A method of axially pressing a corrugated pipe

A corrugated tube and tube shaft technology, which is applied in the field of corrugated tube axial pressing, can solve the problems of complex manufacturing process, low production efficiency, and unstable size, and achieve good dimensional stability, high production efficiency, and reduced production costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The invention is a tube axial pressing forming method for forming corrugated tubes. The tube blank of the bellows is a 6061-T4 aluminum alloy circular tube, and the dimensions of the tube blank in each embodiment are shown in Table 1:

[0036] The size of the tube blank in each embodiment of table 1

[0037]

[0038]

[0039] Concrete forming steps of the present invention are as follows:

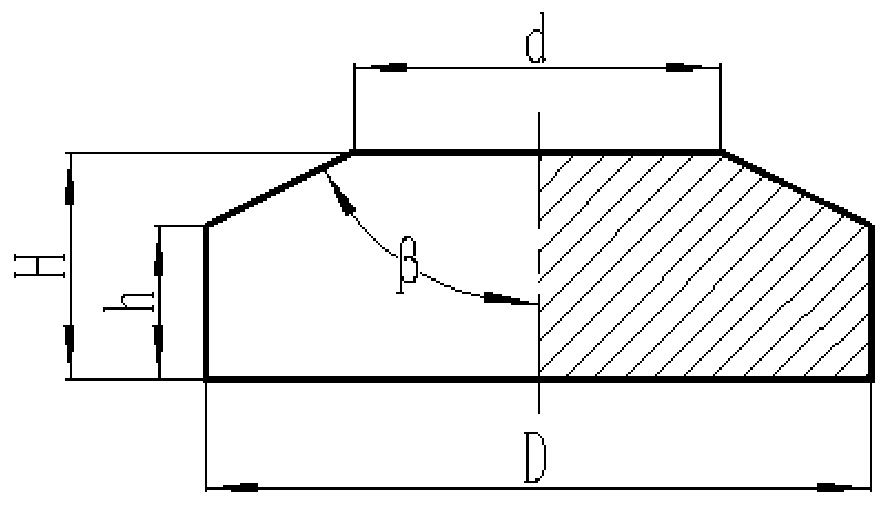

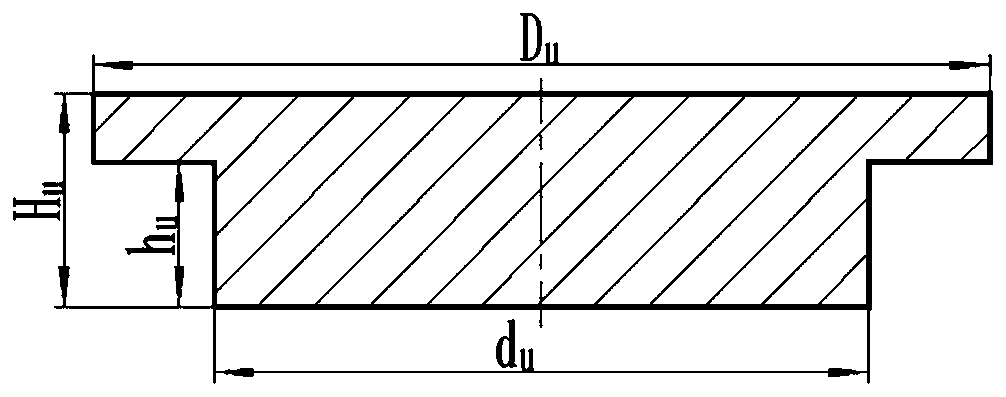

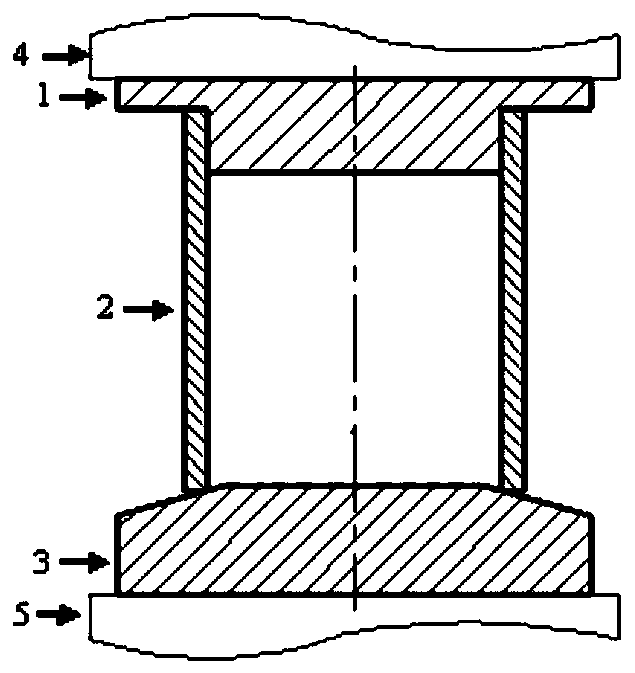

[0040] Step 1: Make the lower mold 3. The lower die is cylindrical, and its outer peripheral surface is divided into a conical forming section and a cylindrical supporting section. The half-cone angle β of the forming section is 75°-89°. The total height of the lower mold is H, and the height of the supporting section is h. The maximum diameter of the lower mold is D, and the minimum diameter is d. In order to ensure that the tube blank 2 is just set on the lower mold 3 and is formed stably, d is smaller than the inner diameter of the tube blank d G Small 3 ~ 5mm. The spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com