products is as follows:

[0011] The original "111" product fluorine content exceeds the standard uranium production enterprises, after applying this invention, the problem of "111" product fluorine content exceeding the standard has never occurred. In addition, the present invention can also be applied to the reprocessing of "111" products whose fluorine content exceeds the standard, and has also been verified through production practice. This invention has been applied to the production practice of many uranium mine enterprises with excessive fluorine content in the original "111" products. After more than two years of production and application, it has been shown that this invention is easy to operate, low in fluorine removal cost, and good in fluorine removal effect. The fluorine content of all "111" products has reached the national standard of less than 0.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com