Patents

Literature

64results about How to "Low requirements for processing equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Application of nanometer copper oxide and the method of preparing the same

InactiveCN101041119AHigh desulfurization precisionSimple preparation processNanostructure manufactureDispersed particle separationLow demandSulfur

The invention relates to an application of nanometer copper oxide and the preparing method, belonging to an application of compound and the preparing method. Before the invention, there are not reports that single nanometer copper oxide is used as ambient temperature desulfurizer and the purity of nanometer copper oxide prepared by prior preparing method for nanometer copper oxide is low. In the invention, the nanometer copper oxide is used as the ambient temperature desulfurizer and the nanometer copper oxide is the only component of ambient temperature desulfuizer. The preparation of nanometer copper oxide is that sodium hydroxide is added in the copper nitrate solution and then it is filtered, dried and baked or the preparation of nanometer copper oxide is that sodium hydroxide is added in the copper nitrate solution and then it is filtered and dried. The desulfurization accuracy of nanometer copper oxide in the invention is high in ambient temperature condition and the sulfur capacity is high to 18.3%-28.7%. The purity of nanometer copper oxide prepared in the invention is higher than 99.9%. It is provided with simple preparing process, low demand for machining equipment, small energy consumption and low production cost. It is easy to be developed and implemented.

Owner:HARBIN INST OF TECH

1-methylcyclopropene liquid preparation

InactiveCN101715760AEasy to useApplicable varietiesBiocidePlant growth regulatorsOrganic solventAbscisic acid

The invention belongs to the field of agriculture technology, particularly discloses a 1-methylcyclopropene liquid preparation which is prepared by adding an organic solvent, emulsifier and an auxiliary agent on the basis of a 1-methylcyclopropene stead solution. The 1-methylcyclopropene liquid preparation acts on plants or part of the plants by methods of sprinkling, dipping and the like, and performs a preservation function or functions of resisting environmental threats, inhibiting the generation of hormones of plant ethylene, abscisic acid and the like, and enhancing resistance and the like. Compared with traditional products, the invention has convenient use and wide application range and maximizes the function of 1-methylcyclopropene (MCP), and meanwhile, the invention has the advantages of novel processing idea, simple technology, low cost, low equipment requirement and stable product performance.

Owner:山东营养源食品科技有限公司

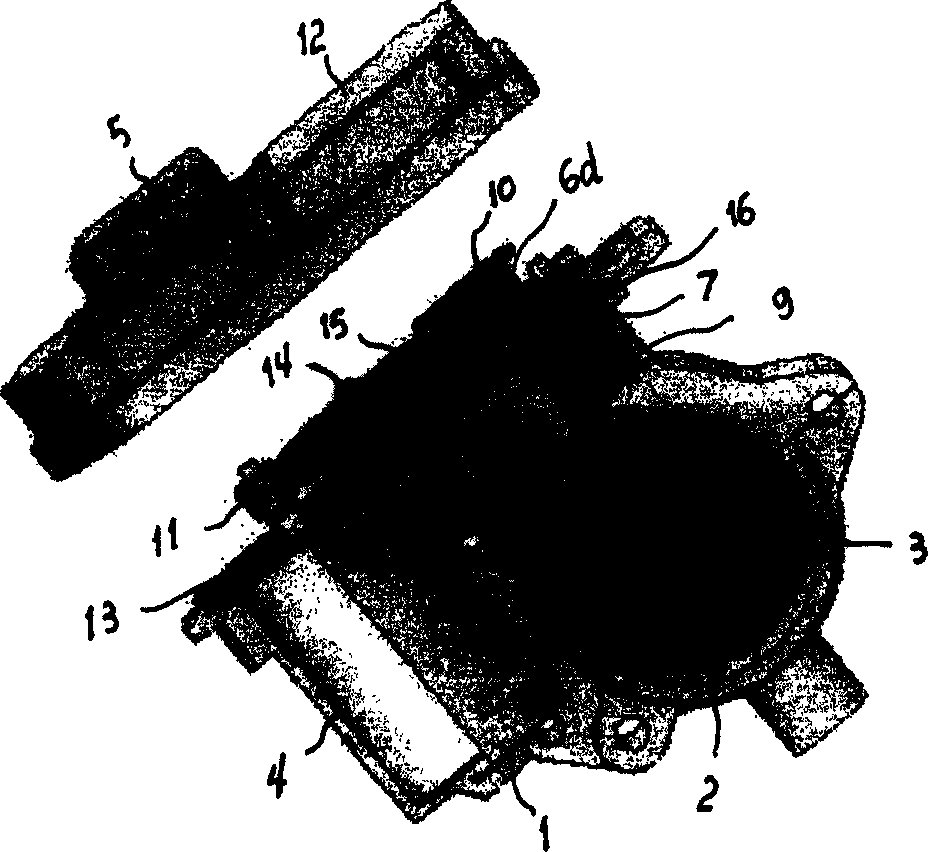

Electronic throttle body

InactiveCN1710267APrecise control of air intakeReduce wearEngine controllersMachines/enginesLow speedElectric machine

This is about a kind of electronic door of saving gas, which belongs to the system of saving air in the engine in the car. It includes the saving gas body, valve chip of saving air, the axis of saving air, DC engine, gear structure for decreasing speed, location sensor and spring, one of whose side is fixed on the body of saving gas, the other side is fixed on the axis of saving gas door. there is also the structure of changing speed. The outside bolt is fixed on the body of saving gas and the inside one on the inside of changing bolt. The spring is fixed between them. In the invention the position is capable to change. The amount of inside gas can be controlled accurately in the low speed, and at the same time it cuts the precision of the production.

Owner:SICHUAN HONGGUANG AUTO MACHINERY ELECTRONICS

Black master batch for AS system plastic and preparation method thereof

InactiveCN101319074AGood dispersionLow requirements for processing equipmentCITRATE ESTERPolymer science

The invention discloses a black master batch applied to a multipolymer (AS series plastic) containing acrylonitrile and styrene and a preparation method thereof. The black master batch consists of an acrylonitrile-styrene multipolymer, acetyl tri-n-butyl citrate, ethylene bis stearamide and a black pigment. Partial acrylonitrile-styrene multipolymer, the acetyl tri-n-butyl citrate and the ethylene bis stearamide are subjected to melting and banburying in a banbury mixer evenly, the black pigment is added, the mixture is subjected to banburying and dispersed evenly as well as cooled and crushed, and the mixture is mixed with the remaining acrylonitrile-styrene multipolymer and is extruded and granulated on a twin screw. The produced black master batch is easy to disperse in the AS series plastic, the process equipment requirement of the subsequent coloration of the plastic product is reduced, the equipment efficiency is improved, the coloured plastic product has even color, no color difference and high lustrousness.

Owner:MALION NEW MATERIALS CO LTD

Normal temperature nanometer desulfurizing agent and its preparation process

InactiveCN1907544ALow requirements for processing equipmentReduce manufacturing costDispersed particle separationNitrateSulfur

The invention relates to a normal-temperature nanometer desulfurizer and a relative preparation, wherein the mol rate between nanometer ferric oxide and nanometer zinc oxide is 1:13-47; the preparation comprises: (1), dissolving the ferric nitrate into concentrated zinc nitrate solution, to make the mol rate between zinc ion and ferric ion as 100:2-5; (2), adding aquacare based on the mol rate between metal ion and aquacare as 1:3.45; (3), arranging the solution at 85-110Deg. C, to react 1-3hours; (4), filtering, washing solid and drying; (5), baking solid, to obtain the normal-temperature nanometer desulfurizer. The diameter of desulfurizer is 12.4-14nm, with high desulfurization speed, and 10-16% sulfur capacity. The invention has simple process and low cost.

Owner:HARBIN INST OF TECH

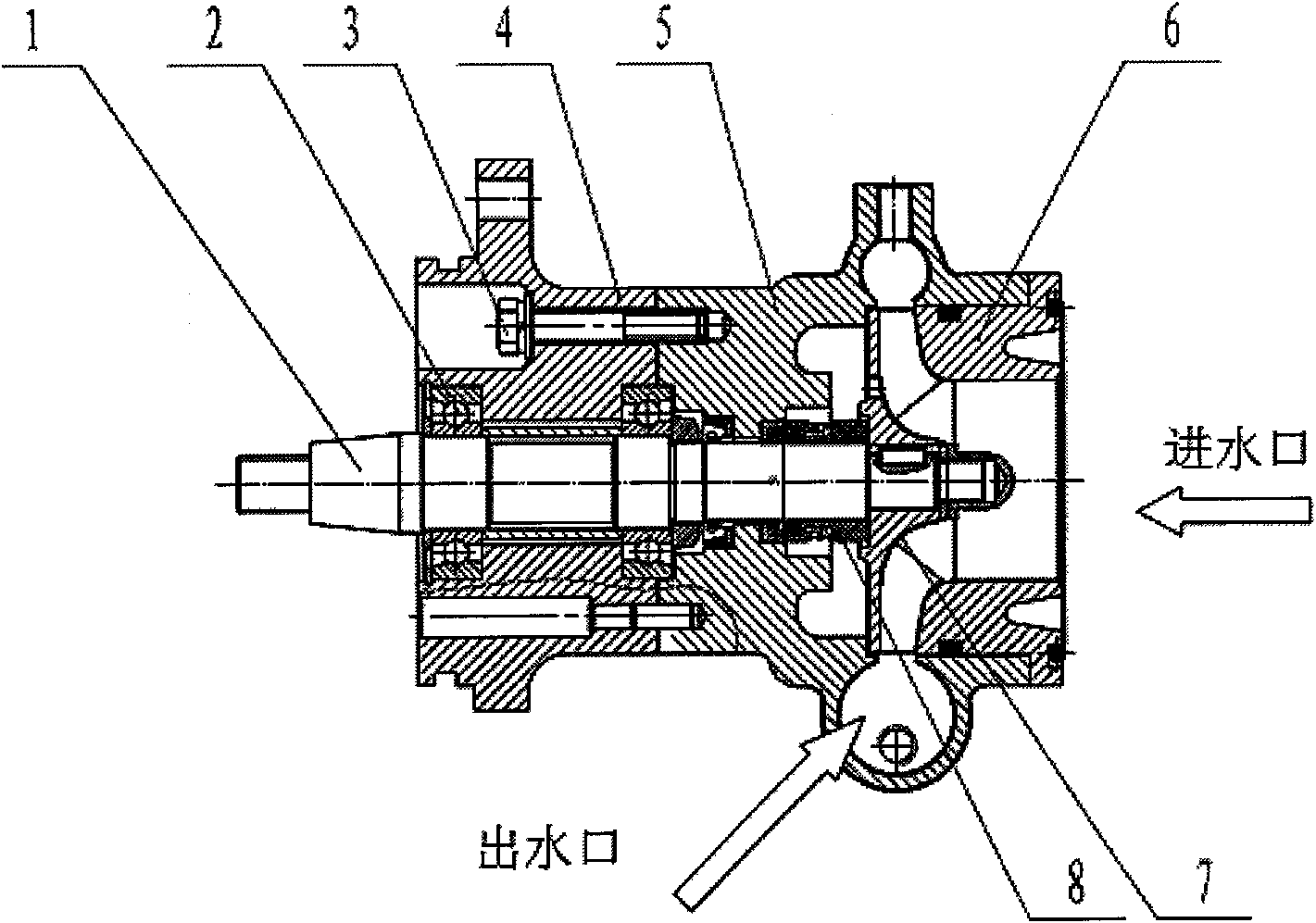

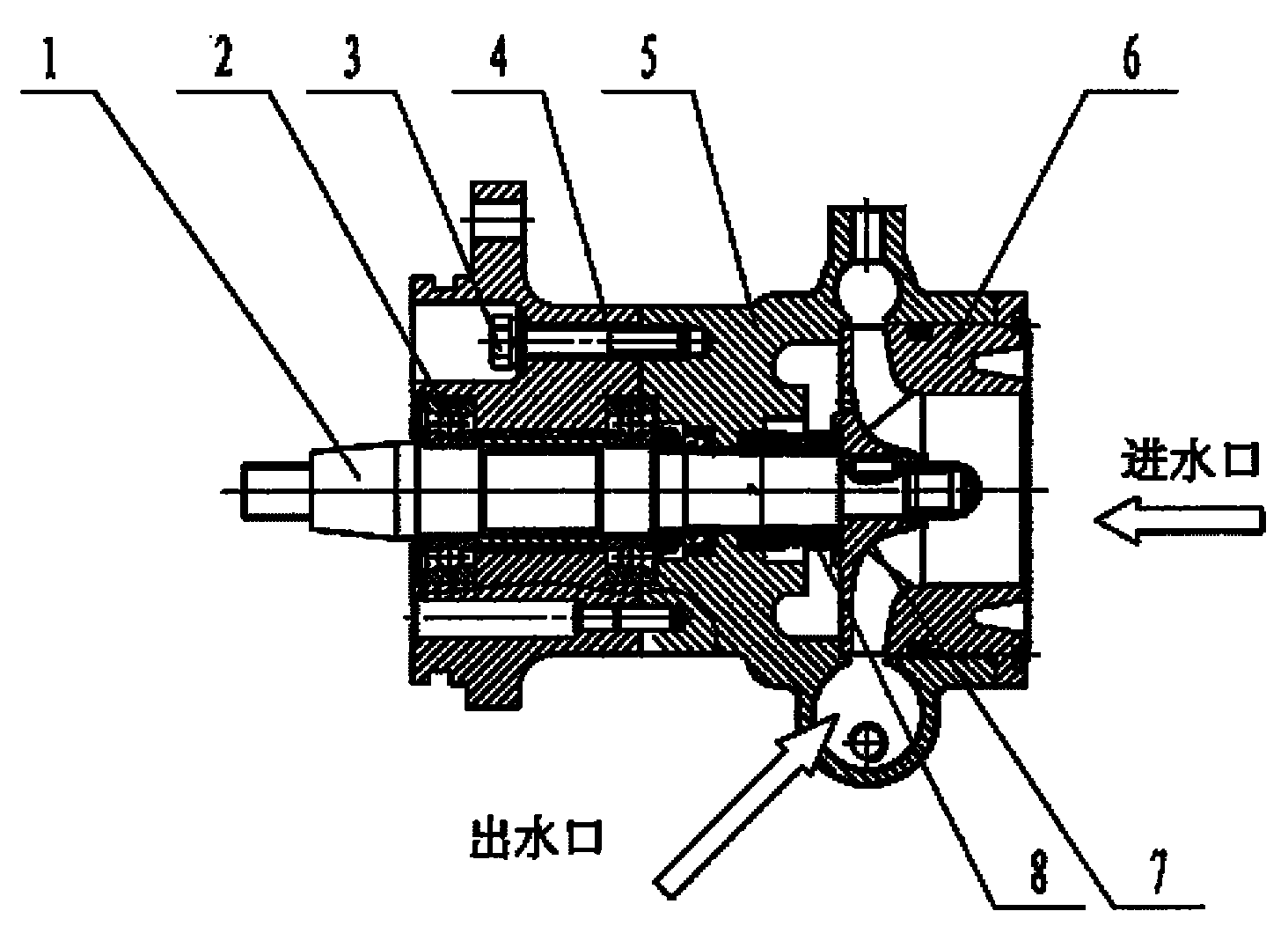

Centrifugal water pump

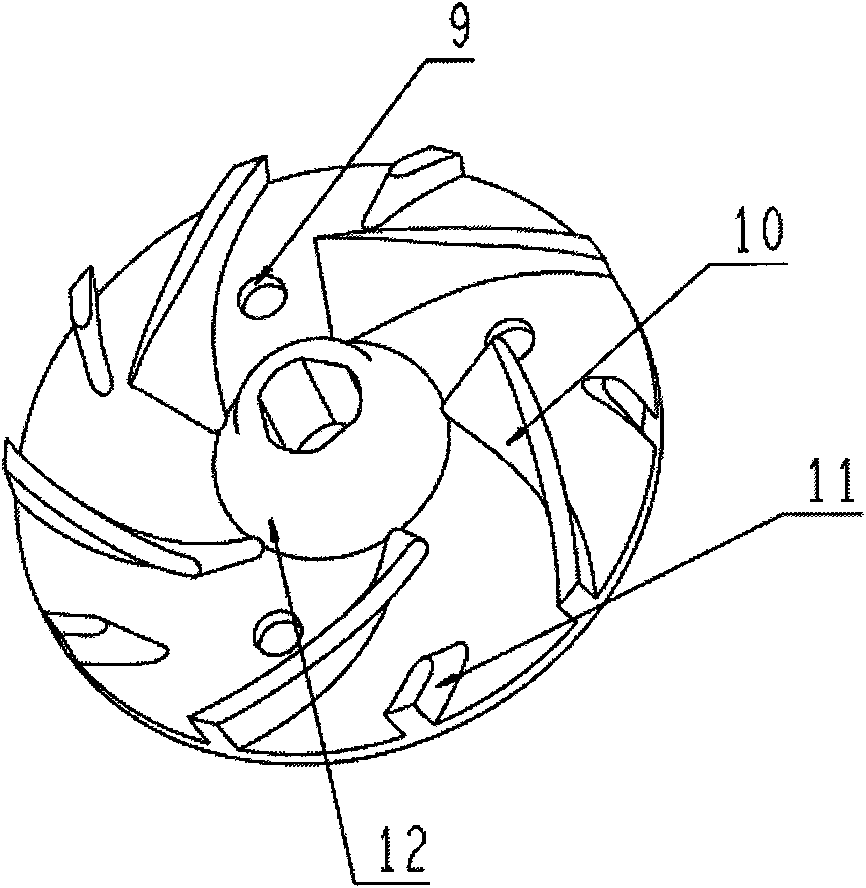

InactiveCN101865157AReduce hydraulic lossMeet the requirements of high-efficiency and energy-saving water pumpsPump componentsPumpsDrive shaftPulp and paper industry

The invention relates to a centrifugal water pump, belonging to the hydraulic technical field. The centrifugal water pump comprises a transmission shaft, a bearing, a fastening piece, a bearing seat, a volute, an inlet water pan, an impeller and a mechanical seal. The impeller consists of long blades and short blades. Five long blades and five short blades are arranged in a spacing way. The diameter of the middle shaft hole of the impeller is 18mm, the diameter of a hub is 24mm, the outer diameter of the impeller is 133.6mm, the length of each long blade is 46.8mm, the length of each short blade is 26.8mm, the diameter of the inlet of the long blade and the short blade is 66mm, the setting angle of the inlet of the long blade and the short blade is 36 degrees, the height of the inlet of the long blade and the short blade is 17mm, the thickness of the long blade and the short blade is 3.5mm, the setting angle of the outlet of the long blade and the short blade is 45 degrees and the height of the outlet of the long blade and the short blade is 10.3mm. The runner of the volute is matched with the impeller. The taper of the suction chamber of the inlet water pan is 12.5 degrees. The invention has the advantages of high efficiency, energy saving, good workability, light weight and small volume.

