Patents

Literature

57results about How to "Easy regeneration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

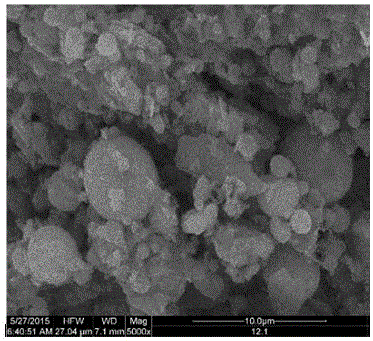

Preparation of iron-managanese compounded oxide/diatomite adsorbant, its using and regenerating method

ActiveCN101024160AImprove adsorption capacityGood arsenic removal effectOther chemical processesWater/sewage treatment by sorptionSorbentManganese oxide

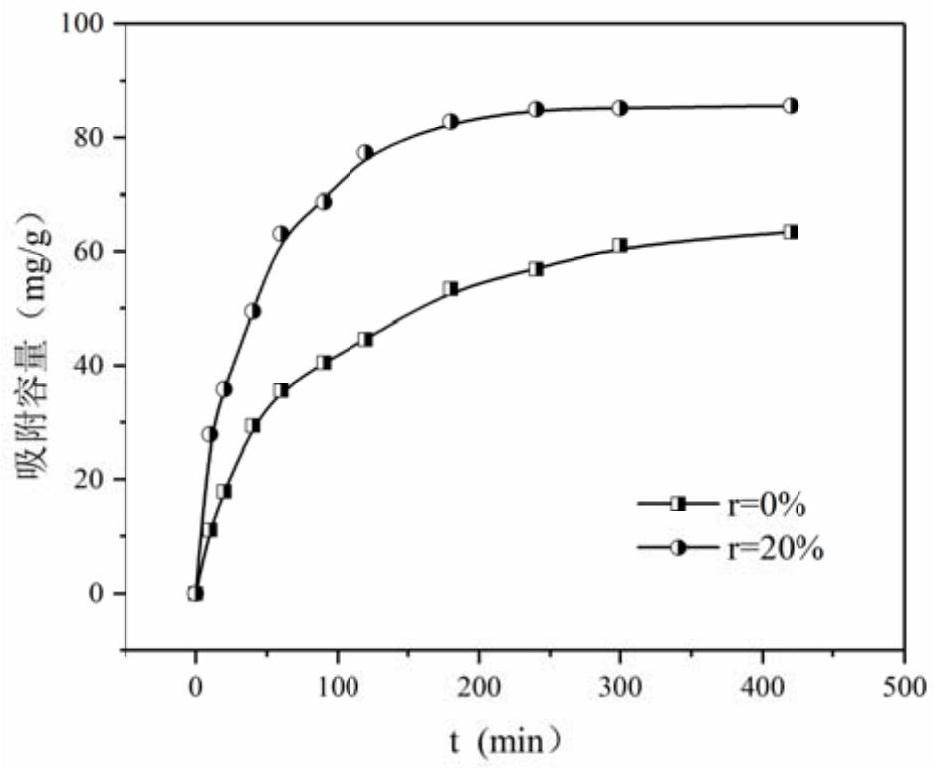

The invention supplies a new type adsorbent--mixed oxide of iron and manganese / diatomite preparation, use and regeneration method, belongs to the treatment of technology. The method used the soluble ferrous permanganate and salt as raw materials, respectively prepared the solutions, after adequate lye into permanganate solution, mixed two salt solutions, by adding diatomite particles, full oscillation, standing aging, neutralize, washing and drying to get the manganese oxide / silicon algae absorbent. The adsorbent is larger than the surface area and good adsorption properties can be used to remove arsenic in water pollutants (especially tervalence arsenic), and the adsorption surface activity of the saturated absorption of pollutants can be directly passed to load manganese oxide compound to regeneration.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

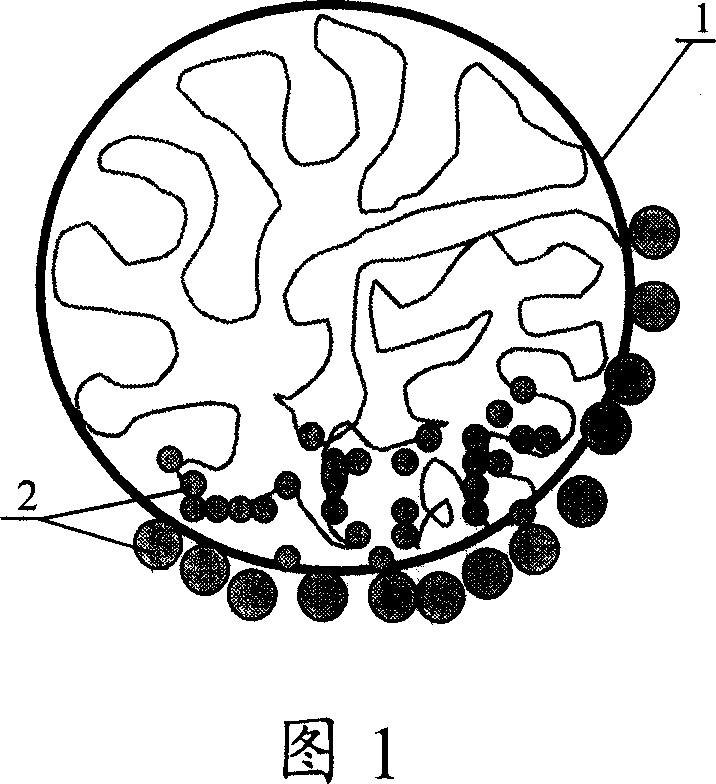

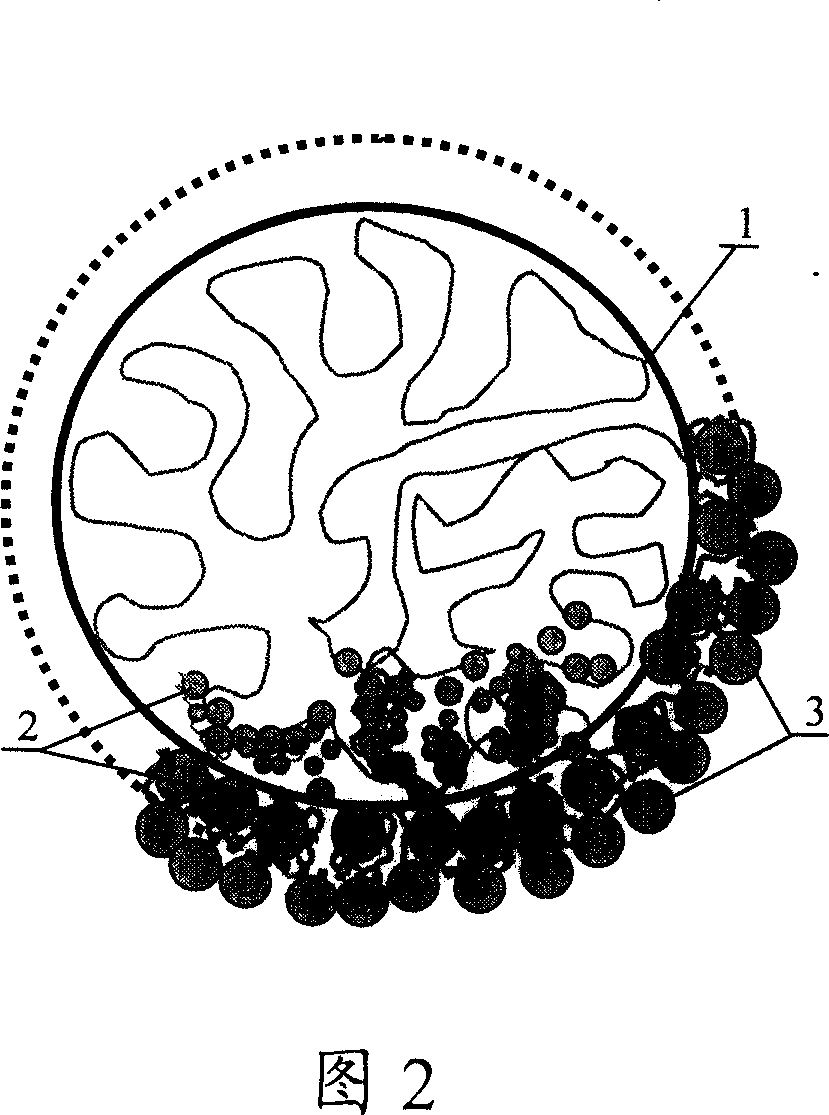

Defluorination absorbing material based on aluminum base composite oxides and its preparation method and use and special device of the preparation method

ActiveCN101507911AExcellent adsorption and defluorination performanceGood defluoridation effectOther chemical processesChemical reactionWater source

The invention belongs to the field of materials for removing fluorine in water, and in particular relates to a fluorine-removal adsorption material based on alanate and aluminum-based composite oxide, a preparation method and uses of the same, and a special device for the preparation method. The fluorine-removal adsorption material based on the aluminum-based composite oxide, which is prepared by a heterotopic preparation method or an in-situ preparation method, comprises two parts of an active composition and a porous supported substrate, wherein the active composition is the aluminum-based composite oxide prepared from an aluminum salt solution and an inorganic alkaline solution by chemical reaction; and the aluminum-based composite oxide is loaded on the surface of the porous supported substrate by an in-situ loading method, and the mass ratio of the aluminum-based composite oxide to the porous supported substrate is 0.25-25:100. The fluorine-removal adsorption material based on the aluminum-based composite oxide can be used for the adsorption of fluorine pollutants in the water and particularly common fluorine in underground drinking water sources. In addition, the material can also be used for removing pollutants such as arsenic, iron, manganese, phosphate, and the like in the water.

