Rotary impeller transmission connection method and connection structure

A technology of rotating impeller and transmission connection, which is applied to the supporting elements of blades, engine elements, machines/engines, etc., can solve the problems of small application range, large rigidity change, unsuitable for high speed, etc., and meets the requirements of wide application range and processing equipment. No, processing equipment requires high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

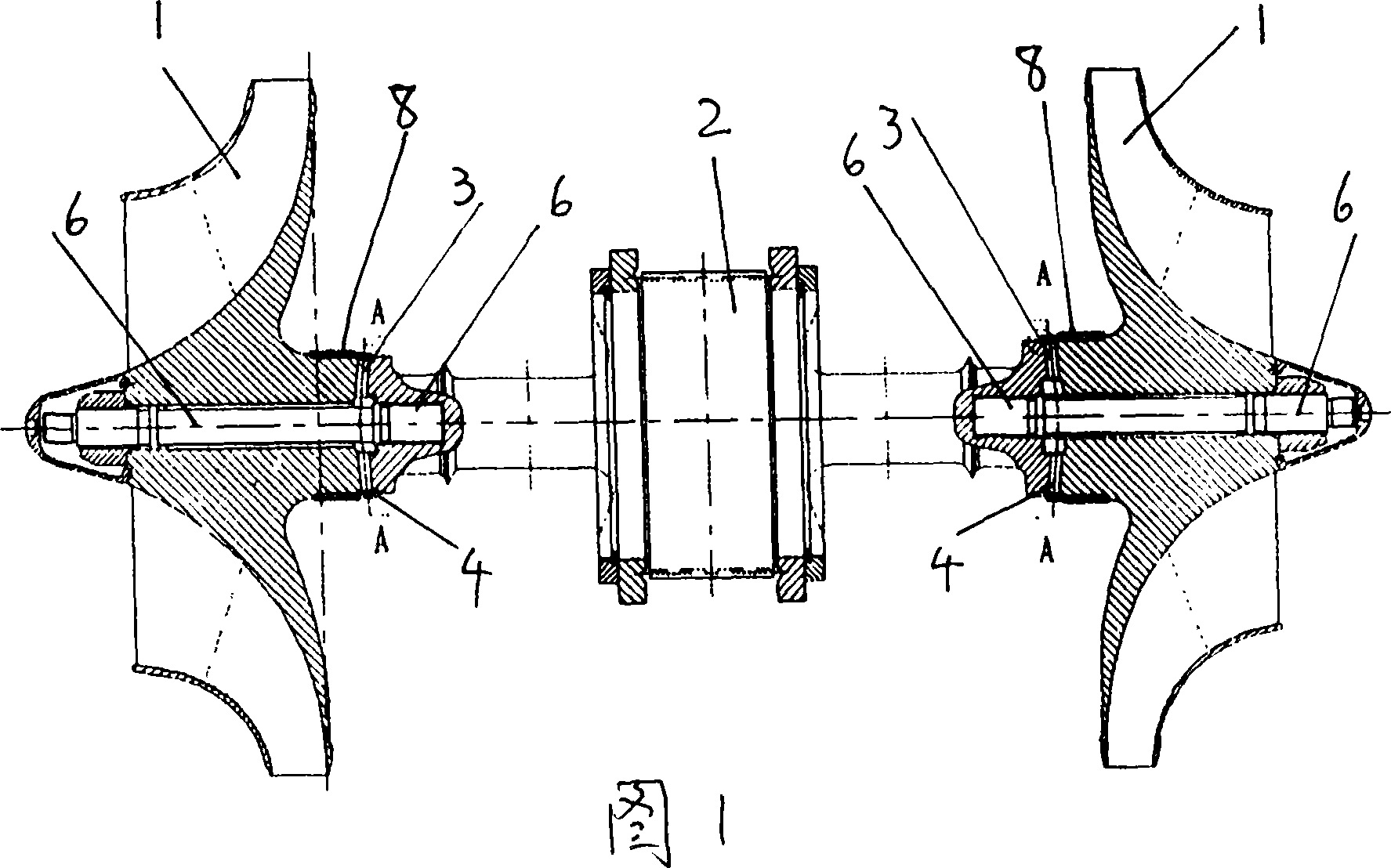