Owner:CHINA NORTH IND GRP NO 70 RES INST

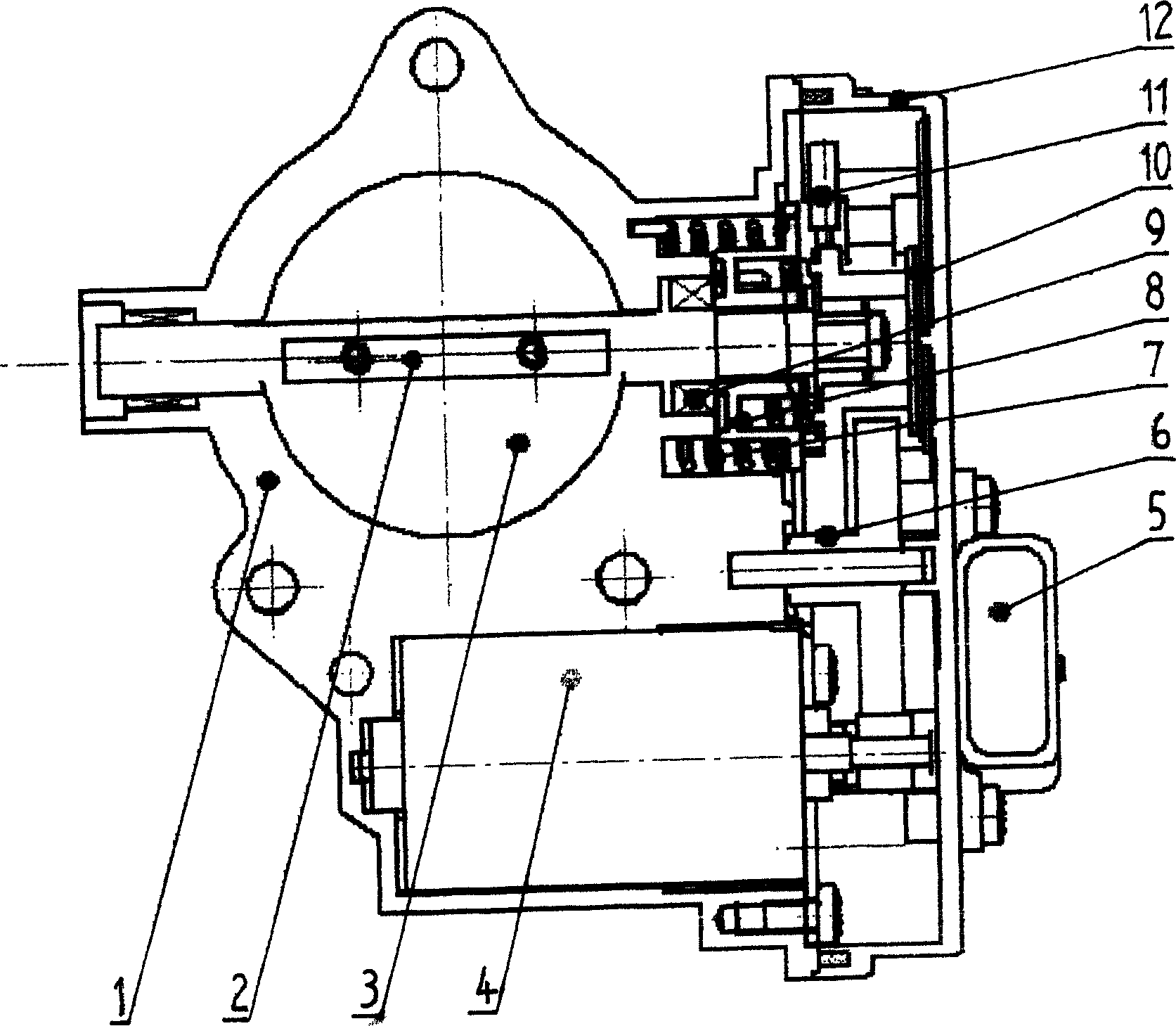

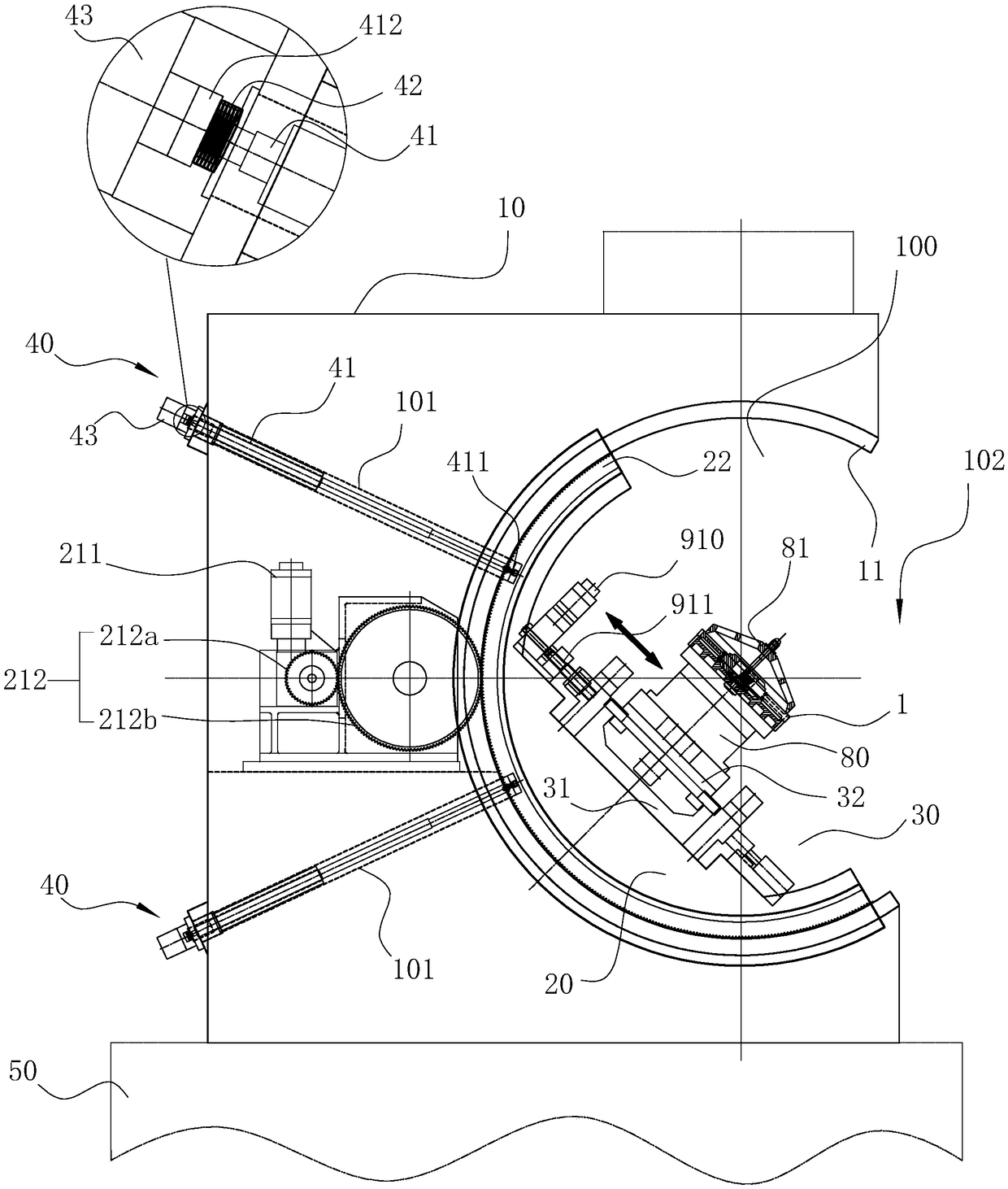

Workbench for broaching machine tool

PendingCN109434188AEasy to processStable processingLarge fixed membersBroaching machinesLocking mechanismEngineering

The invention relates to a workbench for a broaching machine tool. The workbench comprises a fixed base and an arc-shaped sliding seat, and further comprises a sliding table mechanism for fixing a to-be-machined workpiece; an arc-shaped sliding groove is formed in the fixed base, and the arc-shaped sliding seat is mounted in the arc-shaped sliding groove; a first arc-shaped guide rail is correspondingly arranged on the inner wall of the arc-shaped sliding groove, and the arc-shaped sliding seat is slidably connected to the first arc-shaped guide rail and can be locked with the fixed base in the process of sliding along the first arc-shaped guide rail so as to stay at any tilt angle; the sliding table mechanism is slidably arranged on the arc-shaped sliding seat; and a locking mechanism forlocking the sliding table mechanism and the arc-shaped sliding seat is arranged between the sliding table mechanism and the arc-shaped sliding seat. According to the workbench, a turbine disc can beprecisely adjusted to the corresponding machining posture through driving mechanisms of shafts, then the workpiece is conveniently machined by a cutter, a tooth shape or a groove shape with the corresponding tilt angle and cone angle is formed, the machining efficiency of the workbench is greatly improved, the production cost is lowered, and the machining quality is guaranteed.

Owner:ZHEJIANG CHR INTELLIGENT EQUIP

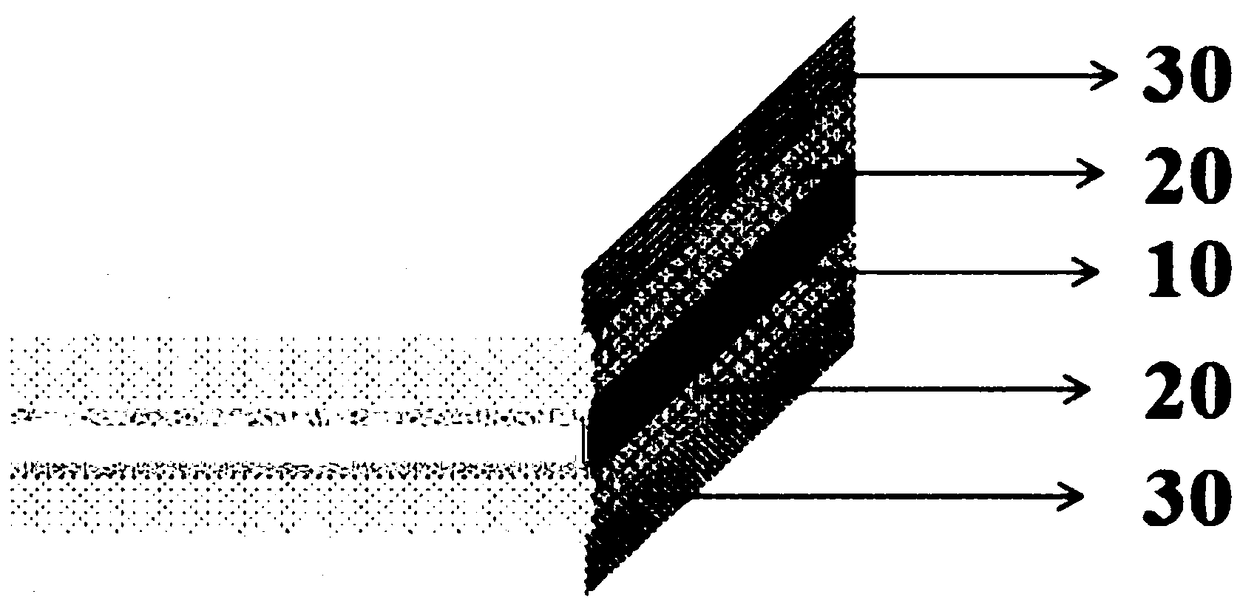

Single-layer double-sided electrode of capacitive touch screen and preparation method thereof

InactiveCN108984025AGood weather resistanceExtended service lifeInput/output processes for data processingEtchingAdhesive

The invention provides a single-layer double-sided electrode of a capacitive touch screen and a preparation method thereof. The conductive circuit comprises a silver nanowire thin film layer and a transparent ink layer printed on the surface of the silver nanowire thin film layer. The preparation process of the single-layer double-sided electrode of the capacitive touch screen is as follows: 1) preparing a nano silver wire transparent conductive film layer on the two side surfaces of the substrate; 2) printing transparent ink on that surface of the nano silver wire thin film lay to form a protective layer; 3) performing chemical etching to form a single lay double-sided electrode of that capacitive touch screen. In the electrode of the present invention, the transparent ink layer preventsthe transparent conductive layer of the silver nanowires from contacting with air. The invention effectively overcomes the problems of chemical stability deterioration and electric conductivity reduction of the nano silver wire layer caused by the phenomena of electric corrosion of the nano silver wire and silver migration, solves the problem that the double-layer electrode can not be prepared bylaser etching at present, and saves a bonding process and the use of an optical adhesive layer.

Owner:湖南兴威新材料有限公司

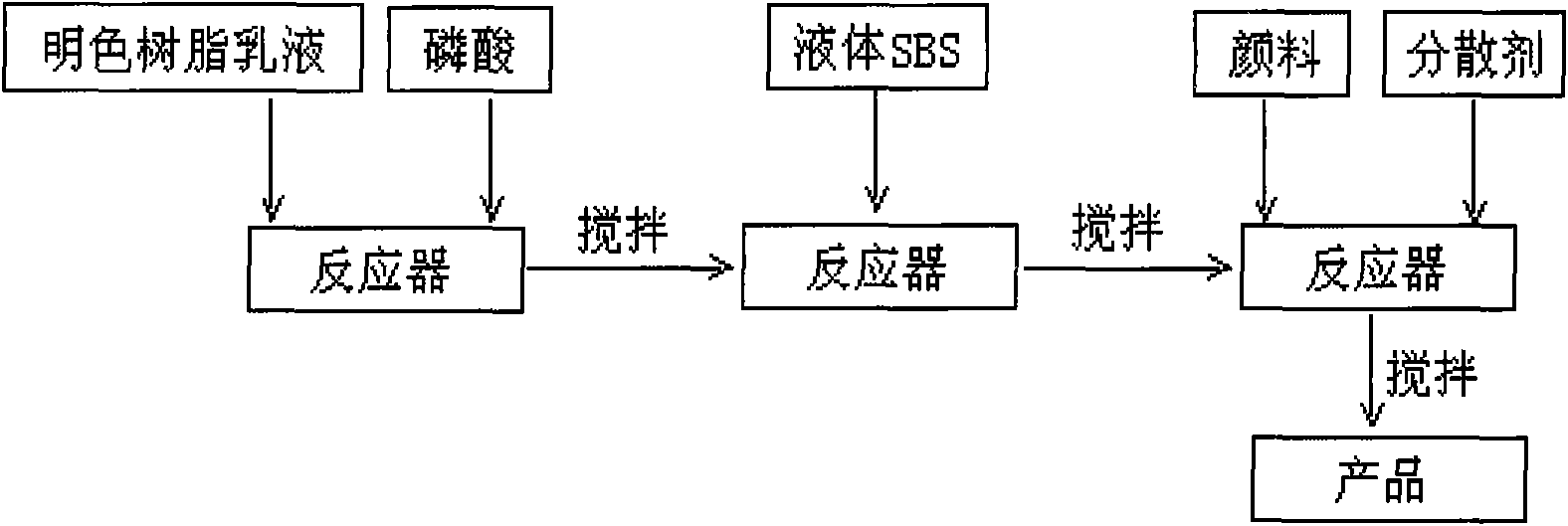

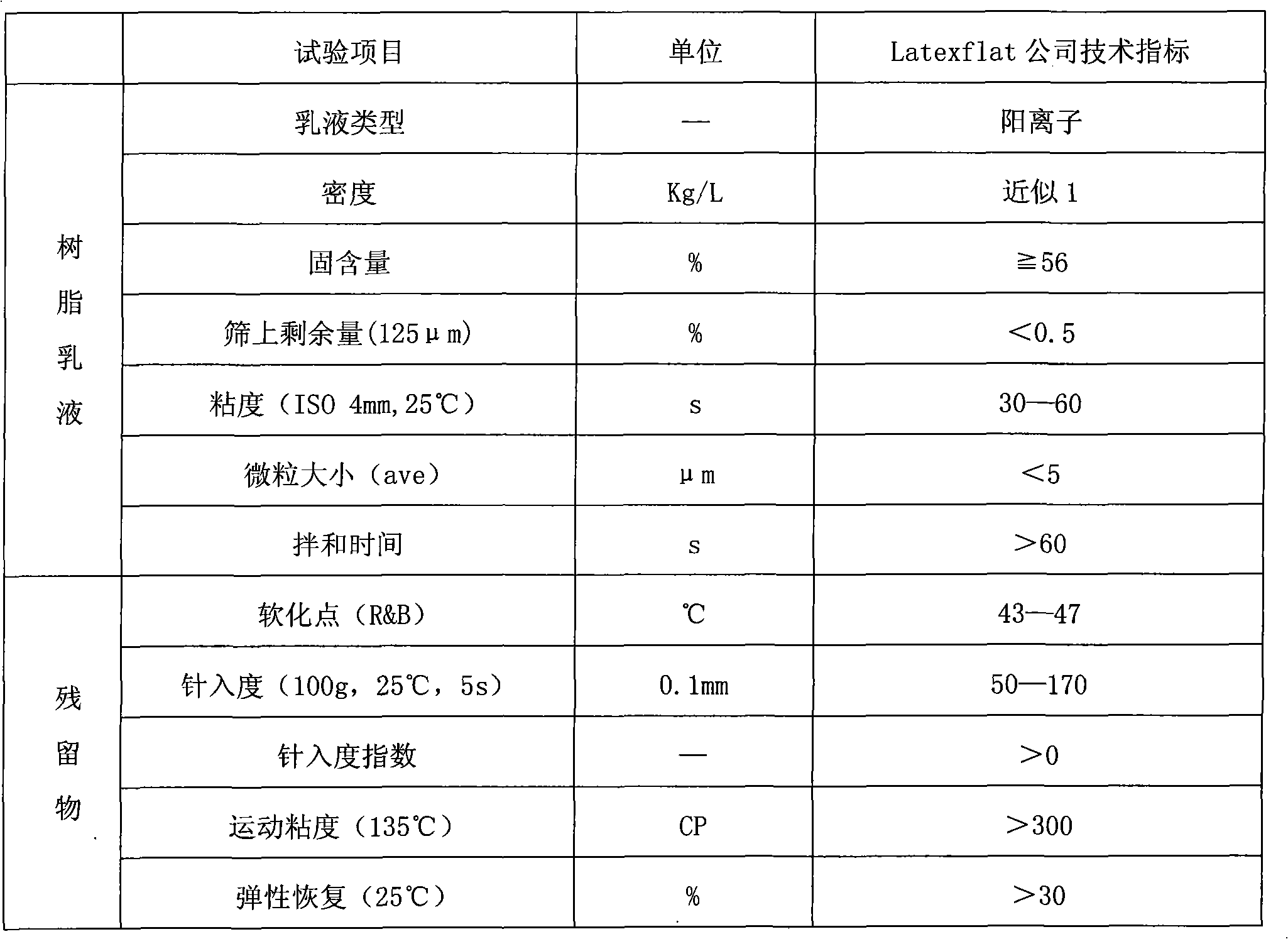

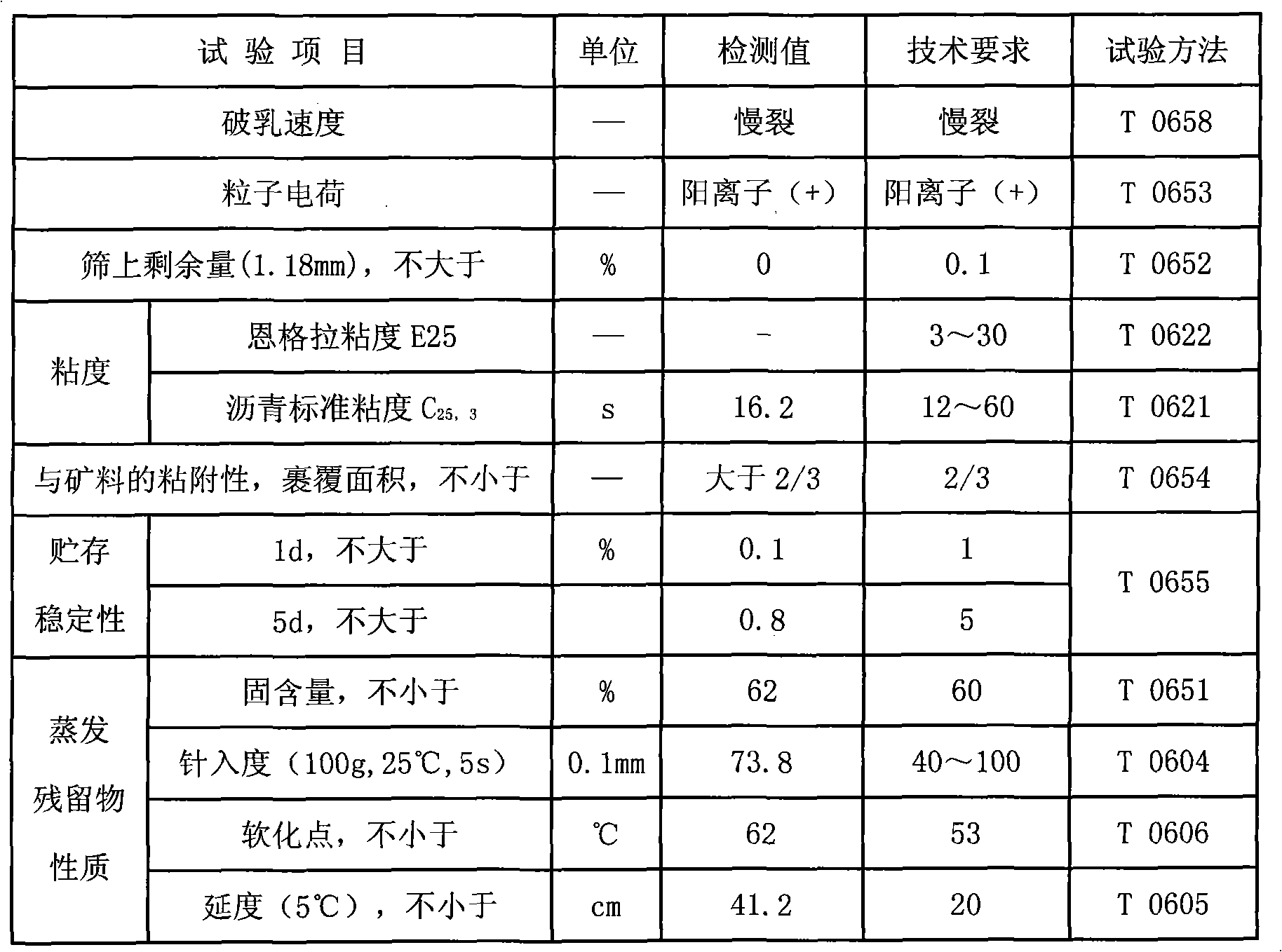

Method for preparing color liquid SBS modified emulsion resin

ActiveCN101565533AImprove road performanceNothing producedBuilding insulationsPhosphoric acidRoad surface

The invention aims at solving the technical problems that the environment is polluted, the production cost is high and the product can not be used as the color micro-surface cementing material due to poor performance in the process for preparing the existing color modified emulsion discolored asphalt, and provides a method for preparing color liquid SBS modified emulsion resin which consists of the following raw materials: light color resin emulsion, liquid SBS modifier, inorganic pigment 307 chrome molybdenum red pigment or SGC-M chrome green pigment, pigment dispersant polycarboxylic acid sodium salt or polyacrylic acid ammonium salt. The method comprises the steps of: when in preparation, adding the raw materials into a reactor, maintaining the temperature of the reactor within 20 DEG C to 30 DEG C, adding phosphoric acid to adjust the pH value of the system to be 2.5-4.5, uniformly stirring the system and then obtaining the high-performance color liquid SBS modified emulsion resin. The method has the advantages of simple preparation process, low production cost and non-toxic harmless performance, can be constructed at room temperature, and can prepare the high-performance color micro-surface cementing material to be used for heavy traffic roads by choosing appropriate modifier.