Owner:清华苏州环境创新研究院

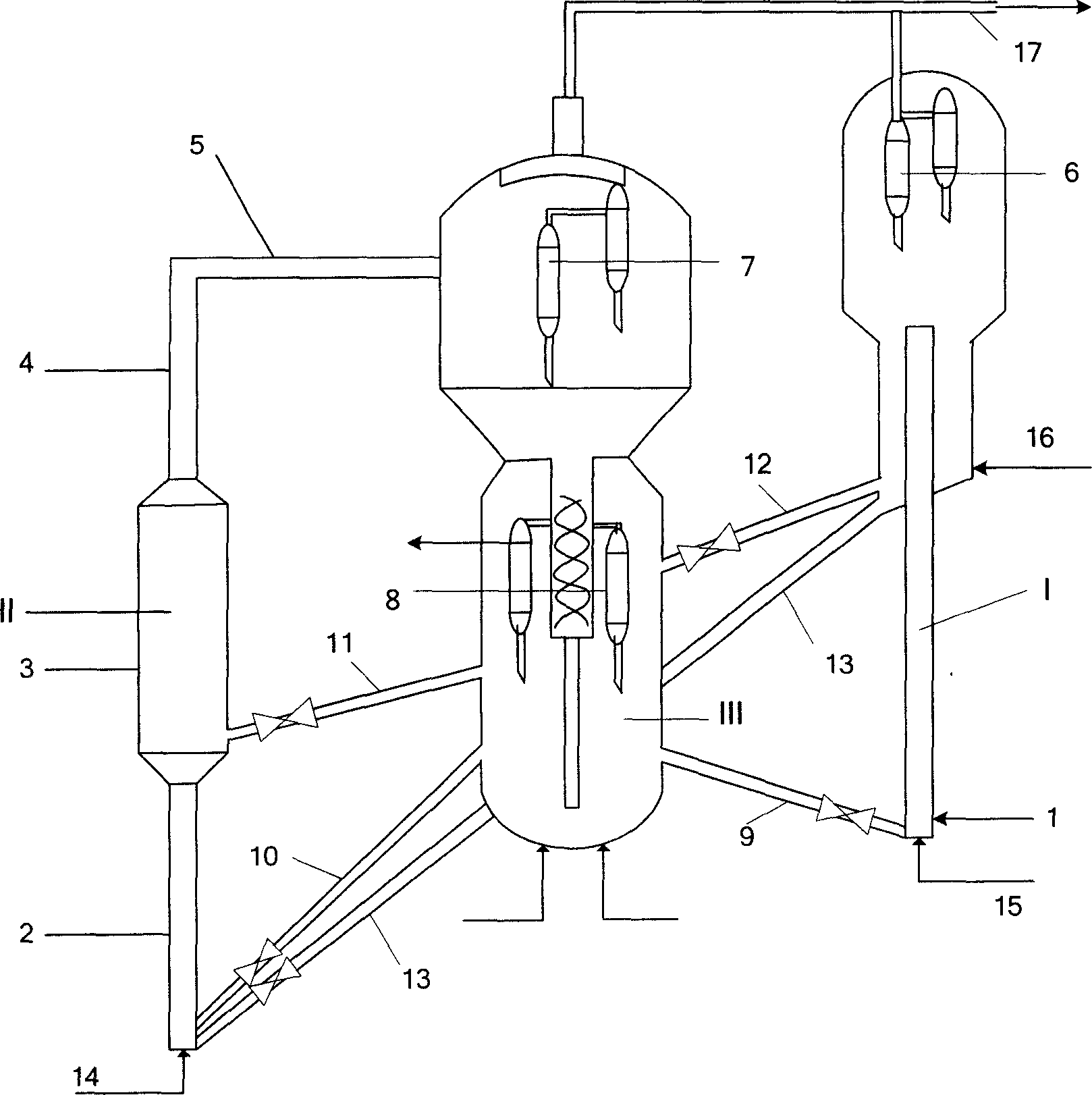

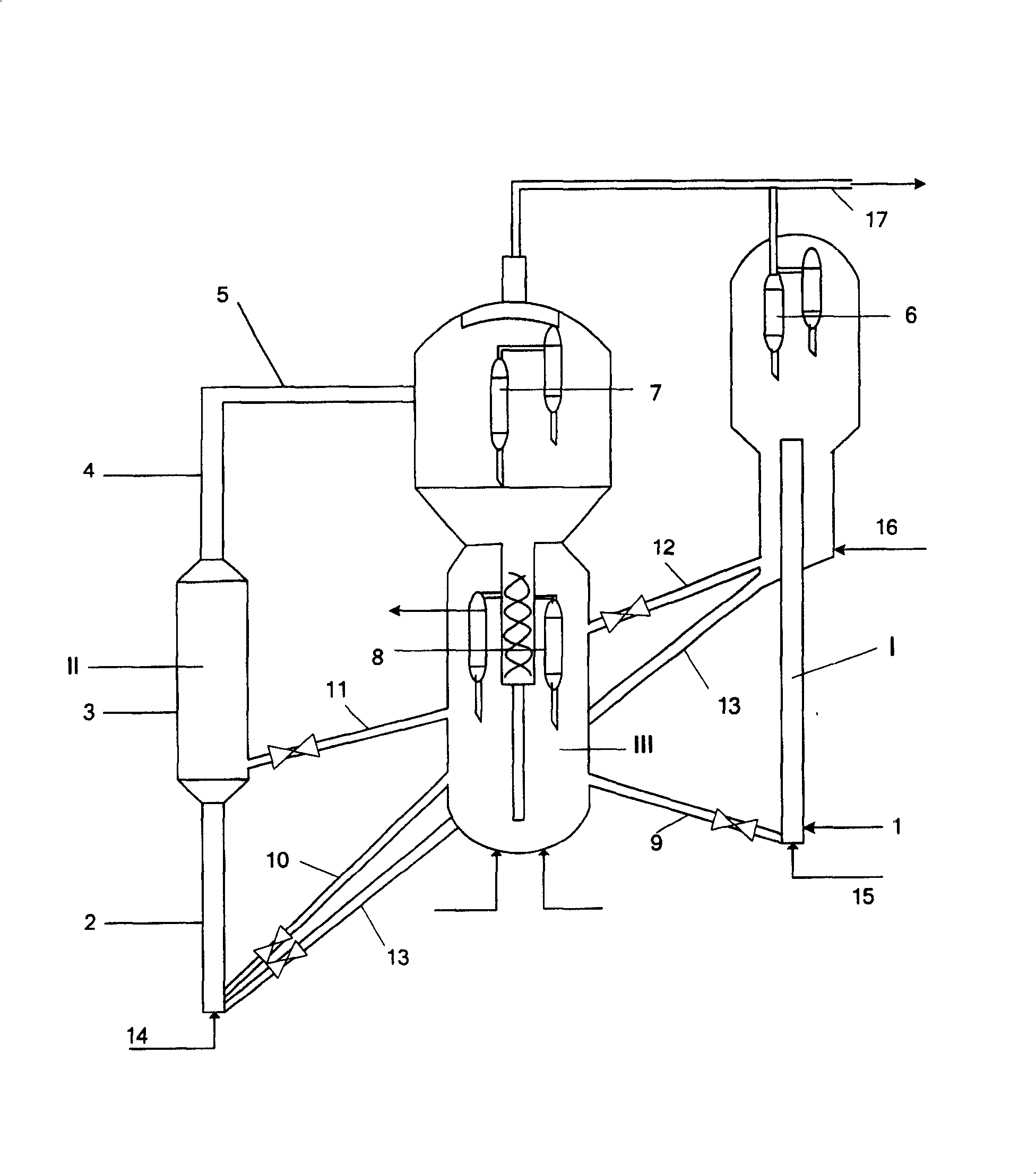

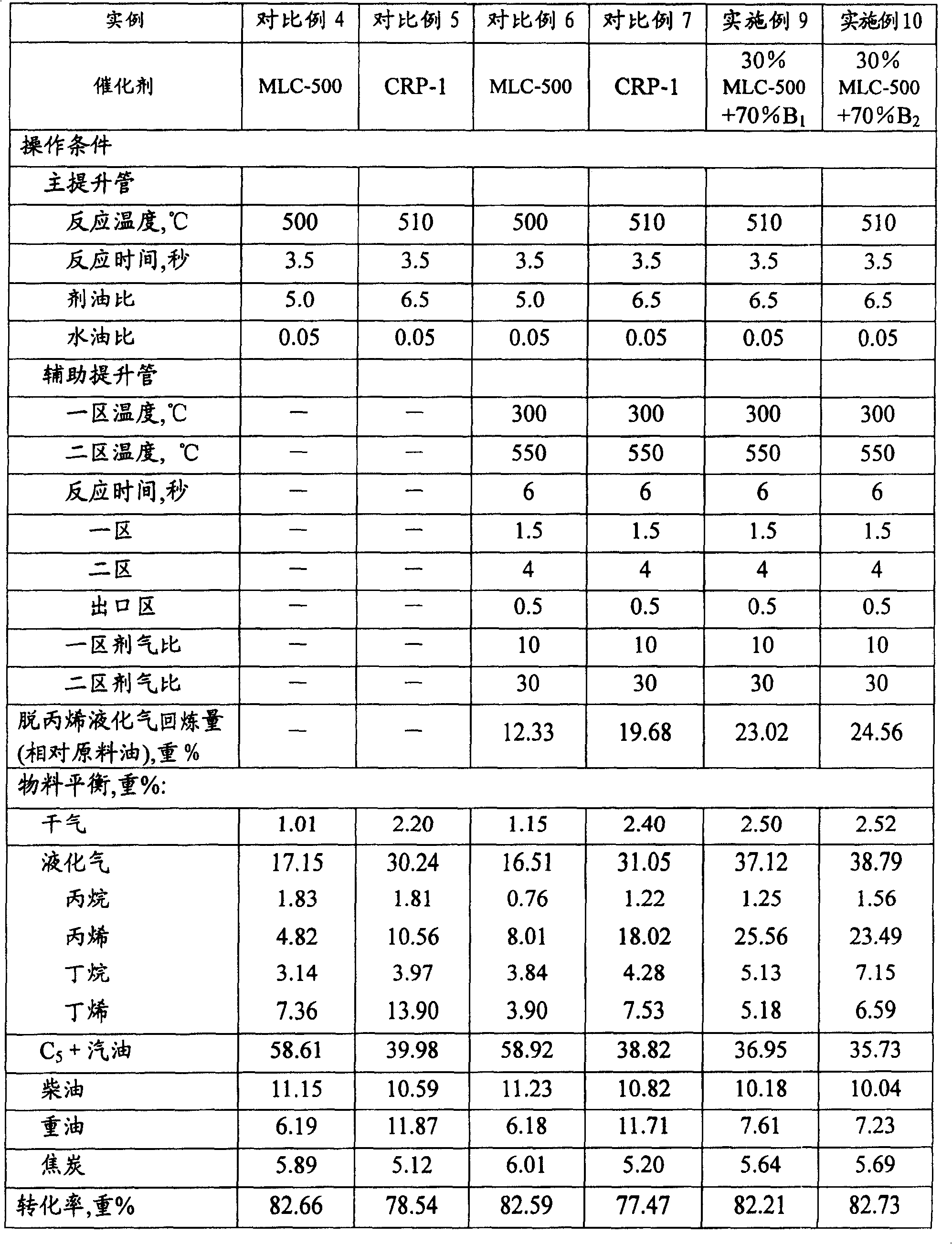

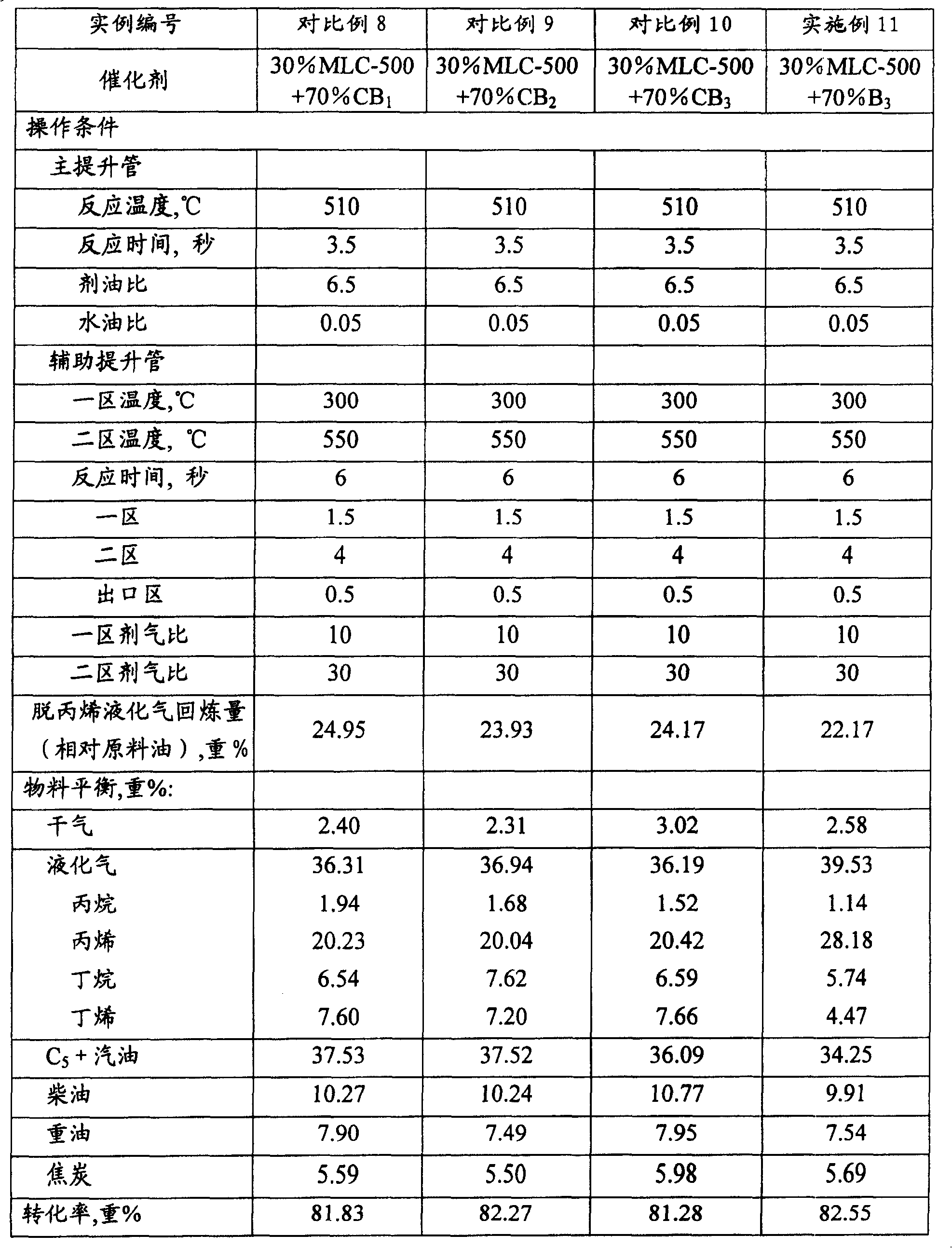

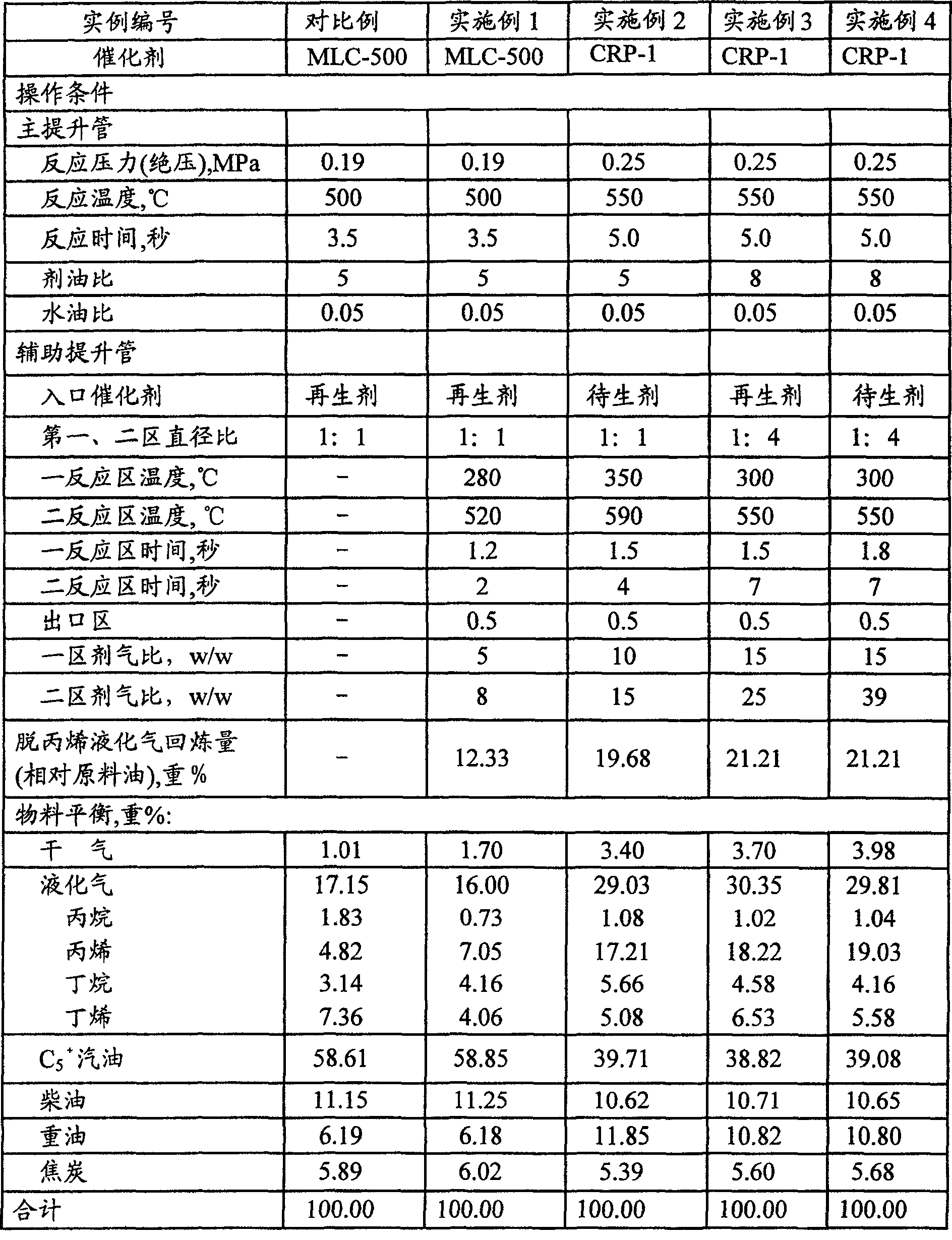

Catalytic conversion method capable of increasing propylene yield

ActiveCN1923971AHigh yieldTake advantage ofOrganic chemistryTreatment with plural serial stages onlyAlkaneCracking reaction

The invention discloses a catalytic conversing method of increasing production propylene, which comprises the following steps: injecting preheat crude oil in the main elevating pipe of double-elevating reacting regenerating system; contacting with heat catalyst to proceed catalytic cracking reaction; separating production; recycling re-living agent; injecting liquid propylene in the auxiliary elevating pipe; proceeding olefin superposition; cracking and dehydrogenizing the superposition product; separating production; recycling the re-living agent. The catalyst is compound of two catalysts, which contains first cracking catalyst with Y-typed molecular sieve and second cracking catalyst agent with ZSM-5 molecular sieve, transition metal additive and phosphorus additive with the dried weight rate of first and second catalysts at 10-70:30-90.

Owner:CHINA PETROLEUM & CHEM CORP +1

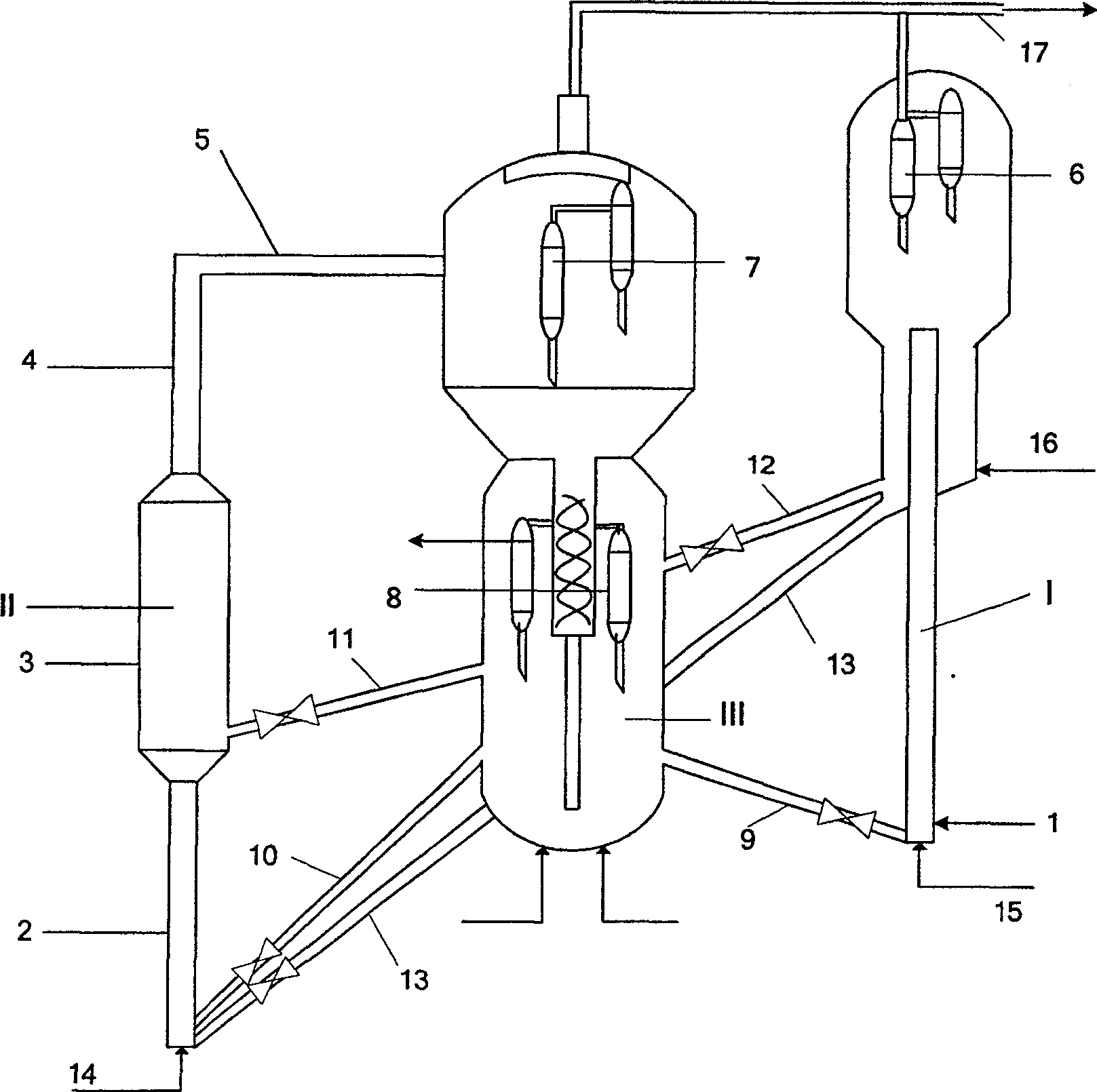

Catalytic conversion method for preducing more propylene

ActiveCN1912065AHigh yieldTake advantage ofOrganic chemistryTreatment with plural serial stages onlyCatalytic transformationAlkane

The invention is a productive propylene catalytic conversion method, injecting preheated raw materials into the main riser of a double-riser reaction regenerating system to contact with hot catalyst so as to make catalytic cracking reaction, and separating products, where the coked products are recycled after raw catalyst is stripped and regenerated; injecting liquefied gas product into an auxiliary riser to contact with hot catalyst so as to make superposition and catalytic cracking and paraffin dehydrogenation reactions in two reacting regions in the auxiliary riser, respectively, and separating products for recycle after raw catalyst is regenerated. And it further converts the liquefied gas products into propylene, and remarkably raises the yield of propylene on the premise of not increasing the productivity of liquefied gas.

Owner:CHINA PETROLEUM & CHEM CORP

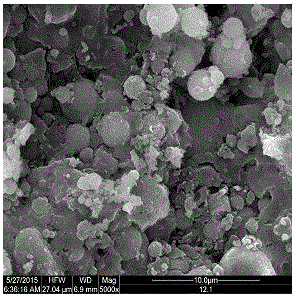

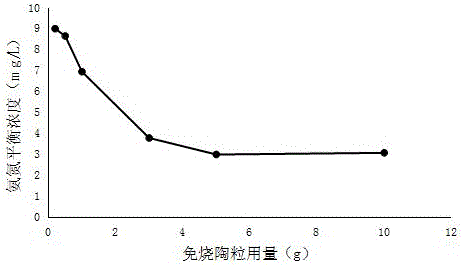

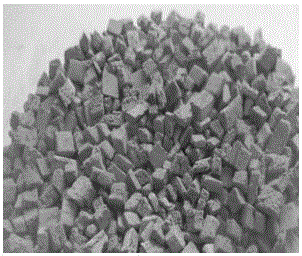

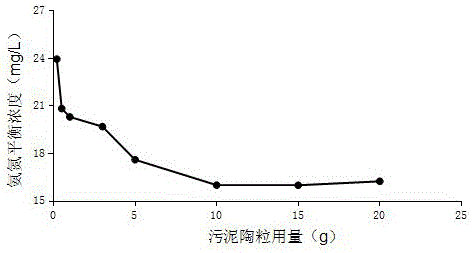

Preparation method of non-sintered ceramsite with ammonia nitrogen adsorption function

InactiveCN105819887AHigh mass percentageLow costSolid waste managementCeramicwareSodium bicarbonateSludge

The invention provides a preparation method of non-sintered ceramsite with an ammonia nitrogen adsorption function. The method comprises the following steps: 1) preprocessing raw materials: immersing fly ash in a NaOH solution, washing the immersed fly ash with water, and drying the washed fly ash; drying excess sludge, calcium oxide, sodium bicarbonate and portland cement; and drying all above raw materials, crushing the dried raw materials, and sieving the crushed raw materials; 2) mixing the raw materials: mixing the above preprocessed raw materials, by mass, 66-85% of fly ash, 3-8% of calcium oxide, 7-13% of excess sludge, 1-5% of sodium bicarbonate and 3-9% of portland cement; 3) granulating: dissolving water glass in water, pouring the obtained water glass solution to the mixed raw materials, and uniformly stirring to make a blank; 4) curing: covering the blank with a wet gauze, regularly watering the blank, putting the blank in a sterilization pot, and carrying out steam curing; and 5) ageing: putting the cured blank in dry environment to prepare the non-sintered ceramsite with an ammonia nitrogen adsorption function. The non-sintered ceramsite prepared in the invention has the advantages of low price, high economical efficiency, environmental protection, and suitableness for treatment of medium and low concentrations of ammonia nitrogen wastewater.

Owner:WUHAN UNIV

Catalytic conversion method capable of increasing propylene yield

ActiveCN100448954CHigh yieldTake advantage ofOrganic chemistryTreatment with plural serial stages onlyAlkaneCracking reaction

The invention discloses a catalytic conversing method of increasing production propylene, which comprises the following steps: injecting preheat crude oil in the main elevating pipe of double-elevating reacting regenerating system; contacting with heat catalyst to proceed catalytic cracking reaction; separating production; recycling re-living agent; injecting liquid propylene in the auxiliary elevating pipe; proceeding olefin superposition; cracking and dehydrogenizing the superposition product; separating production; recycling the re-living agent. The catalyst is compound of two catalysts, which contains first cracking catalyst with Y-typed molecular sieve and second cracking catalyst agent with ZSM-5 molecular sieve, transition metal additive and phosphorus additive with the dried weight rate of first and second catalysts at 10-70:30-90.

