Patents

Literature

132results about How to "Guaranteed continuous stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

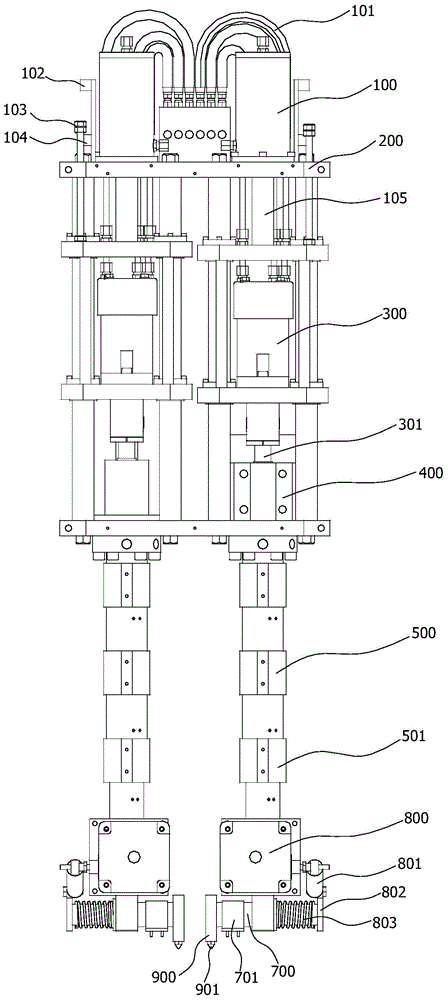

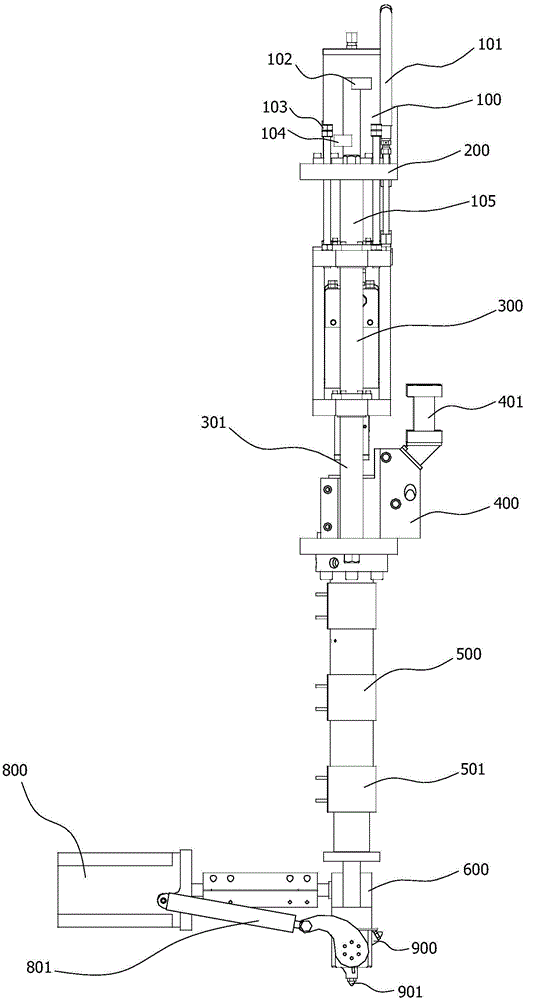

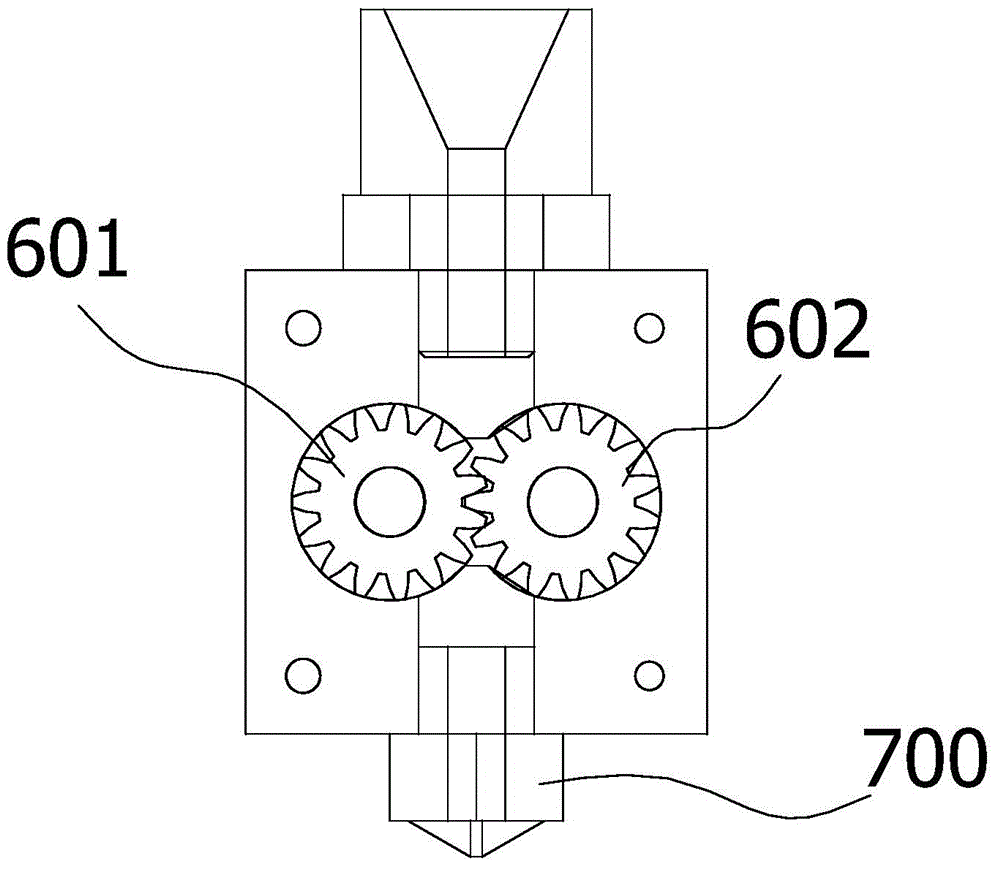

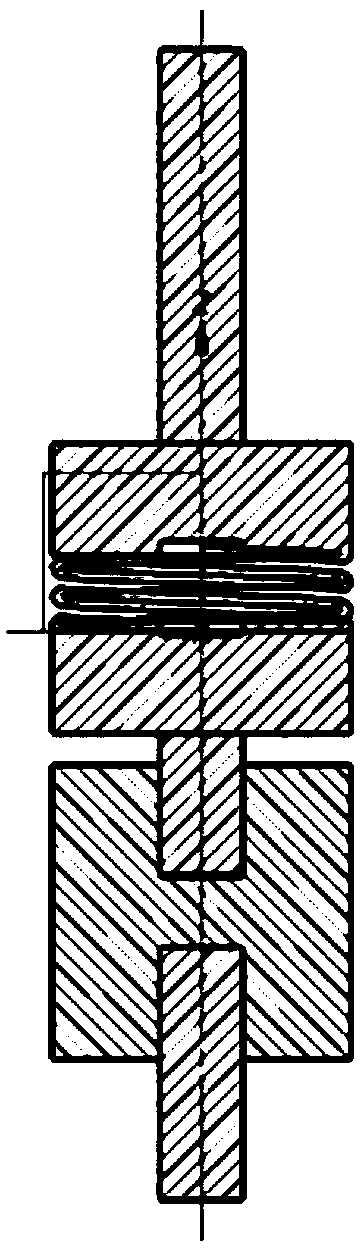

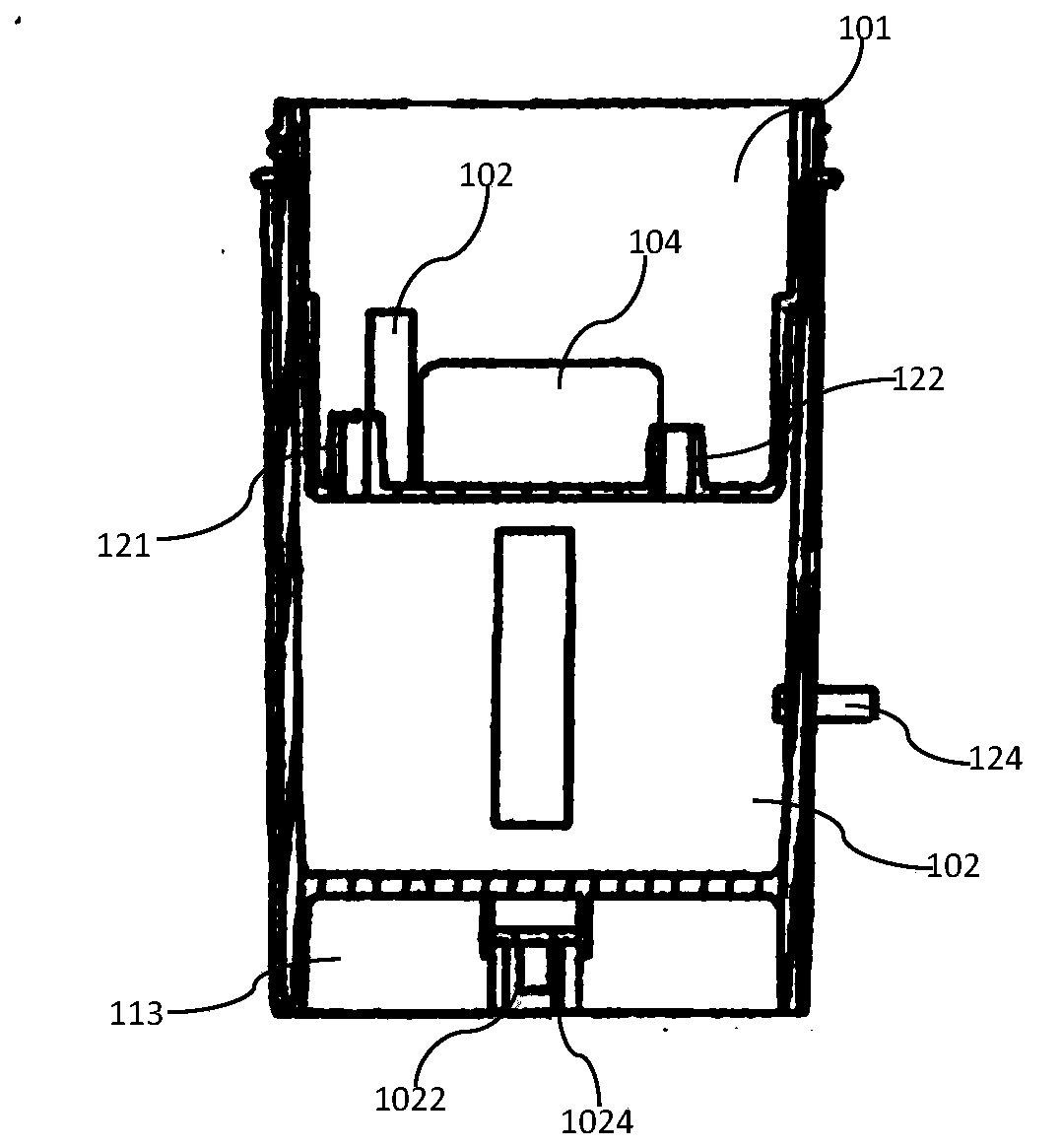

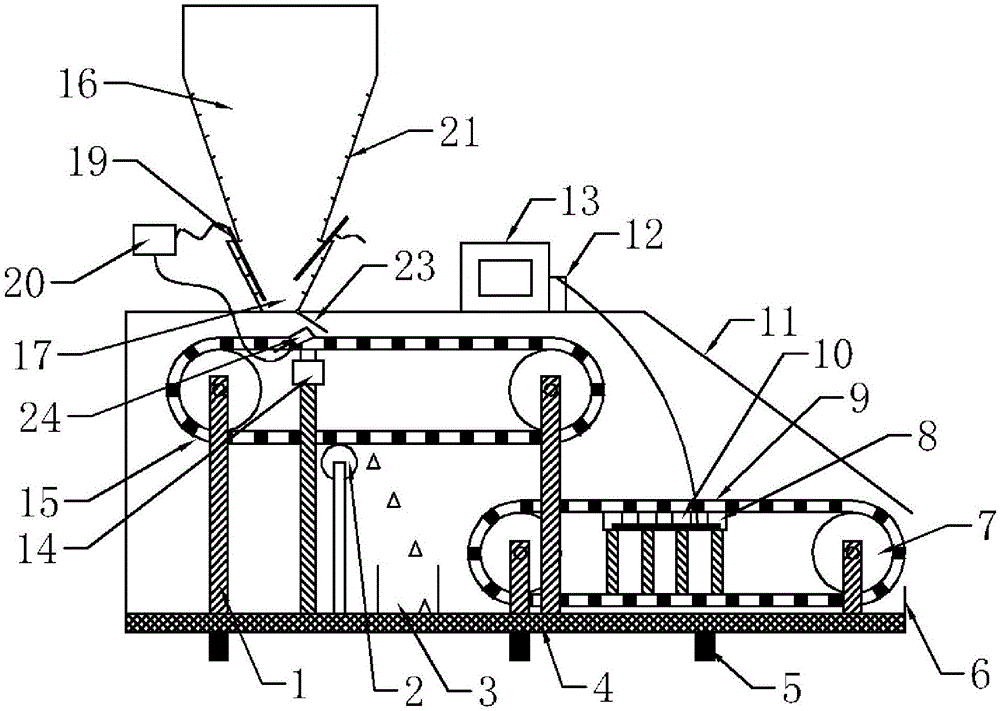

High-speed printing head of 3D printer

InactiveCN104552949AImprove liquidityInhibit refluxAdditive manufacturing apparatusHydraulic cylinderSpray nozzle

The invention discloses a high-speed printing head of a 3D (three-dimensional) printer. The printing head comprises a rack, wherein a hydraulic cylinder is fixed above the rack; a piston of the hydraulic cylinder is fixed with a feeding device capable of sliding up and down along the rack; an outlet of the feeding device is communicated with a nozzle structure through a volumetric metering pump; a feeding pipe is longitudinally arranged on the rack; the feeding device comprises a drive device and a screw rod driven by the drive device to rotate; the feeding pipe encircles the screw rod; a feeding hole is formed above the feeding pipe; a feeding hot-melting cavity is formed below the feeding pipe; the end of the screw rod is sleeved with a one-way valve; the nozzle structure comprises a nozzle pipe communicated with the volumetric metering pump; a multi-nozzle head is rotationally arranged at an outlet end of the nozzle pipe and provided with at least two nozzles with different pore diameters; when an opening, rotated to any nozzle, of the multi-nozzle head points to a workpiece, only the nozzle is communicated with the nozzle pipe; the multi-nozzle head is driven by a rotary power device to rotate. The printing head has the advantages that the printing speed can be increased while a high-precision printing effect is guaranteed.

Owner:SHENZHEN WANWEI IM TECH CO LTD

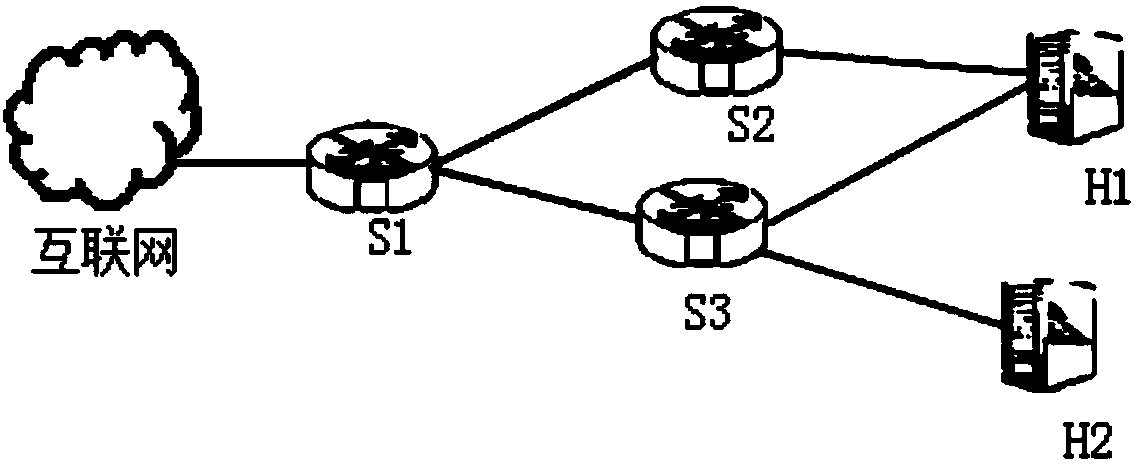

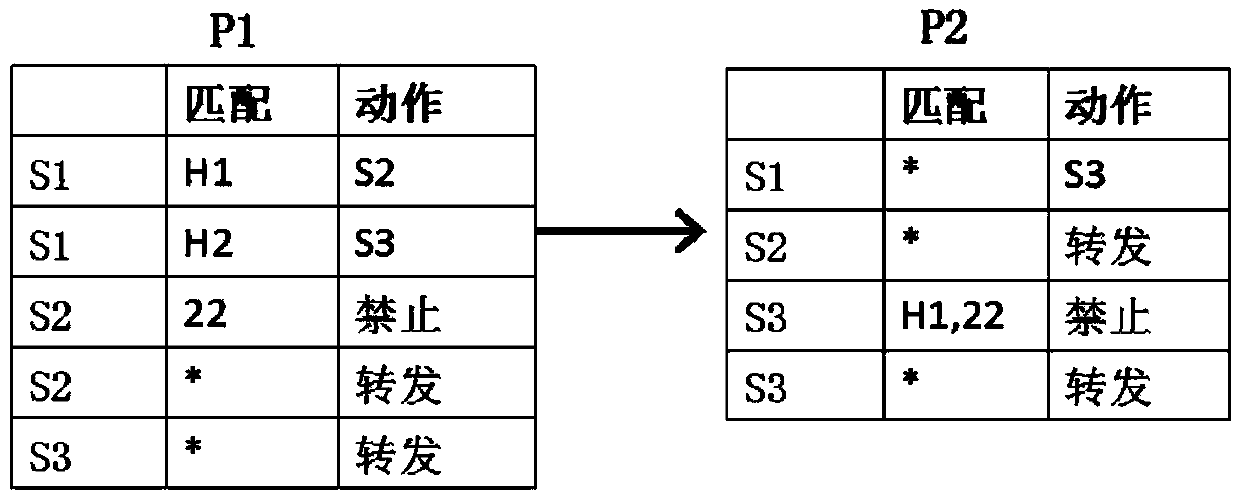

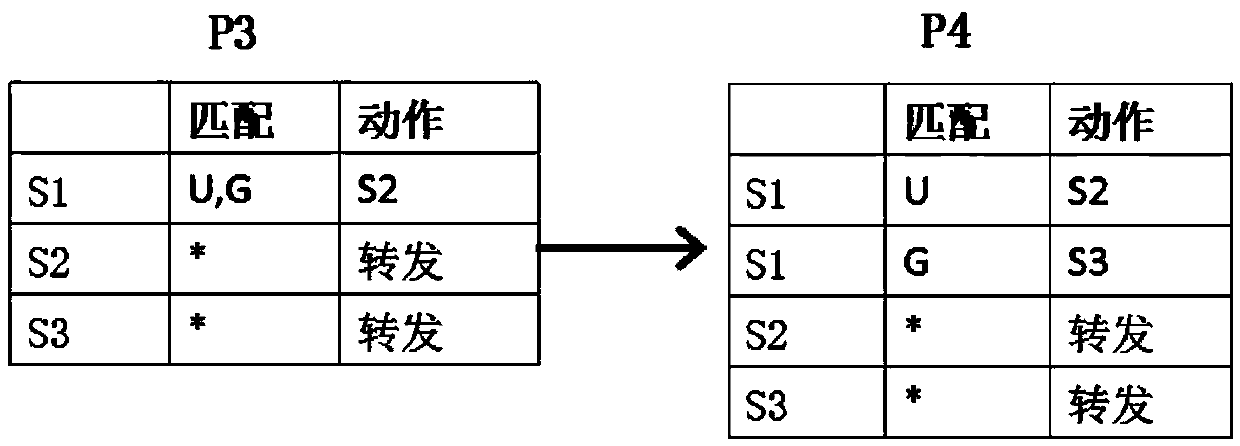

Method and device for solving SDN (software defined networking) flow level configuration consistency updating

InactiveCN104202183AGuaranteed continuous stabilityEnsure configuration consistencyData switching networksIp addressNetwork packet

The invention discloses a method and a device for solving SDN (software defined networking) flow level configuration consistency updating. The method comprises allocating version numbers to different configurations to process a data packet in an SDN through the configuration with the version number identical to that of the data packet; when configuration updating occurs, installing new configurations for an internal network, adding an old version number to the data packet when the data packet passes by a boundary network and processing the data packet through an old configuration when the data packet enter the internal network, wherein the new configurations do not affect the data packet and guarantee continuous and stable processing of existing flows through the old configurations, and then deleting the version number when the data packet flows out of the SDN; after the internal network finishing the updating, installing temporary configurations for the boundary network at a high priority to transmit flows influenced by the updating to a controller and to still process the flows through the old configurations, and installing the new configurations carrying the new version numbers for the boundary network at a low priority; structuring minimum K-prefix cover set covering existing flow IP (Internet protocol) addresses, and based on K prefixes, structuring configuration shards; deleting overtime shards, and performing periodical updating until all the shards are deleted to complete boundary network updating.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

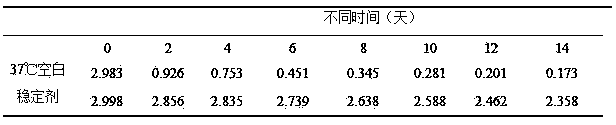

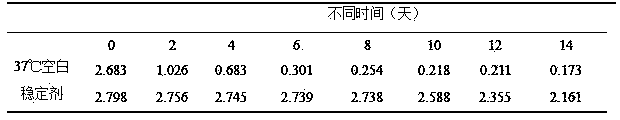

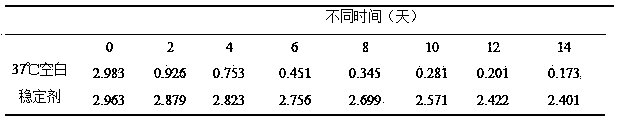

Long-acting ELISA plate stabilizing agent

ActiveCN103472222AGuaranteed continuous stabilityLow costMaterial analysisProtein activityBULK ACTIVE INGREDIENT

The invention relates to a long-acting ELISA (Enzyme-linked Immunosorbent Assay) plate stabilizing agent for keeping protein activity in an ELISA plate. The agent comprises 0.1-5g protein, 1-15g sugar, 0.1-10g organic matter, 0.01-0.1%(V / V) of preservative, and 10-200mmol buffer solution salt per 100ml water, and a pH (Potential of Hydrogen) value is 7.2-7.4. The stabilizing agent adopts a technical route integrating a closing process and a stabilization process, and can effectively close excessive sites in the ELISA plate, and some active ingredients in the stabilizing agent can ensure continuous stabilization of the ELISA plate. The agent is simple in formula, can stabilize the ELISA plate, and does not produce any influence on a result simultaneously. The ingredients of the agent are easy to obtain, and the formula is simple, so that the cost of the stabilizing agent is lowered.