Owner:SHANXI PROVINCIAL RES INST OF COMM

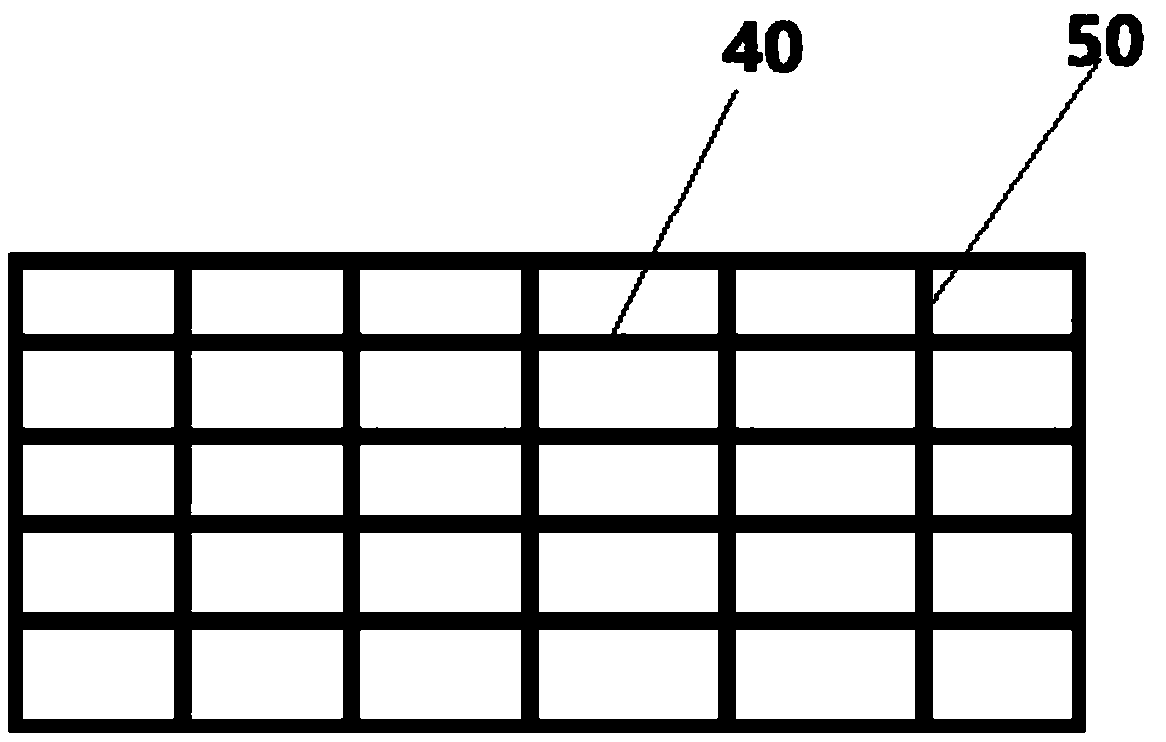

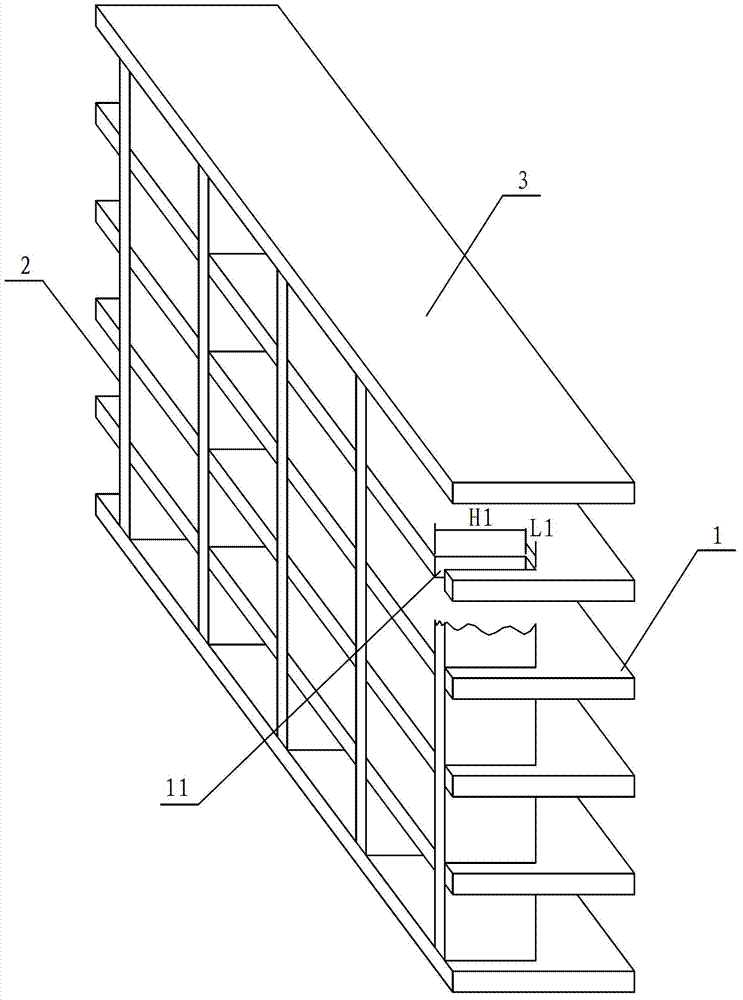

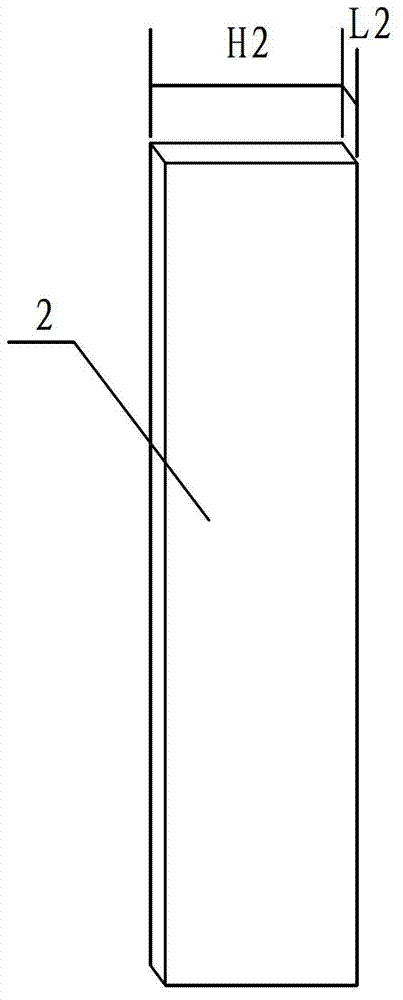

Steel grating plate production process

The invention discloses a steel grating plate production process, which comprises the following steps of grooving: a plurality of longitudinal strips are fixed, and a plurality of grooves are formed on the longitudinal strips; embedding: a transverse rod is embedded into the grooves, the transverse rod is embedded into the groove of one longitudinal strip, the depth of the groove is smaller than the height of the transverse rod, and the width of the groove is greater than the thickness of the transverse rod; pressure welding: the transverse rod and the groove are welded by an electric resistance welding method, and in addition, the upper surface of the transverse rod and the upper surface of the longitudinal strips are flatly pressed when the welding position of the transverse rod and the groove is still in a high-temperature state; repeated embedding and pressure welding: the welding of the next transverse rod is completed, the many-time repeated embedding and the pressure welding are carried out until the welding between the transverse rod and the grooves is completed, and a steel grating plate is formed; cuttings: the steel grating plate is cut into steel grating plate units; end plate welding: the end surface of the transverse rod and the end surfaces of all longitudinal strips are welded with an end plate, and a steel grating plate finished product is formed; and zinc plating: the steel grating plate finished product is subjected to zinc plating treatment. The energy is saved, the production is easy, and in addition, the requirements on raw materials and processing equipment are lower.

Owner:TIANCHANG FEILONG BRAND STEEL GRID

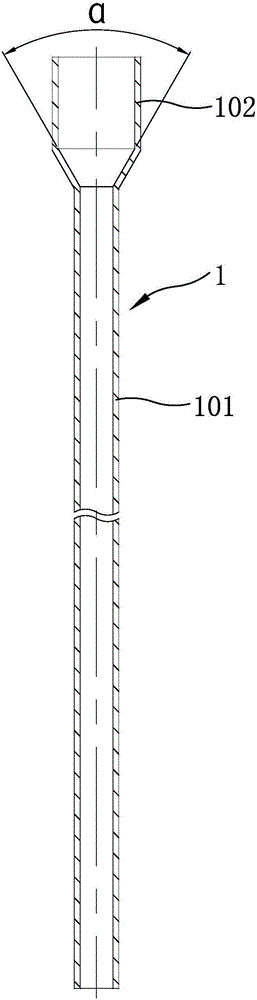

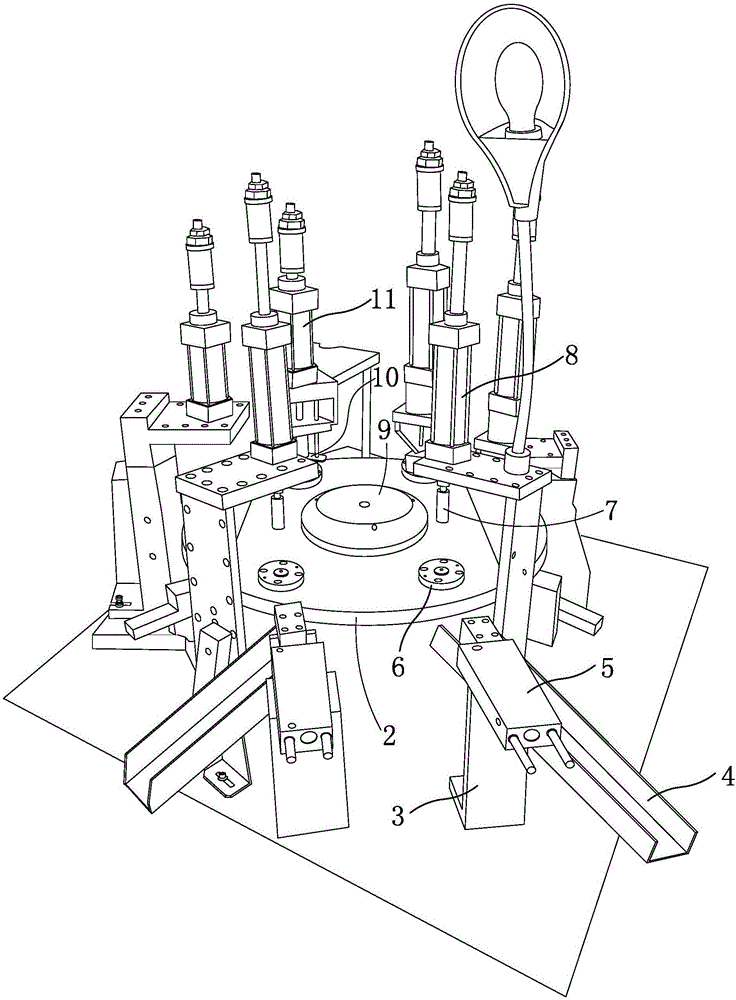

Manufacturing method for opening pulling copper pipe

The invention relates to a manufacturing method for an opening pulling copper pipe. Design is performed in order to solve the technical problems that a manufacturing method and a machining process of existing like products cannot meet the requirements of a specific conical angle and a large hole diameter difference easily, and the automation degree is low. The manufacturing method is characterized in that after the first time of head driving of a copper pipe head driving machine and drawing oil irrigating, first-pass disk pulling is performed through a copper pipe disk pulling machine; then the second time of head driving is performed, and second-pass disk pulling is performed through the copper pipe disk pulling machine; the third time of head driving through the copper pipe head driving machine and drawing oil irrigating are performed, and third-pass disk pulling is performed through the copper pipe disk pulling machine; and then the copper pipe is straightened and cut off through a straightening and cutting-off machine, one end of the copper pipe is subjected to hole shrinkage through an expanding and shrinking machine at the two ends, the other end of the copper pipe is subjected to hole expanding through the expanding and shrinking machine at the two ends, and the finished copper pipe is manufactured. A workbench of the expanding and shrinking machine at the two ends is provided with a large work disk and a small middle round table; a support is provided with a hole expanding cylinder, a hole shrinking cylinder, a discharging groove and a discharging cylinder; the hole expanding cylinder is provided with a hole expanding head; and the hole shrinking cylinder is provided with a hole shrinking head.

Owner:宁波赛夫科技有限公司

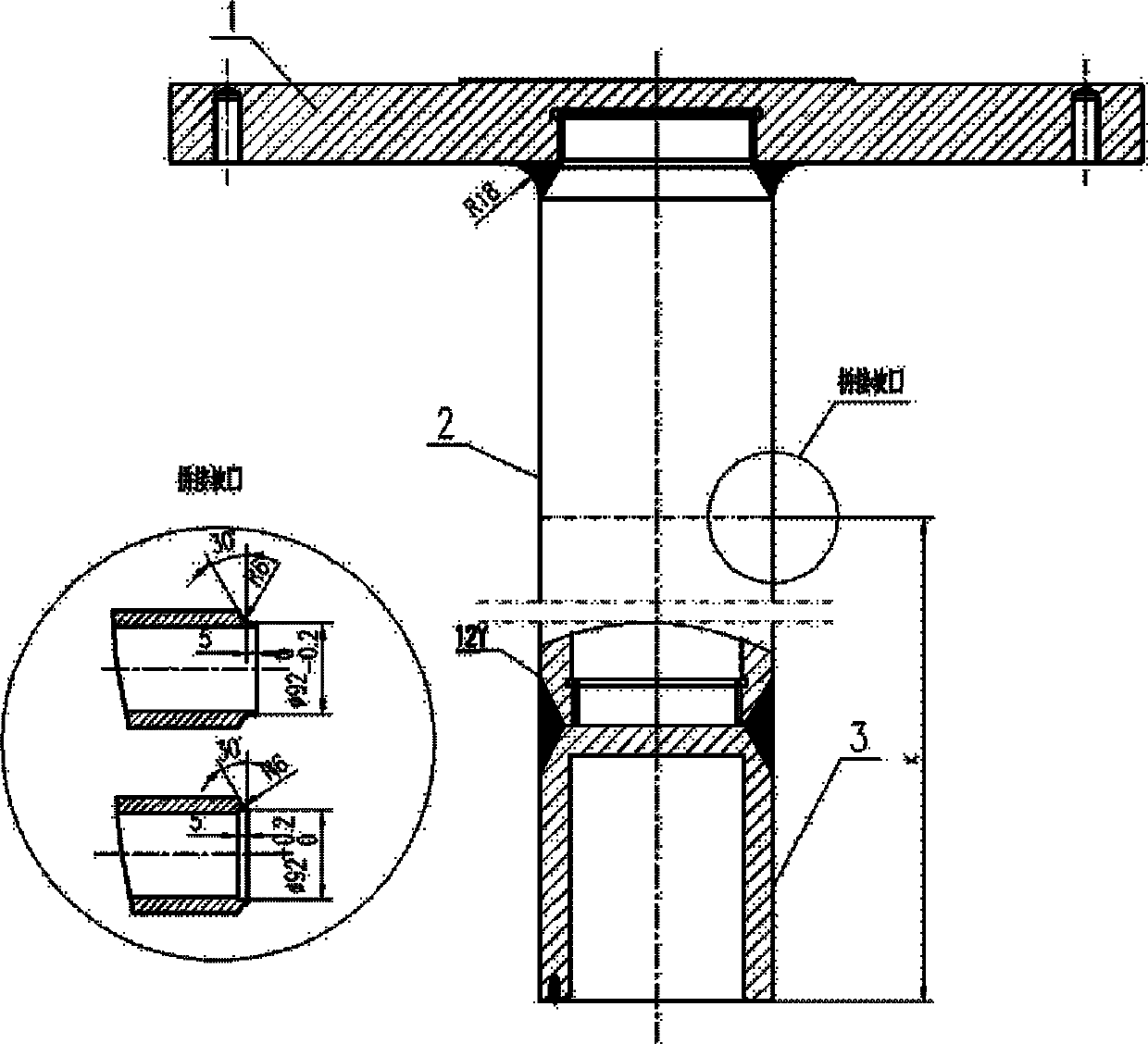

Conducting rod assembly of ultrahigh-voltage outgoing line sleeve

ActiveCN102437529AReduce contact resistanceSolve the problem of increased temperature riseArrangements with metal casingConnection contact member materialElectrical conductorEngineering

The invention relates to a conducting rod assembly of an ultrahigh-voltage outgoing line sleeve. The conducting rod assembly comprises a cover plate, a conducting tube and a plug; a cylindrical screw hole is machined at the center of the lower end surface of the cover plate, and the conducting tube is formed by welding two sections of conductor together; one end of the conducting tube is provided with thread, the other end of the conducting tube is integrally welded to the plug, and the threaded end of the conducting tube is screwed into the cylindrical screw hole at the center of the lower end surface of the cover plate; and the cover plate and the threaded end of the conducting tube are matched and then are welded. The conducting rod assembly can not only guide ultrahigh-voltage electric potential of an overhead line or a cable into a metal fully-sealed combined electric appliance, but also can ensure the characteristic of ultralow contact resistance by mechanical matching between the cover plate and the conducting tube. By a two-section welding process of the conducting tube, a machining process is simplified, and the requirements on machining devices and the operation costs of components are reduced. According to the design of the plug, the defect that an electrode of the ultrahigh-voltage outgoing line sleeve is broken through due to incomplete cleaning and residual metal scraps or suspended matters of the inner wall of the conducting tube is overcome.

