Automatic braking device for main shaft of machine head of numerically controlled lathe

A CNC lathe and automatic braking technology, which is applied to mechanical equipment, brake types, brake actuators, etc., can solve the problems of poor practicability of the device and performance degradation of the brake device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

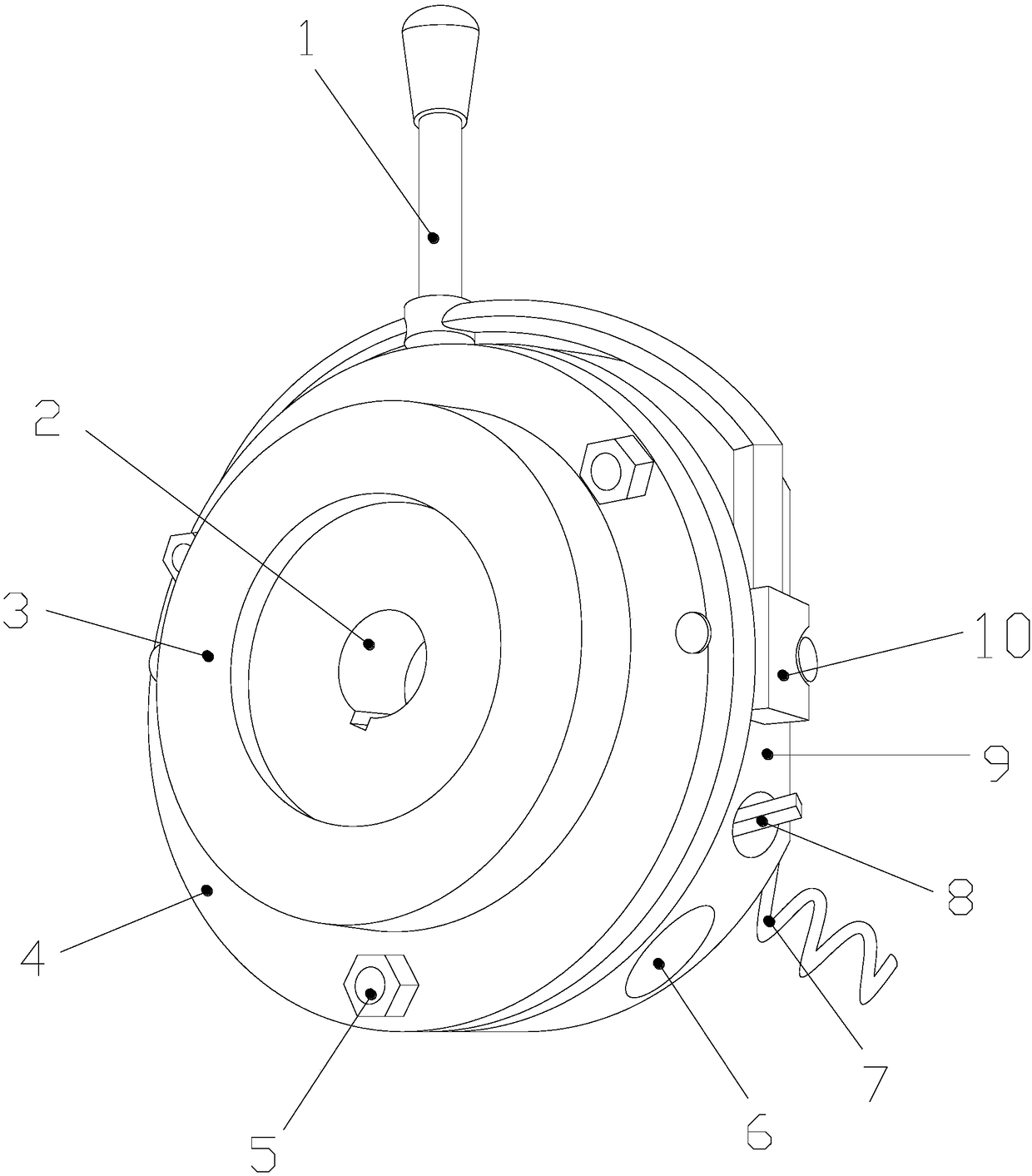

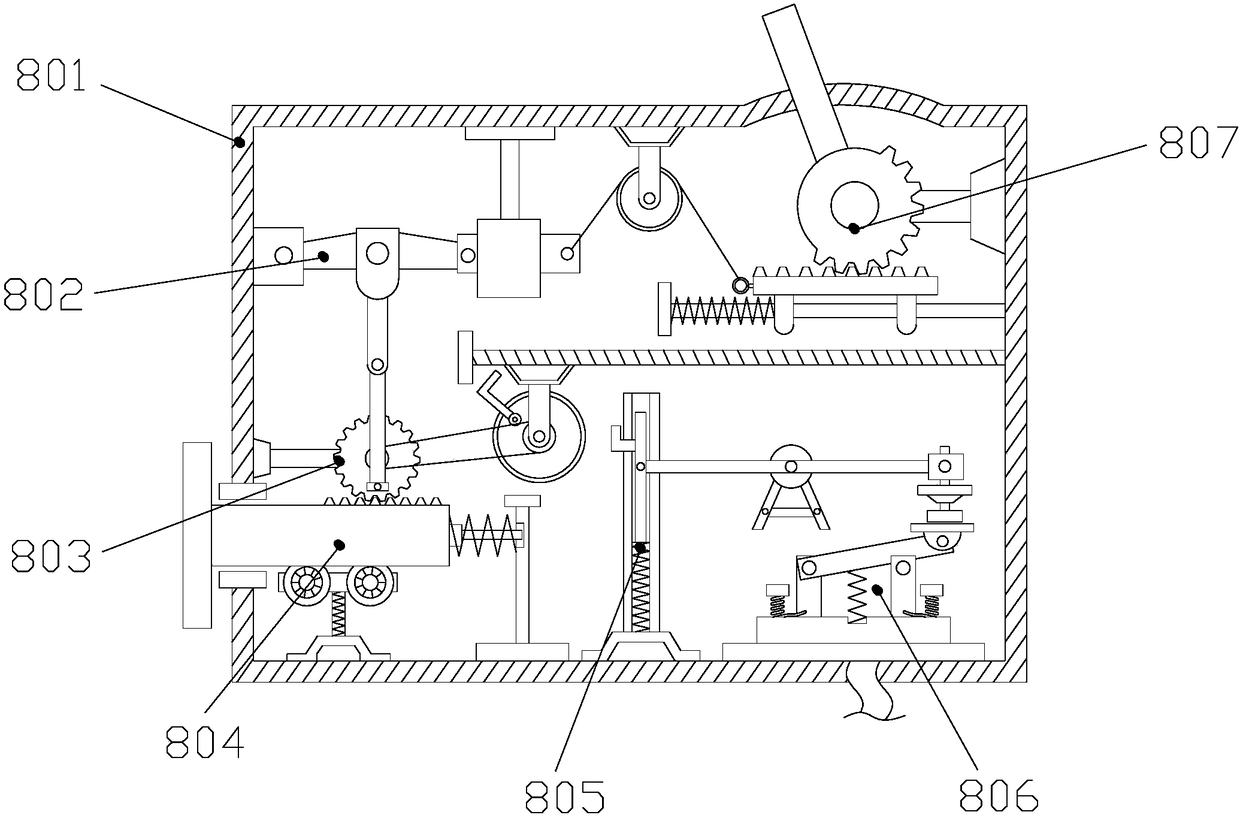

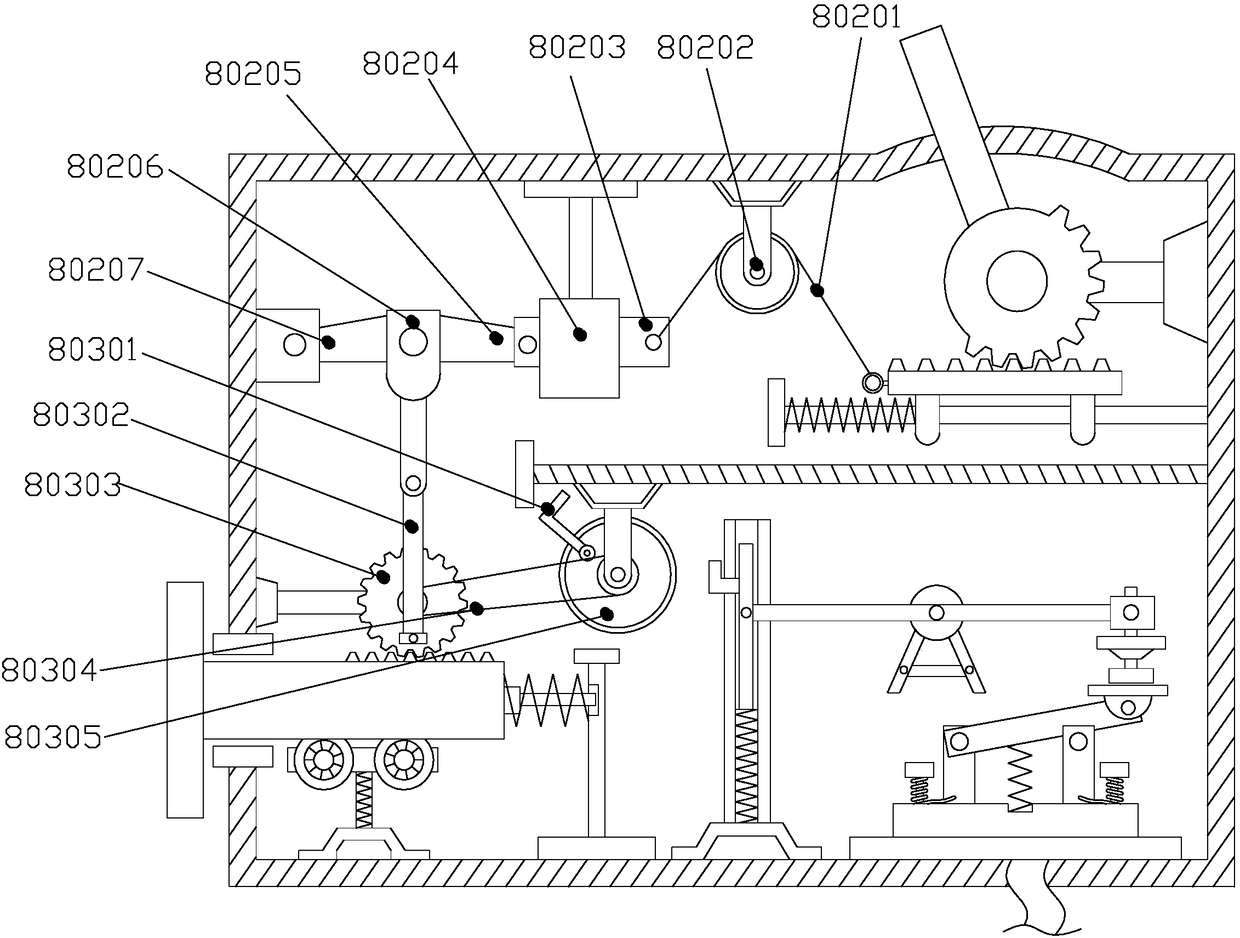

[0021] Such as Figure 1-Figure 5As shown, the present invention provides an automatic braking device for the main shaft of a numerically controlled lathe head. Brake protection device 8, brake stator 9, handle fixing part 10, the brake armature 4 is located in front of the brake stator 9 and the back of the brake armature 4 is close to the front of the brake stator 9, and the main shaft fixing groove 2 is connected through the brake armature 4 and the brake stator 9, the handle fixing part 10 is welded on the left and right sides of the brake stator 9, the release operation handle 1 is located above the brake stator 9 and is mechanically connected with the handle fixing part 10, and the friction plate 3 is installed on the brake The middle of the front of the armature 4 is concentric with the brake armature 4. The back of the product nameplate 6 is glued to the right side of the brake stator 9, and the brake protection device 8 is mechanically connected to the top of the prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com