Owner:河北渤腾医药技术有限公司

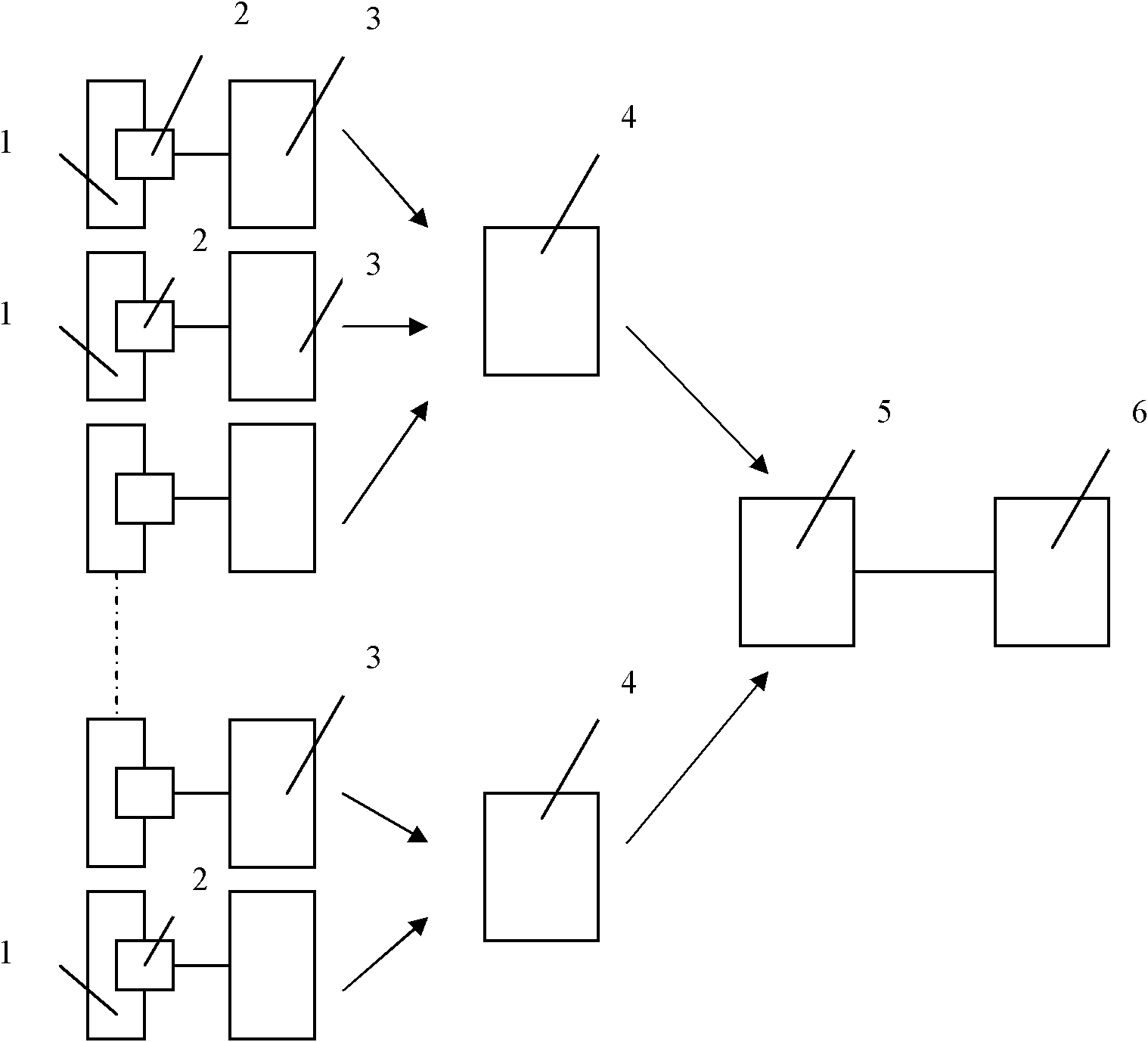

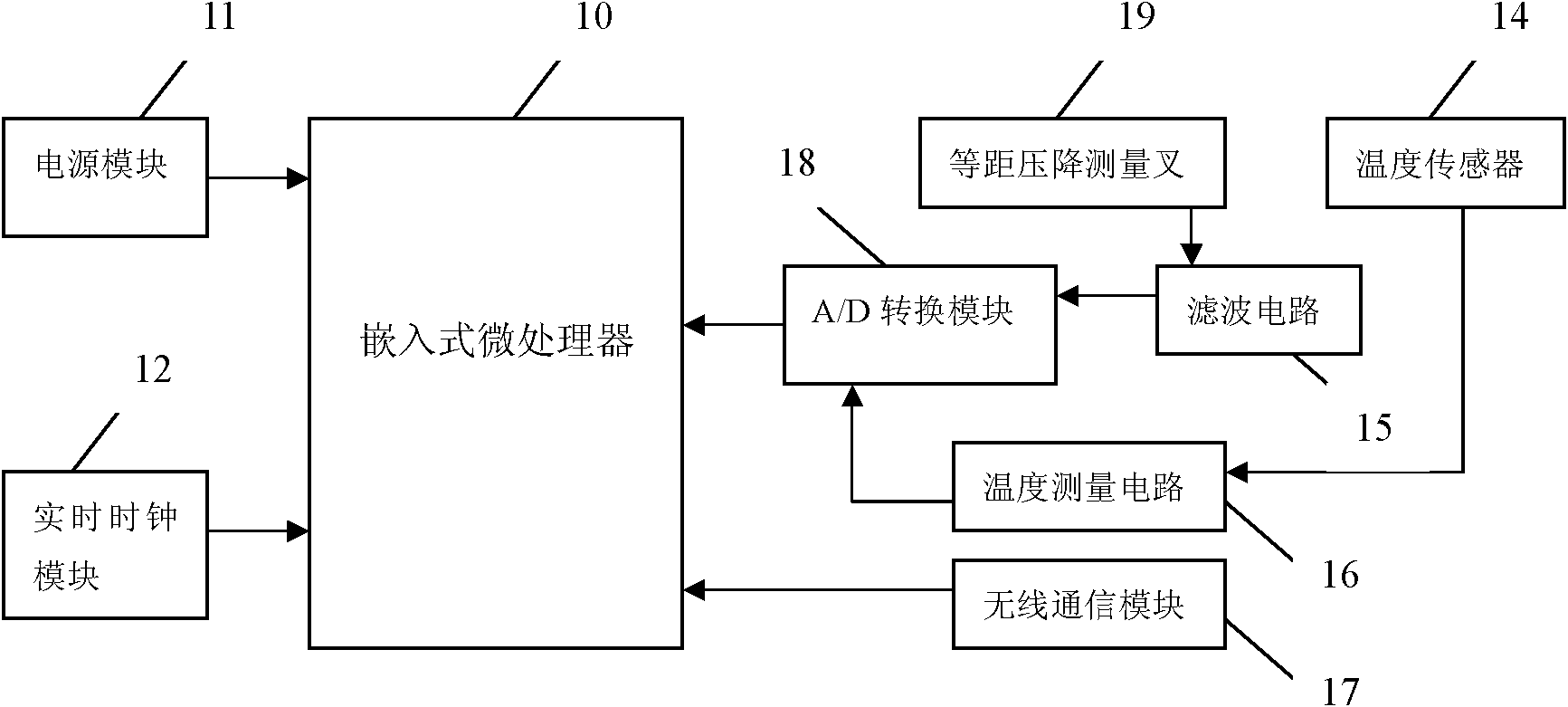

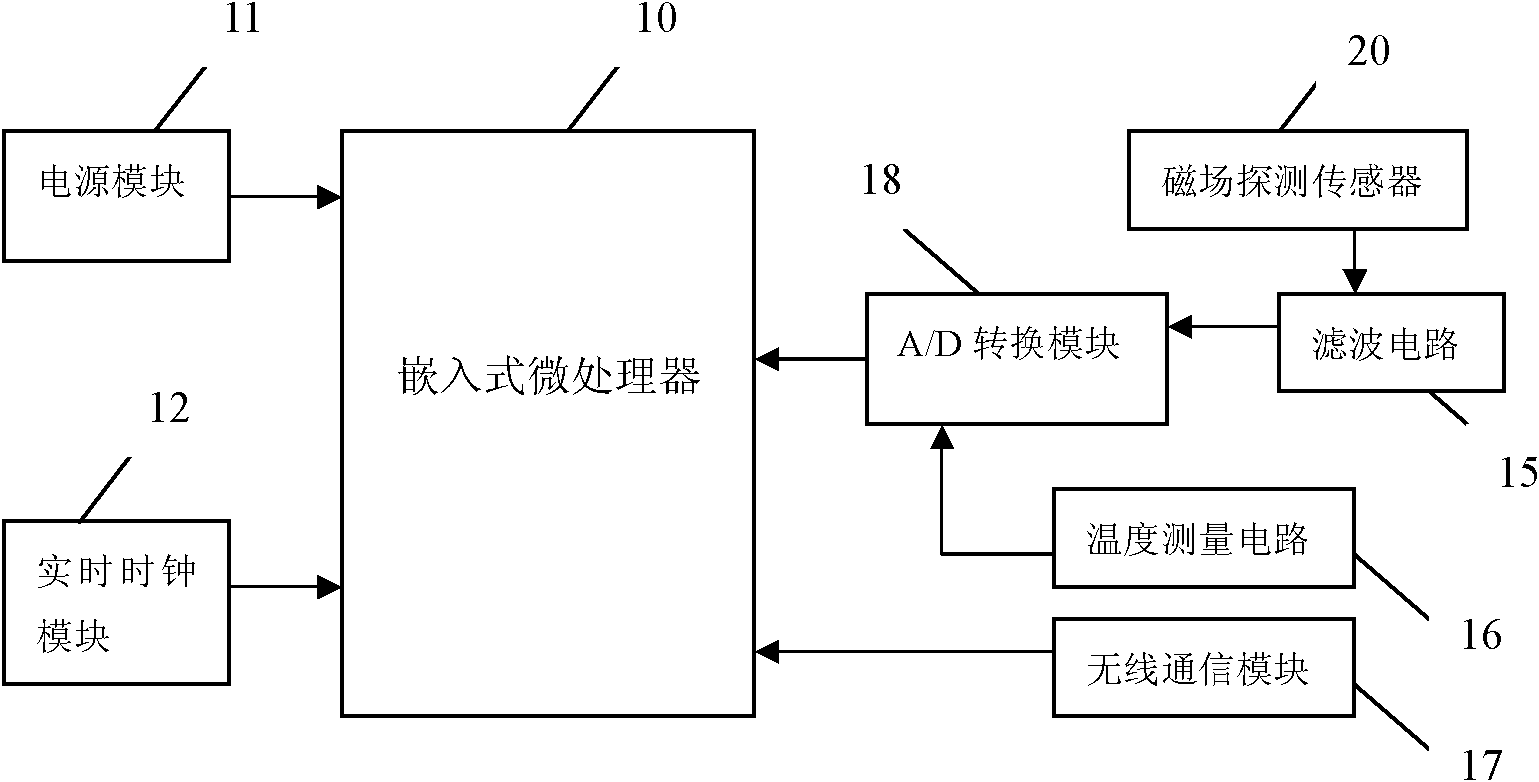

Online monitoring system for current distribution of aluminum electrolytic tank

The invention discloses an online monitoring system for the current distribution of an aluminum electrolytic tank, belonging to the technical field of aluminum electrolysis. The online monitoring system for the current distribution of the aluminum electrolytic tank comprises at least one measuring device comprising an isometric pressure drop measurement fork or a magnetic field detection sensor, the isometric pressure drop measurement fork is used for measuring the isometric pressure drop value of an anode guide rod or a cathode steel bar of the aluminum electrolytic tank to be tested, the magnetic field detection sensor converts the magnetic induction intensity around the anode guide rod or the cathode steel bar into a proportional voltage value according to a Hall principle, and the measuring device is sequentially connected with a data processing device, a wireless network and an upper computer. The invention satisfies the measurement requirements under high-temperature high-dust environment with high magnetic field intensity, has high system flexibility, is favorable to far-distance signal transmission and can simultaneously monitor a plurality of aluminum electrolytic tanks.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

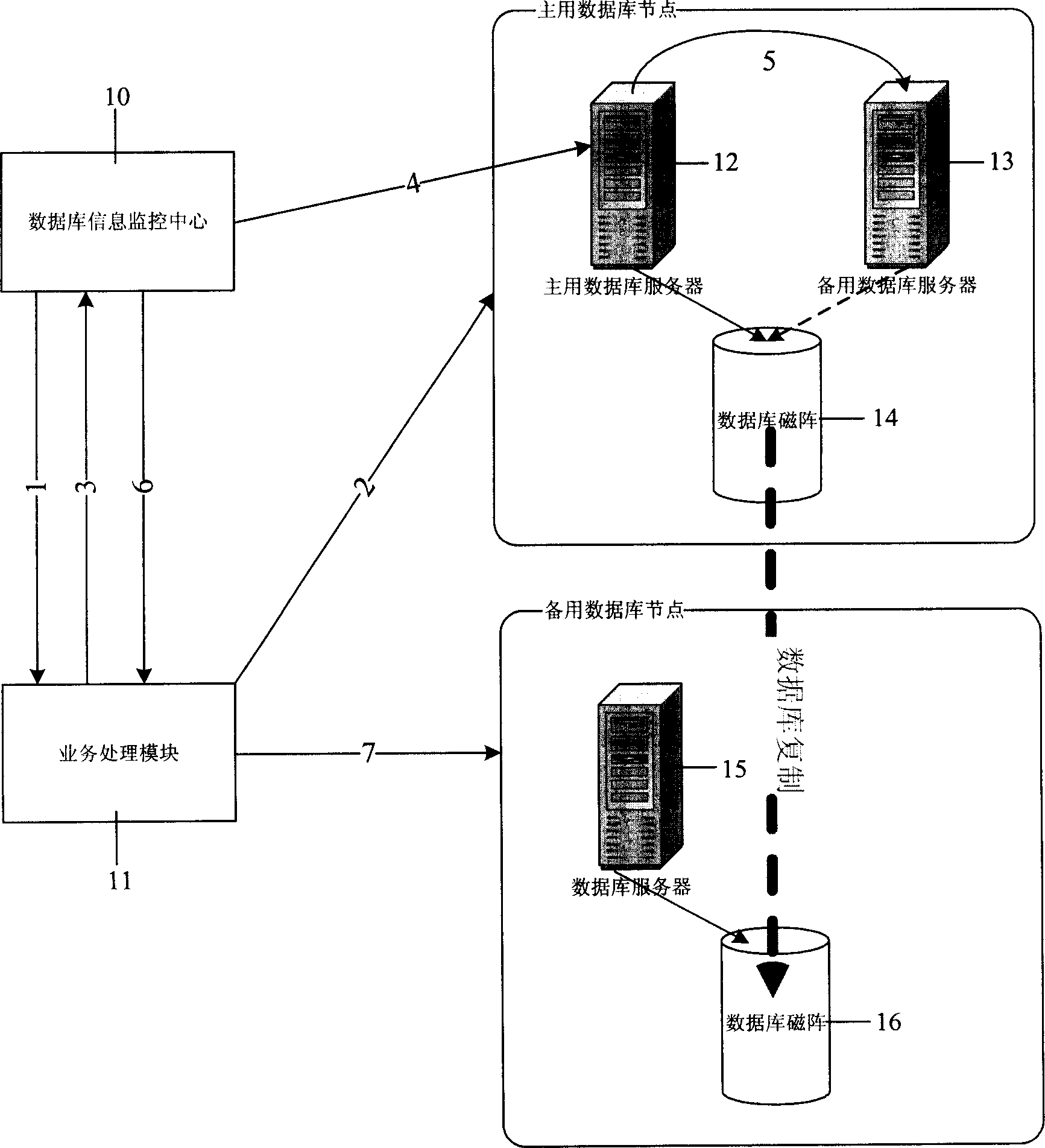

System for automatic switching database in imputation position register and method thereof

InactiveCN1848989AGuaranteed continuous stabilityWireless communicationProcessor registerComputer science

An automatic switch-over system of databank on attribution position register comprises service processing module connected to mainly used databank node, spare databank node for connected separately said module and mainly used databank node as well as used for copying data from mainly used databank node, databank information monitor center connected separately to said module and mainly used databank node as well as used for monitoring operation state in access to databank of said module according to data configuration of mainly used databank node and issuing switch-over command of databank when operation state of databank is abnormal.

Owner:ZTE CORP

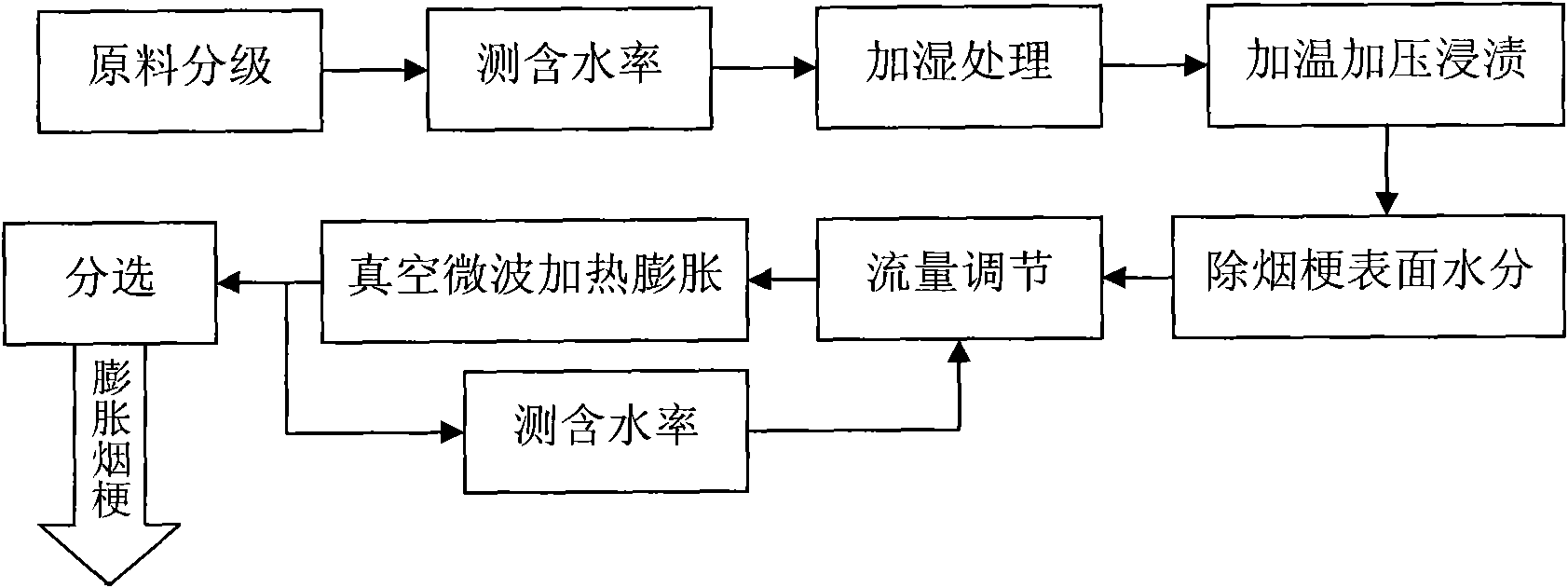

Tobacco stalk expansion method

InactiveCN101862023AUniform moistureUniform expansionTobacco preparationTobacco treatmentMicrowaveEngineering

The invention provides a tobacco stalk expansion method, which comprises the following steps of: grading tobacco stalks, performing impregnation remoistening on the graded tobacco stalks and expanding the tobacco stalks, wherein a microwave heating expansion method is adopted in the expansion of the tobacco stalks; preferably, the microwave heating expansion is performed on the tobacco stalks under a vacuum condition; more preferably, the microwave heating expansion is performed on the tobacco stalks by adopting more than two different kinds of continuous microwave output power under the vacuum condition, wherein the former two kinds of continuous microwave output power are 4.0 to 8.0 kw and 1.5 to 2.5 kw respectively for every kilogram of remoistened tobacco stalks; and the impregnation remoistening comprises the steps of: spraying water onto the tobacco stalks, and performing the impregnation remoistening under the pressure of 0.112 to 0.203 MPa and at the temperature of 50 to 100 DEG C. The expanded tobacco stalk has the characteristics of greater volume that is 1 to 3 times that of the conventional tobacco stalk, uniform expansion, remarkable fragrance, less wood smell, high resilience, the water content of 0.5 to 3 percent, high combustibility, improved intrinsic quality and relatively better smoke characteristic maintenance.