Owner:CHINA PETROLEUM & CHEM CORP +1

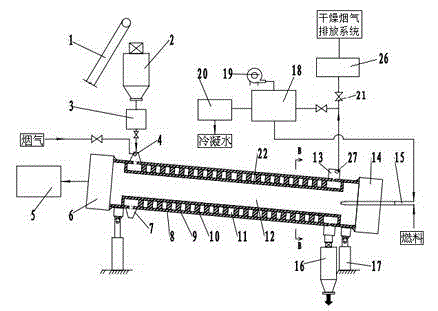

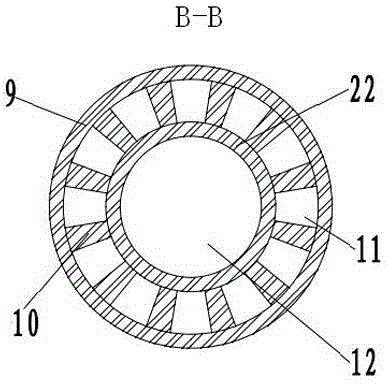

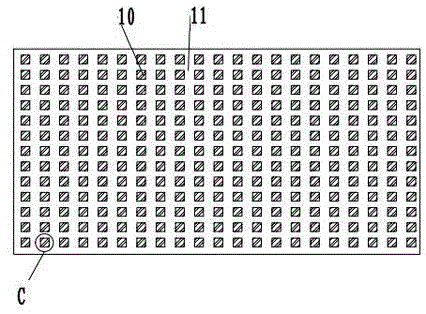

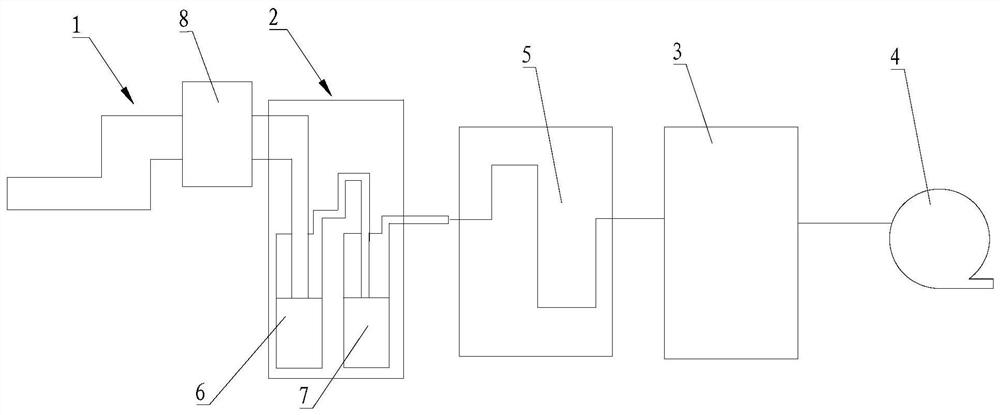

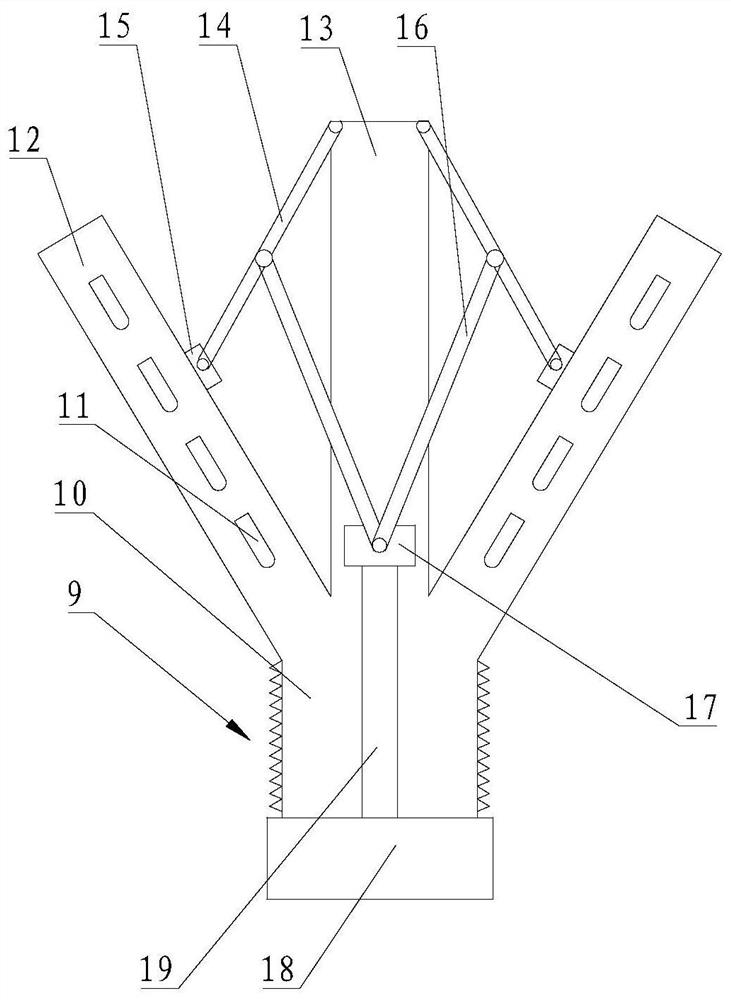

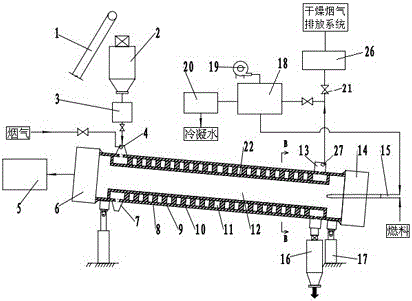

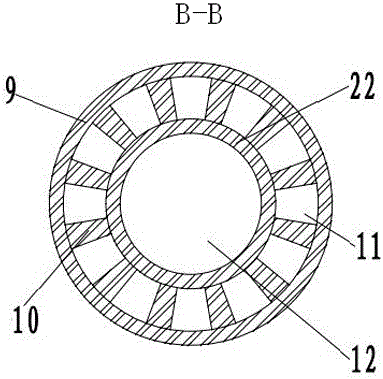

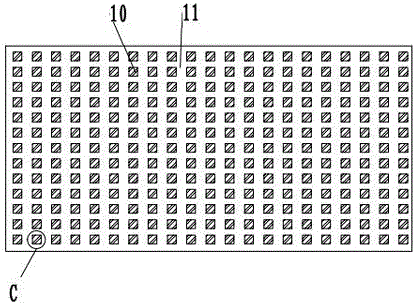

Dividing wall rotary kiln device for flue gas dehydration

ActiveCN104923042AImprove diffusion abilityReduce acid rain and air pollutionRotary drum furnacesDispersed particle separationProcess engineeringRotary kiln

The invention relates to a dividing wall rotary kiln device for flue gas dehydration. The dividing wall rotary kiln device comprises loading equipment, a charging bin, a conveyor, a rotary kiln, waste heat generating equipment and a spare unloading bin, wherein the rotary kiln is a dividing wall rotary kiln, and is composed of an outer ring and an inner ring which are coaxially mounted; a ring-shaped material channel is arranged between the inner ring and the outer ring; the ring-shaped material channel is provided with refractory material support; and a furnace hearth is arranged in the center of the inner ring. The furnace hearth is connected with the waste heat generating equipment by a kiln tail cover. The loading equipment is communicated with the ring-shaped material channel by the loading bin, the conveyor and a charging ring; the ring-shaped material channel is connected with the spare unloading bin by a discharge ring. A wet flue gas inlet is connected with a flue gas pipeline; a gas outlet is divided into two paths, one path is connected with a dry flue gas exhaustion system, and the other path is connected with a condenser; and connecting pipelines are provided with valves respectively. According to the dividing wall rotary kiln device, lime is used as a dryer, and the ring-shaped material channel of the dividing wall rotary kiln is used for drying and dehydrating the industrial flue gas, so that the flue gas diffusion capacity is improved in a facilitated mode, the acid rain and atmospheric contamination is reduced, and the dwelling and living environment of people is improved.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

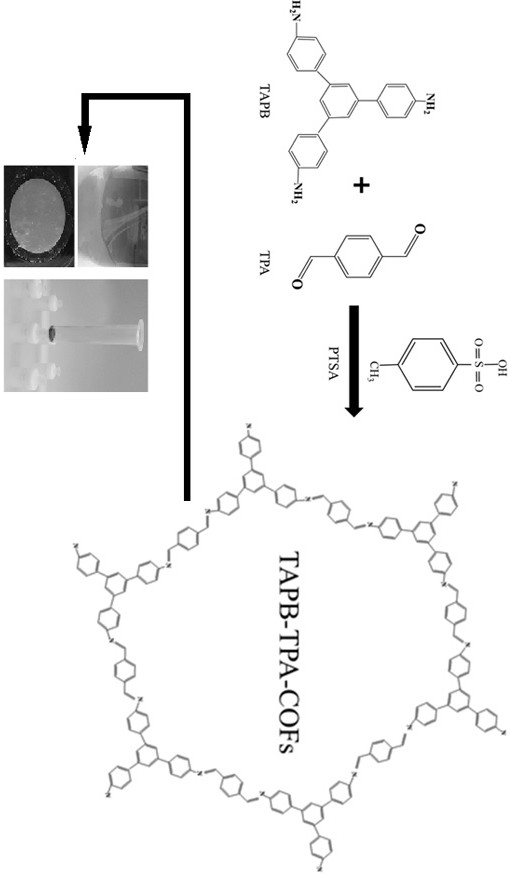

Covalent organic framework film material for removing triclosan in environmental water as well as preparation method and application of same

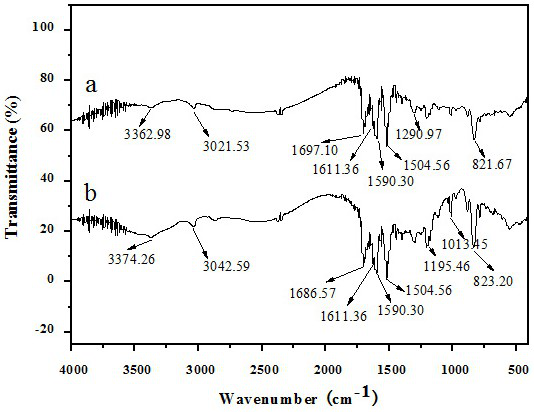

ActiveCN111647184AImprove performanceResilientOther chemical processesWater contaminantsTriclosanPtru catalyst

The invention discloses a covalent organic framework film material for removing triclosan in environmental water as well as a preparation method and application of same. In particular, terephthalaldehyde and 1,3,5-tri-(4-aminophenyl) benzene are used as bridging monomers, p-toluenesulfonic acid monohydrate is used as a catalyst, an acetonitrile-water solution and an ethyl acetate solution are usedas two-phase solvents, and the novel TAPB-TPA-COFs film is polymerized at room temperature through a liquid phase interface method. The prepared film material is prepared into a small solid-phase extraction column, an excellent adsorption effect on triclosan in environmental water is achieved, the maximum adsorption capacity can reach 12.21 mg / g, and the optimal removal rate of TCS can reach 99.72%. The TAPB-TPA-COFs membrane is relatively good in crystallinity, high in thermal stability and low in cost, has efficient adsorption performance on TCS, can be repeatedly utilized, and has a greatapplication prospect in the field of environmental pollutant enrichment and separation.

Owner:MINJIANG UNIV

Catalytic conversion method for preducing more propylene

ActiveCN100537721CHigh yieldTake advantage ofOrganic chemistryTreatment with plural serial stages onlyCatalytic transformationAlkane

Owner:CHINA PETROLEUM & CHEM CORP

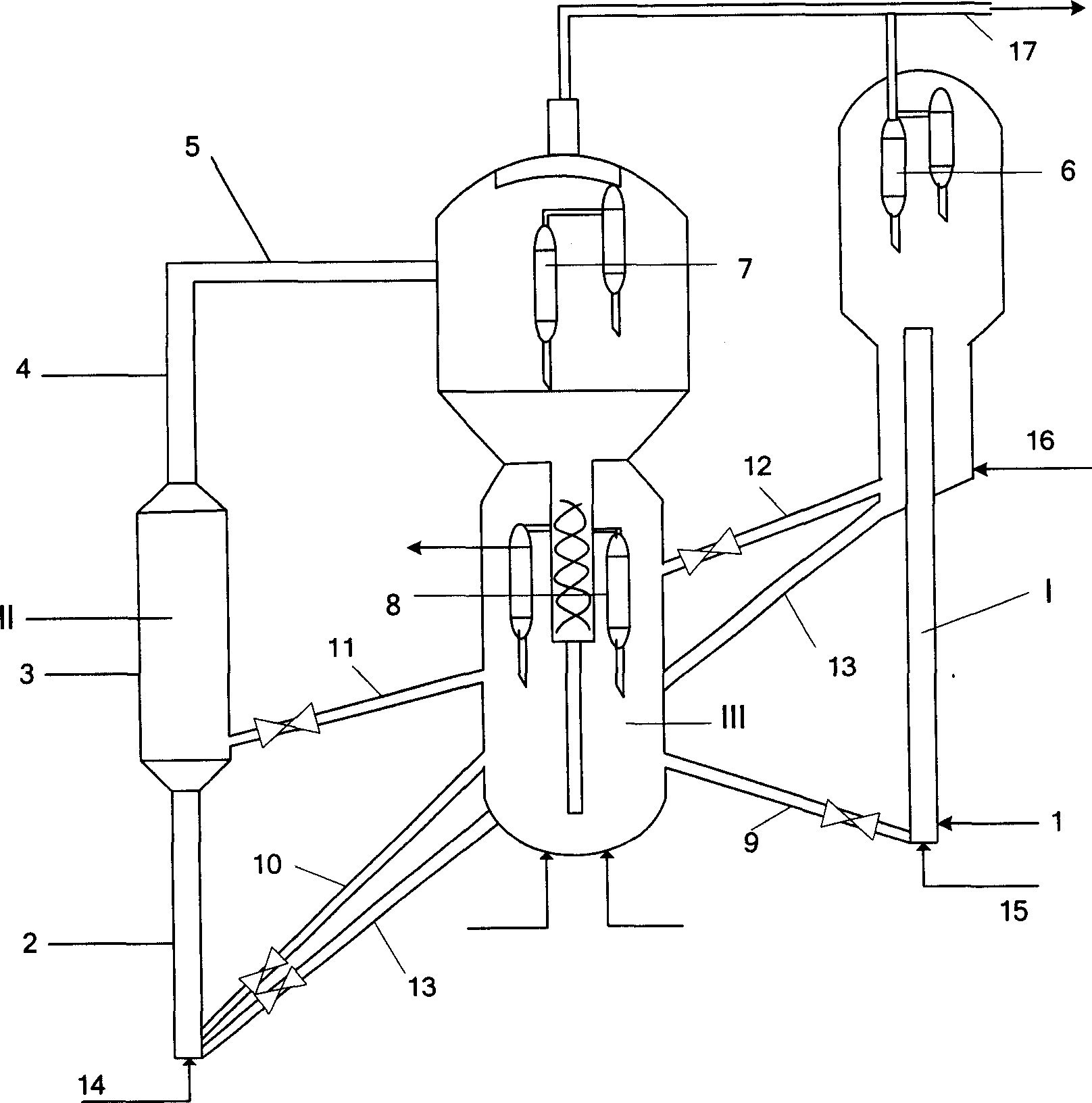

Preparation method for core-shell perovskite-type catalyst for preparing methanol through methane

InactiveCN103962142AReduced activityHigh activityPreparation by oxidation reactionsMetal/metal-oxides/metal-hydroxide catalystsUltrasound - actionCatalytic oxidation

The invention relates to a preparation method for a core-shell perovskite-type catalyst for preparing methanol through methane. The general formula of the core-shell perovskite-type catalyst is Fe2O3@A(1-m)A'mB(1-n)B'nO3. The preparation method for the core-shell perovskite-type catalyst comprises the following steps: adding nano-sized or micron-sized Fe2O3 into ethanol; dispersing under the effect of ultrasonic waves; removing the supernatant after complete precipitation; using ultrasonic waves to disperse Fe2O3 into deionized water to obtain a Fe2O3 suspension; adding soluble salts corresponding to A, A', B and B' to deionized water; stirring to allow the soluble salts to dissolve completely; adding a complexing agent; after heating and stirring for complexing, adding to the Fe2O3 suspension; stirring evenly; adding glycol; after thorough stirring, evaporating to obtain a colloidal mixture; drying and roasting to obtain the core-shell perovskite-type catalyst. The core-shell perovskite-type catalyst is a perovskite-type oxide catalyst of a core-shell structure; the active constituent, namely Fe2O3 is wrapped in the perovskite oxide, so that the phenomenon that the Fe2O3 is reduced to elementary substance Fe in the catalytic oxidation process, and the activity of the core-shell perovskite-type catalyst declines due to the sintering and accumulation of the Fe, is effectively prevented.

Owner:NORTHEAST GASOLINEEUM UNIV

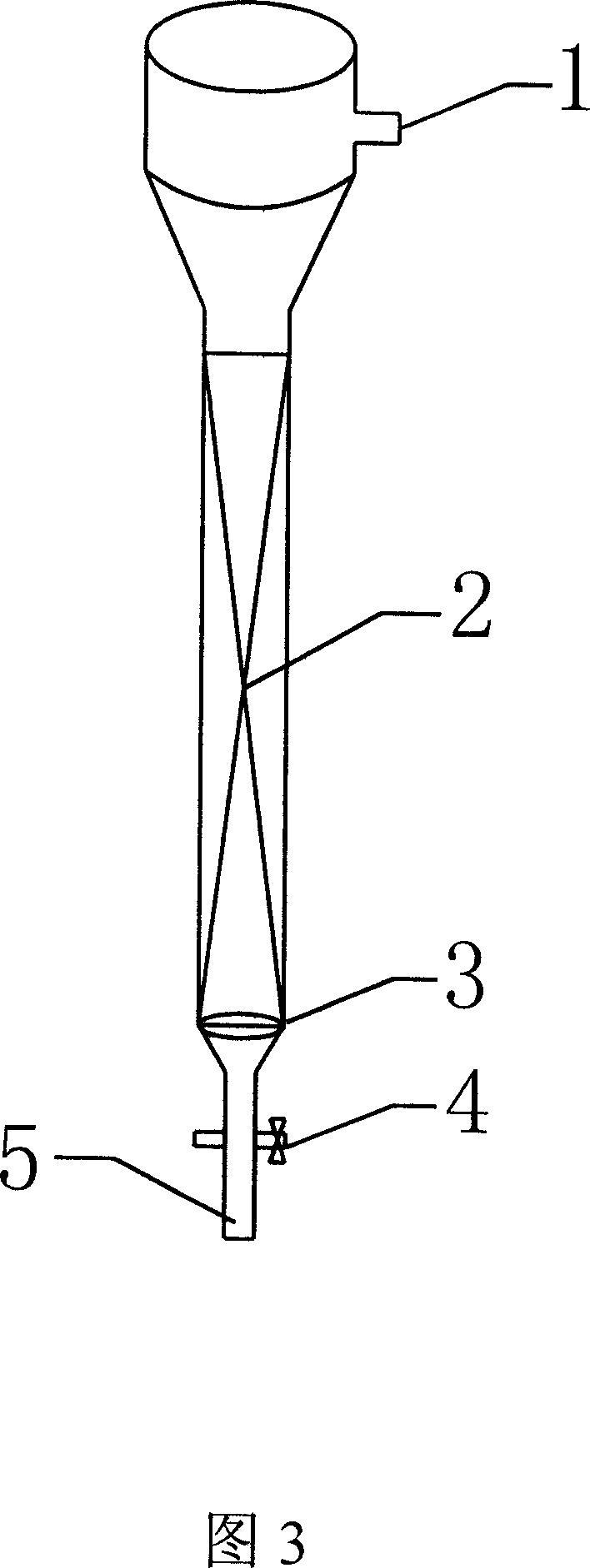

In situ load preparation of catalyst and catalytic ozonation drinking water deep purification method thereof