Owner:CHINA ELECTRIC POWER RES INST +1

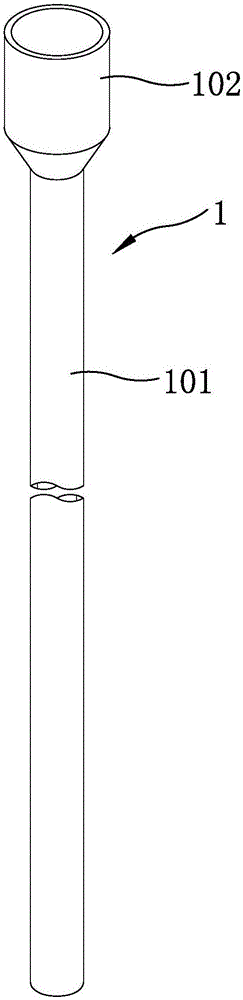

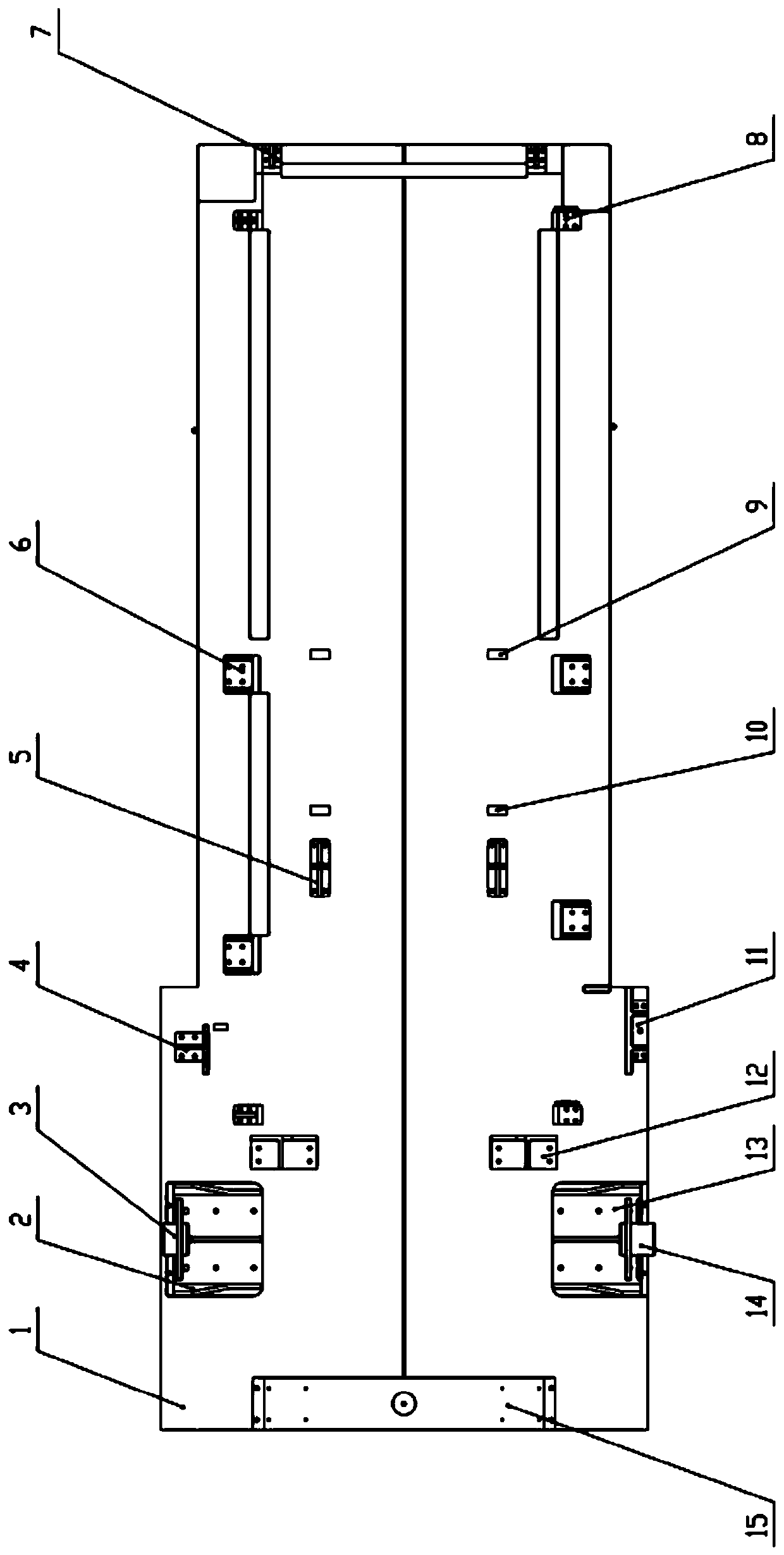

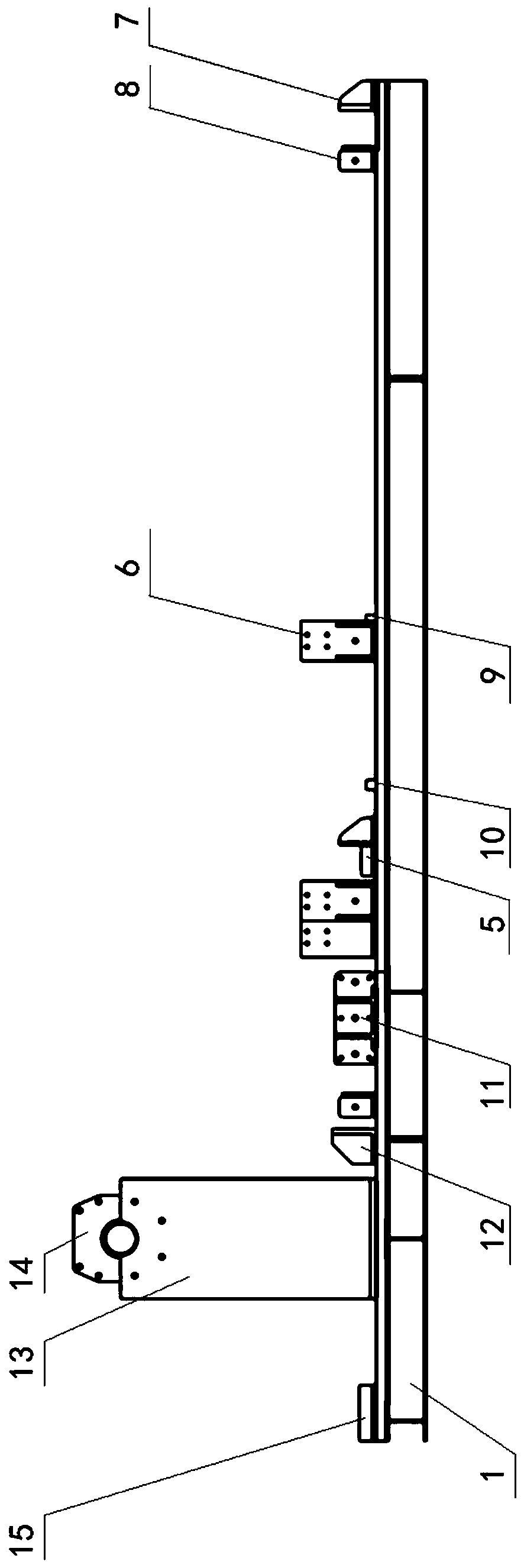

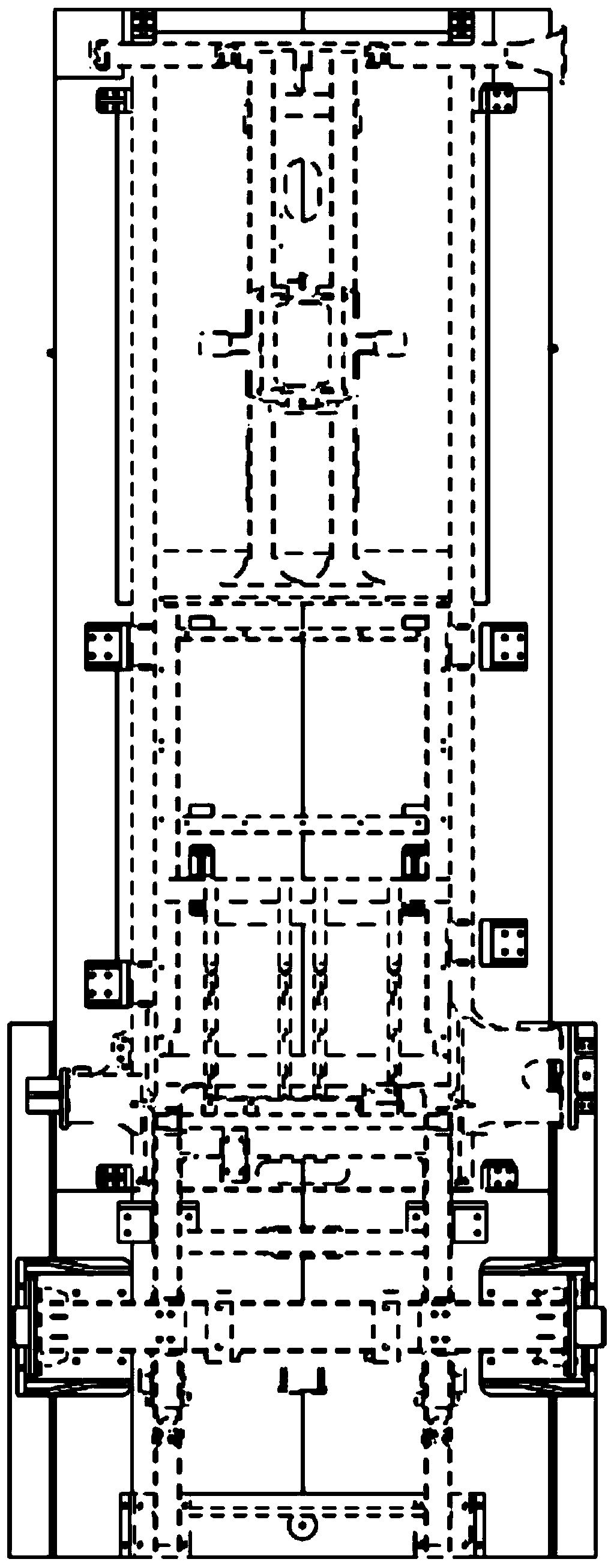

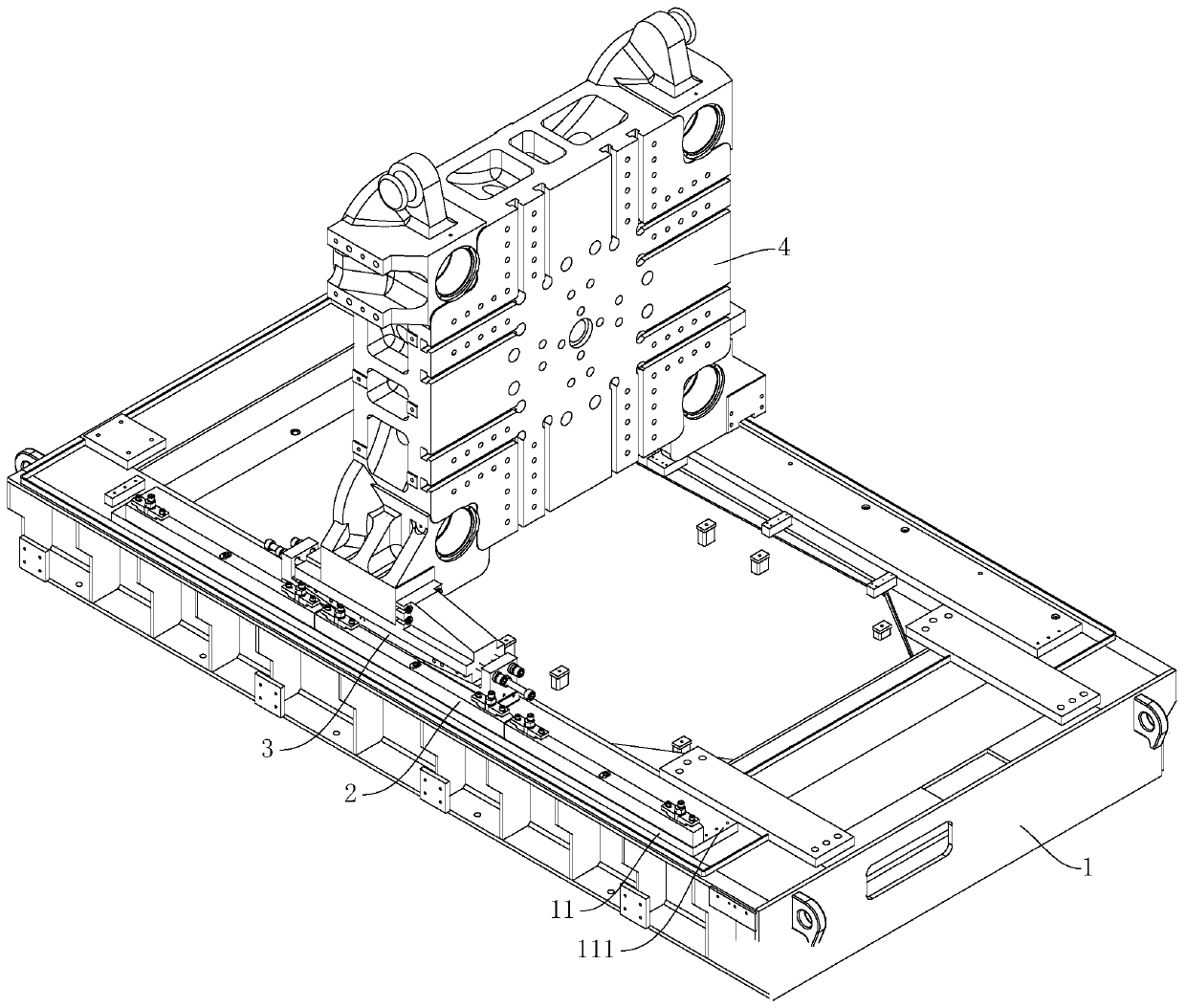

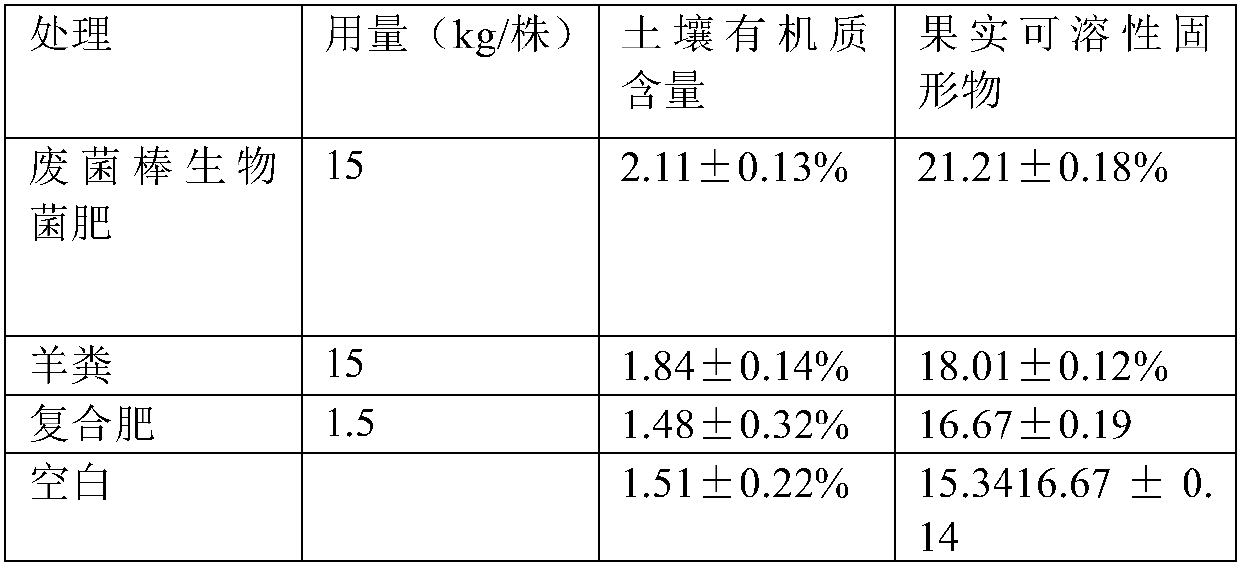

Riveting and positioning tool for chassis of cotton picker

PendingCN110340605AGuarantee product qualityLow requirements for processing equipmentWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachining

The invention discloses a riveting and positioning tool for a chassis of a cotton picker. The riveting and positioning tool comprises a bottom supporting platform, a mounting plate positioning seat, atransverse beam positioning seat, a first flange supporting seat, a second flange supporting seat, a first positioning half shaft, a second positioning half shaft and positioning assemblies, whereinthe mounting plate positioning seat and the transverse beam positioning seat are arranged on the bottom supporting platform, the mounting plate positioning seat and the transverse beam positioning seat extend in the width direction of the bottom supporting platform, the first flange supporting seat and the second flange supporting seat, wherein the first flange supporting seat and the second flange supporting seat are arranged at the end, close to the mounting plate positioning seat, of the bottom supporting platform, the first positioning half shaft is arranged at the top end of the first flange supporting seat, the second positioning half shaft is arranged at the top end of the second flange supporting seat, the mounting plate positioning seat, the first positioning half shaft and the second positioning half shaft are used for positioning a front bridge frame of the chassis of the cotton picker, and the positioning assemblies are correspondingly arranged between the first flange supporting seat and the transverse beam positioning seat and between the second flange supporting seat and the transverse beam positioning seat. According to the riveting and positioning tool for the chassis of the cotton picker, the requirements for machining equipment can be reduced, the machining period can be shortened, meanwhile, the riveting and welding efficiency can be effectively improved, the riveting and welding precision of workpieces can be guaranteed, and the labor intensity of workers can be reduced.