Owner:BEIJING INST OF AEROSPACE TESTING TECH

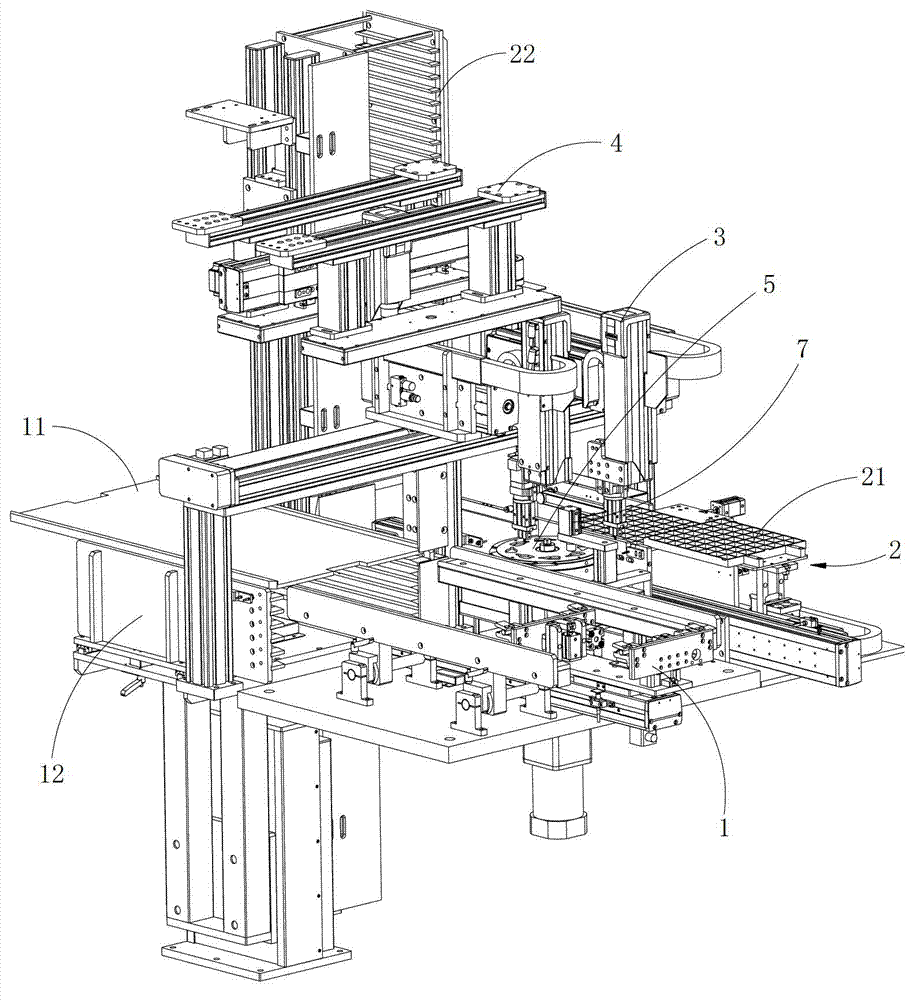

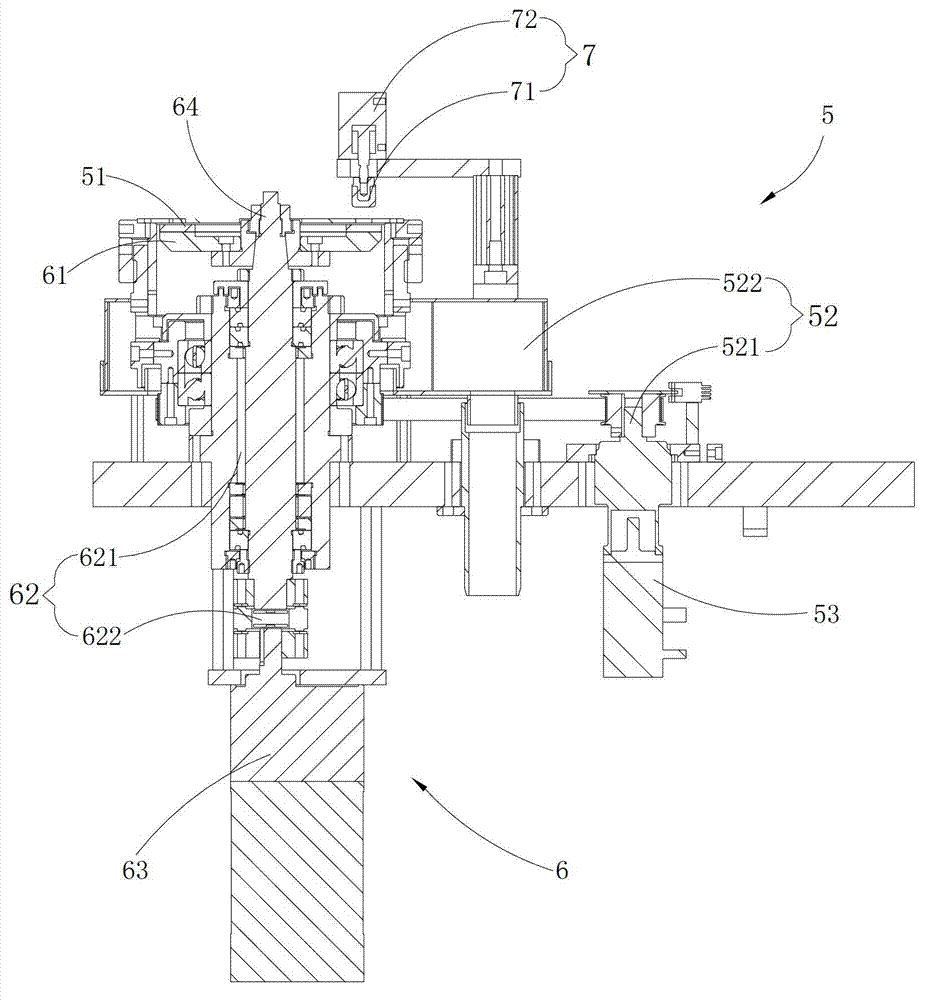

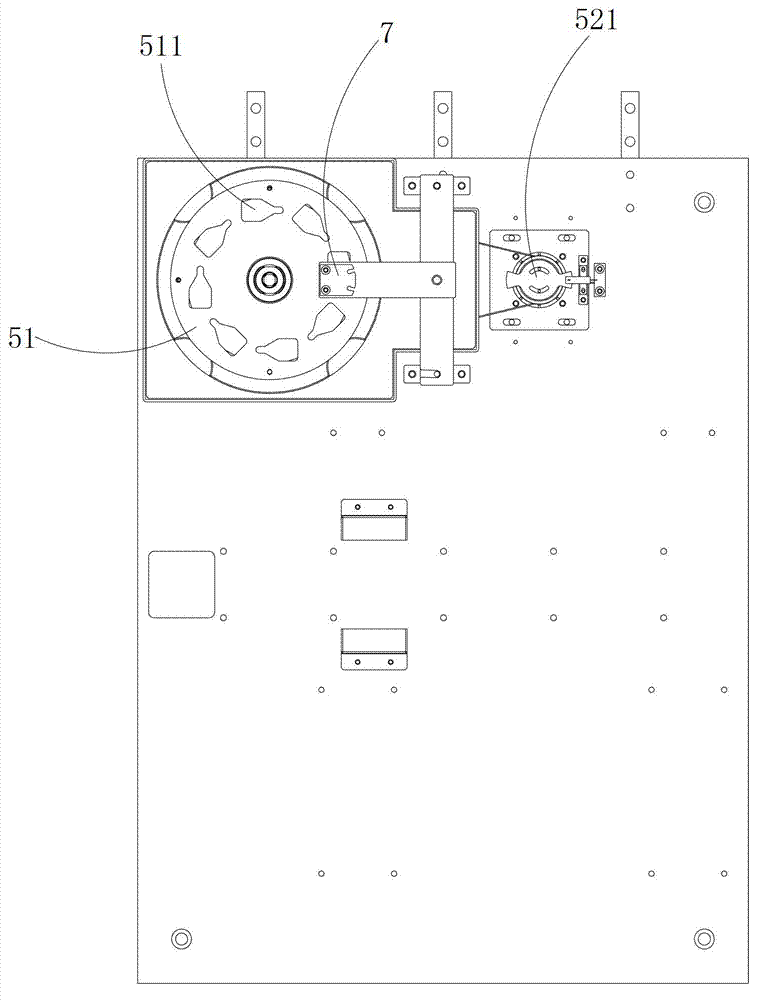

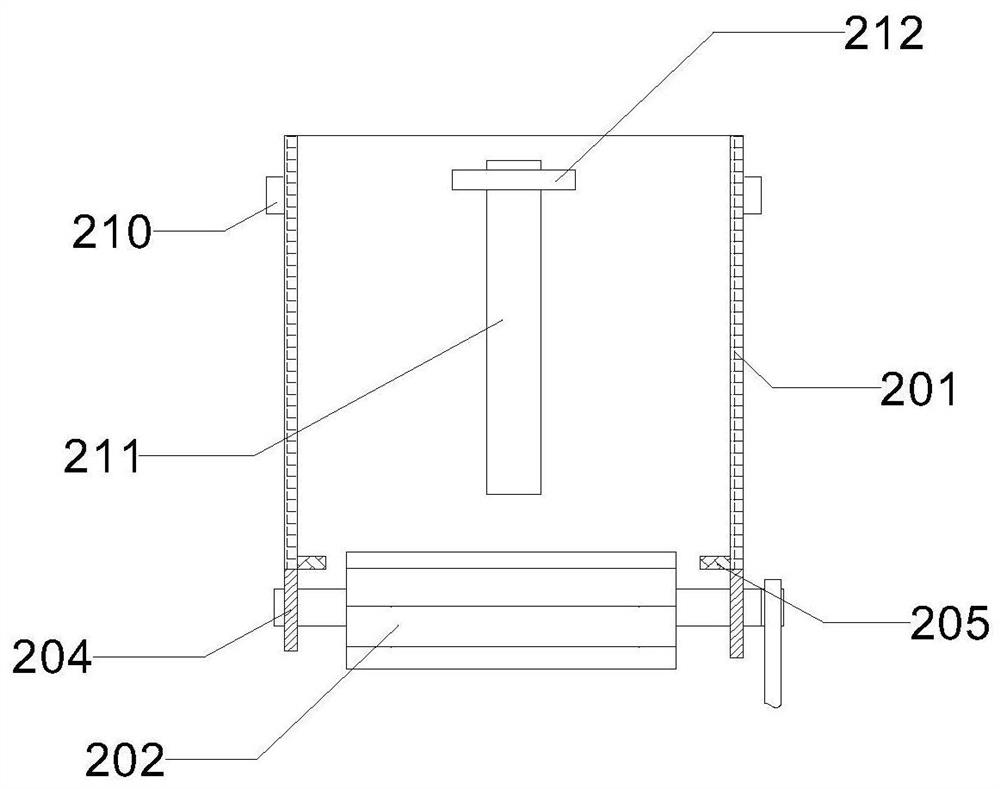

Material discharge device

ActiveCN103112714AImprove accuracyRemove in timeLapping machinesConveyor partsEngineeringUltimate tensile strength

The invention belongs to the product collecting and discharging technical field, and discloses a material discharge device. The material discharge device is used for sequentially collecting and discharging of products, wherein the material discharge device comprises a feed mechanism, a material collecting mechanism, a tracking and positioning mechanism, a mechanical hand assembly and a control center. The feed mechanism comprises a feed material plate, a feed material support and a first transmitting mechanism, the material collecting mechanism comprises a material collecting material plate, a material collecting material support and a transmitting platform, and the tracking and positioning mechanism comprises a positioner and a first push rod assembly. The mechanical hand assembly is used for clipping and collecting the products which are arranged disorderly on the feed material plate on the material collecting material plate, and therefore the purpose of sequentially collecting and discharging the products is achieved; the tracking and positioning mechanism is used for tracking and positioning locations of the products, and therefore an accuracy rate of clipping the products of the mechanical hand assembly is effectively improved. Further, the control center is used for uniformly controlling operation of all parts, and therefore the material discharge device is high in automation degree, accurate and reliable in action, and capable of reducing labor intensity of people, reducing output of labor cost, and improving working efficiency.

Owner:SHENZHEN SHENLAN PRECISION MACHINERY

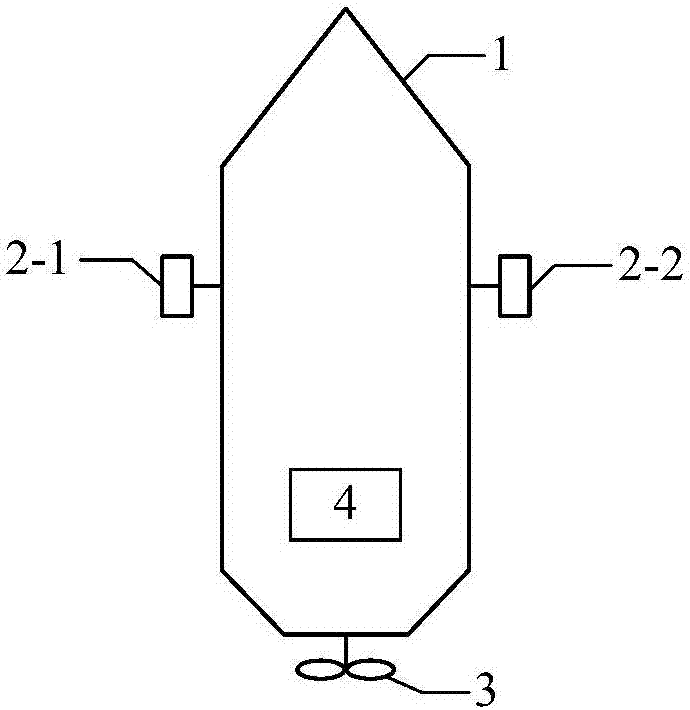

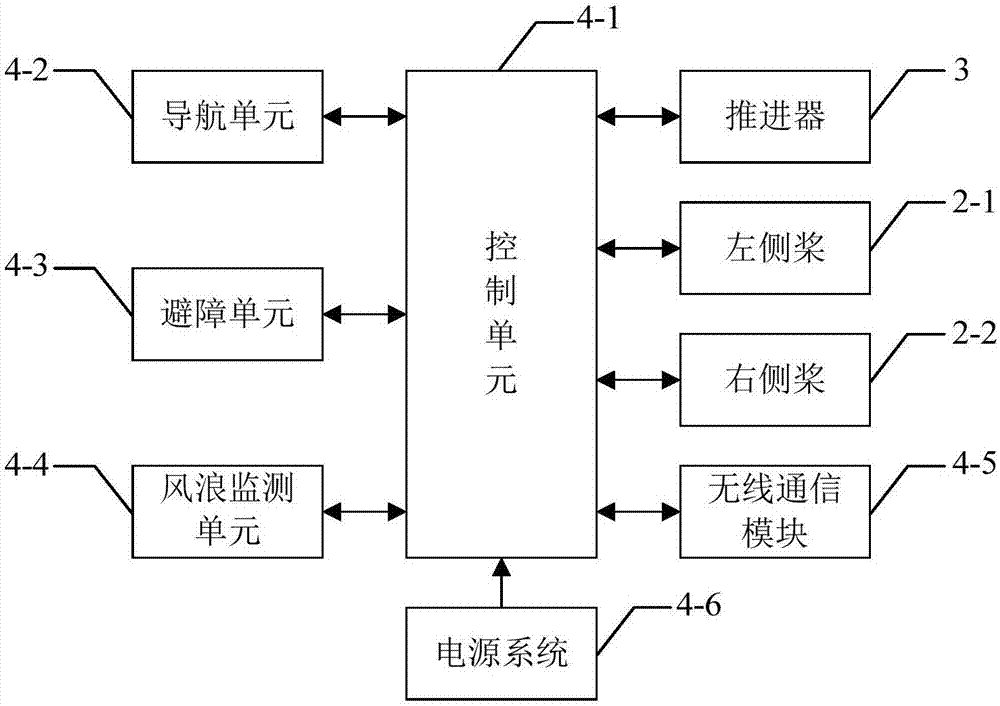

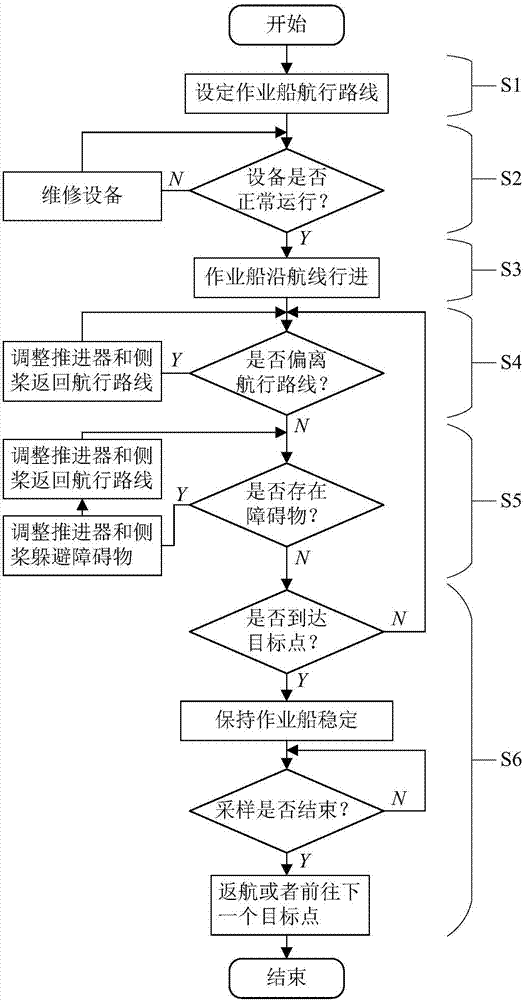

Online automatic control method for dual direction-changing side paddles of lake and reservoir workboat

ActiveCN106950960AFlexible motion controlEfficient sailingPosition/course control in two dimensionsStable stateAutomatic control

The invention discloses an online automatic control method for dual direction-changing side paddles of a lake and reservoir workboat. The workboat mainly comprises a boat body, side paddles, a propeller and a monitoring system. The monitoring system comprises a control unit, a navigation unit, an obstacle avoidance unit, a wind-wave monitoring unit, a wireless communication module and a power supply system. The method comprises the steps of setting a sailing path of the workboat; detecting the working state of the workboat; controlling the moving state of the workboat; performing adjustment on deviation of the workboat from the sailing path; performing adjustment on obstacle avoidance of the workboat; and keeping a stable state of the workboat at a target point. According to the invention, the propeller and dual side paddles capable of adjusting the speed in direction changing are used, and the control unit is utilized to control the direction and the rotating speed, so that efficient sailing of the workboat in various moving modes is realized. Meanwhile, the working state of the workboat is monitored by using a sensor, so that the flexibility of motion control for the workboat is enhanced, influences imposed on the workboat by wind and water flow are effectively resisted, and the workboat is enabled to keep stable at the target point under interference of wind and waves.

Owner:DALIAN UNIV OF TECH

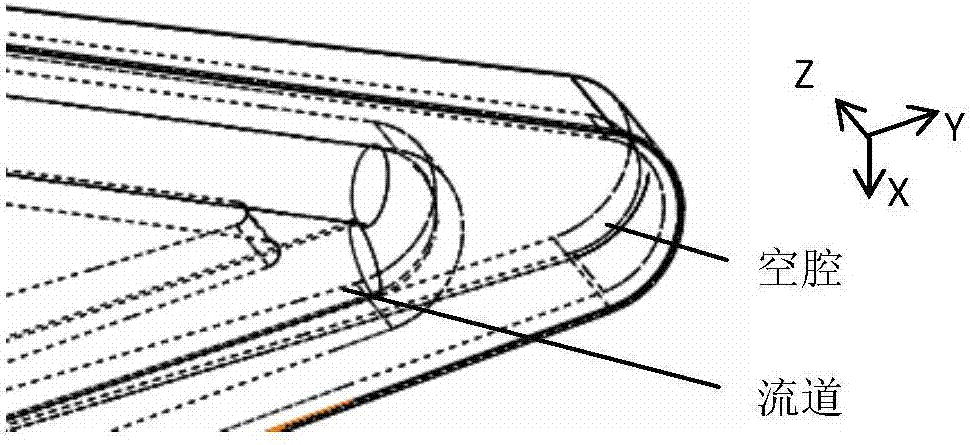

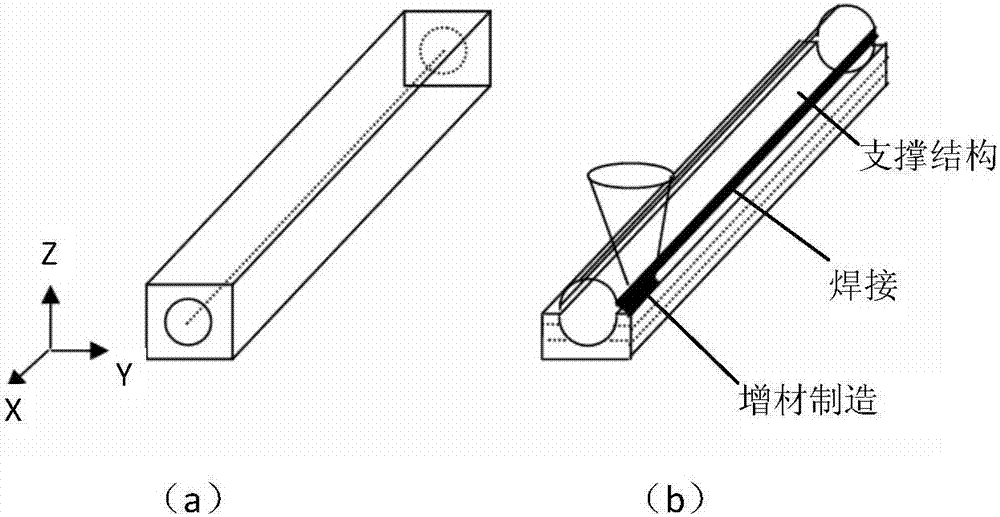

Laser additive manufacturing method for multi-support surface structure of cavity thin-wall structural part

ActiveCN107321979AMeet the manufacturing processGuaranteed surface qualityAdditive manufacturing apparatusIncreasing energy efficiencySuperalloyLaser additive manufacturing

The invention discloses a laser additive manufacturing method for a multi-support surface structure of a cavity thin-wall structural part, and belongs to the technical field of laser additive manufacturing. The method adopts a laser additive manufacturing technology to form a high-temperature alloy cavity thin-wall structural part; the direction of maximum orthographic projection area of the structural part is selected as an additive manufacturing accumulation direction; in the additive manufacturing process, the lower part of the part structure cavity position is subjected to additive manufacturing; after the lower part of the cavity position is formed, a support structure with the same material is welded in the corresponding position of the formed part; and then, the support structure is used as support, and the additive manufacturing is continuously performed on the outer surface of the support structure until the whole structural part is formed. The method can realize stable and efficient formation of large cavity thin-wall structure.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

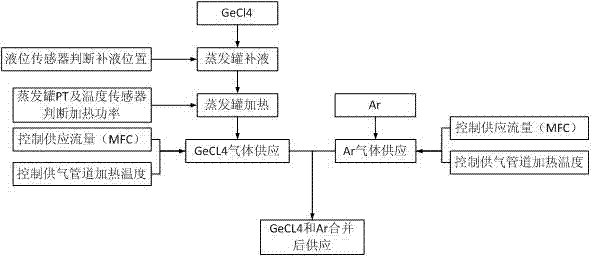

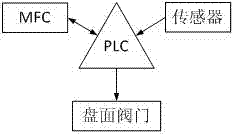

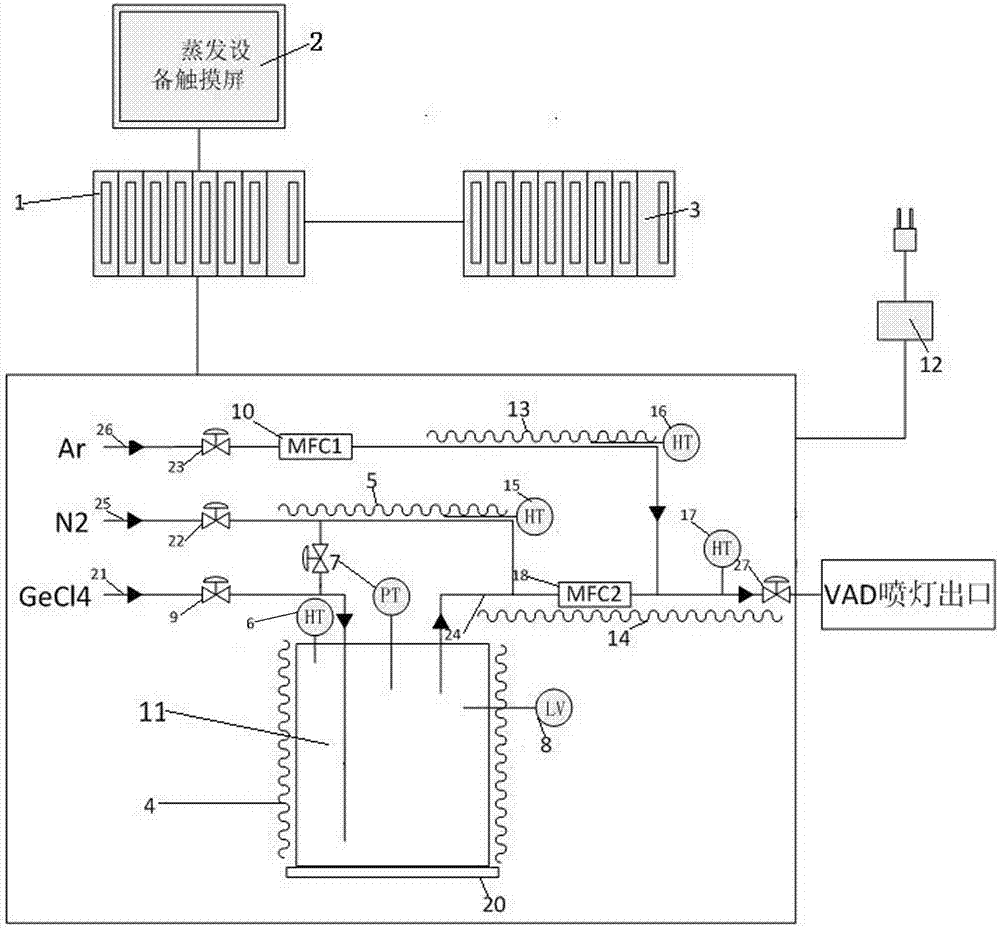

High-precision germanium tetrachloride (GeCl4) supplying method and high-precision germanium tetrachloride supplying equipment