InactiveCN102580760AExcellent ability to catalyze the ozone oxidation processCatalytic strongCatalyst regeneration/reactivationCatalyst activation/preparationPurification methodsFerrous salts

The invention discloses a drinking water deep purification method, which is economic, effective, simple and practical to prepare catalytic materials, catalyze ozonation pollutants with a catalyst and regenerate the catalytic materials. Permanganate, manganese salt, ferric salt, ferrous salt and the like are treated as raw materials, and ferric manganese compound oxide with good catalytic activity is loaded on a base body material through in situ reactions to be manufactured into a catalyst. The catalyst is applied to catalytic ozonation processes and can effectively improve removal effects of ozone on pollutants difficult to degrade in water. When the catalyst is inactivated or washed away, a simple in situ regeneration method can be used for leading active materials to be loaded and regenerated.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI +1

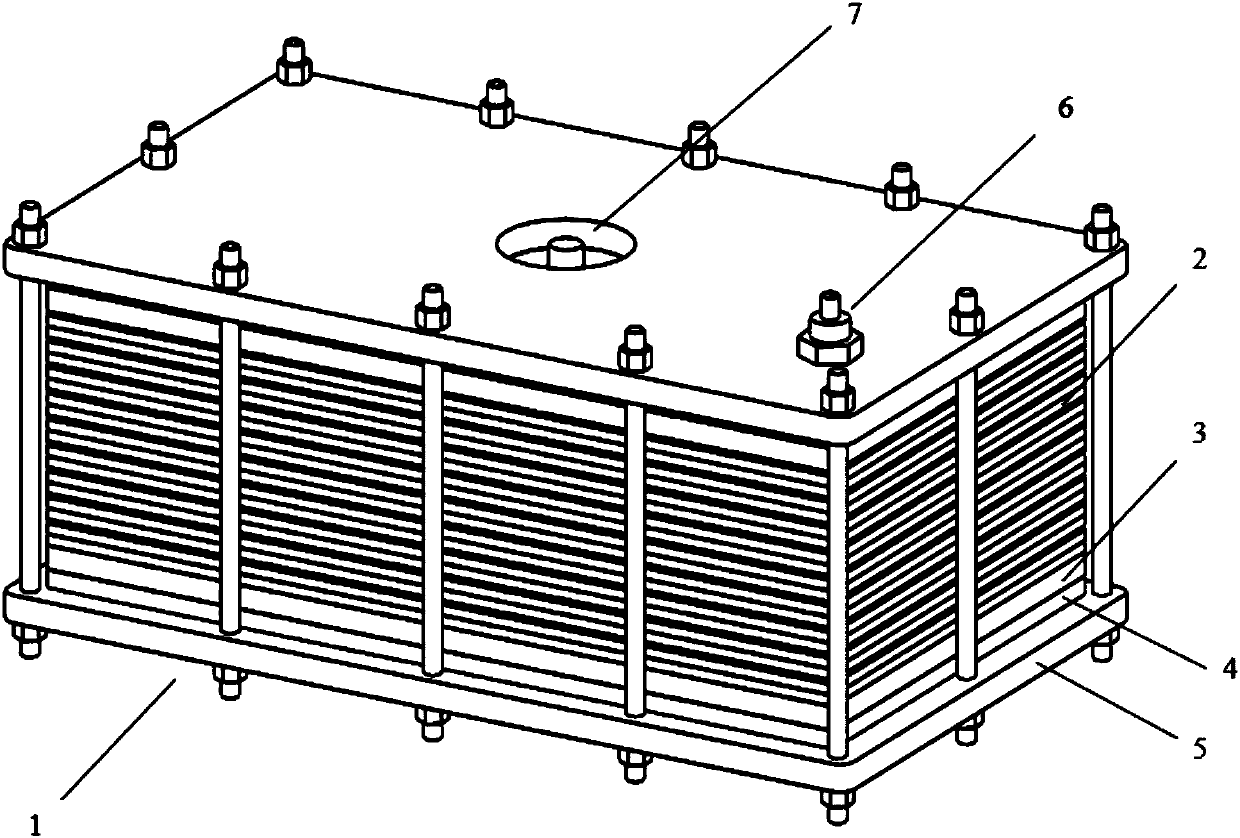

Isoalkane/olefin alkylation method and device

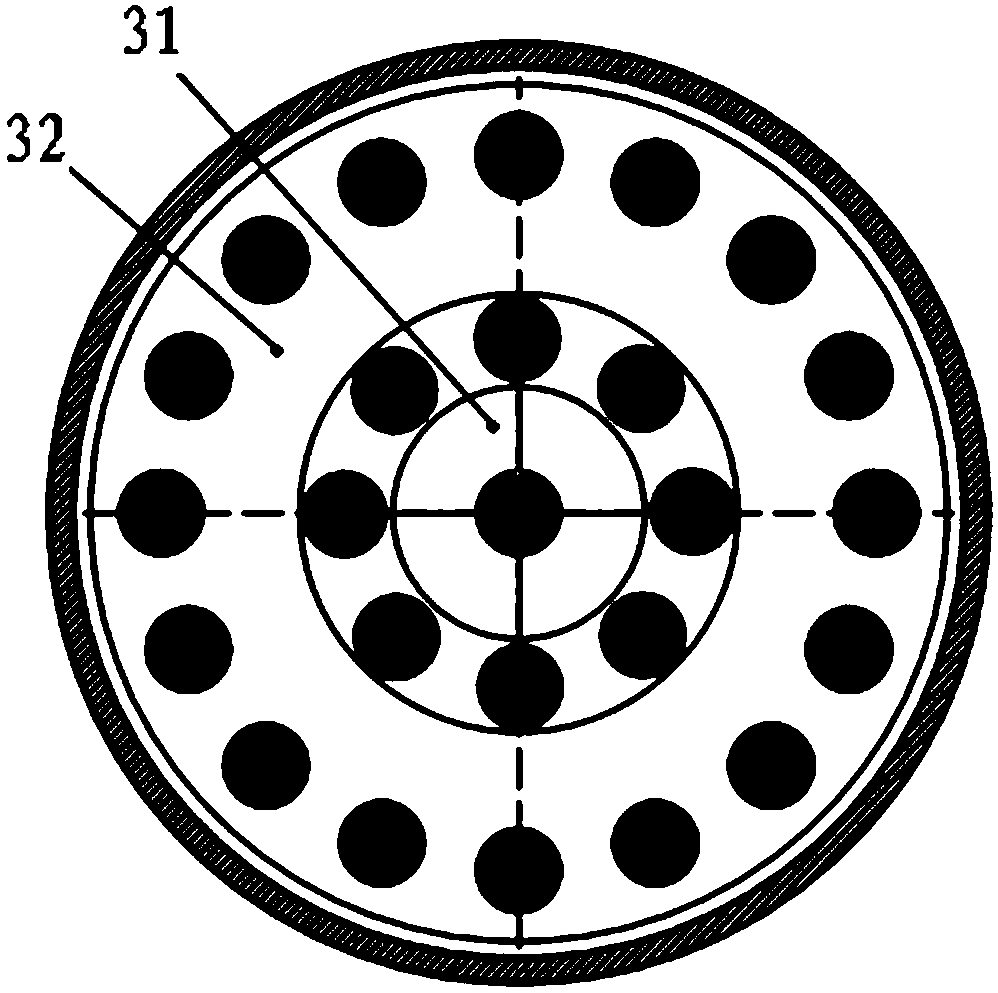

ActiveCN105061129AImproved area/volume ratioEnhance mass transfer and heat transferLiquid hydrocarbon mixtures productionHydrocarbonsAlkaneSide reaction

The invention relates to the technical field of isoalkane / olefin alkylation, particularly an isoalkane / olefin alkylation method and device. The alkylation method comprises the following steps: under the action of a catalyst, reacting isoalkane and olefin in a microreactor set at 40-200 DEG C under the reaction pressure of 1.5-4.5 MPa; separating the reaction product to respectively obtain the target reaction product, unreacted reactants and catalyst; and sending the unreacted reactants and catalyst into the microreactor again. The device provided by the invention implements continuous production, accelerates the alkylation reaction, greatly shortens the time, enhances the safety of the device and the selectivity of the reaction process, and prevents the side reaction from generation. The whole process does not generate any waste, thereby saving the cost and preventing pollution. Besides, the plurality of microreactors can be connected in parallel and implement control on simultaneous reaction, thereby saving the development cost on enlarging the reaction scale, and further saving the cost.

Owner:SINOPEC ENG GRP CO LTD

Preparation method of sludge ceramsite used for medium and low concentration ammonia nitrogen wastewater treatment

InactiveCN105819891ASolve disposal problemsAchieve resource utilizationCeramic materials productionCeramicwareSludgePre treatment

The invention provides a preparation method of sludge ceramsite used for medium and low concentration ammonia nitrogen wastewater treatment. The preparation method comprises the following steps: immersing fly ash in a 3-6% NaOH solution at 20-30DEG C for 3-4d, washing the immersed fly ash with deionized water, and drying the washed fly ash at 100-110DEG C; drying excess sludge and clay at 100-110DEG C; drying above three raw materials, crushing the dried three raw materials, and sieving the crushed three raw materials for later use; fully mixing, by mass, 30-60% of the preprocessed fly ash, 30-60% of the preprocessed excess sludge and 10% of the preprocessed clay to obtain a dry material; adding a proper amount of deionized water to the dry material, uniformly stirring to prepare a 1-3mm blank, placing the blank in a tray, and drying the tray in a 110DEG C oven until the surface of the blank has no water; putting the dried blank in a muffle furnace, heating the blank to 350-500DEG C, preheating the blank for 10-40min, heating the blank to 800-1100DEG C, sintering the blank for 10-25min, cooling the obtained product in the furnace to 180-200DEG C, and taking out the cooled product to obtain the sludge ceramsite. The sludge ceramsite prepared in the invention has the advantages of low price, economical property, high efficiency, environmental protection, and suitableness for treatment of medium and low concentration ammonia nitrogen wastewaters.

Owner:WUHAN UNIV

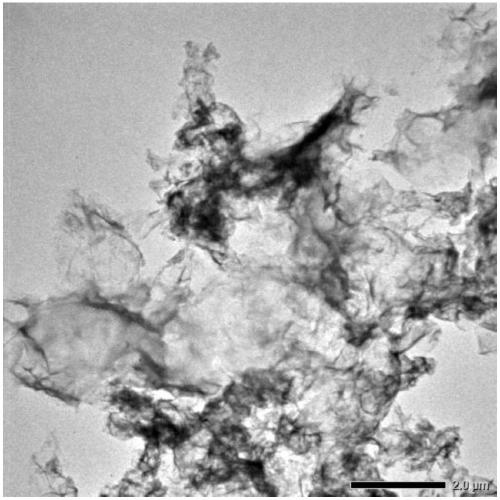

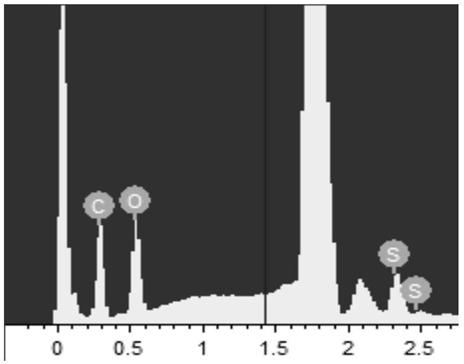

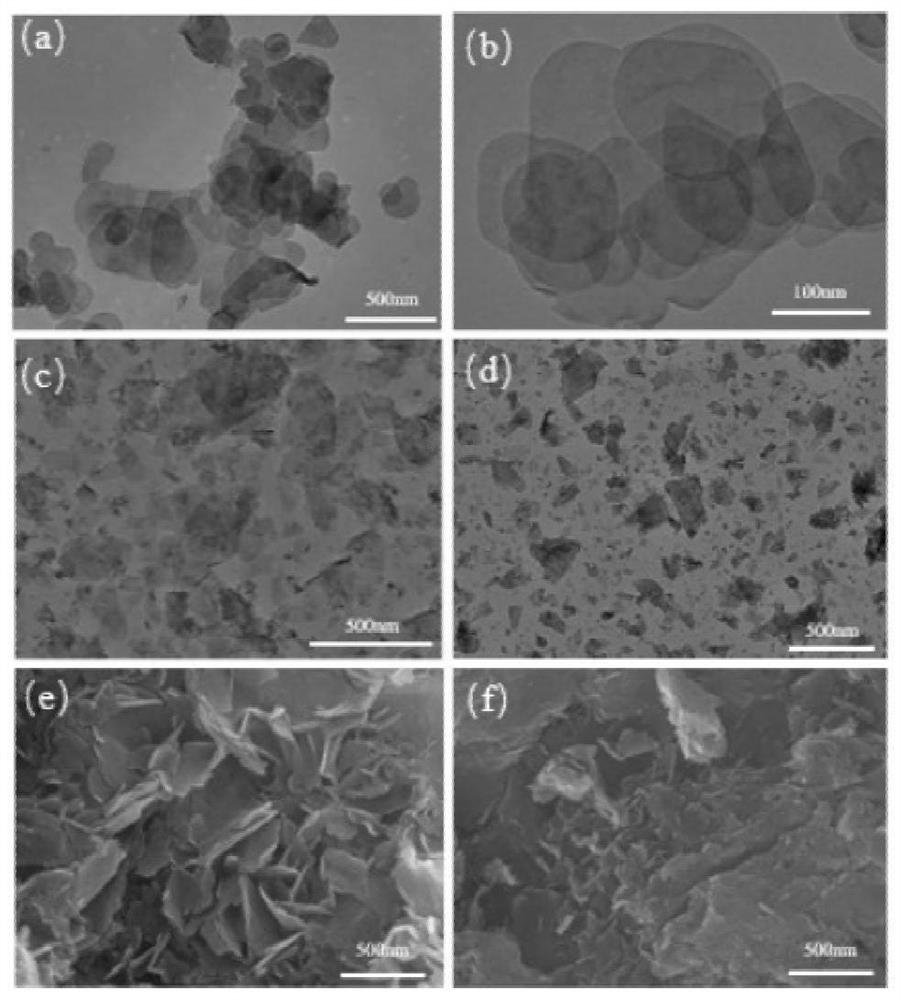

Preparation method and application of fold hydrosulphonyl functionalized graphene oxide material

InactiveCN109607525AEasy to makeReduce manufacturing costCarbon compoundsWater/sewage treatment by ion-exchangeFiberTriethoxysilane

The invention provides a preparation method and application of a fold hydrosulphonyl functionalized graphene oxide material, relates to a preparation method and application of a functionalized graphene oxide material, and aims to solve the technical problem that existing hydrosulphonyl-containing macroporous ion exchange fiber for treating mercury-containing sewage is easy to age and high in cost.The method comprises the steps that 1, graphene oxide is prepared; 2, the graphene oxide is dispersed in water, 3-mercaptopropyltriethoxysilane is added for a reaction, and then washing and drying are carried out to obtain the fold hydrosulphonyl functionalized graphene oxide material. The fold hydrosulphonyl functionalized graphene oxide material is used for removing the mercury in the sewage. The graphene oxide material modified by the hydrosulphonyl has good acid resistance, is simple in regeneration mode and can be used repeatedly; the removal rate of the mercury of the treated sewage containing the mercury reaches 94% or above, and the method can be applied to the field of sewage treatment.

Owner:HARBIN INST OF TECH

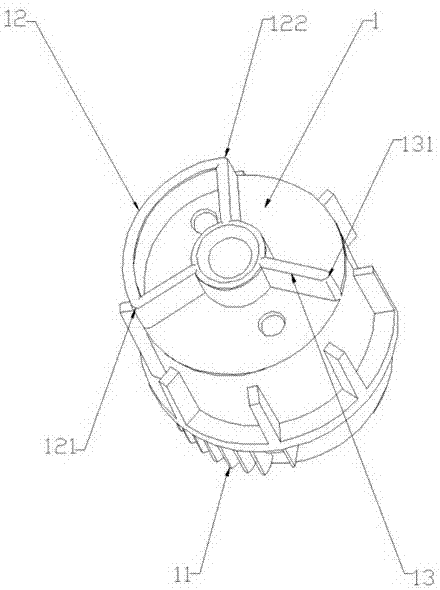

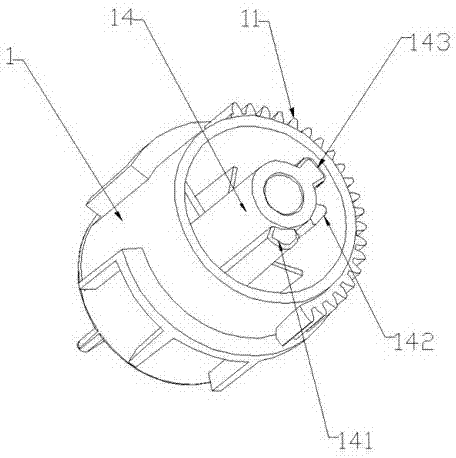

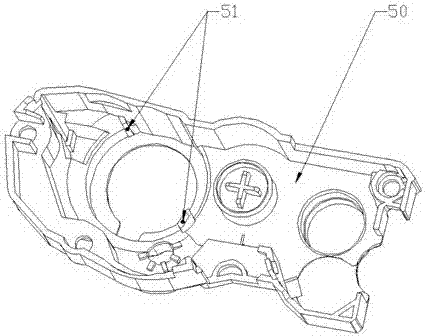

Development box counting gear

InactiveCN103760755ASimple processing technologyReduce processing costsPortable liftingElectrographic process apparatusEngineeringProcessing cost

The invention discloses a development box counting gear and aims to provide the development box counting gear which is simple in structure and low in processing cost and enables a development box to be reproduced without disassembly of a gear end cover. The development box counting gear comprises a gear body (1) and a toothed part (11), wherein the toothed part (11) is arranged on the gear body (1); the gear body (1) rotates without interference to the inner side of the gear end cover; a circular arc part (12) and a contact pin (13) are arranged on the top surface of the gear body (1); the central angle of the circular arc part (12) is between 95 degrees and 135 degrees; the central angle of a circular arc formed between a tail end (122) of the circular arc part (12) and an end part (131) of the contact pin (13) is between 92 degrees and 132 degrees. The development box counting gear can be applied to the technical field of development box reproduction and processing.

