Water electrolyzing hydrogen production device

A hydrogen production device, water electrolysis technology, applied in the electrolysis process, electrolysis components, respirators, etc., can solve the problems of poor hydrogen quality, rising gas temperature, poor application effect, etc., to ensure continuous stability and avoid temperature rise high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

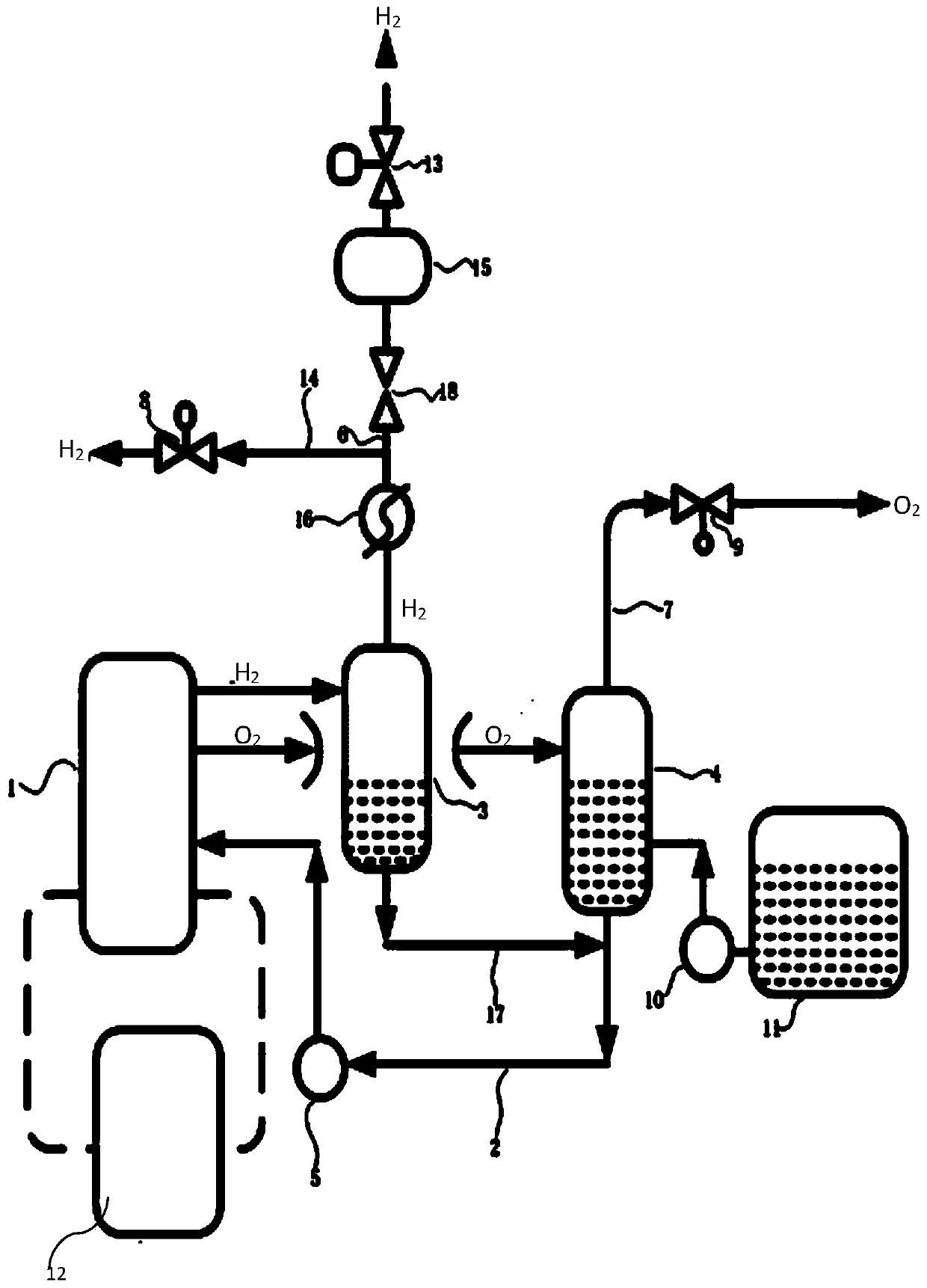

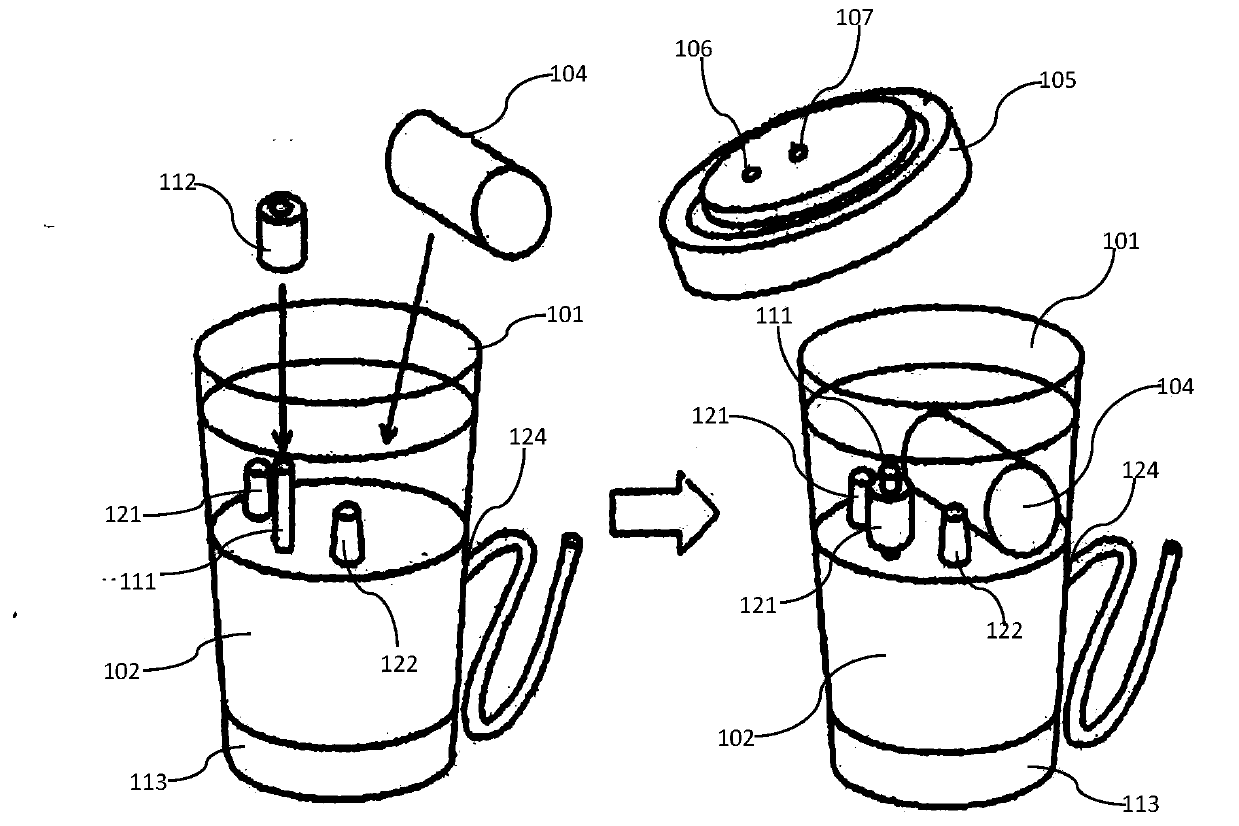

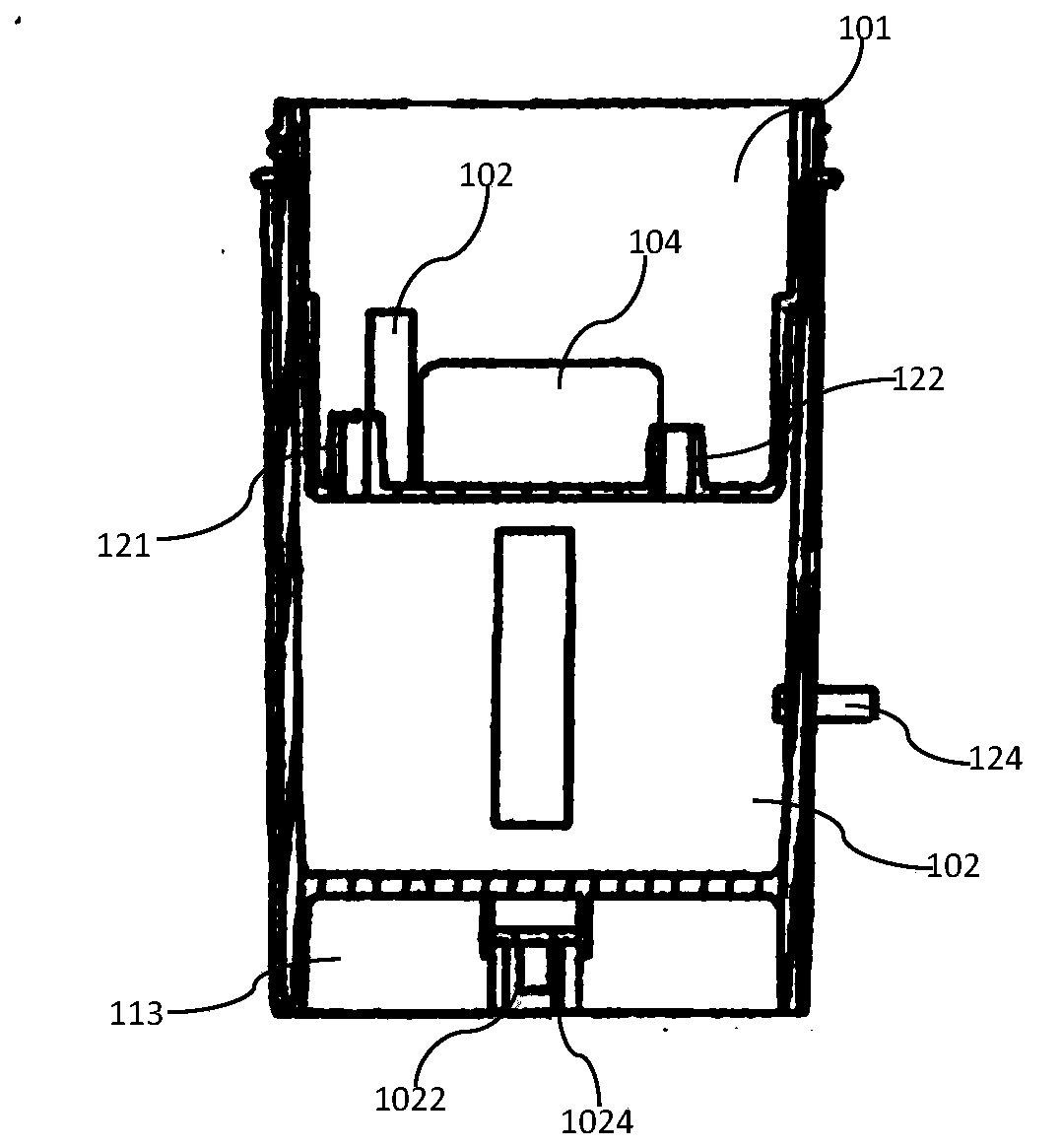

[0065] Combined with the manual Figure 1-5, turn on the water suction pump 10, inject the purified water from the refined water storage tank 11 into the oxygen gas-liquid separator 4, and the purified water separated from excess oxygen through the oxygen gas-liquid separator 4 enters the water circulation pipeline 2 from the bottom of the oxygen gas-liquid separator 4 , the circulating pump 5 injects the purified water into the purified water container 101 in the hydrogen generating cup 1, and in the purified water container 101, the purified water is further purified by the liquid purification rod 104 to ensure that the prepared small molecular hydrogen gas has a higher purity and is The refined water further purified by the liquid purification rod 104 enters the electrolytic cell 102 through the liquid inlet 122 to undergo an electrolytic reaction (the purified water is consumed during the electrolytic reaction, and no outlet for the purified water is provided), so that the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com