Renewable compound ionic liquid desulfurizing agent as well as preparation method and application thereof

A technology of ionic liquid and desulfurizing agent, which is applied in the field of compound ionic liquid desulfurizing agent and its preparation, can solve the problems of cumbersome preparation methods and high cost, and achieve the effects of good selectivity, low cost and significant environmental protection benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

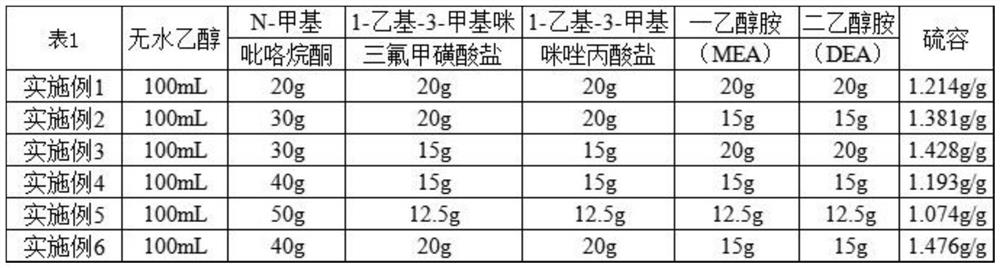

Embodiment 1

[0023] Measure 100mL of absolute ethanol, then weigh 20g of N-methylpyrrolidone, 20g of 1-ethyl-3-methylimidazole trifluoromethanesulfonate, 20g of 1-ethyl-3-methyl Imidazole propionate, 20 g of monoethanolamine (MEA) and 20 g of diethanolamine (DEA). Add the weighed ionic liquid, alcohol amine solution and enhancer dropwise into the measured anhydrous ethanol at room temperature through a constant pressure dropping funnel, and stir for 30 minutes to obtain Compound Ionic Liquid Desulfurizer Example No. 1 product.

[0024] Take 10mL of the above product as the absorption liquid and put it in the reaction bottle. After the purified COS standard gas is dried by the drying tube, the COS content in it is monitored in real time by gas chromatography. During the test process, the COS content is detected every 10 minutes. When the COS content in the COS standard gas processed by the absorption liquid of the product No. 1 of Example 1 rises to 50% of the inlet concentration, it is re...

Embodiment 2

[0026] Measure 100mL of absolute ethanol, then weigh 30g of N-methylpyrrolidone, 20g of 1-ethyl-3-methylimidazole trifluoromethanesulfonate, 20g of 1-ethyl-3-methyl Imidazole propionate, 15 g of monoethanolamine (MEA) and 15 g of diethanolamine (DEA). Add the weighed ionic liquid, alcohol amine solution and enhancer dropwise into the measured anhydrous ethanol at room temperature through a constant pressure dropping funnel, and stir for 30 minutes to obtain compound ionic liquid desulfurizer Example 2 product.

[0027] Take 10mL of the above product as the absorption liquid and put it in the reaction bottle. After the purified COS standard gas is dried by the drying tube, the COS content in it is monitored in real time by gas chromatography. During the test process, the COS content is detected every 10 minutes. When the COS content in the COS standard gas processed by the absorption liquid of the product No. 2 of Example 2 rises to 50% of the inlet concentration, it is regard...

Embodiment 3

[0029] Measure 100mL of absolute ethanol, then weigh 30g of N-methylpyrrolidone, 15g of 1-ethyl-3-methylimidazole trifluoromethanesulfonate, 15g of 1-ethyl-3-methyl Imidazole propionate, 20 g of monoethanolamine (MEA) and 20 g of diethanolamine (DEA). Add the weighed ionic liquid, alcohol amine solution and enhancer dropwise into the measured anhydrous ethanol at room temperature through the constant pressure dropping funnel, and stir for 30 minutes to obtain the composite ionic liquid desulfurizer Example No. 3 product.

[0030] Take 10mL of the above product as the absorption liquid and put it in the reaction bottle. After the purified COS standard gas is dried by the drying tube, the COS content in it is monitored in real time by gas chromatography. During the test process, the COS content is detected every 10 minutes. When the COS content in the COS standard gas processed by the absorption solution of the product No. 3 of Example 3 rises to 50% of the inlet concentration,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com