Single-layer double-sided electrode of capacitive touch screen and preparation method thereof

A capacitive touch, single-layer technology, applied in electrical digital data processing, data processing input/output process, instruments, etc., can solve problems such as reducing material costs, unable to prepare double-layer electrodes, and increasing product yield, etc. Achieve the effect of reducing etch, ensuring overlap probability and uniform distribution, and improving wetting and corrosion uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

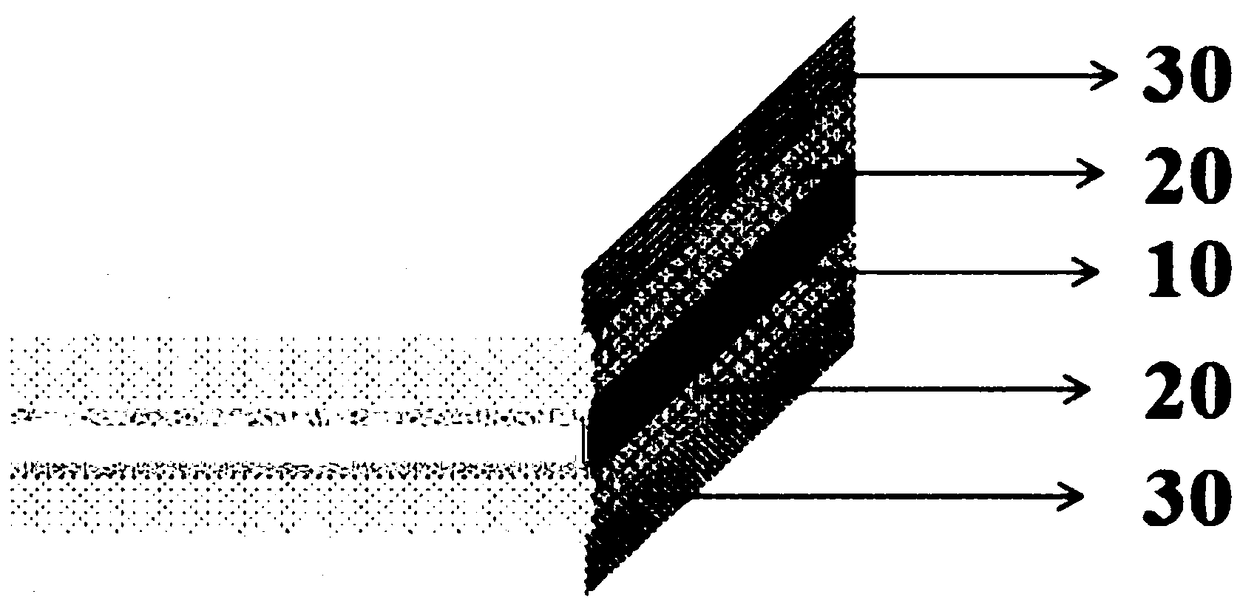

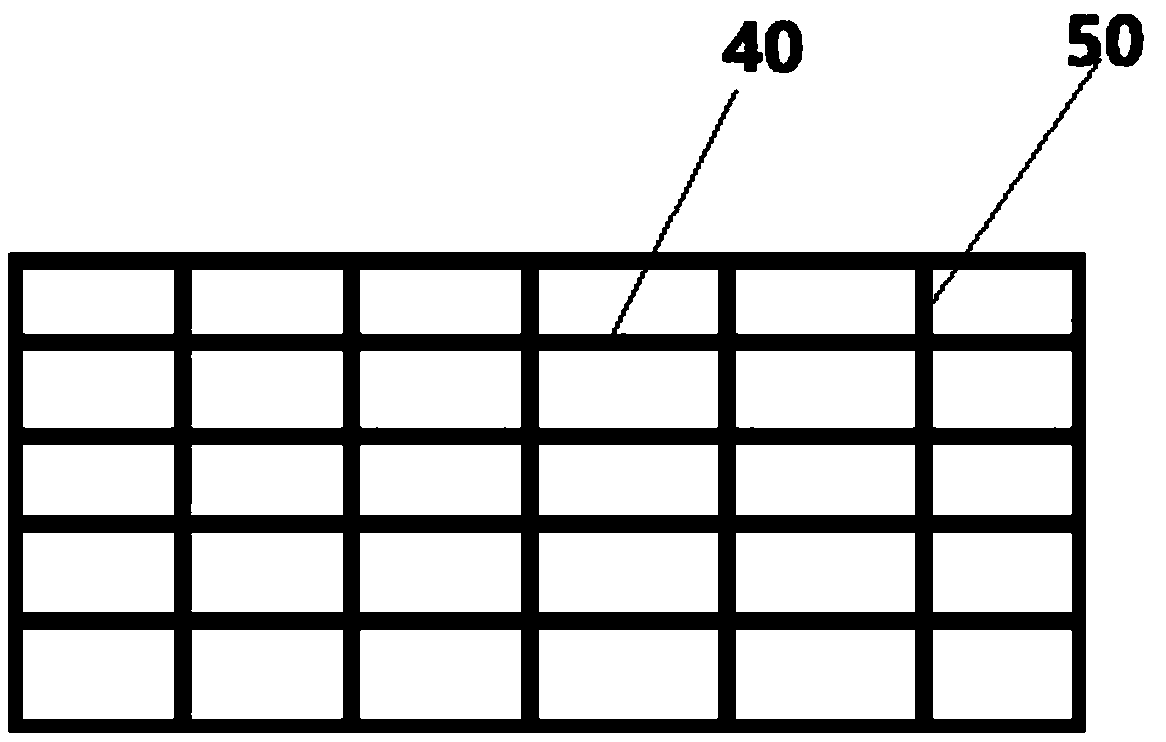

[0052] This embodiment provides a single-layer double-sided electrode of a capacitive touch screen, combined with figure 1 The schematic diagram of the layout structure shown includes a base material 10, the upper and lower surfaces of the base material are respectively provided with conductive lines, and the shown conductive lines include a silver nano wire transparent conductive layer 20 and a transparent ink layer 30 printed on the surface of the silver nano wire transparent conductive layer 20 ;Such as figure 2 As shown, wherein, the conductive lines include horizontal conductive lines 40 and vertical conductive lines 50 arranged in an array pattern arranged on different sides of the substrate 10, and the horizontal conductive lines of the single-layer double-sided electrodes in the transparent capacitive touch screen The lines 40 and the longitudinal conductive lines 50 are in a state of intersecting when viewed from above.

[0053] In this embodiment, the base film is ...

Embodiment 2

[0057] On the basis of Embodiment 1, the present invention further provides a method for preparing a single-layer double-sided electrode of a capacitive touch screen, specifically, it includes the following steps:

[0058] Step 1. Prepare nano-silver wire transparent conductive layers 20 on both sides of a PET substrate 10 with a thickness of 125 μm; bake at 100-120° C. for 5-8 minutes to prepare a double-sided silver nano-wire conductive film;

[0059] Step 2. Cut out a portion of the silver nanowire transparent conductive film obtained in step 1 that can be used to make a 21.5-inch touch screen. On one side of the silver nanowire transparent conductive layer 20, ink-jet print a transparent ink with a horizontal cell array pattern. One side is ink-jet printed with transparent ink with vertical unit array graphics. Specifically, a transparent thermoplastic resin is ink-jet printed on one side of the transparent conductive layer of silver nanowires, and an alignment point is se...

Embodiment 3

[0065] The present invention further provides a method for preparing a single-layer double-sided electrode of a large-size capacitive touch screen, specifically, it includes the following steps:

[0066] Step 1. Prepare nano-silver wire transparent conductive layers 20 on both sides of a PET substrate 10 with a thickness of 125 μm; bake at 100-120° C. for 5-8 minutes to prepare a double-sided silver nano-wire conductive film;

[0067] Step 2: Cut out a portion of the silver nano wire transparent conductive film obtained in step 1 that can be used to make a touch screen with a size of 86 inches. On one side of the silver nano wire transparent conductive layer 20, inkjet printing is provided with a transparent ink with a horizontal cell array pattern. One side is ink-jet printed with transparent ink with vertical unit array graphics. Specifically, a transparent thermosetting resin is ink-jet printed on one side of the transparent conductive layer of silver nanowires, and counter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com