Owner:ZHUHAI XINCHENG TECH

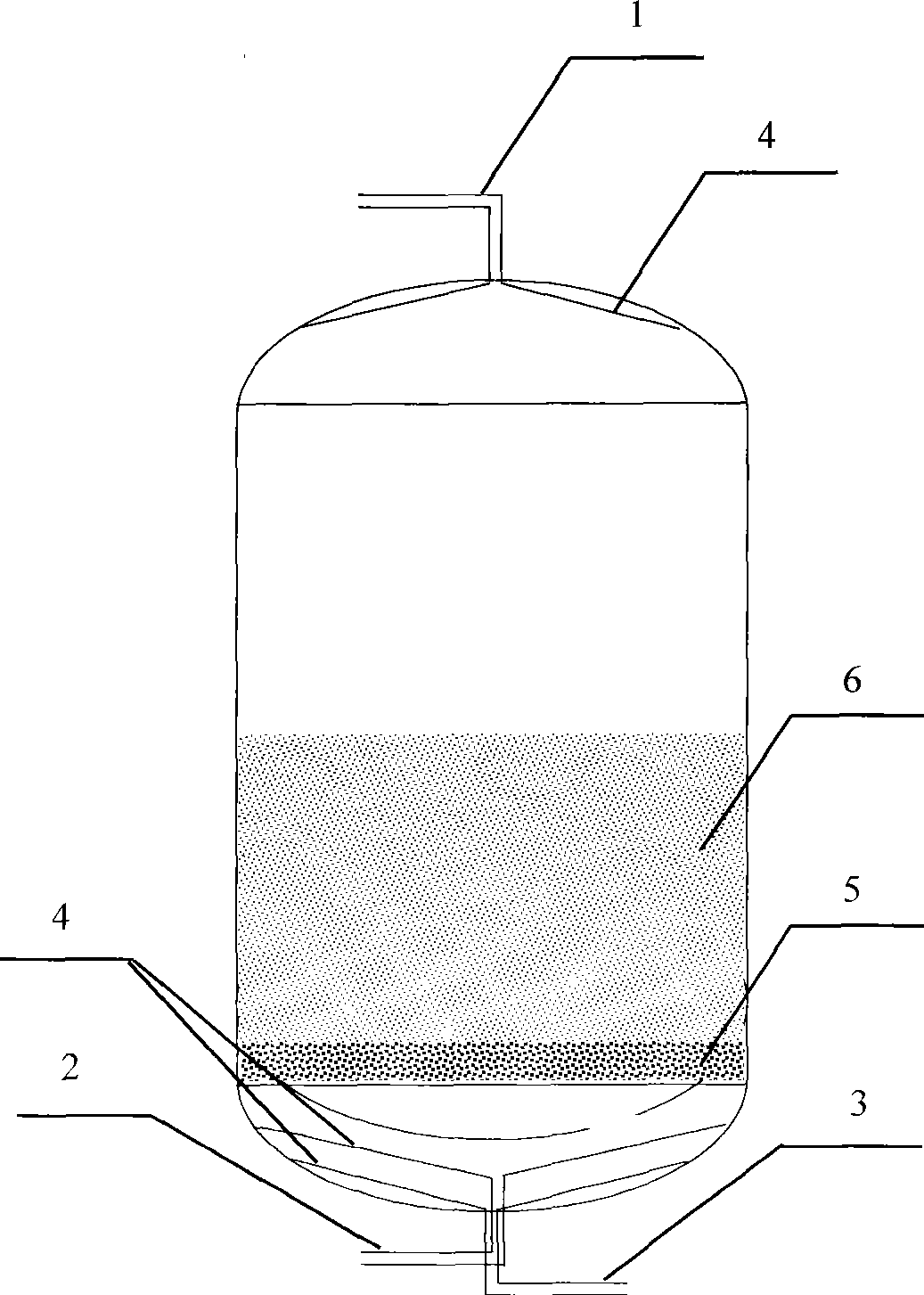

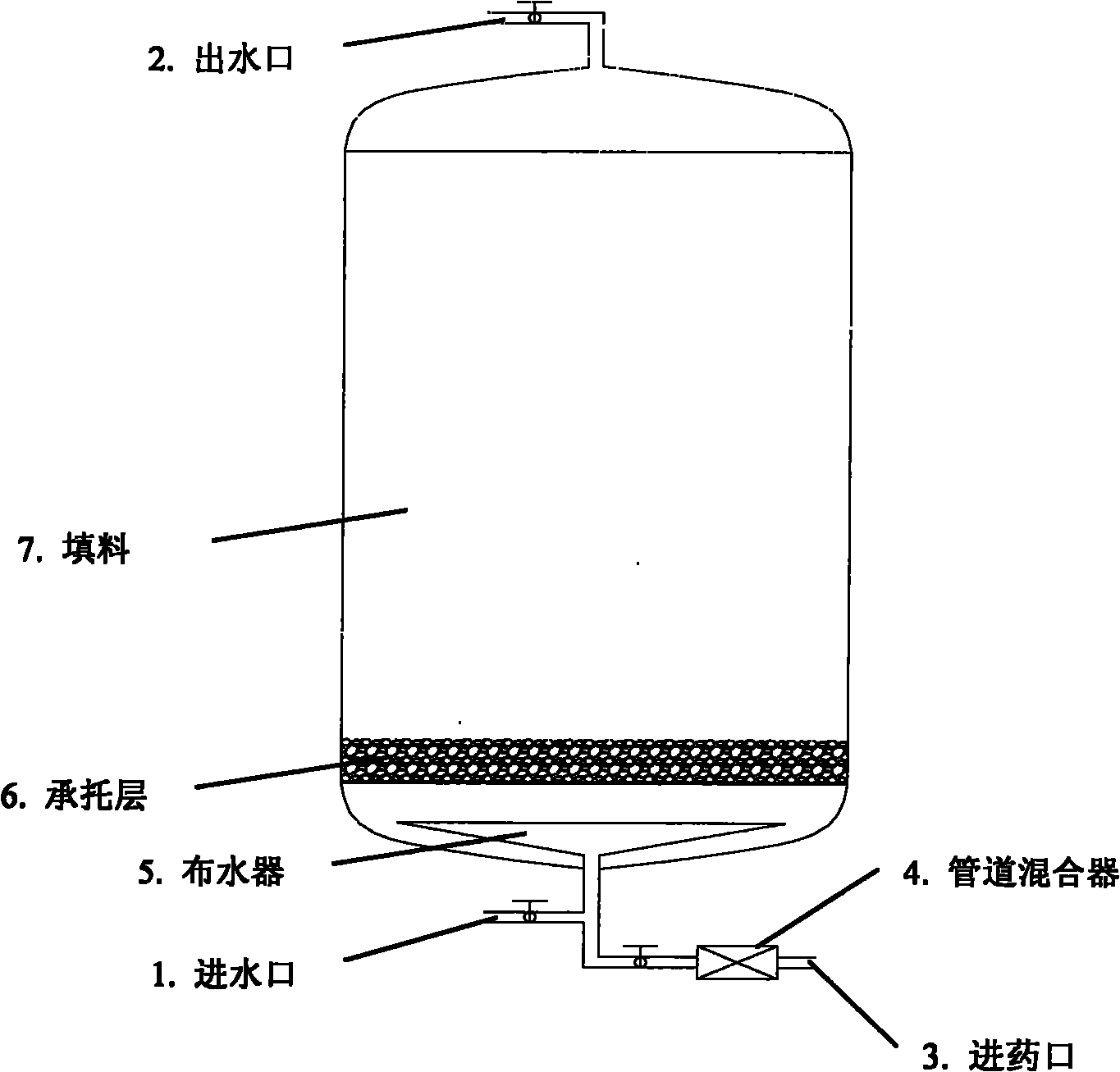

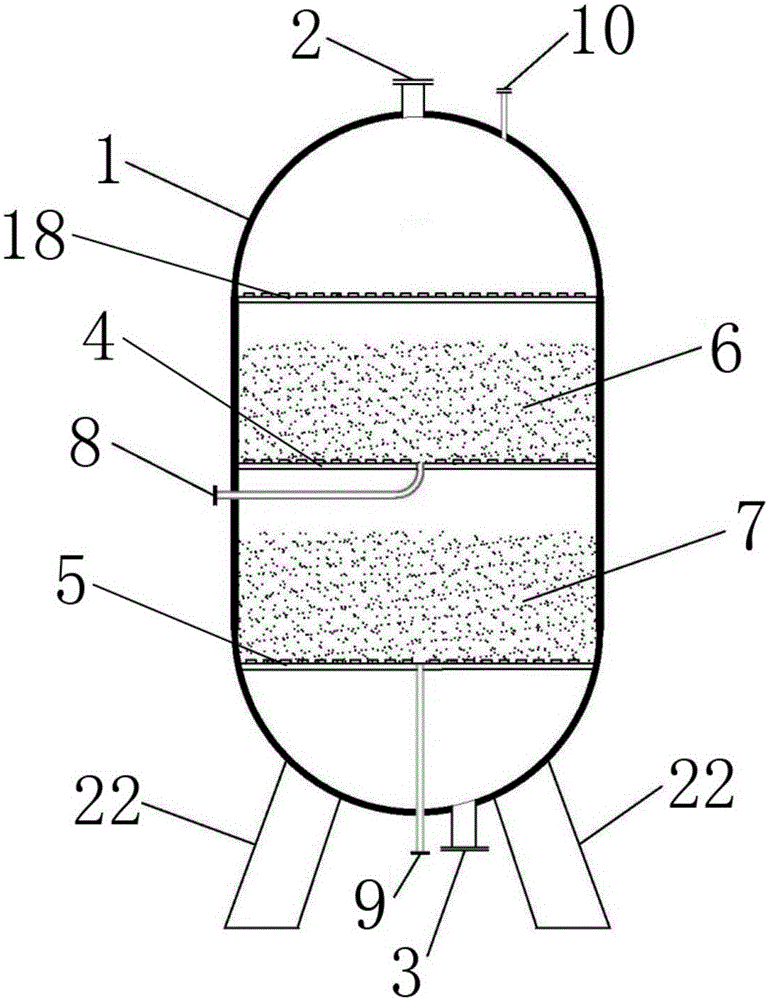

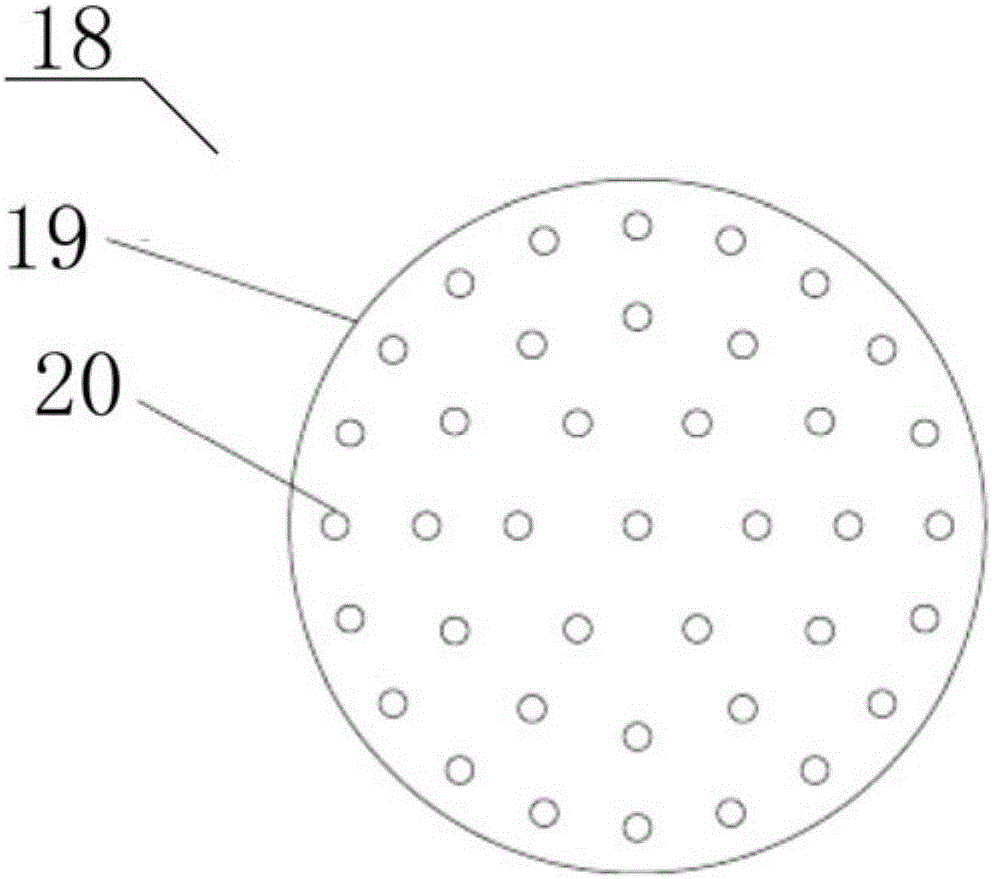

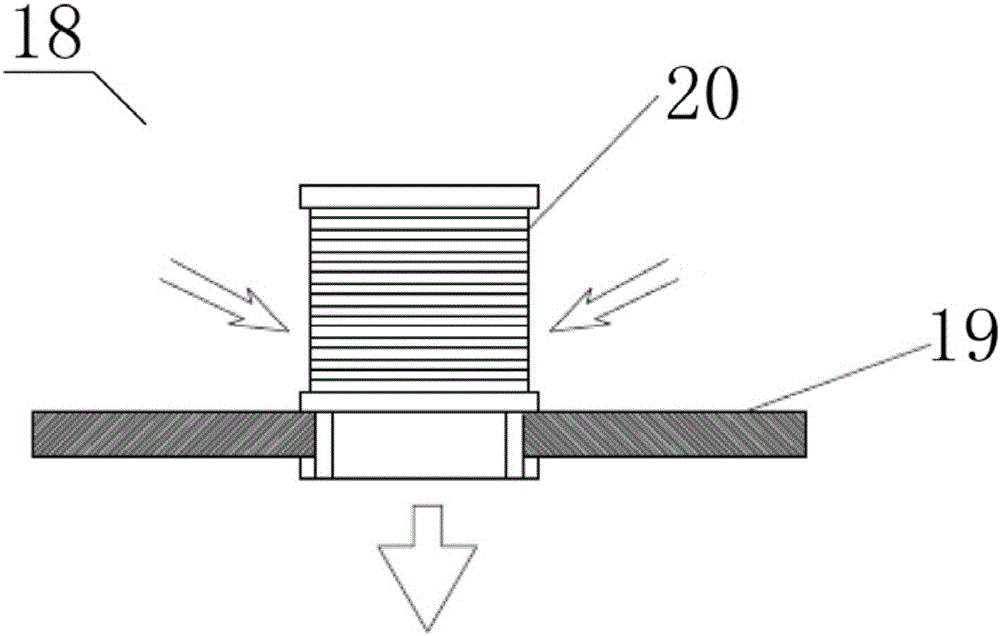

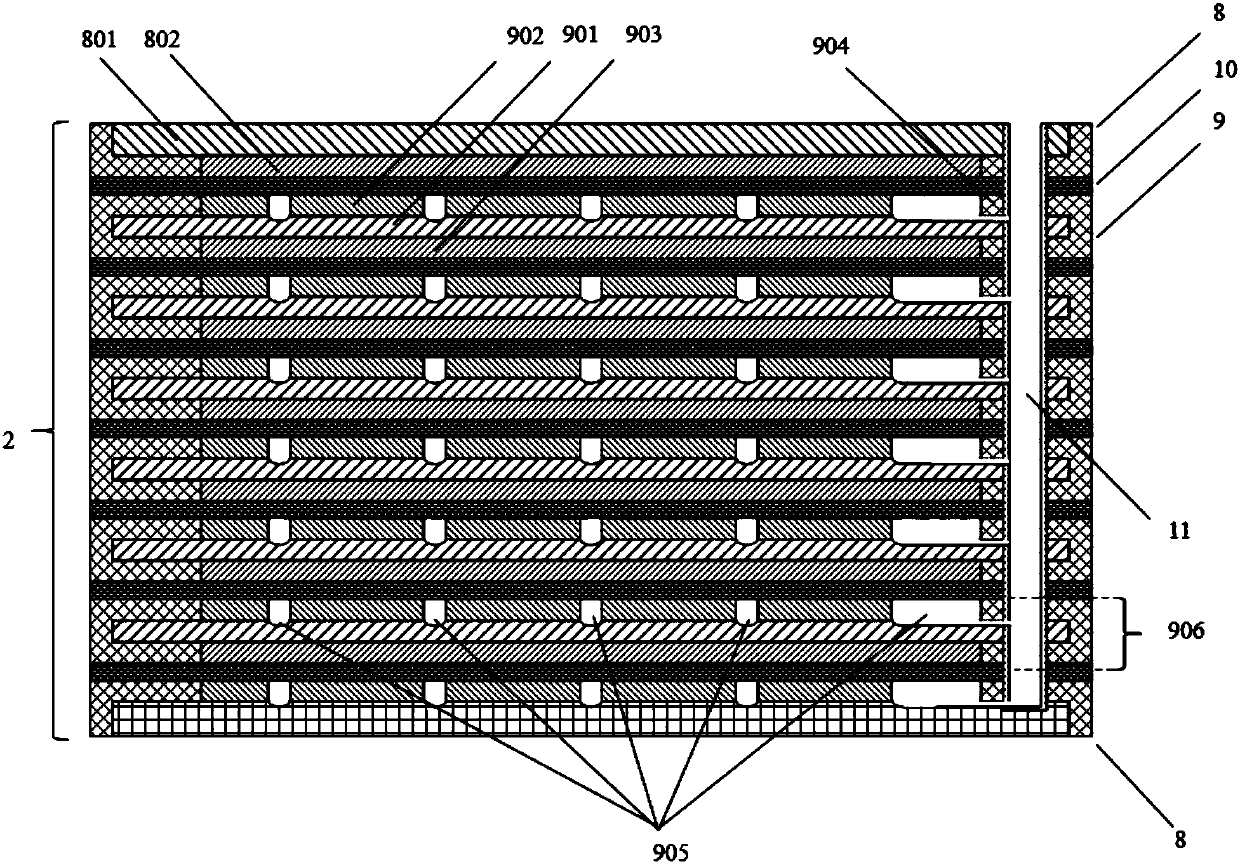

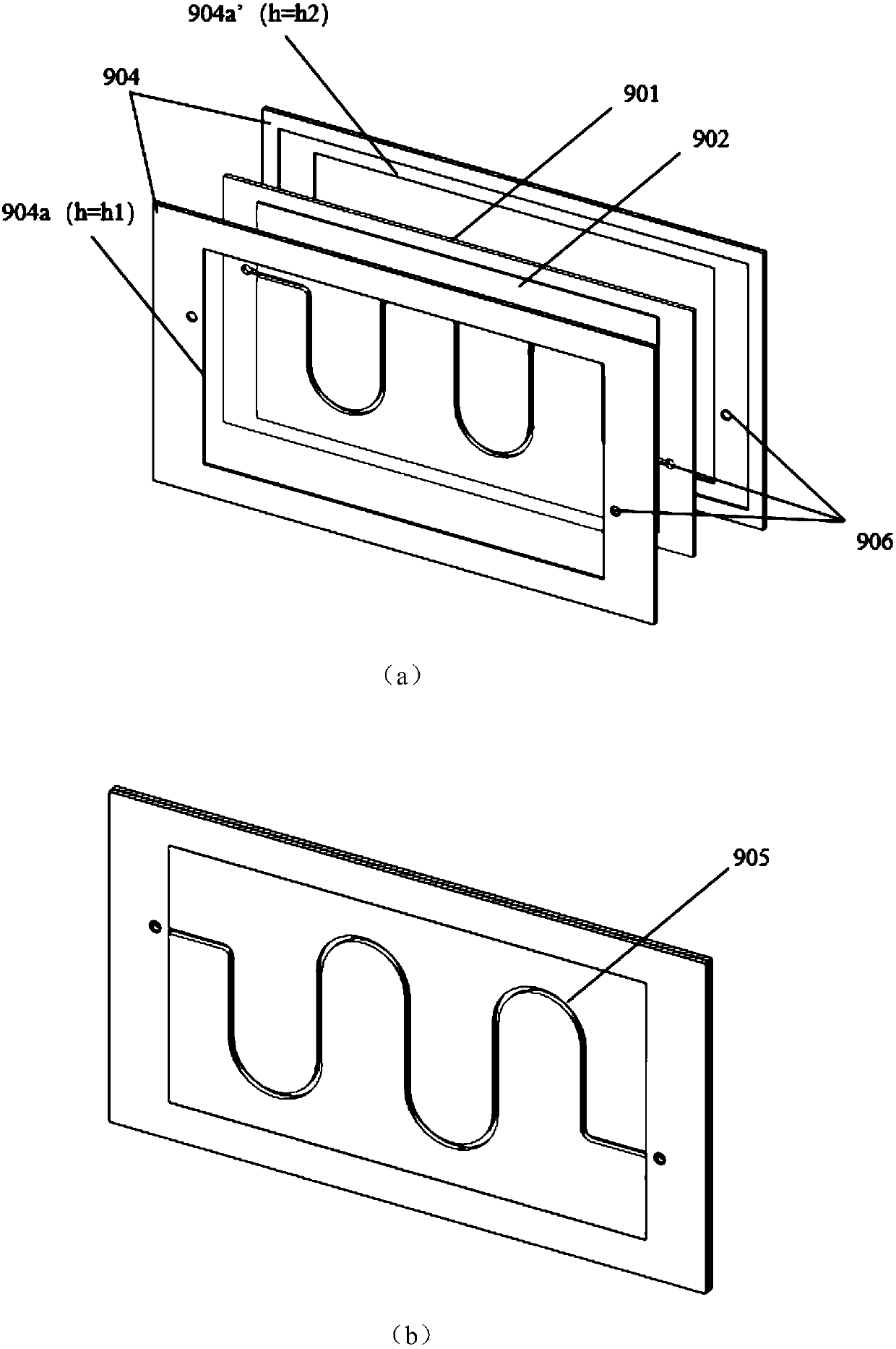

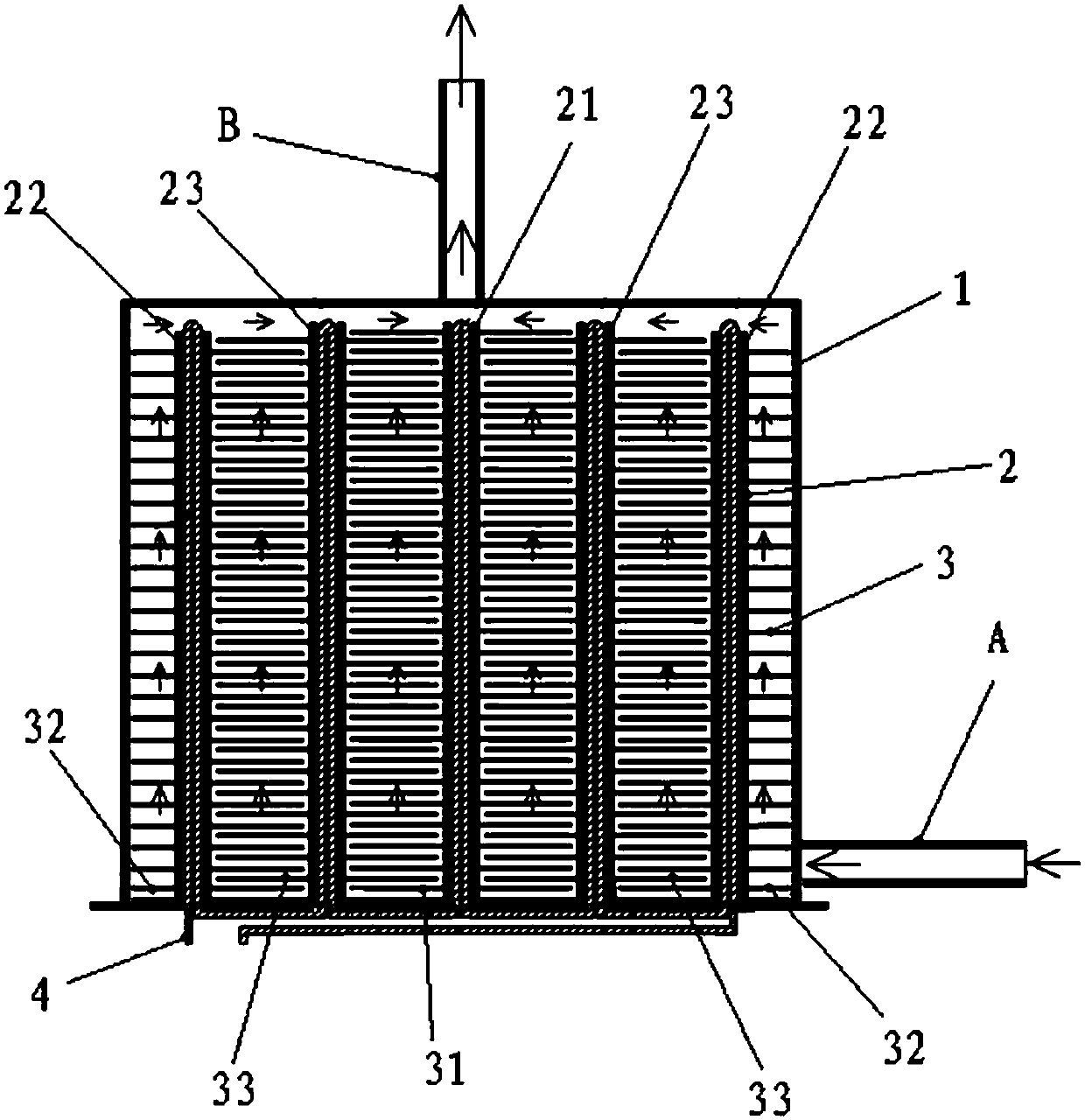

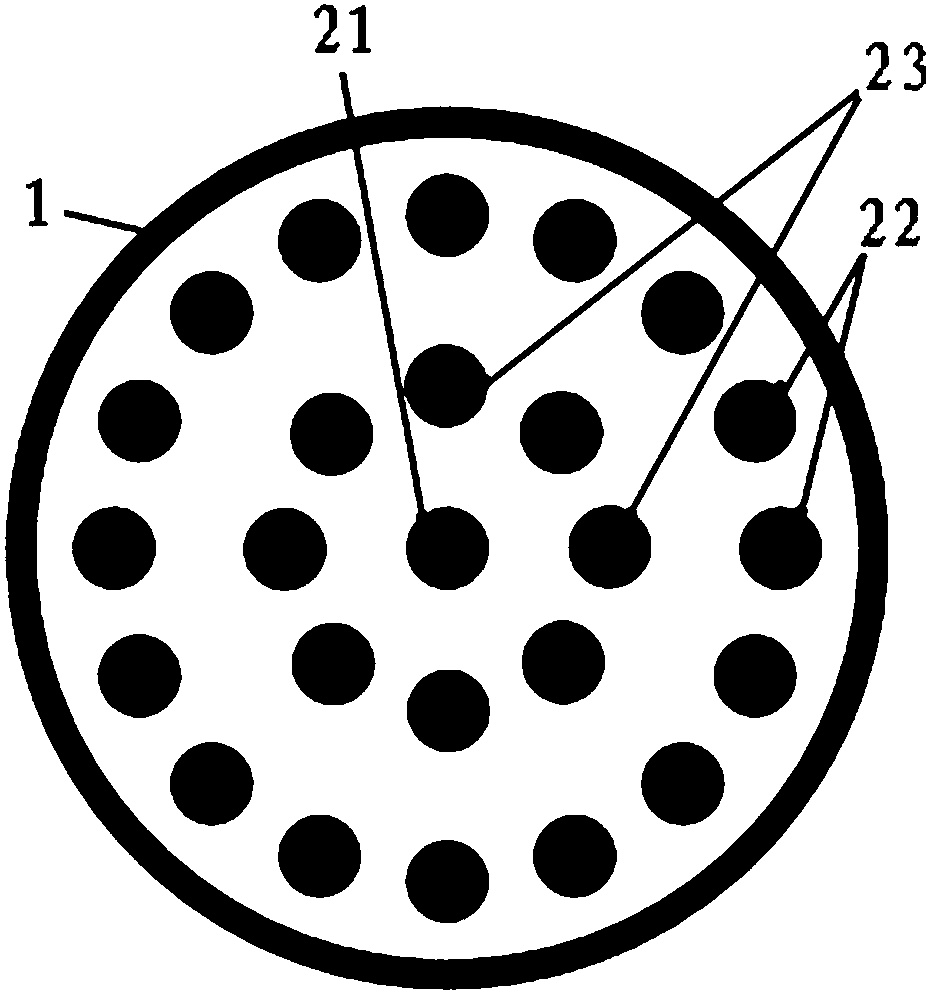

Ion exchange device and condensed water fine processing equipment

InactiveCN105948172AEasy regenerationSmall footprintWater/sewage treatment by ion-exchangeWater/sewage treatment apparatusIon exchangeWater collection

The invention relates to the field of condensed water fine processing, and discloses an ion exchange device and condensed water fine processing equipment. The ion exchange device comprises a pot body. A cavity of the pot body is provided with a water inlet and a water outlet. A positive resin layer drained water collection device and a negative resin layer drained water collection device are arranged in the cavity in the axial direction of the pot body in a separated mode and located between the water inlet and the water outlet. A negative resin layer is arranged in the negative resin layer drained water collection device, so that condensed water can penetrate through the positive resin layer drained water collection device and the negative resin layer drained water collection device after entering the cavity through the water inlet and then is drained from the water outlet. The ion exchange device has the effects that resin regeneration operation is easy, and a pipeline system is simplified.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

Dual-polarity battery stack

ActiveCN109873110AImprove reliabilityAvoid short circuitFinal product manufactureActive material electrodesEngineeringElectrolyte

The invention provides a dual-polarity battery stack. Liquid holes formed in same positions on a single pole plate and a bipolar plate form a tubular liquid injection passage, a liquid injection and sealing device is arranged in the liquid injection passage of the dual-polarity battery stack and comprises a cylinder, a liquid injection hole is formed in the cylinder, the cylinder is a movable cylinder capable of rotating or moving upwards and downwards, and connection or staggering of the liquid injection hole and an electrolyte runner of the dual-polarity battery is achieved by rotation or moving of the rotatable cylinder; or the cylinder is a fixed cylinder, the fixed cylinder is