Owner:CHINA RAILWAY CONSTR HEAVY IND

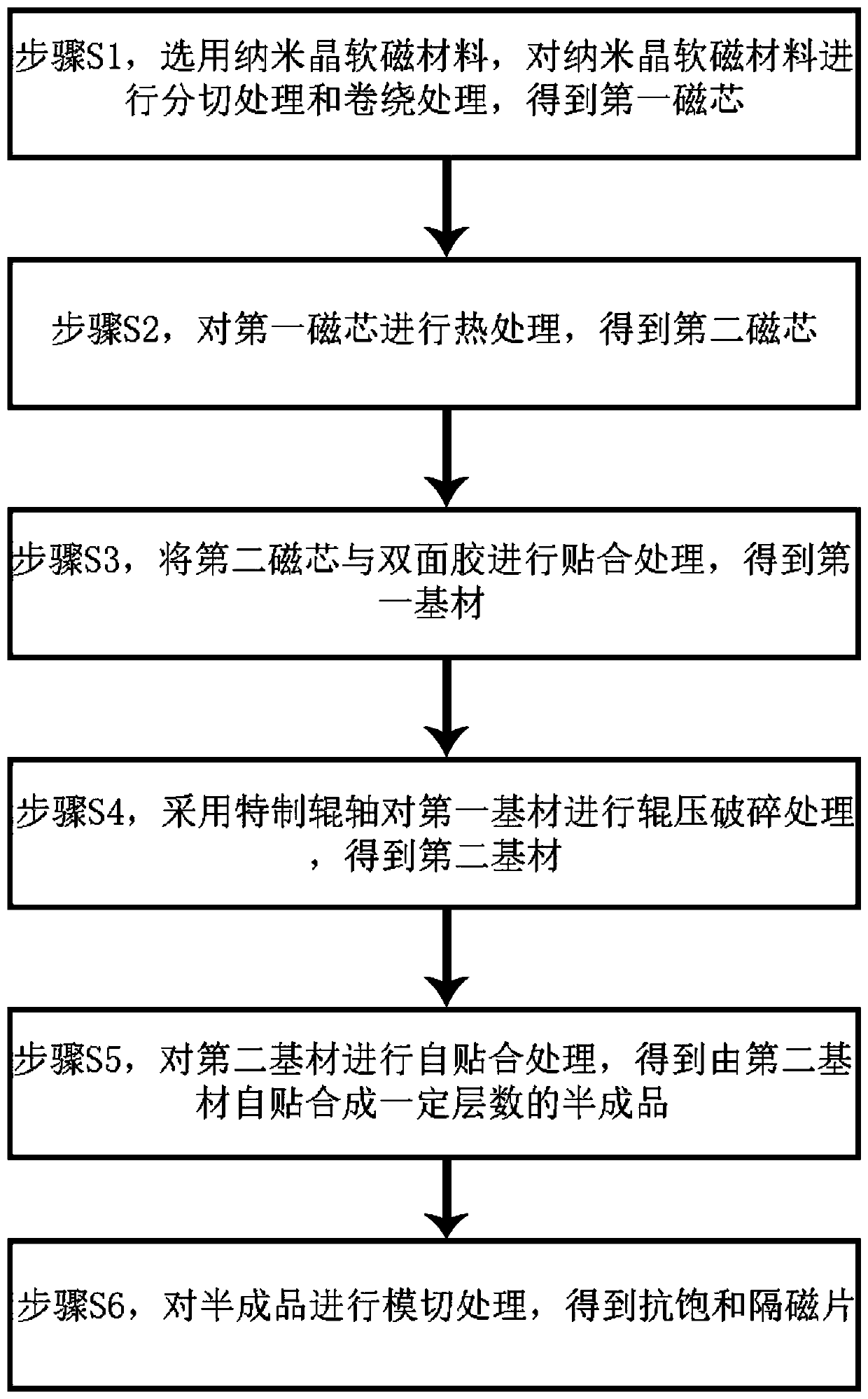

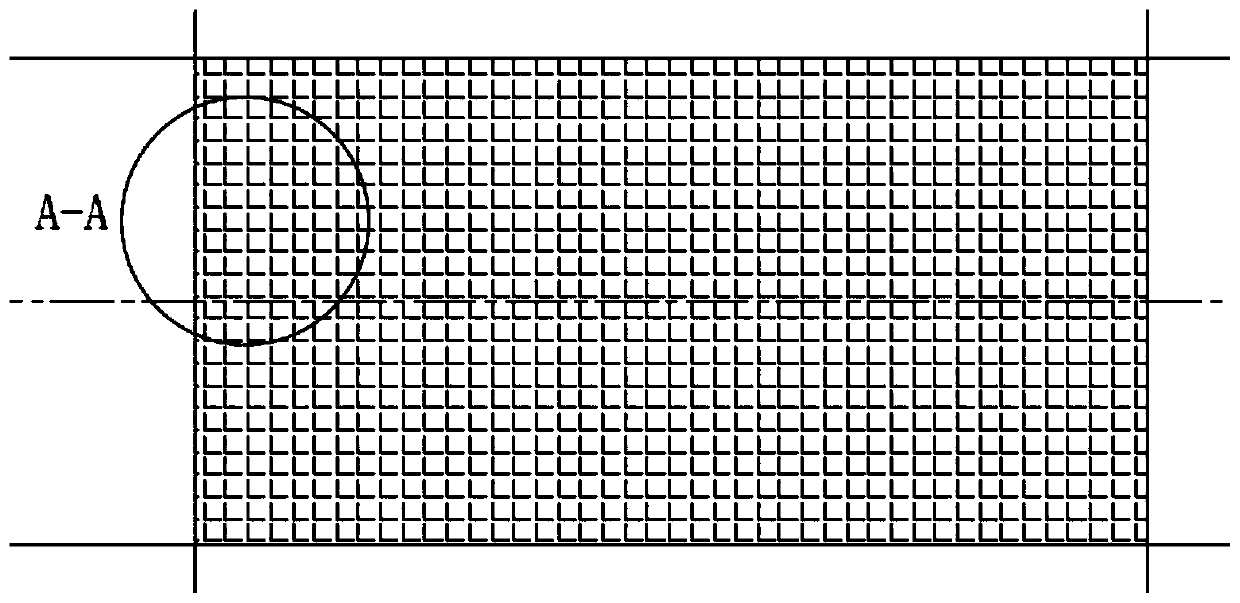

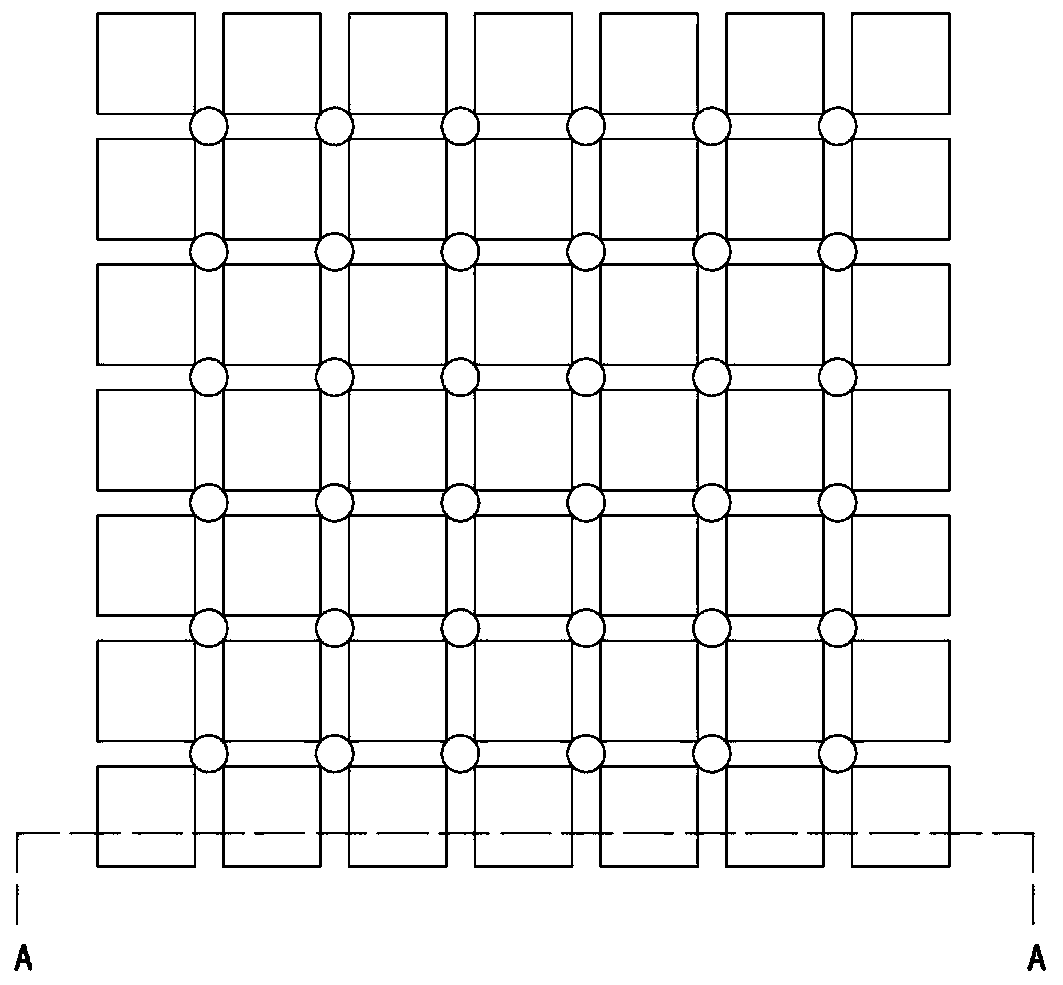

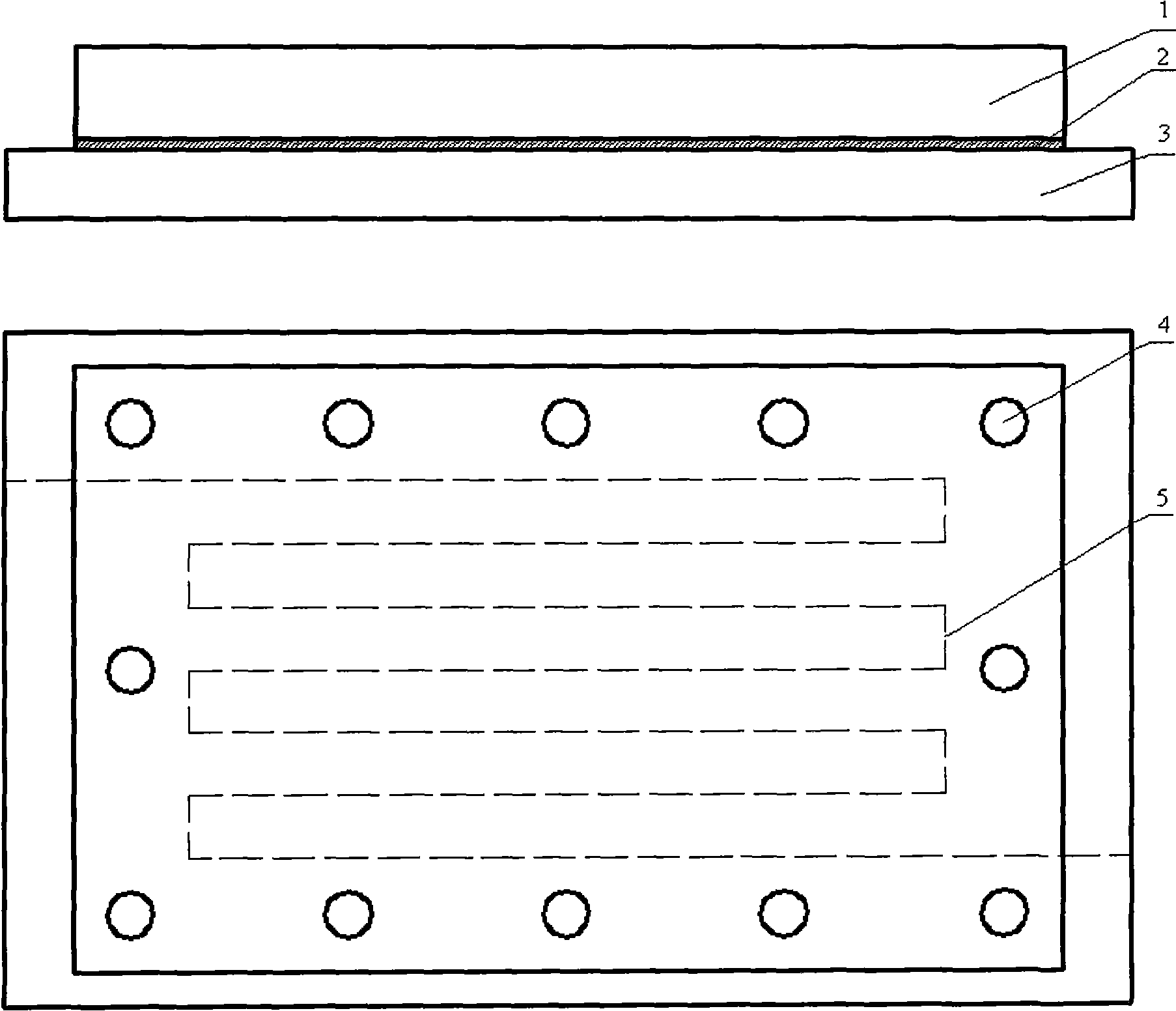

Anti-saturation magnetism isolating sheet and preparation method thereof

The invention discloses an anti-saturation magnetism isolating sheet and a preparation method thereof. The anti-saturation magnetism isolating sheet is applied to the field of wireless charging. The preparation method specifically comprises the steps: S1, selecting a nanocrystalline soft magnetic material and carrying out slitting treatment and winding treatment on the nanocrystalline soft magnetic material to obtain a first magnetic core; S2, performing heat treatment on the first magnetic core to obtain a second magnetic core; S3, carrying out attaching treatment on the second magnetic coreand a double faced adhesive tape to obtain a first base material; S4, carrying out rolling crushing treatment on the first base material through a specially-made roller shaft to obtain a second base material; S5, carrying out self-adhesion treatment on the second base material to obtain a semi-finished product with a certain number of layers formed by self-adhesion of the second base material; andS6, carrying out die cutting treatment on the semi-finished product to obtain the anti-saturation magnetism isolating sheet. The magnetism isolating sheet prepared by the invention has high saturation current, is thin in product thickness and simple to prepare, and is suitable for batch production in factories.

Owner:SHANGHAI LINEPRINTING MATERIALS CO LTD

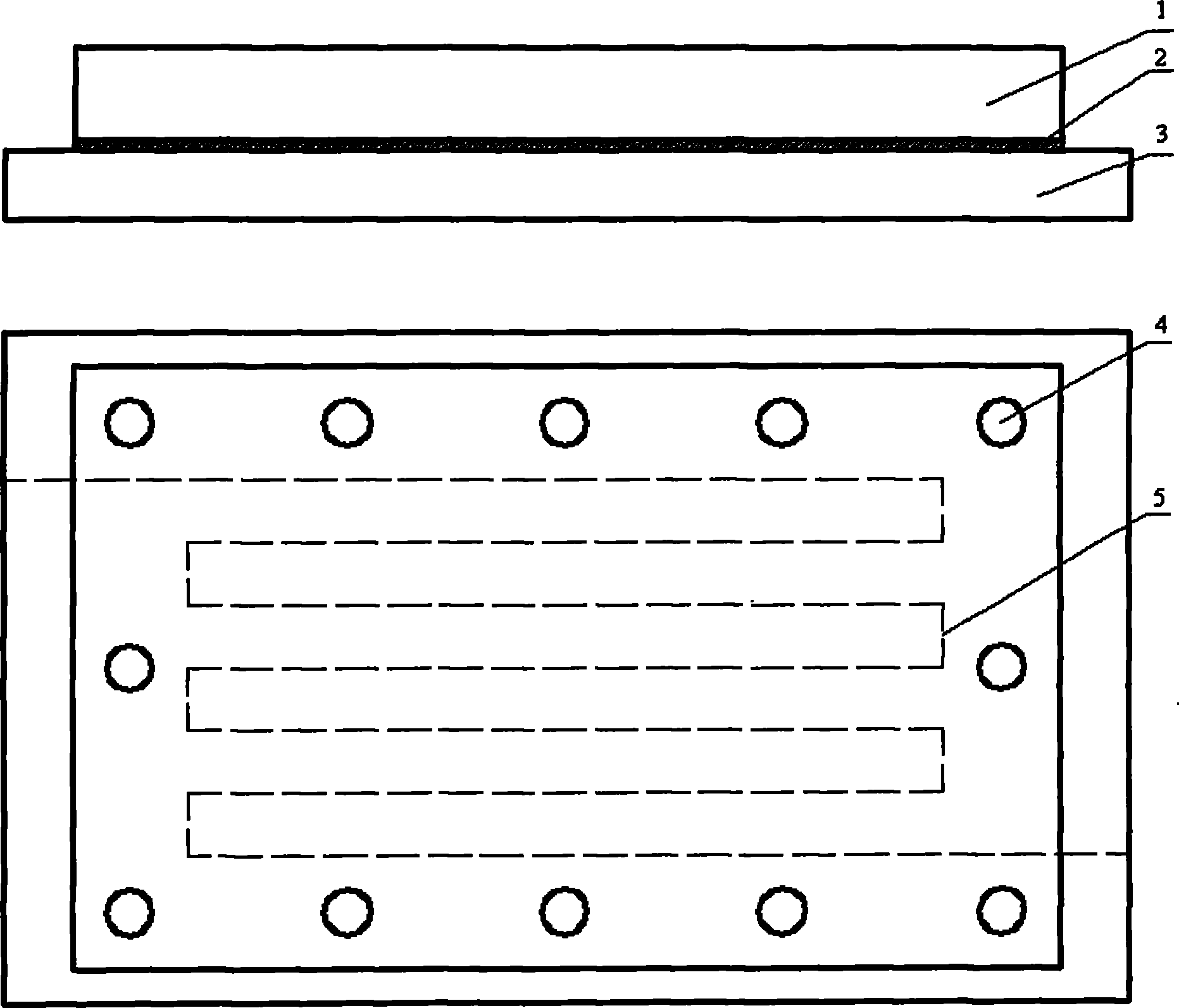

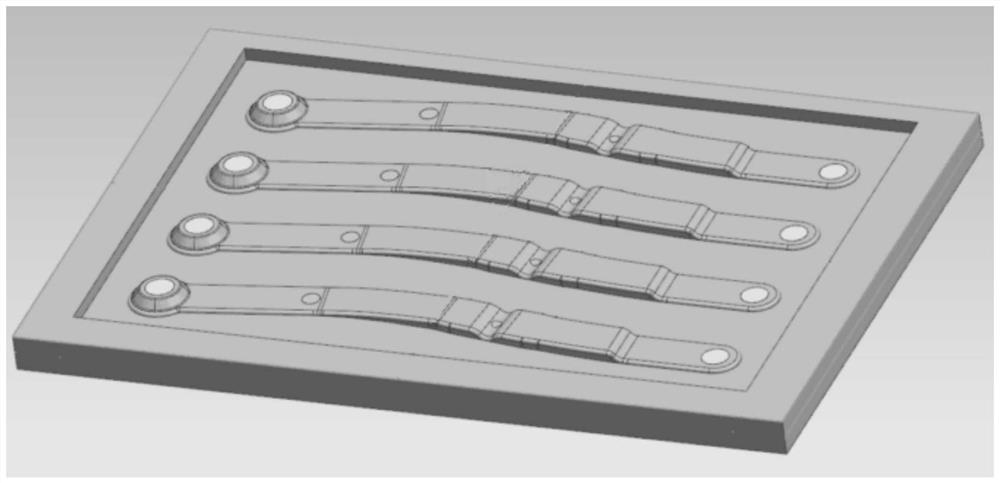

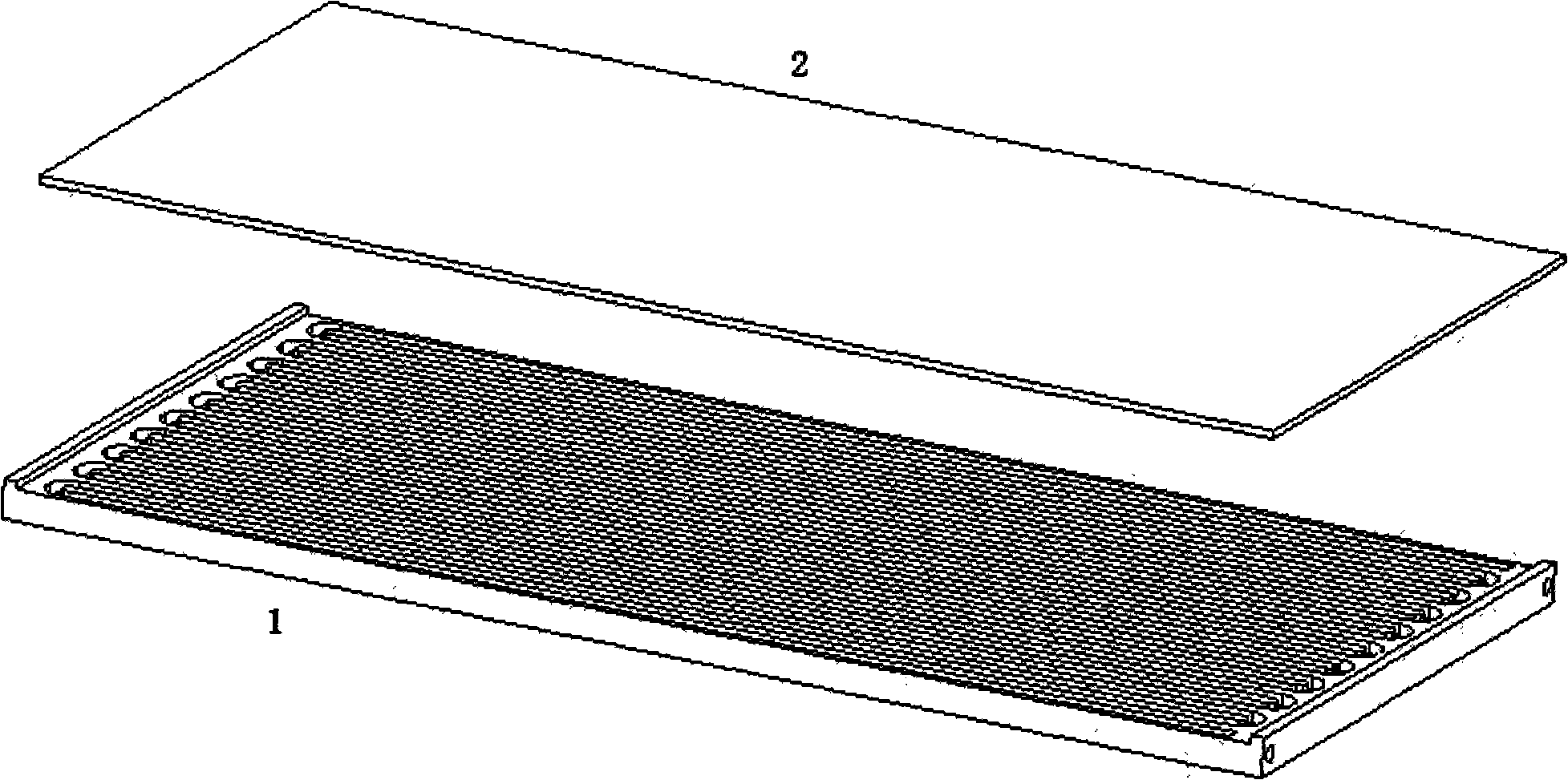

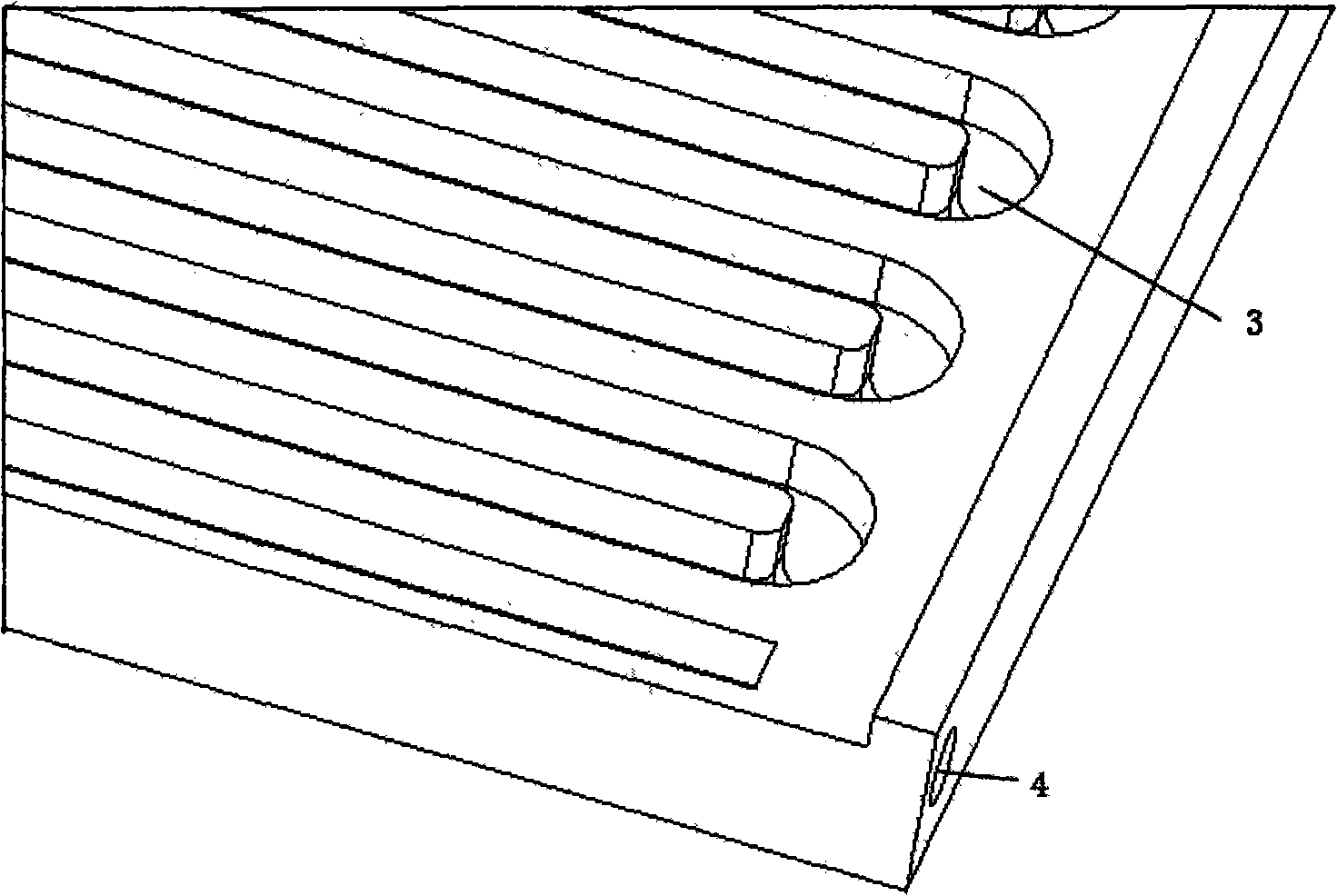

Design method of water-cooling radiator

InactiveCN102137583AImprove yield and yieldIncrease freedomCooling/ventilation/heating modificationsAluminiumDesign methods

