Detecting and controlling method for liquid level of high-temperature solution

A control method and technology for high-temperature solutions, which are applied in liquid level control, non-electric variable control, control/regulation systems, etc., can solve the problems of difficulty in measuring the liquid level of high-temperature solutions, high rejection rate, and low measurement accuracy, so as to increase output and pass rate, reducing corrosion, and the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further elaborated below in conjunction with the accompanying drawings.

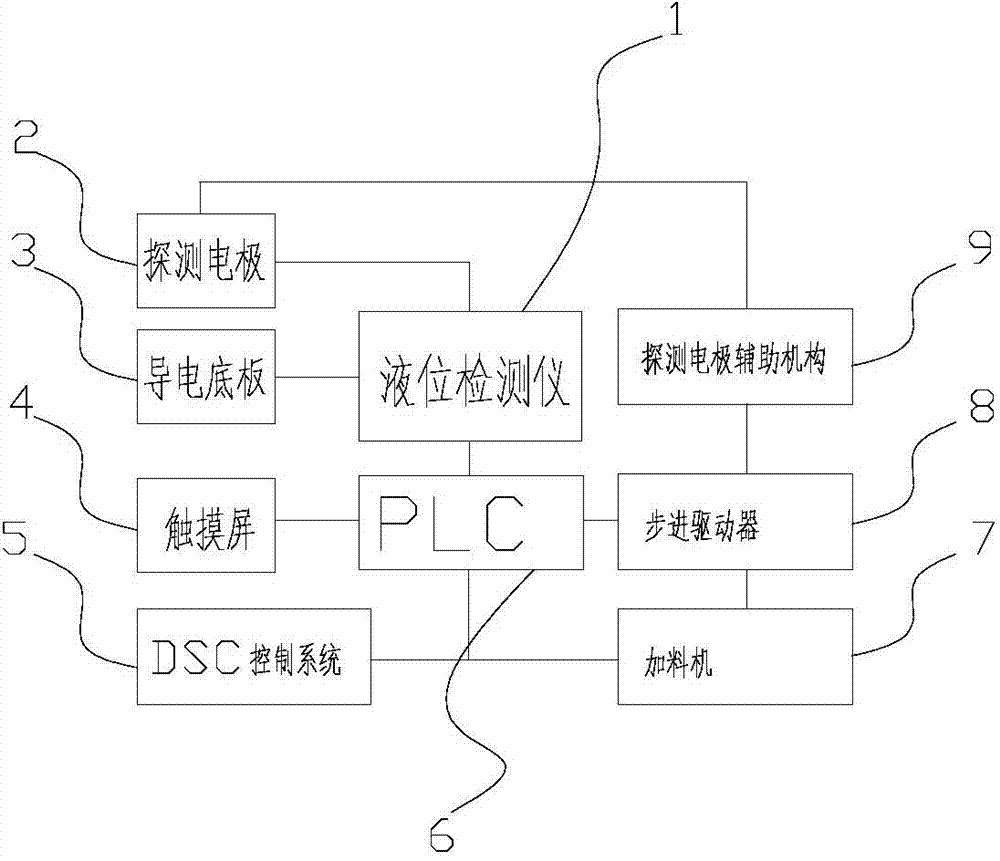

[0044] A detection and control method for the liquid level of a high-temperature solution, the detection and control method is realized based on a liquid level detection system, which includes:

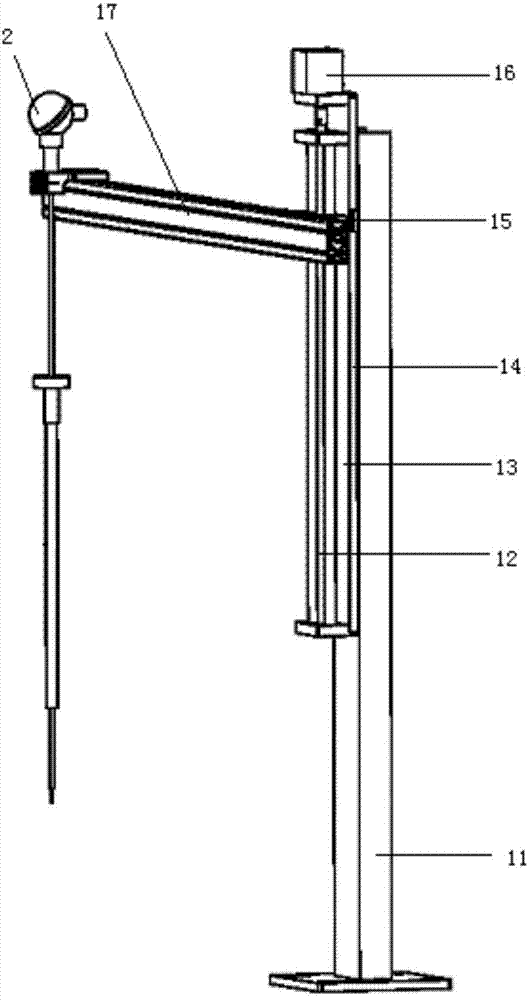

[0045] a. At the bottom of the high-temperature solution kiln, a conductive bottom plate 3 for transmitting radio signals is provided, and a detection electrode 2 for sampling radio signals is provided above the high-temperature liquid;

[0046] b. Control the detection electrode 2 to move close to the surface of the high-temperature liquid until the detection electrode 2 touches the high-temperature liquid, and the detection electrode 2 starts sampling to obtain a contact signal;

[0047] c. Control the detection electrode 2 to move away from the surface of the high-temperature liquid until the detection electrode 2 leaves the high-temperature liquid, and the detection elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com