fixedly arranged in the liquid injection passage, a liquid injection hole of the fixed cylinder communicateswith the electrolyte runner of the dual-polarity electrode plate, a movable piece is arranged in the fixed cylinder, and opening or closing of the liquid injection hole is achieved by rotation or upward-downward moving of the movable piece in the fixed cylinder. By the liquid injection and sealing device, electrolyte injection can be effectively completed, and the problem of short circuit in the battery stack caused by an electrolyte passing through the liquid injection passage also can be effectively solved.

Owner:BEIJING HAWAGA POWER STORAGE TECH

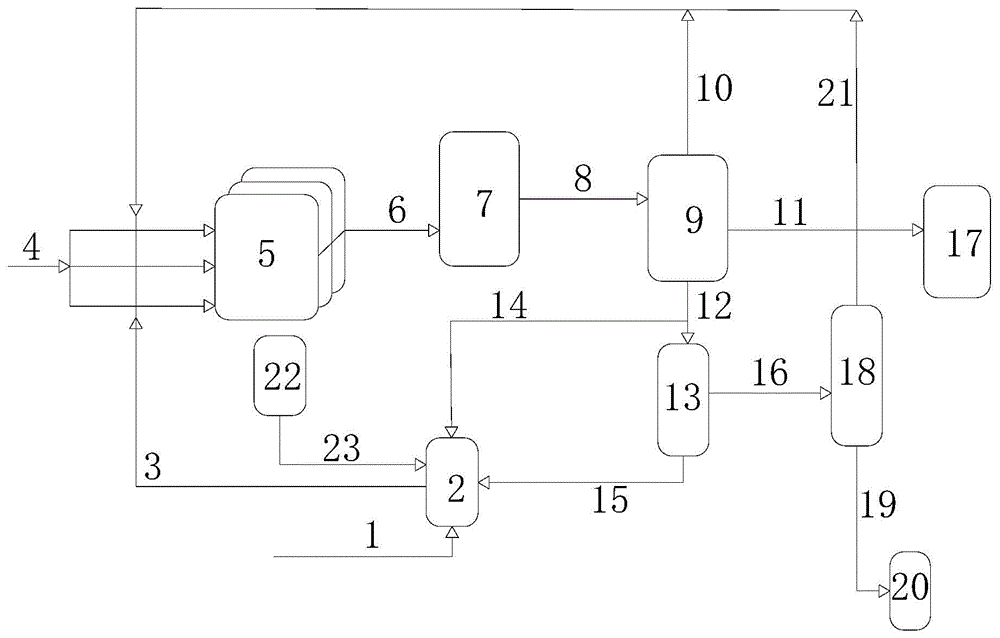

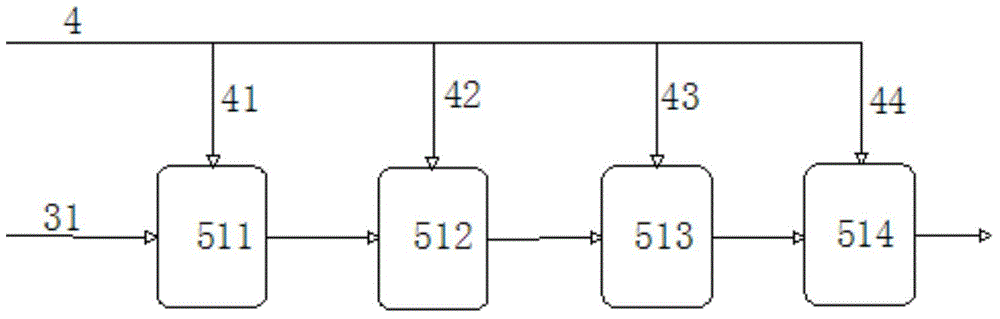

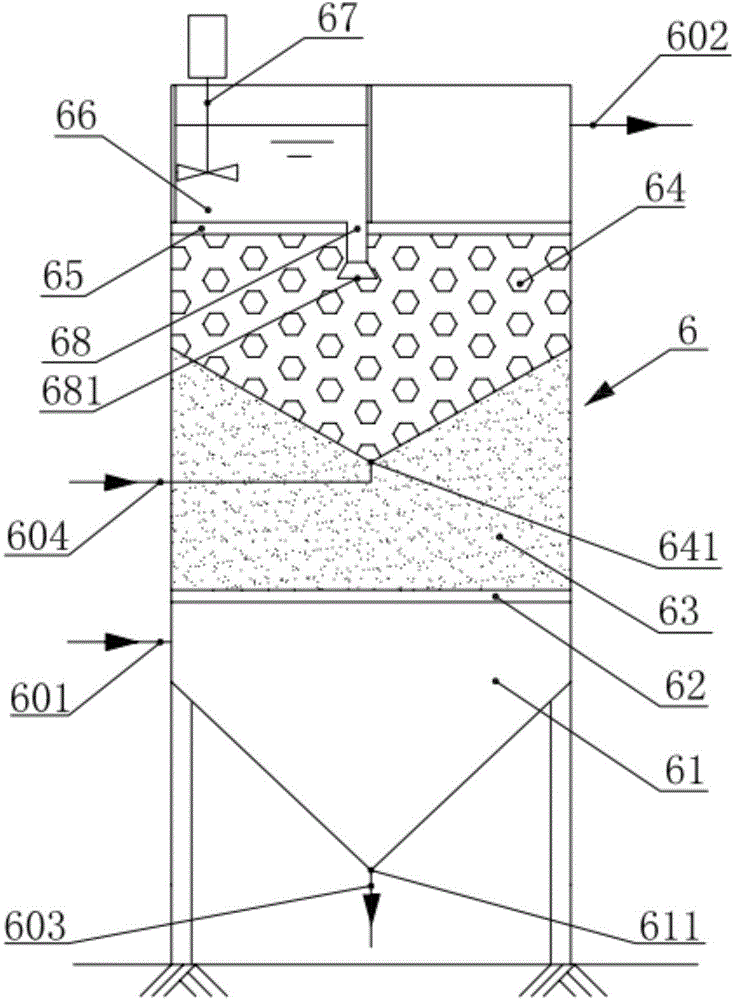

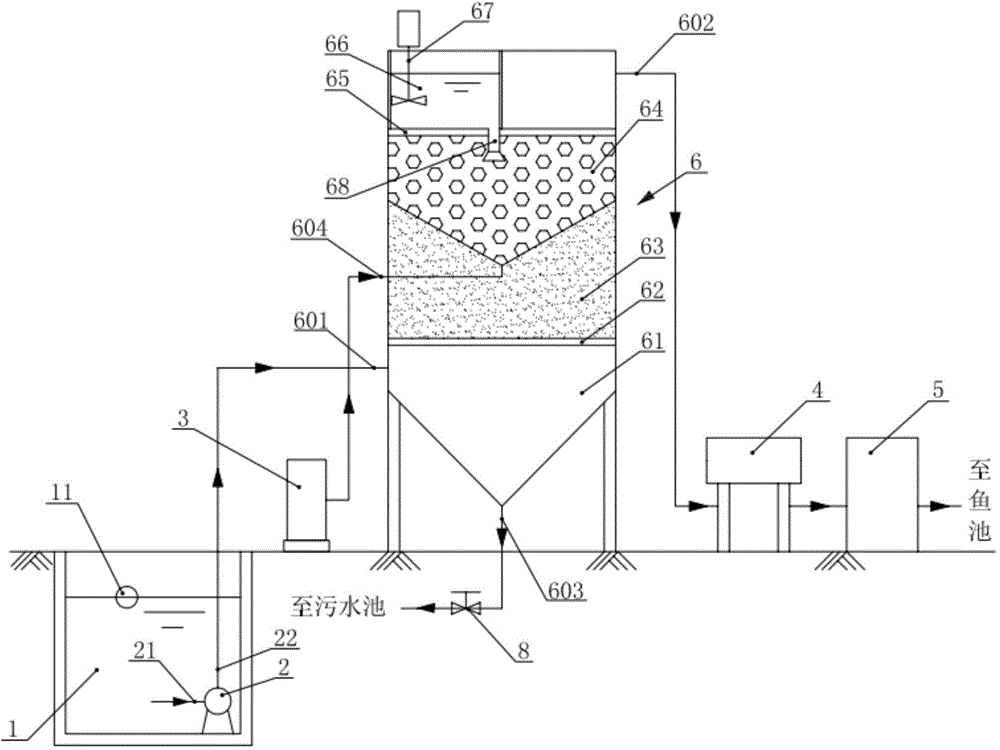

Fish enhancement and releasing station circulation water treatment tower and treatment system of water-power engineering

ActiveCN104310624ABoth aeration and oxygenationEasy regenerationWater/sewage treatment by irradiationTreatment involving filtrationWater resourcesPower engineering

The invention discloses a fish enhancement and releasing station circulation water treatment tower and a treatment system of water-power engineering, belonging to the field of water resources and hydropower engineering, and providing a fish enhancement and releasing station circulation water treatment tower which is relatively simple in structure, relatively convenient to operate and maintain and meanwhile capable of increasing the content of dissolved oxygen in purified water, of the hydropower engineering. A first screening plate, a packing filtering layer, a zeolite fluidized bed layer and a second screening plate are arranged inside the treatment tower, so as to achieve purification treatment on wastewater. Meanwhile, by feeding air into the zeolite fluidized bed layer, the fluidization effect is improved, and the content of dissolved oxygen in water is increased; in addition, a salt dissolving pond can be constructed, and regeneration operation on zeolite can be conveniently performed. By adopting the fish enhancement and releasing station circulation water treatment tower and the treatment system, the sewage purification effect is improved, the equipment occupied space is reduced, the content of dissolved oxygen in purified water is increased, the operation and the maintenance are convenient, the regeneration operation on zeolite is simplified, and the regeneration efficiency is improved.