The invention provides a planar water-cooling radiator capable of cooling an electronic component. The water-cooling radiator consists of two aluminium plates or copper plates, which are connected and fastened through bolt. Windscreen sealant is smeared at the connection position for improving the sealing effect. Rotary type slots which are communicated mutually are processed on the opposite planes of the two plates to form water passages. A water source and external radiators are connected through a water inlet and a water outlet to form a cooling loop so as to cool the heating electronic component attached onto the cooling loop.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

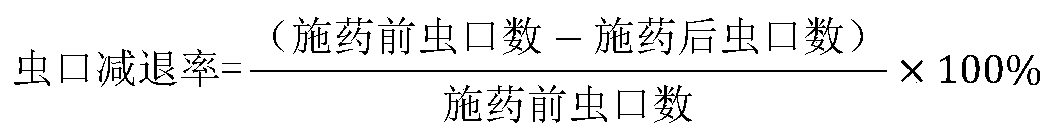

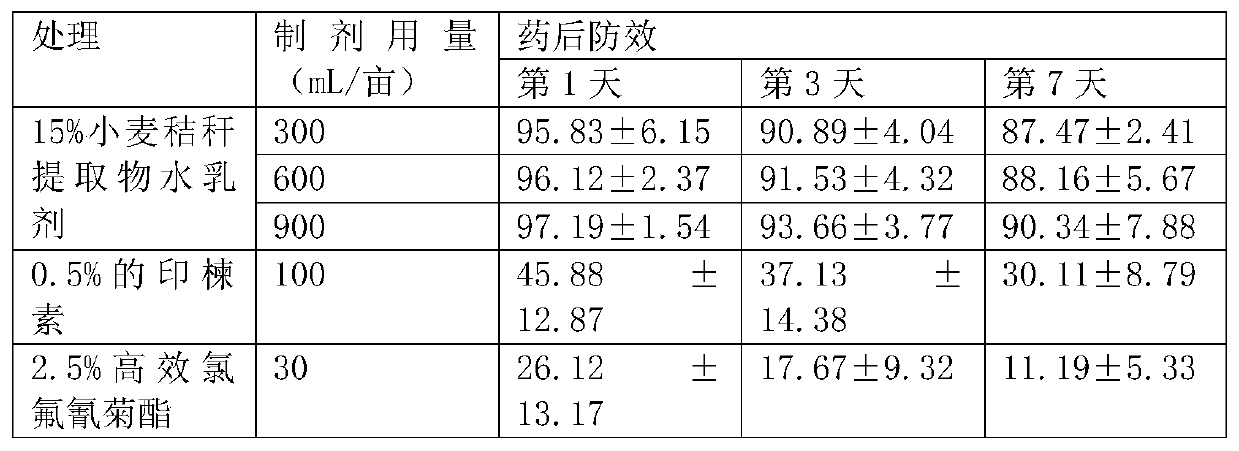

Plant-derived repellent for maladera orientalis motschulsky and preparation method thereof

InactiveCN109793019AReduce dosageRaw materials are easy to getBiocidePest repellentsProcess equipmentPlant Sources

The invention discloses a plant-derived repellent for maladera orientalis motschulsky and a preparation method thereof. The plant-sourced repellent is prepared from, by mass, 1-45% of wheat straw ethanol extraction dry powder, 10-30% of a solvent, 5-10% of an emulsifier, 0.1-1.5% of a defoaming agent, 0.3-5% of other auxiliaries and the balance water. The preparation is an emulsion in water, the use quantity of the organic solvent is small, the repellent is environmentally friendly and is a pollution-free plant-derived pesticide, the raw materials are easy to obtain, the resources are abundant, the cost is low, the waste is turned into treasure, and the wheat straw resources are comprehensively utilized; the requirement of the repellent for processing equipment is low, the processing technology is simple, and good popularization prospects are provided. The repellent can be used for repelling prevention and control of scarabs on fruit trees and forest trees. The repellent has the advantages of being high in repelling activity, environmentally friendly, unlikely to generate resistance and the like.