ActiveCN103803790AReal-time monitoring and control of refractive index profilesPrecise control of the refractive index profileGlass making apparatusProgrammable logic controllerEngineering

Owner:ZHONGTIAN TECH ADVANCED MATERIALS CO LTD +1

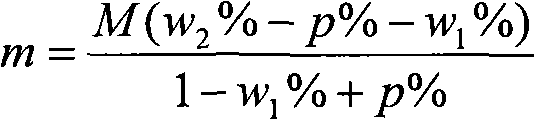

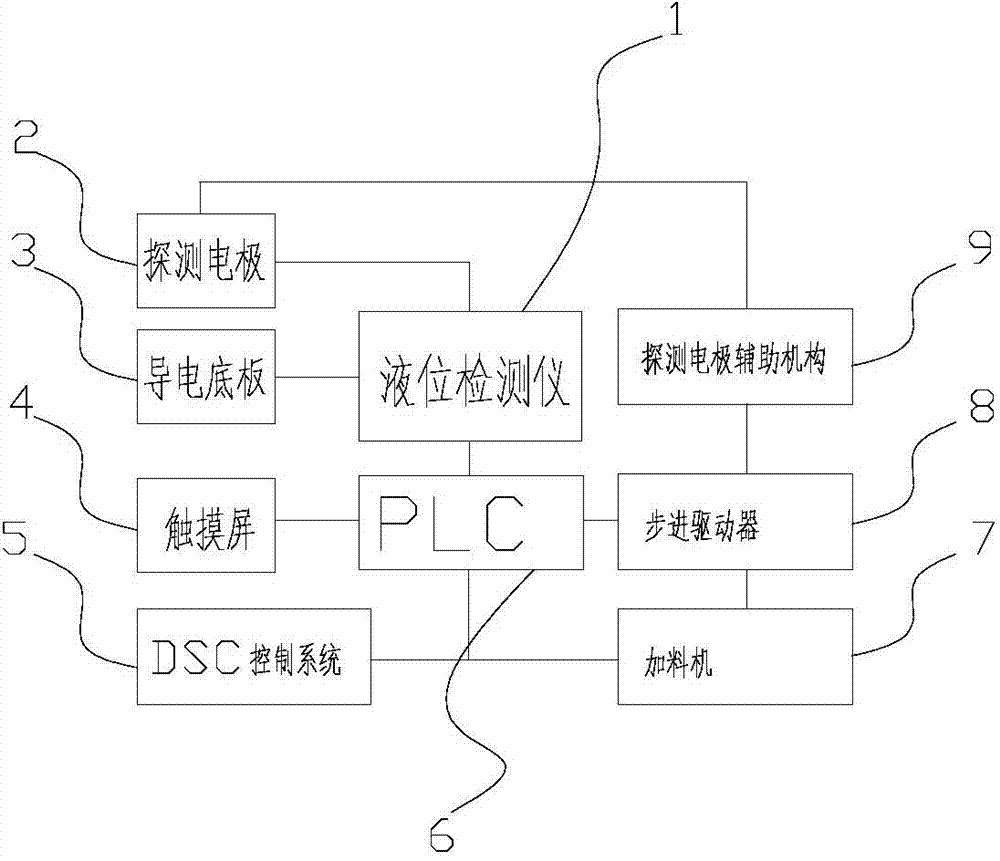

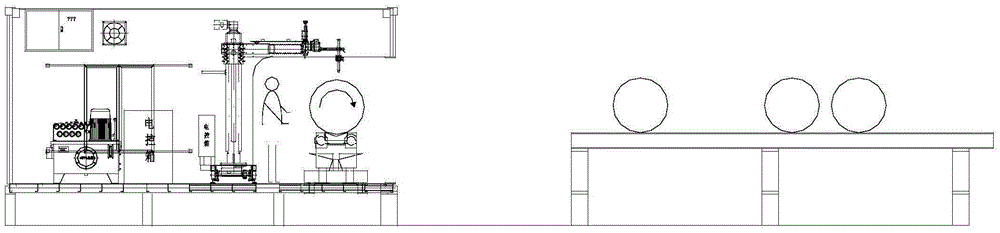

Detecting and controlling method for liquid level of high-temperature solution

ActiveCN104267752AImprove yield and yieldReduce contact timeLevel controlLevel indicators by physical variable measurementProgrammable logic controllerWaste product

The invention discloses a detecting and controlling method for the liquid level of a high-temperature solution. The detecting and controlling method is characterized in that an electric conduction baseboard used for transmitting electric wave signals is arranged at the bottom of a high-temperature solution kiln; an exploring electrode used for sampling the electric wave signals is arranged above the high-temperature solution and controlled to move close to the surface of the high-temperature solution until the exploring electrode is in contact with the high-temperature solution, and the exploring electrode starts to sample to obtain contact signals; the exploring electrode is controlled to move far away from the surface of the high-temperature solution until the exploring electrode is separated from the high-temperature solution, and the exploring electrode starts to sample to obtain falling-off signals; a liquid level detector receives the contact signals and the falling-off signals generated from the above steps and transmits the signals to a PLC (Programmable Logic Controller); the liquid level height is obtained through PLC treatment; based on the liquid level height obtained from the above step, and the feeding frequency is obtained through the formula shown in the specification. According to the invention, the detecting and controlling method has the benefits that the liquid level can be kept stable continuously, the technical index in the kiln can be guaranteed to reach technological requirements, the yield and the qualified rate of products can be improved, and the rejection rate is low.

Owner:SICHUAN AEROSPACE TUOXIN BASALT IND

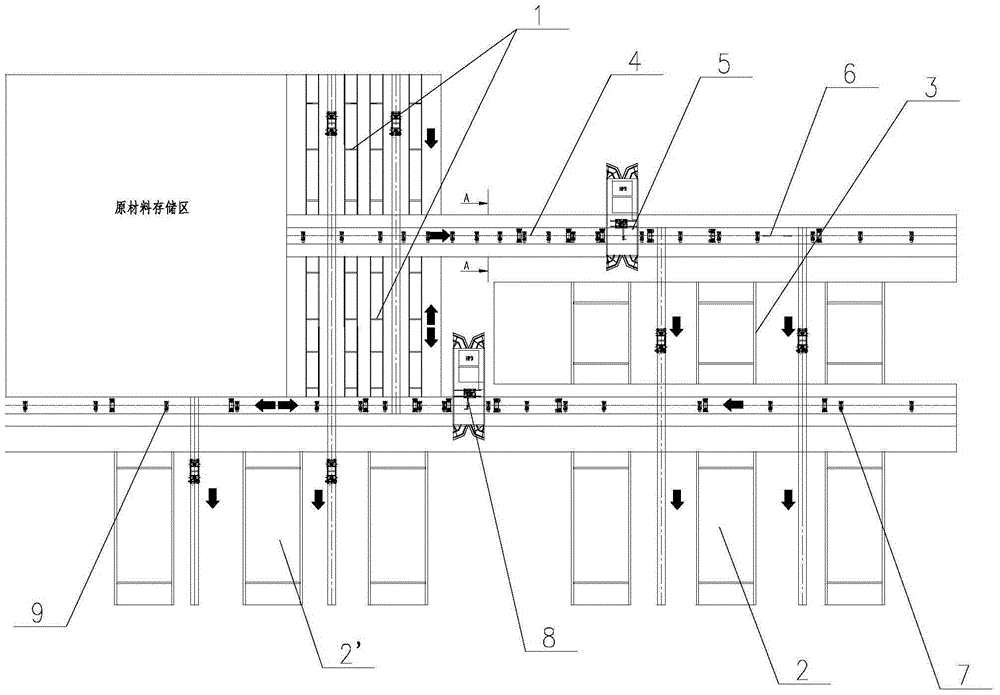

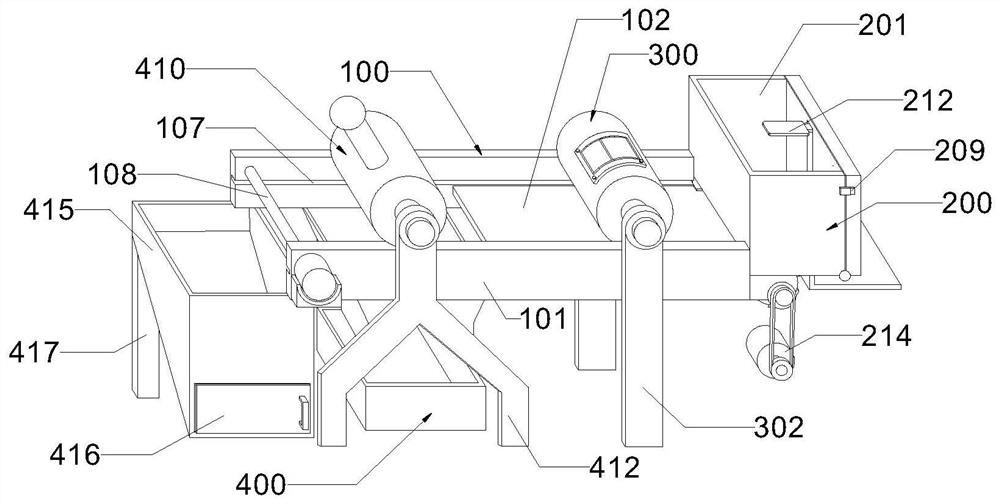

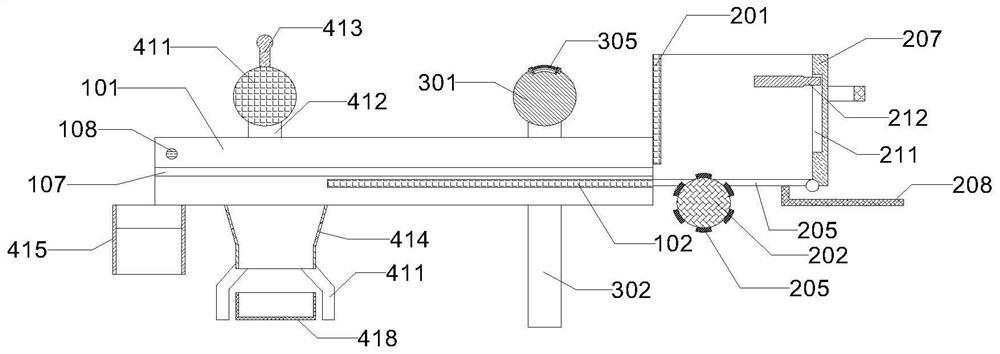

Automatic logistics production line for lengthening and prefabricating of two-in-one pipeline

ActiveCN105197496AAchieve mass productionImprove work efficiencyConveyor partsMechanical conveyorsProduction lineButt welding

The invention discloses an automatic logistics production line for lengthening and prefabricating of a two-in-one pipeline. A first conveying roller way is arranged between two raw material shelf storage areas; the two raw material shelf storage areas are connected to a first butt welding station area through the first conveying roller way; the discharge opening of the first butt welding station area is connected to a buffer material shelf storage area through a second conveying roller way; a discharge opening in the other side of the buffer material shelf storage area is connected to a first finished product material shelf storage area; a third conveying roller way is arranged between the first finished product material shelf storage area and the buffer material shelf storage area; the first finished product material shelf storage area and the buffer material shelf storage area are connected to a second butt welding station area through the third conveying roller way; a fourth conveying roller way is arranged at a discharge opening in the other side of the second butt welding station area; one side of the fourth conveying roller way is connected to one raw material shelf storage area; a second finished product material shelf storage area is arranged on the other side of the fourth conveying roller way. By adopting the automatic logistics production line disclosed by the invention, the working efficiency is improved greatly and the labor intensity is reduced; similar production rhythms are generated among all stations, the logistics route is short, and buffer areas are arranged among the stations reasonably, so as to ensure continuity and stability of production.

Owner:南京奥特自动化有限公司

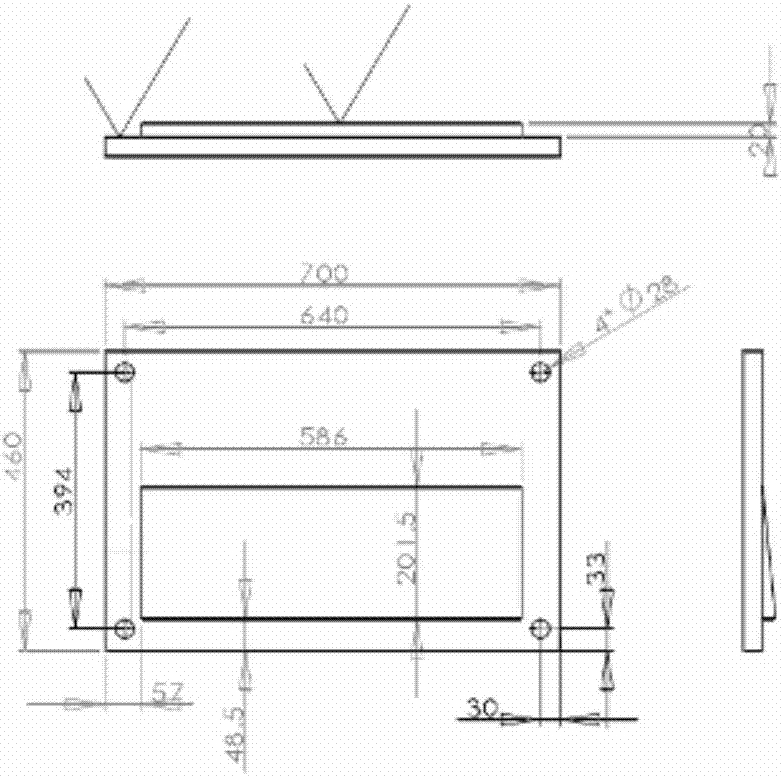

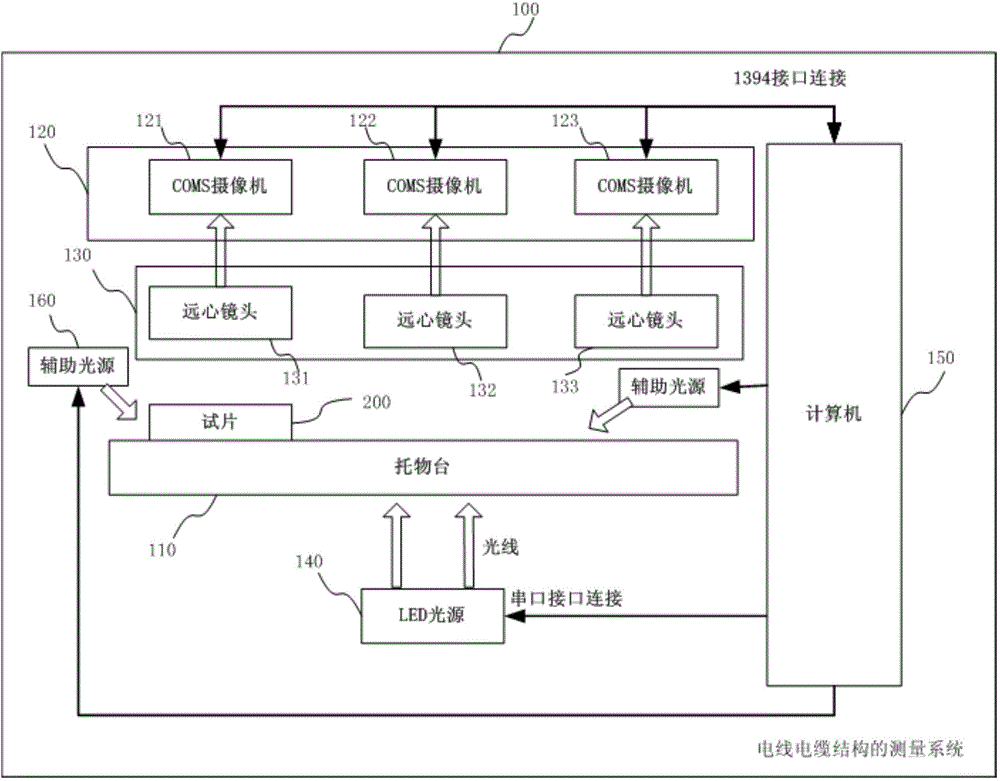

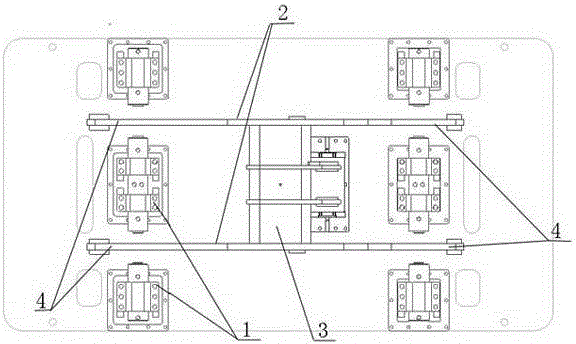

Measuring system for electric wire structure

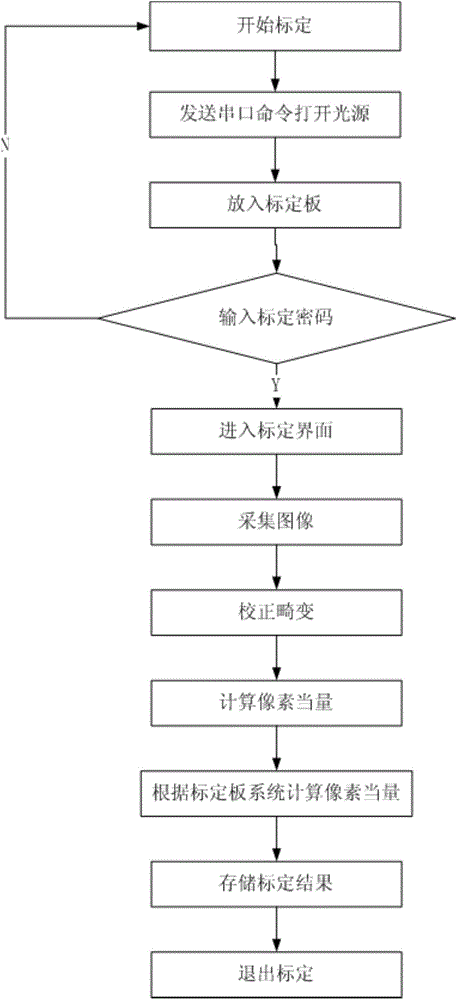

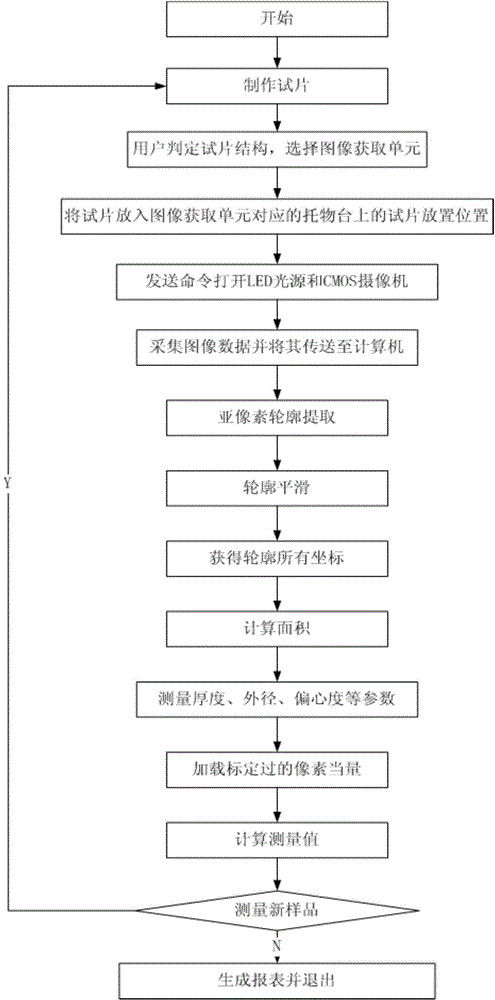

ActiveCN104567680AGuaranteed continuous stabilityHigh precisionUsing optical meansElectric cablesElectric wire

The invention provides a measuring system for an electric wire structure. The measuring system comprises an object supporting table, a computer, an LED light source and a plurality of image obtaining units. The image obtaining units are located on the upper side of the object supporting table and have different pixels. The image obtaining units are connected with the computer, and a plurality of test piece carrying positions are arranged on the object supporting table. The test piece carrying positions correspond to the image obtaining units; a user primarily selects the corresponding image obtaining units according to the diameter of an electric wire, and test pieces are placed on the corresponding test piece carrying positions; the image obtaining units are used for obtaining the images of the test pieces and transmitting the images to the computer, and the computer conducts processing and calculating according to the images. The LED light source is installed facing the image obtaining units and provides the overall light sources for the test pieces. According to the measuring system, the computer is used for automatically conducting detection, a measuring result can be obtained only within a few seconds, and the measuring of electric wires with a large diameter range can be achieved with high precision, high efficiency and high stability.