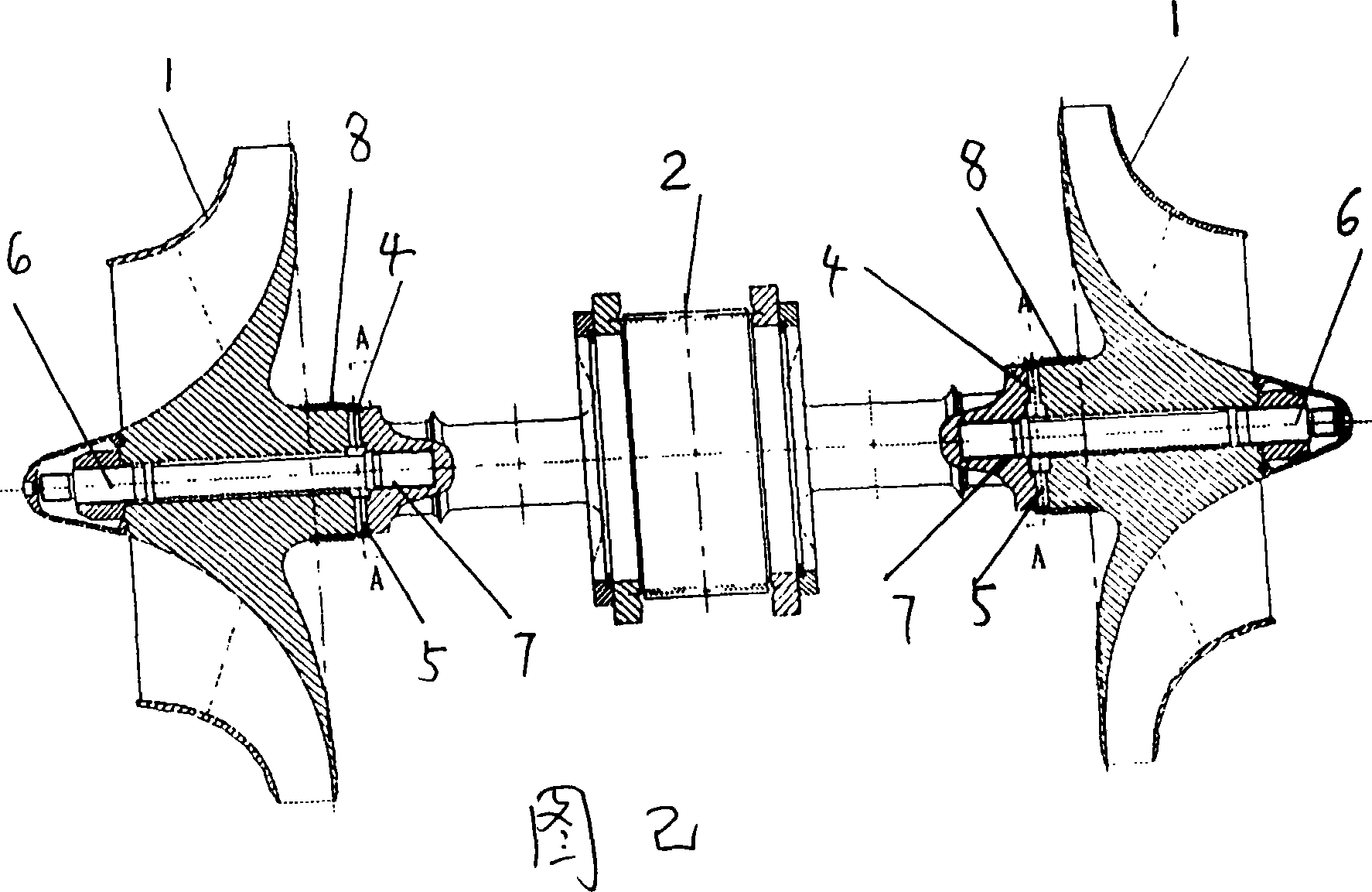

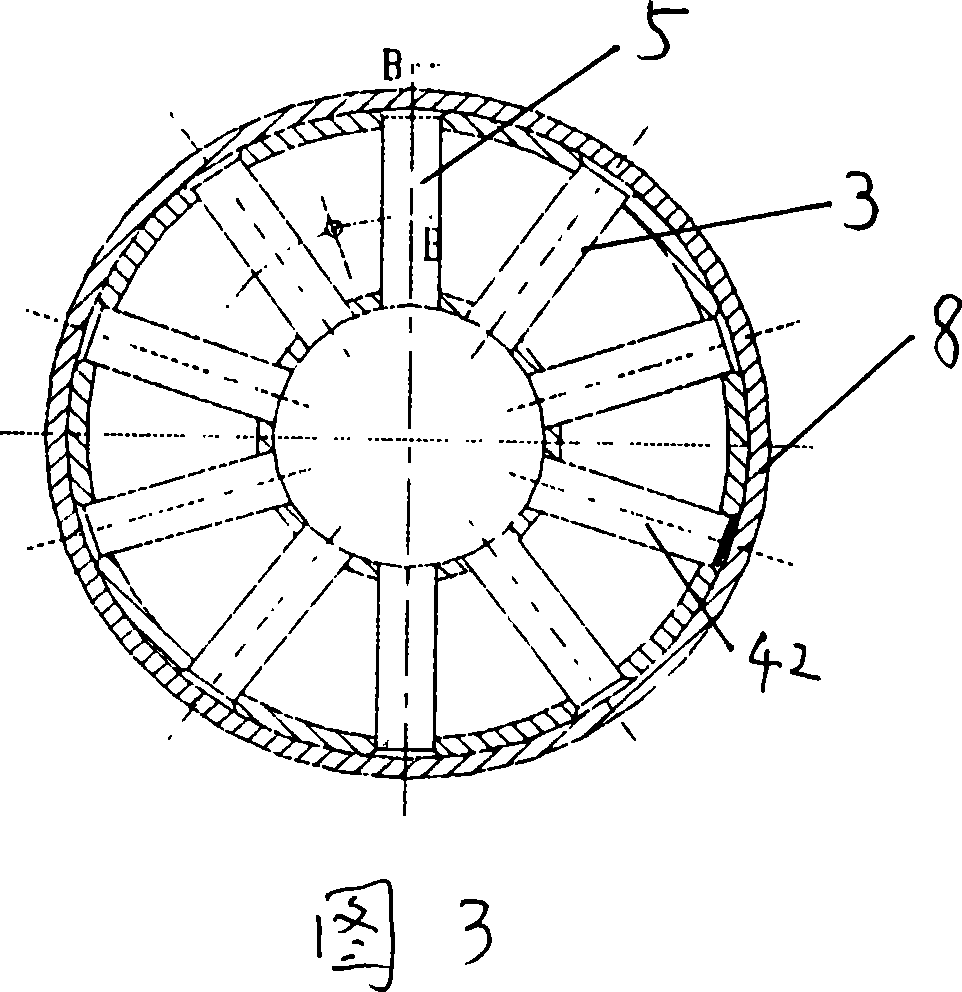

[0021] The present invention will be described in detail below in conjunction with the accompanying drawings: The transmission connection method described in the present invention is: connect the rotating impeller and the transmission shaft with the end face and fix them axially, and insert A plurality of connecting pins are connected to drive the rotating torque, and the rotating impeller is driven to rotate through the connecting pins. The connecting end faces between the rotating impeller and the drive shaft can be connected by end planes or by end cones, and 2-20 joints for transmitting rotational torque are embedded in the form of seams on the connected end faces. connection pin.

[0022] As shown in Fig. 1, the connection structure of the present invention at least includes a rotating impeller 1 and a transmission shaft 2. The rotating impeller 1 and the transmission shaft 2 are connected with the end faces and fixed in the axial direction. There are corresponding 2-20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com