Recovery method for removing fluorine from nickel-cobalt-manganese solution

A recovery method and technology of nickel, cobalt and manganese, applied in battery recycling, recycling technology, recycling by waste collectors, etc., can solve the problems of high defluorination pressure, shortened equipment life, high processing cost, and achieve the loss of nickel, cobalt and manganese. Less, good defluorination effect, great economic benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

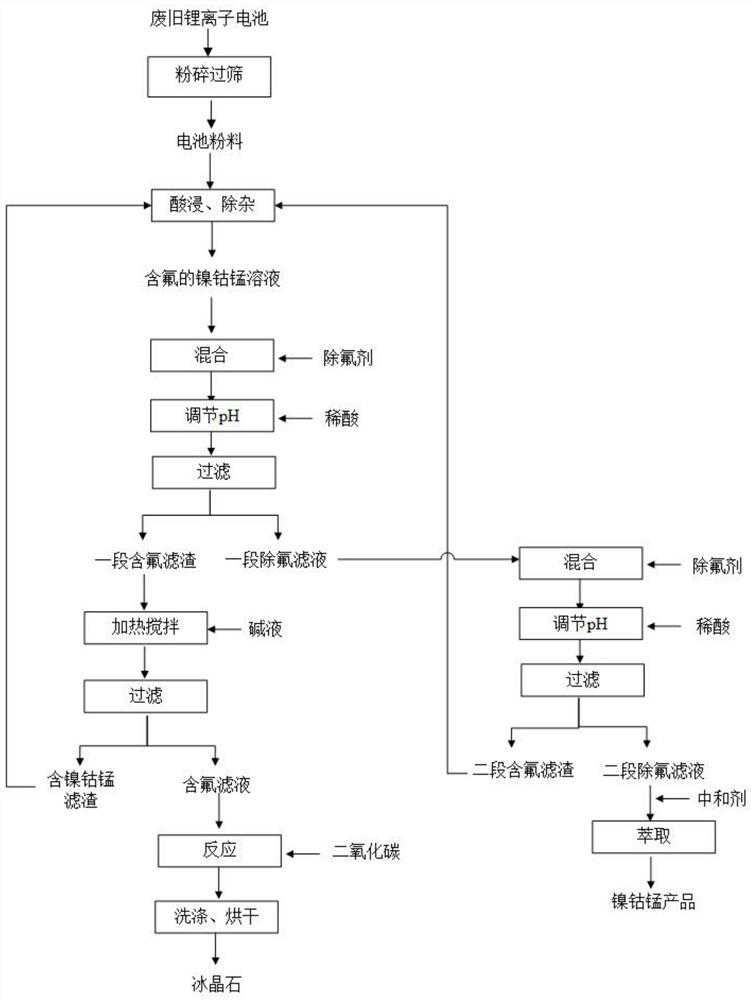

Image

Examples

Embodiment 1

[0040] This embodiment proposes a recovery method for removing fluorine in a nickel-cobalt-manganese solution, comprising the following steps:

[0041](1) crushing and sieving ternary waste battery waste to obtain ternary battery powder;

[0042] (2) After acid leaching and impurity removal are carried out to the ternary battery powder, a nickel-cobalt-manganese solution with a fluorine content of 4.03g / L is obtained;

[0043] (3) Stir after mixing 1L of fluorine-containing nickel-cobalt-manganese solution with 10g of bauxite to obtain a mixed slurry;

[0044] (4) Use 30% dilute sulfuric acid to adjust the pH value of the mixed slurry obtained in step (3) to about 4, and the pH adjustment is completed within 1 hour. After filtration, a section of fluorine-removing filtrate and a section of fluorine-containing filter residue are obtained, wherein one section of fluoride-removing filtrate contains Fluorine 34.6mg / L, (Ni+Co+Mn) in the first-stage fluorine-containing filter resid...

Embodiment 2

[0049] This embodiment proposes a recovery method for removing fluorine in a nickel-cobalt-manganese solution, comprising the following steps:

[0050] (1) crushing and sieving lithium cobalt oxide battery waste to obtain lithium cobalt oxide battery powder;

[0051] (2) After acid leaching and impurity removal are carried out to the lithium cobalt oxide battery powder, a nickel-cobalt-manganese solution with a fluorine content of 4.54g / L is obtained;

[0052] (3) Stir after mixing 1L of fluorine-containing nickel-cobalt-manganese solution with 5g of aluminum hydroxide to obtain a mixed slurry;

[0053] (4) Use 20% dilute sulfuric acid to adjust the pH value of the mixed slurry obtained in step (3) to about 3, and the pH adjustment is completed within 1 hour. After filtration, a section of fluorine-removing filtrate and a section of fluorine-containing filter residue are obtained, wherein one section of fluoride-removing filtrate contains Fluorine 37.4mg / L, (Ni+Co+Mn) in the ...

Embodiment 3

[0058] This embodiment proposes a recovery method for removing fluorine in a nickel-cobalt-manganese solution, comprising the following steps:

[0059] (1) crushing and sieving pole piece waste to obtain pole piece powder;

[0060] (2) After acid leaching and impurity removal are carried out to the pole piece powder, a nickel-cobalt-manganese solution with a fluorine content of 2.65g / L is obtained;

[0061] (3) Stir after mixing 1L of fluorine-containing nickel-cobalt-manganese solution with 10g of sodium alum, to obtain a mixed slurry;

[0062] (4) Use 10% dilute sulfuric acid to adjust the pH value of the mixed slurry obtained in step (3) to about 2, and the pH adjustment is completed within 1 hour. After filtration, a section of fluorine-removing filtrate and a section of fluorine-containing filter residue are obtained, wherein one section of fluoride-removing filtrate contains Fluorine 52.6mg / L, (Ni+Co+Mn) in the first-stage fluorine-containing filter residue is 0.041% (b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com