Owner:SHANGHAI JONSON CABLES TECH

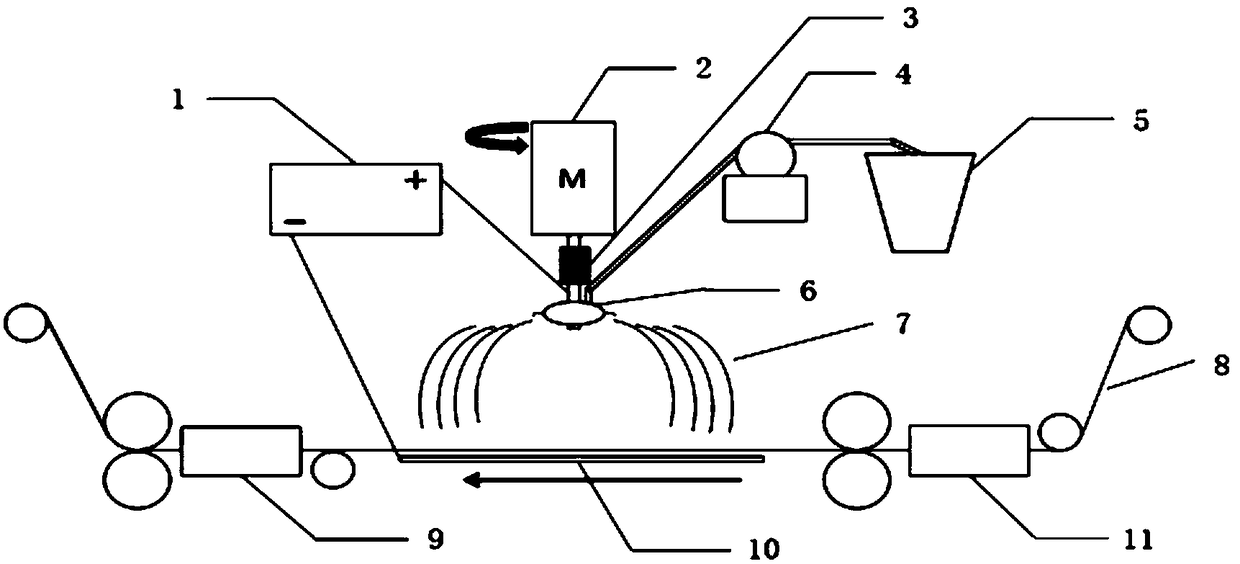

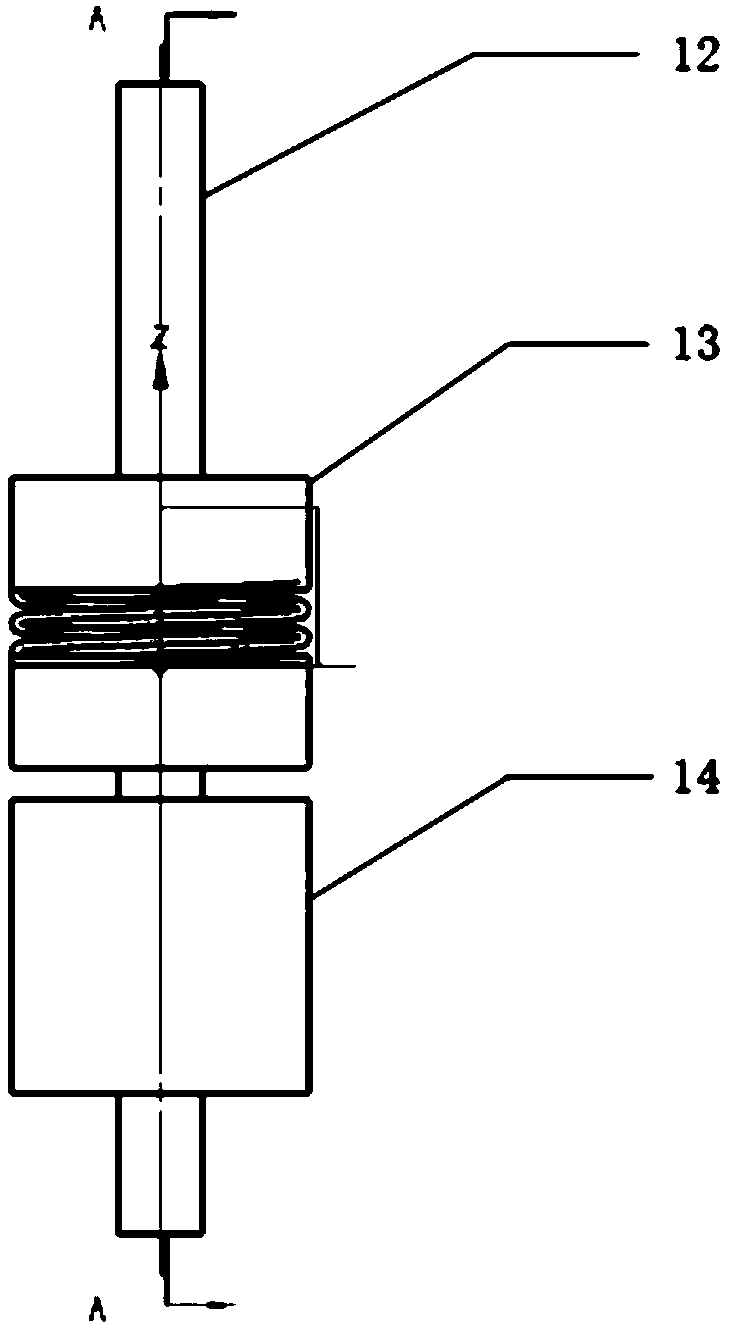

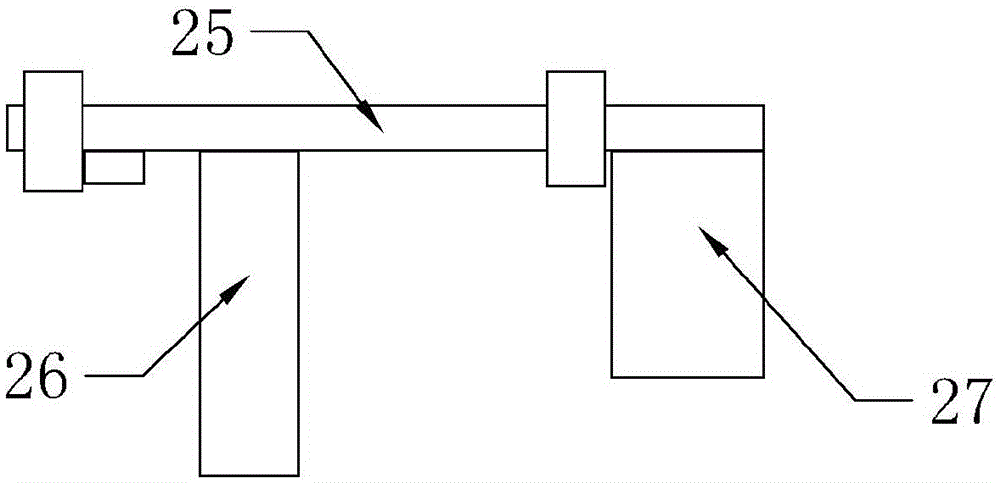

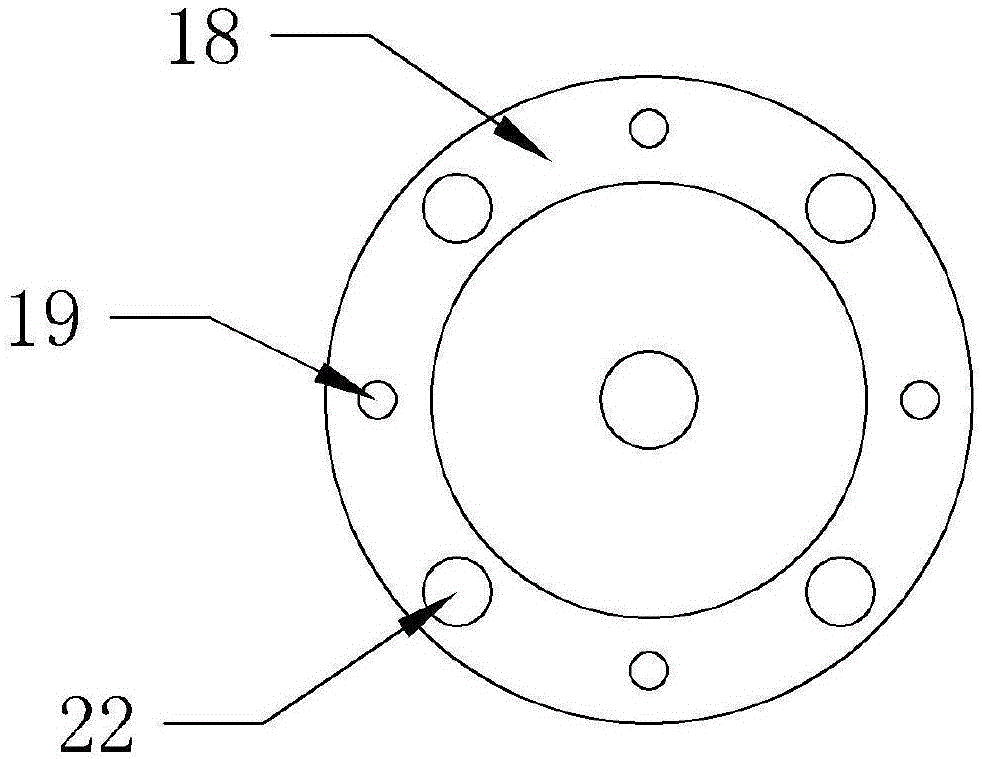

Device for continuously and efficiently forming yarn from reinforced nanofiber and spinning method

InactiveCN108796682AImprove production efficiencyMultiple choiceFilament/thread formingContinuous wound-up machinesYarnFiber

The invention relates to the technical field of textile processing, and aims to provide a device for continuously and efficiently forming yarn from reinforced nanofiber and a spinning method. The device comprises a vertically installed motor, and a rotating shaft at the bottom of the motor is connected with a spinneret through a coupler; a plurality of spinneret holes are uniformly distributed inthe circumferential direction of the spinneret; after the collected yarn is led out from a fixed yarn drum, the yarn sequentially passes through a twister and an untwister and is wound into a spool bya winding roller; a conductive plate is arranged below the collected yarn between the twister and the untwister in parallel, and is perpendicular to the rotating shaft of the motor; the conductive plate is connected to the negative electrode of an electrostatic generator through a cable; the spinneret made of metal is connected to the positive electrode of the electrostatic generator through a cable, so that the spinneret and the spinneret holes have electrical conductivity; the collected yarn is subjected to rough modification and charge addition treatment. The nanofiber in the method is obtained through an electrostatic centrifugal spinning method, and the preparation efficiency is high; the spinning raw materials are soluble and meltable, the conductivity requirement of a spinning solution is not high, the selectivity is higher, and the yield of the nanofiber yarn is high.

Owner:ZHEJIANG SCI-TECH UNIV

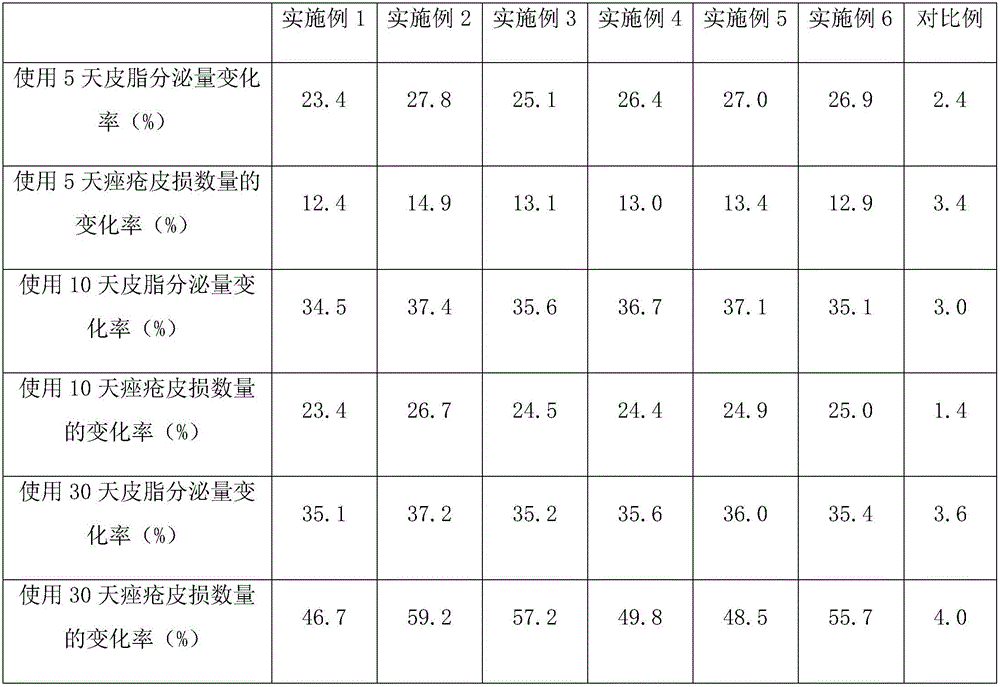

Anti-acne cream based on high-purity herbal extract, and preparation method of anti-acne cream

ActiveCN105662962ABroad-spectrum antibacterialEnhanced inhibitory effectCosmetic preparationsToilet preparationsCream baseReflux extraction

The invention provides anti-acne cream based on high-purity herbal extract, and a preparation method of the anti-acne cream. The preparation method concretely comprises the following steps: (1) cleaning natural herbaceous plants, drying the cleaned herbaceous plants in the air, then cutting the dried herbaceous plants and grinding into powder, mixing the powder of the herbaceous plants according to proportion, adding an ethanol water solution into the mixture, carrying out ultrasonic dispersion, carrying out heat reflux extraction for twice, and carrying out rotary evaporation and concentration on filtrate until the filtrate is free from alcohol taste to obtain extract of the natural herbaceous plants; (2) centrifuging the extract of the natural herbaceous plants and taking supernatant of the extract, putting the supernatant into dry macroporous resin, standing still and carrying out suction filtration; after absorption, transferring the macroporous resin into a 80-90% of ethanol water solution, standing still and carrying out suction filtration; taking out the macroporous resin, carrying out rotary evaporation on filtrate until the filtrate is free from alcohol taste to obtain purified extract of the natural herbaceous plants; (3) mixing auxiliary agents, heating mixture up to 80-90 DEG C, stirring the heated mixture until the mixture is completely dissolved, cooling to 45-50 DEG C, adding the purified extract of the natural herbaceous plants into the mixture, evenly stirring, carrying out heat preservation, and then carrying out rotary evaporation until the mixture is in a cream state to obtain the anti-acne cream based on the high-purity herbal extract.

Owner:GUANGZHOU BAICAOTANG PHARMA

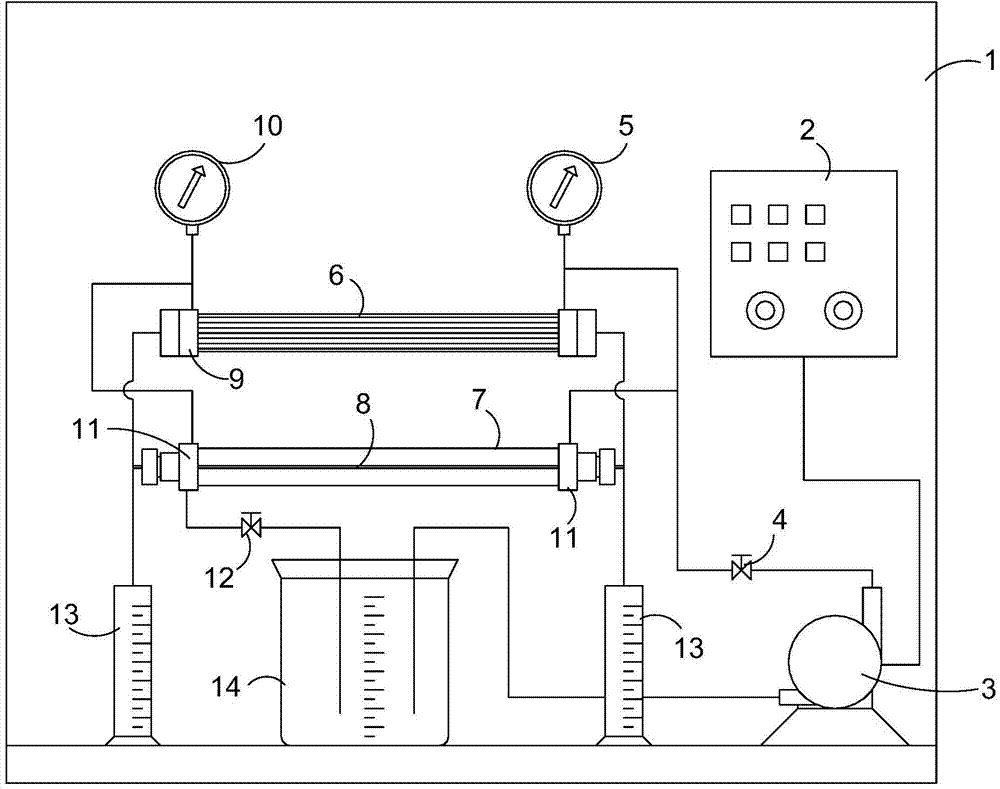

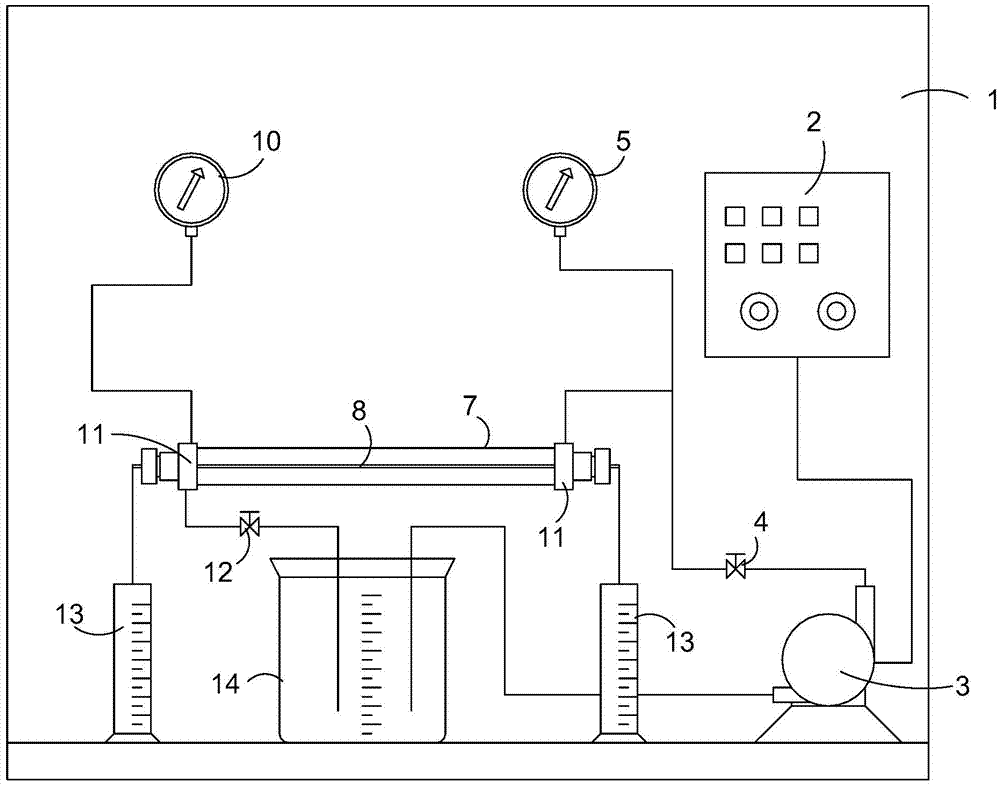

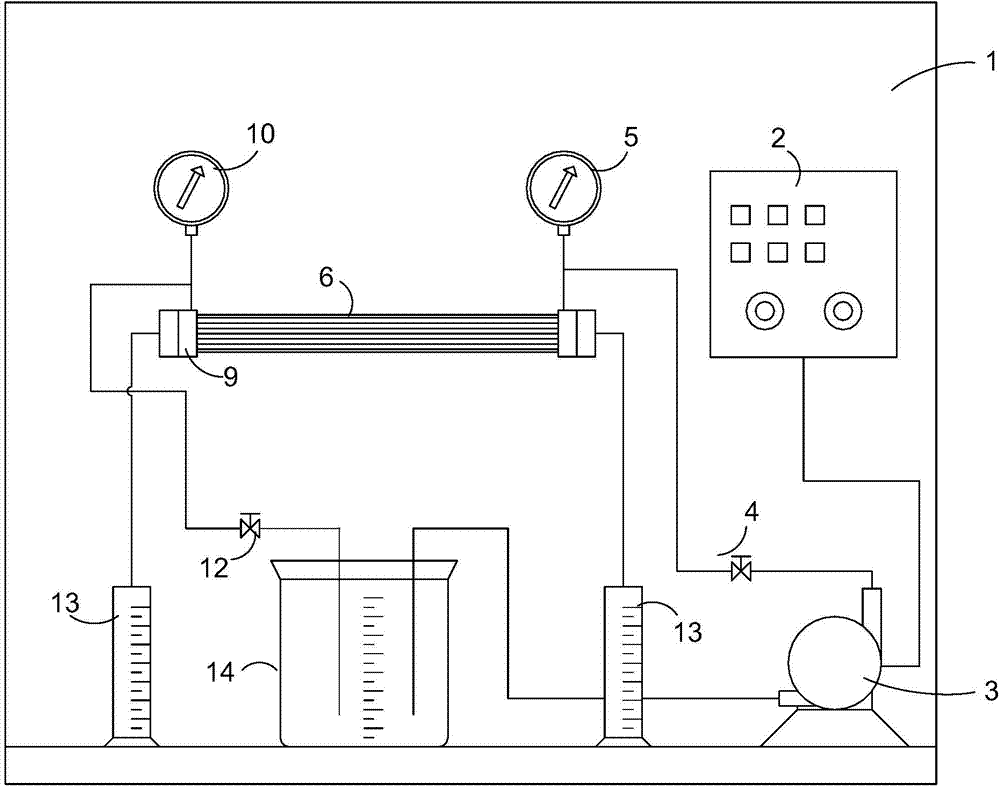

Water flux and retaining rate testing device of hollow fiber membrane

ActiveCN103611423ASimple pressure control systemGuaranteed continuous stabilitySemi-permeable membranesHollow fibre membraneFixed frame

The invention discloses a water flux and retaining rate testing device of a hollow fiber membrane. The water flux and retaining rate testing device comprises a water storage device, a water replenishing device, a fixing frame, a packaging pipe used for packaging a stock solution and a membrane filament, membrane filament fastening end covers respectively sealed and connected with both ends of the packaging pipe, a metering pump, an outlet valve and a metering pump control panel, wherein both ends of the membrane filament respectively pass though filament passing holes of the two membrane filament fastening end covers and then enter the water storage device; the metering pump is connected with the water port of one membrane filament fastening end cover and communicated with the water replenishing device; the outlet valve is connected with the water port of the other membrane filament fastening end cover and communicated with the water replenishing device; the metering pump control panel is electrically connected with the metering pump. The testing device disclosed by the invention has the characteristics that the packaging pipe is used to package the stock solution and the membrane filament, and the pressure of the stock solution in the packaging pipe is controlled within a stable range by the cooperation among the metering pump control panel, the metering pump and the outlet valve. The testing device has the advantages of being simple in the pressure control system, controlling the pressure in the packaging pipe by liquid flow and thus ensuring the continuous stability in the pressure of the testing device.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

