Laser additive manufacturing method for multi-support surface structure of cavity thin-wall structural part

A technology of thin-walled structural parts and laser additive materials, which is applied in the direction of additive manufacturing, additive processing, and improvement of process efficiency, and can solve problems such as complex processes, long manufacturing cycles, and inability to prepare

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

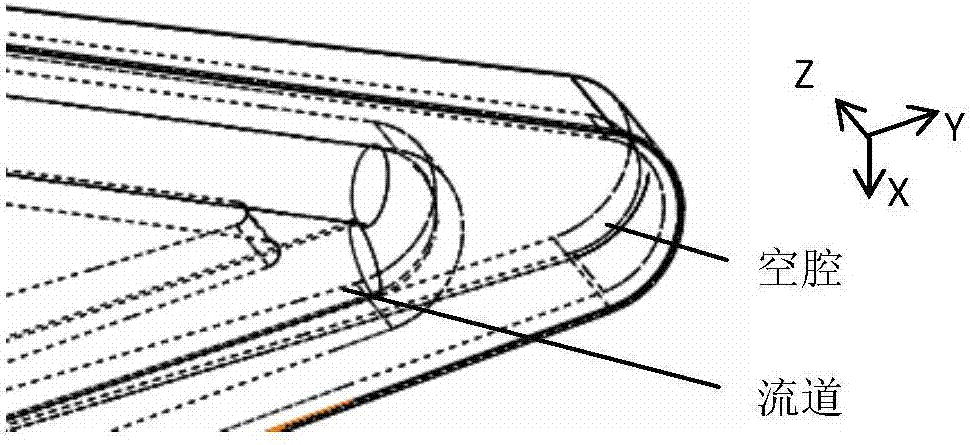

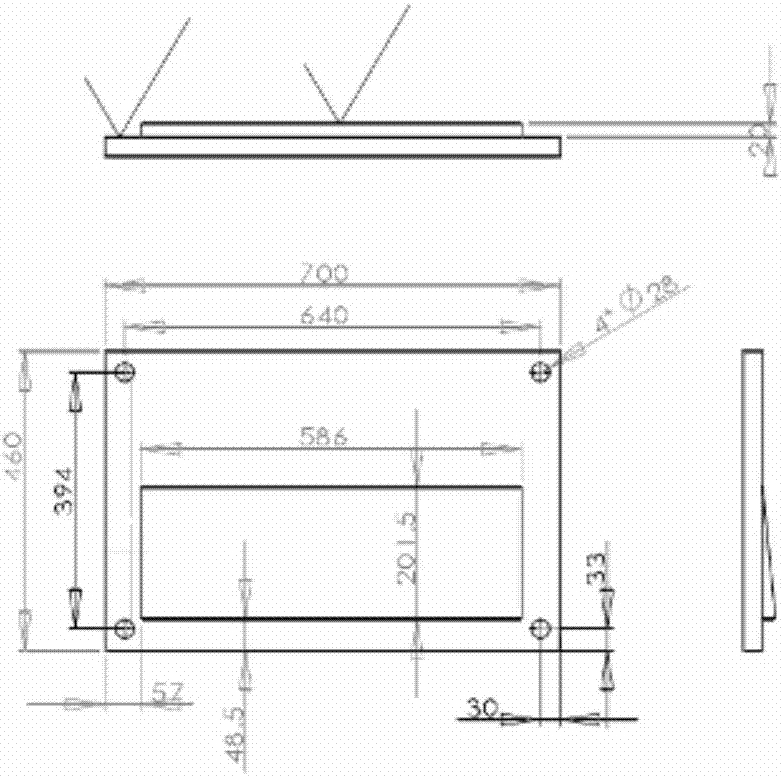

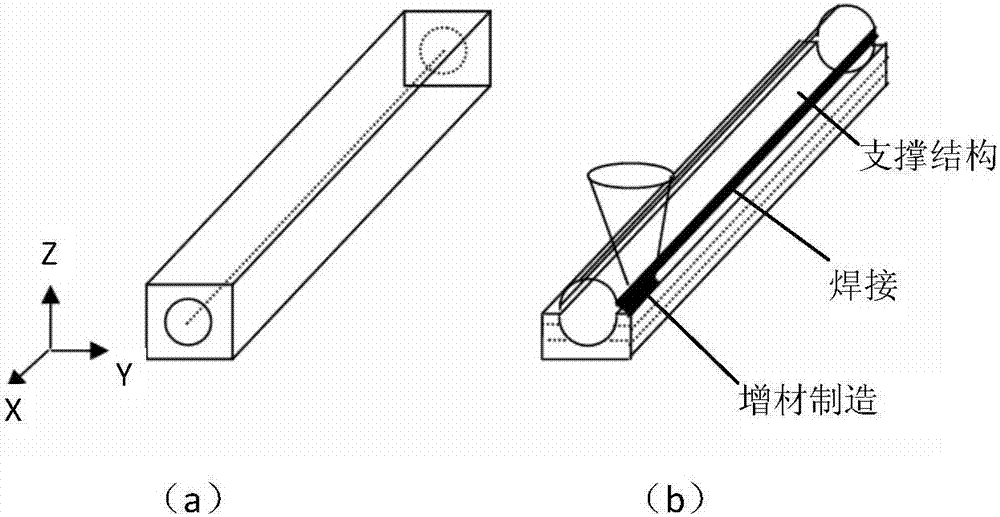

[0037] In this embodiment, the K465 nickel-based alloy multi-cavity aviation complex thin-walled structural part is used as the manufacturing object, and the laser additive manufacturing method with multi-support surface configuration is used to realize the manufacture of the part. Partial structure such as figure 1 As shown in the analysis of the three-dimensional structure of the part, there are multiple cavities and flow channel structures inside the part to be formed. In addition, the part is a thin-walled structure. The realization of the cavity structure and the control of the deformation of the thin-walled structure during the forming process are the key points of the forming process. difficulty. In order to limit the deformation of parts to the greatest extent and ensure the feasibility of adding support structures, the direction with the largest projected area is selected as the stacking direction of additive manufacturing, such as figure 1 Select the Z direction as ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com