Rear cover for enhancing braking performance of hydraulic retarder

A retarder braking and enhancing fluid technology, applied in the field of auto parts, can solve the problems of insufficient braking force of the hydraulic retarder, threatening the driving safety of vehicles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

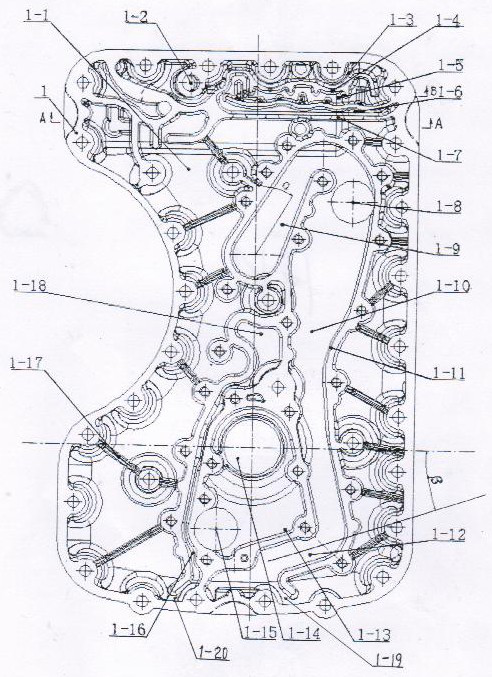

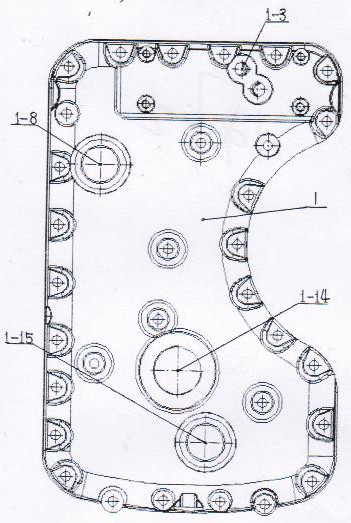

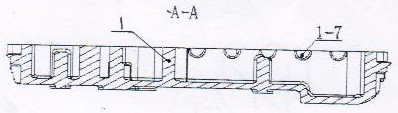

[0012] Examples, see attached Figure 1~4 , the air inlet 1-2 of the electromagnetic air proportional valve is arranged on the left side above the rear cover 1 for enhancing the braking performance of the hydraulic retarder, and the first air passage 1 is arranged on the right side of the air inlet 1-2 -3, the second gas path 1-5, the third gas path 1-6. The first air passage 1-3 is wave-shaped and the right end communicates with the second air passage 1-5. The side wall of the first air passage 1-3 is provided with a ventilation groove 1-4, and at the same time passes through the ventilation groove 1-1- 4 communicates with the second air passage 1-5, and the left end of the first air passage 1-3 communicates with the air inlet 1-2 after being combined with the rear cover 1 and the middle cover. The second air passage 1-5 is still wave-shaped and the left end communicates with the left end of the third air passage 1-6. The third air passage 1-6 is straight and closed at the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com