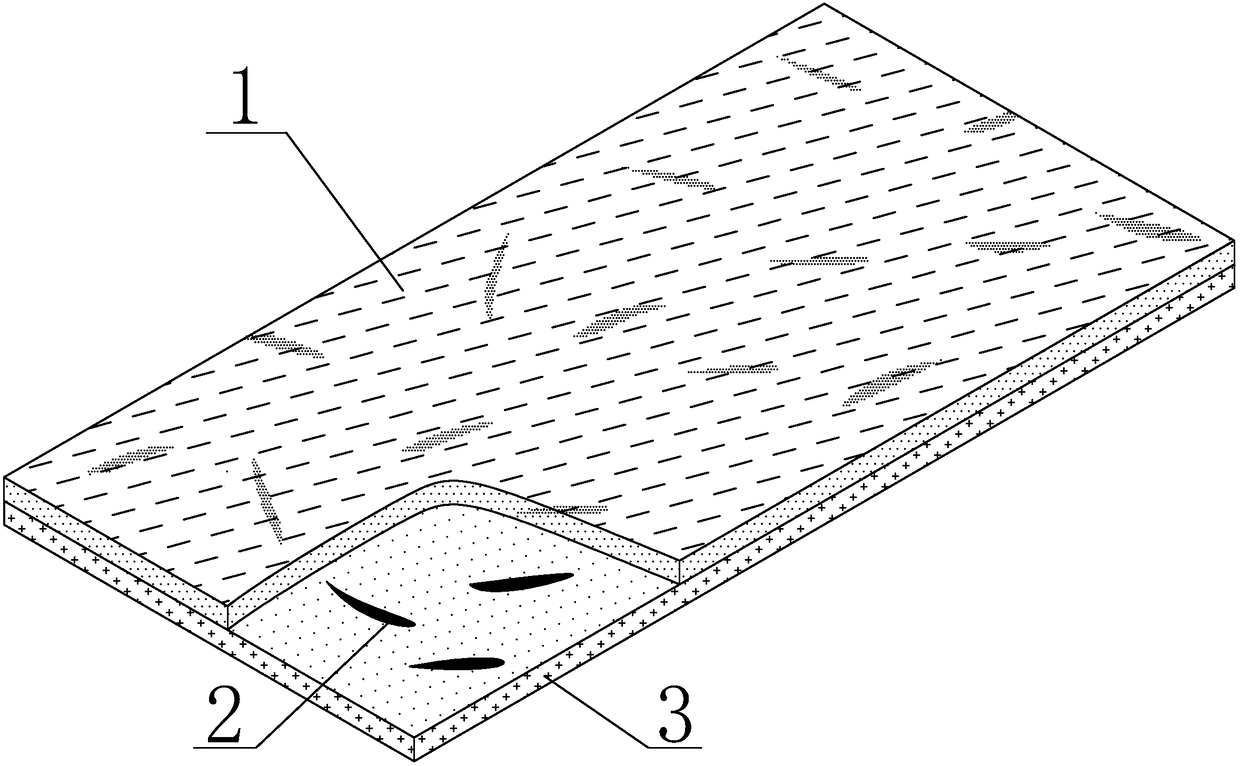

Spunlace non-woven material containing natural dry petals and preparation method thereof

ActiveCN108532123AIncrease health functionNo pollution in the processNon-woven fabricsFiberPersonal care

The invention relates to the technical field of spunlace non-weaving, and discloses a spunlace non-woven material containing natural dry petals and a preparation method thereof. The spunlace non-wovenmaterial comprises dry fiber webs and wet fiber webs which are intertwined, and the intact natural dry petals are placed between the wet fiber webs and the dry fiber webs; the natural dry petals areselected from petals which use carotenoids as main pigments and have colors from yellow to red, and the length-width ratio of the natural dry petals is smaller than 10:1. According to the spunlace non-woven material, the characteristics of dry-laid web and wet-laid web spunlace processes are fully utilized, and the whole petals with natural morphology are uniformly distributed in the spunlace non-woven material, so that the spunlace non-woven material has natural beauty care effects, the aesthetic feeling of cloth covers of personal care materials are enhanced, and the technical problems of petal colour fading, color diffusion, short product storage period and easy falling of petals during the production and use process are effectively solved through reasonable process coordination.

Owner:HANGZHOU NBOND NONWOVENS

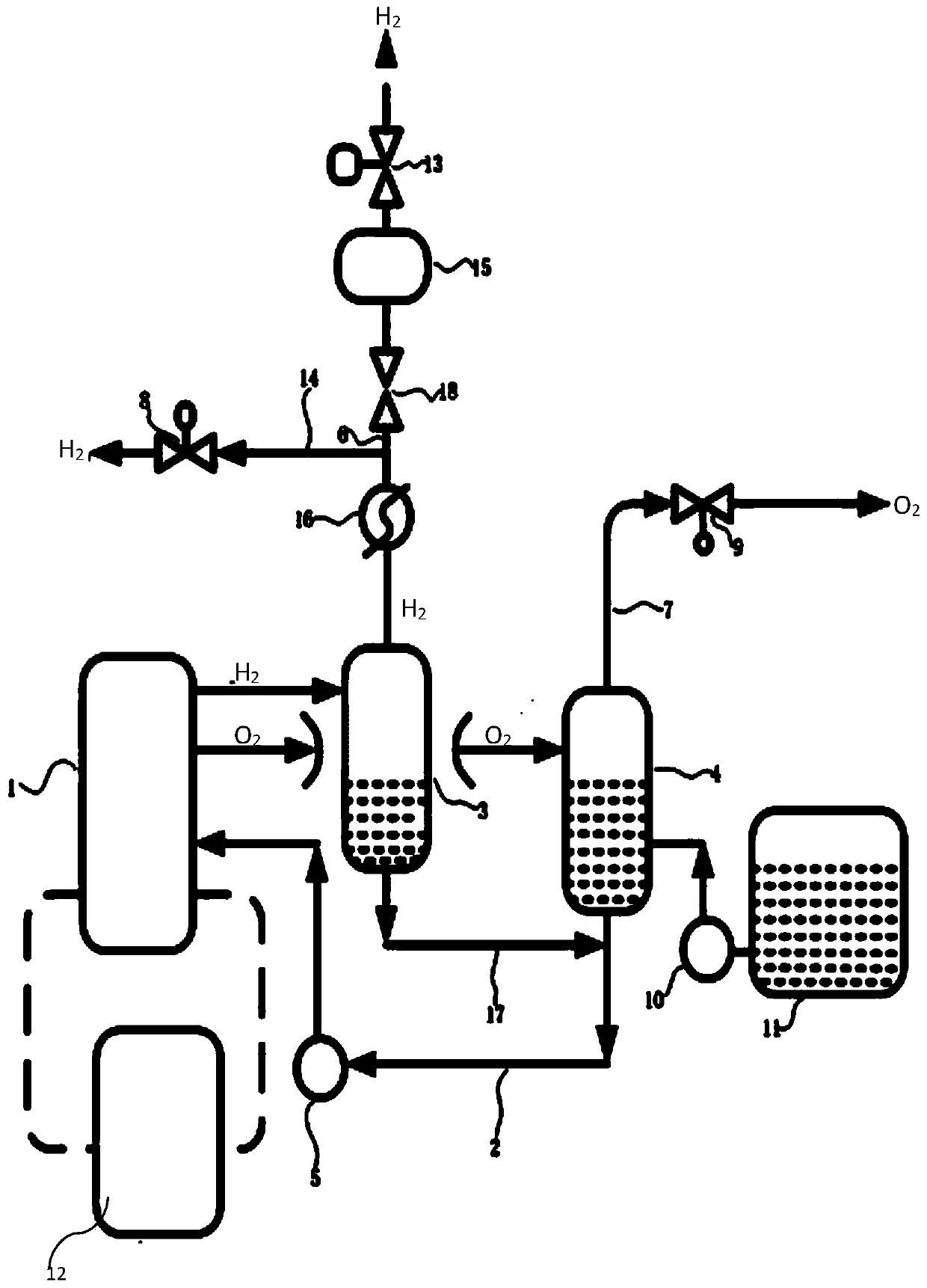

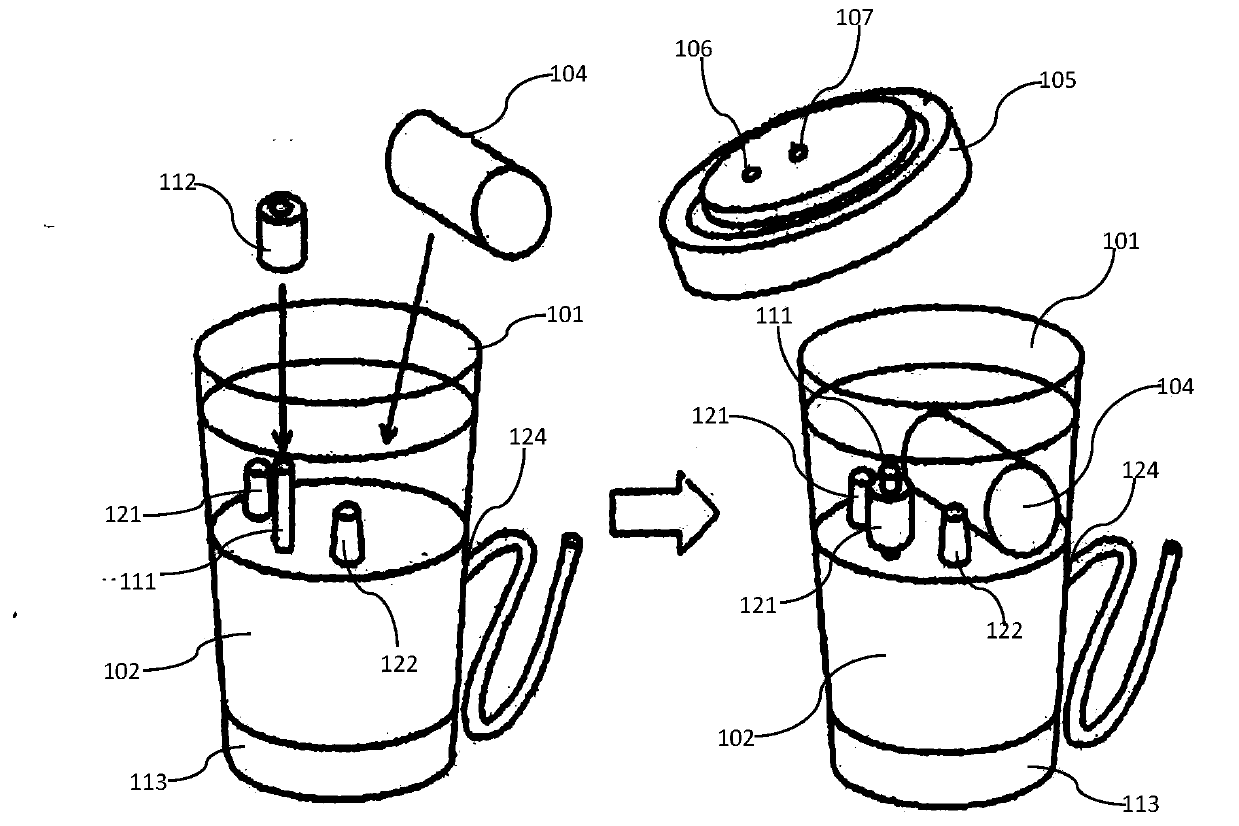

Water electrolyzing hydrogen production device

PendingCN110055547AContinuous and stable productionStable temperatureRespiratorsCellsElectrolysisLow voltage

The invention discloses a water electrolyzing hydrogen production device. Water electrolysis reaction is implemented through an electrolyzing tank in a hydrogen generating cup, the bottom end of the electrolyzing tank is provided with an electrode socket, the electrolyzing tank is electrically connected with a power device through the electrode socket, and the power device is provided with an automatic power converter; meanwhile, an oxygen separating device can exhaust oxygen as the impurity, and a hydrogen gas-liquid separator is sequentially connected with a gas cooler, a gas pressure reducing valve, a hydrogen oxidation catalyst contain and a flow regulating valve through guide pipes. The water electrolyzing hydrogen production device can achieve a hydrogen production process under theaction of low current and lower voltage, effectively control the temperature of control equipment as well as produced hydrogen, and by cooling and oxidizing the produced hydrogen with catalysts, improve the output purity of hydrogen.

Owner:BEIJING JIANYUAN TIANDI ENVIRONMENTAL PROTECTION TECH

Diamond saw blade tip, diamond saw blade and manufacturing method thereof

ActiveCN106799488AReduce heat damageAvoid sharpness lossAbrasion apparatusStone-like material working toolsCopperCobalt

The invention relates to a diamond saw blade tip, a diamond saw blade and a manufacturing method thereof, and belongs to the technical field of diamond tools. The diamond saw blade tip is formed by a front section material, a middle section material and a rear section material. The front section material and the rear section material each comprise, by mass, 20%-22% of diamond particles, 18%-22% of copper powder, 15%-18% of cobalt powder, 20%-30% of tungsten powder, 2%-5% of silver powder and 12%-15% of tin powder, wherein the sum of all the components is 100%. The middle section material comprises, by mass, 15%-18% of diamond particles, 18%-22% of copper powder, 17%-20% of cobalt powder, 22%-32% of tungsten powder, 3%-5% of silver powder and 13%-15% of tin powder, wherein the sum of all the components is 100%. The diamond saw blade tip has excellent sharpness and abrasion resistance, and the cutting efficiency and service life of the diamond saw blade are guaranteed.

Owner:NANAN MINGJI DIAMOND TOOL CO LTD

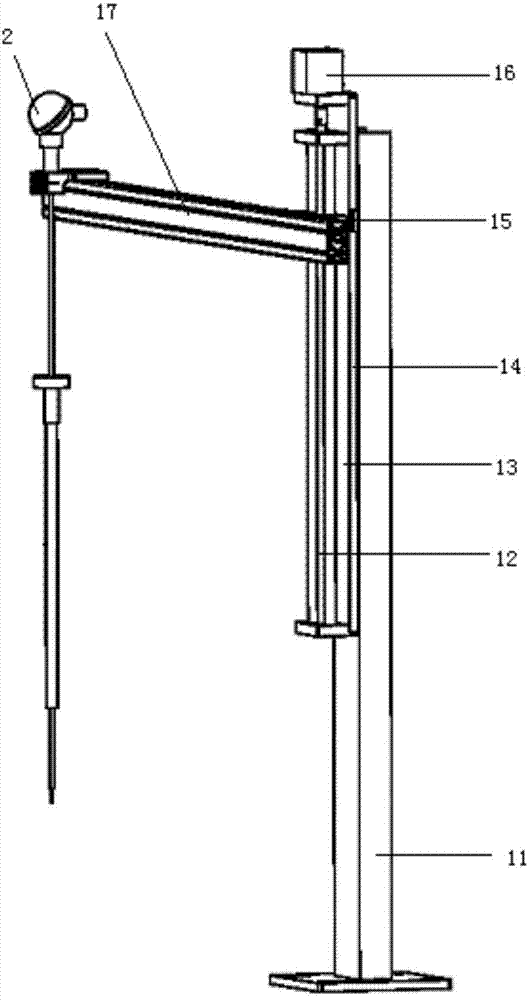

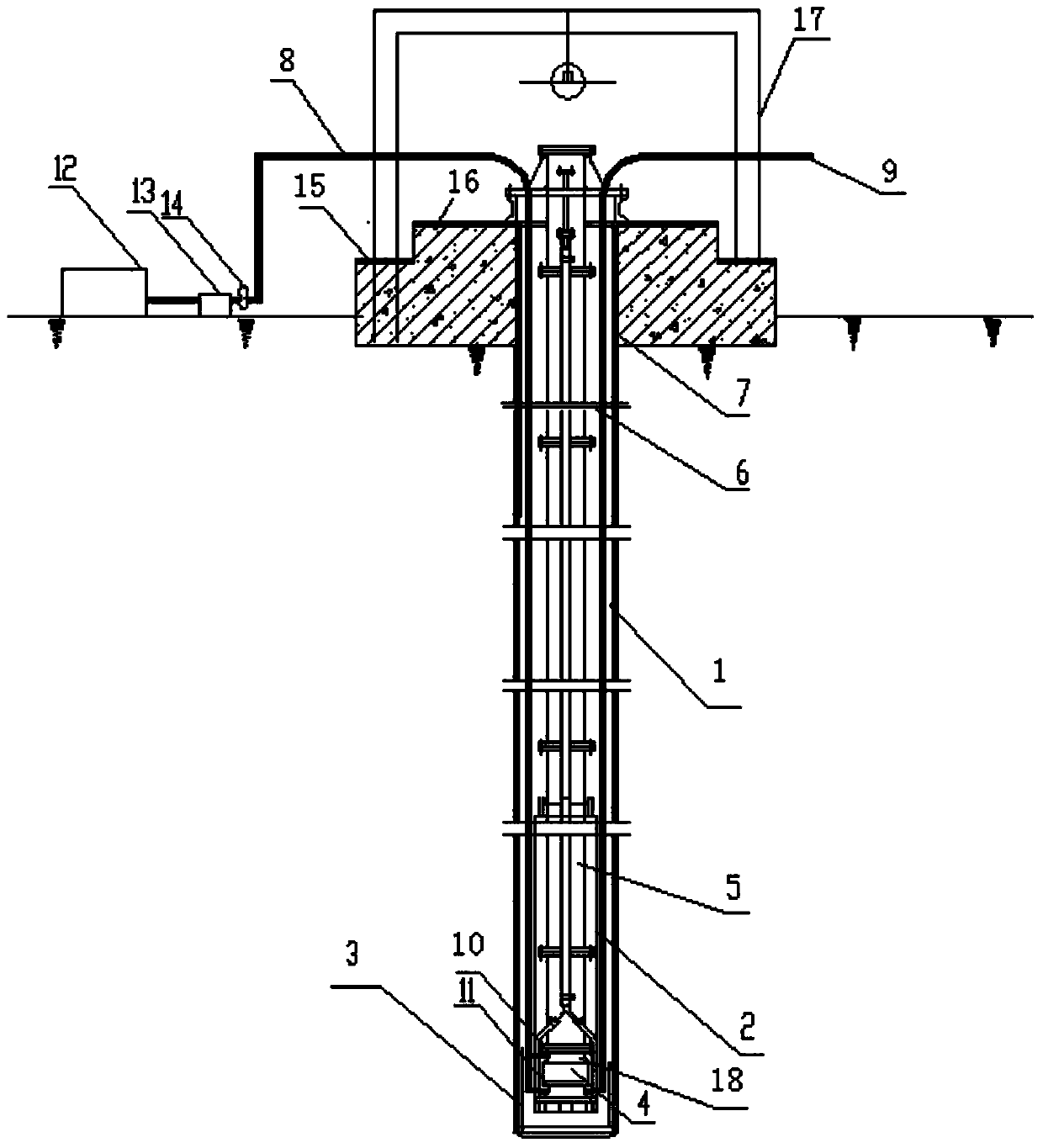

Brine drilling and exploiting system and method for dynamic cleaning and salt deposition resisting in closed cycle mode

ActiveCN104196498AReduce adhesionGuaranteed continuous stabilityPump componentsFluid removalHigh concentrationImpeller

The invention discloses a brine drilling and exploiting system and a method for dynamic cleaning and salt deposition resisting in a closed cycle mode. The drilling system comprises a brine exploiting well (1), a brine diving electromotor (2), a screening pipe (3), a brine diving pump (4), a well inner pipe (5), a well opening pipe fixing steel channel (6) and a well opening pipe (7). A salt resisting brine mud fixing well table (15) and a well lid steel plate (16) are arranged at a well opening, and a support lifting device (17) for overhauling a brine sucking device is arranged on the upper portion of the well lid steel plate (16). The screening pipe (3) is located on the inner side of the bottom well wall of the brine exploiting well (1). The well opening pipe (7) is located at the position, close to the inner side of the well wall, of the salt resisting brine mud fixing well table (15), and the #-shaped well opening pipe fixing steel channel (6) is welded to the position below the well opening pipe. The brine diving pump (4) is fixedly arranged at the position with a certain depth in a well, and a fresh water pipe (8) extends into the well from the ground. A closed cycle dynamic cleaning method is adopted, deposited salt at an impeller and a runner can be dissolved through passing fresh water or lose adhesive force and is finally discharged from a water outlet pipe (9) to be discharged together with collected brine, and therefore stable exploitation of high-concentration and supersaturation brine in the deep portion can be achieved.

Owner:ЦИНХАЙ СОЛТ ЛЕЙК ИНДАСТРИ ГРУП КО ЛТД

Die cutting equipment for carton processing and working method thereof

InactiveCN111805969AAvoid flippingImprove production and processing efficiencyPaper-makingBox making operationsCartonPaperboard

The invention discloses die cutting equipment for carton processing and a working method thereof. The die cutting equipment comprises a conveying mechanism; a feeding mechanism, a die cutting mechanism and a collecting mechanism are sequentially arranged on the conveying path of the conveying mechanism; the feeding mechanism comprises an accommodating box for carrying out posture restraint on a paperboard and a feeding roller for carrying out feeding operation on the paperboard; the collecting mechanism comprises a separating mechanism and a material collecting piece; the separating mechanismis used for separating the board and waste after die cutting of the paperboard; and the material collecting piece is used for collecting the board and waste. According to the die cutting equipment forcarton processing and the working method thereof, the feeding process is continuous and stable to improve the automation rate of the overall machining process, and the board part and the waste part of the paperboard after die cutting are separated, so that the trouble of setting the separating procedures separately is avoided, and the producing and processing efficiency of a factory is improved.

