Brine drilling and exploiting system and method for dynamic cleaning and salt deposition resisting in closed cycle mode

A brine and drilling technology, which is applied in the fields of fluid extraction, earthwork drilling, machine/engine, etc., can solve the problems of increased production cost and loss of economy of brine resources, and achieves the effect of inhibiting crystallization and overcoming the instability of brine extraction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

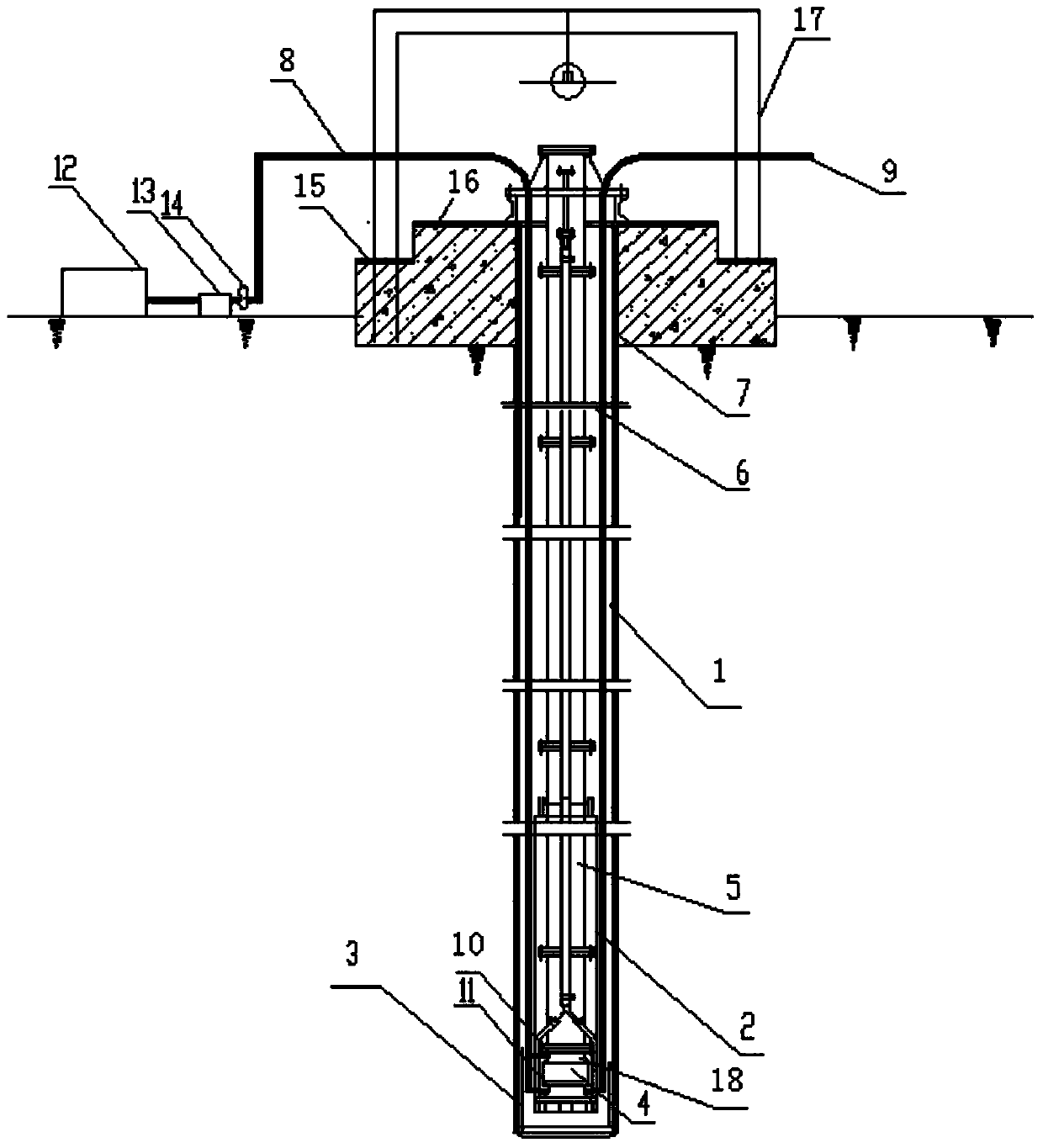

[0022] Specific examples: In order to solve the problems of low efficiency and high cost of brine mining in existing channels, and realize large-scale mining of deep brine in the mining area, Qinghai Salt Lake Industry Co., Ltd. established a project in Biel Beach and Chaerhan District of Chaerhan Salt Lake in the Qaidam Basin Construction of 25 brine production wells in this section, with a diameter of φ1000mm and a well depth of 25-30 meters; the rated brine production capacity of the brine production pump is 200m 3 / h; the cement platform 15 of the well platform is 2.5×2.0m, the thickness of the cement plate is 0.70m, 0.20m below the ground, and 0.50m above the ground, and the top 0.20m is laid with a circular well cover steel plate 16 with a diameter of 1.80m The length of the wellhead pipe is 2.50m, of which 0.50m above the ground, and the "well" shaped wellhead pipe fixed channel steel 6 is welded at 1.0m below the ground of the wellhead pipe, with a single length of 1.50...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com