Owner:ZAOZHUANG UNIV

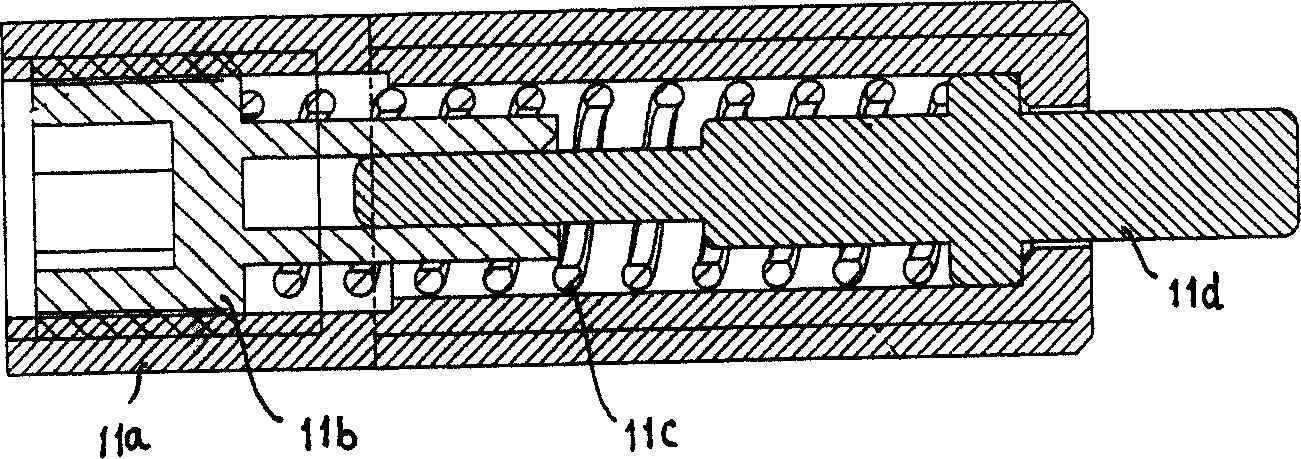

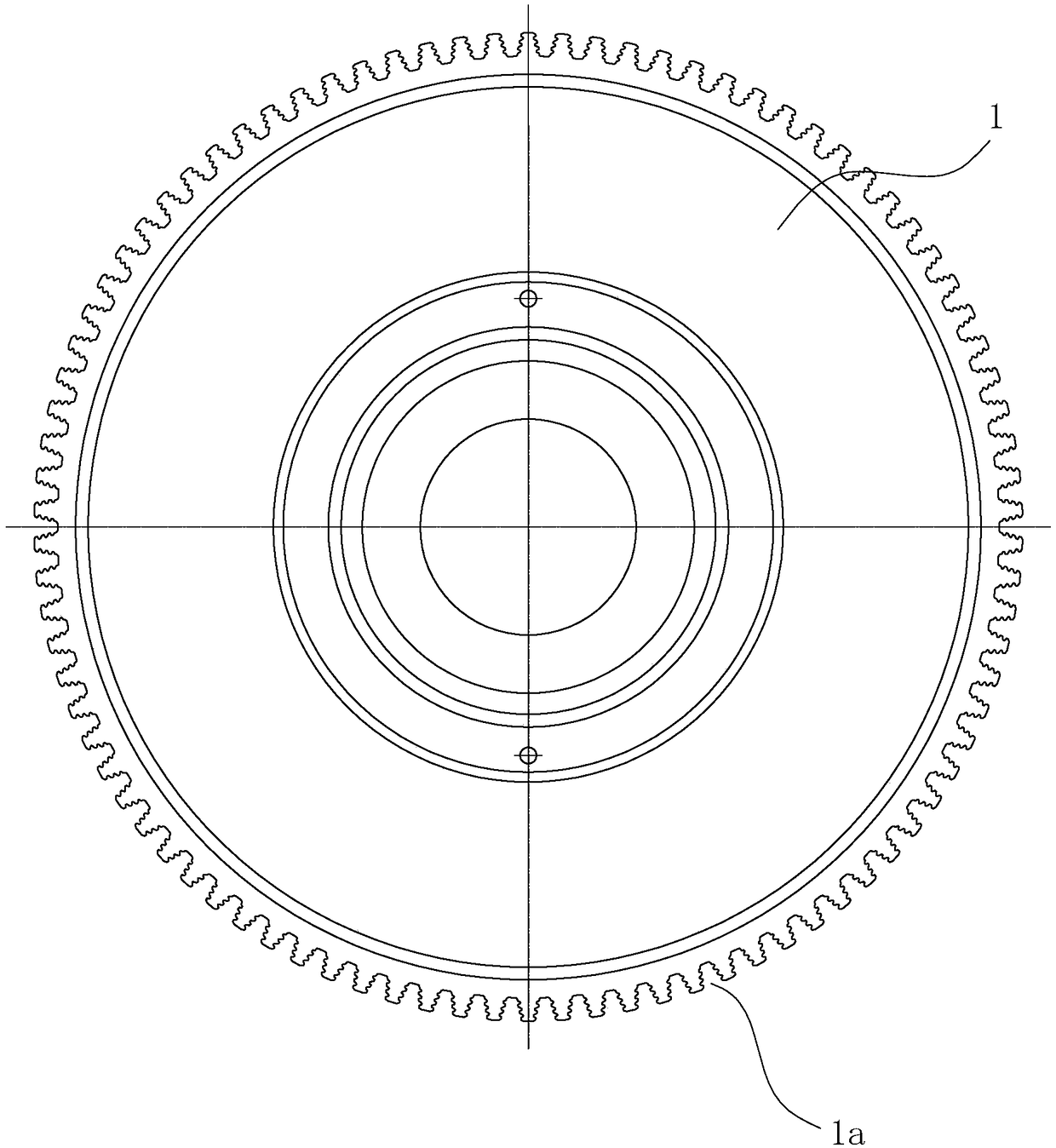

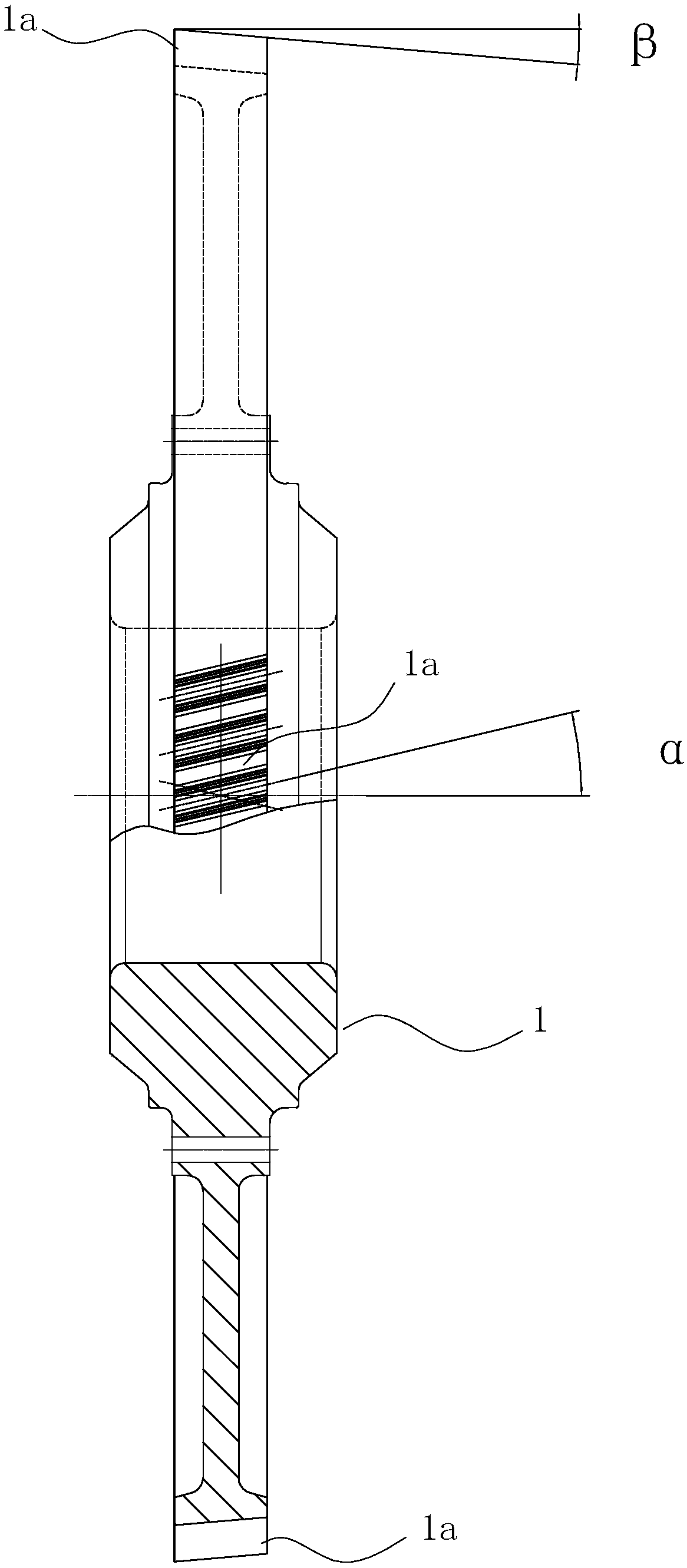

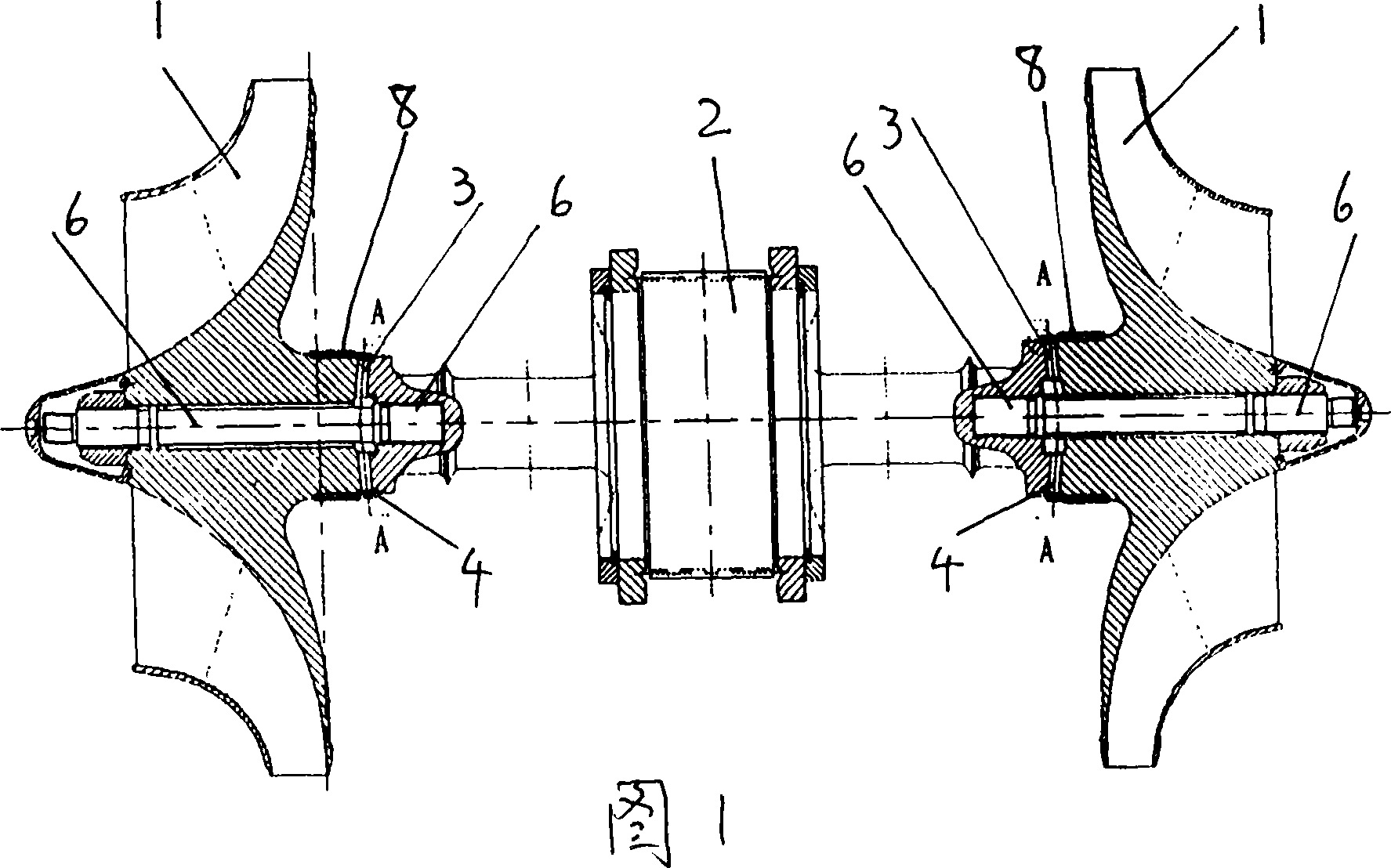

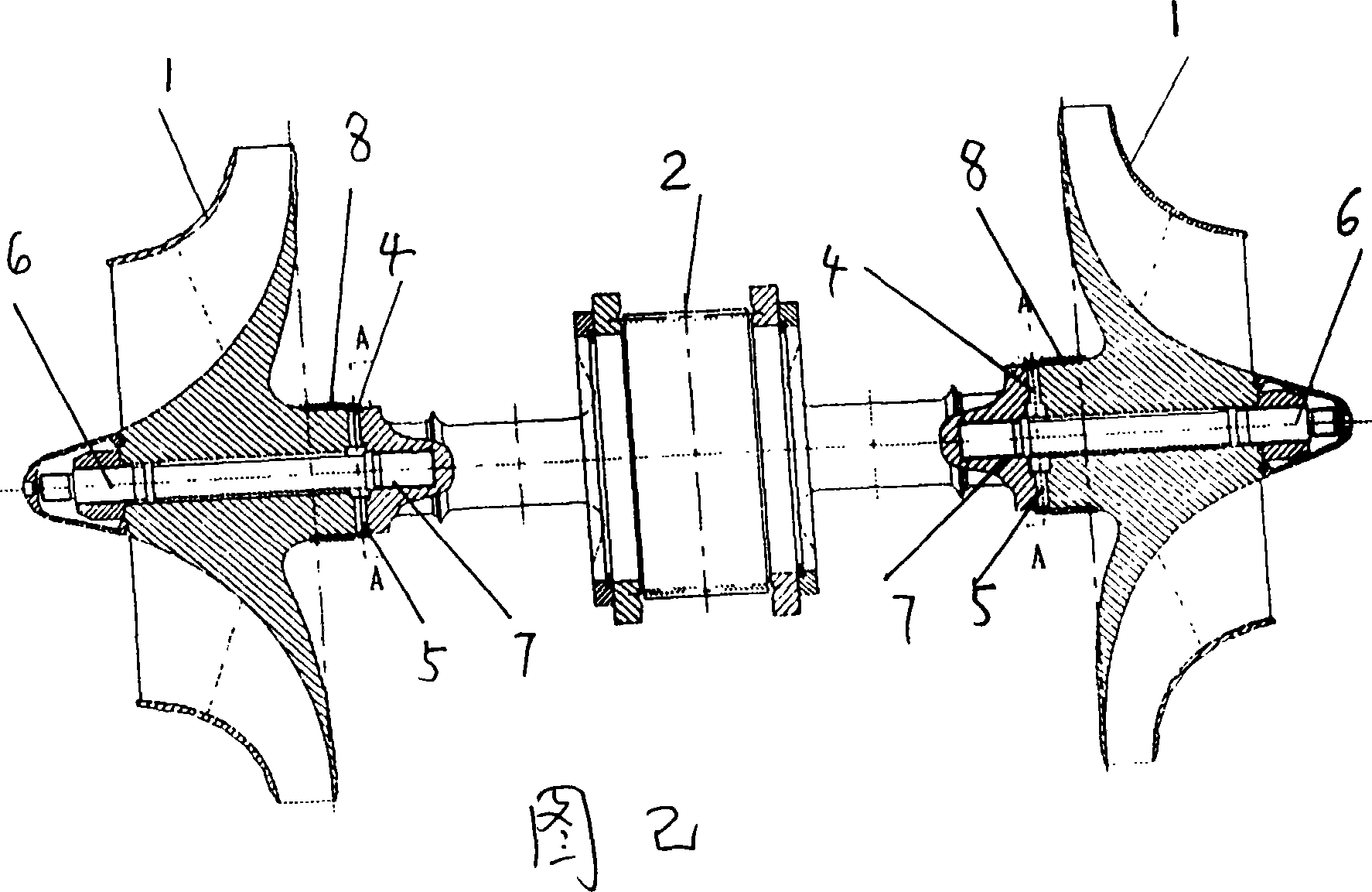

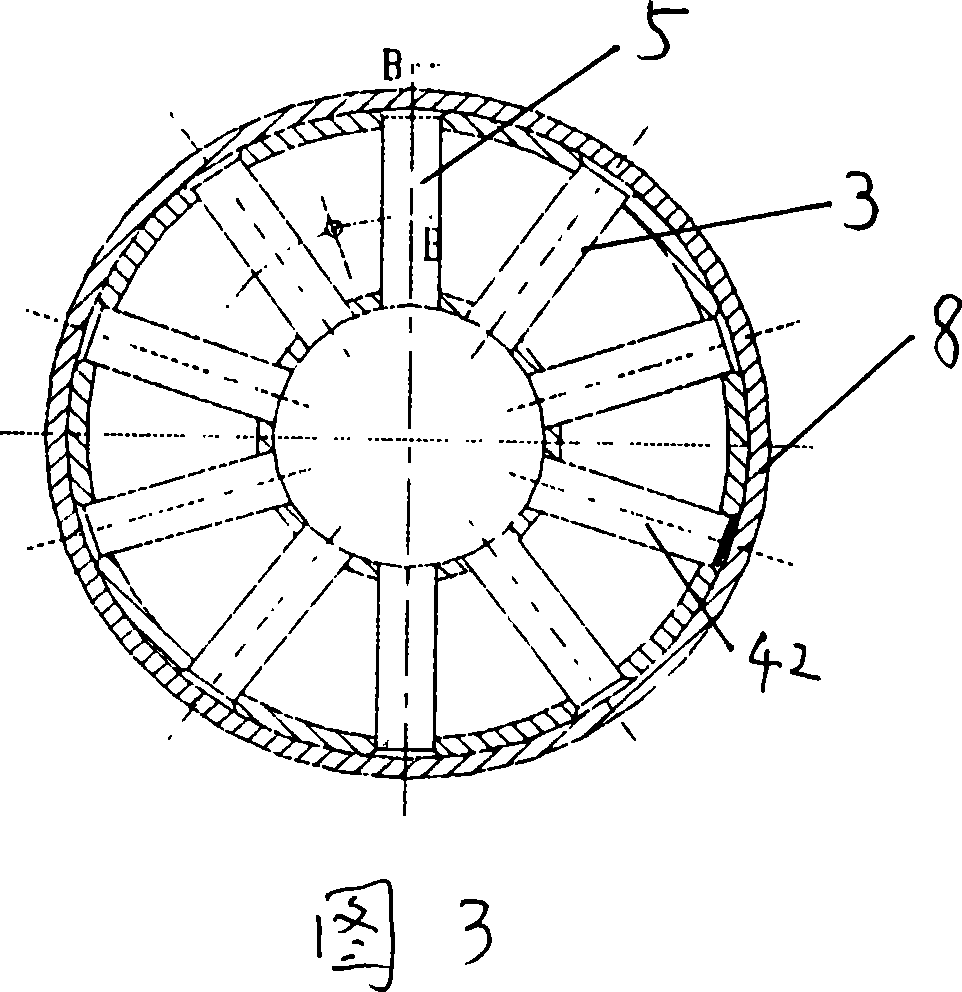

Rotary impeller transmission connection method and connection structure

InactiveCN101054907ALower requirementSimple structurePump componentsBlade accessoriesImpellerDrive shaft

A transmission connecting method and connecting construction of revolving impeller, the transmission connecting method is that: the revolving impeller is connected by end face and is fixed along axial direction with the transmission shaft, a plurality of tally connecting pins are rabbet jointed on the end face connecting the revolving impeller and the transmission to transmit the revolving torsional force to rotate the revolving impeller driven by the connecting pin; the connecting construction at least comprises a revolving impeller and a transmission shaft, the revolving impeller is connected by end face and is fixed along axial direction with the transmission shaft, the corresponding 2-20 semicircle pin holes arranged radically are provided on the connecting end faces to form a whole pin hole, the connecting pin with tally type end face is provided in the pin hole; the revolving impeller and the transmission shaft are fixablely connected by a drag bolt; the pin hole at least comprises a pin hole communicating with the upper to form an upper through hole and a pin hole with two end positioned in the revolving impeller and the transmission shaft to form a hidden hole, after the corresponding connecting pin is provided in the pin hole, an enclasping ring composed of a sealing axle sleeve is shrinking on tally outer ring of the connecting end face; the invention has characteristics that the structure is simple, the reliability is high, the processing cost is low and the range of applicability is wide, the invention has not high processing facility request and is easy to repair.

Owner:杭州杭氧透平机械有限公司

Medicated wine for treating rheumatismal arthritis and rheumatoid arthritis, and its prepn. method

InactiveCN1911292AQuick effectSimple manufacturing methodAntipyreticAnalgesicsCodonopsisCurative effect

A medical wine for treating rheumatic arthritis and rheumatoid arthritis is prepared from liquor and 10 Chinese-medicinal materials including pilose asiabell root, Chuan-xiong rhizome, cinnamon twig, liquorice root, etc through distilling pilose asiabell root, and proportionally immersing all materials in liquor.

Owner:苏国友

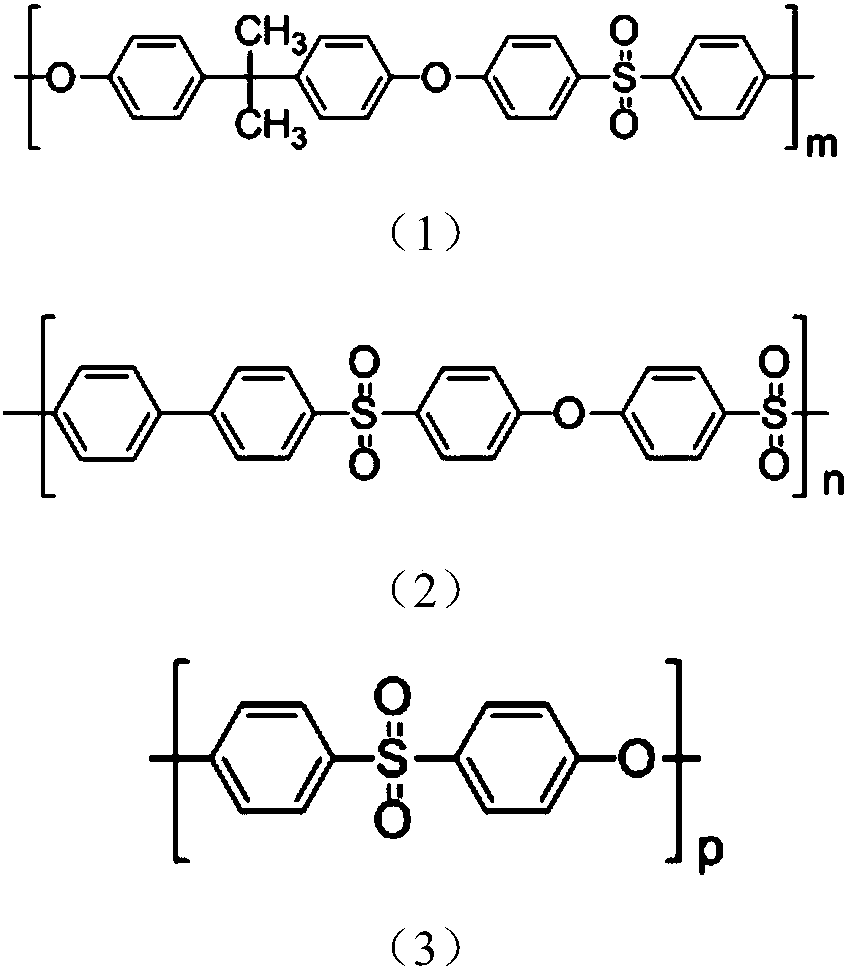

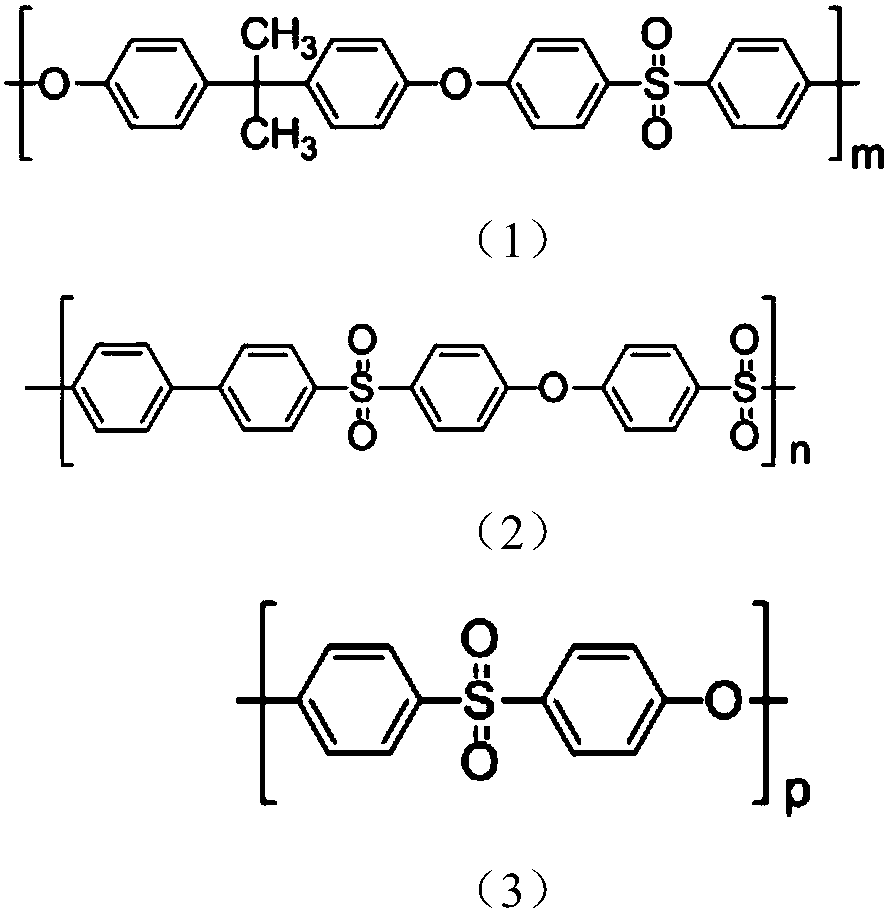

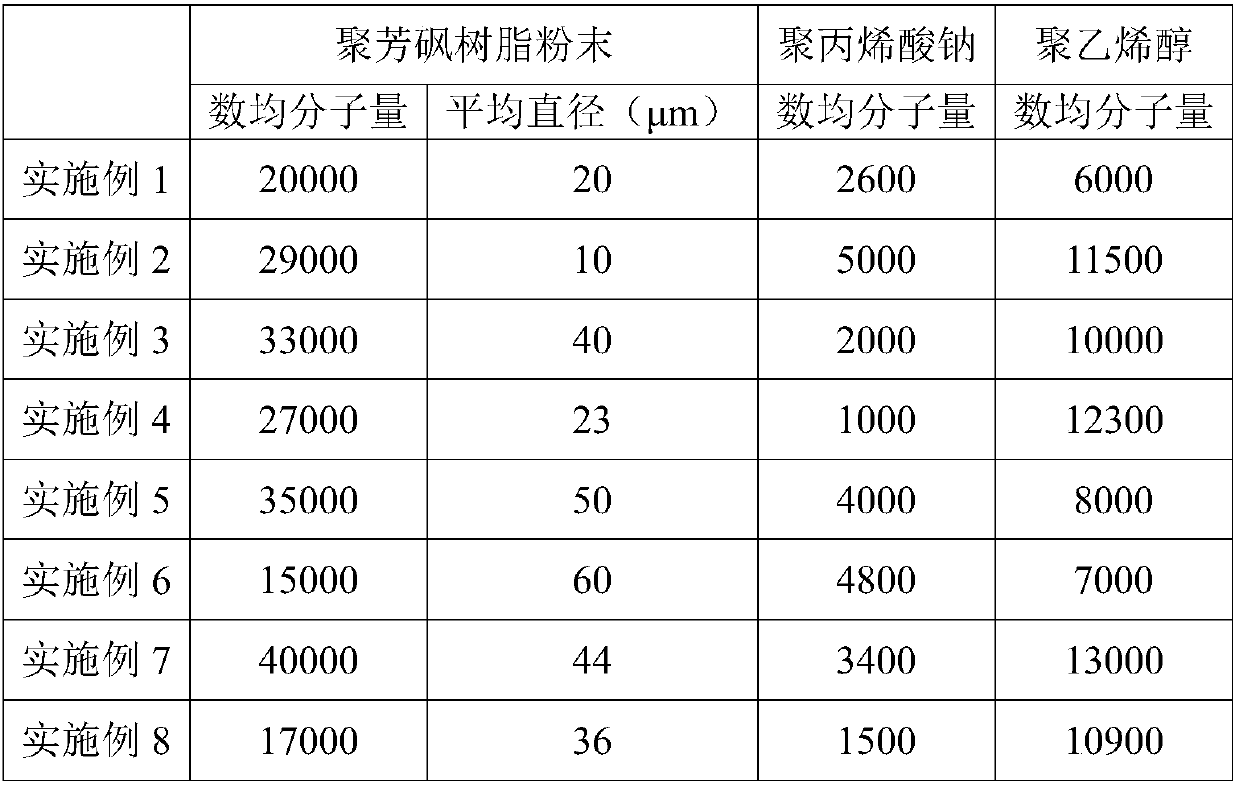

A polysulfone resin-based carbon fiber suspension sizing agent and a preparation method thereof

ActiveCN109722901AGood compatibilityAvoid various application problems such as aging hardeningCarbon fibresSolid componentCarbon fibers

The invention discloses a polysulfone resin-based carbon fiber suspension sizing agent and a preparation method thereof. The polysulfone resin-based carbon fiber suspension sizing agent is composed ofpolysulfone resin powder, sodium polyacrylate, polyvinyl alcohol and deionized water, wherein the polysulfone resin powder accounts for 65-75wt% of the total mass of the solid components, the sodiumpolyacrylate accounts for 10-15wt% of the total mass of the solid components, and the polyvinyl alcohol accounts for 15-20wt% of the total mass of the solid components. The sizing agent prepared by the invention is used for preparing carbon fibers, and the prepared sized carbon fibers are suitable for intermediates such as carbon fiber fabrics and prepregs for polysulfone resin-based composite materials, and have high temperature resistance and strong interface bonding capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Normal temperature nanometer desulfurizing agent and its preparation process

InactiveCN100384515CLow requirements for processing equipmentReduce manufacturing costDispersed particle separationNitrateSulfur

The invention relates to a normal-temperature nanometer desulfurizer and a relative preparation, wherein the mol rate between nanometer ferric oxide and nanometer zinc oxide is 1:13-47; the preparation comprises: (1), dissolving the ferric nitrate into concentrated zinc nitrate solution, to make the mol rate between zinc ion and ferric ion as 100:2-5; (2), adding aquacare based on the mol rate between metal ion and aquacare as 1:3.45; (3), arranging the solution at 85-110Deg. C, to react 1-3hours; (4), filtering, washing solid and drying; (5), baking solid, to obtain the normal-temperature nanometer desulfurizer. The diameter of desulfurizer is 12.4-14nm, with high desulfurization speed, and 10-16% sulfur capacity. The invention has simple process and low cost.

Owner:HARBIN INST OF TECH

Processing method of puffed wheat

ActiveCN103005152ASimple processing methodIncrease productivityAnimal feeding stuffMycotoxinChemical composition

The invention discloses a processing method of puffed wheat, belonging to the technical field of feed processing. The processing method of the puffed wheat comprises the following steps of: screening impurity-contained wheat through a three-layer vibrating screen and a specific-gravity screen; adding the screened wheat to a permanent magnetic pulley for removing the magnetic impurities; brushing and cleaning the wheat through a brushing machine and a water washer in sequence to reduce the content of mycotoxins in the wheat; and drying and puffing the wheat to obtain the puffed wheat. The method is simple, the process setting is reasonable, the requirements on processing equipment and technology are low, and the production efficiency of the puffed wheat can be remarkably improved. No toxic and harmful chemical component is added in the processing method, so that the prepared product is safe and non-toxic; and the content of glucan in the wheat is effectively reduced, and thus the mass requirement of feed processing enterprises on the components of the wheat can be satisfied well. The method not only solves the problems of high mycotoxins content and high viscosity of the wheat and improves the wheat quality, but also increases the dosage of the wheat in the feed processing field, improves the utilization rate of medium-level and low-level wheat, and can effectively restrain resource waste.

Owner:河南天康宏展实业有限公司

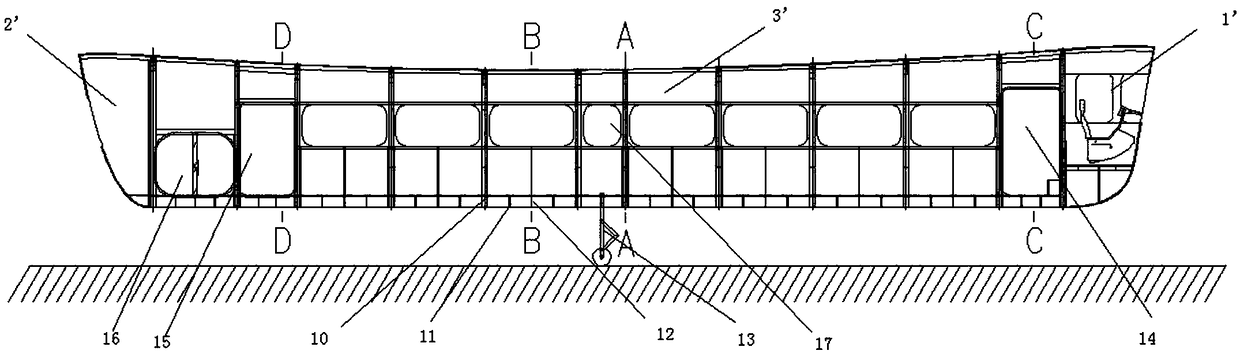

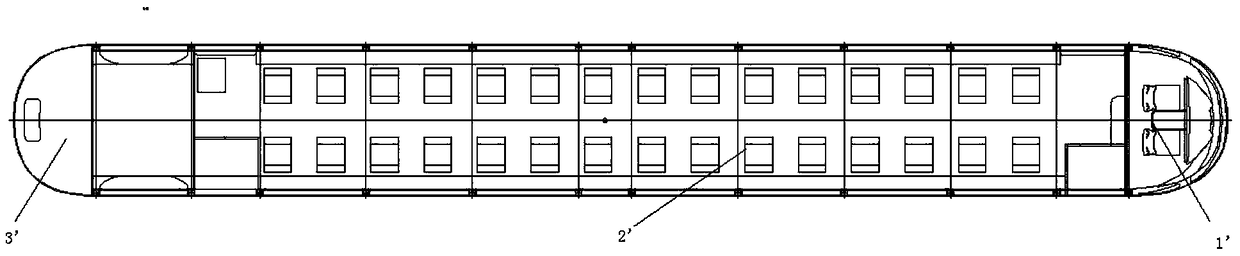

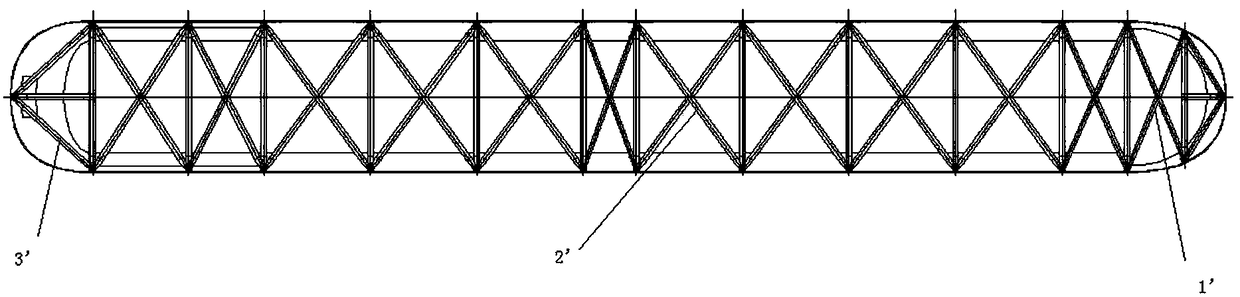

Large-size and low-cost double-deck structured airship pod made of composite material has and having no mechanical connection

A large-size and low-cost double-deck structured airship pod made of composite material has and having no mechanical connection includes an exterior, a front cabin, a rear cabin and a passenger cabin.The front and rear cabins are the same and symmetrical, the upper part is a circular arc, the lower part is a three-dimensional ball, the passenger cabin is symmetrical, the upper part of the side isa straight line, the middle part is a large circular arc, the lower part is a small circular arc, and the bottom part is a large circular arc which is the same as the side large circular arc. The column frames, the floor frames and the outer panels, the frames, the beams, the floors and the hatch doors of the front cabin, the rear cabin and the passenger cabin are all foam sandwich composite structures, and the inner and outer panels, the frames and the beams of the normal hatch doors, the emergency hatch doors, the power hatch doors and the glass windows are all the same foam sandwich composite structures. The invention adopts the composite material structure design to carry out the design in a plurality of factors, and has the advantages of simple overall appearance, no mechanical connection of the whole composite material, light weight and low cost.