Owner:孙同昂

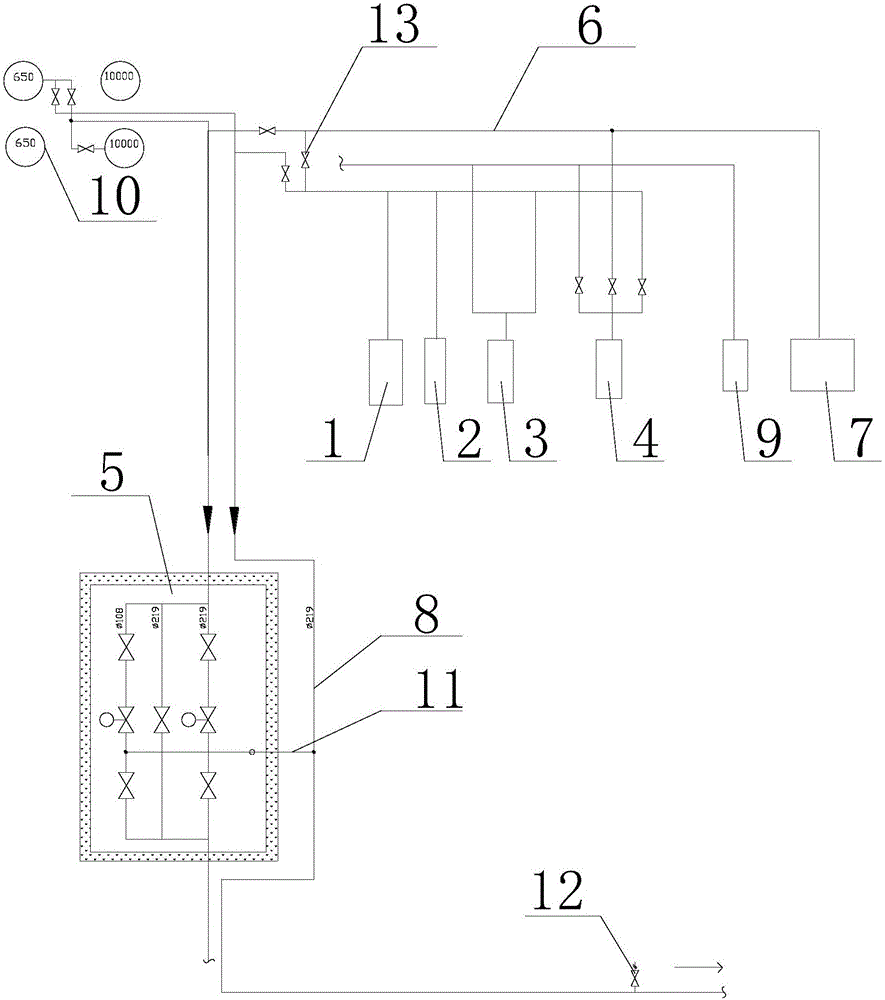

Oxygen partial pressure supply system

ActiveCN105156892AGuaranteed continuous stabilityAvoid production lossPipeline systemsChemistryOxygen supply

The invention discloses an oxygen partial pressure supply system. The oxygen partial pressure supply system comprises an oxygen compressor set and a depressurization station; and the oxygen partial pressure supply system is characterized in that the oxygen compressor set comprises a first oxygen compressor, a second oxygen compressor, a third oxygen compressor and a fourth oxygen compressor. The four oxygen compressors are connected with a medium pressure oxygen pipe through pipes; an oxygen turbocompressor is further connected to the medium pressure oxygen pipe to press out supplied 2.0 MPa oxygen, the medium pressure oxygen pipe is then connected to the depressurization station for oxygen depressurization, and the depressurized oxygen is conveyed to be used for steelmaking; and meanwhile, the oxygen compressor set is further provided with a pipe to be connected to a low-pressure oxygen pipe to press out the oxygen which is 0.8-1.0 MPa and 10000 m<3> / h, and the oxygen is directly supplied to iron making and steel rolling. According to the oxygen partial pressure supply system, a special low-pressure oxygen pipe is arranged, depressurization supply after oxygen pressurization is not needed, the oxygen supply procedure is simplified, energy consumption is effectively reduced accordingly, the production cost is reduced, energy conservation and environment protection are achieved, the safety of the low-pressure oxygen pipe is higher, and the running period is longer.

Owner:SICHUAN DESHENG GRP VANADIUM & TITANIUM CO LTD

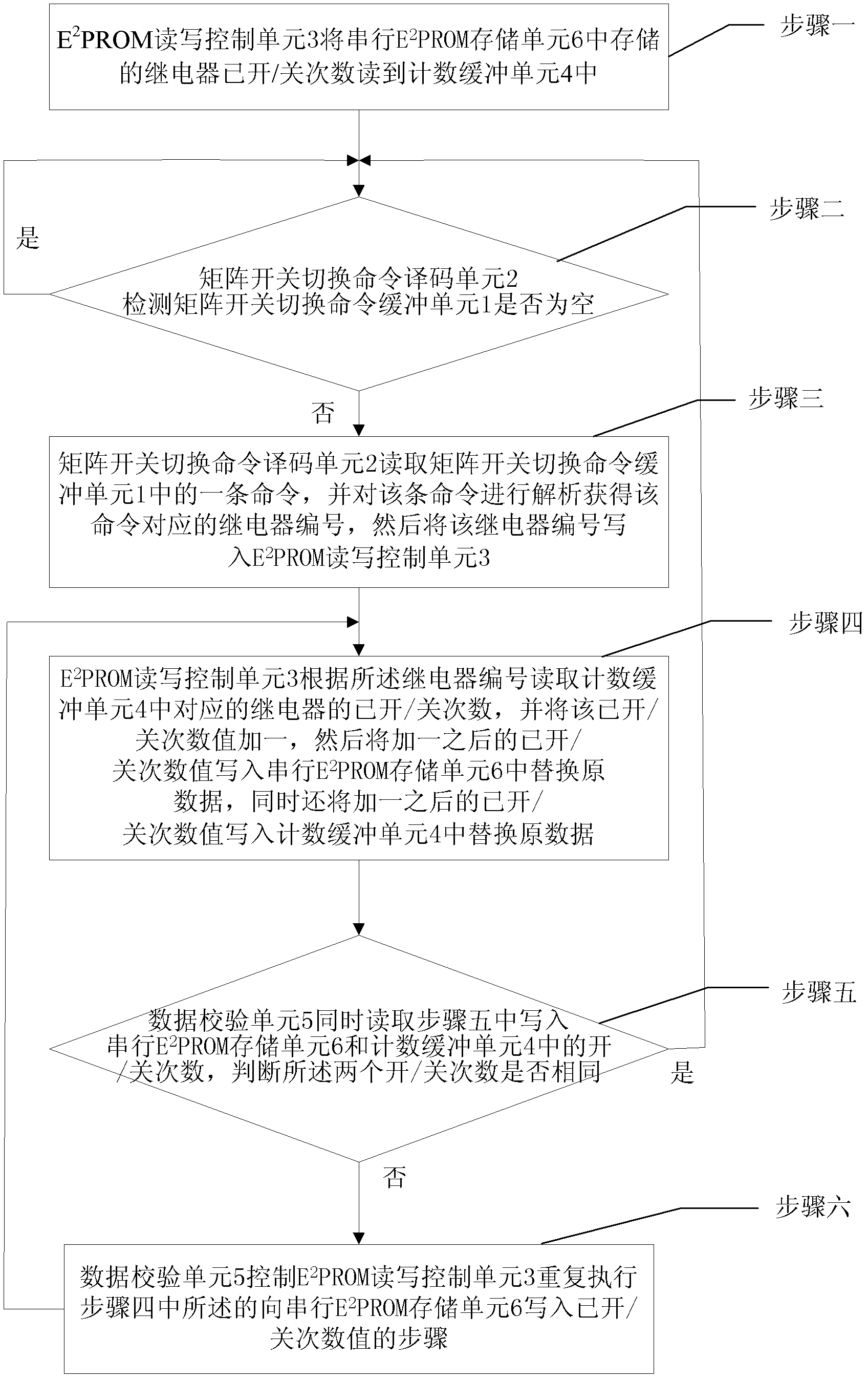

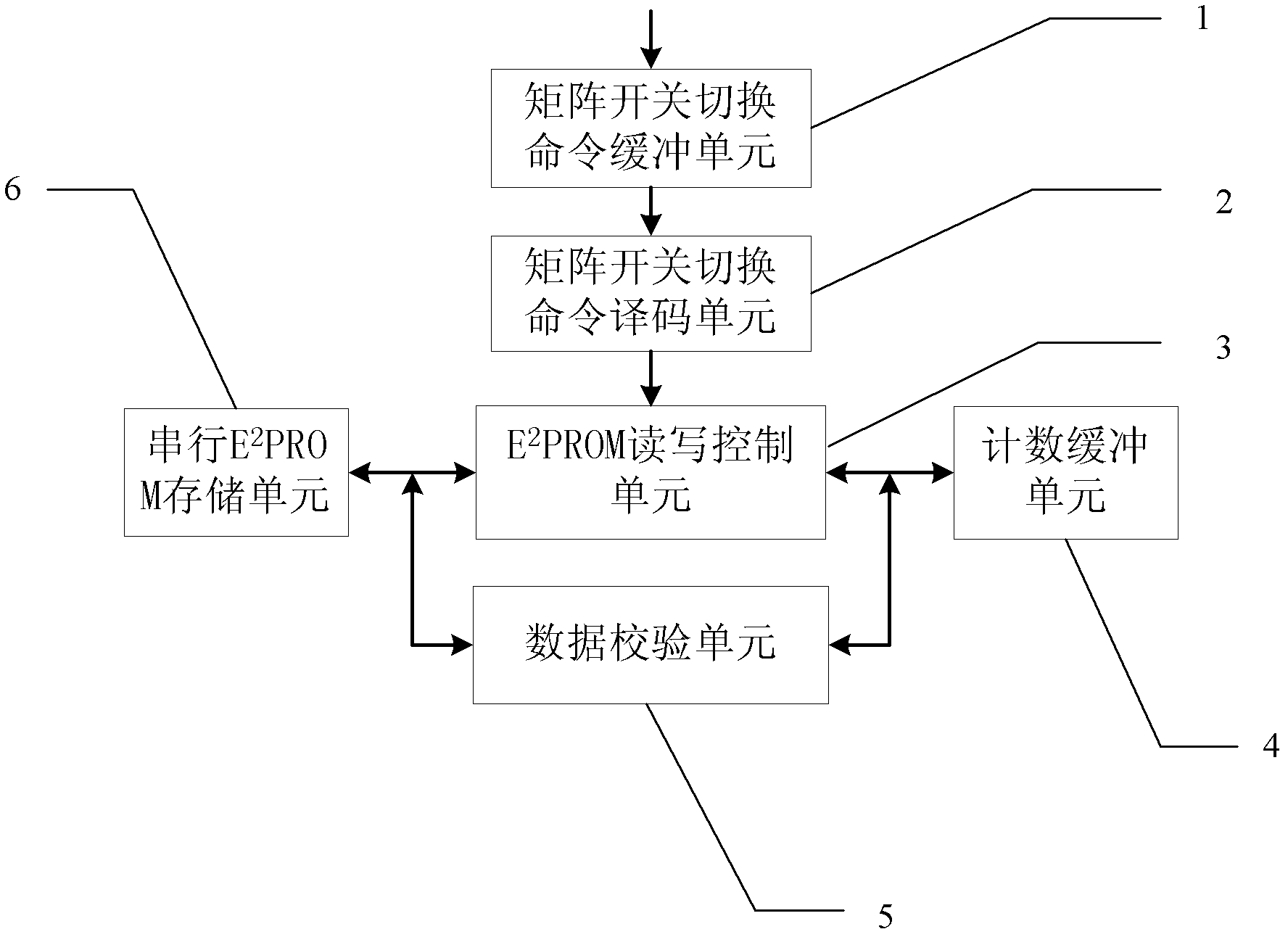

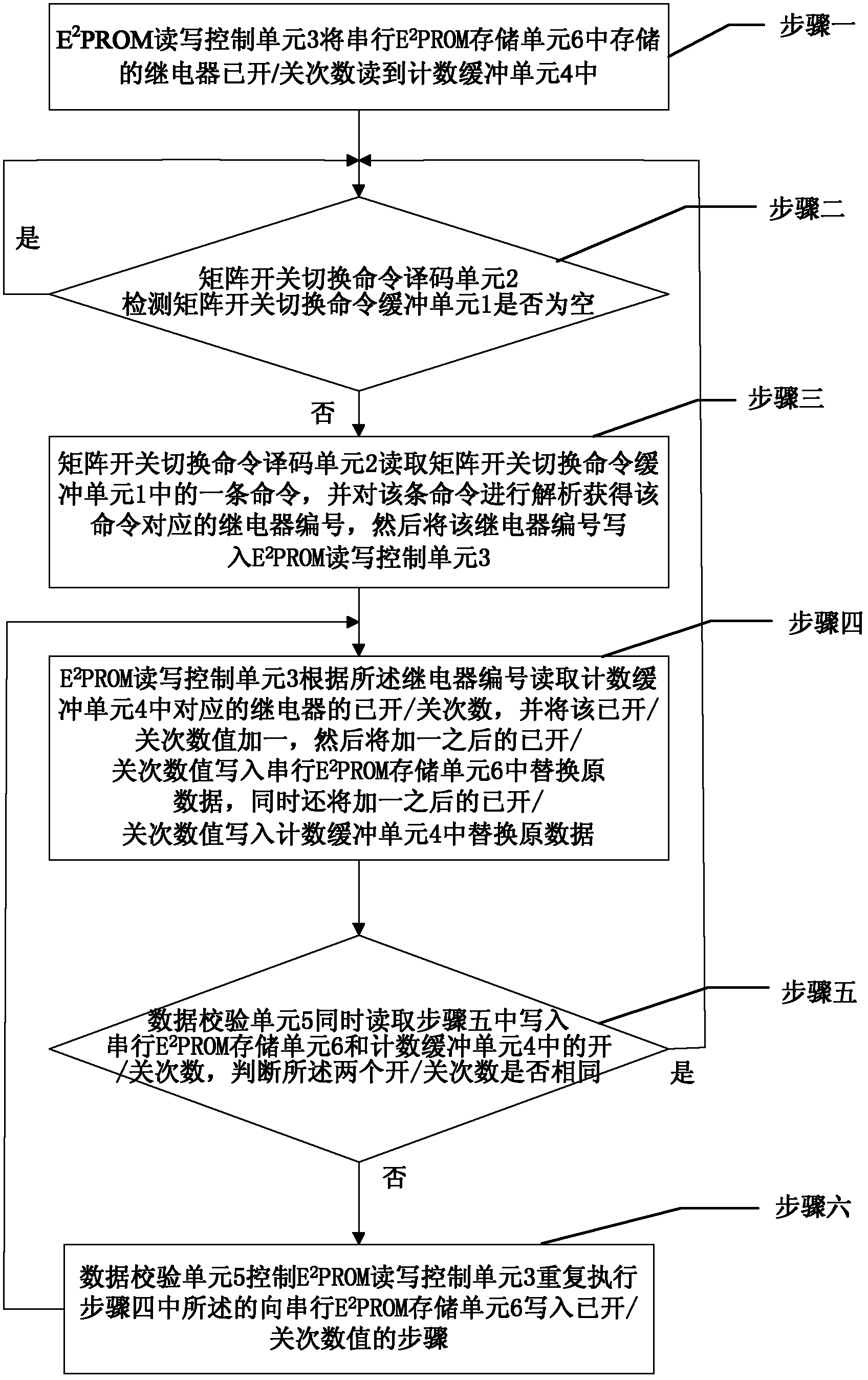

Real-time on-off times recording device for relay in matrix switch module and method for realizing on-off times recording by employing same

InactiveCN102565461AReduce the probability of damageGuaranteed continuous stabilityElectrical measurement instrument detailsElectrical testingData verificationService time

The invention relates to a real-time on-off times recording device for a relay in a matrix switch module, and a method for realizing on-off times recording by employing same. The invention solves the problems that the probability of damage of the relay rises sharply along with the increase of service time, and the electrical life of the relay in the matrix switch is limited. The real-time on-off times recording device comprises a matrix switch switching command buffering unit, a matrix switch switching command decoding unit, an E2PROM reading-writing control unit, a counting buffering unit, a data verification unit and a serial E2PROM memory unit, wherein the matrix switch switching command buffering unit is a first-in-first-out memory. The serial number of the relay executing on-off actions is decoded by analyzing the switch switching command, and the on-off times of the relay is stored in the serial E2PROM memory unit. The device and the method are suitable for the filed of automatic testing.

Owner:HARBIN INST OF TECH

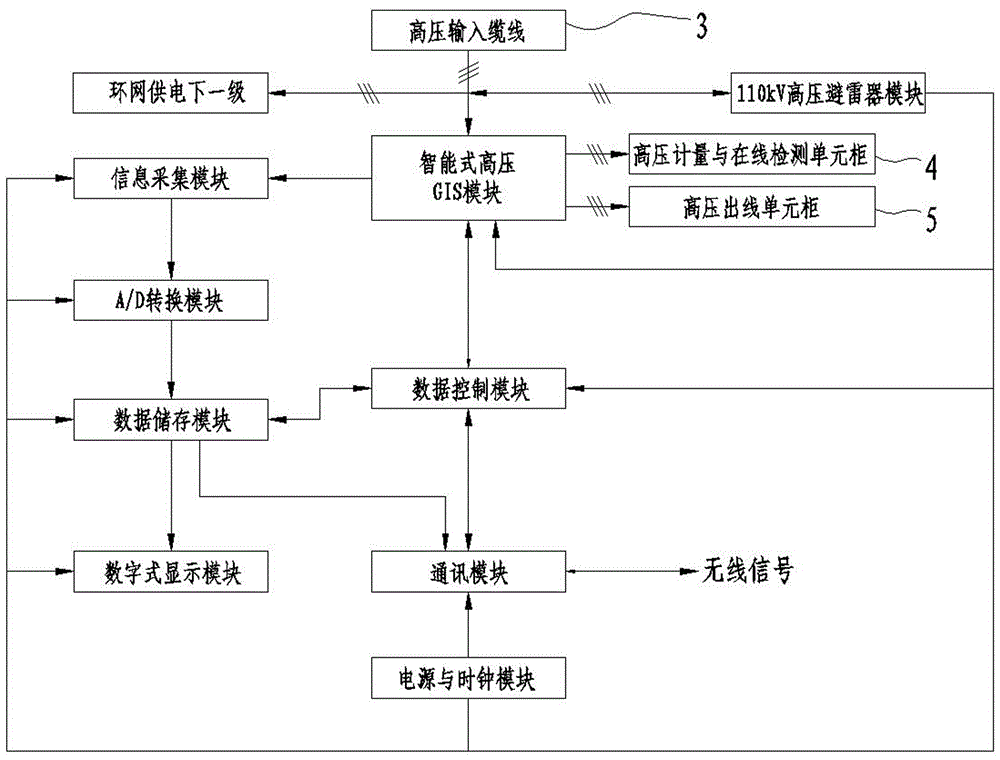

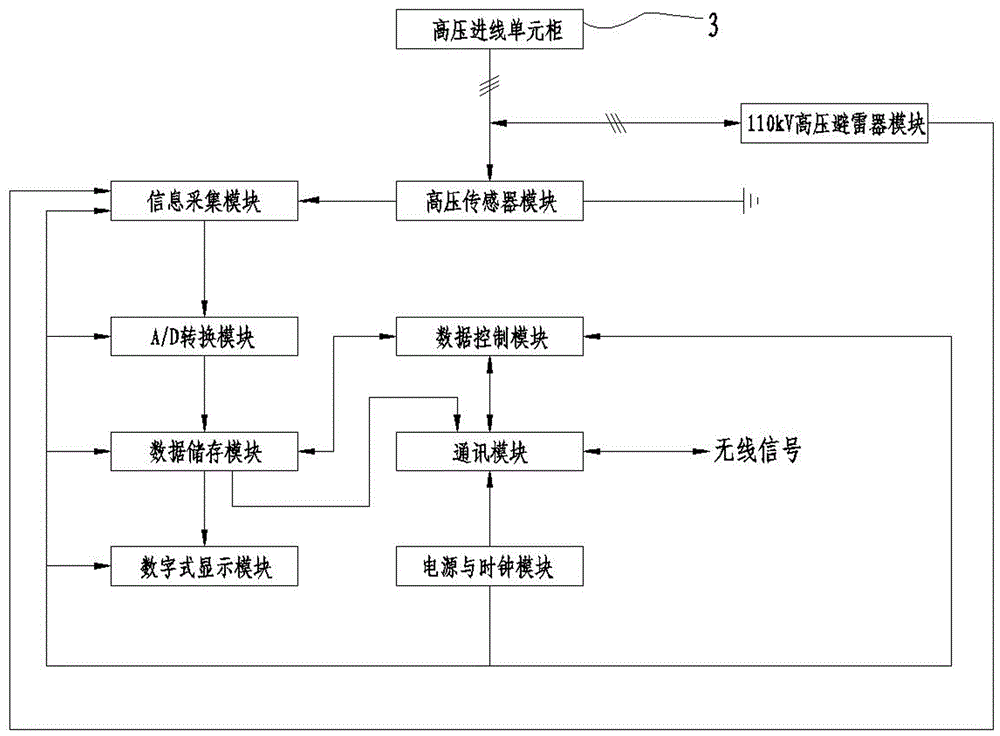

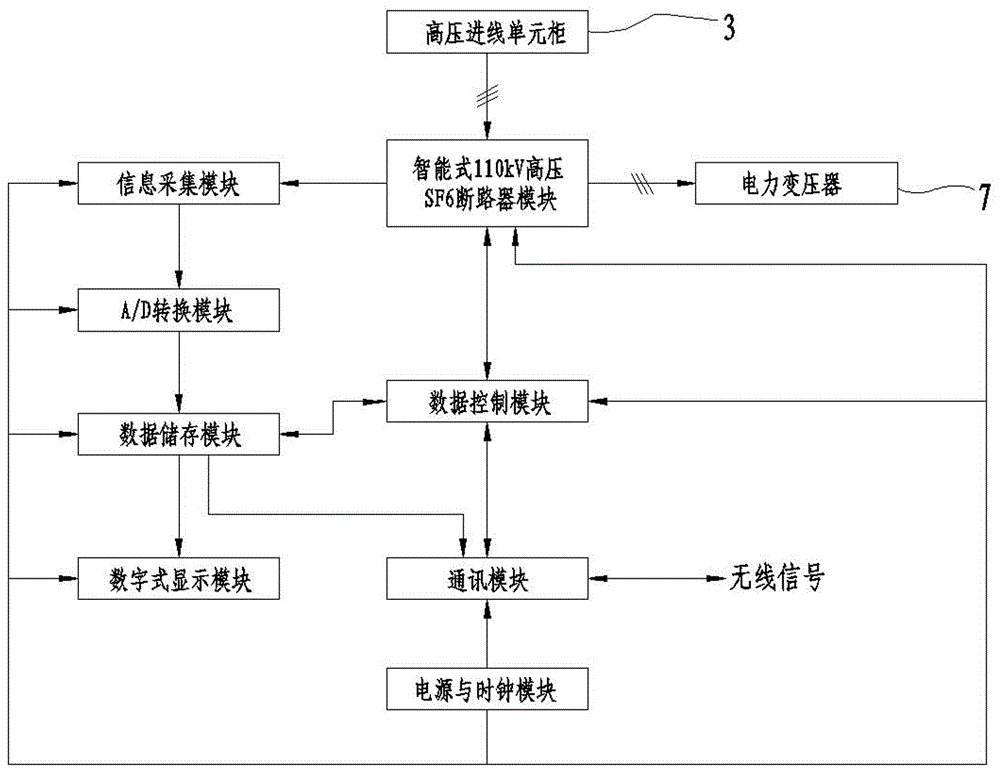

110kV/10kV and 110kV/35kV two pre-installed integrated intelligent substations

ActiveCN105958354ANo electromagnetic radiationReduce noiseBoards/switchyards circuit arrangementsTransformers/inductances coils/windings/connectionsAutomatic controlTransformer

The invention provides 110kV / 10kV and 110kV / 35kV two pre-installed integrated intelligent substations. Transformers are 110kV / 10kV and 110kV / 35kV two three-phase power transformers and are of a five-stem core structure; three phases of 110kV high-voltage windings of the transformers are in YN connection; each phase of 10kV and 35kV low-voltage windings and 10kV and 35kV fuses are connected in series to form a low-voltage phase arm; and three phases of low-voltage phase arms form d connection, and the connection group is labeled as YN, d11, and has a ''three-phase noninterference'' function. Various accessories in the substations are installed in a high-strength steel structure box body in an integrated manner, so that the characteristic of high ''integration'' is highlighted. By the substations, modern high-new technologies of a digital technology, an automatic control technology, an information collection and transmission technology and the like are combined, so that the characteristic of high ''intelligentization'' is highlighted. Production assembly and debugging of various components in the substations are completed once in a factory, so that the characteristic of high ''pre-installation'' is highlighted; the size and the floor area of the 110kV / 10kV and 110kV / 35kV two pre-installed integrated intelligent substations are greatly reduced; and the power supply safety and reliability are ensured.

