Conducting rod assembly of ultrahigh-voltage outgoing line sleeve

A technology of outlet bushing and conductive rod, applied in the field of conductive rod, can solve the problems of low contact resistance of conductive rod components, incomplete cleaning of the inner wall of conductive pipe, etc., achieve low contact resistance, reduce processing equipment requirements and component transfer costs, simplify The effect of processing technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] In order to make the above objects, features and advantages of the present invention more comprehensible, the specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

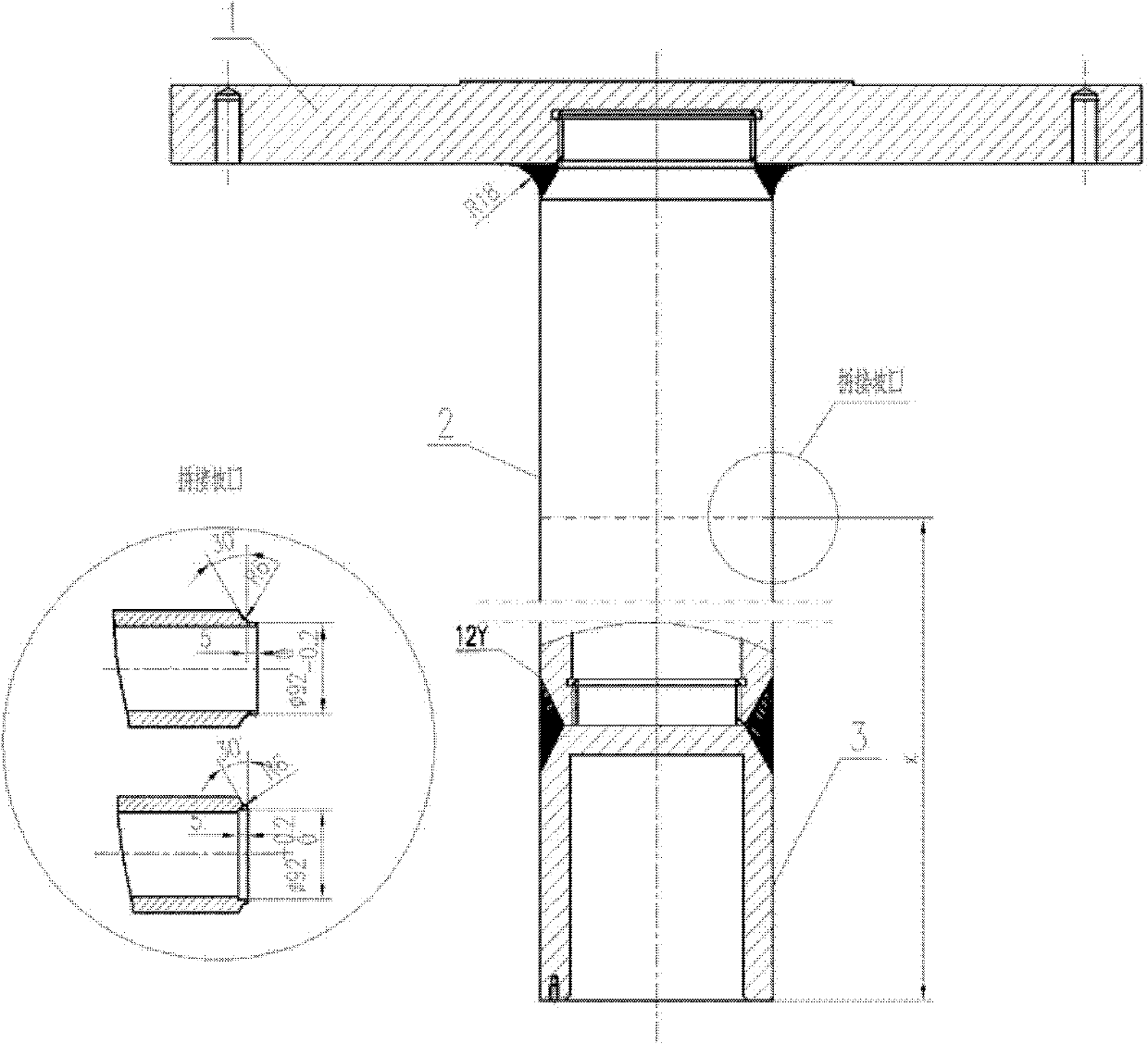

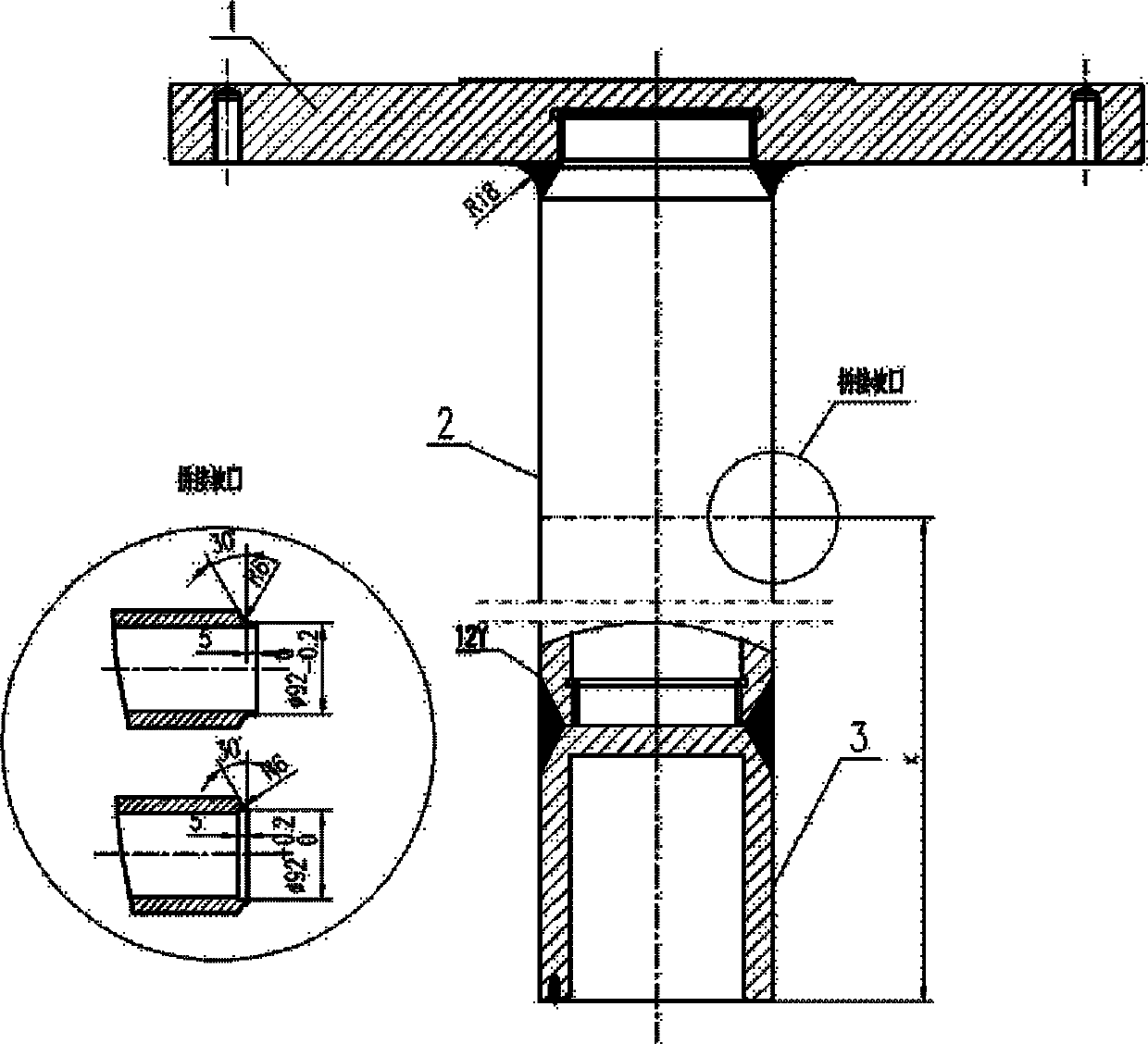

[0019] Such as figure 1 As shown, this figure is a cross-sectional view of an embodiment of the conductive rod assembly based on the ultra-high voltage outlet bushing of the present invention. The conductive rod assembly of the ultra-high voltage outlet bushing provided by the embodiment of the present invention includes a cover plate 1 , a conductive pipe 2 and a plug 3 .

[0020] A cylindrical threaded hole is arranged in the center of the lower end surface of the cover plate 1 .

[0021] The conductive pipe 2 is formed by tailor welding of two sections of conductors, the welding groove angle is 30°, the groove is rounded with R6, and the conductor is made of aluminum alloy, which plays the role of conducting curr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com