Owner:JINLING INST OF TECH

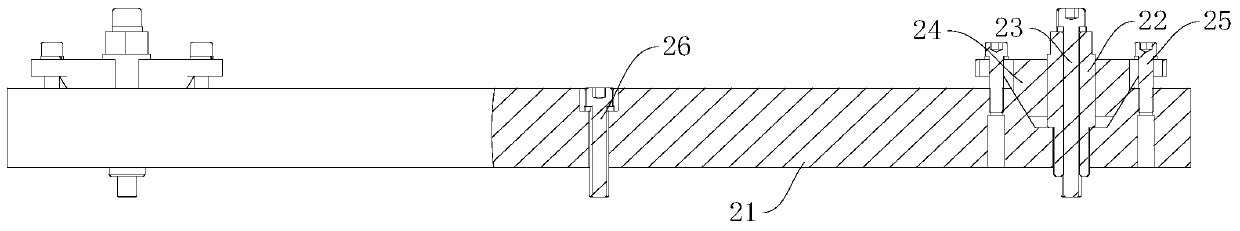

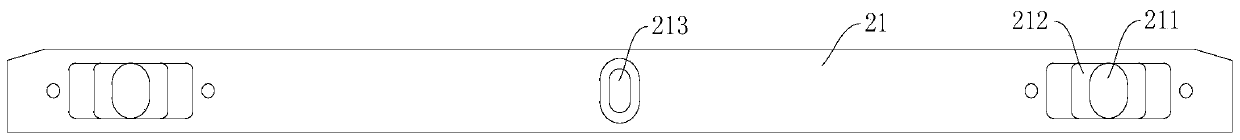

Motion guide device of injection molding motor template and injection molding machine

PendingCN110239029ASave material costReduce processing costsInjection molding machineMechanical engineering

The invention discloses a motion guide device of an injection molding motor template and an injection molding machine. The motion guide device comprises a rack and a lateral guide assemblies, a slideway is arranged on the top surface of the rack, the slideway is used for being in sliding fit with the movable template, at least two groups of lateral guide assemblies are arranged on the two sides of the rack, the side guide assemblies comprise first guide plates, eccentric pins and first fastening screws, the inner side surface of the first guide plates are used for being in sliding fit with the outer side surface of the movable templates, the two ends of the first guide plates are respectively provided with first guide grooves, the eccentric pins comprise first connecting columns and second connecting columns which are connected in sequence, the central axis of the second connecting columns are offset with the central axis of the first connecting columns, the outer diameter of the second connecting columns are smaller than the outer diameter of the first connecting columns, so that parting surfaces are formed between the first connecting columns and the second connecting columns, the eccentric pins penetrate through the first guide grooves and are inserted into the rack, the first fastening screws are used for connecting the eccentric pins, the first guide plates and the rack together. According to the motion guide device, the guide precision is more easily ensured.

Owner:LIUZHOU KAIYU PLASTIC INJECTION MACHINERY CO LTD

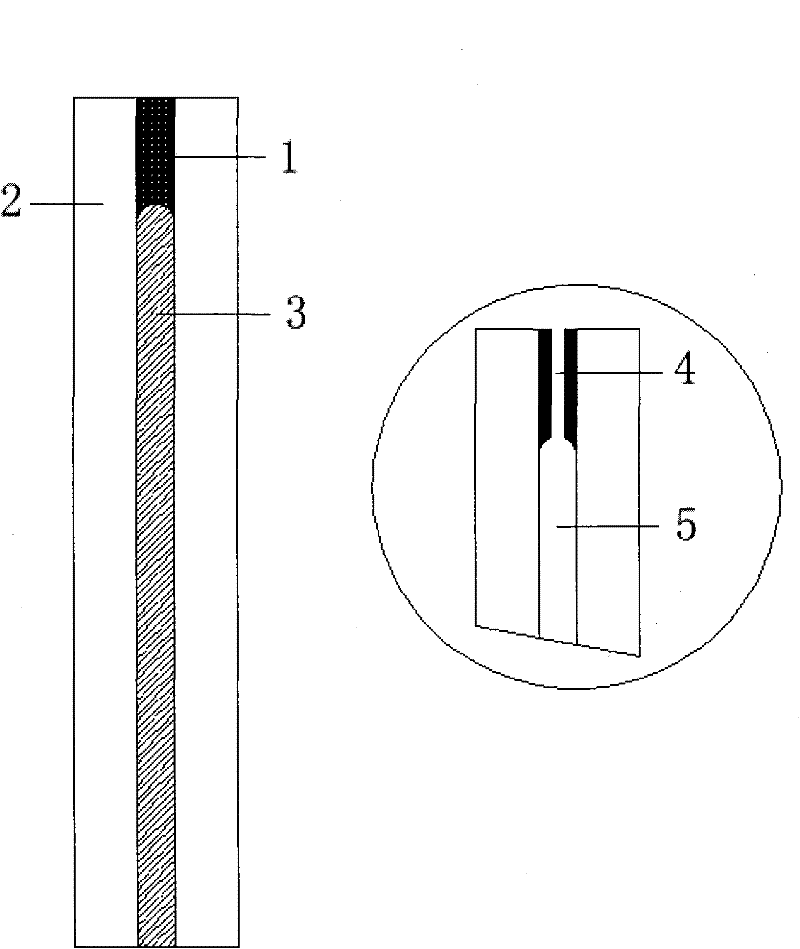

Sound insulation glass with liquid sound insulation layer structure

InactiveCN102237080ALow requirements for processing equipmentReduce consumptionSound producing devicesInsulation layerEngineering

The invention provides sound insulation glass with a liquid sound insulation layer structure aiming at the problem of the conventional sound insulation glass product by combining the advantages of laminated glass and hollow glass and the characteristic of a liquid substance on acoustic wave propagation. The sound insulation glass consists of sheet glass, a sealing material and a liquid sound insulation layer, wherein the peripheries of the sheet glass which has the same shape are sealed by using the sealing material and liquid injection holes are formed in the peripheries of the sheet glass; and after the required liquid is injected, the liquid injection holes are sealed. The manufacturing method of the sound insulation glass is simple; furthermore, the sound insulation glass has a good sound insulation effect and low dependence on energy and can be produced in large scale. Compared with the conventional laminated glass and the hollow glass, the sound insulation glass has higher sound insulation quantity and can be widely applied to sound insulation windows and sound insulation products for noise treatment.

Owner:SHANGHAI JINHE INDAL

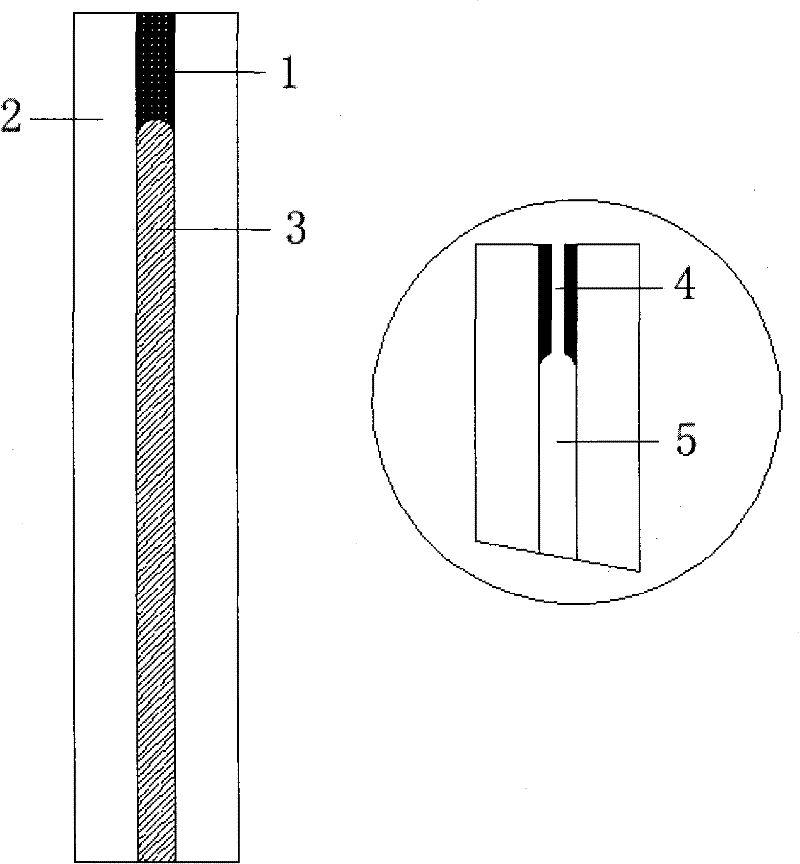

Special fruit tree biological fertilizer based on waste bacteria sticks and preparation method thereof

InactiveCN111533624AAchieve reuseReduce pollutionExcrement fertilisersBioloigcal waste fertilisersAzotobacter chroococcumLivestock manure

The invention relates to the field of biological bacterial fertilizers, in particular to a special fruit tree biological fertilizer based on waste bacteria sticks. The special fruit tree biological fertilizer is prepared from waste bacteria stick powder, fruit tree branch powder, dried livestock manure, a high-humidity enzyme microbial agent, azotobacter chroococcum, bacillus megatherium, bacillussubtilis, bacillus mucilaginosus, purple non-sulfur bacteria and bran. Waste bacteria sticks, fruit tree branches and livestock manure are comprehensively fermented, the nitrogen fixation capacity ofthe fruit tree can be improved, the solidified phosphorus and the solidified potassium in the soil can be reutilized, and nitrogen-fixing, phosphorus-dissolving and potassium-dissolving bacteria areadded to obtain phosphorus-dissolving, potassium-dissolving and nitrogen-fixing biological organic bacterial fertilizer. The biological organic bacterial fertilizer can improve nitrogen fixation capacity of fruit trees and recycle phosphorus and potassium solidified in soil, microbial ecological environment of orchards is improved while organic matter content of orchard soil is increased, and utilization rate of mineral elements is increased.

Owner:ZAOZHUANG UNIV

Application method of nanometer copper oxide

InactiveCN100490940CHigh desulfurization precisionSimple preparation processNanostructure manufactureDispersed particle separationTO-18Low demand

The invention relates to an application of nanometer copper oxide and the preparing method, belonging to an application of compound and the preparing method. Before the invention, there are not reports that single nanometer copper oxide is used as ambient temperature desulfurizer and the purity of nanometer copper oxide prepared by prior preparing method for nanometer copper oxide is low. In the invention, the nanometer copper oxide is used as the ambient temperature desulfurizer and the nanometer copper oxide is the only component of ambient temperature desulfuizer. The preparation of nanometer copper oxide is that sodium hydroxide is added in the copper nitrate solution and then it is filtered, dried and baked or the preparation of nanometer copper oxide is that sodium hydroxide is added in the copper nitrate solution and then it is filtered and dried. The desulfurization accuracy of nanometer copper oxide in the invention is high in ambient temperature condition and the sulfur capacity is high to 18.3%-28.7%. The purity of nanometer copper oxide prepared in the invention is higher than 99.9%. It is provided with simple preparing process, low demand for machining equipment, small energy consumption and low production cost. It is easy to be developed and implemented.

Owner:HARBIN INST OF TECH

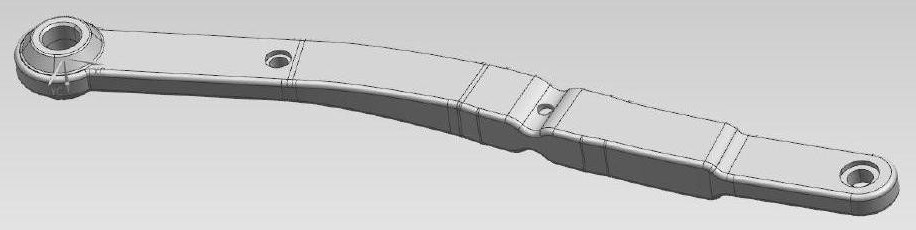

Rapid sample piece manufacturing method for automobile limiting arms

InactiveCN113664468AHigh strengthGuaranteed size requirementsWing fastenersNumerical controlProduct modeling

The invention discloses a rapid sample piece manufacturing method for automobile limiting arms. The method specifically comprises the following steps that S1, product modeling is carried out, the plurality of limiting arms are combined and arranged in three-dimensional software, the appearance is manufactured into a standard rectangle, and six surfaces are vertical; S2, numerical control programming is conducted, programming is conducted according to an established data model, the front face and part holes of a blank are simulated and machined firstly, and then the back face of the blank is simulated and machined; S3, blank machining is carried out, the blank is placed in machining equipment to complete the machining process of the front and back surfaces of the blank; and S4, blank cutting is carried out, and the blank is placed in linear cutting equipment and cut to form a sample piece. According to the method, the plurality of parts are arranged in a combined process manner, use of four-axis and five-axis machining center equipment is avoided, the requirement for machining equipment is reduced, the production efficiency is improved, the strength of the parts in the machining process is improved, stability is enhanced, and the size requirement of the parts is ensured.

Owner:ANHUI JIANGNAN MACHINERY

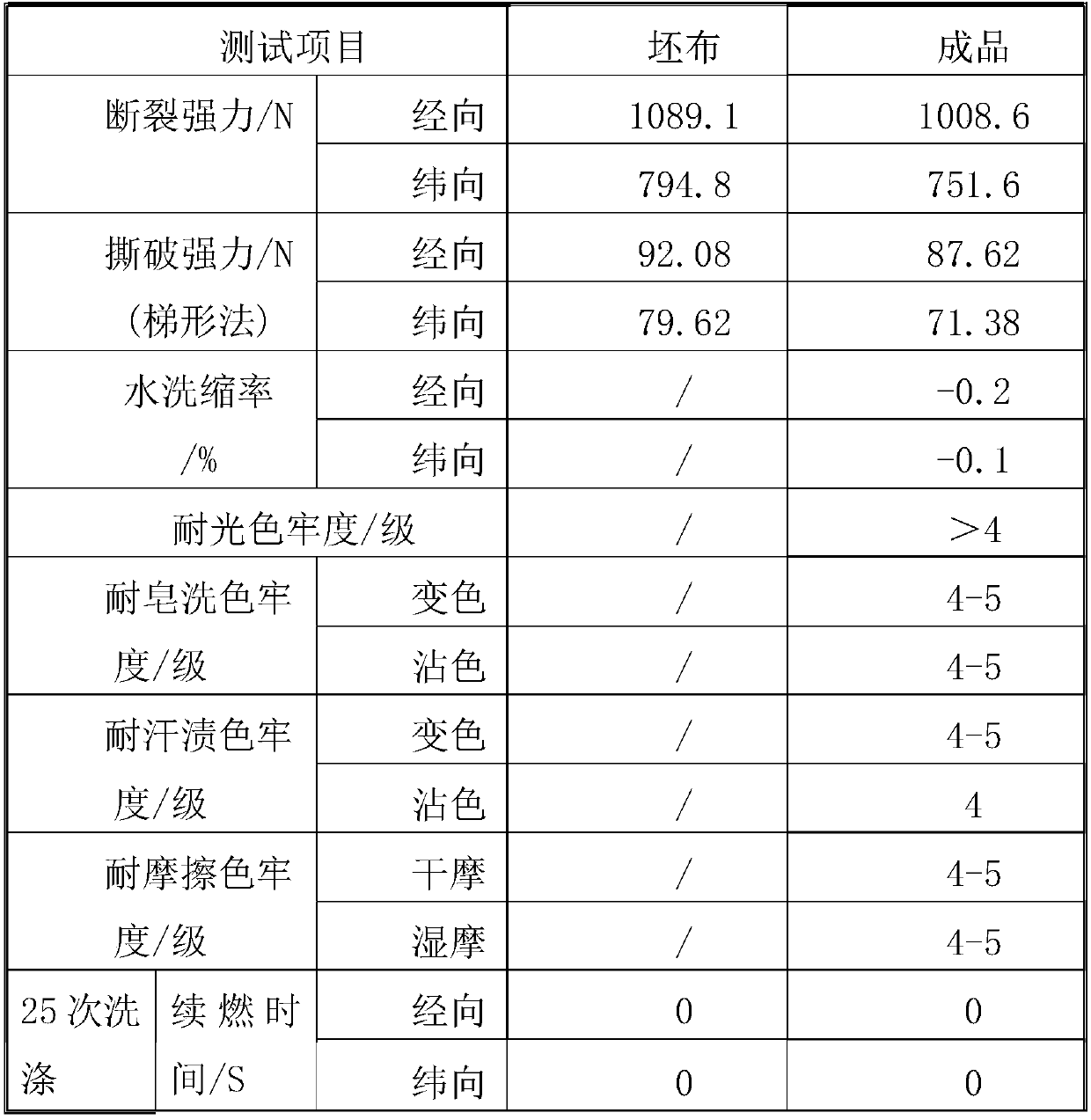

Modacrylic/flame retardant viscose/flame retardant polyester blended flame retardant fabric dyeing technology

ActiveCN110644258AAvoid damageMeet the use requirementsDry-cleaning apparatus for textilesDyeing processDisperse dyePolymer science

The invention discloses a modacrylic / flame retardant viscose / flame retardant polyester blended flame retardant fabric dyeing technology which includes the steps: desizing and scouring a modacrylic / flame retardant viscose / flame retardant polyester blended flame retardant grey fabric; dyeing the treated fabric by the aid of disperse dyes and active dyes; performing after-finishing on the dyed fabric. Flame retardant polyester and modacrylic are dyed by a disperse dye carrier method, the time of two-bath dyeing of two fibers by the disperse dyes and cationic dyes is shortened, dyeing efficiency can be improved, reserve of workshop dye types is decreased, and factory capital backlog is reduced.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +1

Process for manufacturing hot plate in chemical industry

The invention provides a technique for producing a hot-plate used by chemical industry and relates to a producing technique of chemical members. The processing method is characterized in that: circulation channels for heating steam is milled out on the parent material of the hot-plate by utilizing a milling cutter, the inlets and the outlets for heating steam are processed by utilizing an ordinary drilling machine to form complete steam circulating passages with the heating steam circulation channels in the plate; cover plates are utilized for making up open parts formed by milling the steam channels by the milling cutter and are combined with the parent material of the hot-plate; the borders where the parent material of the hot-plate and the cover plates are combined are welded so as to lead the channels in the plate to form a whole; the bulkheads of the milled heating steam circulation channels are provided with sealing gaskets; the distance between the channels are regulated, or the trend and the circulation circuit of the channels are regulated so as to ensure the uniformity of the temperature of the hot-plate structure. The invention has simple processing technique, low requirements on processing devices and is advantageous for popularization and convenient for maintenance and inspection in plants.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Lucerne composite alimentary flour and its preparation method

The invention discloses an alfalfa composite alimentary paste and preparing method, which comprises the following parts: 50-60% wheat flour, 30-40% oat flour, 4-5% soy bean and 1.5-2% dried alfalfa. the preparing method comprises the following steps: (1) immersing soy bean and dried alfalfa through water separately; (2) grinding soy bean and alfalfa; filtering; (3) placing wheat flour, oat flour, soy bean grinding filtrate, alfalfa grinding filtrate and water in the dough mixing machine; moulding; (4) drying the noodle to obtain the product.

Owner:HARBIN FENGTIAN ECOLOGICAL AGRI TECHDEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com