Owner:SHANXI JIDA VOLTAGE TRANSFORMER CO LTD

Rear cover for enhancing braking performance of hydraulic retarder

PendingCN112901681ABraking guaranteeGuaranteed continuous stabilityLiquid resistance brakesBraking elementsProportioning valveRetarder

The invention belongs to automobile parts, and particularly relates to a rear cover for enhancing the braking performance of a hydraulic retarder. An air inlet of an electromagnetic air proportional valve is formed in the left side of the upper portion of the rear cover, and a first air channel, a second air channel and a third air channel are formed in the right side of the air inlet. The included angle between the center line of a first oil channel section and the horizontal direction is beta, a second oil channel section is vertically upward, and the included angle between the center line of a third oil channel section and the vertical direction is alpha. An oil storage chamber is arranged at the top end of a lubricating oil channel and communicates with an oil suction port of a lubricating oil pump, and the lubricating oil channel and an oil inlet channel are surrounded by the lubricating oil channel and the oil inlet channel to form an oil outlet channel. A one-way valve is arranged in a one-way valve seat hole, the one-way valve seat hole is communicated with a middle cover oil outlet channel through the one-way valve, and a heat exchanger oil inlet hole is formed in the lower end of the oil outlet channel. The structure is compact, the function integration level is high, oil liquid entering a working cavity of the hydraulic retarder can be effectively prevented from containing a large amount of air, and the continuous stability of the braking performance of the hydraulic retarder is guaranteed.

Owner:FUXIN DARE AUTOMOTIVE PARTS

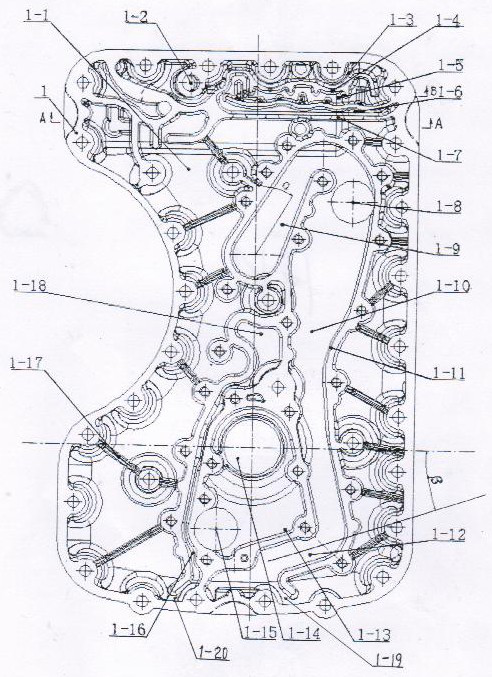

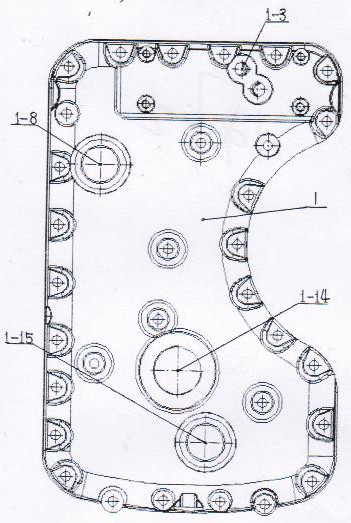

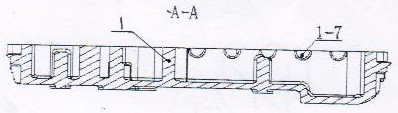

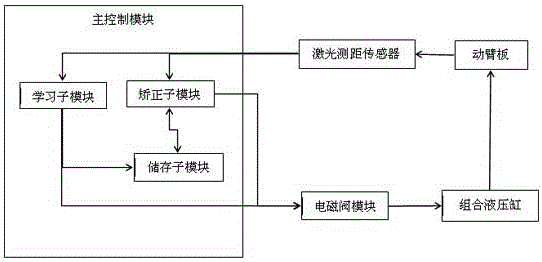

Automatic correction device and correction method for moving arm

ActiveCN105665480AEasy to correctOptimize the whole processMetal working apparatusHydraulic cylinderLaser ranging

The invention discloses an automatic correction device for a moving arm. The automatic correction device comprises a master control module, a laser distance measuring sensor, a battery valve module and a hydraulic cylinder assembly. The master control module is electrically connected with the laser distance measuring sensor and the battery valve module. The laser distance measuring sensor is aligned to all moving arm plates of the moving arm and obtains the positions of all the moving arm plates. A plurality of hydraulic cylinder sets are arranged according to the moving arm plates needing to the corrected. The battery valve module is connected with the hydraulic cylinder assembly. The laser distance measuring sensor detects the position information of all the moving arm plates. The master control module compares the position information with a preset standard position range value and transmits correction distance parameters to the battery valve module. The feeding strokes of hydraulic cylinders are controlled by the battery valve module, and therefore the positions of all the moving arm plates are corrected. According to the automatic correction device, the correction technology of the moving arm of a loader is intelligently controlled, and the problems that in original manual correction, the labor intensity is large, the manual cost is high, and the correction precision and the production efficiency are low are solved.

Owner:GUANGXI UNIVERSITY OF TECHNOLOGY

Anti-coal-interruption coal feeder for thermal power plant

InactiveCN105059871AQuality assuranceGuaranteed continuous stabilityLarge containersControl devices for conveyorsIron removalEngineering

The invention discloses an anti-coal-interruption coal feeder for a thermal power plant. The anti-coal-interruption coal feeder for the thermal power plant comprises a shell and a coal bin. Base legs are arranged at the bottom of the shell. An iron removal conveying belt is arranged on the upper left of a weighing conveying belt in the shell. The iron removal conveying belt and the weighing conveying belt are closed loops. The top of the shell and the upper portion of the left side of the ion removal conveying belt are further provided with a coal inlet. The coal bin is arranged above the coal inlet. The coal bin is formed by connecting an upper conical bin body and a lower conical bin body. When coal powder is fed into the iron removal conveying belt from the coal inlet, scrap iron and screws in the coal powder are attracted by magnets on the iron removal conveying belt and will not fall onto the weighing conveying belt under the action of an electric vibrator. The quality of the coal powder is guaranteed. The coal bin is composed of two layers of bin bodies each of conical structures. When coal enters the lower conical bin body from the upper conical bin body, the section areas of the conical bodies suddenly become large, the pressure of the conical walls on the two sides on raw coal is correspondingly reduced, the descending speed of the raw coal is suddenly increased, a local vibration effect is formed, and material blockage is avoided.

Owner:中国大唐集团科学技术研究总院有限公司

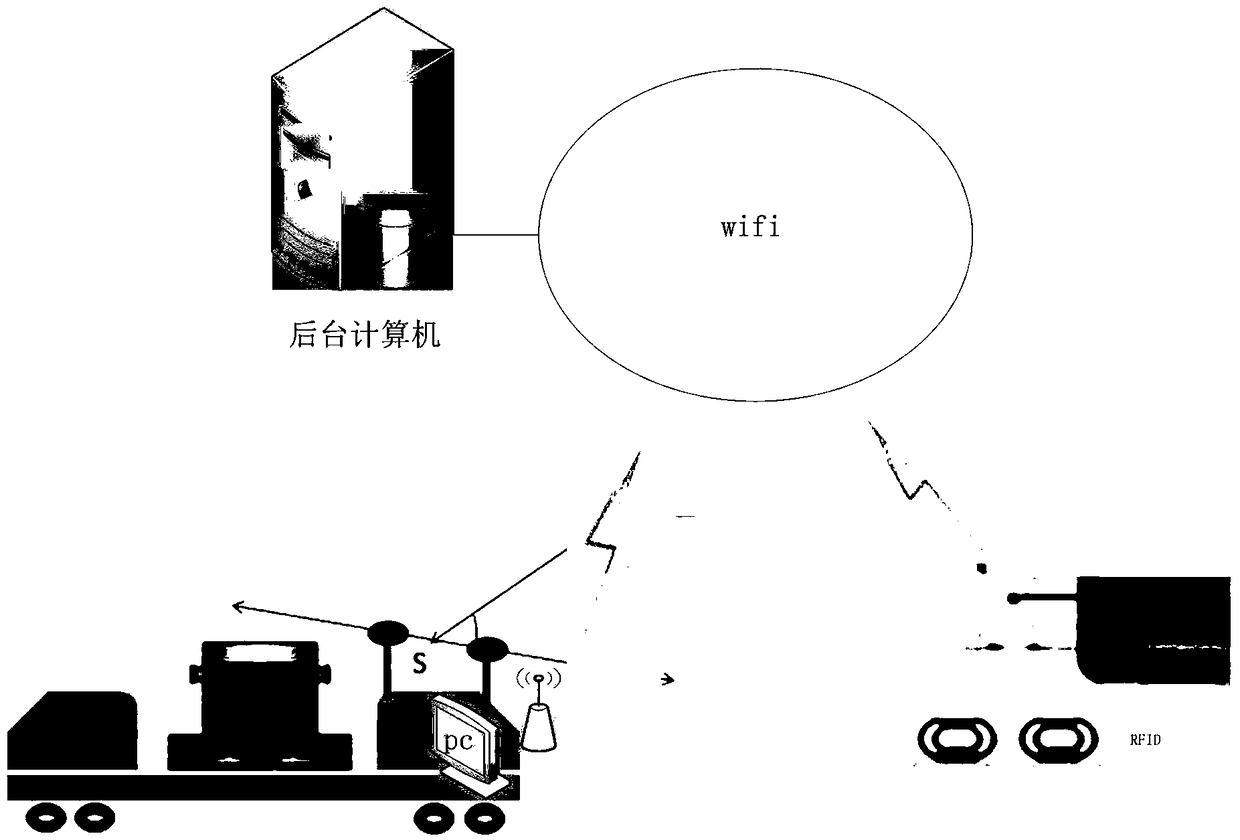

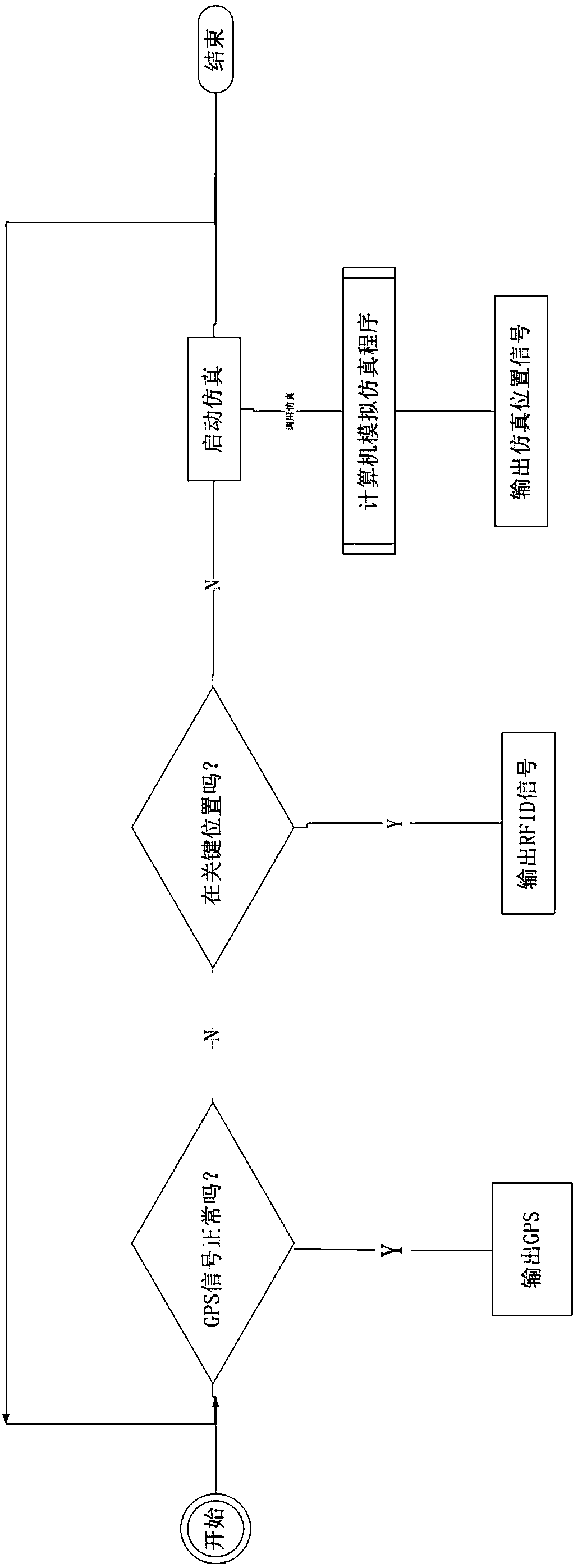

Rapid and precise GPS signal correction and positioning method for hot metal car

PendingCN109116388ADrift obviouslyGuaranteed continuous stabilitySatellite radio beaconingSafe deliveryEngineering

The invention relates to a rapid and precise GPS signal correction and positioning method for a hot metal car. The method comprises the steps: performing the automatic calculation and judgment of thecollected GPS signal, RFID signal and vehicle direction signal through the GPS signal enhancement technology and the RFID positioning technology via a background computer automatic rectification method according to the GPS signal quality and a feedback position signal; automatically selecting a stable position signal; automatically performing the simulation tracing of a vehicle when the GPS signalis not stable; automatically switching to the GPS signal when the signal returns to a normal state, thereby achieving the precise positioning of the hot metal car. The method employs the technologiesof wireless network, RFID, GPS and computer, achieves the whole-process positioning and tracking of the hot metal car in a transportation process, provides a remote electronic eye for a production manager and a scheduling commander, achieves the complete mastering of the continuous track of the operation of the hot metal car, provides accurate and reliable data for the automatic scheduling of thevehicle for the background program, changes the blind adjustment of the hot metal car into the apparent adjustment, guarantees the safe outputting and safe delivery of iron to maximum degree, and improves the hot metal scheduling efficiency.

Owner:SD STEEL RIZHAO CO LTD

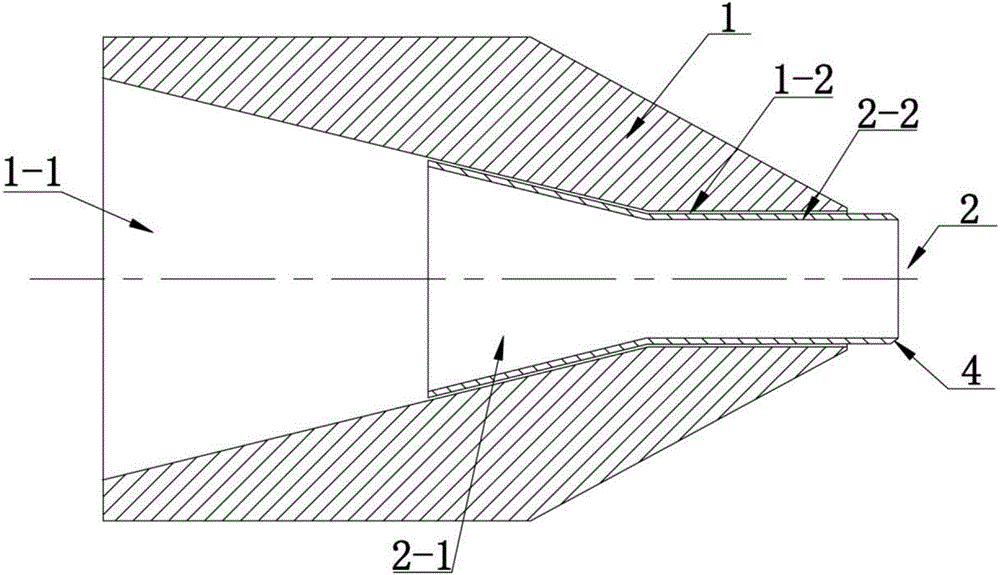

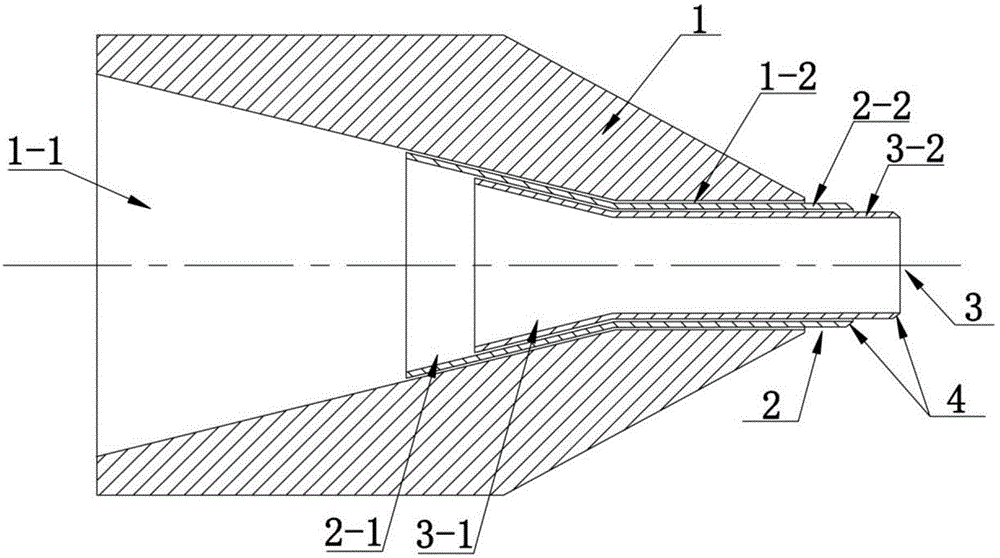

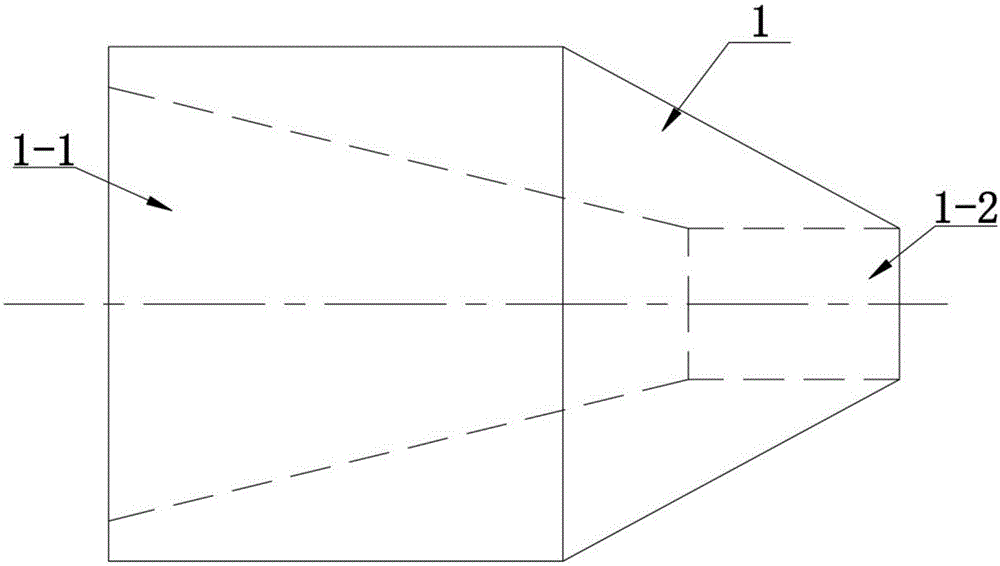

Catenary-chain type cross-linked cable production die and production method

ActiveCN104900346AReduce product quality riskArrive successfullyCable/conductor manufactureCross-linkElectrical conductor

The invention discloses a catenary-chain type cross-linked cable production die and a production method, and belongs to the technical field of wire and cable manufacturing. The die comprises a basic die body, and the interior of the basic die body is provided with a wire-bearing circular hole and an incoming wire tapered hole. The die also comprises a first inner die body and a second inner die body, wherein the inner die bodies are in an integrated structure. The first inner die body is disposed in the basic die body in a sleeved manner, and the second inner die body is disposed in the first inner die body in a sleeve manner. One end of the first inner die body and one end of the second inner die body are respectively provided with a first incoming wire hole and a second incoming wire hole, and the other ends of the first and second inner die bodies are respectively provided with a first bushing and a second bushing. The conical degree of the first incoming wire hole is consistent with the conical degree of the incoming wire tapered hole. The conical degree of the second incoming wire hole is consistent with the conical degree of the first incoming wire hole. The production method needs to produce different types of cable conductors, and enables the corresponding first inner die body to be inserted into the basic die body or enables the second inner die body to be inserted into the first inner die body. The die and method are quick and convenient in die replacement, improve the production efficiency, and achieve the continuous production of adjacent types of conductors.

Owner:YANTAI CABLE FACTORY

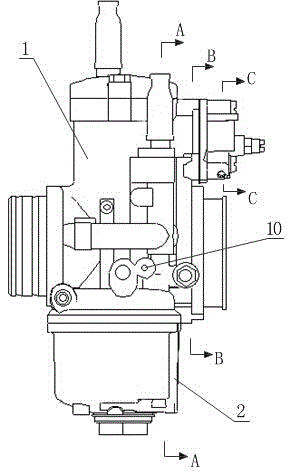

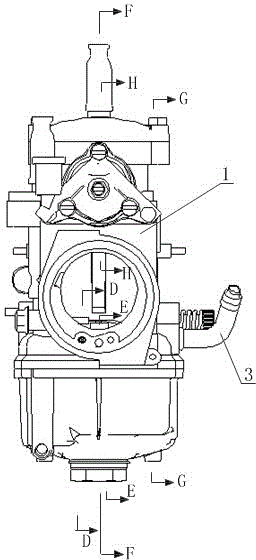

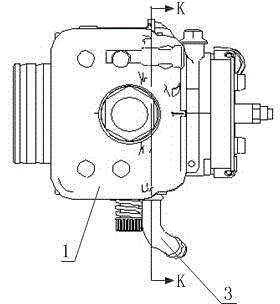

Horizontal draught type plunger piston type carburetor for large-emission competitive scrambling motorcycle

ActiveCN104481736AResponsive and timelyImprove responsivenessIdling devicesMachines/enginesOvertakingEngineering

The invention discloses a horizontal draught type plunger piston type carburetor for a large-emission competitive scrambling motorcycle. The carburetor comprises a carburetor body assembly (1), and a floater chamber assembly (2) which is mounted on the lower surface of the carburetor body assembly (1); an oil feeding system, a starting system, an idling system, a main oil system and an acceleration system are arranged in the carburetor body assembly (1). The carburetor has the beneficial effects that the structure is compact, the scrambling motorcycle can be started and run at a constant speed in an environment under a low temperature less than -40 DEG C; an accelerator can be timely responded, the acceleration for overtaking can be timely responded, the oil returning during acceleration can be effectively avoided, and the safety and reliability can be ensured.

Owner:成都恒高机械电子有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com