Owner:CHINA HYDROELECTRIC ENGINEERING CONSULTING GROUP CHENGDU RESEARCH HYDROELECTRIC INVESTIGATION DESIGN AND INSTITUTE

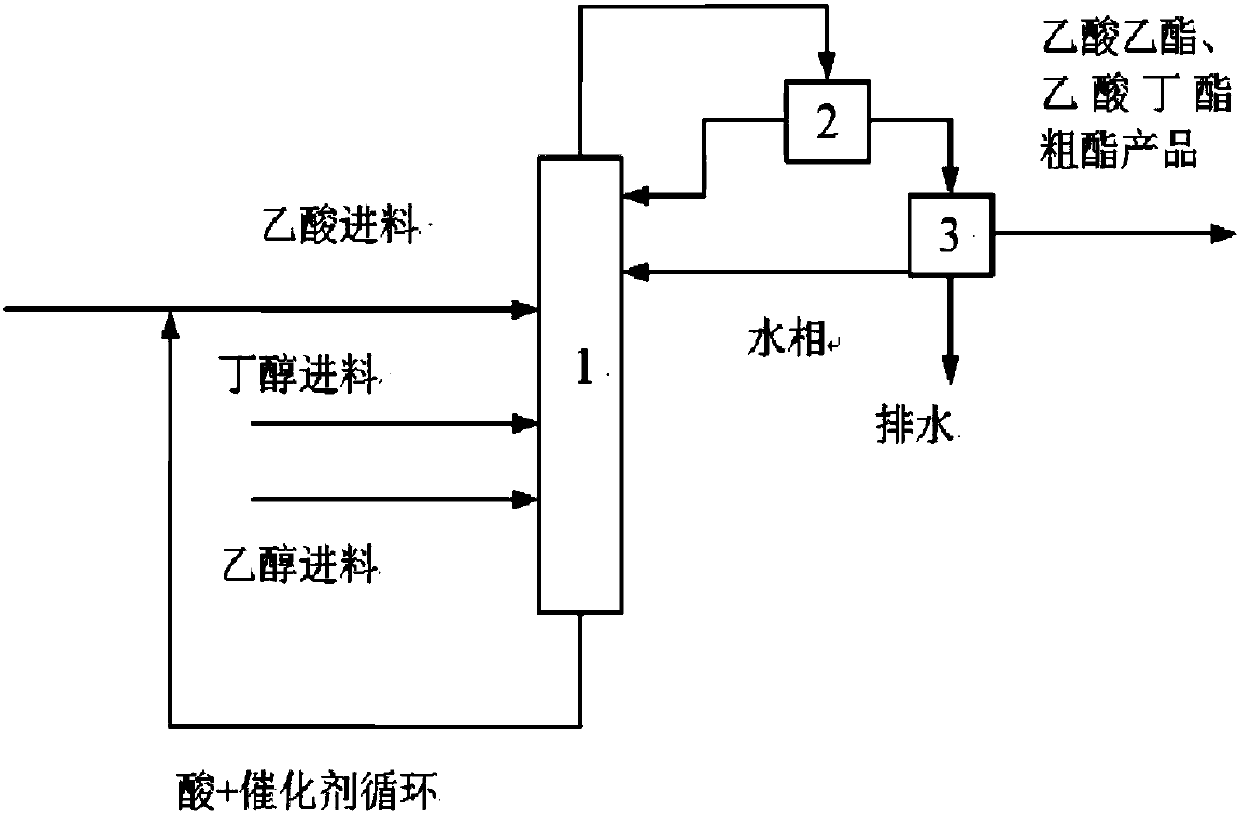

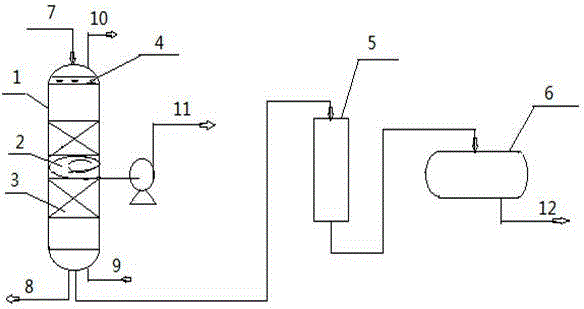

Method for synthesizing mixed ester through catalyst distillation

InactiveCN107827746AReduce difficultyIncrease acetic acid contentOrganic compound preparationChemical industryStrong acidsCatalytic distillation

The invention discloses a method for synthesizing mixed ester through catalyst distillation. The method comprises the following steps: by taking ethanol, n-butyl alcohol and acetic acid as raw materials, a strong acid cation exchange resin as a catalyst and a catalyst distillation tower as a reactor, performing a catalyst distillation backflow reaction, and finally performing phase separation, thereby obtaining mixed ester of ethyl acetate and butyl acetate. According to the method, the intense water carrying power of the butyl acetate is utilized, azeotrope is prepared from the butyl acetate,butanol and water, and water generated from reactions is completely carried out from a tower top. Therefore, the conversion rate of alcohol reactants and the content of the acetic acid in the catalyst distillation tower can be increased, and the influence of product water to the reaction process in the tower is also eliminated. A tower top product is generally an ester-water mixture and comprisesa very small amount of acetic acid, so that the later purification difficulty of the ethyl acetate and the butyl acetate is greatly reduced, the production procedures are simplified, the production efficiency is improved, and the energy consumption is reduced.

Owner:GUANGXI UNIV FOR NATITIES

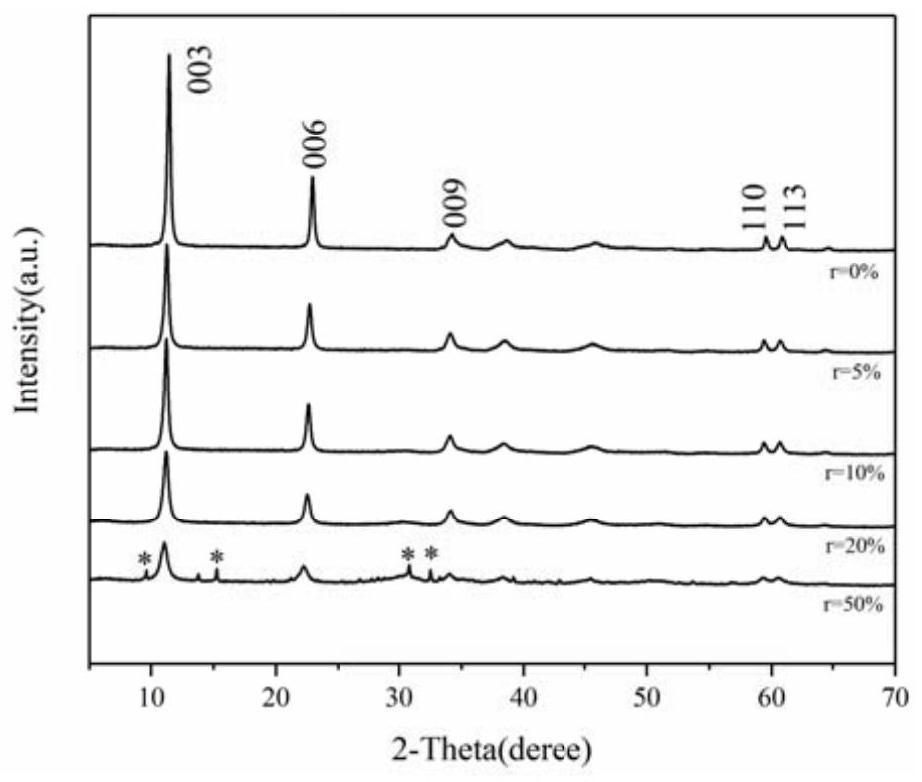

Preparation of zirconium-doped hydrotalcite-like adsorbent and application of zirconium-doped hydrotalcite-like adsorbent in treatment of phosphorus-containing wastewater

PendingCN113134339ASimple methodLow costOther chemical processesSpecific water treatment objectivesPhysical chemistryHydrotalcite

The invention relates to preparation of a zirconium-doped hydrotalcite-like adsorbent and application of the zirconium-doped hydrotalcite-like adsorbent in treatment of phosphorus-containing wastewater. According to the invention, the hydrotalcite-like material has a permanent positive charge laminate and a good anion exchange capability, and can generate a good adsorption effect on anions (such as phosphate radicals) in wastewater; and Zr < 4 + > has higher cationic charges, so that the electrostatic attraction between Zr < 4 + > and anionic adsorbate can be increased. Zr < 4 + > is introduced into the hydrotalcite-like laminate, so that the phosphorus-containing wastewater adsorbent which is large in adsorption capacity, easy to regenerate and recyclable can be constructed.

Owner:BEIJING UNIV OF CHEM TECH

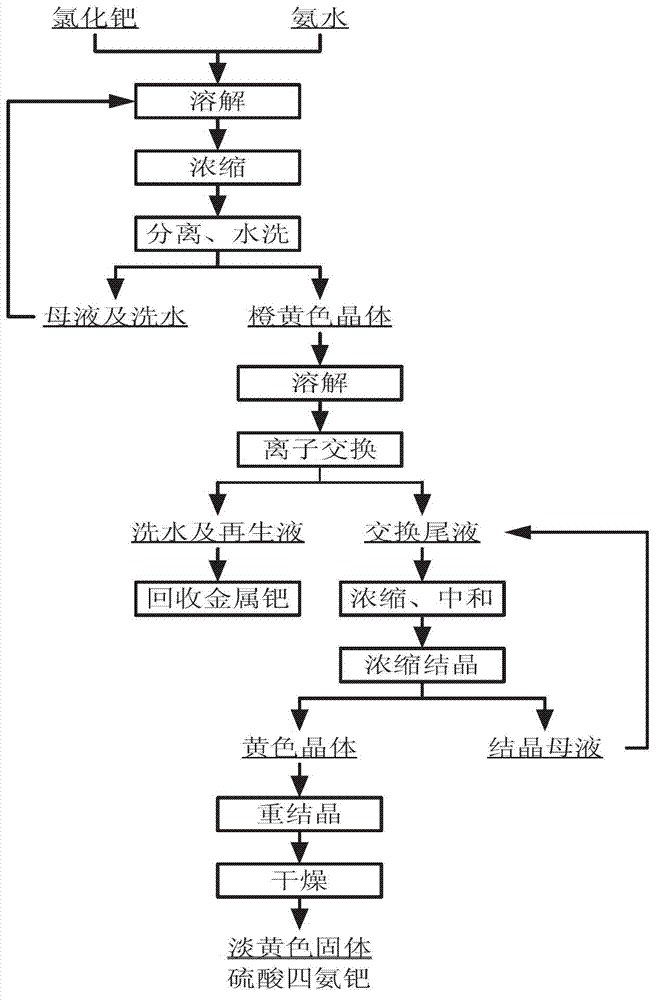

Synthetic method of palladium tetra-ammino sulfate

ActiveCN102786100BGood choiceLarge exchange capacityRuthenium/rhodium/palladium/osmium/iridium/platinum compoundsSulfateTetra

The invention discloses a synthetic method of palladium tetra-ammino sulfate, comprising the following steps of: (1) adding ammonia water in reagent level palladium chloride in order to dissolve palladium chloride; (2) concentrating and crystallizing the obtained solution, and drying the crystals to obtain orange solids; (3) confecting yellow solids into solution with a certain concentration; (4) flowing the solution through a negative ion exchange resin, exchanging repeatedly till Cl<-> ion cannot be detected in tail solution; (5) concentrating the exchanged solution to a certain concentration, adding sulfuric acid in a quantitative form, keeping on concentrating till crystals are generated; (6) separating out the crystals, re-crystallizing for 2-3 times, obtaining yellow crystals; and (7) drying crystals at a low temperature, so as to obtain faint yellow palladium tetra-ammino sulfate solids. The method has the following characteristics of simple process, few by-products, high product purity, and high product yield of more than 95%.

Owner:GUIYAN RESOURCE YIMEN

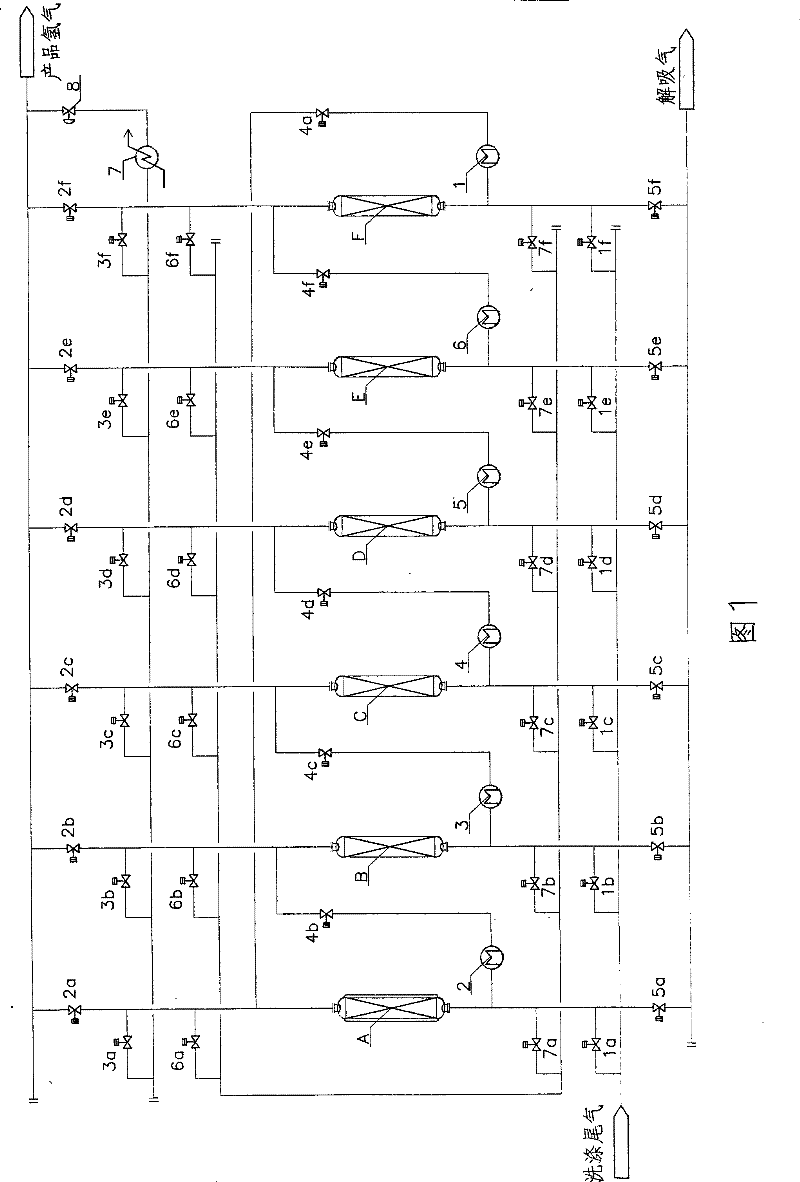

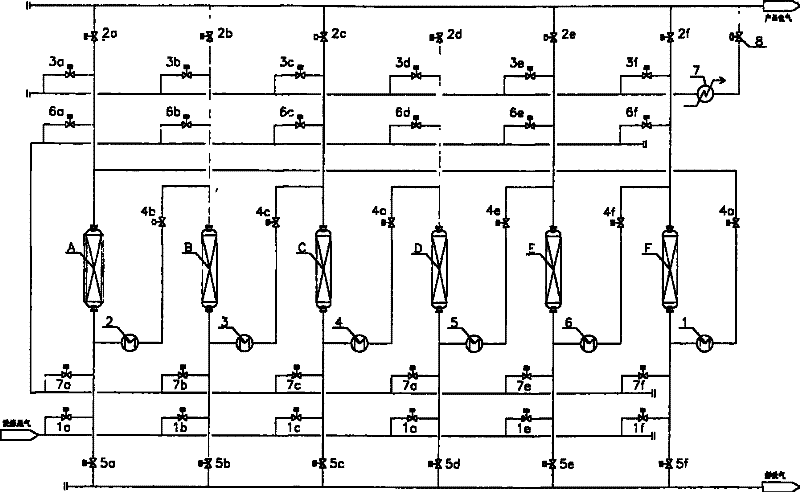

Multi-stage absorption, regeneration and purification method of polysilicon tail gas

InactiveCN101396632BIncrease profitReduce usagePolycrystalline material growthSiliconPurification methodsSorbent

