Design method of water-cooling radiator

A radiator and water cooling technology, which is applied in the direction of cooling/ventilation/heating transformation, etc., can solve the problems of increasing processing difficulty, drill bit limitation, increasing input cost, etc., so as to enhance work reliability and durability, increase output rate and Yield, reduction of processing man-hours and cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

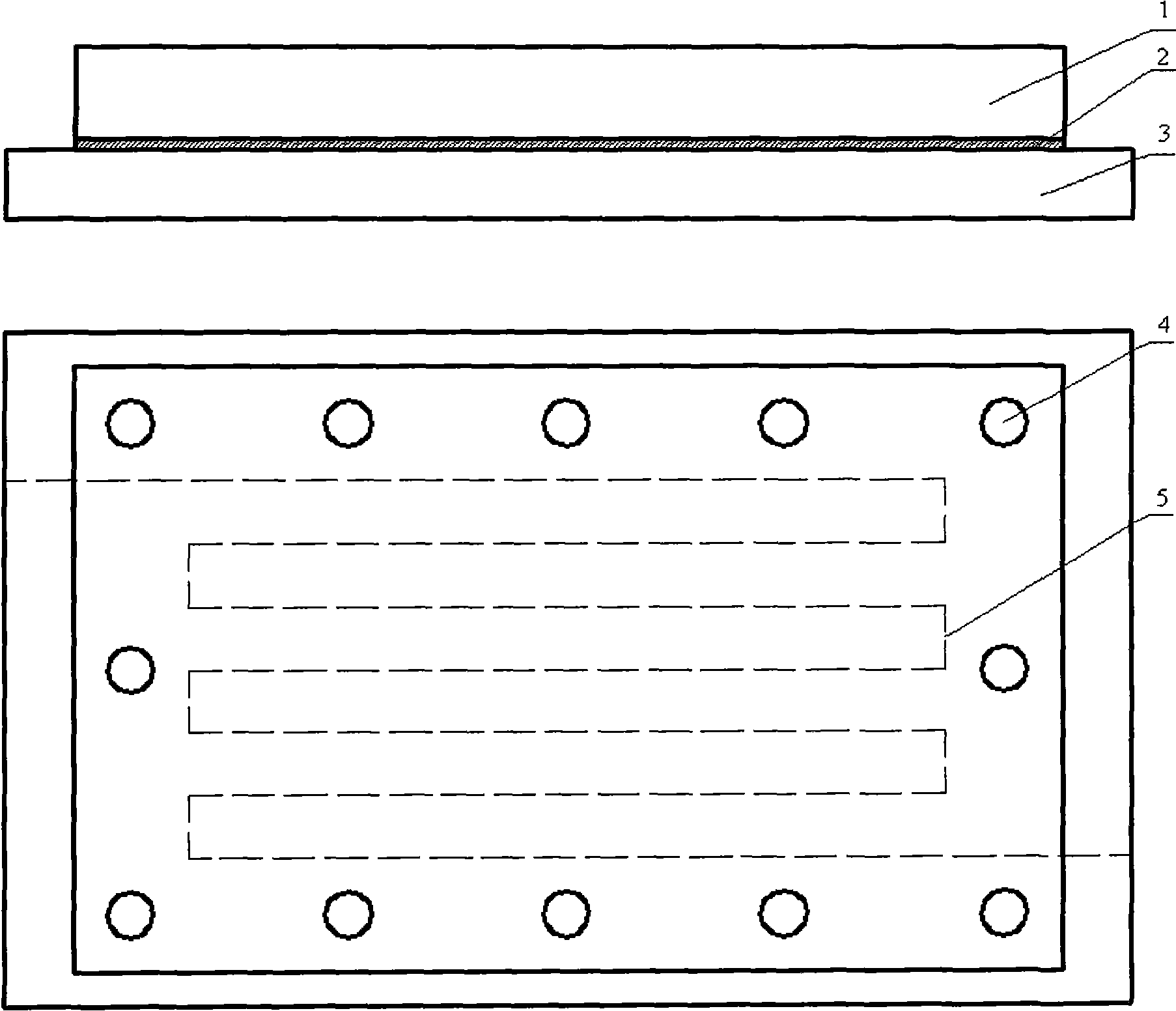

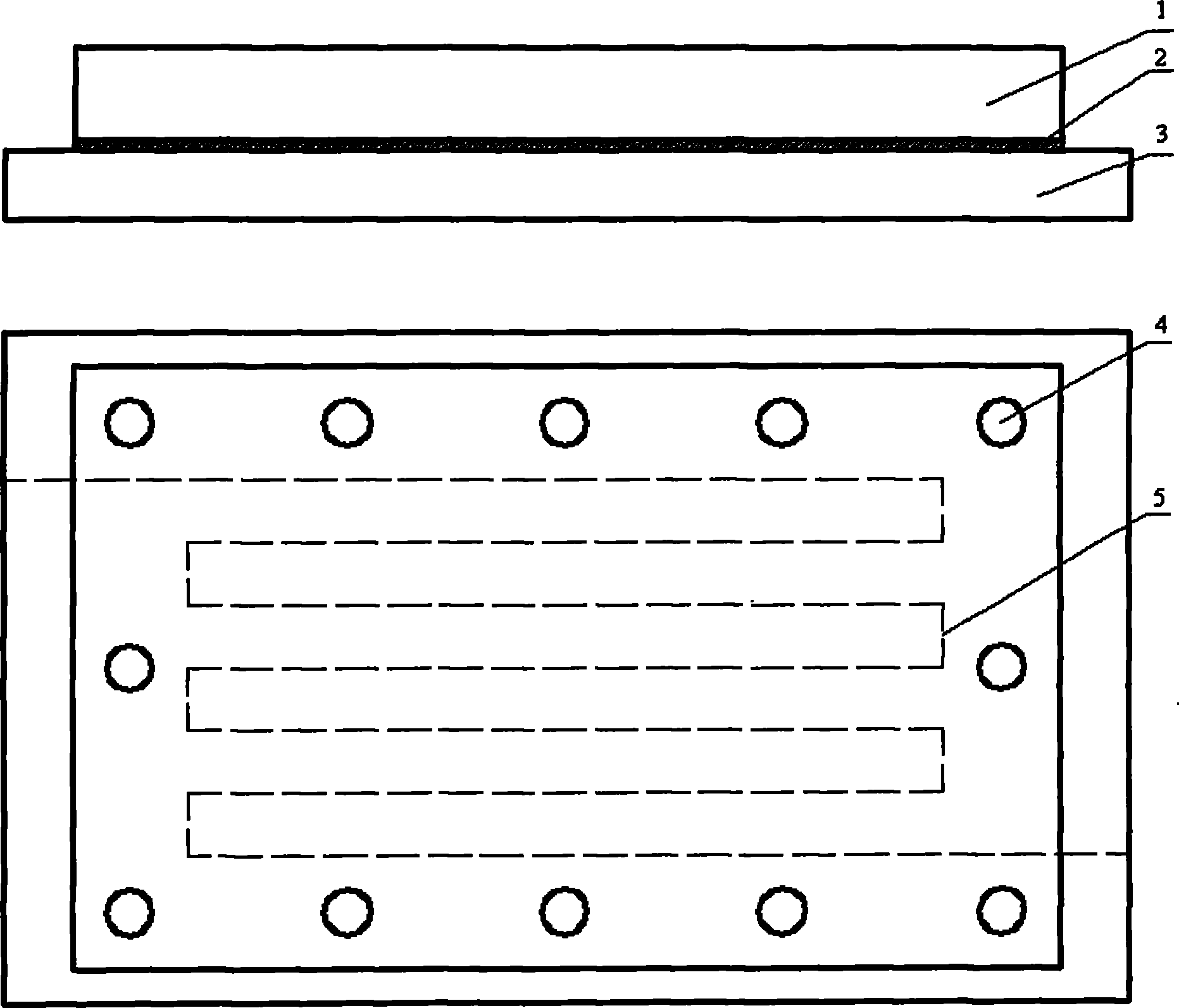

[0012] Specific embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

[0013] The water cooling radiator of the present invention is composed of a heat dissipation plate 1, a windshield glue 2 for automobiles, a heat dissipation plate 3, bolts 4, and a long rotary groove 5. It consists of two radiating plates 1 and 3 which are directly pressed together and sealed. The material of the radiating plates 1 and 3 can be made of aluminum or copper as required. Directly process the connected rotary long groove 5 on the heat dissipation plate that forms the radiator body. When assembling, the upper and lower plates are butted, so that the rotary long groove is sealed inside the radiator body to form a water channel. In order to strengthen the tightness of the pressing surface between the cooling plates and ensure that the water does not leak out when flowing through the gyratory tank, the windshield glass glue 2 for automo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com