Owner:SICHUAN TECHAIRS

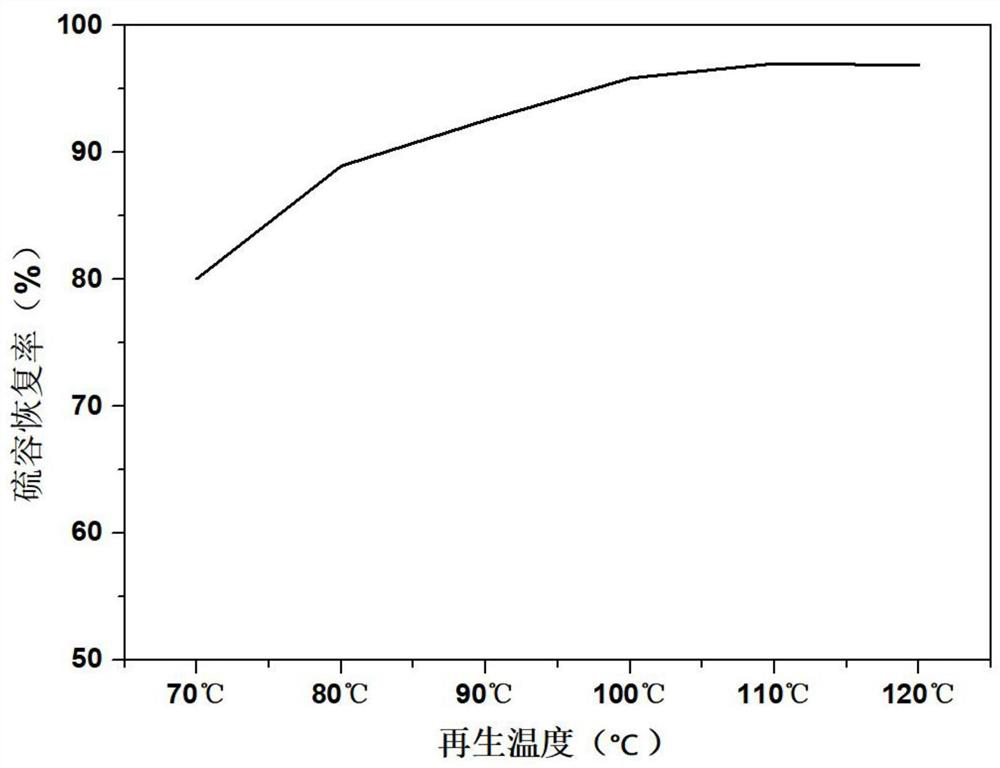

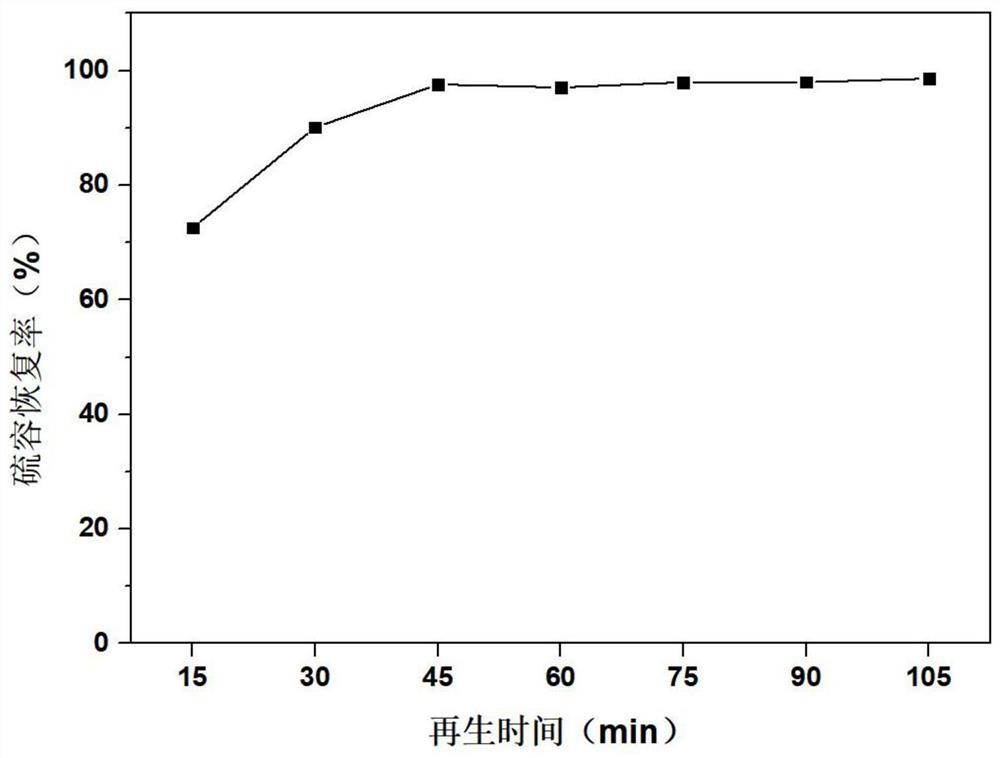

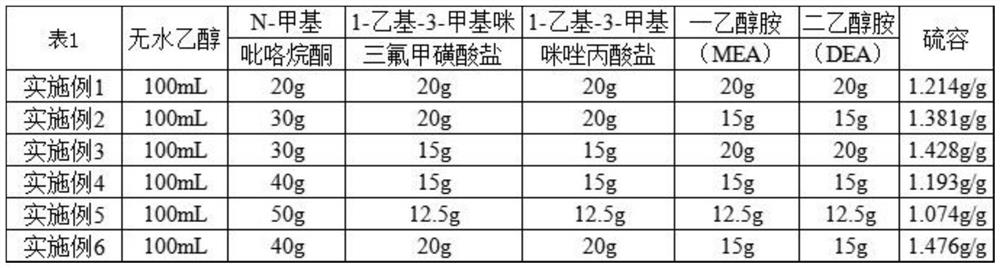

Renewable compound ionic liquid desulfurizing agent as well as preparation method and application thereof

ActiveCN113368665AHigh sulfur capacityGood choiceGas treatmentDispersed particle separationPropanoic acidCarbonyl sulfide

The invention discloses a regenerable compound ionic liquid desulfurizing agent and a preparation method and an application thereof. The regenerable compound ionic liquid desulfurizing agent is formed by mixing a desulfurization component and a diluting solvent, the desulfurization component is composed of, by mass, ionic liquid, an alcohol amine solution and an enhancer, and the mass fraction of the ionic liquid accounts for 25-40% of that of the desulfurization component; the alcohol amine solution accounts for 25-40% of the mass fraction of the desulfurization component, and the enhancer accounts for 20-50% of the mass fraction of the desulfurization component; the ionic liquid is at least two of 1-ethyl-3-methylimidazole trifluoromethanesulfonate, 1-ethyl-3-methylimidazole propionate, 1-ethyl-3-methylimidazole diamine nitrile, 1-ethyl-3-methylimidazole bis (trifluoromethanesulfonyl) imide, 1-ethyl-3-methylimidazole histidine, 1-ethyl-3-methylimidazole glycolate, and 1-methyl-3-sulfobutyl imidazole bisulfate. The desulfurizing agent has a good removal effect on organic sulfur such as carbonyl sulfide, carbon disulfide and mercaptan, the adsorbed organic sulfur is desorbed through heating after adsorption saturation, and the desulfurizing agent can be regenerated and reused for multiple times.

Owner:ZHEJIANG UNIV OF TECH

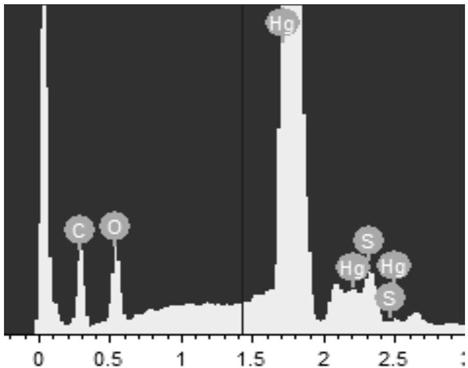

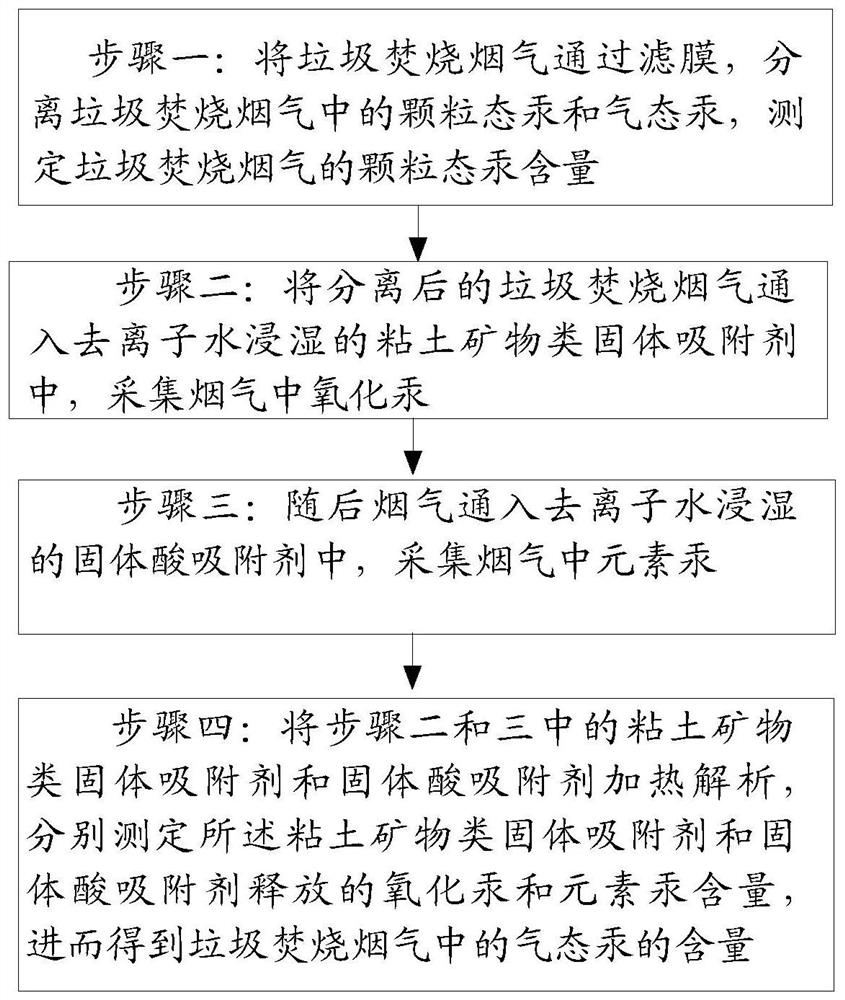

Detection method and collection device for mercury in waste incineration flue gas

PendingCN113325133AEasy to collectEasy regenerationWithdrawing sample devicesGas analyser construction detailsClay mineralsSorbent

The invention relates to the technical field of environmental monitoring, in particular to a method for detecting mercury in waste incineration flue gas, which comprises the following steps: separating particulate mercury and gaseous mercury in flue gas through a filter membrane, and measuring the content of the particulate mercury in the flue gas; introducing the flue gas into a clay mineral solid adsorbent wetted by deionized water, and collecting mercuric oxide in the flue gas; introducing the flue gas into a solid acid adsorbent wetted by deionized water, and collecting the element mercury in the flue gas; heating and desorpting the clay mineral solid adsorbent and the solid acid adsorbent to respectively measure the content of mercuric oxide and the content of elemental mercury. The invention further relates to a collecting device which comprises a constant-temperature sampling gun and a constant-temperature adsorption bottle box, wherein a constant-temperature filter is arranged in the constant-temperature sampling gun; a first bottle body filled with a clay mineral solid adsorbent and a second bottle body filled with a solid acid adsorbent are sequentially communicated in the constant-temperature adsorption bottle box in the flue gas flowing direction. The device is suitable for a high-temperature, high-humidity and high-corrosion flue gas detection environment, and the higher the temperature, humidity and acidity of the flue gas are, the more beneficial to mercury collection of a clay mineral solid adsorbent and a solid acid adsorbent.

Owner:福建省锅炉压力容器检验研究院

Method for clearing copper bonded on starting sheet

InactiveCN108048880AAvoid damageAvoid deformationPhotography auxillary processesElectrolysis componentsFerric hydroxideSulfate

The invention relates to a method for clearing copper bonded on a starting sheet. The method for clearing the copper bonded on the starting sheet comprises the following steps that the starting sheetof which the copper is bonded on the surface is put into a ferric sulfate solution for soaking, the soaked starting sheet is put into clean water for cleaning after being taken out, and the starting sheet which is subjected to clearing of the bonded copper; and the ferric sulfate solution can be prepared by ferric sulfate, ferric hydroxide, ferrous sulfate or ferrous hydroxide and dilute sulfuricacid with the density of 200-250g / L. Compared with the prior art, the method for clearing the copper bonded on the starting sheet has the advantages that operation is simple, damage to the starting sheet is small, and the labor cost is saved.

Owner:SHENZHEN ZHONGJIN LINGNAN NONFEMET COMPANY

Phosphine ligand as well as preparation method thereof, application thereof and method of extracting high-purity alkyl aluminum compound

InactiveCN108003184AEasy regenerationIncrease usageGroup 3/13 element organic compoundsPolystyrenePhosphine

The invention discloses phosphine ligand loaded on a styrene polymer as well as a preparation method thereof, application thereof and a method of extracting a high-purity alkyl aluminum compound by utilizing the phosphine ligand. According to the technical scheme adopted by the invention, phosphine ligand loaded on polystyrene is good in stability, and purity of alkyl aluminum is not lower than amass fraction of 99.99995% after distribution and rectification; and the phosphine ligand loaded on polystyrene is simple in regeneration operation in a later stage. The method can remarkably increaseuse times of the ligand and can solve the defect that the ligand is not liable to regenerate. The method has the advantages of being simple in a ligand circulating process in purification of alkyl aluminum crude products such as trimethyl aluminum and triethyl aluminum, reducing cost, being suitable for large-scale production and the like.

Owner:JIANGXI JIAYIN PHOTOELECTRIC MATERIAL

Water vapor capturing device

PendingCN110613949AEfficient removalMultiple contact areasVapor condensationMolecular sieveWater vapor

The invention discloses a water vapor capturing device, which comprises a condensation cavity used for capturing water vapor. A gas inlet for inputting to-be-treated gas and a gas outlet for outputting treated gas are formed in a shell of the condensation cavity; a column-shaped condensation rod and a plurality of groups of water vapor capture sheets are arranged in the condensation cavity; the water vapor capture sheets are installed on the column-shaped condensation rod and are arranged in a multi-layer staggered mode, wherein gaps are formed between the water vapor capture pieces in each layer. Compared with an existing molecular sieve device, the condensation capture structure provides a larger water vapor contact area, and a large-volume molecular sieve device does not need to be built with a large amount of cost; and moreover, the water vapor is captured by adopting a condensation principle, so that the captured water vapor is converted into solids (such as ice crystals) througha condensation effect, the condensate can be molten only by heating operation in a regeneration process, electronic gas does not need to be consumed, and toxic by-products cannot be introduced or secondarily generated.

Owner:紫石能源有限公司

Method for improving stability of gasoline by decoloring by using activated carbon fiber

ActiveCN104449828AImprove adsorption capacityEasy to useTreatment with plural serial refining stagesHydrocarbon oils treatment productsFiberActivated carbon

The invention discloses a method for ensuring the stability of gasoline by decoloring the gasoline by using activated carbon fiber. According to the method, activated carbon fiber of which the specific surface area is 1200-1600m<2> / g, the benzene absorption amount is 38-58wt%, the iodine absorption value is 1100-1500mg / g, the pore volume is 0.40-0.60ml / g and the average aperture is 0.60-0.80nm is adopted to decolor the gasoline, the regeneration mode is simple, the chromaticity of the decolored gasoline is relatively good, and the stability of the gasoline is greatly improved.

Owner:NINGXIA BAOTA PETROCHEM SCI & TECH IND DEV

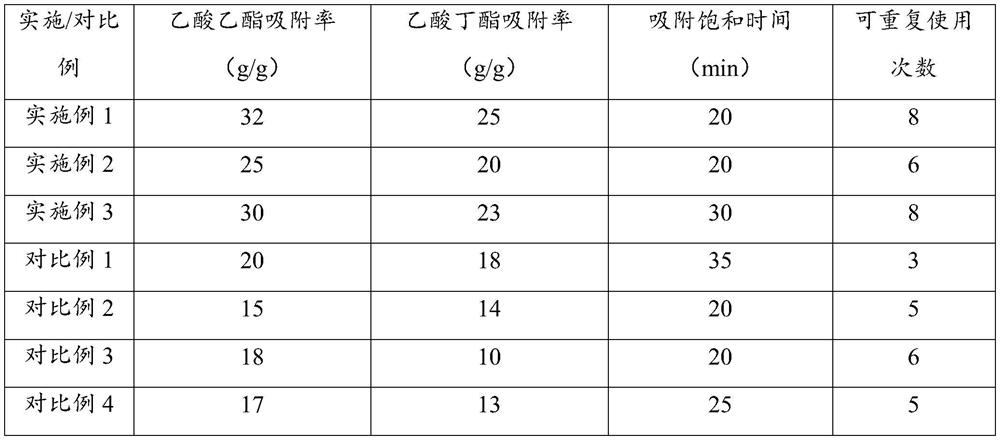

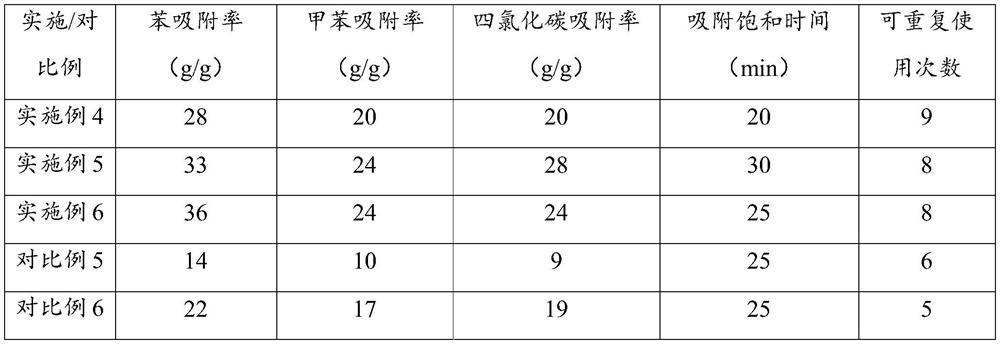

High-adsorbability resin and preparation method thereof

ActiveCN111957303AImprove adsorption capacityEasy regenerationOther chemical processesSolid sorbent liquid separationMethacrylateAcetic acid

The invention discloses high-adsorbability resin which comprises the following raw material components in parts by weight: 1-15 parts of water, 15-30 parts of methacrylate, 5-15 parts of acrylate, 15-50 parts of acrylate and 10-30 parts of styrene. The high-adsorbability resin also comprises a pore-foaming agent and an initiator. The product is stable in polarity, easy to store and moderate in viscosity, has the advantages of being high in adsorption rate, high in adsorption capacity, good in mechanical strength, simple in regeneration mode and the like, and can effectively adsorb an organic poison solvent and solve the leakage problem of the organic poison solvent. The invention further discloses a preparation method of the high-adsorbability resin. The preparation method is simple to operate, safe in preparation process, free of by-products, high in repeatability and beneficial to large-scale preparation. The invention also discloses an application of the high-adsorbability resin inorganic poison adsorption. The product can be used for adsorption treatment of organic toxicants such as acetic acid short-chain ester, benzene compounds and chlorides.

Owner:谦信化工集团有限公司 +1

A Partitioning Wall Rotary Kiln Device for Flue Gas Dehydration

ActiveCN104923042BEasy to adjust the stateEasy regenerationDispersed particle separationRotary drum furnacesAtmospheric contaminationFlue gas

The invention relates to a dividing wall rotary kiln device for flue gas dehydration. The dividing wall rotary kiln device comprises loading equipment, a charging bin, a conveyor, a rotary kiln, waste heat generating equipment and a spare unloading bin, wherein the rotary kiln is a dividing wall rotary kiln, and is composed of an outer ring and an inner ring which are coaxially mounted; a ring-shaped material channel is arranged between the inner ring and the outer ring; the ring-shaped material channel is provided with refractory material support; and a furnace hearth is arranged in the center of the inner ring. The furnace hearth is connected with the waste heat generating equipment by a kiln tail cover. The loading equipment is communicated with the ring-shaped material channel by the loading bin, the conveyor and a charging ring; the ring-shaped material channel is connected with the spare unloading bin by a discharge ring. A wet flue gas inlet is connected with a flue gas pipeline; a gas outlet is divided into two paths, one path is connected with a dry flue gas exhaustion system, and the other path is connected with a condenser; and connecting pipelines are provided with valves respectively. According to the dividing wall rotary kiln device, lime is used as a dryer, and the ring-shaped material channel of the dividing wall rotary kiln is used for drying and dehydrating the industrial flue gas, so that the flue gas diffusion capacity is improved in a facilitated mode, the acid rain and atmospheric contamination is reduced, and the dwelling and living environment of people is improved.

Owner:SHIJIAZHUANG XINHUA IND FURNACE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com